Application of Silver-Loaded Composite Track-Etched Membranes for Photocatalytic Decomposition of Methylene Blue under Visible Light

Abstract

:1. Introduction

2. Materials and Methods

2.1. Chemical Reagents

2.2. Synthesis of Ag/PET Composite Catalyst

2.3. Characterization

2.4. Photocatalytic Activity

3. Results and Discussions

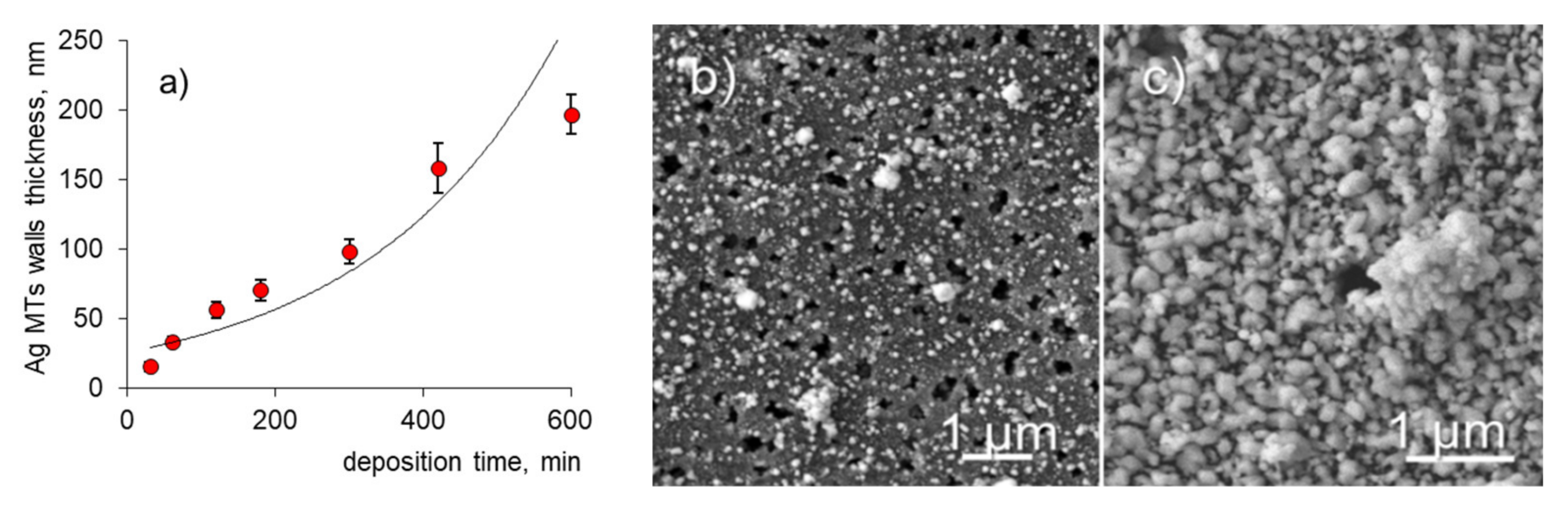

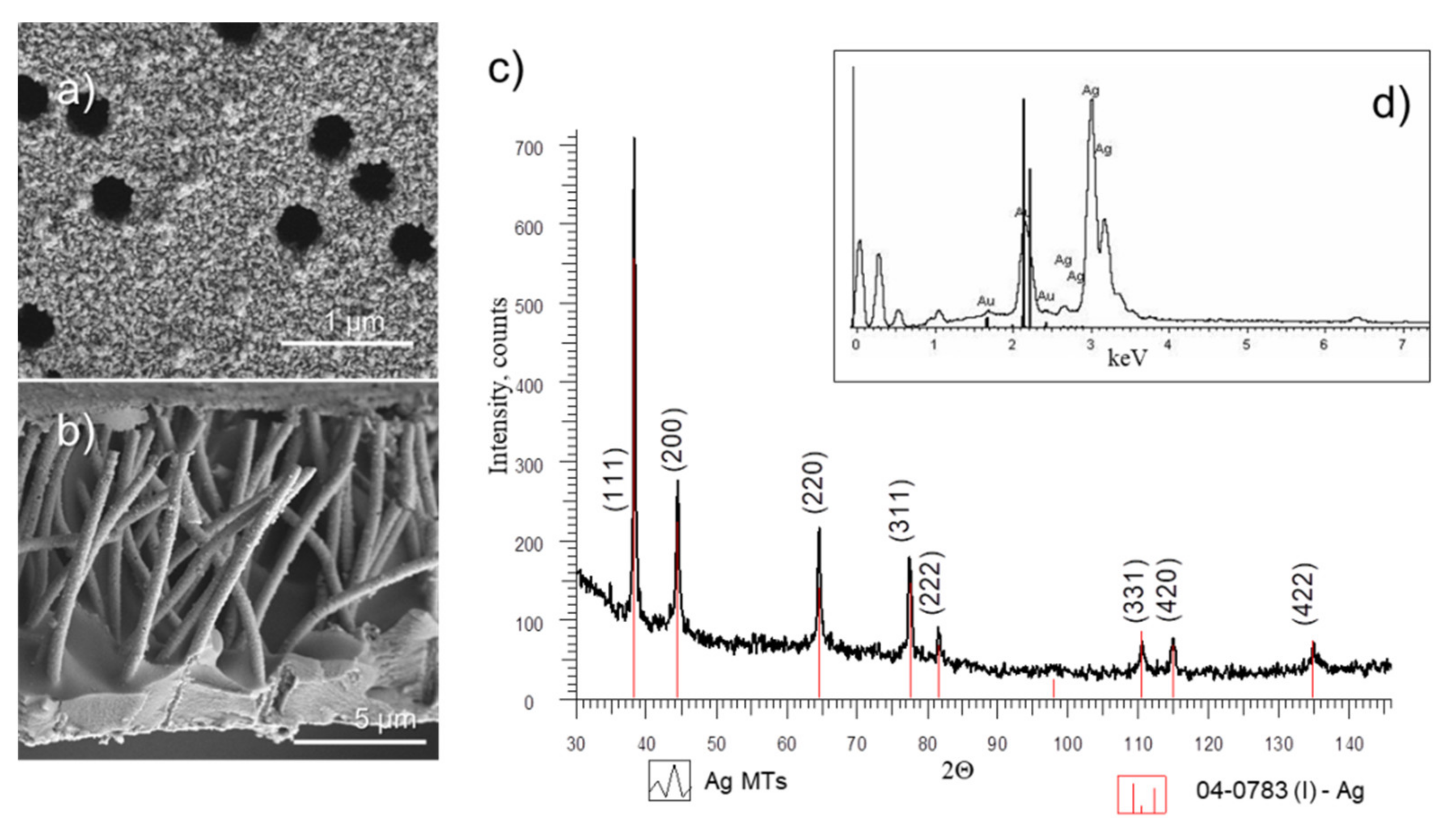

3.1. Ag/PET Composite Synthesis

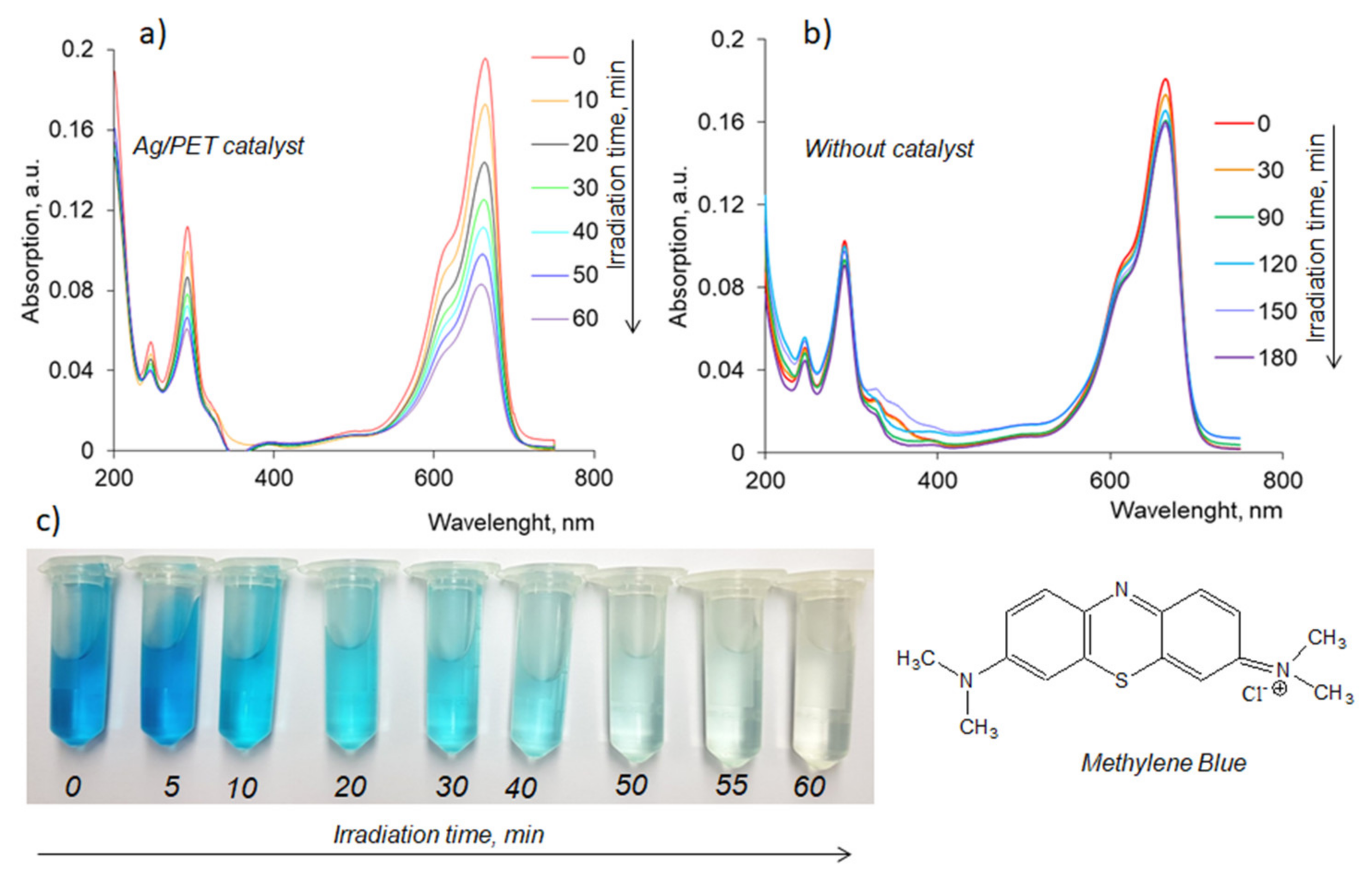

3.2. Catalytic Activity Results

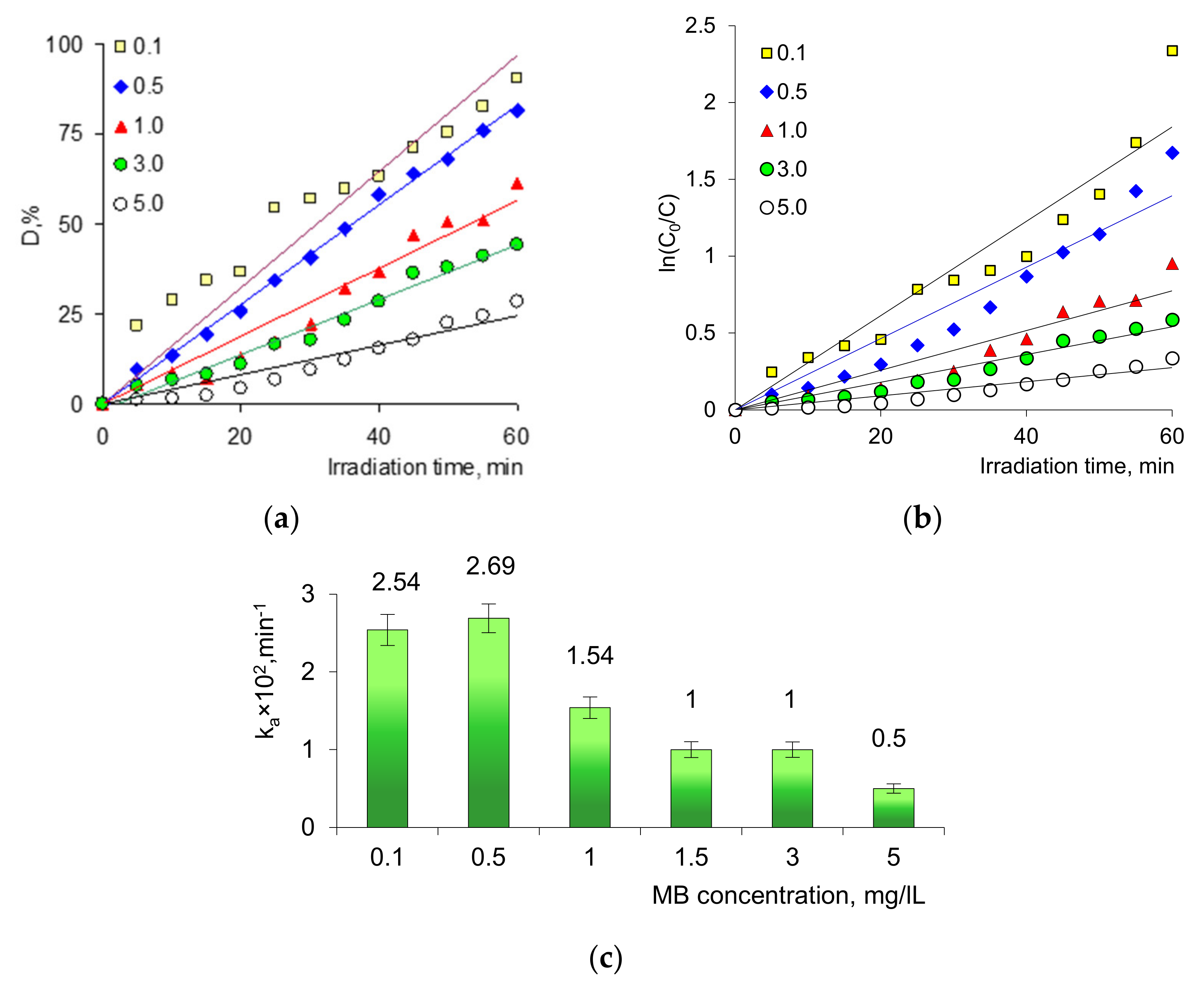

3.2.1. Effect of Initial Dye Concentration

3.2.2. Effect of Temperature on the Decomposition of MB

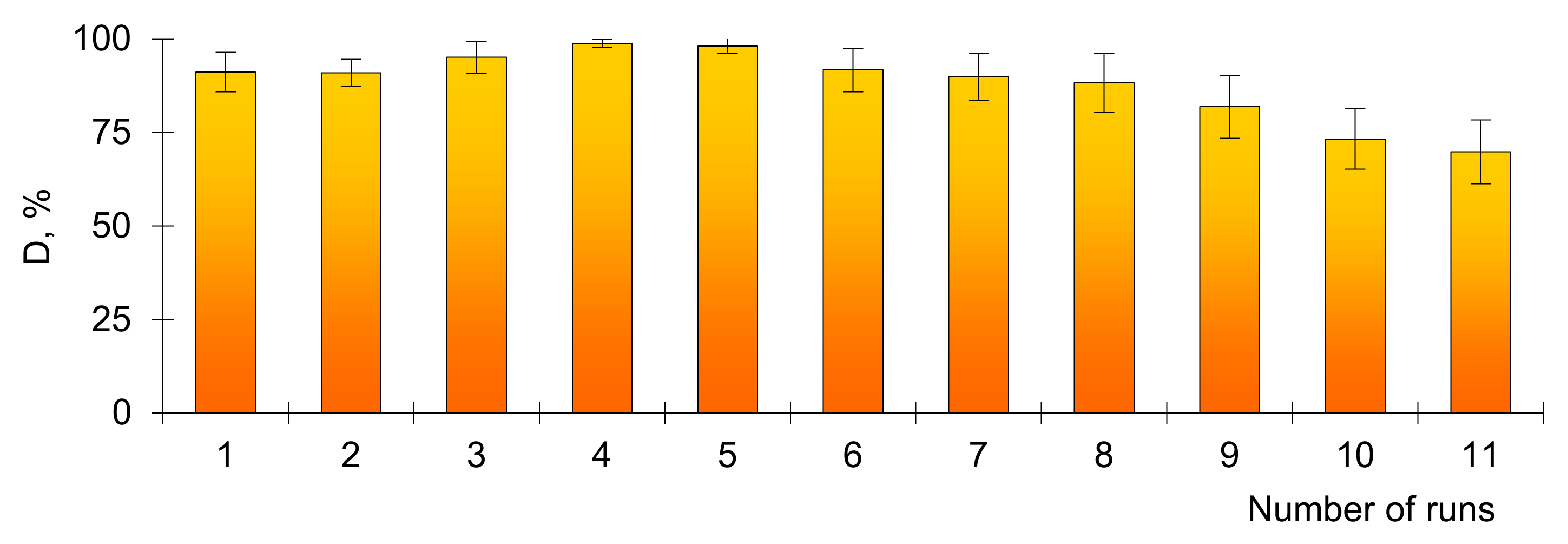

