Controlling the Thermal Conductivity of Monolayer Graphene with Kirigami Structure

Abstract

:1. Introduction

2. Methods

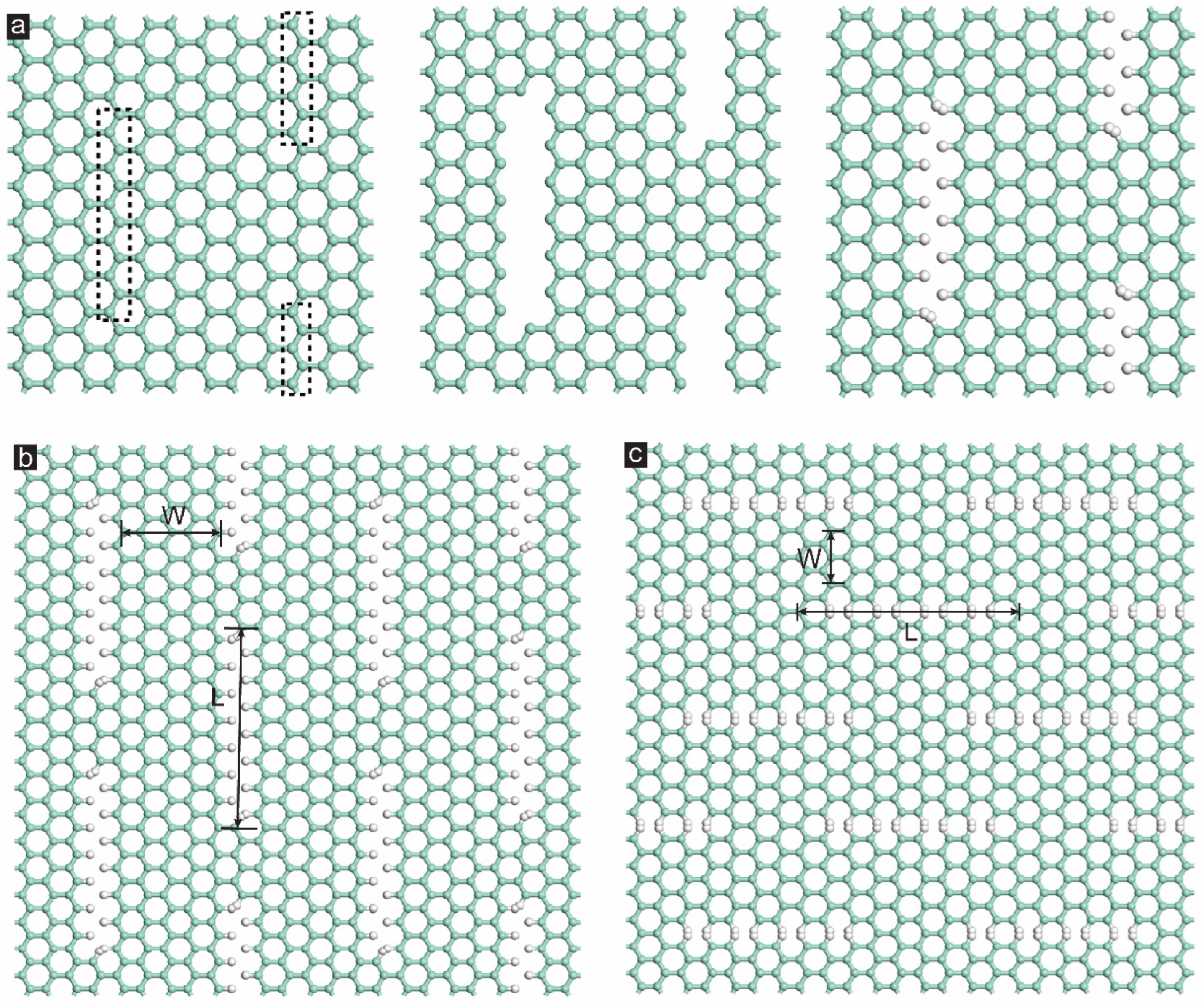

2.1. Model Establishment

