Advanced Technologies for Stabilization and High Performance of Seawater RO Membrane Desalination Plants

Abstract

:1. Introduction

2. Basic History of SWRO Membrane Development

3. Typical Types of Seawater Intake and Their Advantages and Notices

4. Pre-Treatment Process

4.1. Typical Pre-Treatment Processes

4.2. Water Quality Indices of the Pre-Treatment Performance

4.2.1. Silt Density Index (SDI)

4.2.2. Membrane Biofilm Formation Rate (mBFR) as a Biofouling Index

4.3. Chemical Dosage of the Membrane for Sterilization and Protection from Oxidation Deterioration

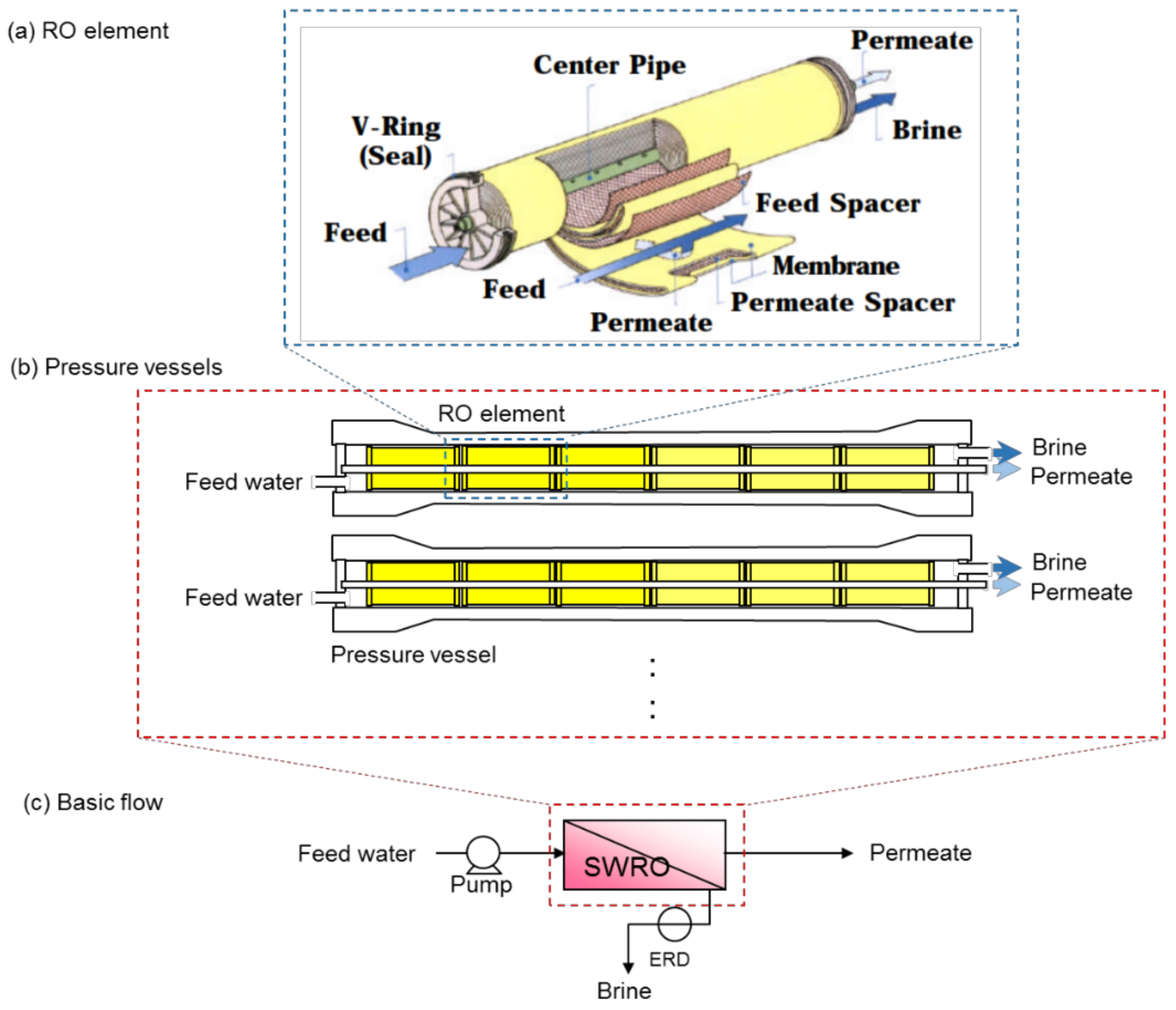

5. RO Process

5.1. Single Pass and Single Stage

5.1.1. Basic Configuration

5.1.2. Energy Recovery Device (ERD)

5.2. Multi-Pass to Improve Permeate Water Quality

5.3. Multi-Stage for High Recovery Ratio

5.4. Hybrid System

5.4.1. Integrated System of Sewage Reclamation and Seawater Desalination

5.4.2. Variable Salinity Desalination (VSD)

5.4.3. Closed Circuit Desalination System (CCD)

5.4.4. Deep Sea RO

5.5. Tools for Basic Design of a Seawater Desalination Plant

5.5.1. Calculation Software for the Basic Design of Seawater Desalination Plants

5.5.2. Determination of Scale Inhibitor Dosage

6. Concluding Remarks

Funding

Institutional Review Board Statement

Informed Consent Statement

Conflicts of Interest

References

- Fujiwara, M.; Aoshima, Y.; Miki, T. Development of Polyamide Composite Reverse Osmosis Membrane and Reverse Osmosis, Membrane System: A case study of Toray Industries, Inc.; Institute of Innovation Research at Hitotsubashi University, Research Support Office: Tokyo, Japan, 2012. [Google Scholar]

- Global Water Intelligence. DesalData, Desalination Projects, December 2020. Available online: https://www.desaldata.com/projects (accessed on 27 December 2020).

