Oxidized Carbon-Based Spacers for Pressure-Resistant Graphene Oxide Membranes

Abstract

:1. Introduction

2. Experimental Part

2.1. Preparation of Oxidized Graphitic Carbon Precursors

2.2. Preparation of Composite Membranes

2.3. Characterization of Composite Membranes

3. Results and Discussion

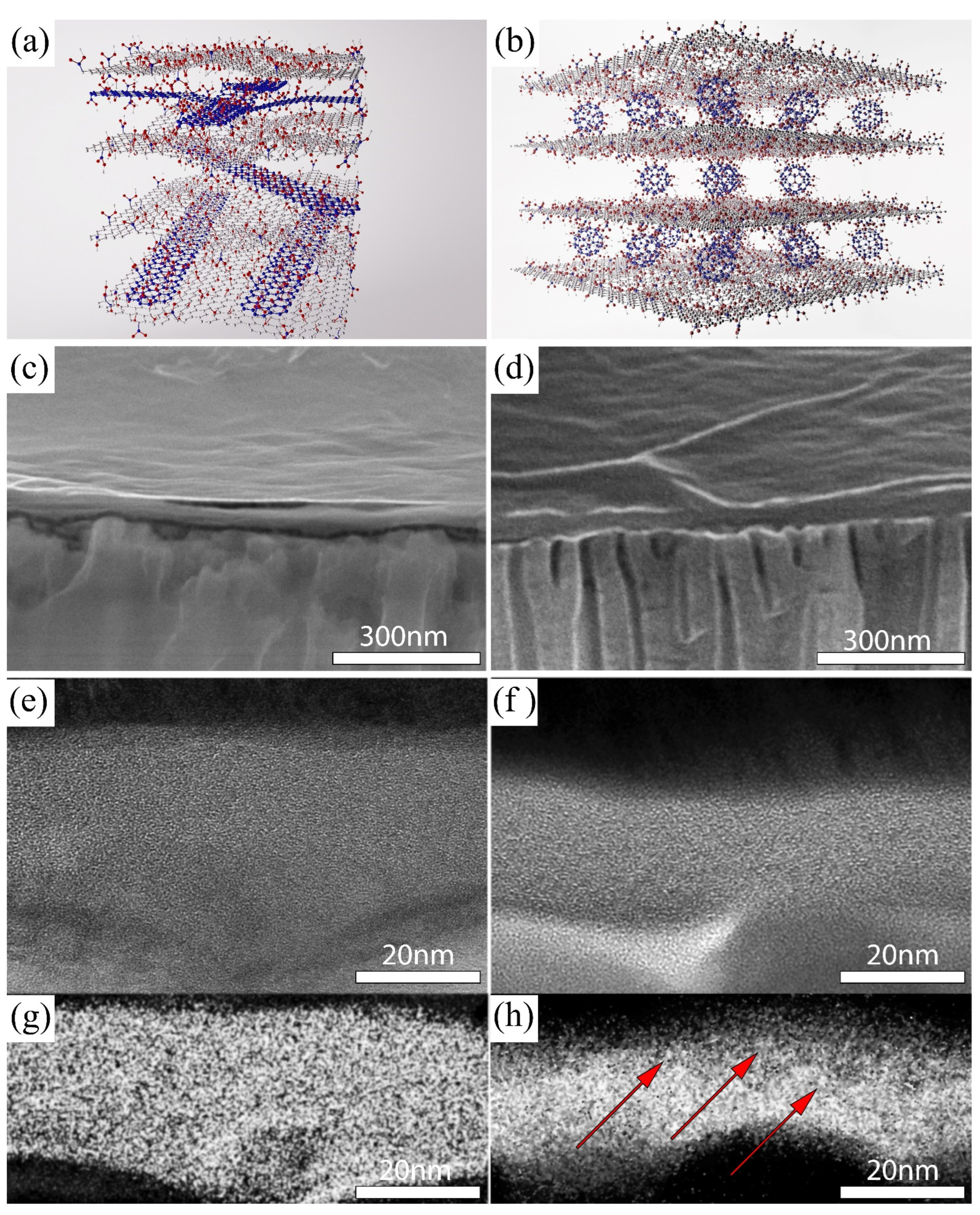

3.1. Microstructure of the Membranes

3.2. Nanoflakes Arrangement and Mass-Transport Properties of the Membranes

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Petukhov, D.I.; Kapitanova, O.O.; Eremina, E.A.; Goodilin, E.A. Preparation, Chemical Features, Structure and Applications of Membrane Materials Based on Graphene Oxide. Mendeleev Commun. 2021, 1, 137–148. [Google Scholar] [CrossRef]

