Development of Filter Media by Electrospinning for Air Filtration of Nanoparticles from PET Bottles

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Electrospinning process

2.3. Characterization of the electrospun mats

2.4. Evaluation of PM removal efficiencies

3. Results

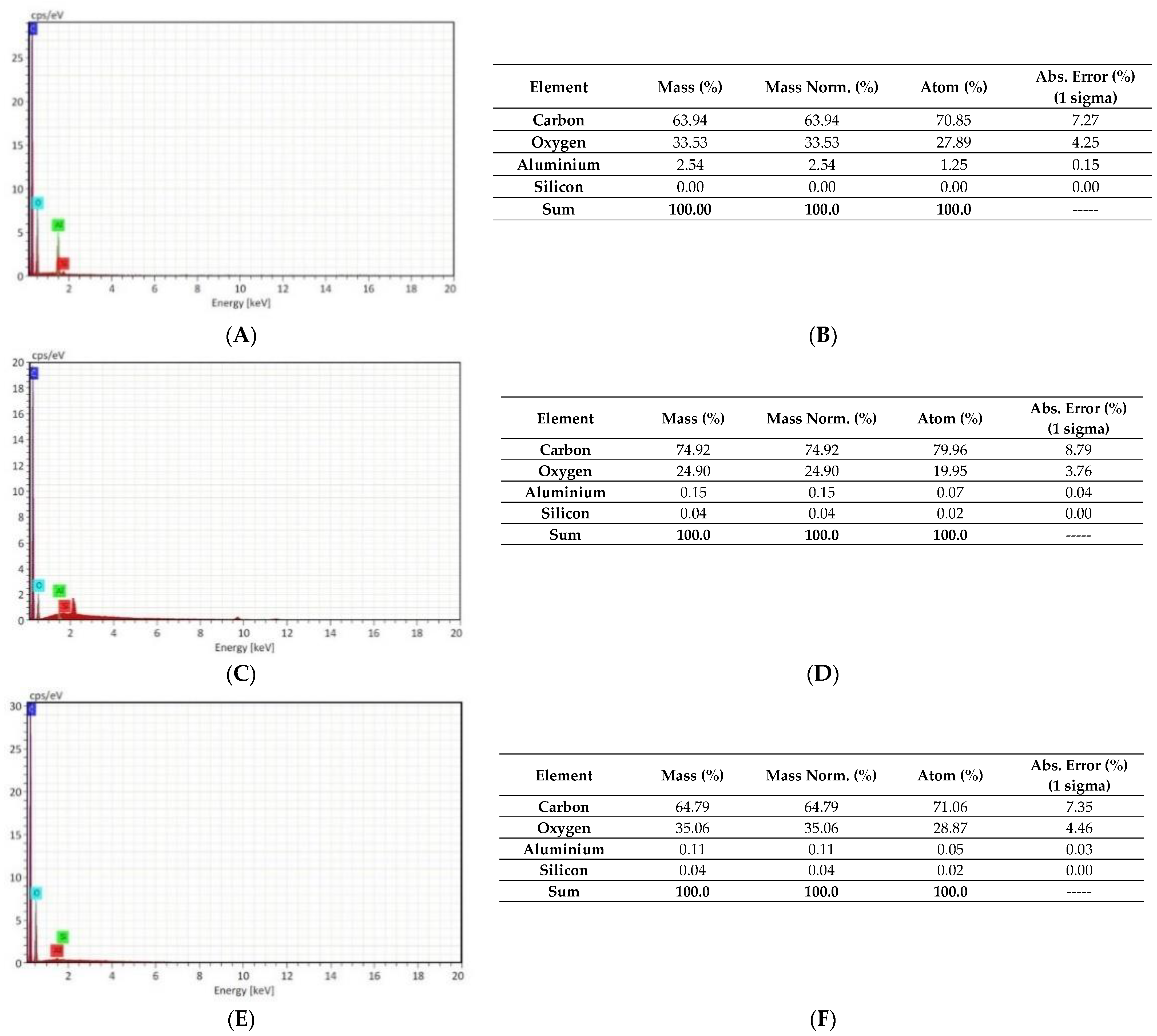

3.1. Morphological characteristics of the fibers

3.2. Permeability, pressure drop and filtration performance of filters media

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Geng, L.; Wu, Z.; Zhang, S.; Zhou, K. The end effect in air pollution: The role of perceived difference. J. Environ. Manag. 2019, 232, 413–420. [Google Scholar] [CrossRef] [PubMed]