- Kurihara, M.; Takeuchi, H. SWRO-PRO system in “Mega-ton Water System” for energy reduction and low environmental impact. Water 2018, 10, 48. [Google Scholar] [CrossRef] [Green Version]

- Kurihara, M.; Sasaki, T. The most advanced membrane analysis and the save-energy type membrane-low-pressure seawater reverse osmosis membrane developed by “Mega-ton Water System” project. Compr. Membr. Eng. II 2017, 4, 131–149. [Google Scholar]

- Kurihara, M.; Hanakawa, M. Mega-ton Water System: Japanese national research and development project on seawater desalination and wastewater reclamation. Desalination 2013, 308, 131–137. [Google Scholar] [CrossRef]

- Cadotte, J.E. Reverse Osmosis Membrane. U.S. Patent 4,039,440, 2 August 1977. [Google Scholar]

- Kurihara, M.; Fusaoka, Y.; Uemura, T. Development of Excellent Performance Crosslinked Aromatic Polyamide Composite Membranes and their Practical Application for seawater desalination. In Proceedings of the International Congress on Membranes and Membrane Processes, Heidelberg, Germany, 30 August–3 September 1993. Poster Session 1.12. [Google Scholar]

- Kurihara, M.; Himeshima, Y.; Uemura, T. Crosslinked aromatic polyamide ultra-thin composite membrane from 1,3,5-triaminobenzene. In Proceedings of the International Congress on Membranes and Membrane Processes, Chicago, IL, USA, 20–24 August 1990; Volume 2, p. 1034. [Google Scholar]

- Kurihara, M.; Fusaoka, Y.; Sasaki, T.; Bairinji, R.; Uemura, T. Development of crosslinked fully aromatic polyamide ultra-thin composite membranes for seawater desalination. Desalination 1994, 96, 133. [Google Scholar] [CrossRef]

- Global Water Intelligence. DesalData, September 2018; Global Water Intelligence: Oxford, UK, 2018. [Google Scholar]