- Song, N.; Gao, X.; Ma, Z.; Wang, X.; Wei, Y.; Gao, C. A Review of Graphene-Based Separation Membrane: Materials, Characteristics, Preparation and Applications. Desalination 2018, 437, 59–72. [Google Scholar] [CrossRef]

- Alen, S.K.; Nam, S.; Dastgheib, S.A. Recent Advances in Graphene Oxide Membranes for Gas Separation Applications. Int. J. Mol. Sci. 2019, 20, 5609. [Google Scholar] [CrossRef]

- Lyu, J.; Wen, X.; Kumar, U.; You, Y.; Chen, V.; Joshi, R.K. Separation and Purification Using GO and R-GO Membranes. RSC Adv. 2018, 8, 23130–23151. [Google Scholar] [CrossRef]

- Hung, W.-S.; Tsou, C.-H.; De Guzman, M.; An, Q.-F.; Liu, Y.-L.; Zhang, Y.-M.; Hu, C.-C.; Lee, K.-R.; Lai, J.-Y. Cross-Linking with Diamine Monomers To Prepare Composite Graphene Oxide-Framework Membranes with Varying d-Spacing. Chem. Mater. 2014, 26, 2983–2990. [Google Scholar] [CrossRef]

- You, Y.; Sahajwalla, V.; Yoshimura, M.; Joshi, R.K. Graphene and Graphene Oxide for Desalination. Nanoscale 2016, 8, 117–119. [Google Scholar] [CrossRef]

- Petukhov, D.I.; Chernova, E.A.; Kapitanova, O.O.; Boytsova, O.V.; Valeev, R.G.; Chumakov, A.P.; Konovalov, O.V.; Eliseev, A.A. Thin Graphene Oxide Membranes for Gas Dehumidification. J. Memb. Sci. 2019, 577, 184–194. [Google Scholar] [CrossRef]

- Vorobiev, A.; Dennison, A.; Chernyshov, D.; Skrypnychuk, V.; Barbero, D.; Talyzin, A.V. Graphene Oxide Hydration and Solvation: An in Situ Neutron Reflectivity Study. Nanoscale 2014, 6, 12151–12156. [Google Scholar] [CrossRef] [PubMed]

- Klechikov, A.; You, S.; Lackner, L.; Sun, J.; Iakunkov, A.; Rebrikova, A.; Korobov, M.; Baburin, I.; Seifert, G.; Talyzin, A.V. Graphite Oxide Swelling in Molten Sugar Alcohols and Their Aqueous Solutions. Carbon 2018, 140, 157–163. [Google Scholar] [CrossRef]

- Su, P.; Wang, F.; Li, Z.; Tang, C.Y.; Li, W. Graphene Oxide Membranes: Controlling Their Transport Pathways. J. Mater. Chem. A 2020, 8, 15319–15340. [Google Scholar] [CrossRef]

- Chong, J.Y.; Wang, B.; Mattevi, C.; Li, K. Dynamic Microstructure of Graphene Oxide Membranes and the Permeation Flux. J. Memb. Sci. 2018, 549, 385–392. [Google Scholar] [CrossRef]

- Amadei, C.A.; Arribas, P.; Cruzado, L.; Vecitis, C.D. Graphene Oxide Membranes on a Hierarchical Elemental Carbon-Based Support. Environ. Sci. Nano 2020, 7, 891–902. [Google Scholar] [CrossRef]

- Eliseev, A.A.; Poyarkov, A.A.; Chernova, E.A.; Eliseev, A.A.; Chumakov, A.P.; Konovalov, O.; Petukhov, D.I. Operando Study of Water Vapor Transport through Ultra-Thin Graphene Oxide Membranes. 2D Mater. 2019, 6, 035039. [Google Scholar] [CrossRef]

