Reverse Osmosis Membrane Zero Liquid Discharge for Agriculture Drainage Water Desalination: Technical, Economic, and Environmental Assessment

Abstract

:1. Introduction

2. Methods

2.1. Identification of Typical Characteristics of ADW

2.2. Rationale of Developed Proposed Treatment Scheme

3. Results

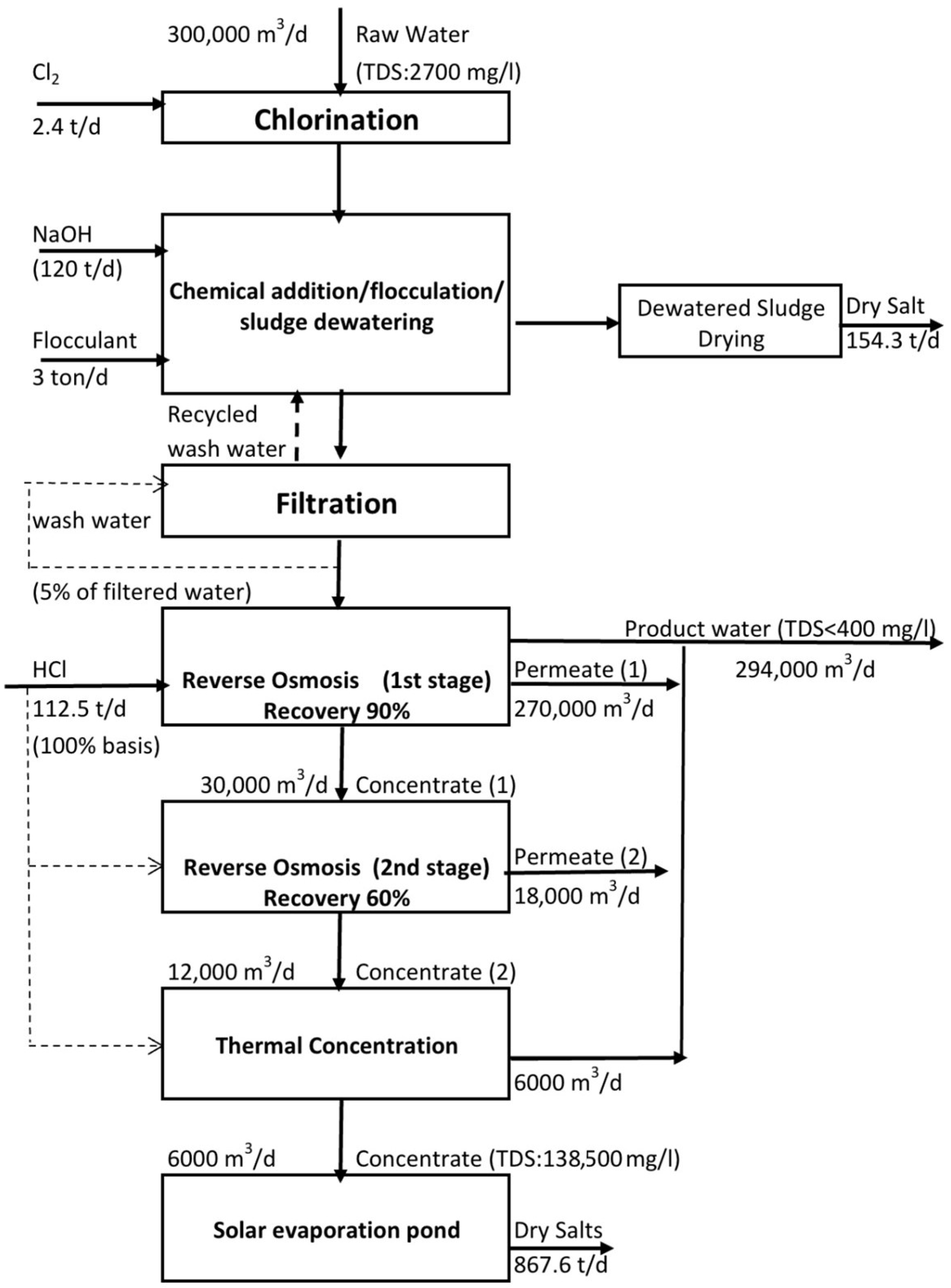

3.1. Basic Engineering of Proposed System

- WatPro, version 4.0, Hydromantis, water treatment simulator for predicting water quality, Hamilton, Ontario, Canada

