Transparent Flexible IGZO Thin Film Transistors Fabricated at Room Temperature

Abstract

:1. Introduction

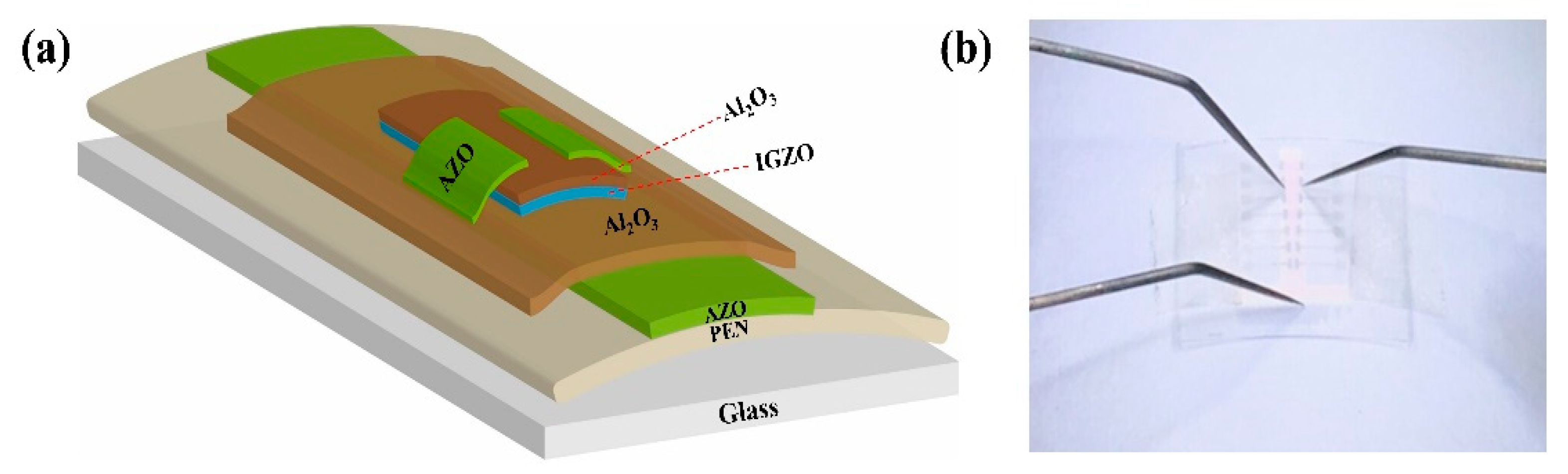

2. Materials and Methods

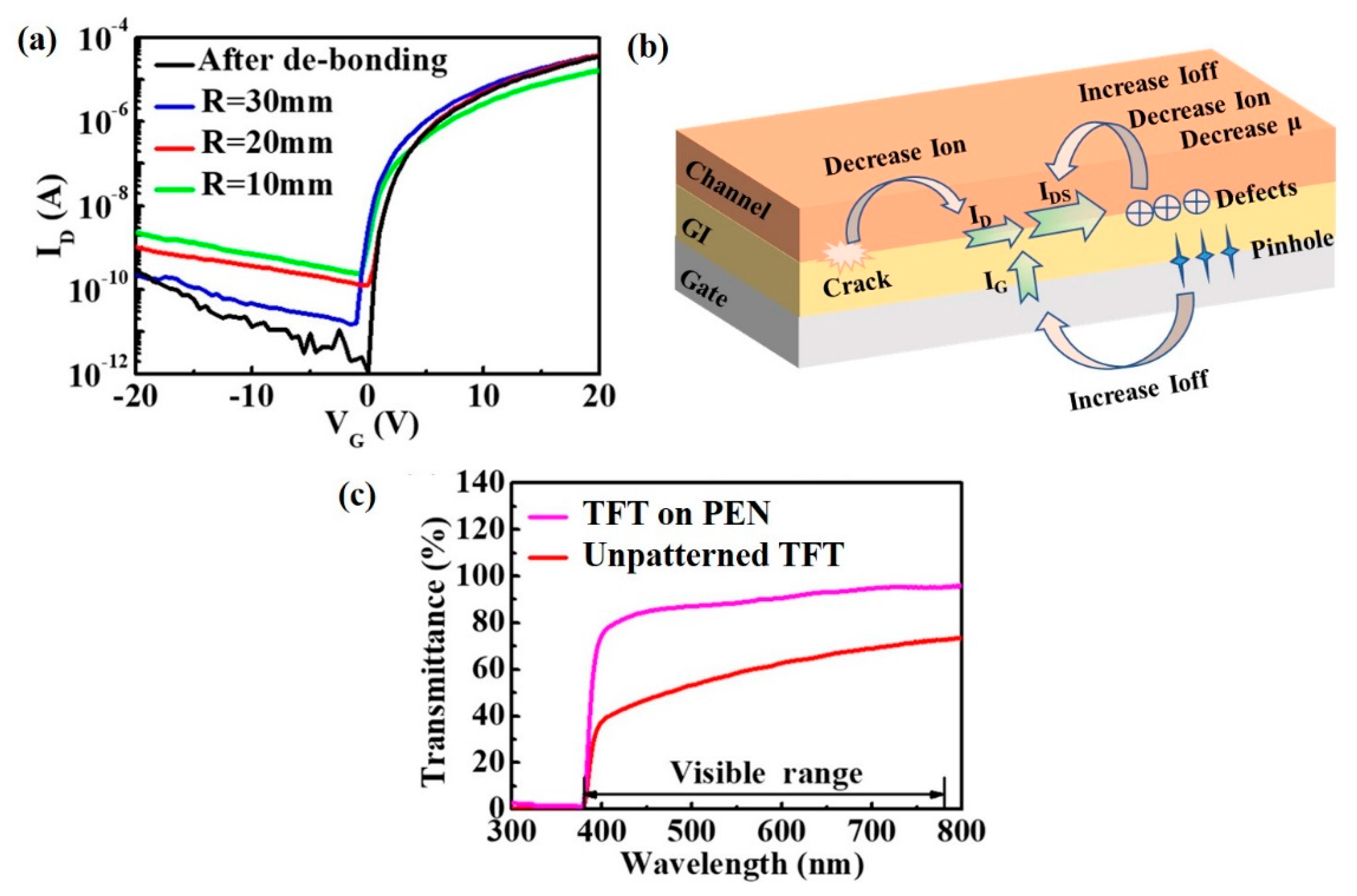

3. Results

4. Discussion

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Bukke, R.N.; Mude, N.N.; Saha, J.K.; Lee, S.; Jang, J. P-22: Flexible La Doped ZnO TFTs and Circuits on Polyimide Substrate for Foldable Display. SID Symp. Dig. Tech. Pap. 2021, 52, 1135–1138. [Google Scholar] [CrossRef]

- Cao, W.; Hsu, Y.; Jiang, Z.; Liu, F.; Wu, Y.; Zhang, X. High Performance Top Gate Oxide TFT Technology for Large Area Flexible AMOLED Display. SID Int. Symp. Dig. Tech. Pap. 2021, 52, 21–24. [Google Scholar] [CrossRef]

- Hu, Y.; Guo, L.Q.; Huo, C.; Dai, M.; Webster, T.J.; Ding, J. Transparent Nano Thin-Film Transistors for Medical Sensors, OLED and Display Applications. Int. J. Nanomed. 2020, 15, 3597–3603. [Google Scholar] [CrossRef] [PubMed]

- Ko, J.B.; Lee, S.H.; Lee, T.I.; Lee, S.; Kim, J.; Kim, H.; Kim, T.S.; Park, S.H.K. Ultrathin, Flexible, and Transparent Oxide Thin-Film Transistors by Delamination and Transfer Methods for Deformable Displays. Adv. Mater. Technol. 2021, 6, 2100431. [Google Scholar] [CrossRef]

