Crosslinking Multilayer Graphene by Gas Cluster Ion Bombardment

Abstract

:1. Introduction

2. Materials and Methods

2.1. Multilayer Graphene Synthesis

2.2. GCIB Process

2.3. Measurements and Characterization

3. Results and Discussion

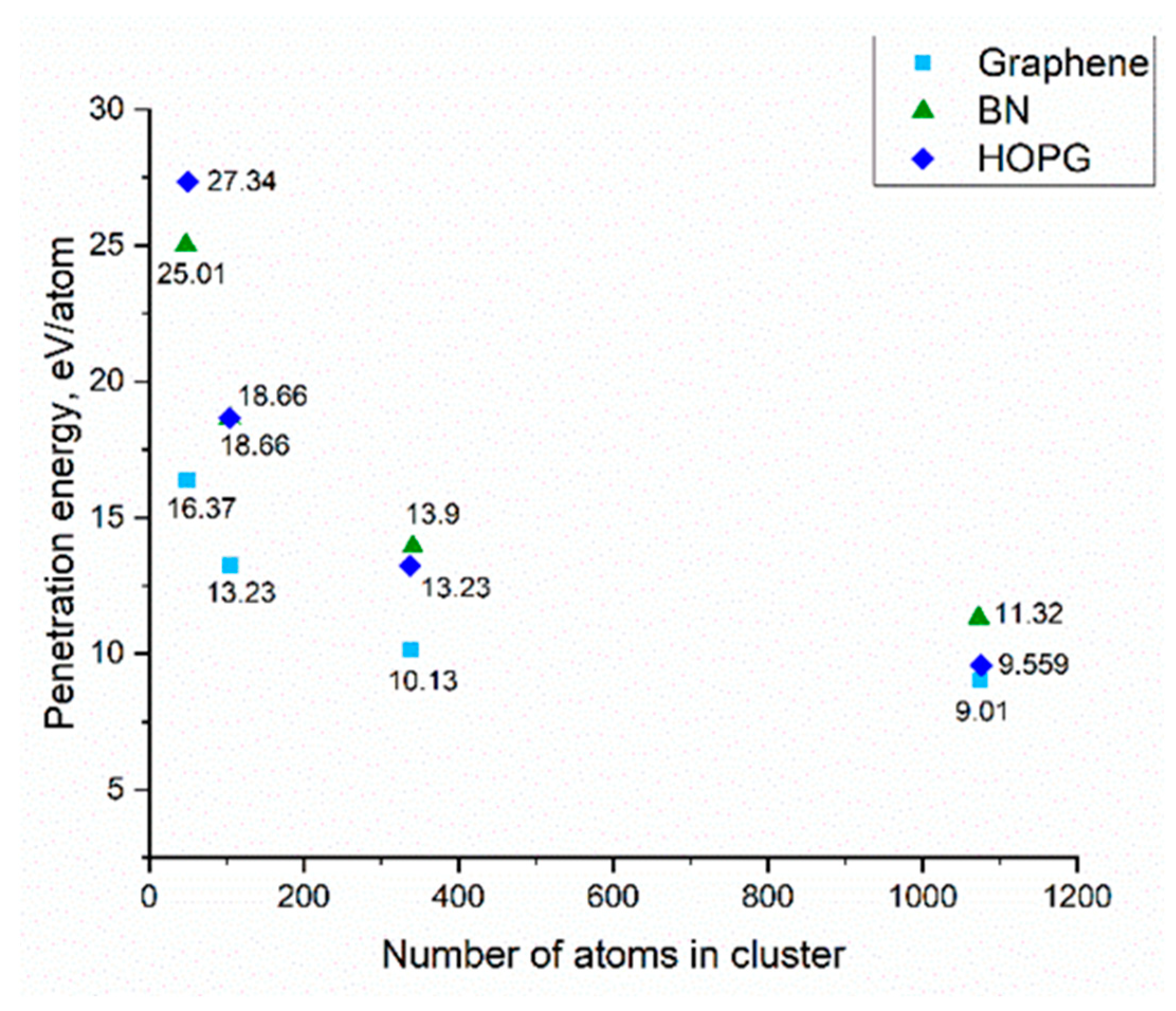

3.1. Molecular Dynamics Simulation

3.2. Raman Spectroscopy

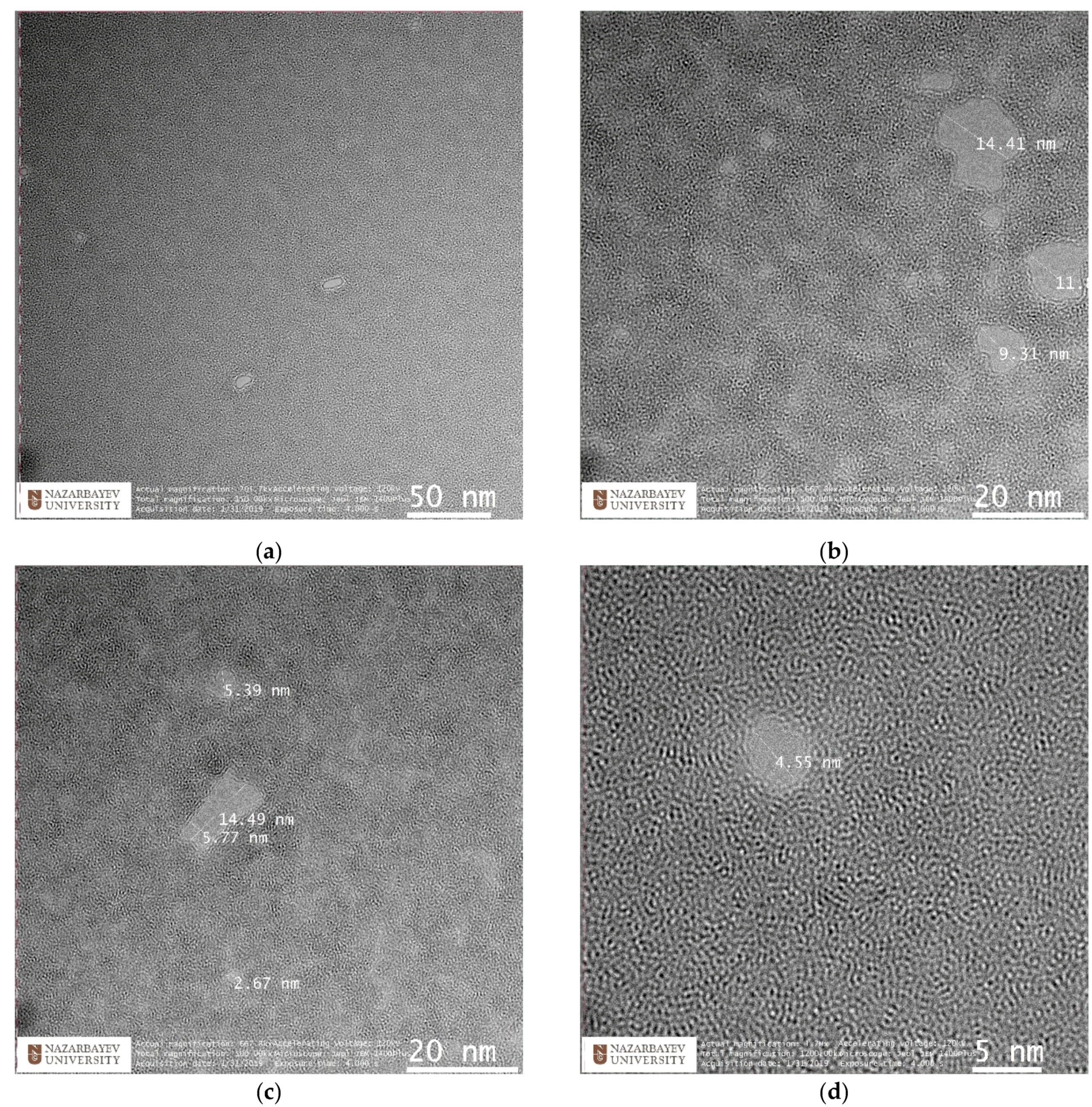

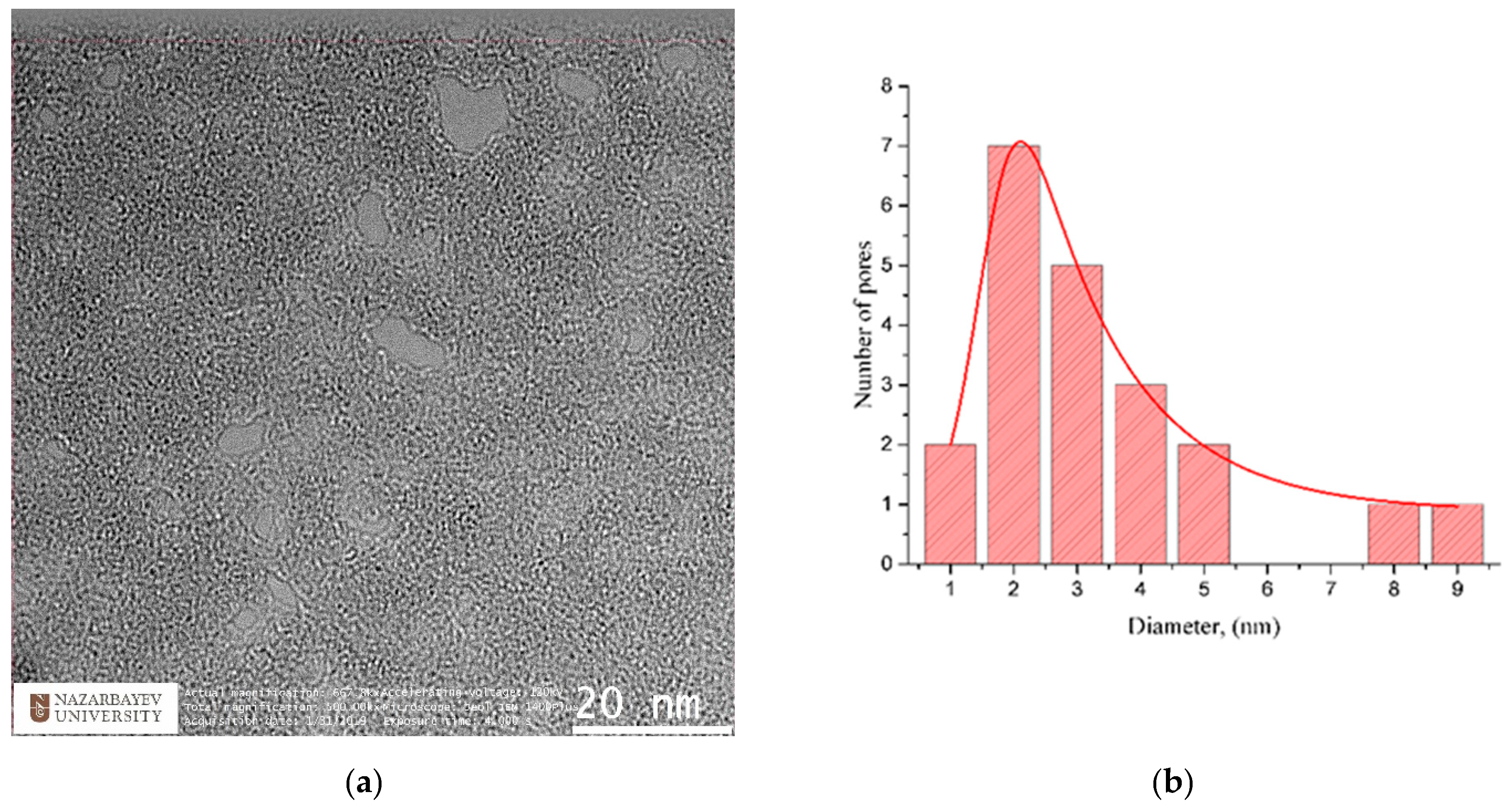

3.3. Transmission Electron Microscopy

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Lee, C.; Wei, X.; Kysar, J.W.; Hone, J. Measurement of the elastic properties and intrinsic strength of monolayer graphene. Science 2008, 321, 385–388. [Google Scholar] [CrossRef] [PubMed]