- RO using LewaPlus®, version 5.0, Calculation and Design Software, LANXESS, Deutschland GmbH Liquid Purification Technologies Kennedy platz 150569 Cologne, Germany,

- Thermal desalination using WT Cost II© software developed by the Bureau of Reclamation and Moch Associates, U.S. Department of the Interior, Bureau of Reclamation Technical Service Center, Denver, Colorado, according to the design features provided, and solar evaporation ponds using Excel.

3.2. Material Balance

3.3. Technical Features and Specifications of the Proposed System

4. Financial Indicators for ZLD System

4.1. Cost Estimation and Financial Indicators

4.2. Construction Cost Estimates

4.3. Operating Costs Estimates

4.4. Annual Production Costs Estimates

5. Environmental Considerations

6. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Water Resources Group. Valuing Water, Enabling Change; Annual Report; Water Resources Group: Washington, DC, USA, 2020. [Google Scholar]

- UNU-INWEH. Global-Water-Crisis-The-Facts; Technical Report; UNU-INWEH: Hamilton, ON, Canada, 2017. [Google Scholar]

- He, C.; Liu, Z.; Wu, J.; Pan, X.; Fang, Z.; Li, J.; Bryan, B.A. Future global urban water scarcity and potential solutions. Nat. Commun. 2021, 12, 4667. [Google Scholar] [CrossRef] [PubMed]

- Nakoa, K.; Rahaoui, K.; Date, A.; Akbarzadeh, A. Sustainable zero liquid discharge desalination (SZLDD). Sol. Energy 2016, 135, 337–347. [Google Scholar] [CrossRef]

- Thi, H.; Pasztor, T.; Fozer, D.; Manenti, F.; Toth, A.J. Comparison of Desalination Technologies Using RenewableEnergy Sources with Life Cycle, PESTLE, and Multi-CriteriaDecision Analyses. Water 2021, 13, 3023. [Google Scholar] [CrossRef]

- Eke, K.; Yusuf, A.; Giwa, A.; Sodiq, A. The global status of desalination: An assessment of current desalinationtechnologies, plants and capacity. Desalination 2020, 495, 114633. [Google Scholar] [CrossRef]

- Amy, G.; Ghaffour, N.; Li, Z.; Francis, L.; Linares, R.V.; Missimer, T.; Lattemann, S. Membrane-based seawater desalination: Present and future prospects. Desalination 2017, 401, 16–21. [Google Scholar] [CrossRef]

- Kumar, R.; Ahmed, M.; Bhadrachari, G.; Jibu, P.T. Desalination for agriculture: Water quality and plant chemistry, technologies and challenges. Water Sci. Technol. Water Supply 2018, 18, 1505–1517. [Google Scholar] [CrossRef]

- Matin, A.; Laoui, T.; Falath, W.; Farooque, M. Fouling control in reverse osmosis for water desalination & reuse: Current practices & emerging environment-friendly technologies. Sci. Total Environ. 2021, 765, 142721. [Google Scholar] [PubMed]

- Shi, Y.; Zhang, C.; Li, R.; Zhuo, S.; Jin, Y.; Shi, L.; Wang, P. Solar evaporator with controlled salt precipitation for zero liquid discharge desalination. Environ. Sci. Technol. 2018, 52, 11822–11830. [Google Scholar] [CrossRef] [PubMed]

- Nofal, I. Desal brackish water for agriculture. In Proceedings of the Regional Water Knowledge Sharing Forum, Sharm El Sheikh, Egypt, 12–14 May 2015. [Google Scholar]