- Wilf, M. The Guidebook to Membrane Desalination Technology; Balaban Desalination Publications: Hopkinton, MA, USA, 2007. [Google Scholar]

- Messimer, T.M.; Maliva, R.G. Environmental issues in seawater reverse osmosis desalination: Intakes and outfalls. Desalination 2018, 434, 198–215. [Google Scholar] [CrossRef]

- Ito, Y.; Hanada, S.; Kitade, T.; Tanaka, Y.; Kurihara, M. Clarification of impact of biofouling triggered by chemical Addition for Designing of Mega-Ton SWRO Plant. In Proceedings of the IDA World Congress, Tianjin, China, 20–25 October 2013. TIAN13-062. [Google Scholar]

- Nigeme, E.; Yoshihara, S. Research on low cost pumping of deep seawater and its regional business promotion. Deep Ocean Water Res. 2004, 5, 15–30. [Google Scholar]

- Shahabi, M.P.; McHugh, A.; Ho, G. Environmental and economic assessment of beach well intake versus open intake for seawater reverse osmosis desalination. Desalination 2015, 357, 259–266. [Google Scholar] [CrossRef]

- Missimer, T.M.; Ghaffour, N.; Dehwah, A.H.A.; Rachman, R.; Maliva, R.G.; Amy, G. Subsurface intakes for seawater reverse osmosis facilities: Capacity limitation, water quality improvement, and economics. Desalination 2013, 322, 37–51. [Google Scholar]

- Kurihara, M.; Takeuchi, H.; Ito, Y. Reliable seawater desalination system based on the membrane technology and the biotechnology considering Environmental Impacts. Environments 2018, 5, 127. [Google Scholar] [CrossRef] [Green Version]

- Kiernan, J. Construction and Startup of the Largest Seawater Desalination Plant in the Western Hemisphere. In Proceedings of the IDA World Congress, Paradise Island, Bahamas, 28 September–3 October 2003. BAH03-159. [Google Scholar]

- Sallangos, O.V.; Kantilaftis, E. Operating experience of the Dhekelia seawater desalination plant. Desalination 2001, 139, 115–123. [Google Scholar] [CrossRef]

- Sallagos, O.V. The Importance of Pretreatment in Reverse Osmosis Desalination. In Proceedings of the IDA RO Pretreatment Workshops, San Antonio, TX, USA, 4 August 2004. [Google Scholar]

- IDA. IDA Water Security Yearbook 2008–2009; IDA: Washington, DC, USA, 2009. [Google Scholar]

- IDA. IDA Water Security Yearbook 2009–2010; IDA: Washington, DC, USA, 2010. [Google Scholar]

- IDA. IDA Desalination Yearbook 2013–2014; IDA: Washington, DC, USA, 2014. [Google Scholar]

- IDA. IDA Desalination Yearbook 2014–2015; IDA: Washington, DC, USA, 2015. [Google Scholar]

- IDA. IDA Desalination Yearbook 2016–2017; IDA: Washington, DC, USA, 2017. [Google Scholar]

- IDA. IDA Desalination Yearbook 2017–2018; IDA: Washington, DC, USA, 2018. [Google Scholar]

- IDA. IDA Water Security Handbook 2019–2020; IDA: Washington, DC, USA, 2020. [Google Scholar]

- Sim, L.N.; Chong, T.H.; Taheri, A.H.; Sim, S.T.V.; Lai, L.; Kranz, W.B.; Fane, A.G. A review of fouling indices and monitoring techniques for reverse osmosis. Desalination 2018, 434, 169–188. [Google Scholar] [CrossRef]

- ASTM. ASTM D4189-95, Standard Test Method for Silt Density Index (SDI) of Water; ASTM: West Conshohocken, PA, USA, 1995. [Google Scholar]

- ASTM. ASTM D4189-07, Standard Test Method for Silt Density Index (SDI) of Water; ASTM: West Conshohocken, PA, USA, 2007. [Google Scholar]

