Highly Dispersed CeOx Hybrid Nanoparticles for Perfluorinated Sulfonic Acid Ionomer–Poly(tetrafluoethylene) Reinforced Membranes with Improved Service Life

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Synthesis of CeOx Hybrid Nanoparticles

2.3. Fabrication of PFSA–PTFE Reinforced Membranes

2.4. Characterization

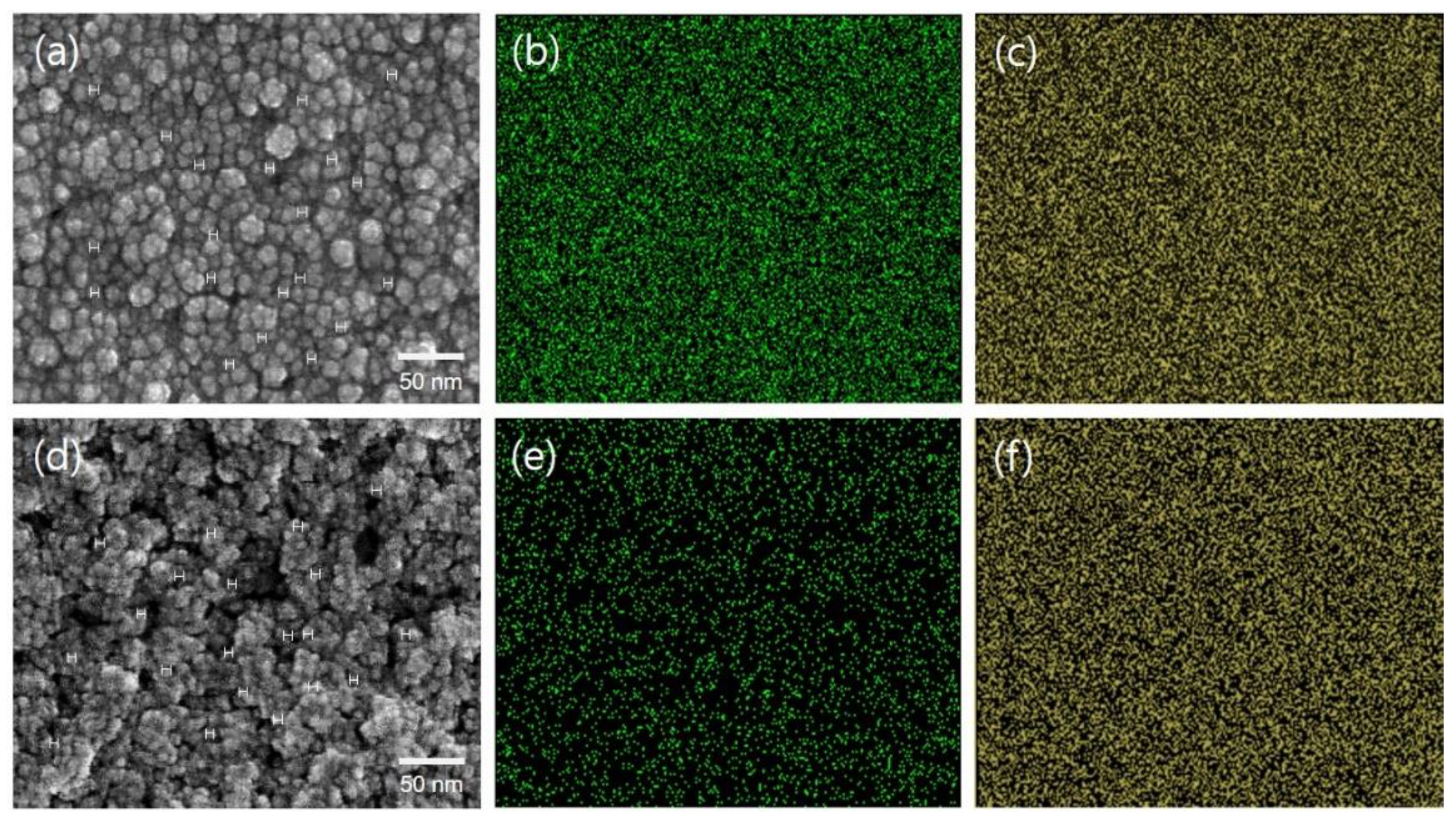

