Amorphous NdIZO Thin Film Transistors with Contact-Resistance-Adjustable Cu S/D Electrodes

Abstract

1. Introduction

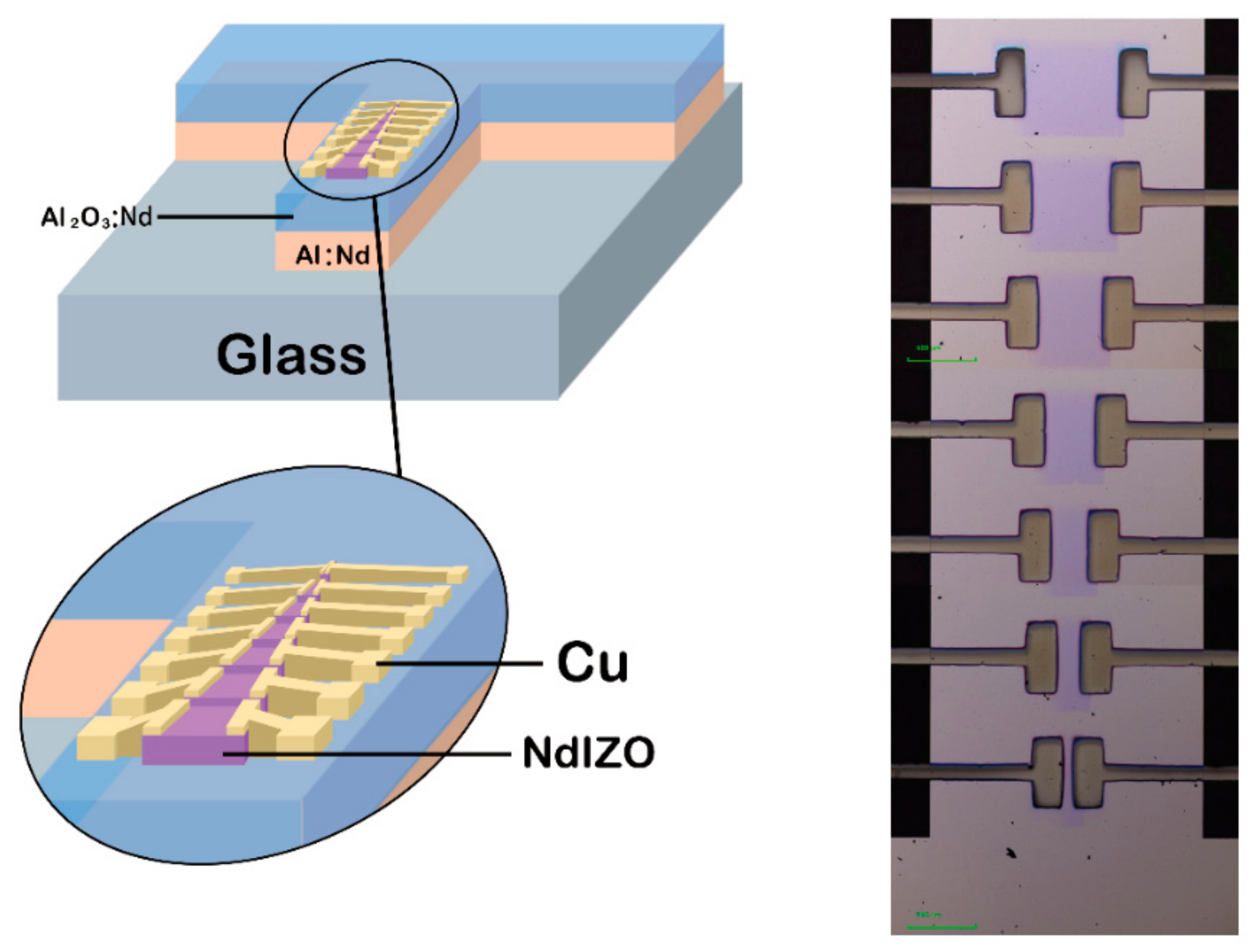

2. Materials and Methods