- Li, V.O.; Han, Y.; Lam, J.; Zhu, Y.; Bacon-Shone, J. Air pollution and environmental injustice: Are the socially deprived exposed to more PM2.5 pollution in Hong Kong? Environ. Sci. Policy 2018, 80, 53–61. [Google Scholar] [CrossRef]

- Yang, J.; Zhang, B. Air pollution and healthcare expenditure: Implication for the benefit of air pollution control in China. Environ. Int. 2018, 120, 443–455. [Google Scholar] [CrossRef]

- Aunan, K.; Liu, Z.; Wang, S. The Hidden Hazard of Household Air Pollution in Rural China. Environ. Sci. Policy 2019, 93, 27–33. [Google Scholar] [CrossRef]

- Karimi, B.; Samadi, S. Mortality and hospitalizations due to cardiovascular and respiratory diseases associated with air pollution in Iran: A systematic review and meta- analysis. Atmos. Environ. 2019, 198, 438–447. [Google Scholar] [CrossRef]

- Li, Y.; Yin, X.; Yu, J.; Ding, B. Electrospun nanofibers for high-performance air filtration. Compos. Commun. 2019, 15, 6–19. [Google Scholar] [CrossRef]

- Chinchillas-Chinchillas, M.J.; Gaxiola, A.; Alvarado-Beltrán, C.G.; Orozco-Carmona, V.M.; Pellegrini-Cervantes, M.J.; Rodríguez-Rodríguez, M.; Castro-Beltrán, A. A new application of recycled-PET/PAN composite nanofibers to cement–based materials. J. Clean. Prod. 2020, 252, 119827. [Google Scholar] [CrossRef]

- Dutt, K.; Soni, R.K. A review on synthesis of value added products from polyethylene terephthalate (PET) waste. Polym. Sci. Ser. B 2013, 55, 430–452. [Google Scholar] [CrossRef]

- Al-Attabi, R.; Dumée, L.F.; Schütz, J.A.; Morsi, Y. Pore engineering towards highly efficient electrospun nanofibrous membranes for aerosol particle removal. Sci. Total Environ. 2018, 625, 706–715. [Google Scholar] [CrossRef]

- Cho, D.; Naydich, A.; Frey, M.W.; Lak, Y. Further improvement of air filtration efficiency of cellulose filters coated with nanofibers via inclusion of electrostatically active nanoparticles. Polymer (Guildf) 2013, 54, 2364–2372. [Google Scholar] [CrossRef]

- Leung, W.W.F.; Hung, C.H.; Yuen, P.T. Effect of face velocity, nanofiber packing density and thickness on filtration performance of filters with nanofibers coated on a substrate. Sep. Purif. Technol. 2010, 71, 30–37. [Google Scholar] [CrossRef]

- Zhu, M.; Hua, D.; Zhong, M.; Zhang, L.; Wang, F.; Gao, B. Antibacterial and Effective Air Filtration Membranes by “ Green ” Electrospinning and Citric Acid Crosslinking. Colloid Interface Sci. Commun. 2018, 23, 52–58. [Google Scholar] [CrossRef]

- Di, X.; Zhang, W.; Zang, D.; Liu, F.; Wang, Y.; Wang, C. A novel method for the fabrication of superhydrophobic nylon net. Chem. Eng. J. 2016, 306, 53–59. [Google Scholar] [CrossRef]

- Matulevicius, J.; Kliucininkas, L.; Prasauskas, T.; Buivydiene, D.; Martuzevicius, D. The comparative study of aerosol filtration by electrospun polyamide, polyvinyl acetate, polyacrylonitrile and cellulose acetate nanofiber media. J. Aerosol Sci. 2016, 92, 27–37. [Google Scholar] [CrossRef]

- Barhate, R.S.; Ramakrishna, S. Nanofibrous filtering media: Filtration problems and solutions from tiny materials. J. Memb. Sci. 2007, 296, 1–8. [Google Scholar] [CrossRef]

- Khorram, M.; Mousavi, A.; Mehranbod, N. Chromium removal using adsorptive membranes composed of electrospun plasma-treated functionalized polyethylene terephthalate (PET) with chitosan. J. Environ. Chem. Eng. 2017, 5, 2366–2377. [Google Scholar] [CrossRef]

- Mercante, L.A.; Scagion, V.P.; Migliorini, F.L.; Mattoso, L.H.C.; Correa, D.S. Trends in Analytical Chemistry Electrospinning-based (bio) sensors for food and agricultural applications: A review. Trends Anal. Chem. 2017, 91, 91–103. [Google Scholar] [CrossRef]