- Rachman, R.M.; Ghaffour, N.; Wali, F.; Amy, G.L. Assessment of silt density index (SDI) as fouling propensity parameter in reverse osmosis (RO) desalination systems. Desalin. Water Treat. 2013, 51, 1091–1103. [Google Scholar] [CrossRef]

- Yiantsios, S.G.; Karabelas, A.J. An assessment of the Silt Density Index based on RO membrane colloidal fouling experiments with iron oxide particles. Desalination 2002, 151, 229–238. [Google Scholar] [CrossRef]

- Rabie, H.R.; Cote, P.; Adams, N. A method for assessing membrane fouling in pilot and full-scale systems. Desalination 2001, 141, 237–243. [Google Scholar] [CrossRef]

- Schippers, J.C. SDI and MFI workshop: Conclusions and recommendations. Desalin. Water Treat. 2013, 51, 1114–1115. [Google Scholar] [CrossRef]

- Ito, Y.; Kantani, S.; Uemura, T.; Kitade, T. Method for Operating Reverse Osmosis Membrane Filtration Plant, and Reverse Osmosis Membrane Filtration Plant. EU Patent 2067520B1, 20 September 2007. [Google Scholar]

- Ito, Y.; Kantani, S.; Maeda, T.; Okubo, K.; Taniguchi, M. Innovative Biofouling Monitoring Device and Its Criteria for Reverse Osmosis Plant Operation and Optimization. In Proceedings of the IDA World Congress, San Diego, CA, USA, 31 August–4 September 2015. [Google Scholar]

- Kurihara, M.; Ito, Y. Sustainable seawater reverse osmosis desalination as green desalination in the 21st century. J. Membr. Sci. Res. 2020, 6, 20–29. [Google Scholar]

- Cortes, P.; Hijos, G. Performance Study of Sulphuric Acid Shocks in Reverse Osmosis Membranes in the Umm Al Houl Project SWRO Plant. In Proceedings of the IDA World Congress, Dubai, United Arab Emirates, 20–24 October 2019. [Google Scholar]

- Abushaban, A.; Salinas-Rodriguez, S.G.; Kapala, M.; Pastorelli, D.; Schippers, J.C.; Mondal, S.; Gaueli, S.; Kennedy, M.D. Monitoring biofouling potential using ATP-based bacterial growth potential in SWRO pre-treatment of a full-scale plant. Membranes 2020, 10, 360. [Google Scholar] [CrossRef]

- Uemura, T.; Kurihara, M. Chlorine resistance of reverse osmosis membranes and changes in membrane structure and performance caused by chlorination degradation. Bull. Soc. Sea Water Sci. Jpn. 2003, 57, 498–507. [Google Scholar]

- Uno, T.; Okumura, K.; Kuroda, Y. Mechanism of Fujiwara reaction: Structural investigation of reaction products from benzotrichloride. J. Org. Chem. 1981, 46, 3175–3178. [Google Scholar] [CrossRef]

- Sugita, K.; Fusaoka, Y.; Kotera, K.; Fujiwara, K.; Uemura, T. Quantitative Analysis on the Oxidation of SWRO Membrane. In Proceedings of the IDA World Congress, San Diego, CA, USA, 31 August–4 September 2015. [Google Scholar]

- Brandt, C.; van Eldik, R. Transition metal-catalyzed oxidation of sulphur(IV) oxides atmospheric-relevant processes and mechanisms. Chem. Rev. 1995, 95, 119. [Google Scholar]

- Neta, P.; Huie, R.E. Free-radical chemistry of sulphite. Environ. Health Perspect. 1985, 64, 209. [Google Scholar] [CrossRef]

- Kuo, D.T.E.; Kirk, D.W.; Jia, C.Q. The chemistry of aqueous S(IV)-Fe-O2 system: State of the art. J. Sulfur Chem. 2006, 27, 461. [Google Scholar] [CrossRef]

- Nada, N.; Attenborough, T.; Ito, Y.; Maeda, Y.; Tokunaga, K.; Iwahashi, H. SWRO drinking water project in Shuqaiq: Advanced BWRO, membrane oxidation, and scaling. IDA J. 2011, 3, 30–39. [Google Scholar] [CrossRef]