3. Results and Discussion

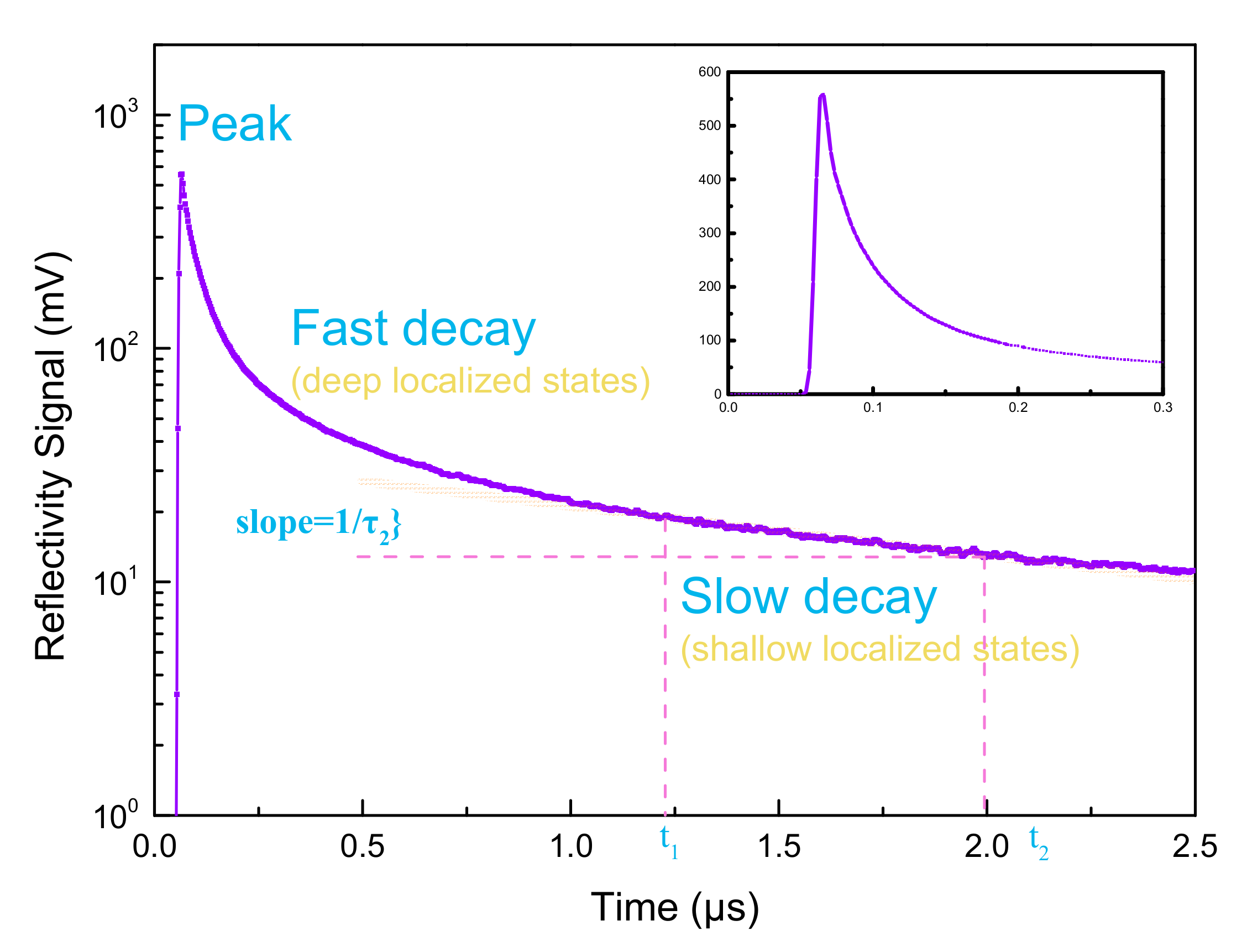

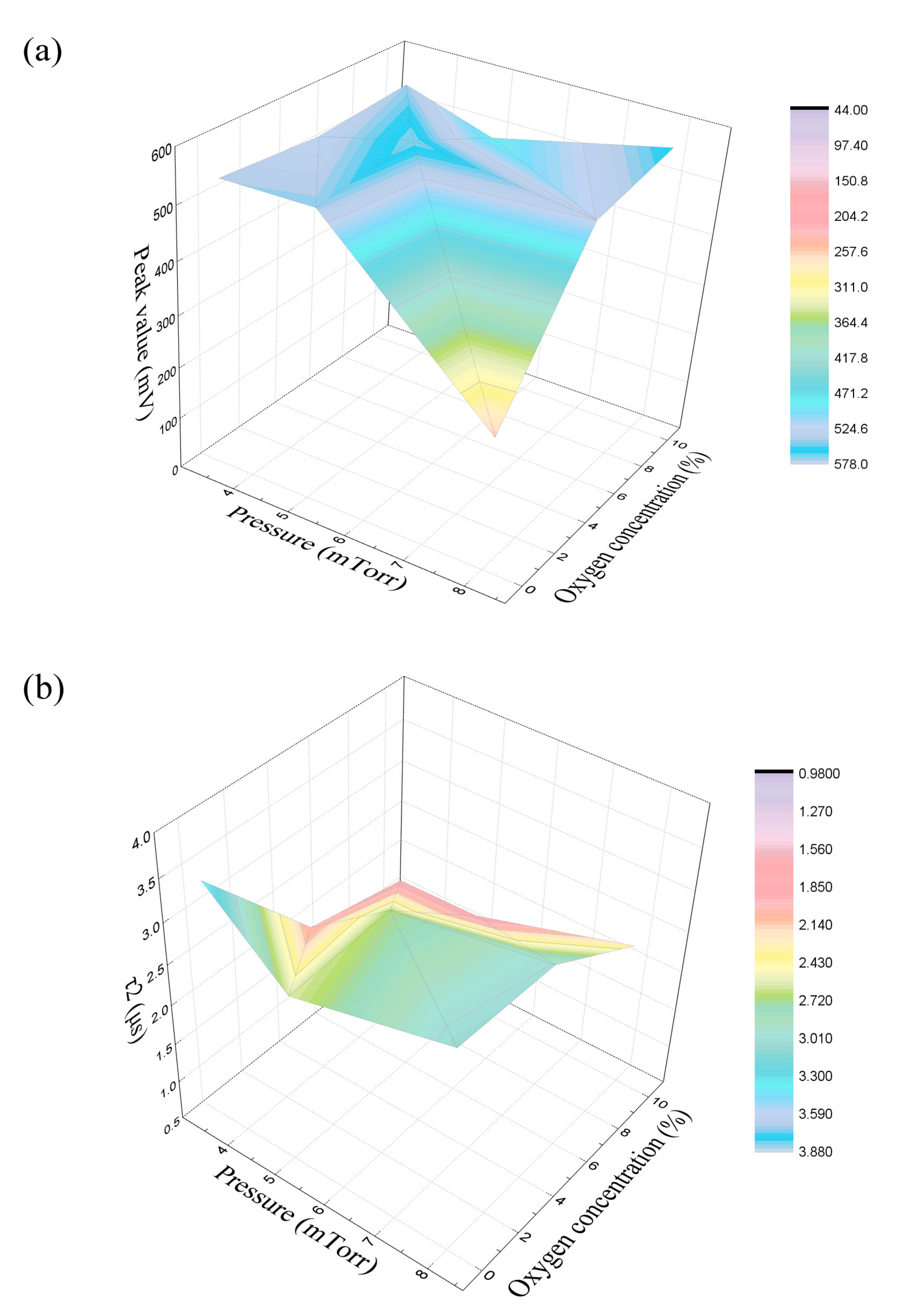

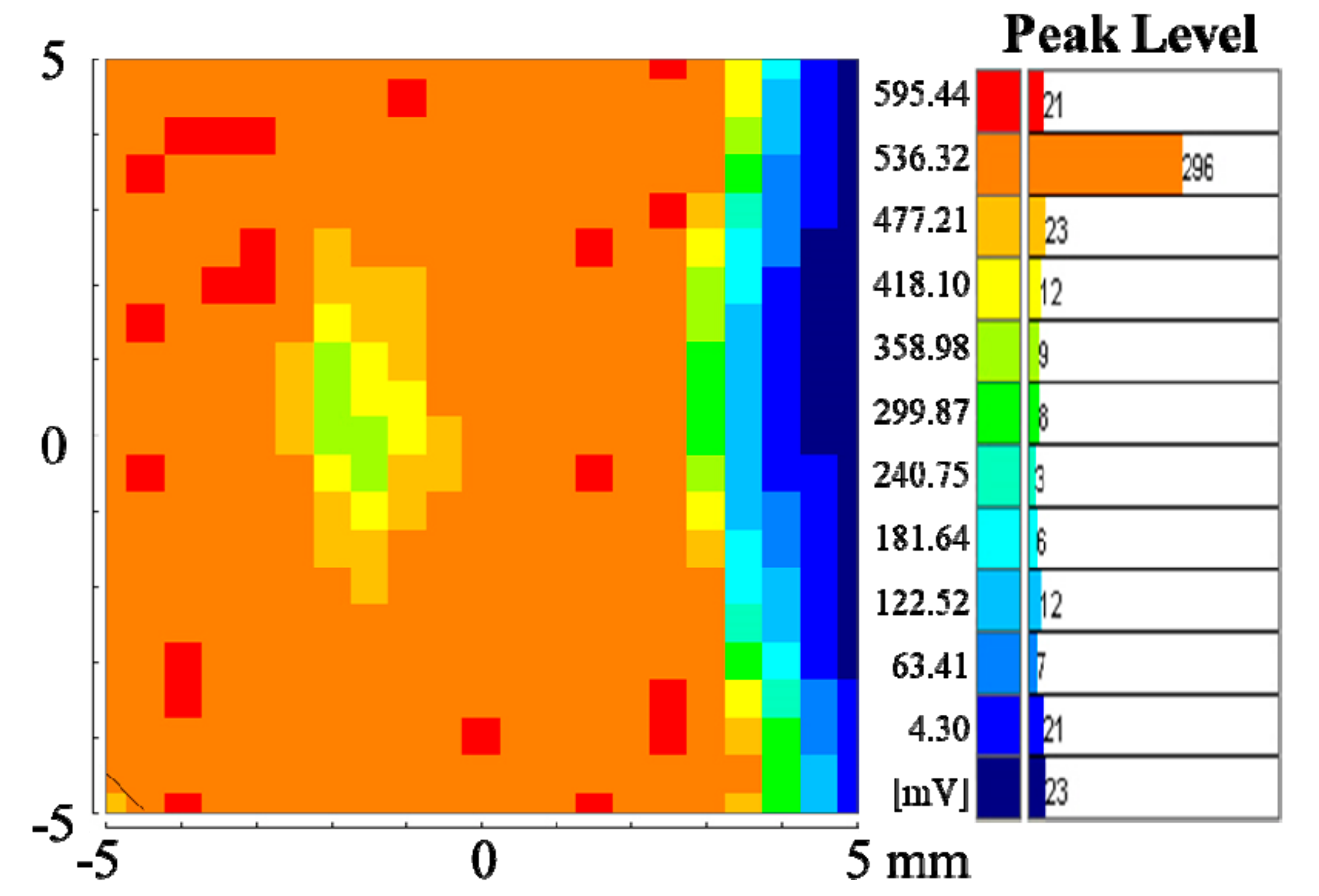

3.1. Film Deposition