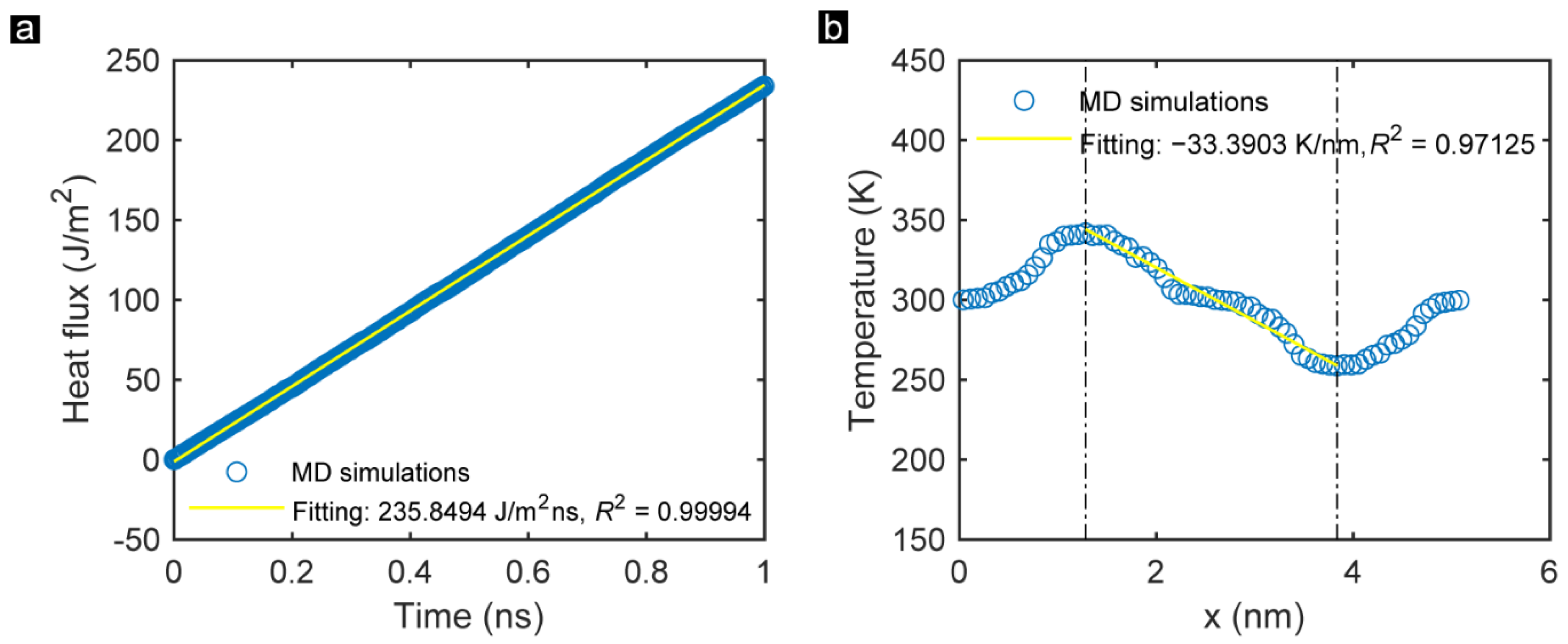

2.2. Simulation Details

3. Results and Discussion