3.2.3. The Stability of the Properties of the Composite Catalyst

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Forgacs, E.; Cserháti, T.; Oros, G. Removal of synthetic dyes from wastewaters: A review. Environ. Int. 2004, 30, 953–971. [Google Scholar] [CrossRef] [PubMed]

- Clarke, E.A.; Anliker, R. Organic Dyes and Pigments; Springer: Berlin/Heidelberg, Germany, 1980; pp. 181–215. [Google Scholar]

- Chung, K.T.; Fulk, G.E.; Egan, M. Reduction of azo dyes by intestinal anaerobes. Appl. Environ. Microbiol. 1978, 35, 558–562. [Google Scholar] [CrossRef] [Green Version]

- Ajmal, A.; Majeed, I.; Malik, R.N.; Idriss, H.; Nadeem, M.A. Principles and mechanisms of photocatalytic dye degradation on TiO 2 based photocatalysts: A comparative overview. RSC Adv. 2014, 4, 37003–37026. [Google Scholar] [CrossRef]

- Kant, R. Textile dyeing industry an environmental hazard. Nat. Sci. 2012, 04, 22–26. [Google Scholar] [CrossRef] [Green Version]

- Platzek, T.; Lang, C.; Grohmann, G.; Gi, U.-S.; Baltes, W. Formation of a carcinogenic aromatic amine from an azo dye by human skin bacteria in vitro. Hum. Exp. Toxicol. 1999, 18, 552–559. [Google Scholar] [CrossRef]

- Lellis, B.; Fávaro-Polonio, C.Z.; Pamphile, J.A.; Polonio, J.C. Effects of textile dyes on health and the environment and bioremediation potential of living organisms. Biotechnol. Res. Innov. 2019, 3, 275–290. [Google Scholar] [CrossRef]

- Lazar, M.; Varghese, S.; Nair, S. Photocatalytic Water Treatment by Titanium Dioxide: Recent Updates. Catalysts 2012, 2, 572–601. [Google Scholar] [CrossRef] [Green Version]

- Cai, Z.; Sun, Y.; Liu, W.; Pan, F.; Sun, P.; Fu, J. An overview of nanomaterials applied for removing dyes from wastewater. Environ. Sci. Pollut. Res. 2017, 24, 15882–15904. [Google Scholar] [CrossRef]

- Sarkar, S.; Ponce, N.T.; Banerjee, A.; Bandopadhyay, R.; Rajendran, S.; Lichtfouse, E. Green polymeric nanomaterials for the photocatalytic degradation of dyes: A review. Environ. Chem. Lett. 2020, 18, 1569–1580. [Google Scholar] [CrossRef]

- Anjum, M.; Miandad, R.; Waqas, M.; Gehany, F.; Barakat, M.A. Remediation of wastewater using various nano-materials. Arab. J. Chem. 2019, 12, 4897–4919. [Google Scholar] [CrossRef] [Green Version]