- Abou-Elanwar, A.M.; Shirke, Y.M.; Yoo, C.H.; Kwon, S.J.; Choi, W.-K.; Lee, J.S.; Hong, S.U.; Lee, H.K.; Jeon, J.-D. Water Vapor Dehumidification Using Thin-Film Nanocomposite Membranes by the in Situ Formation of Ultrasmall Size Iron-Chelated Nanoparticles. Appl. Surf. Sci. 2021, 542, 148562. [Google Scholar] [CrossRef]

- Liu, Y.; Phillips, B.; Li, W.; Zhang, Z.; Fang, L.; Qiu, J.; Wang, S. Fullerene-Tailored Graphene Oxide Interlayer Spacing for Energy-Efficient Water Desalination. ACS Appl. Nano Mater. 2018, 1, 6168–6175. [Google Scholar] [CrossRef]

- Suzuki, S.; Tsuru, T. Analysis and Prediction of Water Vapor Permeation through Perfluorosulfonic Acid Membranes via the Solution-Diffusion Model in a Single-Membrane Dehumidifier Module. Sep. Purif. Technol. 2021, 279, 119694. [Google Scholar] [CrossRef]

- Han, Y.; Jiang, Y.; Gao, C. High-Flux Graphene Oxide Nanofiltration Membrane Intercalated by Carbon Nanotubes. ACS Appl. Mater. Interfaces 2015, 7, 8147–8155. [Google Scholar] [CrossRef]

- Huang, H.; Song, Z.; Wei, N.; Shi, L.; Mao, Y.; Ying, Y.; Sun, L.; Xu, Z.; Peng, X. Ultrafast Viscous Water Flow through Nanostrand-Channelled Graphene Oxide Membranes. Nat. Commun. 2013, 4, 2979. [Google Scholar] [CrossRef] [PubMed]

- Li, W.; Zhang, Y.; Su, P.; Xu, Z.; Zhang, G.; Shen, C.; Meng, Q. Metal–Organic Framework Channelled Graphene Composite Membranes for H2/CO2 Separation. J. Mater. Chem. A 2016, 4, 18747–18752. [Google Scholar] [CrossRef]

- Zhang, W.-H.; Yin, M.-J.; Zhao, Q.; Jin, C.-G.; Wang, N.; Ji, S.; Ritt, C.L.; Elimelech, M.; An, Q.-F. Graphene Oxide Membranes with Stable Porous Structure for Ultrafast Water Transport. Nat. Nanotechnol. 2021, 16, 337–343. [Google Scholar] [CrossRef]

- Liu, L.; Zhou, Y.; Xue, J.; Wang, H. Enhanced Antipressure Ability through Graphene Oxide Membrane by Intercalating G-C3N4 Nanosheets for Water Purification. AIChE J. 2019, 65, e16699. [Google Scholar] [CrossRef]

- Tang, X.; Qu, Y.; Deng, S.-L.; Tan, Y.-Z.; Zhang, Q.; Liu, Q. Fullerene-Regulated Graphene Oxide Nanosheet Membranes with Well-Defined Laminar Nanochannels for Precise Molecule Sieving. J. Mater. Chem. A 2018, 6, 22590–22598. [Google Scholar] [CrossRef]

- Chen, X.; Ching, K.; Rawal, A.; Lawes, D.J.; Tajik, M.; Donald, W.A.; Zhao, C.; Lee, S.H.; Ruoff, R.S. Stage-1 Cationic C60 Intercalated Graphene Oxide Films. Carbon 2021, 175, 131–140. [Google Scholar] [CrossRef]

- Marcano, D.C.; Kosynkin, D.V.; Berlin, J.M.; Sinitskii, A.; Sun, Z.; Slesarev, A.; Alemany, L.B.; Lu, W.; Tour, J.M. Improved Synthesis of Graphene Oxide. ACS Nano 2010, 4, 4806–4814. [Google Scholar] [CrossRef]

- Chernova, E.A.; Petukhov, D.I.; Chumakov, A.P.; Kirianova, A.V.; Sadilov, I.S.; Kapitanova, O.O.; Boytsova, O.V.; Valeev, R.G.; Roth, S.V.; Eliseev, A.; et al. The Role of Oxidation Level in Mass-Transport Properties and Dehumidification Performance of Graphene Oxide Membranes. Carbon 2021, 183, 404–414. [Google Scholar] [CrossRef]