- Sommariva, C.; Attenborough, A.; Poggi, F.; Al-Mahdi, A.A.M.; Hori, T.; Tokunaga, T.K.; Ito, Y.; Maeda, Y. Matching hollow-fiber with spiral-wound membranes: Process compatibility and optimization. IDA J. 2012, 4, 40–44. [Google Scholar] [CrossRef]

- Voutchkov, N. Desalination Cost Assessment and Management; Water Treatment Academy: Johannesburg, South Africa, 2011. [Google Scholar]

- Mubeen, F.M. Unique Design Features of Commercial SWRO Plants. In Proceedings of the IDA World Congress, Albuqerqe, NM, USA, 12–15 November 2007. MP07-001. [Google Scholar]

- Alnouri, S.Y.; Linke, P. Optimal SWRO Network Synthesis with Specifications for Multiple Permeate Components. In Proceedings of the IDA World Congress, Tianjin, China, 20–25 October 2013. TIAN13-221. [Google Scholar]

- Yamamura, H.; Fusaoka, Y.; Kurihara, M. Reverse Osmosis Separation Unit and Operation Method. J.P. Patent 3,351,127, 20 September 2002. [Google Scholar]

- Bhattacharyya, D.; Ridgway, H.; Wilf, M. Future Research Needs to Move Technology forward by Magnitude Note Increment. In Proceedings of the Pacific Rim “Quantum Leap” Membrane Search Symposium, Honolulu, Hawaii, 29–31 March 2004; p. 384. [Google Scholar]

- Du, Y.; Xie, L.; Wang, Y.; Xu, Y.; Wang, S. Optimal Design and Operation of Reverse Osmosis Desalination Process with Spiral Wound Modules. In Proceedings of the IDA World Congress, Tianjin, China, 20–25 October 2013. TIAN13-221. [Google Scholar]

- Gude, V.G. Energy consumption and recovery in reverse osmosis. Desalin. Water Treat. 2011, 36, 239–260. [Google Scholar] [CrossRef]

- Guirguis, M.J. Energy Recovery Devices in Seawater Reverse Osmosis Desalination Plants with Emphasis on Efficiency and Economical Analysis of Isobaric Versus Centrifugal Devices. Ph.D. Thesis, University of South Florida, Tampa, FL, USA, 2011. [Google Scholar]

- Faroque, A. Parametric analysis of energy consumption and losses in SWCC SWRO plants utilizing energy recovery devices. Desalination 2008, 219, 137–159. [Google Scholar] [CrossRef]

- Oklejas, E.; Moch, I.; Nielsen, K. Low cost incremental seawater plant capacity increase by coupling advanced pumping and RO technologies. Desalination 1995, 102, 189–197. [Google Scholar] [CrossRef]

- Penate, B.; Garcia-Rodriguez, L. Energy optimization of existing SWRO (seawater reverse osmosis) plants with ERT (energy recovery turbines): Technical and thermoeconomic assessment. Energy 2011, 36, 613–626. [Google Scholar] [CrossRef]

- Schneider, B. Selection, operation and control of a work exchanger energy recovery system based on the Singapore project. Desalination 2005, 184, 197–210. [Google Scholar] [CrossRef]

- SWRO desalination plant uses ERI pressure exchanger. Membr. Technol. September 2008, 2–3.