- Ruan, W.; Hu, J.; Qi, J.; Hou, Y.; Zhou, C.; Wei, X. Removal of Dyes from Wastewater By Nanomaterials: A Review. Adv. Mater. Lett. 2019, 10, 9–20. [Google Scholar] [CrossRef]

- Chong, M.N.; Jin, B.; Chow, C.W.K.; Saint, C. Recent developments in photocatalytic water treatment technology: A review. Water Res. 2010, 44, 2997–3027. [Google Scholar] [CrossRef] [PubMed]

- Gaya, U.I.; Abdullah, A.H. Heterogeneous photocatalytic degradation of organic contaminants over titanium dioxide: A review of fundamentals, progress and problems. J. Photochem. Photobiol. C Photochem. Rev. 2008, 9, 1–12. [Google Scholar] [CrossRef]

- Lu, J.; Zhang, T.; Ma, J.; Chen, Z. Evaluation of disinfection by-products formation during chlorination and chloramination of dissolved natural organic matter fractions isolated from a filtered river water. J. Hazard. Mater. 2009, 162, 140–145. [Google Scholar] [CrossRef]

- Deng, Y.; Zhao, R. Advanced Oxidation Processes (AOPs) in Wastewater Treatment. Curr. Pollut. Reports 2015, 1, 167–176. [Google Scholar] [CrossRef] [Green Version]

- Miklos, D.B.; Remy, C.; Jekel, M.; Linden, K.G.; Drewes, J.E.; Hübner, U. Evaluation of advanced oxidation processes for water and wastewater treatment—A critical review. Water Res. 2018, 139, 118–131. [Google Scholar] [CrossRef]

- Shaham-Waldmann, N.; Paz, Y. Away from TiO2: A critical minireview on the developing of new photocatalysts for degradation of contaminants in water. Mater. Sci. Semicond. Process. 2016, 42, 72–80. [Google Scholar] [CrossRef]

- Wu, J.; Xue, D. Progress of science and technology of ZnO as advanced material. Sci. Adv. Mater. 2011, 3, 127–149. [Google Scholar] [CrossRef]

- Byrne, C.; Subramanian, G.; Pillai, S.C. Recent advances in photocatalysis for environmental applications. J. Environ. Chem. Eng. 2018, 6, 3531–3555. [Google Scholar] [CrossRef]

- Khanna, D.P.; More, P. V Electro-photocatalytic degradation of methylene blue dye using various nanoparticles: A demonstration for undergraduates. J. Nanomed. Res. 2018, 7, 254–257. [Google Scholar]

- Wang, L.; Wang, P.; Huang, B.; Ma, X.; Wang, G.; Dai, Y.; Zhang, X.; Qin, X. Synthesis of Mn-doped ZnS microspheres with enhanced visible light photocatalytic activity. Appl. Surf. Sci. 2017, 391, 557–564. [Google Scholar] [CrossRef]

- Carbajo, J.; Bahamonde, A.; Faraldos, M. Photocatalyst performance in wastewater treatment applications: Towards the role of TiO 2 properties. Mol. Catal. 2017, 434, 167–174. [Google Scholar] [CrossRef]

- Ye, Z.; Kong, L.; Chen, F.; Chen, Z.; Lin, Y.; Liu, C. A comparative study of photocatalytic activity of ZnS photocatalyst for degradation of various dyes. Optik Stuttg. 2018, 164, 345–354. [Google Scholar] [CrossRef]

- Hatat-Fraile, M.; Mendret, J.; Rivallin, M.; Brosillon, S. Photocatalytic Membranes for the Treatment of Refractory Organic Pollutants. Procedia Eng. 2012, 44, 440–442. [Google Scholar] [CrossRef] [Green Version]

- Zheng, X.; Shen, Z.-P.; Shi, L.; Cheng, R.; Yuan, D.-H. Photocatalytic Membrane Reactors (PMRs) in Water Treatment: Configurations and Influencing Factors. Catalysts 2017, 7, 224. [Google Scholar] [CrossRef]

- Boettcher, T.; Schaefer, S.; Antoni, M.; Stohr, T.; Kunz, U.; Dürrschnabel, M.; Molina-Luna, L.; Ensinger, W.; Muench, F. Shape-Selective Electroless Plating within Expanding Template Pores: Etching-Assisted Deposition of Spiky Nickel Nanotube Networks. Langmuir 2019, 35, 4246–4253. [Google Scholar] [CrossRef]

- Pérez-Mitta, G.; Toimil-Molares, M.E.; Trautmann, C.; Marmisollé, W.A.; Azzaroni, O. Molecular Design of Solid-State Nanopores: Fundamental Concepts and Applications. Adv. Mater. 2019, 31, 1901483. [Google Scholar] [CrossRef]

- Yeszhanov, A.B.; Mashentseva, A.A.; Korolkov, I.V.; Gorin, Y.G.; Kozlovskiy, A.L.; Zdorovets, M.V. Copper nanotube composite membrane as a catalyst in Mannich reaction. Chem. Pap. 2018, 72, 3189–3194. [Google Scholar] [CrossRef]