- Lee, H.C.; Liu, W.W.; Chai, S.P.; Mohamed, A.R.; Aziz, A.; Khe, C.S.; Hidayah, N.M.S.; Hashim, U. Review of the synthesis, transfer, characterization and growth mechanisms of single and multilayer graphene. RSC Adv. 2017, 7, 15644–15693. [Google Scholar] [CrossRef]

- Sood, A.K.; Lund, I.; Puri, Y.R.; Efstathiadis, H.; Haldar, P.; Dhar, N.K.; Lewis, J.; Dubey, M.; Zakar, E.; Wijewarnasuriya, P.; et al. Review of Graphene Technology and Its Applications for Electronic Devices. Int. J. Eng. Res. Technol. 2015, 8, 125–141. [Google Scholar] [CrossRef] [Green Version]

- Aïssa, B.; Memon, N.K.; Ali, A.; Khraisheh, M.K. Recent progress in the growth and applications of graphene as a smart material: A review. Front. Mater. 2015, 2, 58. [Google Scholar] [CrossRef] [Green Version]

- Du, X.; Skachko, I.; Barker, A.; Andrei, E.Y. Approaching ballistic transport in suspended graphene. Nat. Nanotechnol. 2008, 3, 491–495. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Balandin, A.A.; Ghosh, S.; Bao, W.; Calizo, I.; Teweldebrhan, D.; Miao, F.; Lau, C.N. Superior Thermal Conductivity of Single-Layer Graphene. Nano Lett. 2008, 8, 902–907. [Google Scholar] [CrossRef] [PubMed]

- Papageorgiou, D.G.; Kinloch, I.A.; Young, R.J. Mechanical properties of graphene and graphene-based nanocomposites. Prog. Mater. Sci. 2017, 90, 75–127. [Google Scholar] [CrossRef]

- Tian, W.; Li, W.; Yu, W.; Liu, X. A Review on Lattice Defects in Graphene: Types, Generation, Effects and Regulation. Micromachines 2017, 8, 163. [Google Scholar] [CrossRef] [Green Version]

- Mahmoud, K.A.; Mansoor, B.; Mansour, A.; Khraisheh, M. Functional graphene nanosheets: The next generation membranes for water desalination. Desalination 2015, 356, 208–225. [Google Scholar] [CrossRef]

- You, Y.; Sahajwalla, V.; Yoshimura, M.; Joshi, R.K. Graphene and graphene oxide for desalination. Nanoscale 2015, 8, 117–119. [Google Scholar] [CrossRef] [PubMed]

- Du, H.; Li, J.; Zhang, J.; Su, G.; Li, X.; Zhao, Y. Separation of hydrogen and nitrogen gases with porous graphene membrane. J. Phys. Chem. C 2011, 115, 23261–23266. [Google Scholar] [CrossRef]

- Kidambi, P.R.; Nguyen, G.D.; Zhang, S.; Chen, Q.; Kong, J.; Warner, J.; Li, A.-P.; Karnik, R. Facile Fabrication of Large-Area Atomically Thin Membranes by Direct Synthesis of Graphene with Nanoscale Porosity. Adv. Mater. 2018, 30, 1804977. [Google Scholar] [CrossRef] [PubMed]

- Ravanchi, M.T.; Kaghazchi, T.; Kargari, A. Application of membrane separation processes in petrochemical industry: A review. Desalination 2009, 235, 199–244. [Google Scholar] [CrossRef]

- Stamatialis, D.F.; Papenburg, B.J.; Gironés, M.; Saiful, S.; Bettahalli, S.N.M.; Schmitmeier, S.; Wessling, M. Medical applications of membranes: Drug delivery, artificial organs and tissue engineering. J. Membr. Sci. 2008, 308, 1–34. [Google Scholar] [CrossRef] [Green Version]