- Kosynkin, D.V.; Higginbotham, A.L.; Sinitskii, A.; Lomeda, J.R.; Dimiev, A.; Price, K.; Tour, J.M. Longitudinal Unzipping of Carbon Nanotubes to Form Graphene Nanoribbons. Nature 2009, 458, 872–876. [Google Scholar] [CrossRef] [PubMed]

- Wang, N.; Sun, L.; Zhang, X.; Bao, X.; Zheng, W.; Yang, R. Easily-Accessible Fullerenol as a Cathode Buffer Layer for Inverted Organic Photovoltaic Devices. RSC Adv. 2014, 4, 25886–25891. [Google Scholar] [CrossRef]

- Chaudhuri, P.; Paraskar, A.; Soni, S.; Mashelkar, R.A.; Sengupta, S. Fullerenol−Cytotoxic Conjugates for Cancer Chemotherapy. ACS Nano 2009, 3, 2505–2514. [Google Scholar] [CrossRef]

- Petukhov, D.I.; Napolskii, K.S.; Eliseev, A.A. Permeability of Anodic Alumina Membranes with Branched Channels. Nanotechnology 2012, 23, 335601. [Google Scholar] [CrossRef] [PubMed]

- Petukhov, D.I.; Buldakov, D.A.; Tishkin, A.A.; Lukashin, A.V.; Eliseev, A.A. Liquid Permeation and Chemical Stability of Anodic Alumina Membranes. Beilstein J. Nanotechnol. 2017, 8, 561–570. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Petukhov, D.I.; Eliseev, A.A. Gas Permeation through Nanoporous Membranes in the Transitional Flow Region. Nanotechnology 2016, 27, 085707. [Google Scholar] [CrossRef] [PubMed]

- Benecke, G.; Wagermaier, W.; Li, C.; Schwartzkopf, M.; Flucke, G.; Hoerth, R.; Zizak, I.; Burghammer, M.; Metwalli, E.; Müller-Buschbaum, P.; et al. A Customizable Software for Fast Reduction and Analysis of Large X-ray Scattering Data Sets: Applications of the New DPDAK Package to Small-Angle X-ray Scattering and Grazing-Incidence Small-Angle X-ray Scattering. J. Appl. Crystallogr. 2014, 47, 1797–1803. [Google Scholar] [CrossRef] [PubMed]

- Chernova, E.; Petukhov, D.; Boytsova, O.; Alentiev, A.; Budd, P.; Yampolskii, Y.; Eliseev, A. Enhanced Gas Separation Factors of Microporous Polymer Constrained in the Channels of Anodic Alumina Membranes. Sci. Rep. 2016, 6, 31183. [Google Scholar] [CrossRef] [PubMed]

- Erbahar, D.; Susi, T.; Rocquefelte, X.; Bittencourt, C.; Scardamaglia, M.; Blaha, P.; Guttmann, P.; Rotas, G.; Tagmatarchis, N.; Zhu, X.; et al. Spectromicroscopy of C60 and Azafullerene C59N: Identifying Surface Adsorbed Water. Sci. Rep. 2016, 6, 35605. [Google Scholar] [CrossRef] [PubMed]

- Valeev, R.; Petukhov, D.; Eliseev, A. XPS Analysis of True Oxidation Levels in Low-Dimensional Carbons. Appl. Surf. Sci. submitted.

- Klechikov, A.; Yu, J.; Thomas, D.; Sharifi, T.; Talyzin, A.V. Structure of Graphene Oxide Membranes in Solvents and Solutions. Nanoscale 2015, 7, 15374–15384. [Google Scholar] [CrossRef]

- Petukhov, D.I.; Sadilov, I.S.; Vasiliev, R.B.; Kozina, L.D.; Eliseev, A.A. Labyrinthine Transport of Hydrocarbons through the Grafted Laminar CdTe Nanosheet Membranes. J. Mater. Chem. A 2019, 7, 21684–21692. [Google Scholar] [CrossRef]