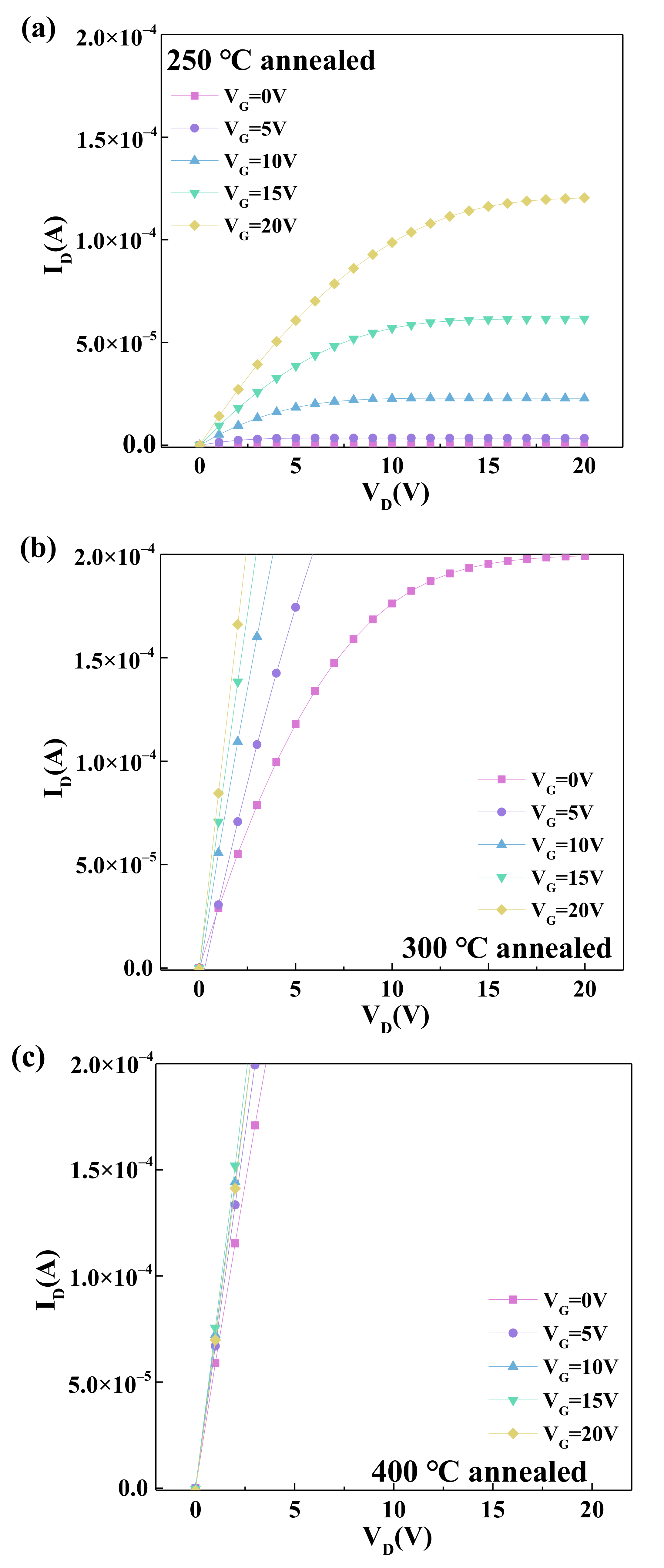

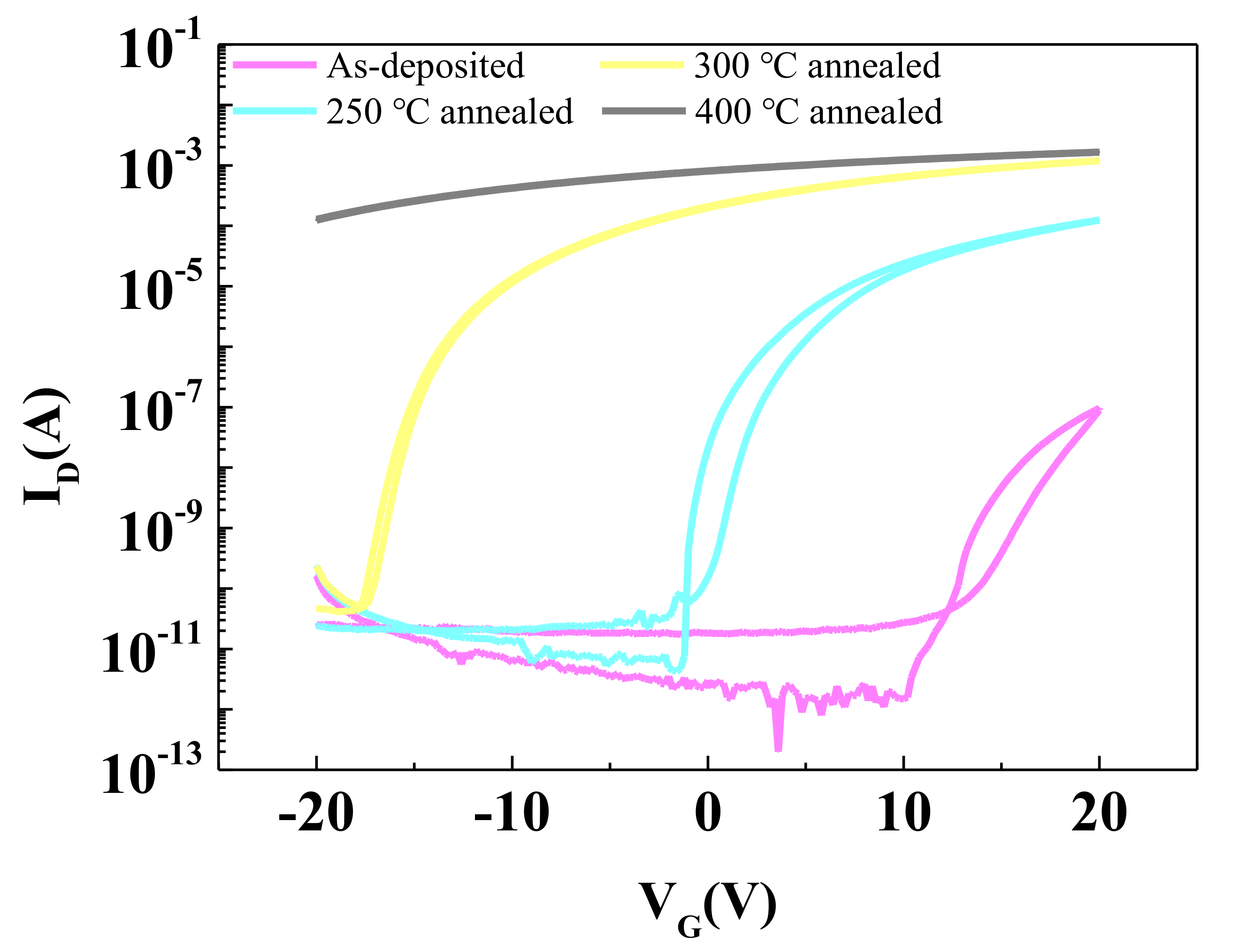

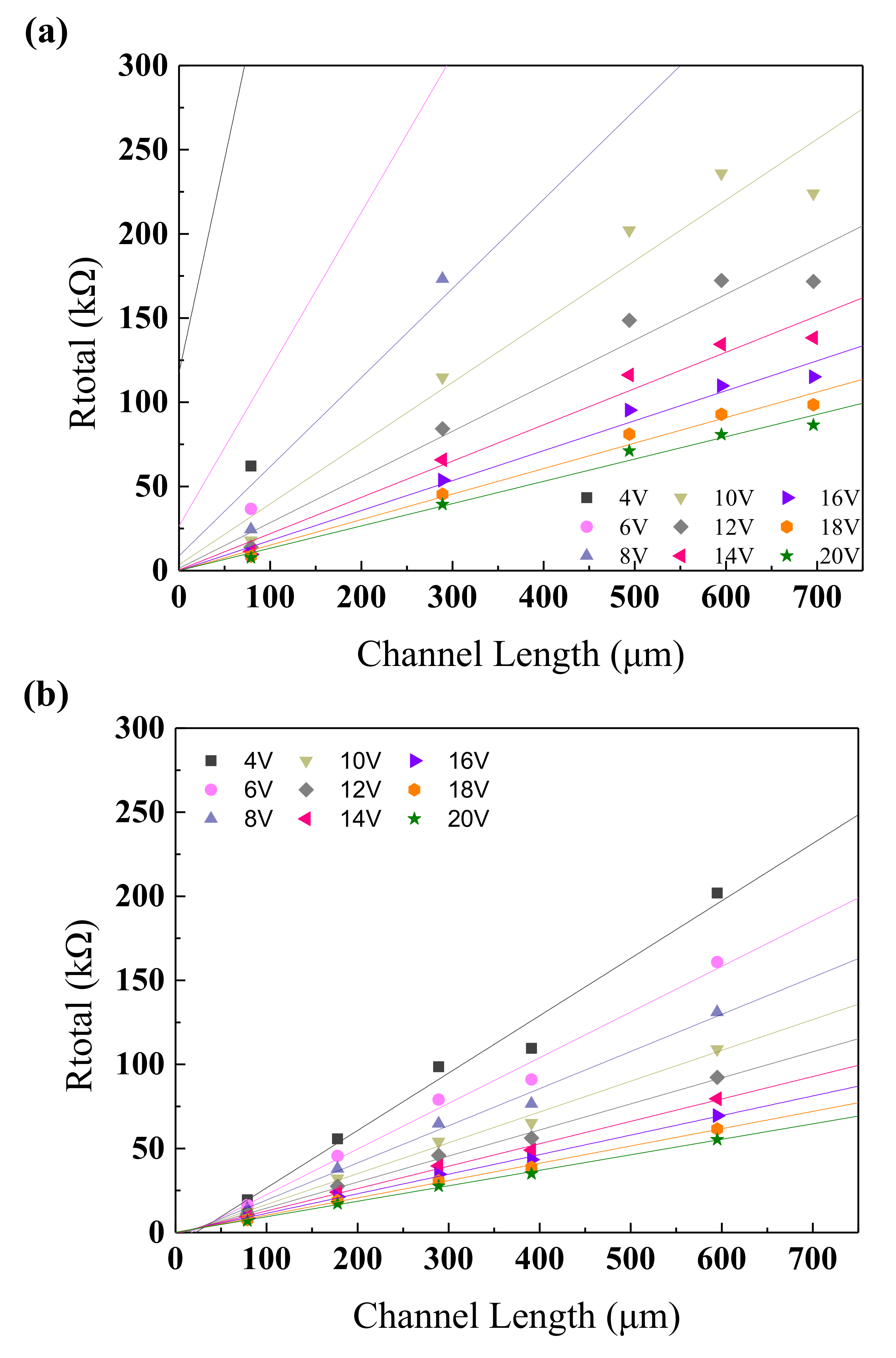

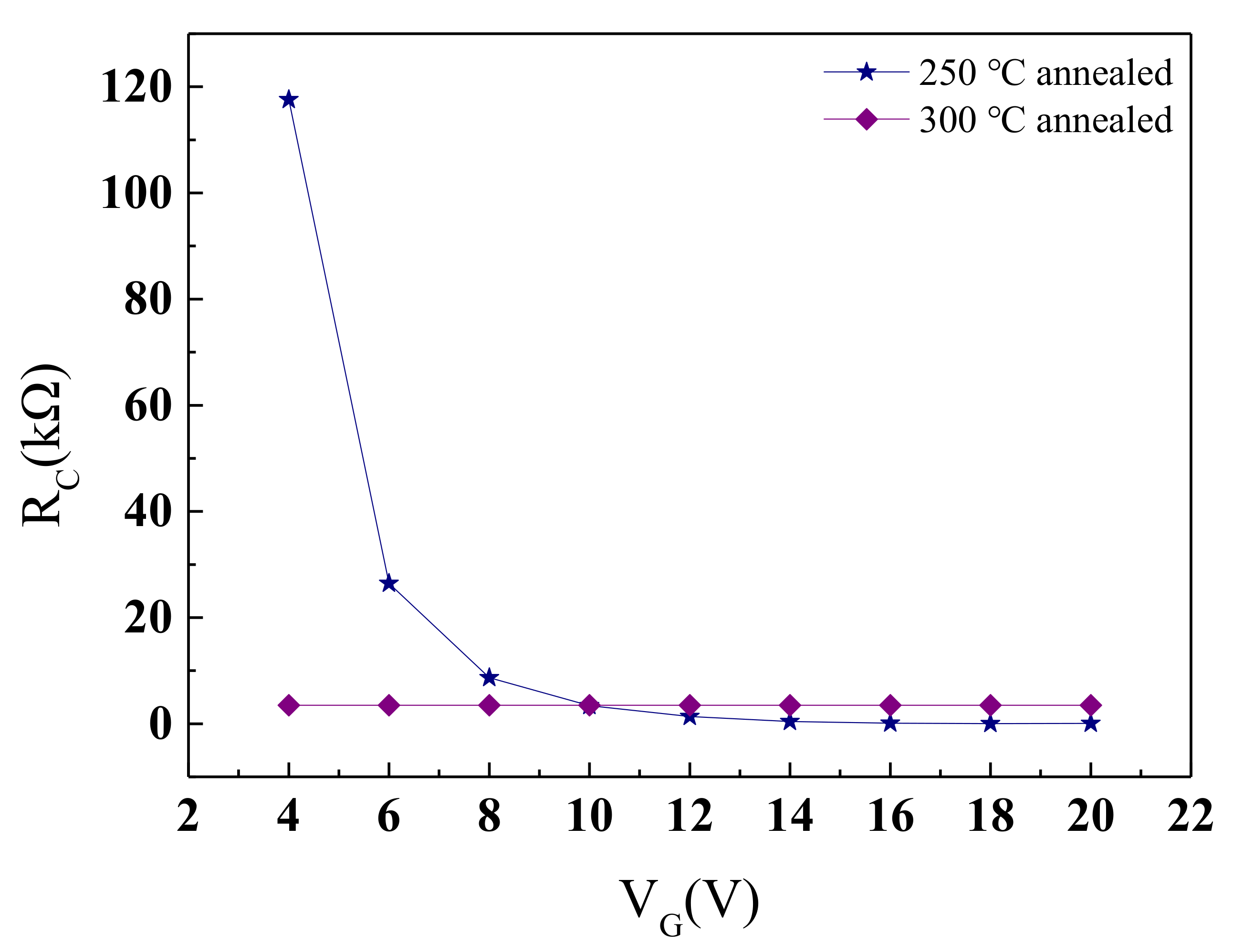

3.2. Thin Film Transistors

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Conflicts of Interest

References

- Heremans, P.; Tripathi, A.K.; Meux, A.D.; Smits, E.C.P.; Hou, B.; Pourtois, G.; Gelinck, G.H. Mechanical and Electronic Properties of Thin-Film Transistors on Plastic, and Their Integration in Flexible Electronic Applications. Adv. Mater. 2016, 28, 4266–4282. [Google Scholar] [CrossRef]