- Kalbac, M.; Lehtinen, O.; Krasheninnikov, A.V.; Keinonen, J.; Kalbac, M.; Heyrovský, J.; Lehtinen, O.; Krasheninnikov, A.V.; Keinonen, J. Ion-Irradiation-Induced Defects in Isotopically-Labeled Two Layered Graphene: Enhanced In-Situ Annealing of the Damage. Adv. Mater. 2013, 25, 1004–1009. [Google Scholar] [CrossRef] [PubMed]

- Kim, J.-H.; Hwang, J.H.; Suh, J.; Tongay, S.; Kwon, S.; Hwang, C.C.; Wu, J.; Park, J.Y. Work function engineering of single layer graphene by irradiation-induced defects. Appl. Phys. Lett. 2013, 103, 171604. [Google Scholar] [CrossRef] [Green Version]

- Robertson, A.W.; Allen, C.S.; Wu, Y.A.; He, K.; Olivier, J.; Neethling, J.; Kirkland, A.I.; Warner, J.H. Spatial control of defect creation in graphene at the nanoscale. Nat. Commun. 2012, 3, 1144. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Lin, Y.C.; Lu, C.C.; Yeh, C.H.; Jin, C.; Suenaga, K.; Chiu, P.W. Graphene annealing: How clean can it be? Nano Lett. 2012, 12, 414–419. [Google Scholar] [CrossRef] [PubMed]

- Marciano, O.; Gonen, S.; Levy, N.; Teblum, E.; Yemini, R.; Daniel Nessim, G.; Ruthstein, S.; Elbaz, L. Modulation of oxygen content in graphene surfaces using temperature-programmed reductive annealing: Electron paramagnetic resonance and electrochemical study. Langmuir 2016, 32, 11672–11680. [Google Scholar] [CrossRef]

- Wang, B.; Pantelides, S.T. Controllable healing of defects and nitrogen doping of graphene by CO and NO molecules. Phys. Rev. B 2011, 83, 245403. [Google Scholar] [CrossRef]

- Daukiya, L.; Mattioli, C.; Aubel, D.; Hajjar-Garreau, S.; Vonau, F.; Denys, E.; Reiter, G.; Fransson, J.; Perrin, E.; Bocquet, M.-L.; et al. Covalent Functionalization by Cycloaddition Reactions of Pristine Defect-Free Graphene. ACS Nano 2016, 11, 627–634. [Google Scholar] [CrossRef]

- Kumar, S.B.; Guo, J. Strain-Induced Conductance Modulation in Graphene Grain Boundary. Nano Lett. 2012, 12, 1362–1366. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Du, H.; Xue, T.; Xu, C.; Kang, Y.; Dou, W. Improvement of mechanical properties of graphene/substrate interface via regulation of initial strain through cyclic loading. Opt. Lasers Eng. 2018, 110, 356–363. [Google Scholar] [CrossRef]

- Fischbein, M.D.; Drndić, M. Electron beam nanosculpting of suspended graphene sheets. Appl. Phys. Lett. 2008, 93, 113107. [Google Scholar] [CrossRef] [Green Version]

- Krasheninnikov, A.V.; Banhart, F. Engineering of nanostructured carbon materials with electron or ion beams. Nat. Mater. 2007, 6, 723–733. [Google Scholar] [CrossRef] [PubMed]

- Egerton, R.F.; McLeod, R.; Wang, F.; Malac, M. Basic questions related to electron-induced sputtering in the TEM. Ultramicroscopy 2010, 110, 991–997. [Google Scholar] [CrossRef]

- Zobelli, A.; Gloter, A.; Ewels, C.P.; Seifert, G.; Colliex, C. Electron knock-on cross section of carbon and boron nitride nanotubes. Phys. Rev. B 2007, 75, 245402. [Google Scholar] [CrossRef] [Green Version]

- Smith, B.W.; Luzzi, D.E. Electron irradiation effects in single wall carbon nanotubes. J. Appl. Phys. 2001, 90, 3509. [Google Scholar] [CrossRef] [Green Version]