- Gu, Y.; Zhang, T.; Chen, H.; Wang, F.; Pu, Y.; Gao, C.; Li, S. Mini Review on Flexible and Wearable Electronics for Monitoring Human Health Information. Nanoscale Res. Lett. 2019, 14, 263. [Google Scholar] [CrossRef] [Green Version]

- Fang, G.; Li, D.; Yao, B. Fabrication and vacuum annealing of transparent conductive AZO thin films prepared by DC magnetron sputtering. Vacuum 2002, 68, 363–372. [Google Scholar] [CrossRef]

- Myny, K. The development of flexible integrated circuits based on thin-film transistors. Nat. Electron. 2018, 1, 30–39. [Google Scholar] [CrossRef]

- Sharma, S.; Shriwastava, S.; Kumar, S.; Bhatt, K.; Tripathi, C.C. Alternative transparent conducting electrode materials for flexible optoelectronic devices. Opto-Electron. Rev. 2018, 26, 223–235. [Google Scholar] [CrossRef]

- Park, H.; Oh, D.S.; Lee, K.J.; Jung, D.Y.; Lee, S.; Yoo, S.; Choi, S. Flexible and Transparent Thin-Film Transistors Based on Two-Dimensional Materials for Active-Matrix Display. ACS Appl. Mater. Interfaces 2020, 12, 4749–4754. [Google Scholar] [CrossRef]