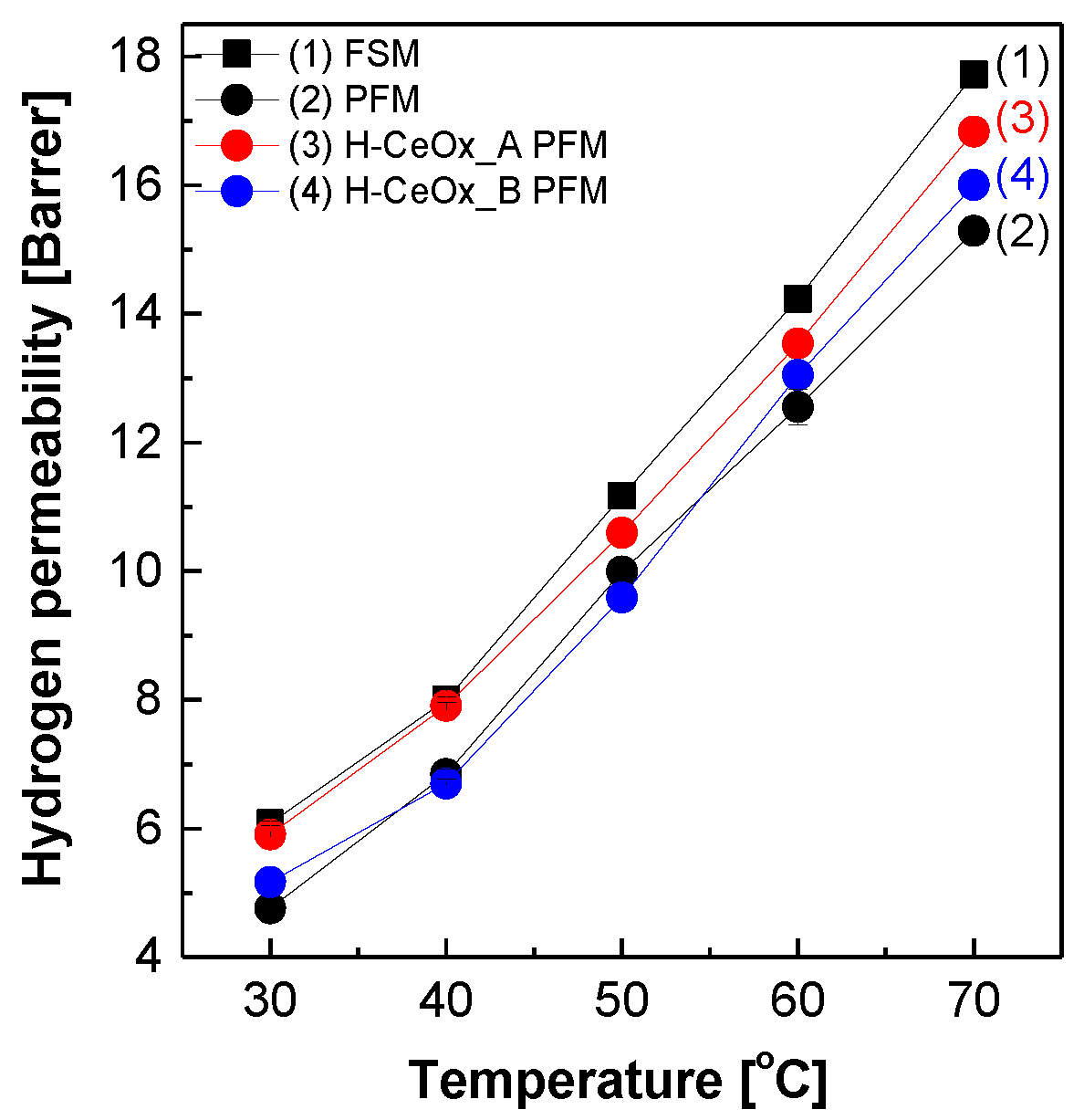

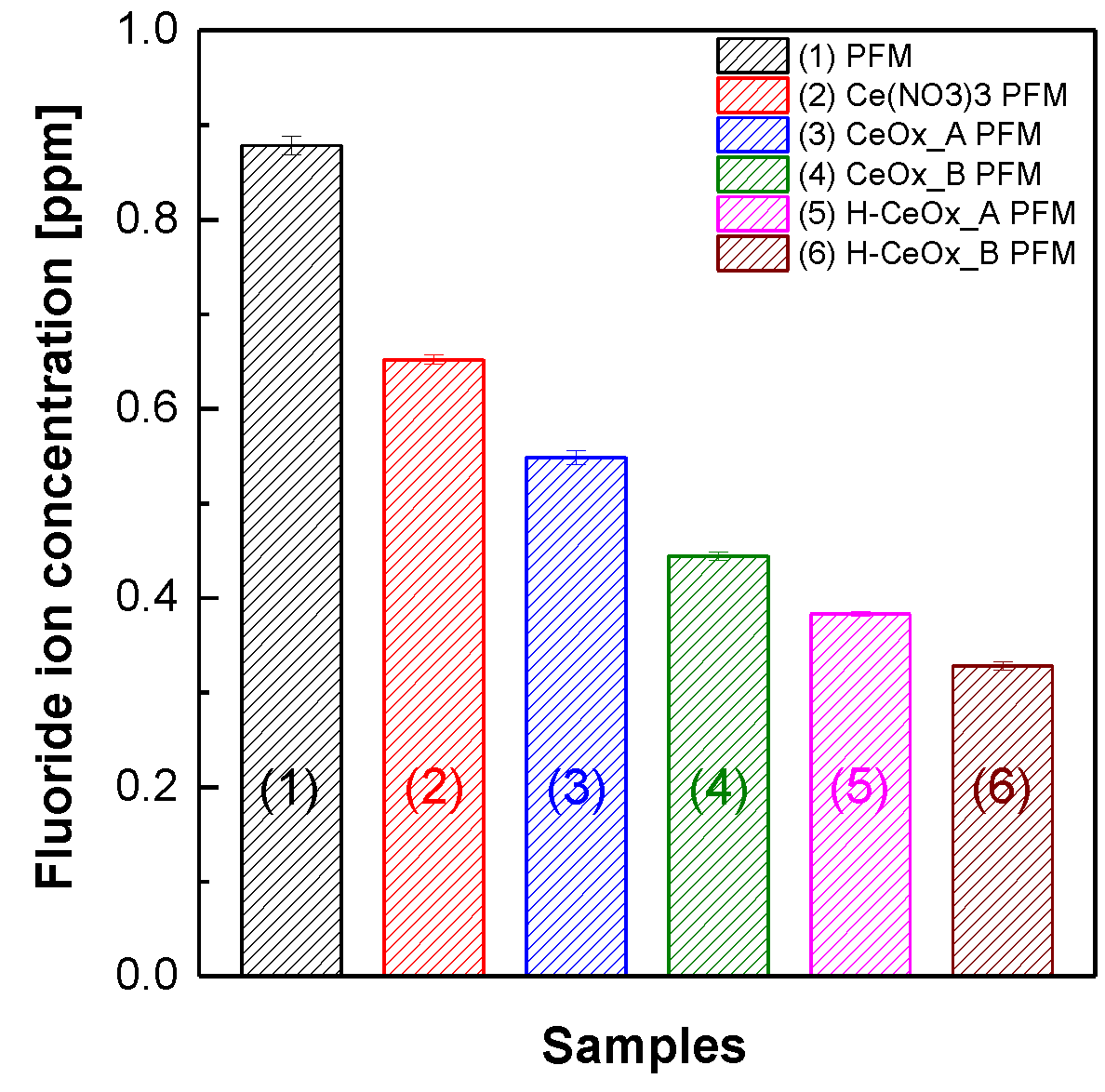

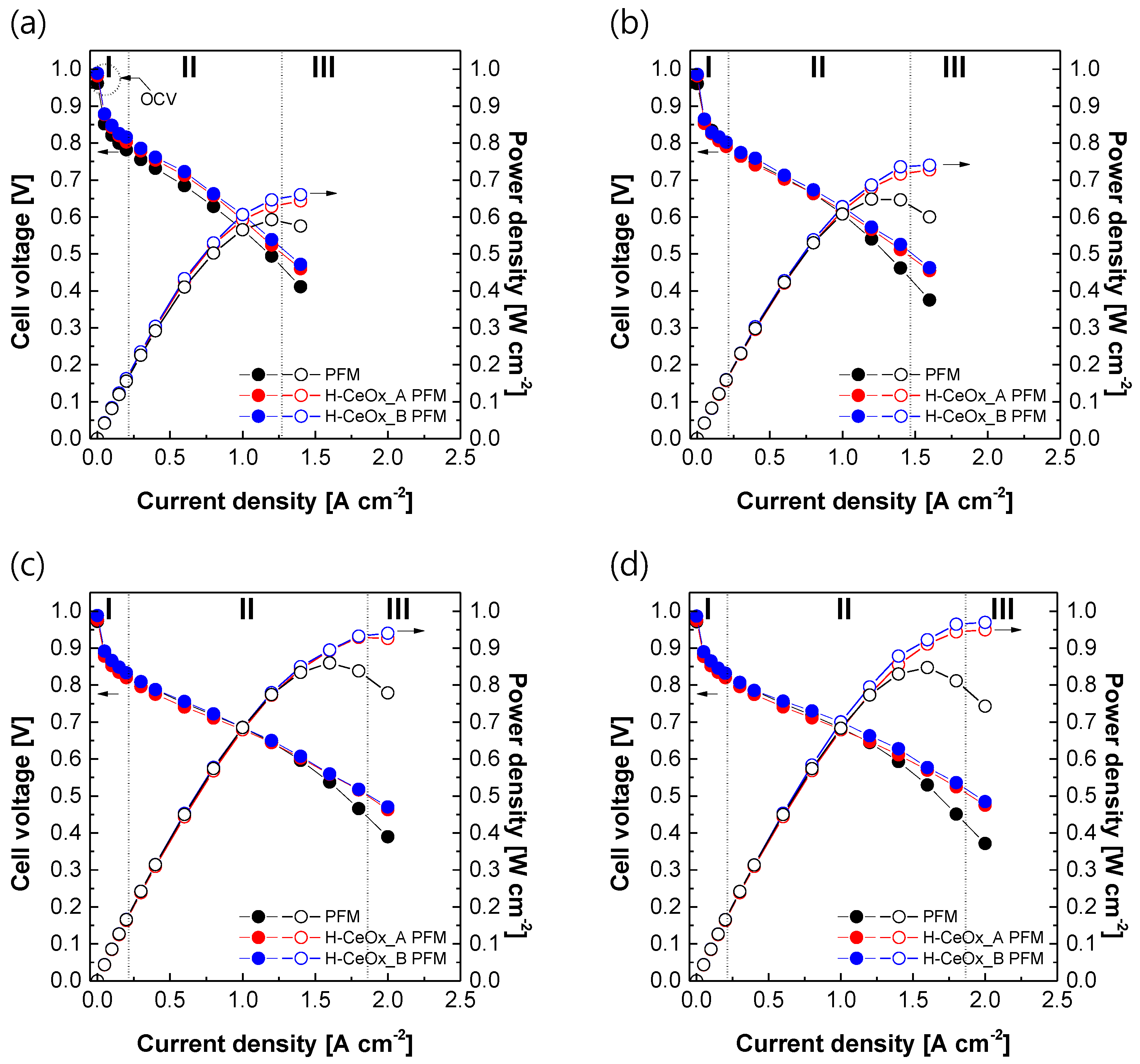

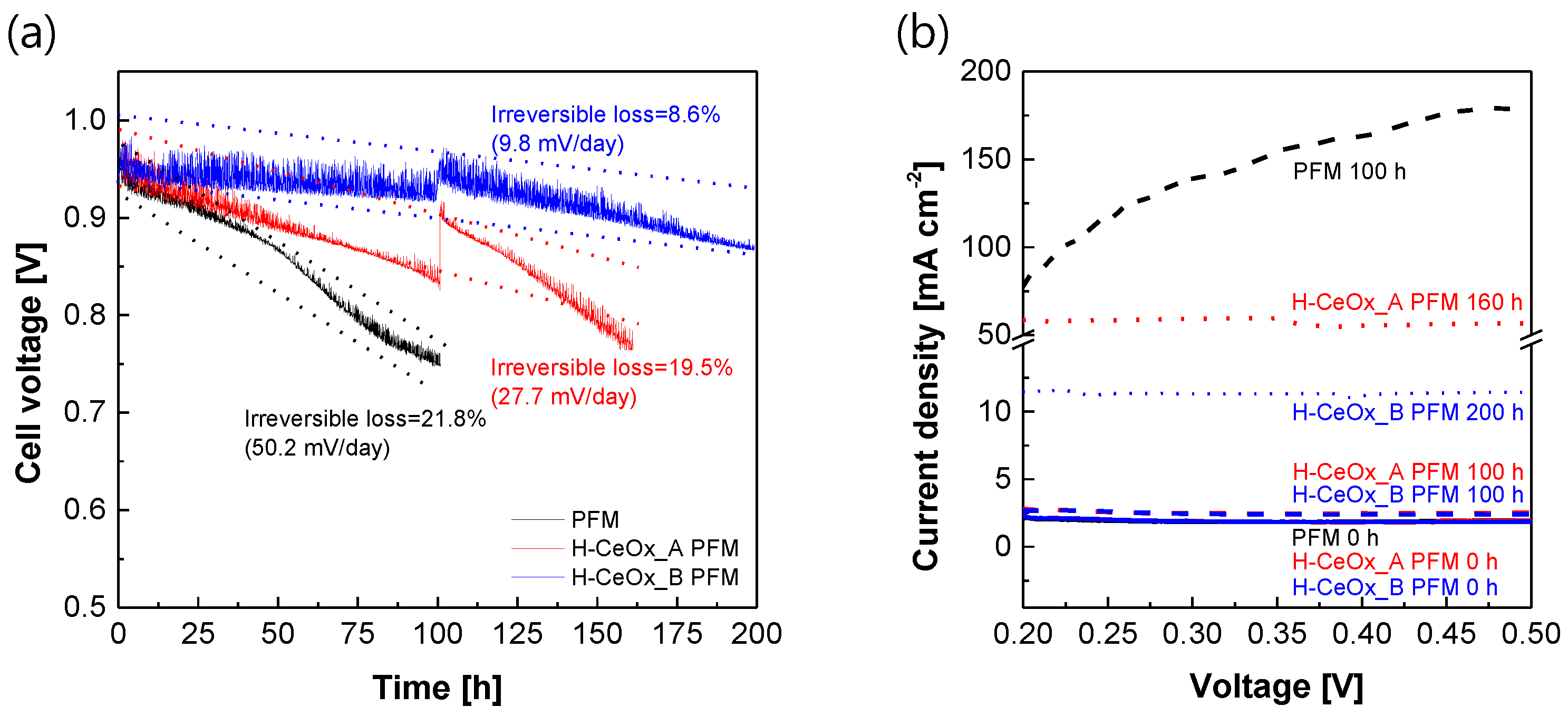

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Carrette, L.; Friedrich, K.A.; Stimming, U. Fuel Cells – Fundamentals and Applications. Fuel Cells 2001, 1, 5–39. [Google Scholar] [CrossRef]