- Crespi, V.H.; Chopra, N.G.; Cohen, M.L.; Zettl, A.; Louie, S.G. Anisotropic electron-beam damage and the collapse of carbon nanotubes. Phys. Rev. B 1996, 54, 5927. [Google Scholar] [CrossRef] [Green Version]

- Saito, R.; Dresselhaus, G.; Dresselhaus, M.S. Physical Properties of Carbon Nanotubes; Imperial College Press: London, UK, 1998; pp. 73–89. [Google Scholar]

- Girit, Ç.Ö.; Meyer, J.C.; Erni, R.; Rossell, M.D.; Kisielowski, C.; Yang, L.; Park, C.-H.; Crommie, M.F.; Marvin, L.C.; Steven, G.L.; et al. Graphene at the edge: Stability and dynamics. Science 2009, 323, 1705–1708. [Google Scholar] [CrossRef]

- Tapasztó, L.; Dobrik, G.; Nemes-Incze, P.; Vertesy, G.; Lambin, P.; Biró, L.P. Tuning the electronic structure of graphene by ion irradiation. Phys. Rev. B 2008, 78, 233407. [Google Scholar] [CrossRef] [Green Version]

- Buchowicz, G.; Stone, P.R.; Robinson, J.T.; Cress, C.D.; Beeman, J.W.; Dubon, O.D. Correlation between structure and electrical transport in ion-irradiated graphene grown on Cu foils. Appl. Phys. Lett. 2011, 98, 032102. [Google Scholar] [CrossRef]

- Song, B.; Schneider, G.F.; Xu, Q.; Pandraud, G.; Dekker, C.; Zandbergen, H. Atomic-scale electron-beam sculpting of near-defect-free graphene nanostructures. Nano Lett. 2011, 11, 2247. [Google Scholar] [CrossRef] [Green Version]

- Venkatesan, B.M.; Bashir, R. Nanopore sensors for nucleic acid analysis. Nat. Nanotechnol. 2011, 6, 615–624. [Google Scholar] [CrossRef] [PubMed]

- Arjmandi-Tash, H.; Belyaeva, L.A.; Schneider, G.F. Single molecule detection with graphene and other two-dimensional materials: Nanopores and beyond. Chem. Soc. Rev. 2016, 45, 476–493. [Google Scholar] [CrossRef] [Green Version]

- Yamada, I.; Matsuo, J.; Toyoda, N.; Kirkpatrick, A. Materials processing by gas cluster ion beams. Mater. Sci. Eng. R Rep. 2001, 34, 231–295. [Google Scholar] [CrossRef]

- Yamada, I. Materials Processing by Cluster Ion Beams: History, Technology, and Applications; CRC Press: Boca Raton, FL, USA, 2015; pp. 131–157. [Google Scholar]

- Insepov, Z. Cluster Ion-Solid Interactions: Theory, Simulation, and Experiment; CRC Press: Boca Raton, FL, USA, 2016; pp. 213–222. [Google Scholar]

- Insepov, Z.; Ainabayev, A.; Shaikhov, A.; Zhuldassov, A.; Ramazanova, Z.; Kirkpatrick, S.; Walsh, M. Nanoporous graphene film fabrication with cluster ion beams. In Proceedings of the 12th International New Diamond and Nano Carbons Conference, Flagstaff, AZ, USA, 20–24 May 2018; pp. 37–38. [Google Scholar]

- Insepov, Z.; Ainabayev, A.; Zhuldassov, A.; Shaikhov, A.; Terasawa, M. Ultrathin 2D film irradiation by highly charged ions. In Proceedings of the 12th International New Diamond and Nano Carbons Conference, Flagstaff, AZ, USA, 20–24 May 2018; p. 52. [Google Scholar]

- Kim, S.; Ievlev, A.V.; Jakowski, J.; Vlassiouk, I.V.; Sang, X.; Brown, C.; Dyck, O.; Unocic, R.R.; Kalinin, S.V.; Belianinov, A.; et al. Multi-purposed Ar gas cluster ion beam processing for graphene engineering. Carbon 2018, 131, 142–148. [Google Scholar] [CrossRef]