- Ha, T. High-Performance Solution-Processed Zinc–Tin-Oxide Thin-Film Transistors Employing Ferroelectric Copolymers Fabricated at Low Temperature for Transparent Flexible Displays. IEEE Electron Device Lett. 2016, 37, 1586–1589. [Google Scholar] [CrossRef]

- Sarma, K.R. Flexible Displays: Substrate and TFT Technology Options and Processing Strategies. In Handbook of Visual Display Technology; Springer International Publishing: Cham, Switzerland, 2016; pp. 1389–1429. [Google Scholar]

- Li, Y.; Yao, R.; Wang, H.; Wu, X.; Wu, J.; Wu, X.; Qin, W. Enhanced Performance in Al-Doped ZnO Based Transparent Flexible Transparent Thin-Film Transistors Due to Oxygen Vacancy in ZnO Film with Zn–Al–O Interfaces Fabricated by Atomic Layer Deposition. ACS Appl. Mater. Interfaces 2017, 9, 11711–11720. [Google Scholar] [CrossRef] [PubMed]

- Zhang, H.; Li, X.; Fang, Z.; Yao, R.; Zhang, X.; Deng, Y.; Lu, X.; Tao, H.; Ning, H.; Peng, J. Highly Conductive and Transparent AZO Films Fabricated by PLD as Source/Drain Electrodes for TFTs. Materials 2018, 11, 2480. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Lee, J.; Park, Y.S. Characteristics of Al-doped ZnO films annealed at various temperatures for InGaZnO-based thin-film transistors. Thin Solid Film. 2015, 587, 94–99. [Google Scholar] [CrossRef]

- Hernandez-Como, N.; Morales-Acevedo, A.; Aleman, M.; Mejia, I.; Quevedo-Lopez, M.A. Al-doped ZnO thin films deposited by confocal sputtering as electrodes in ZnO-based thin-film transistors. Microelectron. Eng. 2016, 150, 26–31. [Google Scholar] [CrossRef]

- Ma, P.; Dai, C.; Wang, H.; Li, Z.; Liu, H.; Li, W.; Yang, C. A review on high temperature resistant polyimide films: Heterocyclic structures and nanocomposites. Compos. Commun. 2019, 16, 84–93. [Google Scholar] [CrossRef]

- Zhang, Y.; Qu, L.; Liu, J.; Wu, X.; Zhang, Y.; Zhang, R.; Qi, H.; Zhang, X. Synthesis and characterization of high-temperature-resistant and optically transparent polyimide coatings for potential applications in quartz optical fibers protection. J. Coatings Technol. Res. 2018, 16, 511–520. [Google Scholar] [CrossRef]

- Zheng, Z.; Zeng, Y.; Yao, R.; Fang, Z.; Zhang, H.; Hu, S.; Li, X.; Ning, H.; Peng, J.; Xie, W.; et al. All-sputtered, flexible, bottom-gate IGZO/Al2O3 bi-layer thin film transistors on PEN fabricated by a fully room temperature process. J. Mater. Chem. C 2017, 5, 7043–7050. [Google Scholar] [CrossRef]

- Yao, J.; Xu, N.; Deng, S.; Chen, J.; She, J.; Shieh, H.D.; Liu, P.; Huang, Y. Electrical and Photosensitive Characteristics of a-IGZO TFTs Related to Oxygen Vacancy. IEEE Trans. Electron Devices 2011, 58, 1121–1126. [Google Scholar]

- Hosono, H. Ionic amorphous oxide semiconductors: Material design, carrier transport, and device application. J. Non Cryst. Solids 2006, 352, 851–858. [Google Scholar] [CrossRef]

- Jeong, J.K.; Won Yang, H.; Jeong, J.H.; Mo, Y.; Kim, H.D. Origin of threshold voltage instability in indium-gallium-zinc oxide thin film transistors. Appl. Phys. Lett. 2008, 93, 123508. [Google Scholar] [CrossRef]

- Wang, X.; Wang, M.; Jiang, W.; Zhang, D.; Wang, H.; Shan, Q. Mechanical Reliability of Flexible a-InGaZnO TFTs under Dynamic Stretch Stress. IEEE Trans. Electron Devices 2018, 65, 2863–2869. [Google Scholar] [CrossRef]

- Lee, K.; Kim, Y.; Kim, J.; Oh, M.S. Transparent and Flexible Zinc Tin Oxide Thin Film Transistors and Inverters using Low-pressure Oxygen Annealing Process. J. Korean Phys. Soc. 2018, 72, 1073–1077. [Google Scholar] [CrossRef]