- Tu, K.L.; Nghiem, L.D.; Chivas, A.R. Boron removal by reverse osmosis membranes in seawater desalination applications. Separat. Purif. Technol. 2010, 75, 87–101. [Google Scholar] [CrossRef]

- Argust, P. Distribution of boron in the environment. Biol. Trace Elem. Res. 1998, 66, 131–143. [Google Scholar] [CrossRef]

- Busch, M.; Mickois, W.E.; Jons, S.; Redondo, J.; Write, J.D. Boron Removal in Sea Water Desalination. In Proceedings of the IDA World Congress, Paradise Island, Bahamas, 28 September–3 October 2003. BAH03-039. [Google Scholar]

- Rodriguez, M.; Ruiz, A.F.; Chilin, M.F.; Rico, D.P. Influence of pH in the elimination of boron by means of reverse osmosis. Desalination 2001, 140, 145–152. [Google Scholar] [CrossRef]

- Hyung, H.; Kim, J.H. A mechanistic study on boron rejection by sea water reverse osmosis membranes. J. Membr. Sci. 2006, 286, 269–278. [Google Scholar] [CrossRef]

- Henmi, M.; Fusaoka, Y.; Tomioka, H.; Kurihara, M. High performance RO membranes for desalination and wastewater reclamation and their operation results. Water Sci. Technol. 2010, 62, 2134–2140. [Google Scholar] [CrossRef] [PubMed]

- Kurihara, M.; Yamamura, H.; Nakanishi, T. High recovery/high pressure membranes for brine conversion SWRO process development and its performance data. Desalination 1999, 125, 9–15. [Google Scholar] [CrossRef]

- Kurihara, M.; Yamamura, H.; Nakanishi, T.; Jinno, S. Operation and reliability of very high-recovery seawater desalination technologies by brine conversion two-stage RO desalination system. Desalination 2001, 138, 191–199. [Google Scholar] [CrossRef]

- Taniguchi, M.; Kurihara, M.; Kimura, S. Behavior of a reverse osmosis plant adopting a brine conversion two-stage process and its computer simulation. J. Membr. Sci. 2001, 183, 249–257. [Google Scholar] [CrossRef]

- Yamamura, H.; Kurihara, M.; Maeda, K. Apparatus and Method for Multistage Reverse Osmosis Separation. U.S. Patent 6,187,200,B1, 13 February 2001. [Google Scholar]

- Kitamura, K.; Yoshikawa, S. Low Fouling and Energy Save Seawater Reverse Osmosis Desalination System for High Recovery Rate. In Proceedings of the IDA World Congress on Desalination and Water Reuse, San Diego, CA, USA, 31 August–4 September 2015. [Google Scholar]

- Kitamura, K.; Miyakawa, H. Verification of advanced designed seawater RO system for low energy and operation cost. In Proceedings of the IDA World Congress on Desalination and Water Reuse, São Paulo, Brazil, 15–20 October 2017. [Google Scholar]

- Ayumantakath, M.F.; Al Shaiae, M.M.; Green, T.N.; Miyakawa, H.; Ito, Y.; Kurokawa, H.; Fusaoka, Y.; Al Amoudi, A.S. Reliable Sea Water RO Operation with High Water Recovery and No-Chlorine/No-SBS Dosing in Arabian Gulf, Saudi Arabia. In Proceedings of the IDA World Congress on Desalination and Water Reuse, Dubai, United Arab Emirates, 20–24 October 2019. [Google Scholar]

- Kishizawa, N.; Tsuzuki, K.; Hayatsu, M. Low pressure multi-stage RO system developed in “Mega-ton Water System” for large-scaled SWRO plant. Desalination 2015, 368, 81–88. [Google Scholar] [CrossRef]

- Kurihara, M.; Sasaki, T.; Nakatsuji, K.; Kimura, M.; Henmi, M. Low pressure SWRO membrane for desalination in the Mega-ton Water System. Desalination 2015, 368, 135–139. [Google Scholar] [CrossRef]

- Wei, Q.; McGovern, R.; Lienhard, J.H.V. Saving energy with an optimized two-stage reverse osmosis system. Environ. Sci. Water Res. Technol. 2017, 3, 659–670. [Google Scholar] [CrossRef] [Green Version]

- Wei, Q.; McGovern, R.; Lienhard, J.H.V. Two-Stage Reverse Osmosis: Optimal Element Configuration and Energy Savings. In Proceedings of the IDA World Congress, São Paulo, Brazil, 15–20 October 2017. [Google Scholar]