- Zabihi, Z.; Araghi, H. Formation of nanopore in a suspended graphene sheet with argon cluster bombardment: A molecular dynamics simulation study. Nucl. Instrum. Methods Phys. Res. B Beam Interact. Mater. At. 2015, 343, 48–51. [Google Scholar] [CrossRef]

- Gołuński, M.; Hrabar, S.; Postawa, Z. Mechanisms of particle ejection from free-standing two-layered graphene stimulated by keV argon gas cluster projectile bombardment–Molecular dynamics study. Surf. Coat. Technol. 2020, 391, 125683. [Google Scholar] [CrossRef]

- Dybyspayeva, K.B.; Zhuldassov, A.; Ainabayev, A.; Vyatkin, A.F.; Alekseev, K.; Insepov, Z. Multiscale simulation of ion beam impacts on a graphene surface. J. Phys. Conf. Ser. 2016, 751, 012029. [Google Scholar] [CrossRef] [Green Version]

- Geng, S.; Verkhoturov, S.V.; Eller, M.J.; Della-Negra, S.; Schweikert, E.A. The collision of a hypervelocity massive projectile with free-standing graphene: Investigation of secondary ion emission and projectile fragmentation. J. Chem. Phys. 2017, 146, 054305. [Google Scholar] [CrossRef]

- Verkhoturov, S.V.; Gołuński, M.; Verkhoturov, D.S.; Czerwinski, B.; Eller, M.J.; Geng, S.; Postawa, Z.; Schweikert, E.A. Hypervelocity cluster ion impacts on free standing graphene: Experiment, theory, and applications. J. Chem. Phys. 2019, 150, 160901. [Google Scholar] [CrossRef] [Green Version]

- Li, X.; Cai, W.; An, J.; Kim, S.; Nah, J.; Yang, D.; Piner, R.; Velamakanni, A.; Jung, I.; Tutuc, E.; et al. Large-Area Synthesis of High-Quality and Uniform Graphene Films on Copper Foils. Science 2009, 324, 1312–1314. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Regan, W.; Alem, N.; Alemán, B.; Geng, B.; Girit, Ç.; Maserati, L.; Wang, F.; Crommie, M.; Zettl, A. A direct transfer of layer-area graphene. Appl. Phys. Lett. 2010, 96, 113102. [Google Scholar] [CrossRef] [Green Version]

- Insepov, Z.; Manory, R.; Matsuo, J.; Yamada, I. Proposal for a hardness measurement technique without indentor by gas-cluster-beam bombardment. Phys. Rev. B 2000, 61, 8744. [Google Scholar] [CrossRef] [Green Version]

- Cançado, L.G.; Jorio, A.; Ferreira, E.H.M.; Stavale, F.; Achete, C.A.; Capaz, R.B.; Moutinho, M.V.O.; Lombardo, A.; Kulmala, T.S.; Ferrari, A.C. Quantifying Defects in Graphene via Raman Spectroscopy at Different Excitation Energies. Nano Lett. 2011, 11, 3190–3196. [Google Scholar] [CrossRef] [Green Version]

- Childres, I.; Jauregui, L.; Tian, J.; Chen, Y.P. Effect of oxygen plasma etching on graphene studied using Raman spectroscopy and electronic transport measurements. New J. Phys. 2011, 13, 025008. [Google Scholar] [CrossRef]

- Eckmann, A.; Felten, A.; Mishchenko, A.; Britnell, L.; Krupke, R.; Novoselov, K.S.; Casiraghi, C. Probing the nature of defects in graphene by Raman spectroscopy. Nano Lett. 2012, 12, 3925–3930. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Wu, X.; Zhao, H.; Zhong, M.; Murakawa, H.; Tsukamoto, M. Molecular dynamics simulation of graphene sheets joining under ion beam irradiation. Carbon 2014, 66, 31–38. [Google Scholar] [CrossRef]