- Nomura, K.; Ohta, H.; Takagi, A.; Kamiya, T.; Hirano, M.; Hosono, H. Room-temperature fabrication of transparent flexible thin-film transistors using amorphous oxide semiconductors. Nature 2004, 432, 488–492. [Google Scholar] [CrossRef]

- Sheng, J.; Hong, T.; Lee, H.; Kim, K.; Sasase, M.; Kim, J.; Hosono, H.; Park, J. Amorphous IGZO TFT with High Mobility of ∼70 cm2/(V·s) via Vertical Dimension Control Using PEALD. ACS Appl. Mater. Interfaces 2019, 11, 40300–40309. [Google Scholar] [CrossRef]

- Zhang, L.; Wei, J.; Zhou, K.; Wan, C.; Sun, H. Highly transparent IGZO-TFTs uses IGZO source and drain electrodes with a composite insulation layer structure. Optik 2020, 204, 163654. [Google Scholar] [CrossRef]

- Prušáková, L.; Hubík, P.; Aijaz, A.; Nyberg, T.; Kubart, T. Room Temperature Reactive Deposition of InGaZnO and ZnSnO Amorphous Oxide Semiconductors for Flexible Electronics. Coatings 2020, 10, 2. [Google Scholar] [CrossRef]

- Jeong, J.K.; Jeong, J.H.; Yang, H.W.; Park, J.; Mo, Y.; Kim, H.D. High performance thin film transistors with cosputtered amorphous indium gallium zinc oxide channel. Appl. Phys. Lett. 2007, 91, 113505. [Google Scholar] [CrossRef]

- Lan, L.; Peng, J. High-Performance Indium-Gallium-Zinc Oxide Thin-Film Transistors Based on Anodic Aluminum Oxide. IEEE Trans. Electron. Devices 2011, 58, 1452–1455. [Google Scholar]

- Jeong, J.H.; Yang, H.W.; Park, J.; Jeong, J.K.; Mo, Y.; Kim, H.D.; Song, J.; Hwang, C.S. Origin of Subthreshold Swing Improvement in Amorphous Indium Gallium Zinc Oxide Transistors. Electrochem. Solid State Lett. 2008, 11, H157. [Google Scholar] [CrossRef]

- Luo, D.; Lan, L.; Xu, M.; Xu, H.; Li, M.; Wang, L.; Peng, J. Role of Rare Earth Ions in Anodic Gate Dielectrics for Indium-Zinc-Oxide Thin-Film Transistors. J. Electrochem. Soc. 2012, 159, H502–H506. [Google Scholar] [CrossRef]

- Lin, Z.; Lan, L.; Xiao, P.; Sun, S.; Li, Y.; Song, W.; Gao, P.; Wang, L.; Ning, H.; Peng, J. High-mobility thin film transistors with neodymium-substituted indium oxide active layer. Appl. Phys. Lett. 2015, 107, 112108. [Google Scholar] [CrossRef]

- Song, E.; Lan, L.; Xiao, P.; Lin, Z.; Sun, S.; Li, Y.; Song, W.; Gao, P.; Peng, J. Thin-Film Transistors With Neodymium-Incorporated Indium–Zinc-Oxide Semiconductors. IEEE Trans. Electron. Devices 2016, 63, 1916–1920. [Google Scholar] [CrossRef]

- Lan, L.; Song, W.; Lin, Z.; Xiao, P.; Wang, L.; Ning, H.; Wang, D.; Peng, J. Effects of Nd in NdxIn1-xO3 Semiconductors for Thin-Film Transistors. IEEE Trans. Electron. Devices 2015, 62, 2226–2230. [Google Scholar]

- Lin, Z.; Lan, L.; Xiao, P.; Sun, S.; Li, Y.; Song, W.; Gao, P.; Peng, J. Studies on NdxIn1−xO3 semiconducting thin films prepared by rf magnetron sputtering. Appl. Phys. Lett. 2014, 105, 142104. [Google Scholar] [CrossRef]

- Lu, K.K.; Zhang, J.; Guo, D.; Xiang, J.; Lin, Z.; Zhang, X.; Wang, T.; Ning, H.; Yao, R.; Peng, J. High-Performance and Flexible Neodymium-Doped Indium-Zinc-Oxide Thin-Film Transistor With All Copper Alloy Electrodes. IEEE Electron. Device Lett. 2020, 41, 417–420. [Google Scholar] [CrossRef]

- Hu, S.S.; Ning, H.; Lu, K.; Fang, Z.; Li, Y.; Yao, R.; Xu, M.; Wang, L.; Peng, J.; Lu, X. Mobility Enhancement in Amorphous In-Ga-Zn-O Thin-Film Transistor by Induced Metallic in Nanoparticles and Cu Electrodes. Nanomaterials 2018, 8, 197. [Google Scholar] [CrossRef] [PubMed]

- Oh, J.; Huang, J.; Chen, Y.T.; Ok, I.; Jeon, K.; Lee, S.H.; Sassman, B.; Loh, W.Y.; Lee, H.D.; Ko, D.H.; et al. Comparison of Ohmic contact resistances of n- and p-type Ge source/drain and their impact on transport characteristics of Ge metal oxide semiconductor field effect transistors. Thin Solid Films 2011, 520, 442–444. [Google Scholar] [CrossRef]

- Park, W.; Shaikh, S.F.; Min, J.W.; Lee, S.K.; Lee, B.H.; Hussain, M.M. Contact resistance reduction of ZnO thin film transistors (TFTs) with saw-shaped electrode. Nanotechnology 2018, 29, 325202. [Google Scholar] [CrossRef]