- Mashentseva, A.A.; Shlimas, D.I.; Kozlovskiy, A.L.; Zdorovets, M.V.; Russakova, A.V.; Kassymzhanov, M.; Borisenko, A.N. Electron Beam Induced Enhancement of the Catalytic Properties of Ion-Track Membranes Supported Copper Nanotubes in the Reaction of the P-Nitrophenol Reduction. Catalysts 2019, 9, 737. [Google Scholar] [CrossRef] [Green Version]

- El-Nagar, G.A.; Muench, F.; Roth, C. Tailored dendritic platinum nanostructures as a robust and efficient direct formic acid fuel cell anode. New J. Chem. 2019, 43, 4100–4105. [Google Scholar] [CrossRef]

- Stohr, T.; Fischer, A.; Muench, F.; Antoni, M.; Wollstadt, S.; Lohaus, C.; Kunz, U.; Clemens, O.; Klein, A.; Ensinger, W. Electroless Nanoplating of Pd−Pt Alloy Nanotube Networks: Catalysts with Full Compositional Control for the Methanol Oxidation Reaction. ChemElectroChem 2020, 7, 855–864. [Google Scholar] [CrossRef]

- Spain, E.; McCooey, A.; Joyce, K.; Keyes, T.E.; Forster, R.J. Gold nanowires and nanotubes for high sensitivity detection of pathogen DNA. Sens. Actuat. B Chem. 2015, 215, 159–165. [Google Scholar] [CrossRef]

- Muench, F.; De Carolis, D.M.; Felix, E.M.; Brötz, J.; Kunz, U.; Kleebe, H.J.; Ayata, S.; Trautmann, C.; Ensinger, W. Self-Supporting Metal Nanotube Networks Obtained by Highly Conformal Electroless Plating. Chempluschem 2015, 80, 1448–1456. [Google Scholar] [CrossRef] [PubMed]

- Zdorovets, M.V.; Kozlovskiy, A.L. Investigation of phase transformations and corrosion resistance in Co/CoCo2O4 nanowires and their potential use as a basis for lithium-ion batteries. Sci. Rep. 2019, 9, 16646. [Google Scholar] [CrossRef] [Green Version]

- Kozlovskiy, А.; Shlimas, D.; Zdorovets, M. Investigation of the effect of ionizing radiation on the structural and conductive characteristics of Ni nanostructures. Vacuum 2019, 163, 103–109. [Google Scholar] [CrossRef]

- Mashentseva, A.A.; Zdorovets, M.V. Composites based on polyethylene terephthalate track-etched membranes and silver as hydrogen peroxide decomposition catalysts. Pet. Chem. 2017, 57, 954–960. [Google Scholar] [CrossRef]

- Borgekov, D.; Mashentseva, A.; Kislitsin, S.; Kozlovskiy, A.; Russakova, A.; Zdorovets, M. Temperature Dependent Catalytic Activity of Ag/PET Ion-Track Membranes Composites. Acta Phys. Pol. A 2015, 128, 871–875. [Google Scholar] [CrossRef]

- Mashentseva, A.A.; Borgekov, D.B.; Niyazova, D.T.; Zdorovets, M.V. Evaluation of the catalytic activity of the composite track-etched membranes for p-nitrophenol reduction reaction. Pet. Chem. 2015, 55, 810–815. [Google Scholar] [CrossRef]

- Dong, X.-Y.; Gao, Z.-W.; Yang, K.-F.; Zhang, W.-Q.; Xu, L.-W. Nanosilver as a new generation of silver catalysts in organic transformations for efficient synthesis of fine chemicals. Catal. Sci. Technol. 2015, 5, 2554–2574. [Google Scholar] [CrossRef]

- Kumari, R.M.; Thapa, N.; Gupta, N.; Kumar, A.; Nimesh, S. Antibacterial and photocatalytic degradation efficacy of silver nanoparticles biosynthesized using Cordia dichotoma leaf extract. Adv. Nat. Sci. Nanosci. Nanotechnol. 2016, 7, 045009. [Google Scholar] [CrossRef] [Green Version]

- Sarina, S.; Waclawik, E.R.; Zhu, H. Photocatalysis on supported gold and silver nanoparticles under ultraviolet and visible light irradiation. Green Chem. 2013, 15, 1814. [Google Scholar] [CrossRef]

- Shokouhimehr, M. Magnetically separable and sustainable nanostructured catalysts for heterogeneous reduction of nitroaromatics. Catalysts 2015, 5, 534–560. [Google Scholar] [CrossRef]

- Muench, F.; Rauber, M.; Stegmann, C.; Lauterbach, S.; Kunz, U.; Kleebe, H.-J.; Ensinger, W. Ligand-optimized electroless synthesis of silver nanotubes and their activity in the reduction of 4-nitrophenol. Nanotechnology 2011, 22, 415602. [Google Scholar] [CrossRef]

- Scopece, P.; Baker, L.A.; Ugo, P.; Martin, C.R. Conical nanopore membranes: Solvent shaping of nanopores. Nanotechnology 2006, 17, 3951–3956. [Google Scholar] [CrossRef]