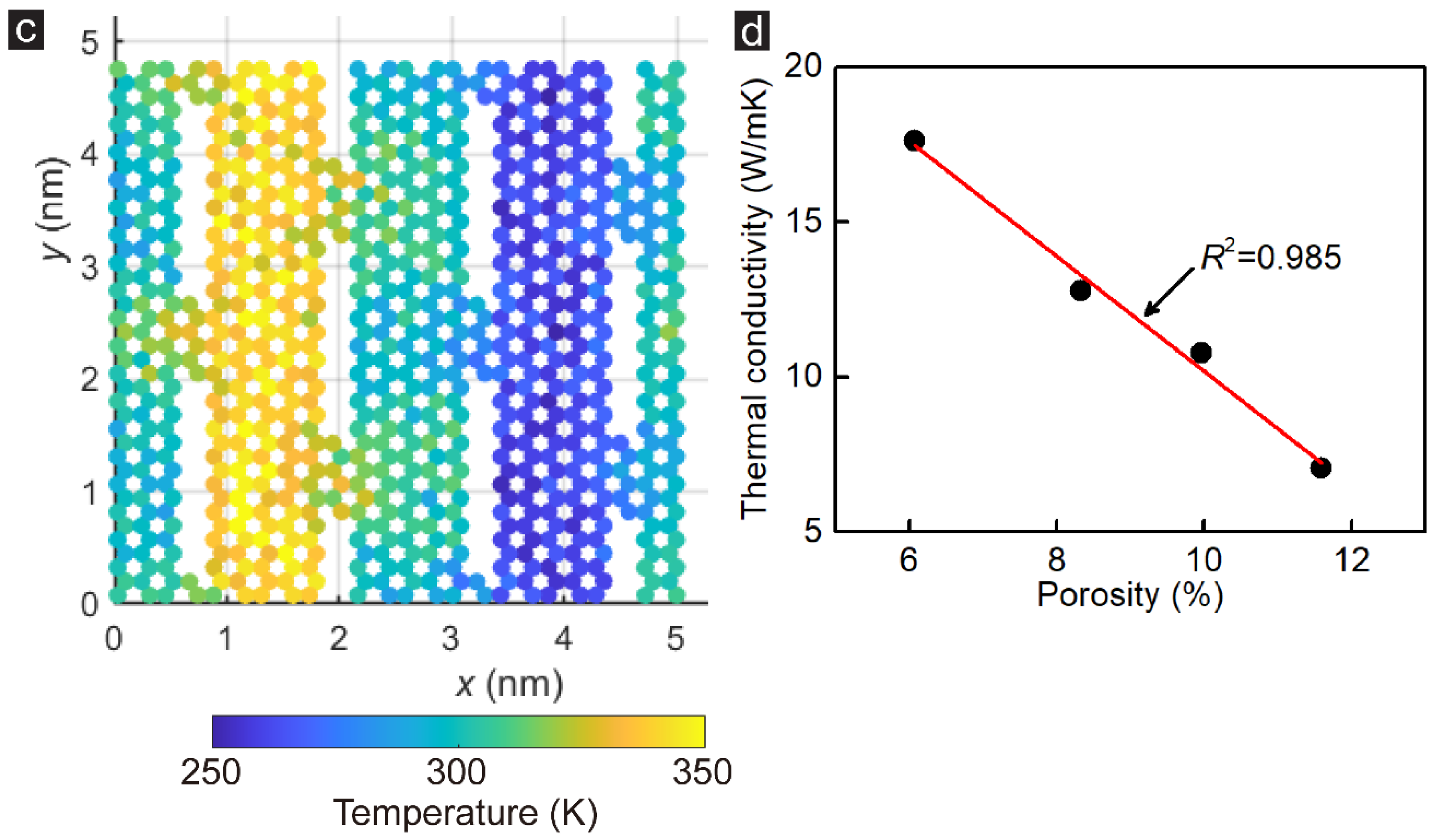

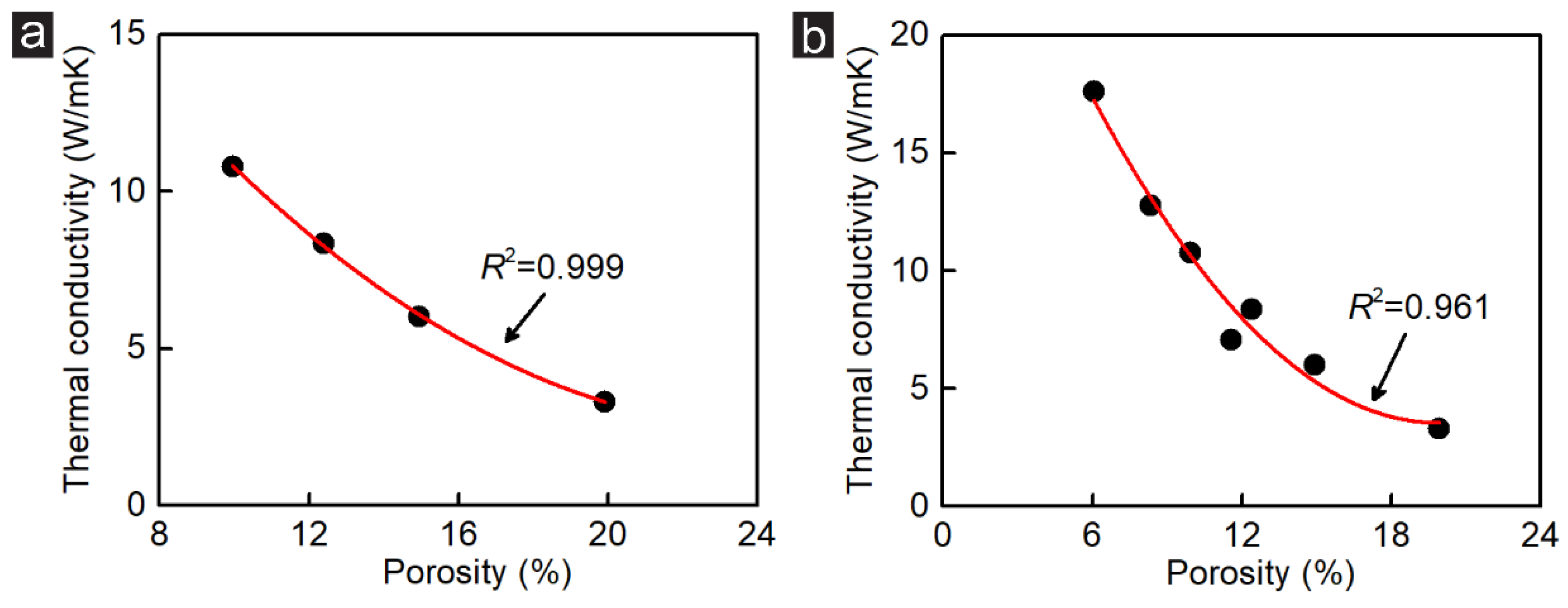