- Katelyn, K.K.; Jurchescu, O.D. Conductivity Measurements of Organic Materials Using Field-Effect Transistors (FETs) and Space-Charge-Limited Current (SCLC) Techniques. In Handbook of Organic Materials for Electronic and Photonic Devices; Wake Forest University: Winston-Salem, NC, USA, 2019. [Google Scholar]

- Glowacki, I.I.; Jung, J.; Ulanski, J. Polymer Science: A Comprehensive Reference; Newnes: London, UK, 2012. [Google Scholar]

- Lu, K.K.; Yao, R.; Wang, Y.; Ning, H.; Guo, D.; Liu, X.; Tao, R.; Xu, M.; Wang, L.; Peng, J. Effects of praseodymium doping on the electrical properties and aging effect of InZnO thin-film transistor. J. Mater. Sci. 2019, 54, 14778–14786. [Google Scholar] [CrossRef]

- Zhang, J.J.; Fu, X.; Zhou, S.; Ning, H.; Wang, Y.; Guo, D.; Cai, W.; Liang, Z.; Yao, R.; Peng, J. The Effect of Zirconium Doping on Solution-Processed Indium Oxide Thin Films Measured by a Novel Nondestructive Testing Method (Microwave Photoconductivity Decay). Coatings 2019, 9, 426. [Google Scholar] [CrossRef]

- Nam, Y.Y.; Yang, J.; Jeong, P.; Kwon, O.; Pi, J.; Cho, S.H.; Hwang, C.; Ahn, J.; Ji, S.; Park, S.K. Effect of a rapid thermal annealing process on the electrical properties of an aluminum-doped indium zinc tin oxide thin film transistor. Phys. Status Solidi A 2017, 214, 1600490. [Google Scholar] [CrossRef]

- Liu, X.; Cai, W.; Chen, J.; Fang, Z.; Ning, H.; Hu, S.; Tao, R.; Zeng, Y.; Zheng, Z.; Yao, R.; et al. A novel nondestructive testing method for amorphous Si-Sn-O films. J. Phys. D Appl. Phys. 2016, 49, 505102. [Google Scholar] [CrossRef]

- Hu, S.S.; Lu, K.; Ning, H.; Yao, R.; Gong, Y.; Pan, Z.; Guo, C.; Wang, J.; Pang, C.; Gong, Z.; et al. Study of the Correlation between the Amorphous Indium-Gallium-Zinc Oxide Film Quality and the Thin-Film Transistor Performance. Nanomaterials 2021, 11, 522. [Google Scholar] [CrossRef]

- Goto, H.; Tao, H.; Morita, S.; Takanashi, Y.; Hino, A.; Kishi, T.; Ochi, M.; Hayashi, K.; Kugimiya, T. In-line Process Monitoring for Amorphous Oxide Semiconductor TFT Fabrication using Microwave-detected Photoconductivity Decay Technique. IEICE Trans. Electron. 2014, E97.C, 1055–1062. [Google Scholar] [CrossRef]

- Takatsuji, H.H.; Arai, T. Pinholes in Al thin films: Their effects on TFT characteristics and a taguchi method analysis of their origins. Vacuum 2000. [Google Scholar] [CrossRef]

- Lin, C.S.; Shih, S.J.; Lu, A.T.; Hung, S.S.; Chiu, C.C. The quality improvement of PI coating process of TFT-LCD panels with Taguchi methods. Optik 2012, 123, 703–710. [Google Scholar] [CrossRef]

- Park, J.J.; Rim, Y.S.; Li, C.; Kim, H.; Goorsky, M.; Streit, D. Deep-level defect distribution as a function of oxygen partial pressure in sputtered ZnO thin-film transistors. Curr. Appl. Phys. 2016. [Google Scholar] [CrossRef]

- Cai, W.W.; Ning, H.; Zhou, S.; Zhu, Z.; Yao, R.; Chen, J.; Tao, R.; Fang, Z.; Lu, X.; Peng, J. Effective Evaluation Strategy Toward Low Temperature Solution-Processed Oxide Dielectrics for TFT Device. IEEE J. Electron. Devices Soc. 2019, 7, 1140–1144. [Google Scholar] [CrossRef]

- Yao, R.R.; Zheng, Z.; Fang, Z.; Zhang, H.; Zhang, X.; Ning, H.; Wang, L.; Peng, J.; Xie, W.; Lu, X. High-performance flexible oxide TFTs: Optimization of a-IGZO film by modulating the voltage waveform of pulse DC magnetron sputtering without post treatment. J. Mater. Chem. C 2018, 6, 2522–2532. [Google Scholar] [CrossRef]

- Simpson, T.T.W.; Peplinski, D.J.; Koch, P.N.; Allen, J.K. Metamodels for Computer-based Engineering Design: Survey and recommendations. Eng. Comput. 2001, 17, 129–150. [Google Scholar] [CrossRef]

- Beyer, H.H.; Sendhoff, B. Robust optimization—A comprehensive survey. Comput. Methods Appl. Mech. Eng. 2007, 196, 3190–3218. [Google Scholar] [CrossRef]

- Dong, C.C.; Xu, J.; Zhou, Y.; Zhang, Y.; Xie, H. Light-illumination stability of amorphous InGaZnO thin film transistors in oxygen and moisture ambience. Solid-State Electron. 2019, 153, 74–78. [Google Scholar] [CrossRef]

- Weis, M.M.; Lee, K.; Taguchi, D.; Manaka, T.; Iwamoto, M. Modified transmission-line method for evaluation of the contact resistance: Effect of channel-length-dependent threshold voltage. Jpn. J. Appl. Phys. 2013, 53, 11601. [Google Scholar] [CrossRef]

- Lee, S.S.; Borrelli, C.D.; Gleason, K.K. Air-stable polythiophene-based thin film transistors processed using oxidative chemical vapor deposition: Carrier transport and channel/metallization contact interface. Organ. Electron. 2016, 33, 253–262. [Google Scholar] [CrossRef]

- Nguyen, C.C.P.T.; Trinh, T.T.; Raja, J.; Le, A.H.T.; Lee, Y.; Dao, V.A.; Yi, J. Source/drain metallization effects on the specific contact resistance of indium tin zinc oxide thin film transistors. Mater. Sci. Semicond. Process. 2015, 39, 649–653. [Google Scholar] [CrossRef]