- Elimelech, M.; Phillip, W.A. The Future of Seawater Desalination: Energy, Technology, and the Environment. Science 2011, 333, 712. [Google Scholar] [CrossRef] [PubMed]

- Florea, A.F.; Lu, C.; Hansen, H.C.B. A zero-valent iron and zeolite filter for nitrate recycling from agricultural drainage water. Chemosphere 2022, 287, 131993. [Google Scholar] [CrossRef] [PubMed]

- Bhojwani, S.; Topolski, K.; Mukherjee, R.; Sengupta, D.; El-Halwagi, M.M. Technology review and data analysis for cost assessment of water treatment systems. Sci. Total Environ. 2019, 651, 2749–2761. [Google Scholar] [CrossRef] [PubMed]

- Generous, M.M.; Qasem, N.A.A.; Akbar, U.A.; Zubair, S.S. Techno-economic assessment of electrodialysis and reverse osmosis desalination plants. Sep. Purif. Technol. 2021, 272, 118875. [Google Scholar] [CrossRef]

- Pearson, J.L.; Michael, P.R.; Ghaffour, N.; Missimer, T.M. Economics and Energy Consumption of Brackish Water Reverse Osmosis Desalination: Innovations and Impacts of Feedwater Quality. Membranes 2021, 11, 616. [Google Scholar] [CrossRef] [PubMed]

- Panagopoulos, A. Energetic, economic and environmental assessment of zero liquid discharge (ZLD) brackish water and seawater desalination systems. Energy Convers. Manag. 2021, 235, 113957. [Google Scholar] [CrossRef]

| Item | Na | K | Mg | Ca | Cl | HCO3 | SO4 | NO3 |

|---|---|---|---|---|---|---|---|---|

| Conc. (mg/L) | 596 | 30 | 140 | 110 | 1070 | 370 | 355 | 40 |

| Item | Fe | Mn | TDS | TP | pH | TSS | COD | BOD |

| Conc. (mg/L) | 2 | 1 | 2705 | 1 | 7.7 | 80 | 20 | 10 |

| 1. Pre-Treatment | ||

|---|---|---|

| Raw Water Feed Flowrate | 300,000 m3/d | |

| Chlorine dose | 8 mg/L | |

| Sodium hydroxide dose | 400 mg/L | |

| Flocculant | 10 mg/L | |

| System | Low pressure-pumping station, In-line chlorination, chemicals (caustic soda and flocculant) addition, flocculation, and clarification, in one tank, followed by dual media filtration. | |

| Power | 1525 kW | |

| 2. RO stages | ||

| First Stage RO | Second Stage RO | |

| Feed flow rate | 300,000 m3/d | 30,000 m3/d |

| Recovery | 90% | 60% |

| 3. Thermal Concentration | ||

| Feed flowrate | 12,000 m3/day | |

| System | Thermo vapor compression (TVC) | |

| Power | 913 kW | |

| Recovery | 50% | |

| 4. Solar Pond | ||

| Feed flow rate | 6000 m3/d | |

| Average climate conditions: | ||

| Temperature | 24 °C | |

| Humidity | 50% | |

| Solar irradiation | 412.2 W/m2 | |

| Wind speed | 3.5 m/s | |

| Rainfall | 65 mm/y | |

| Elevation above sea | 15 | |

| Raw Water | Sedimentation Effluent | Filtration Effluent | |

|---|---|---|---|

| Na (mg/L) | 596 | 945 | 945 |

| Ca (mg/L) | 110 | 28 | 28 |

| Mg (mg/L) | 140 | 46 | 46 |

| K (mg/L) | 30 | 30 | 30 |

| Cl (mg/L) | 1070 | 1070 | 1070 |

| SO4 (mg/L) | 355 | 355 | 355 |

| CO3 (mg/L) | - | 147 | 147 |

| HCO3 (mg/L) | 370 | 232 | 232 |

| NO3 (mg/L) | 40 | 40 | 40 |

| Fe (mg/L) | 2 | - | - |

| Mn (mg/L) | 1 | - | - |

| TOC (mg/L) | 10 | 1 | - |

| TDS (mg/L) | 2705 | 2896 | 2892 |

| pH | 7.7 | 9.8 | 9.8 |

| TOC (mg/L) | 10 | 1 | - |

| Turbidity (NTU) | 100 | 5 | 1 |

| Solid ppt | CaCO3 205.6 mg/L | ||

| Mg (OH)2 228.6 mg/L | |||

| Stream Item | Feed Raw Water | Permeate (1) | Permeate (2) | Concentrate (1) | Concentrate (2) |