- He, K.; Chen, N.; Wang, C.; Wei, L.; Chen, J. Method for Determining Crystal Grain Size by X-Ray Diffraction. Cryst. Res. Technol. 2018, 53, 1700157. [Google Scholar] [CrossRef]

- Mashentseva, A.A.; Barsbay, M.; Zdorovets, M.V.; Zheltov, D.A.; Güven, O. Cu/CuO Composite Track-Etched Membranes for Catalytic Decomposition of Nitrophenols and Removal of As(III). Nanomaterials 2020, 10, 1552. [Google Scholar] [CrossRef]

- Mashentseva, A.A.; Aimanova, N.A.; Temirgaziev, B.S.; Zhumazhanova, A.T.; Tuleuov, B.I. Photocatalytic Activity of Copper(II) Oxide Nanoparticles Synthesized Using Serratula Coronata L. Extract. Pet. Chem. 2020, 60, 1141–1147. [Google Scholar] [CrossRef]

- Mashentseva, A.A.; Kozlovskiy, A.L.; Zdorovets, M. V Influence of deposition temperature on the structure and catalytic properties of the copper nanotubes composite membranes. Mater. Res. Express 2018, 5, 065041. [Google Scholar] [CrossRef]

- Ginimuge, P.R.; Jyothi, S.D. Methylene blue: Revisited. J. Anaesthesiol. Clin. Pharmacol. 2010, 26, 517–520. [Google Scholar]

- Carmen, Z.; Daniel, S. Textile Organic Dyes—Characteristics, Polluting Effects and Separation/Elimination Procedures from Industrial Effluents—A Critical Overview. In Organic Pollutants Ten Years after the Stockholm Convention—Environmental and Analytical Update; InTech: London, UK, 2012; pp. 55–86. [Google Scholar]

- Coto, M.; Troughton, S.C.; Duan, J.; Kumar, R.V.; Clyne, T.W. Development and assessment of photo-catalytic membranes for water purification using solar radiation. Appl. Surf. Sci. 2018, 433, 101–107. [Google Scholar] [CrossRef]

- Sahoo, C.; Gupta, A.K.; Sasidharan Pillai, I.M. Photocatalytic degradation of methylene blue dye from aqueous solution using silver ion-doped TiO 2 and its application to the degradation of real textile wastewater. J. Environ. Sci. Health Part A 2012, 47, 1428–1438. [Google Scholar] [CrossRef] [PubMed]

- Mahanthappa, M.; Kottam, N.; Yellappa, S. Enhanced photocatalytic degradation of methylene blue dye using CuS CdS nanocomposite under visible light irradiation. Appl. Surf. Sci. 2019, 475, 828–838. [Google Scholar] [CrossRef]

- Gago, D.; Chagas, R.; Ferreira, L.M.; Velizarov, S.; Coelhoso, I. A Novel Cellulose-Based Polymer for Efficient Removal of Methylene Blue. Membranes 2020, 10, 13. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Ahmad, R.; Mondal, P.K. Adsorption and Photodegradation of Methylene Blue by Using PAni/TiO 2 Nanocomposite. J. Dispers. Sci. Technol. 2012, 33, 380–386. [Google Scholar] [CrossRef]

- Tsuchiya, N.; Kuwabara, K.; Hidaka, A.; Oda, K.; Katayama, K. Reaction kinetics of dye decomposition processes monitored inside a photocatalytic microreactor. Phys. Chem. Chem. Phys. 2012, 14, 4734. [Google Scholar] [CrossRef]

- Shang, H.; Pan, K.; Zhang, L.; Zhang, B.; Xiang, X. Enhanced Activity of Supported Ni Catalysts Promoted by Pt for Rapid Reduction of Aromatic Nitro Compounds. Nanomaterials 2016, 6, 103. [Google Scholar] [CrossRef] [Green Version]

- Saeed, M.; Muneer, M.; Khosa, M.K.K.; Akram, N.; Khalid, S.; Adeel, M.; Nisar, A.; Sherazi, S. Azadirachta indica leaves extract assisted green synthesis of Ag-TiO2 for degradation of Methylene blue and Rhodamine B dyes in aqueous medium. Green Process. Synth. 2019, 8, 659–666. [Google Scholar] [CrossRef]

- Konstantinou, I.K.; Albanis, T.A. TiO2-assisted photocatalytic degradation of azo dyes in aqueous solution: Kinetic and mechanistic investigations. Appl. Catal. B Environ. 2004, 49, 1–14. [Google Scholar] [CrossRef]

- Saeed, M.; Muneer, M.; Akram, N.; ul Haq, A.; Afzal, N.; Hamayun, M. Synthesis and characterization of silver loaded alumina and evaluation of its photo catalytic activity on photo degradation of methylene blue dye. Chem. Eng. Res. Des. 2019, 148, 218–226. [Google Scholar] [CrossRef]

- Rodríguez, A.; Ovejero, G.; Mestanza, M.; García, J. Removal of Dyes from Wastewaters by Adsorption on Sepiolite and Pansil. Ind. Eng. Chem. Res. 2010, 49, 3207–3216. [Google Scholar] [CrossRef]

- Malakootian, M.; Nasiri, A.; Amiri Gharaghani, M. Photocatalytic degradation of ciprofloxacin antibiotic by TiO2 nanoparticles immobilized on a glass plate. Chem. Eng. Commun. 2020, 207, 56–72. [Google Scholar] [CrossRef]