- Schnurnberger, W. Fuel Cells and Their Applications. KARL KORDESCH. GÜNTER SIMADER VCH Verlagsgesellschaft, Weinheim, 1996, 320 Seiten, geb., DM 248,-, ISBN 3-527-28579-2. Chem. Ing. Tech. 1997, 69, 852. [Google Scholar] [CrossRef]

- De Bruijn, F.D.; Dam, V.A.T.; Janssen, G.J.M. Review: Durability and Degradation Issues of PEM Fuel Cell Components. Fuel Cells 2008, 8, 3–22. [Google Scholar] [CrossRef]

- Wang, Y.; Chen, K.S.; Mishler, J.; Cho, S.C.; Adroher, X.C. A review of polymer electrolyte membrane fuel cells: Technology, applications, and needs on fundamental research. Appl. Energy 2011, 88, 981–1007. [Google Scholar] [CrossRef]

- Wu, J.; Yuan, X.Z.; Martin, J.J.; Wang, H.; Zhang, J.; Shen, J.; Wu, S.; Merida, W. A review of PEM fuel cell durability: Degradation mechanisms and mitigation strategies. J. Power Sources 2008, 184, 104–119. [Google Scholar] [CrossRef]

- Zhao, H.; Burke, A.F. Optimization of fuel cell system operating conditions for fuel cell vehicles. J. Power Sources 2009, 186, 408–416. [Google Scholar] [CrossRef]

- Kreuer, K. On the development of proton conducting materials for technological applications. Solid State Ionics 1997, 97, 1–15. [Google Scholar] [CrossRef]

- Kreuer, K.-D.; Paddison, S.J.; Spohr, E.; Schuster, M. Transport in Proton Conductors for Fuel-Cell Applications: Simulations, Elementary Reactions, and Phenomenology. Chem. Rev. 2004, 104, 4637–4678. [Google Scholar] [CrossRef] [PubMed]

- Paddison, S.J. The modelling of molecular structure and ion transport in sulfonic acid based ionomer membranes. J. New. Mat. Electrochem. System 2001, 4, 197–207. [Google Scholar]

- Collier, A.; Wang, H.; Yuan, X.Z.; Zhang, J.; Wilkinson, D.P. Degradation of polymer electrolyte membranes. Int. J. Hydrogen Energy 2006, 31, 1838–1854. [Google Scholar] [CrossRef]

- Rodgers, M.P.; Bonville, L.J.; Kunz, H.R.; Slattery, D.K.; Fenton, J.M. Fuel Cell Perfluorinated Sulfonic Acid Membrane Degradation Correlating Accelerated Stress Testing and Lifetime. Chem. Rev. 2012, 112, 6075–6103. [Google Scholar] [CrossRef]

- Yamaguchi, T.; Ibe, M.; Nair, B.N.; Nakao, S.-I. A Pore-Filling Electrolyte Membrane-Electrode Integrated System for a Direct Methanol Fuel Cell Application. J. Electrochem. Soc. 2002, 149, A1448. [Google Scholar] [CrossRef]

- Yamaguchi, T.; Miyata, F.; Nakao, S. Polymer Electrolyte Membranes with a Pore-Filling Structure for a Direct Methanol Fuel Cell. Adv. Mater. 2003, 15, 1198–1201. [Google Scholar] [CrossRef]

- Yamaguchi, T.; Miyata, F.; Nakao, S.-I. Pore-filling type polymer electrolyte membranes for a direct methanol fuel cell. J. Membr. Sci. 2003, 214, 283–292. [Google Scholar] [CrossRef]

- Yamaguchi, T.; Zhou, H.; Nakazawa, S.; Hara, N. An Extremely Low Methanol Crossover and Highly Durable Aromatic Pore-Filling Electrolyte Membrane for Direct Methanol Fuel Cells. Adv. Mater. 2007, 19, 592–596. [Google Scholar] [CrossRef]

- Shim, J.; Ha, H.Y.; Hong, S.-A.; Oh, I.-H. Characteristics of the Nafion ionomer-impregnated composite membrane for polymer electrolyte fuel cells. J. Power Sources 2002, 109, 412–417. [Google Scholar] [CrossRef]