- Krasheninnikov, A.V.; Nordlund, K.; Keinonen, J.; Banhart, F. Ion-irradiation-induced welding of carbon nanotubes. Phys. Rev. B 2002, 66, 245403. [Google Scholar] [CrossRef] [Green Version]

- Abdol, M.A.; Sadeghzadeh, S.; Jalaly, M.; Khatibi, M.M. Constructing a three-dimensional graphene structure via bonding layers by ion beam irradiation. Sci. Rep. 2019, 9, 8127. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Dumée, L.F.; Feng, C.; He, L.; Yi, Z.; She, F.; Peng, Z.; Gao, W.; Banos, C.; Davies, J.B.; Huynh, C.; et al. Single step preparation of meso-porous and reduced graphene oxide by gamma-ray irradiation in gaseous phase. Carbon 2014, 70, 313–318. [Google Scholar] [CrossRef]

- Fox, D.; O’Neill, A.; Zhou, D.; Boese, M.; Coleman, J.N.; Zhang, H.Z. Nitrogen assisted etching of graphene layers in a scanning electron microscope. Appl. Phys. Lett. 2011, 98, 243117. [Google Scholar] [CrossRef]

- Celebi, K.; Buchheim, J.; Wyss, R.M.; Droudian, A.; Gasser, P.; Shorubalko, I.; Kye, J.-I.; Lee, C.; Park, H.G. Ultimate permeation across atomically thin porous graphene. Science 2014, 344, 289–292. [Google Scholar] [CrossRef]

- O’Hern, S.C.; Boutilier, M.S.; Idrobo, J.C.; Song, Y.; Kong, J.; Laoui, T.; Atieh, M.; Karnik, R. Selective ionic transport through tunable subnanometer pores in single-layer graphene membranes. Nano Lett. 2014, 14, 1234–1241. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Akhavan, O. Graphene nanomesh by ZnO nanorod photocatalysts. ACS Nano 2010, 4, 4174–4180. [Google Scholar] [CrossRef] [PubMed]

| Parameter | Value/Coordinates |

|---|---|

| Lattice constant | 1.421 A |

| Lattice constant | (3, 0, 0) |

| Lattice constant | (0, 1.732, 0) |

| Lattice constant | (0, 0, 2.357) |

| Basis atom 1 | (0, 0, 0) |

| Basis atom 2 | (0.333, 0, 0) |

| Basis atom 3 | (0.5, 0.5, 0) |

| Basis atom 4 | (0.833, 0.5, 0) |

| Interaction | ϵ (A) | σ (kcal/mol) | Cutoff (A) |

|---|---|---|---|

| Ar–Ar | 0.238 | 3.4 | 7.65 |

| Interaction | A (kcal) | ρ (A) | C |

|---|---|---|---|

| C-Ar | 74,569.79 | 0.2863 | 0.1 × 10−9 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Almassov, N.; Kirkpatrick, S.; Alsar, Z.; Serik, N.; Spitas, C.; Kostas, K.; Insepov, Z. Crosslinking Multilayer Graphene by Gas Cluster Ion Bombardment. Membranes 2022, 12, 27. https://doi.org/10.3390/membranes12010027

Almassov N, Kirkpatrick S, Alsar Z, Serik N, Spitas C, Kostas K, Insepov Z. Crosslinking Multilayer Graphene by Gas Cluster Ion Bombardment. Membranes. 2022; 12(1):27. https://doi.org/10.3390/membranes12010027

Chicago/Turabian StyleAlmassov, Nurlan, Sean Kirkpatrick, Zhanna Alsar, Nurzhan Serik, Christos Spitas, Konstantinos Kostas, and Zinetula Insepov. 2022. "Crosslinking Multilayer Graphene by Gas Cluster Ion Bombardment" Membranes 12, no. 1: 27. https://doi.org/10.3390/membranes12010027

APA StyleAlmassov, N., Kirkpatrick, S., Alsar, Z., Serik, N., Spitas, C., Kostas, K., & Insepov, Z. (2022). Crosslinking Multilayer Graphene by Gas Cluster Ion Bombardment. Membranes, 12(1), 27. https://doi.org/10.3390/membranes12010027

_Insepov.png)