- Sill, T.J.; von Recum, H.A. Electrospinning: Applications in drug delivery and tissue engineering. Biomaterials 2008, 29, 1989–2006. [Google Scholar] [CrossRef] [PubMed]

- Cramariuc, B.; Cramariuc, R.; Scarlet, R.; Rozemarie, L.; Lupu, I.G. Fiber diameter in electrospinning process. J. Electrost. 2013, 71, 189–198. [Google Scholar] [CrossRef]

- Wan, H.; Wang, N.; Yang, J.; Si, Y.; Chen, K.; Ding, B.; Sun, G.; El-Newehy, M.; Al-Deyab, S.S.; Yu, J. Hierarchically structured polysulfone/titania fibrous membranes with enhanced air filtration performance. J. Colloid Interface Sci. 2014, 417, 18–26. [Google Scholar] [CrossRef]

- Zhu, M.; Han, J.; Wang, F.; Shao, W.; Xiong, R. Electrospun Nanofibers Membranes for Effective Air Filtration. Macromol. Mater. Eng. 2017, 302, 1600353. [Google Scholar] [CrossRef]

- Guibo, Y.; Qing, Z.; Yahong, Z.; Yin, Y.; Yumin, Y. The Electrospun Polyamide 6 Nanofiber Membranes Used as High Efficiency Filter Materials: Filtration Potential, Thermal Treatment, and Their Continuous Production. J. Appl. Polym. Sci. 2013, 128, 1061–1069. [Google Scholar] [CrossRef]

- Strain, I.N.; Wu, Q.; Pourrahimi, A.M.; Hedenqvist, M.S.; Olsson, R.T.; Andersson, R.L. Electrospinning of recycled PET to generate tough mesomorphic fibre membranes for smoke. J. Mater. Chem. A 2015, 1632–1640. [Google Scholar] [CrossRef] [Green Version]

- Veleirinho, B.; Rei, M.F.; Lopes-da-Silva, J.A. Solvent and Concentration Effects on the Properties of Electrospun Poly(ethylene terephthalate) Nanofiber Mats. J. Polym. Sci. Part B Polym. Phys. 2008, 46, 460–471. [Google Scholar] [CrossRef]

- Mahalingam, S.; Raimi-abraham, B.T.; Craig, D.Q.M. Solubility—Spinnability map and model for the preparation of fibres of polyethylene (terephthalate) using gyration and pressure. Chem. Eng. J. 2015, 280, 344–353. [Google Scholar] [CrossRef] [Green Version]

- Zander, N.E.; Gillan, M.; Sweetser, D. Recycled PET Nanofibers for Water Filtration Applications. Materials 2016, 9, 247. [Google Scholar] [CrossRef] [Green Version]

- Salussoglia, A.I.P.; Tanabe, E.H.; Aguiar, M.L. Evaluation of a vacuum collection system in the preparation of PAN fibers by forcespinning for application in ultrafine particle filtration. J. Appl. Polym. Sci. 2020, 137, 49334. [Google Scholar] [CrossRef]

- Bortolassi, A.C.C.; Guerra, V.G.; Aguiar, M.L. Characterization and evaluate the efficiency of different filter media in removing nanoparticles. Sep. Purif. Technol. 2017, 175, 79–86. [Google Scholar] [CrossRef]

- Bortolassi, A.C.C.; Nagarajan, S.; Lima, B.d.; Guerra, V.G.; Aguiar, M.L.; Huon, V.; Soussan, L.; Cornu, D.; Miele, P.; Bechelany, M. Efficient nanoparticles removal and bactericidal action of electrospun nanofibers membranes for air filtration. Mater. Sci. Eng. C 2019, 102, 718–729. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Cao, M.; Gu, F.; Rao, C.; Fu, J.; Zhao, P. Improving the electrospinning process of fabricating nanofibrous membranes to filter PM2.5. Sci. Total Environ. 2019, 666, 1011–1021. [Google Scholar] [CrossRef] [PubMed]

- Benavides, P.T.; Dunn, J.B.; Han, J.; Biddy, M.; Markham, J. Exploring Comparative Energy and Environmental Benefits of Virgin, Recycled, and Bio-Derived PET Bottles. ACS Sustain. Chem. Eng. 2018, 6, 9725–9733. [Google Scholar] [CrossRef]