- Danilczuk, M.; Coms, F.D.; Schlick, S. Visualizing Chemical Reactions and Crossover Processes in a Fuel Cell Inserted in the ESR Resonator: Detection by Spin Trapping of Oxygen Radicals, Nafion-Derived Fragments, and Hydrogen and Deuterium Atoms. J. Phys. Chem. B 2009, 113, 8031–8042. [Google Scholar] [CrossRef]

- Ishimoto, T.; Koyama, M. A Review of Molecular-Level Mechanism of Membrane Degradation in the Polymer Electrolyte Fuel Cell. Membranes 2012, 2, 395–414. [Google Scholar] [CrossRef] [PubMed]

- Luo, X.; Ghassemzadeh, L.; Holdcroft, S. Effect of free radical-induced degradation on water permeation through PFSA ionomer membranes. Int. J. Hydrogen Energy 2015, 40, 16714–16723. [Google Scholar] [CrossRef]

- Zaton, M.; Rozière, J.; Jones, D. Current understanding of chemical degradation mechanisms of perfluorosulfonic acid membranes and their mitigation strategies: A review. Sustain. Energy Fuels 2017, 1, 409–438. [Google Scholar] [CrossRef]

- Chiodelli, G.; Malavasi, L. Electrochemical open circuit voltage (OCV) characterization of SOFC materials. Ionics 2013, 19, 1135–1144. [Google Scholar] [CrossRef]

- Park, C.H.; Lee, C.H. Disulfonated copolyimide-boehmite nanocomposite fuel cell membranes with improved chemical resistance. Macromol. Res. 2014, 23, 45–52. [Google Scholar] [CrossRef]

- Frey, M.H.; Pierpont, D.M.; Hamrock, S.J. High durability fuel cell components with cerium salt additives. U.S. Patent 9,431,670 B2, 30 August 2016. [Google Scholar]

- Wang, L.; Advani, S.G.; Prasad, A.K. Degradation reduction of polymer electrolyte membranes using CeO2 as a free-radical scavenger in catalyst layer. Electrochimica Acta 2013, 109, 775–780. [Google Scholar] [CrossRef]

- Lei, M.; Yang, T.; Wang, W.; Huang, K.; Zhang, Y.; Zhang, R.; Jiao, R.; Fu, X.; Yang, H.; Wang, Y.; et al. One-dimensional manganese oxide nanostructures as radical scavenger to improve membrane electrolyte assembly durability of proton exchange membrane fuel cells. J. Power Sources 2013, 230, 96–100. [Google Scholar] [CrossRef]

- Xing, D.; Zhang, H.; Wang, L.; Zhai, Y.; Yi, B. Investigation of the Ag-SiO2/sulfonated poly(biphenyl ether sulfone) composite membranes for fuel cell. J. Membr. Sci. 2007, 296, 9–14. [Google Scholar] [CrossRef]

- Binks, B.P.; Lumsdon, S.O. Stability of oil-in-water emulsions stabilised by silica particles. Phys. Chem. Chem. Phys. 1999, 1, 3007–3016. [Google Scholar] [CrossRef]

- Adjemian, K.T.; Dominey, R.; Krishnan, L.; Ota, H.; Majsztrik, P.; Zhang, T.; Mann, J.; Kirby, B.; Gatto, L.; Velo-Simpson, M.; et al. Function and Characterization of Metal Oxide−Nafion Composite Membranes for Elevated-Temperature H2/O2 PEM Fuel Cells. Chem. Mater. 2006, 18, 2238–2248. [Google Scholar] [CrossRef]

- Apichatachutapan, W.; Moore, R.B.; Mauritz, K.A. Asymmetric nafion/(zirconium oxide) hybrid membranes via in situ sol-gel chemistry. J. Appl. Polym. Sci. 1996, 62, 417–426. [Google Scholar] [CrossRef]

- Ahn, C.-Y.; Ahn, J.; Kang, S.Y.; Kim, O.-H.; Lee, D.W.; Lee, J.H.; Shim, J.G.; Lee, C.H.; Cho, Y.-H.; Sung, Y.-E. Enhancement of service life of polymer electrolyte fuel cells through application of nanodispersed ionomer. Sci. Adv. 2020, 6, eaaw0870. [Google Scholar] [CrossRef]

- Lee, C.H.; Lee, K.-S.; Lane, O.; McGrath, J.E.; Chen, Y.; Wi, S.; Lee, S.Y.; Lee, Y.M. Solvent-assisted thermal annealing of disulfonated poly(arylene ether sulfone) random copolymers for low humidity polymer electrolyte membrane fuel cells. RSC Adv. 2011, 2, 1025–1032. [Google Scholar] [CrossRef]

- Li, Y.; Wang, F.; Yang, J.; Liu, D.; Roy, A.; Case, S.; Lesko, J.; McGrath, J.E. Synthesis and characterization of controlled molecular weight disulfonated poly(arylene ether sulfone) copolymers and their applications to proton exchange membranes. Polymer 2006, 47, 4210–4217. [Google Scholar] [CrossRef]