|---|---|---|---|---|---|

| Na (mg/L) | 945 | 17.5 | 130 | 9291 | 23,080 |

| Ca (mg/L) | 28 | 0.2 | 1.4 | 278.4 | 694 |

| Mg (mg/L) | 46 | 0.3 | 224 | 457.4 | 1140 |

| K (mg/L) | 30 | 0.83 | 6.12 | 292.7 | 722.5 |

| Cl (mg/L) | 1070 | 25 | 1863 | 13,622 | 33,772 |

| SO4 (mg/L) | 355 | 1.3 | 9.7 | 3538.3 | 8831 |

| CO3 (mg/L) | 147 | 0 | 0 | 0 | 0.003 |

| HCO3(mg/L) | 232 | 0.04 | 0.28 | 20.3 | 50.3 |

| NO3 (mg/L) | 40 | 5.4 | 37.3 | 350.3 | 819 |

| CO2 (mg/L) | 0.05 | 0 | 273.6 | 273.6 | 273.6 |

| TDS (mg/L) | 2892 | 273.6 | 373.3 | 24,850 | 69,108 |

| pH | 9.8 | 2.32 | 3.18 | 4.9 | 5.26 |

| Item | Specifications |

|---|---|

| Chlorination | Chlorine gas vacuum feeding system 2 × 100 kg/h, with 10 chlorine gas cylinders (1 t capacity), with pumps and accessories, control and chlorine detection, and elimination system included in a separate building provided with proper ventilation. |

| Chemical handling system | NaOH storage tanks (3000) m3 capacity, pumps centrifugal, CI, 20 m3/h, 50 m head, feed tanks 100 m3 capacity feed pumps CI 10 m3/h, 20 m. Flocculant preparation tank (30 m3) and pumps, (tanks 10 m3 with mixers), feeding pumps 1 m3/h, variable speed, 5 bar pressure. |

| Chemical treatment/flocculation/clarification tank | 4 tanks each 40 m diameter, with 4 m side wall depth, with chemical addition/flocculation section inlet, discharge wires, and sludge discharge arrangements. Mixers for rapid mixing and flocculation and sludge scraper. |

| Sludge dewatering | The system includes sludge pumps 8 × 10 m3/h, head 50 m. 4 sludge continuous belt filters, each 10 m3/h. 4 belt conveyers for cake (1 m width, 20 m length). 4 filtrate recycling pumps 10 m3/h, 20 m head. |

| Filtration unit | Dual media pressure filters (anthracite/sand). Operating pressure 3 bar. Diameter 3.5 m. Filtration rate 30 m3/m2 h. No. 50 With automatic backwash system. |

| Item | Specifications | |

|---|---|---|

| 1st Stage | 2nd Stage | |

| Feed flow rate | 300,000 m3/d | 30,000 m3/d |

| Recovery | 90% | 60% |

| Feed pressure “bar” | 28.7 | 57.0 |

| Pump pressure “bar” | 5 | 5 |

| Concentrate pressure “bar” | 30 | 30 |

| High pressure pump Pump/motor efficiency | 84%/94% | 84%/94% |

| High pressure pumps motors power | 12,622 kW | 2502 kW |

| Pump/motor efficiency | 84%/94% | 84%/94% |

| Booster pump motors power. | 626 kW | - |

| System components | Cartridge filters, RO trains, RO membrane elements, high pressure pumps with energy recovery. Inter-connecting piping, post treatment, membrane cleaning unit, electrical system, and instrumentation and control, auxiliary equipment and building. | |