- Yao, R.R.; Zhang, H.; Fang, Z.; Ning, H.; Zheng, Z.; Li, X.; Zhang, X.; Cai, W.; Lu, X.; Peng, J. High conductivity and transparent aluminum-based multi-layer source/drain electrodes for thin film transistors. J. Phys. D Appl. Phys. 2018, 51, 065103. [Google Scholar] [CrossRef]

- Zhao, M.M.; Zhang, Z.; Xu, Y.; Xu, D.; Zhang, J.; Huang, Z. High-Performance Back-Channel-Etched Thin-Film Transistors with an InGaO/InZnO Stacked Channel. Phys. Status Solidi A 2020, 217, 1900773. [Google Scholar] [CrossRef]

- Huang, X.X.D.; Song, Q.J.; Lai, P.T. Improved Performance of Scaled-Down α-InGaZnO Thin-Film Transistor by Ar Plasma Treatment. IEEE Electron. Device Lett. 2016, 37, 1574–1577. [Google Scholar] [CrossRef]

- Pyo, J.J.; Cho, W. Investigation of Parasitic Resistance Components in the Case of Microwave Irradiation in Poly-Si Annealing. J. Korean Phys. Soc. 2018, 73, 978–982. [Google Scholar] [CrossRef]

- Li, J.; Yang, Y.H.; Chen, Q.; Zhu, W.Q.; Zhang, J.H. Low-temperature, high-mobility solution-processed p-channel thin-film transistors with semiconducting single-walled carbon nanotube/NiOx composites. J. Phys. D Appl. Phys. 2019, 52, 385108. [Google Scholar] [CrossRef]

- Aikawa, S.S.; Nabatame, T.; Tsukagoshi, K. Si-incorporated amorphous indium oxide thin-film transistors. Jpn. J. Appl. Phys. 2019, 58, 090506. [Google Scholar] [CrossRef]

- Kim, M.M.; Choi, S.; Jeon, S.; Lim, J.; Choi, D. Stability Behavior of Self-Aligned Coplanar a-IGZO Thin Film Transistors Fabricated by Deep Ultraviolet Irradiation. J. Solid State Sci. Technol. 2018, 7, Q60–Q65. [Google Scholar] [CrossRef]

- Lu, K.K.; Yao, R.; Xu, W.; Ning, H.; Zhang, X.; Zhang, G.; Li, Y.; Zhong, J.; Yang, Y.; Peng, J. Alloy-Electrode-Assisted High-Performance Enhancement-Type Neodymium-Doped Indium-Zinc-Oxide Thin-Film Transistors on Polyimide Flexible Substrate. Research 2021, 2021, 1–9. [Google Scholar]

| Oxygen Concentration | Pressure/mTorr | Annealing/°C | Peak Value/mV | τ2/μs |

|---|---|---|---|---|

| 0% | 3.38 | 25 | 540.63 | 3.57 |

| 5% | 5.00 | 25 | 570.13 | 3.25 |

| 10% | 8.00 | 25 | 571.04 | 2.57 |

| 0% | 3.38 | 200 | 539.58 | 3.28 |

| 5% | 5.00 | 200 | 566.06 | 2.15 |

| 10% | 8.00 | 200 | 549.94 | 2.04 |

| 0% | 5.00 | 250 | 577.27 | 1.75 |

| 5% | 8.00 | 250 | 513.69 | 2.16 |

| 10% | 3.38 | 250 | 520.87 | 1.27 |

| 0% | 8.00 | 300 | 467.21 | 2.66 |

| 5% | 3.38 | 300 | 505.42 | 0.99 |

| 10% | 5.00 | 300 | 490.55 | 1.45 |

| 0% | 5.00 | 350 | 509.45 | 3.45 |

| 5% | 8.00 | 350 | 536.48 | 3.87 |

| 10% | 3.38 | 350 | 560.83 | 2.18 |

| 0% | 8.00 | 400 | 44.06 | 3.47 |

| 5% | 3.38 | 400 | 544.87 | 2.97 |

| 10% | 5.00 | 400 | 482.20 | 2.04 |

| Annealing Temperature (°C) | Ion/Ioff | μsat (cm2/(V·s)) | SS (V/decade) | Vth (V) |

|---|---|---|---|---|

| As-deposited | * | * | * | * |

| 250 | 2.89 × 107 | 24.48 | 1.14 × 10−1 | 2.32 |

| 300 | 2.39 × 107 | 38.90 | 5.96 × 10−1 | −21.52 |

| 400 | * | * | * | * |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, X.; Lu, K.; Xu, Z.; Ning, H.; Lin, Z.; Qiu, T.; Yang, Z.; Zeng, X.; Yao, R.; Peng, J. Amorphous NdIZO Thin Film Transistors with Contact-Resistance-Adjustable Cu S/D Electrodes. Membranes 2021, 11, 337. https://doi.org/10.3390/membranes11050337

Zhang X, Lu K, Xu Z, Ning H, Lin Z, Qiu T, Yang Z, Zeng X, Yao R, Peng J. Amorphous NdIZO Thin Film Transistors with Contact-Resistance-Adjustable Cu S/D Electrodes. Membranes. 2021; 11(5):337. https://doi.org/10.3390/membranes11050337

Chicago/Turabian StyleZhang, Xinyi, Kuankuan Lu, Zhuohui Xu, Honglong Ning, Zimian Lin, Tian Qiu, Zhao Yang, Xuan Zeng, Rihui Yao, and Junbiao Peng. 2021. "Amorphous NdIZO Thin Film Transistors with Contact-Resistance-Adjustable Cu S/D Electrodes" Membranes 11, no. 5: 337. https://doi.org/10.3390/membranes11050337

APA StyleZhang, X., Lu, K., Xu, Z., Ning, H., Lin, Z., Qiu, T., Yang, Z., Zeng, X., Yao, R., & Peng, J. (2021). Amorphous NdIZO Thin Film Transistors with Contact-Resistance-Adjustable Cu S/D Electrodes. Membranes, 11(5), 337. https://doi.org/10.3390/membranes11050337