- Sumner, M.; Harrison, W.; Weyers, R.; Kim, Y.; McGrath, J.; Riffle, J.; Brink, A.; Brink, M. Novel proton conducting sulfonated poly(arylene ether) copolymers containing aromatic nitriles. J. Membr. Sci. 2004, 239, 199–211. [Google Scholar] [CrossRef]

- Wang, F.; Hickner, M.; Kim, Y.S.; Zawodzinski, T.A.; McGrath, J.E. Direct polymerization of sulfonated poly(arylene ether sulfone) random (statistical) copolymers: Candidates for new proton exchange membranes. J. Membr. Sci. 2002, 197, 231–242. [Google Scholar] [CrossRef]

- Lee, C.H.; Park, H.B.; Lee, Y.M.; Lee, R.D. Importance of Proton Conductivity Measurement in Polymer Electrolyte Membrane for Fuel Cell Application. Ind. Eng. Chem. Res. 2005, 44, 7617–7626. [Google Scholar] [CrossRef]

- Rutherford, S.W.; Do, D.D. Review of time lag permeation technique as a method for characterisation of porous media and membranes. Adsorption 1997, 3, 283–312. [Google Scholar] [CrossRef]

- Fuel Cell Technical Team Roadmap, Driving Research and Innovator for Vehicle Efficiency and Energy Sustainability. Available online: https://www.energy.gov/eere/vehicles/downloads/us-drive-fuel-cell-technical-team-roadmap (accessed on 27 November 2017).

- Calvache-Muñoz, J.; Prado, F.A.; Rodríguez-Páez, J.E. Cerium oxide nanoparticles: Synthesis, characterization and tentative mechanism of particle formation. Colloids Surfaces A Physicochem. Eng. Asp. 2017, 529, 146–159. [Google Scholar] [CrossRef]

- He, H.-W.; Wu, X.-Q.; Ren, W.; Shi, P.; Yao, X.; Song, Z.-T. Synthesis of crystalline cerium dioxide hydrosol by a sol–gel method. Ceram. Int. 2012, 38, S501–S504. [Google Scholar] [CrossRef]

- Nabavi, M.; Spalla, O.; Cabane, B. Surface Chemistry of Nanometric Ceria Particles in Aqueous Dispersions. J. Colloid Interface Sci. 1993, 160, 459–471. [Google Scholar] [CrossRef]

- Abellan, P.; Moser, T.H.; Lucas, I.T.; Grate, J.W.; Evans, J.E.; Browning, N.D. The formation of cerium(iii) hydroxide nanoparticles by a radiation mediated increase in local pH. RSC Adv. 2017, 7, 3831–3837. [Google Scholar] [CrossRef]

- Sayle, T.X.T.; Molinari, M.; Das, S.; Bhatta, U.M.; Möbus, G.; Parker, S.C.; Seal, S.; Sayle, D.C. Environment-mediated structure, surface redox activity and reactivity of ceria nanoparticles. Nanoscale 2013, 5, 6063–6073. [Google Scholar] [CrossRef]

- Cerium (IV) Oxide. Available online: https://en.wikipedia.org/wiki/Cerium(IV)_oxide (accessed on 29 January 2021).

- Barany, S.; Bohacs, K.; Chepurna, I.; Meszaros, R. Electrokinetic properties and stability of cerium dioxide suspensions. RSC Adv. 2016, 6, 69343–69351. [Google Scholar] [CrossRef]

- Gulicovski, J.J.; Bračko, I.; Milonjić, S.K. Morphology and the isoelectric point of nanosized aqueous ceria sols. Mater. Chem. Phys. 2014, 148, 868–873. [Google Scholar] [CrossRef]

- Chanteau, B.; Fresnais, J.; Berret, J.-F. Electrosteric Enhanced Stability of Functional Sub-10 nm Cerium and Iron Oxide Particles in Cell Culture Medium. Langmuir 2009, 25, 9064–9070. [Google Scholar] [CrossRef]

- Sehgal, A.; Lalatonne, Y.; Berret, J.-F.; Morvan, M. Precipitation−Redispersion of Cerium Oxide Nanoparticles with Poly(acrylic acid): Toward Stable Dispersions. Langmuir 2005, 21, 9359–9364. [Google Scholar] [CrossRef] [PubMed]

- Curtin, D.E.; Lousenberg, R.D.; Henry, T.J.; Tangeman, P.C.; Tisack, M.E. Advanced materials for improved PEMFC performance and life. J. Power Sources 2004, 131, 41–48. [Google Scholar] [CrossRef]

- Inaba, M.; Sugishita, M.; Wada, J.; Matsuzawa, K.; Yamada, H.; Tasaka, A. Impacts of air bleeding on membrane degradation in polymer electrolyte fuel cells. J. Power Sources 2008, 178, 699–705. [Google Scholar] [CrossRef]