- Zhang, L.; Huang, C.; Li, G.; Zhou, L.; Wu, W.; Xu, M.; Wang, L.; Ning, H.; Yao, R.; Peng, J. A Low-Power High-Stability Flexible Scan Driver Integrated by IZO TFTs. IEEE Trans. Electron Devices 2016, 63, 1779–1782. [Google Scholar] [CrossRef]

- Tiwari, N.; Rajput, M.; John, R.A.; Kulkarni, M.R.; Nguyen, A.C.; Mathews, N. Indium Tungsten Oxide Thin Films for Flexible High-Performance Transistors and Neuromorphic Electronics. ACS Appl. Mater. Interfaces 2018, 10, 30506–30513. [Google Scholar] [CrossRef] [PubMed]

| Radius | Plane | R = 30 mm | R = 20 mm | R = 10 mm |

|---|---|---|---|---|

| µsat (cm2/V·s) | 6 | 5.6 | 5.61 | 4.73 |

| Ion/Ioff | 1.3 × 107 | 2.63 × 106 | 3.05 × 105 | 6.82 × 104 |

| SS (V/dec) | 0.237 | 0.397 | 0.594 | 0.723 |

| Von (V) | 0.17 | −0.88 | −0.07 | −0.45 |

| Ion (A) | 5.36 × 10−5 | 4.05 × 10−5 | 4.00 × 10−5 | 1.58 × 10−5 |

| Ioff (A) | 4.12 × 10−12 | 1.54 × 10−11 | 1.31 × 10−10 | 2.32 × 10−10 |

| Nt (cm−2 eV−1) | 5.01 × 1011 | 9.53 × 1011 | 1.51 × 1012 | 1.87 × 1012 |

| Ref. | This Work | [12] | [23] | [24] | [25] |

|---|---|---|---|---|---|

| Substrate | PEN | PEN | PES | PI | PI/SiO2 |

| Gate electrodes | AZO (RFMS) | ZnO/AZO (ALD) | ITO | Al (DCMS) | Ti (DCMS) |

| S/D electrodes | AZO (PLD) | ZnO/AZO (ALD) | IZO (RFMS) | Mo (DCMS) | ITO (RFMS) |

| Dielectric | Al2O3 (RFMS) | Al2O3 (ALD) | Al2O3 (ALD) | Al2O3 | Al2O3 (ALD) |

| Channel layers | IGZO/Al2O3 (DC/RFMS) | ZnO (ALD) | ZTO (RFMS) | IZO (RFMS) | IWO (RFMS) |

| Maximum temperature | RT | 150 °C | 150 °C | 300 °C | 270 °C |

| Transmittance of TFT | 87.8% | 80% | ~68% | - | - |

| µsat (cm2/V·s) | 5.61 | 2 | - | 6.32 | 24.86 |

| Ion/Ioff | 3.05 × 105 | ~107 | 3.05 × 106 | 9.7 × 107 | ~105 |

| SS(V/dec) | 0.594 | 1.4 | - | 0.39 | 0.28 |

| Bending radius (mm) | 20 | Unbending | unbending | 20 | 20 |

| Year | 2020 | 2017 | 2018 | 2016 | 2018 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ning, H.; Zeng, X.; Zhang, H.; Zhang, X.; Yao, R.; Liu, X.; Luo, D.; Xu, Z.; Ye, Q.; Peng, J. Transparent Flexible IGZO Thin Film Transistors Fabricated at Room Temperature. Membranes 2022, 12, 29. https://doi.org/10.3390/membranes12010029

Ning H, Zeng X, Zhang H, Zhang X, Yao R, Liu X, Luo D, Xu Z, Ye Q, Peng J. Transparent Flexible IGZO Thin Film Transistors Fabricated at Room Temperature. Membranes. 2022; 12(1):29. https://doi.org/10.3390/membranes12010029

Chicago/Turabian StyleNing, Honglong, Xuan Zeng, Hongke Zhang, Xu Zhang, Rihui Yao, Xianzhe Liu, Dongxiang Luo, Zhuohui Xu, Qiannan Ye, and Junbiao Peng. 2022. "Transparent Flexible IGZO Thin Film Transistors Fabricated at Room Temperature" Membranes 12, no. 1: 29. https://doi.org/10.3390/membranes12010029

APA StyleNing, H., Zeng, X., Zhang, H., Zhang, X., Yao, R., Liu, X., Luo, D., Xu, Z., Ye, Q., & Peng, J. (2022). Transparent Flexible IGZO Thin Film Transistors Fabricated at Room Temperature. Membranes, 12(1), 29. https://doi.org/10.3390/membranes12010029