- Chong, J.Y.; Wang, B.; Li, K. Water Transport through Graphene Oxide Membranes: The Roles of Driving Forces. Chem. Commun. 2018, 54, 2554–2557. [Google Scholar] [CrossRef]

- Chernova, E.; Petukhov, D.; Kapitanova, O.; Boytsova, O.; Lukashin, A.; Eliseev, A. Nanoscale Architecture of Graphene Oxide Membranes for Improving Dehumidification Performance. Nanosyst. Phys. Chem. Math. 2018, 9, 614–621. [Google Scholar] [CrossRef]

- Naumkin, A.V.; Kraut-Vass, A.; Gaarenstroom, S.W.; Powell, C.J. NIST X-ray Photoelectron Spectroscopy Database, NIST Standard Reference Database Number 20; National Institute of Standards and Technology: Gaithersburg, MD, USA, 2000. [CrossRef]

| Sample | D + G-Mode | Layer Thickness, nm | Estimated Porosity, % | ||

|---|---|---|---|---|---|

| I, cps∙105 | RSD, % | SEM | TEM | ||

| MFGO | 4.33 | 9.5 | 45 ± 5 | - | 10 |

| CNTGO@MFGO | 1.71 | 8.7 | 37 ± 5 | 31 ± 3 | 50 ± 10 |

| C60(OH)26–32@MFGO | 3.17 | 22.4 | 30 ± 4 | 20 ± 3 | 5 ± 5 |

| Sample | Permeance of Water Vapor, L∙m−2·bar−1·h−1 | α(H2O/N2) at RH 90% | Reversible Permeance Loss at 1 Bar, % | Irreversible Permeance Loss after Pressure Increase-Decrease Cycle, % | |

|---|---|---|---|---|---|

| In a Dynamic Mode (Wet N2, RH~100%) | At 90% RH of Feed Stream | ||||

| MFGO | 2400 | 63,000 | 47,400 | 58 | 36 * |

| CNTGO@MFGO | 1900 | 51,500 | 5300 | 51 | 10 |

| C60(OH)26–32@MFGO | 1720 | 58,200 | 30,000 | 24 | 4.5 |

| C60(OH)26–32@MFGO-33% | - | 46,500 | 6642 | 10 | 2 |

| MFGO | CNT@MFGO | C60(OH)26–32@MFGO | |

|---|---|---|---|

| Thickness, nm | 45 | 37 | 30 |

| D, m2∙s−1 | 1.87 × 10−9 | 4.2 × 10−10 | 8.84 × 10−10 |

| S, mol∙m−3∙Pa−1 | 4.20 | 6.74 | 2.62 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chernova, E.A.; Gurianov, K.E.; Petukhov, D.I.; Chumakov, A.P.; Valeev, R.G.; Brotsman, V.A.; Garshev, A.V.; Eliseev, A.A. Oxidized Carbon-Based Spacers for Pressure-Resistant Graphene Oxide Membranes. Membranes 2022, 12, 934. https://doi.org/10.3390/membranes12100934

Chernova EA, Gurianov KE, Petukhov DI, Chumakov AP, Valeev RG, Brotsman VA, Garshev AV, Eliseev AA. Oxidized Carbon-Based Spacers for Pressure-Resistant Graphene Oxide Membranes. Membranes. 2022; 12(10):934. https://doi.org/10.3390/membranes12100934

Chicago/Turabian StyleChernova, Ekaterina A., Konstantin E. Gurianov, Dmitrii I. Petukhov, Andrei P. Chumakov, Rishat G. Valeev, Victor A. Brotsman, Alexey V. Garshev, and Andrei A. Eliseev. 2022. "Oxidized Carbon-Based Spacers for Pressure-Resistant Graphene Oxide Membranes" Membranes 12, no. 10: 934. https://doi.org/10.3390/membranes12100934

APA StyleChernova, E. A., Gurianov, K. E., Petukhov, D. I., Chumakov, A. P., Valeev, R. G., Brotsman, V. A., Garshev, A. V., & Eliseev, A. A. (2022). Oxidized Carbon-Based Spacers for Pressure-Resistant Graphene Oxide Membranes. Membranes, 12(10), 934. https://doi.org/10.3390/membranes12100934