- Kinumoto, T.; Inaba, M.; Nakayama, Y.; Ogata, K.; Umebayashi, R.; Tasaka, A.; Iriyama, Y.; Abe, T.; Ogumi, Z. Durability of perfluorinated ionomer membrane against hydrogen peroxide. J. Power Sources 2006, 158, 1222–1228. [Google Scholar] [CrossRef]

- Chen, C.; Fuller, T.F. The effect of humidity on the degradation of Nafion® membrane. Polym. Degrad. Stab. 2009, 94, 1436–1447. [Google Scholar] [CrossRef]

- Xu, C.; Qu, X. Cerium oxide nanoparticle: A remarkably versatile rare earth nanomaterial for biological applications. NPG Asia Mater. 2014, 6, e90. [Google Scholar] [CrossRef]

- Akrout, A.; Delrue, A.; Zatoń, M.; Duquet, F.; Spanu, F.; Taillades-Jacquin, M.; Cavaliere, S.; Jones, D.; Rozière, J. Immobilisation and Release of Radical Scavengers on Nanoclays for Chemical Reinforcement of Proton Exchange Membranes. Membranes 2020, 10, 208. [Google Scholar] [CrossRef] [PubMed]

- Baker, A.M.; Dumont, J.H.; Mukundan, R.; Advani, S.G.; Prasad, A.K.; Spernjak, D.; Borup, R.L. The Effects of Cerium Migration on PEM Fuel Cell Performance. ECS Trans. 2017, 80, 643–650. [Google Scholar] [CrossRef]

- D’Urso, C.; Oldani, C.; Baglio, V.; Merlo, L.; Aricò, A. Towards fuel cell membranes with improved lifetime: Aquivion® Perfluorosulfonic Acid membranes containing immobilized radical scavengers. J. Power Sources 2014, 272, 753–758. [Google Scholar] [CrossRef]

- Baker, A.M.; Williams, S.T.D.; Mukundan, R.; Spernjak, D.; Advani, S.G.; Prasad, A.K.; Borup, R.L. Zr-doped ceria additives for enhanced PEM fuel cell durability and radical scavenger stability. J. Mater. Chem. A 2017, 5, 15073–15079. [Google Scholar] [CrossRef]

| Sample | Average Particle Size [nm] | Ce3+ Concentration [ppm] d | CeOx Conversion f [mol%] | |||

|---|---|---|---|---|---|---|

| t e = 0 | t e = 12 | t e = 24 | t e = 12 | t e = 24 | ||

| Pristine dispersion a | 2.2 ± 0.2 | 0 | 0 | 0 | 0 | 0 |

| Ce(NO3)3 dispersion | 2.8 ± 0.3 b | 15,200 b | – | – | – | – |

| CeOx_A dispersion | 61 ± 2 c | 15,200 b | 13,700 | 10,000 | 9.87 | 34.2 |

| CeOx_B dispersion | 152 ± 5 c | 15,200 b | 9700 | 4700 | 36.2 | 69.1 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ahn, J.; Ali, M.I.; Lim, J.H.; Park, Y.; Park, I.K.; Duchesne, D.; Chen, L.; Kim, J.; Lee, C.H. Highly Dispersed CeOx Hybrid Nanoparticles for Perfluorinated Sulfonic Acid Ionomer–Poly(tetrafluoethylene) Reinforced Membranes with Improved Service Life. Membranes 2021, 11, 143. https://doi.org/10.3390/membranes11020143

Ahn J, Ali MI, Lim JH, Park Y, Park IK, Duchesne D, Chen L, Kim J, Lee CH. Highly Dispersed CeOx Hybrid Nanoparticles for Perfluorinated Sulfonic Acid Ionomer–Poly(tetrafluoethylene) Reinforced Membranes with Improved Service Life. Membranes. 2021; 11(2):143. https://doi.org/10.3390/membranes11020143

Chicago/Turabian StyleAhn, Juhee, Mobina Irshad Ali, Jun Hyun Lim, Yejun Park, In Kee Park, Denis Duchesne, Lisa Chen, Juyoung Kim, and Chang Hyun Lee. 2021. "Highly Dispersed CeOx Hybrid Nanoparticles for Perfluorinated Sulfonic Acid Ionomer–Poly(tetrafluoethylene) Reinforced Membranes with Improved Service Life" Membranes 11, no. 2: 143. https://doi.org/10.3390/membranes11020143

APA StyleAhn, J., Ali, M. I., Lim, J. H., Park, Y., Park, I. K., Duchesne, D., Chen, L., Kim, J., & Lee, C. H. (2021). Highly Dispersed CeOx Hybrid Nanoparticles for Perfluorinated Sulfonic Acid Ionomer–Poly(tetrafluoethylene) Reinforced Membranes with Improved Service Life. Membranes, 11(2), 143. https://doi.org/10.3390/membranes11020143