- Nezarati, R.M.; Eifert, M.B.; Cosgriff-hernandez, E. Effects of Humidity and Solution Viscosity on Electrospun Fiber Morphology. Methods Artic. 2013, 19. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Katti, D.S.; Robinson, K.W.; Ko, F.K.; Laurencin, C.T. Bioresorbable Nanofiber-Based Systems for Wound Healing and Drug Delivery: Optimization of Fabrication Parameters. Wiley Intersci. 2004. [Google Scholar] [CrossRef]

- Abunahel, B.M.; Zahirah, N.; Azman, N.; Jamil, M. Effect of Needle Diameter on the Morphological Nanofiber Mats. Int. J. Chem. Mater. Eng. 2018, 12, 296–299. [Google Scholar]

- Thompson, C.J.; Chase, G.G.; Yarin, A.L.; Reneker, D.H. Effects of parameters on nanofiber diameter determined from electrospinning model. Polymer (Guildf) 2007, 48, 6913–6922. [Google Scholar] [CrossRef]

- Matulevicius, J.; Kliucininkas, L.; Martuzevicius, D.; Krugly, E.; Tichonovas, M.; Baltrusaitis, J. Design and Characterization of Electrospun Polyamide Nanofiber Media for Air Filtration Applications. J. Nanomater. 2014, 2014, 859656. [Google Scholar] [CrossRef] [Green Version]

- Papkov, D.; Zou, Y.; Andalib, M.N.; Goponenko, A.; Cheng, S.Z.D.; Dzenis, Y.A. Simultaneously Strong and Tough Ultra fine Continuous Nanofibers. ACS Nano 2013, 7, 3324–3331. [Google Scholar] [CrossRef]

- Wang, N.; Raza, A.; Si, Y.; Yu, J.; Sun, G.; Ding, B. Tortuously structured polyvinyl chloride/polyurethane fibrous membranes for high-efficiency fine particulate filtration. J. Colloid Interface Sci. 2013, 398, 240–246. [Google Scholar] [CrossRef]

- Semnani, D.; Morshed, M. A Novel Method for Porosity Measurement of Various Surface Layers of Nanofibers Mat Using Image Analysis for Tissue Engineering Applications. J. Appl. Polym. Sci. 2007. [Google Scholar] [CrossRef]

- Shahrabi, S.S.; Barzin, J.; Shokrollahi, P. Blood cell separation by novel PET/PVP blend electrospun membranes. Polym. Test. 2018, 66, 94–104. [Google Scholar] [CrossRef]

- Yun, D.; Joon, K.; Kang, J.; Jeong, E.; Jung, S.; Uk, B. Washable antimicrobial polyester/aluminum air filter with a high capture efficiency and low pressure drop. J. Hazard. Mater. 2018, 351, 29–37. [Google Scholar] [CrossRef]

- De Almeida, D.S.; Martins, L.D.; Muniz, E.C.; Rudke, A.P.; Squizzato, R.; Beal, A.; de Souza, P.R.; Bonfim, D.P.F.; Aguiar, M.L.; Gimenes, M.L. Biodegradable CA/CPB electrospun nanofibers for efficient retention of airborne nanoparticles. Process Saf. Environ. Prot. 2020. [Google Scholar] [CrossRef] [PubMed]

- Aruchamy, K.; Mahto, A.; Nataraj, S.K. Electrospun nanofibers, nanocomposites and characterization of art: Insight on establishing fibers as product. Nano-Struct. Nano-Objects 2018, 16, 45–58. [Google Scholar] [CrossRef]

- Abuzade, R.A.; Zadhoush, A.; Gharehaghaji, A.A. Air Permeability of Electrospun Polyacrylonitrile Nanoweb. J. Appl. Polym. Sci. 2012, 126, 232–243. [Google Scholar] [CrossRef]

- Wang, K.; Zhang, W.; Guan, X.; Liu, Y.; Wei, T.; Guo, W. Fabrication of PET/BiOI/SnO2 heterostructure nanocomposites for enhanced visible-light photocatalytic activity. Solid State Sci. 2018, 82, 34–43. [Google Scholar] [CrossRef]

- Balgis, R.; Kartikowati, C.W.; Ogi, T.; Gradon, L.; Bao, L.; Seki, K.; Okuyama, K. Synthesis and evaluation of straight and bead-free nanofibers for improved aerosol filtration. Chem. Eng. Sci. 2015, 137, 947–954. [Google Scholar] [CrossRef]

- Lv, D.; Zhu, M.; Jiang, Z.; Jiang, S.; Zhang, Q.; Xiong, R. Green Electrospun Nanofibers and Their Application in Air Filtration. Macromol. Mater. Eng. 2018, 303, 1800336. [Google Scholar] [CrossRef]