- Sekine, Y.; Takabatake, H.; Noto, K. Start of Product Water Supply from the Integrated System of Seawater Desalination and Sewage Reuse (Water Plaza). Proceedings of Water Environment Symposium, Sapporo, Japan, 18–20 March 2011. [Google Scholar]

- Takabatake, H.; Noto, K.; Uemura, T.; Ueda, S. More than 30% energy saving seawater desalination system by combining with sewage reclamation. Desalin. Water Treat. 2013, 51, 733–741. [Google Scholar] [CrossRef]

- Cheon, J.; Sekine, Y.; Takabatake, H.; Noto, K.; Uemura, T.; Ueda, S. Demonstration of more than 30% of energy saving by the seawater desalination system combined with wastewater treatment system. Water Pract. Technol. 2012, 7, wpt2012059. [Google Scholar] [CrossRef]

- Chin, J.S.S.; Pang, C.M.; Ong, K.W.; Seah, H. Increasing Water Resources through Desalination in Singapore: Planning for a Sustainable Future. In Proceedings of the IDA World Congress, Dubai, United Arab Emirates, 7–12 November 2009. DB09-033. [Google Scholar]

- Seah, H.; Khoo, K.L.; Chua, S.C.; Chua, J.Y.; Toh, C.W. Cost Effective Way to Harvest Estuarine Water Variable Salinity Desalination Concept. In Proceedings of the SIWW 2008, Singapore, 23–27 June 2008. [Google Scholar]

- Closed Circuit RO Eliminates ERD; Water Desalination Report; Global Water Intelligence: Houston, TX, USA, 28 June 2010; Volume 46, p. 24.

- Stover, R. High Recovery Using Closed Circuit Desalination Process for Inland Brackish and Oil and Gas Applications. In Proceedings of the IDA World Congress, Tianjin, China, 20–25 October 2013. TIAN 13-226. [Google Scholar]

- Efaty, A. Apparatus for Continuous Closed Circuit Desalination under Variable Pressure with a Single Container. U.S. Patent 7,628,921B2, 8 December 2009. [Google Scholar]

- Efaty, A. Continuous Closed-Circuit Desalination Apparatus without Containers. U.S. Patent 7,695,614B2, 13 April 2010. [Google Scholar]

- Stover, R.L.; Efraty, N. Record Low Energy Consumption with Closed Circuit Desalination. In Proceedings of the IDA World Congress, Perth, Australia, 4–6 September 2011; pp. 11–375. [Google Scholar]

- Lin, S.; Eimelech, M. Staged reverse osmosis operation: Configurations, energy efficiency, and application potential. Desalination 2015, 366, 9–14. [Google Scholar] [CrossRef]

- Pacenti, P.; de Gerloni, M.; Reali, M.; Chiaramonti, D.; Gartner, S.O.; Helm, P.; Stohr, M. Submarine seawater reverse osmosis desalination system. Desalination 1999, 126, 213–218. [Google Scholar] [CrossRef]

- A New Approach to Deep Sea RO; Water Desalination Report; Global Water Intelligence: Houston, TX, USA, 18 August 2008; Volume 44, pp. 2–3.

- Vuong, D.X. Depth Exposed Membrane for Water Extraction. U.S. Patent 1,908,49A,1, 12 February 2008. [Google Scholar]

- Qiu, T.Y.; Davies, P.A. Concentration polarization model of spiral-wound membrane modules with application to batch-mode RO desalination of brackish water. Desalination 2015, 368, 36–47. [Google Scholar] [CrossRef] [Green Version]

- Brian, P.L.T. Concentration polarization in reverse osmosis desalination with variable flux and incomplete salt rejection. Ind. Eng. Chem. Fundam. 1965, 4, 439–445. [Google Scholar] [CrossRef]

- Taniguchi, M.; Kihara, M.; Yamamura, H.; Kurihara, M. Studies of simulation method based on concentration polarization theory for reverse osmosis seawater desalination plant. Bull. Soc. Sea Water Sci. Jpn. 2002, 56, 247–255. [Google Scholar]