- Vanaja, M.; Paulkumar, K.; Baburaja, M.; Rajeshkumar, S.; Gnanajobitha, G.; Malarkodi, C.; Sivakavinesan, M.; Annadurai, G. Degradation of Methylene Blue Using Biologically Synthesized Silver Nanoparticles. Bioinorg. Chem. Appl. 2014, 2014, 1–8. [Google Scholar] [CrossRef] [PubMed]

- Kuriakose, S.; Choudhary, V.; Satpati, B.; Mohapatra, S. Enhanced photocatalytic activity of Ag–ZnO hybrid plasmonic nanostructures prepared by a facile wet chemical method. Beilstein J. Nanotechnol. 2014, 5, 639–650. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Sun, Y.; Cai, L.; Liu, X.; Cui, Z.; Rao, P. Tailoring heterostructures of Ag/Cu2O hybrids for enhanced photocatalytic degradationdegradation. J. Phys. Chem. Solids 2017, 111, 75–81. [Google Scholar] [CrossRef]

- Abdel Messih, M.F.; Ahmed, M.A.; Soltan, A.; Anis, S.S. Synthesis and characterization of novel Ag/ZnO nanoparticles for photocatalytic degradation of methylene blue under UV and solar irradiation. J. Phys. Chem. Solids 2019, 135, 109086. [Google Scholar] [CrossRef]

- Krishnan, U.; Kaur, M.; Singh, K.; Kaur, G.; Singh, P.; Kumar, M.; Kumar, A. MoS2/Ag nanocomposites for electrochemical sensing and photocatalytic degradation of textile pollutant. J. Mater. Sci. Mater. Electron. 2019, 30, 3711–3721. [Google Scholar] [CrossRef]

- Sangpour, P.; Hashemi, F.; Moshfegh, A.Z. Photoenhanced Degradation of Methylene Blue on Cosputtered M:TiO 2 (M = Au, Ag, Cu) Nanocomposite Systems: A Comparative Study. J. Phys. Chem. C 2010, 114, 13955–13961. [Google Scholar] [CrossRef]

- Jaihindh, D.P.; Chen, C.-C.; Fu, Y.-P. Reduced graphene oxide-supported Ag-loaded Fe-doped TiO 2 for the degradation mechanism of methylene blue and its electrochemical properties. RSC Adv. 2018, 8, 6488–6501. [Google Scholar] [CrossRef] [Green Version]

| Loaded Catalyst | mg | Nanocatalyst Test Conditions | D, % | Reference | ||

|---|---|---|---|---|---|---|

| Light Source | Exposure Time, min | MB, mg/L | ||||

| Ag NPs | 10.0 | sunlight | 120 | 10.0 | 4.7 | [64] |

| Ag/ZnO | 5.0 | sunlight | 20 | 3.2 | 75.3 | [65] |

| Ag/Al2O3 | 100.0 | sunlight | 120 | 100.0 | 100.0 | [61] |

| Ag/Cu2O | 20.0 | 500 W halogen lamp | 120 | 10.0 | 96.5 | [66] |

| Ag-doped ZnO nanorods | 100.0 | 100 W halogen lamp | 120 | 6.0 | 76.0 | [67] |

| Ag/MoS2 | 1000 | 100 W halogen lamp | 80 | 1.0 | 77.9 | [68] |

| Ag/TiO2 | 10.0 | 500 W halogen lamp | 200 | 2.0 | 75.0 | [69] |

| rGO/Ag/Fe-doped TiO2 | 10 | 35 W Xe arc lamp | 150 | 20.0 | 95.3 | [70] |

| Ag/PET TeMs | 2.4 | 500 W halogen lamp | 60 | 1.0 | 61.4 | This work |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Mashentseva, A.A.; Barsbay, M.; Aimanova, N.A.; Zdorovets, M.V. Application of Silver-Loaded Composite Track-Etched Membranes for Photocatalytic Decomposition of Methylene Blue under Visible Light. Membranes 2021, 11, 60. https://doi.org/10.3390/membranes11010060

Mashentseva AA, Barsbay M, Aimanova NA, Zdorovets MV. Application of Silver-Loaded Composite Track-Etched Membranes for Photocatalytic Decomposition of Methylene Blue under Visible Light. Membranes. 2021; 11(1):60. https://doi.org/10.3390/membranes11010060

Chicago/Turabian StyleMashentseva, Anastassiya A., Murat Barsbay, Nurgulim A. Aimanova, and Maxim V. Zdorovets. 2021. "Application of Silver-Loaded Composite Track-Etched Membranes for Photocatalytic Decomposition of Methylene Blue under Visible Light" Membranes 11, no. 1: 60. https://doi.org/10.3390/membranes11010060

APA StyleMashentseva, A. A., Barsbay, M., Aimanova, N. A., & Zdorovets, M. V. (2021). Application of Silver-Loaded Composite Track-Etched Membranes for Photocatalytic Decomposition of Methylene Blue under Visible Light. Membranes, 11(1), 60. https://doi.org/10.3390/membranes11010060