- Woon, W.; Leung, F.; Sun, Q. Electrostatic Charged Nanofiber Filter for Filtering Airborne Novel Coronavirus (COVID-19) and Nano-aerosols. Sep. Purif. Technol. 2020, 116886. [Google Scholar] [CrossRef]

- Balamurugan, R.; Sundarrajan, S.; Ramakrishna, S. Recent trends in nanofibrous membranes and their suitability for air and water filtrations. Membranes 2011, 1, 232–248. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Bucher, T.M.; Tafreshi, H.V.; Tepper, G.C. Modeling performance of thin fibrous coatings with orthogonally layered nanofibers for improved aerosol filtration. Powder Technol. 2013, 249, 43–53. [Google Scholar] [CrossRef]

| Samples | Polymer Concentration (% p/p) | Needle Diameter (mm) | Total Time of Collection (h) | Collector Speed (rpm) |

|---|---|---|---|---|

| PET20% | 20 | 0.7 | 6 | 357 |

| PET12% | 12 | 0.7 | 6 | 357 |

| PET10% | 10 | 0.3 | 3 | 357 |

| PET10%_0.3 | 10 | 0.3 | 3 | 177 |

| PET10%_0.55 | 10 | 0.55 | 3 | 177 |

| Samples | Polymer Concentration (% p/p) | Mean Fiber Diameter (μm) | Thickness (μm) | Tensile Strength (MPa) |

|---|---|---|---|---|

| PET20% | 20 | 3.25 | 392.50 | 3.2 |

| PET12% | 12 | 1.29 | 342.73 | 3.5 |

| PET10% | 10 | 0.67 | 220.79 | 4.5 |

| PET10%_0.3 | 10 | 0.65 | 198.01 | - |

| PET10%_0.55 | 10 | 0.66 | 186.00 | - |

| Samples | Minimum Pore Area (µm2) | Maximum Pore Area (µm2) | Porosity (Ergun Equation) (%) |

|---|---|---|---|

| PET20% | 1.33 | 829.51 | 95.0 ± 0.04 |

| PET12% | 0.07 | 135.06 | 92.4 ± 0.05 |

| PET10% | 0.08 | 27.28 | 96.7 ± 0.05 |

| Samples | Permeability Constant K1 (m2) | Pressure Drop (Pa) (v = 4.8 cm/s) | Global Collection Efficiency (%) (Particle Diameter 7 to 300 nm) | Fractional Collection Efficiency (%) (Particle Diameter 100 to 250 nm) |

|---|---|---|---|---|

| PET20% | 2.2 × 10−7 | 13.5 | 41 | 18 |

| PET12% | 1.07 × 10−8 | 212.5 | 99 | 96 |

| PET10% | 3.6 × 10−8 | 76.1 | 99 | 100 |

| PET_10%_0.3 | 2.6 × 10−8 | 69.8 | 100 | 100 |

| PET_10%_0.55 | 6.3 × 10−8 | 19.4 | 99 | 99.4 |

| Samples | Quality Factor (Pa−1) |

|---|---|

| PET20% | 0.04 |

| PET12% | 0.02 |

| PET10% | 0.06 |

| PET10%_0.3 | 0.12 |

| PET10%_0.55 | 0.35 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Bonfim, D.P.F.; Cruz, F.G.S.; Guerra, V.G.; Aguiar, M.L. Development of Filter Media by Electrospinning for Air Filtration of Nanoparticles from PET Bottles. Membranes 2021, 11, 293. https://doi.org/10.3390/membranes11040293

Bonfim DPF, Cruz FGS, Guerra VG, Aguiar ML. Development of Filter Media by Electrospinning for Air Filtration of Nanoparticles from PET Bottles. Membranes. 2021; 11(4):293. https://doi.org/10.3390/membranes11040293

Chicago/Turabian StyleBonfim, Daniela P. F., Fabiana G. S. Cruz, Vádila G. Guerra, and Mônica L. Aguiar. 2021. "Development of Filter Media by Electrospinning for Air Filtration of Nanoparticles from PET Bottles" Membranes 11, no. 4: 293. https://doi.org/10.3390/membranes11040293

APA StyleBonfim, D. P. F., Cruz, F. G. S., Guerra, V. G., & Aguiar, M. L. (2021). Development of Filter Media by Electrospinning for Air Filtration of Nanoparticles from PET Bottles. Membranes, 11(4), 293. https://doi.org/10.3390/membranes11040293