- Matin, A.; Rahman, F.; Shafi, H.Z.; Zubair, S.M. Scaling of reverse osmosis membranes used in water desalination: Phenomena, impact, and control; future directions. Desalination 2019, 455, 135–157. [Google Scholar] [CrossRef]

- Sweity, A.; Oren, Y.; Ronen, Z.; Herberg, M. The influence of antiscalants on biofouling of RO membranes in seawater desalination. Wat. Res. 2013, 47, 3389–3398. [Google Scholar] [CrossRef] [PubMed]

| Year | Events |

|---|---|

| 1950s | Start of exploratory research on RO membranes at Univ. of Florida followed by ULCA. |

| 1960 | Initial type of CA asymmetric membrane was developed. |

| Middle 1960s | General Atomics started the commercialization of CA flat sheet membrane (spiral-wound type). |

| 1968 | DuPont launched the linear PA hollow fibre membrane. Toray started R&D on spiral wound type of CA and PA flat sheet membrane. |

| 1972 | Toyobo started R&D on RO membrane. |

| 1973 | Nitto Denko started R&D on RO membrane. |

| 1977 | Cadotte and his colleagues succeeded in developing a cross-linked aromatic PA membrane. |

| 1980s | Toray developed a cross-linked polyether composite membrane followed by ultra-thin cross-linked PA composite membrane. |

| 1985 | NittoDenko acquired Hydranautics. |

| 1987 | Dow acquired FilmTech. |

| Current | PA composite membranes are main players of SWRO membrane, and main four companies (Toray, DuPont (formerly Dow), Hydranautics and LG) share more than 90% market in the world. |

| Pre-Treatment Type /Basic Process Flow | Advantages/Disadvantages | Plant Examples |

|---|---|---|

|

- Conventional process applied at many plants - Proven technology and easy operation - Unstable efficiency along with the quality of seawater | Sydney (250) Al Jubail (90) Hamma (200) Perth (130) Alicante II (65) Carboneras (120) Ashkelon (330) Tenes (200) |

|

- Better water quality than single DMF - Unstable efficiency along with the quality of seawater | Okinawa (40) Mostaganem (200) Torrevieja (240) Guadalentin (210) |

|

- Better and stable water quality - Limited applicable location - Limited life of well and necessity for renewal | Fukuoka (50) Alicante I (64) |

|

- Better and stable water quality - Applicable even for red tide and oil pollution - Large consumption of chemicals-High operation cost | Tuas (130) Point Lisas (130) |

|

- Excellent and stable water quality - Stable operation against fluctuation of seawater quality - High initial and operation cost | Shuweikh (130) London (150) Tuas II (380) Tianjin (100) |

|

- Excellent and stable water quality - Compact footprint - CDifficulty in corresponding to oils | Magtaa (500) Adelaide (270) Perth II (150) Carlsbad (190) |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Takabatake, H.; Taniguchi, M.; Kurihara, M. Advanced Technologies for Stabilization and High Performance of Seawater RO Membrane Desalination Plants. Membranes 2021, 11, 138. https://doi.org/10.3390/membranes11020138

Takabatake H, Taniguchi M, Kurihara M. Advanced Technologies for Stabilization and High Performance of Seawater RO Membrane Desalination Plants. Membranes. 2021; 11(2):138. https://doi.org/10.3390/membranes11020138

Chicago/Turabian StyleTakabatake, Hiroo, Masahide Taniguchi, and Masaru Kurihara. 2021. "Advanced Technologies for Stabilization and High Performance of Seawater RO Membrane Desalination Plants" Membranes 11, no. 2: 138. https://doi.org/10.3390/membranes11020138

APA StyleTakabatake, H., Taniguchi, M., & Kurihara, M. (2021). Advanced Technologies for Stabilization and High Performance of Seawater RO Membrane Desalination Plants. Membranes, 11(2), 138. https://doi.org/10.3390/membranes11020138