| System Configuration | ||

| Number of stages/elements | 2/13,150 | 1/1250 |

| Elements number per vessel | SW HR 400 34/10 | SW HR 400 34/10 |

| No | Item | Cost USD 1000 |

|---|---|---|

| 1. | Pumping station | 11,394 |

| 2. | Pretreatment | |

| Chlorination | 2160 | |

| Chemical treatment/flocculation clarification and sludge dewatering | 6933 | |

| Filtration | 5398 | |

| Total pretreatment | 25,885 | |

| 3. | Reverse osmosis units | |

| RO1 | 56,210 | |

| RO2 | 3610 | |

| Total RO units | 59,820 | |

| 4. | Thermal concentration | 15,100 |

| 5. | Solar evaporation | 15,600 |

| Total | 116,405 | |

| No | Item | Annual Cost USD 1000/y | |

|---|---|---|---|

| 1. | Electricity | 10,290 | |

| Electricity consumption: 1.47 × 108 kWh/y @ USD 0.07/kW/h | |||

| 2. | Fuel | 75 t/d @ USD 100/t | 247 |

| 3. | Chemicals | NaOH 120 t/d @ USD 300/t Cl2 2.4 t/d @ USD 150/t HCl (100% basis) 112.5 t/d @ USD 300 t/d Flocculant/anti-scaling 3.6 t/d @ USD 2000/t | 11,826 118.3 11,087 2365.2 |

| 25,396.5 | |||

| 4. | Membrane | Membrane lifetime 3 y | |

| Replacement | Membrane cost USD 400/element | 1920 | |

| 5. | Maintenance | 3% of capital cost | 3492 |

| 6. | Labor | 150 persons @ USD 15,000/y | 2250 |

| Subtotal | 43,595.5 | ||

| 7. | Other operating cost | 10% of subtotal | 4359.5 |

| Total operating cost | 47,955.0 | ||

| Item | Basis | Annual Cost USD 1000 |

|---|---|---|

| Operating cost | According to Table 8 | 47,955 |

| Capital amortization | Plant lifetime 20 y Interest rate 4% | 8566 |

| Total annual cost | 56,521 | |

| Revenues | Mixed salts (NaCl, CaCl2, MgSO4) 245,000 t/y @ USD 50/t | 12,250 |

| Net annual cost | 44,271 | |

| Cost/m3 | Plant operation factor 0.9 | USD 0.46 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

El Sayed, M.M.; Abulnour, A.M.G.; Tewfik, S.R.; Sorour, M.H.; Hani, H.A.; Shaalan, H.F. Reverse Osmosis Membrane Zero Liquid Discharge for Agriculture Drainage Water Desalination: Technical, Economic, and Environmental Assessment. Membranes 2022, 12, 923. https://doi.org/10.3390/membranes12100923

El Sayed MM, Abulnour AMG, Tewfik SR, Sorour MH, Hani HA, Shaalan HF. Reverse Osmosis Membrane Zero Liquid Discharge for Agriculture Drainage Water Desalination: Technical, Economic, and Environmental Assessment. Membranes. 2022; 12(10):923. https://doi.org/10.3390/membranes12100923

Chicago/Turabian StyleEl Sayed, Marwa M., Abdelghani M. G. Abulnour, Shadia R. Tewfik, Mohamed H. Sorour, Heba A. Hani, and Hayam F. Shaalan. 2022. "Reverse Osmosis Membrane Zero Liquid Discharge for Agriculture Drainage Water Desalination: Technical, Economic, and Environmental Assessment" Membranes 12, no. 10: 923. https://doi.org/10.3390/membranes12100923

APA StyleEl Sayed, M. M., Abulnour, A. M. G., Tewfik, S. R., Sorour, M. H., Hani, H. A., & Shaalan, H. F. (2022). Reverse Osmosis Membrane Zero Liquid Discharge for Agriculture Drainage Water Desalination: Technical, Economic, and Environmental Assessment. Membranes, 12(10), 923. https://doi.org/10.3390/membranes12100923