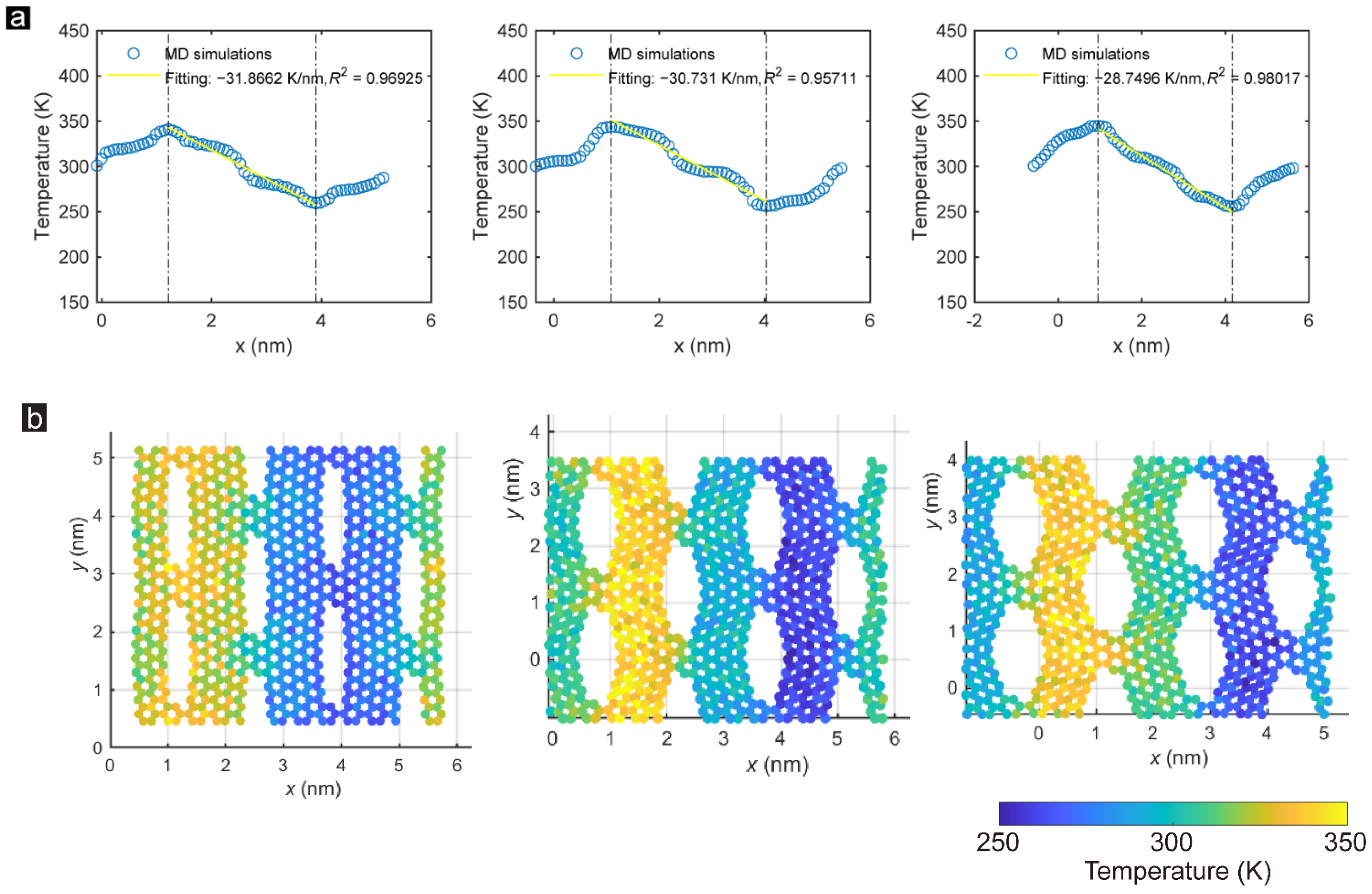

3.1. DD Effects

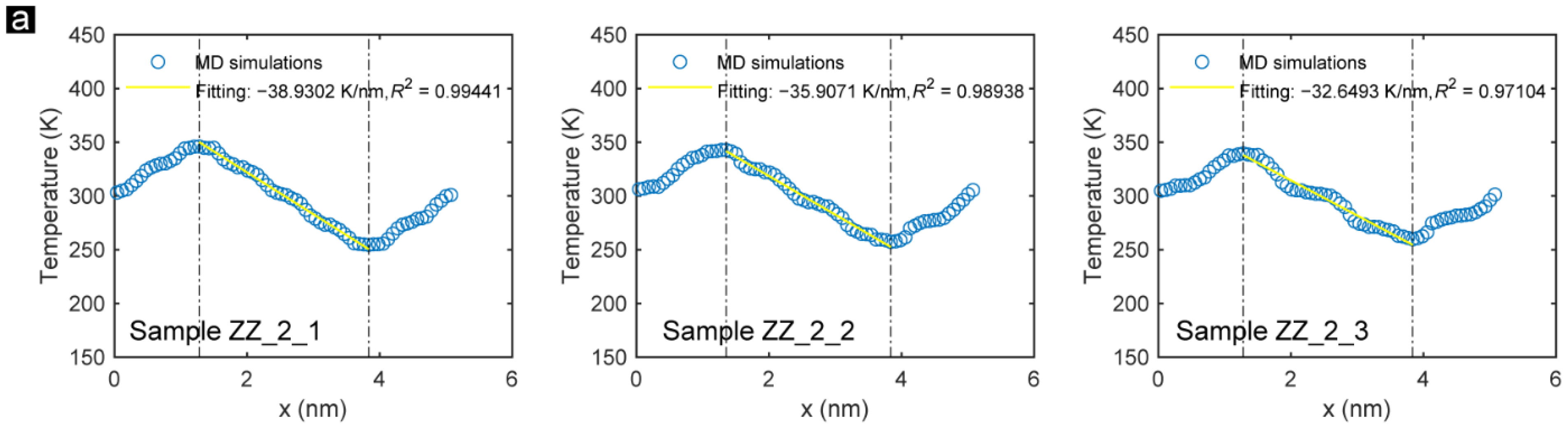

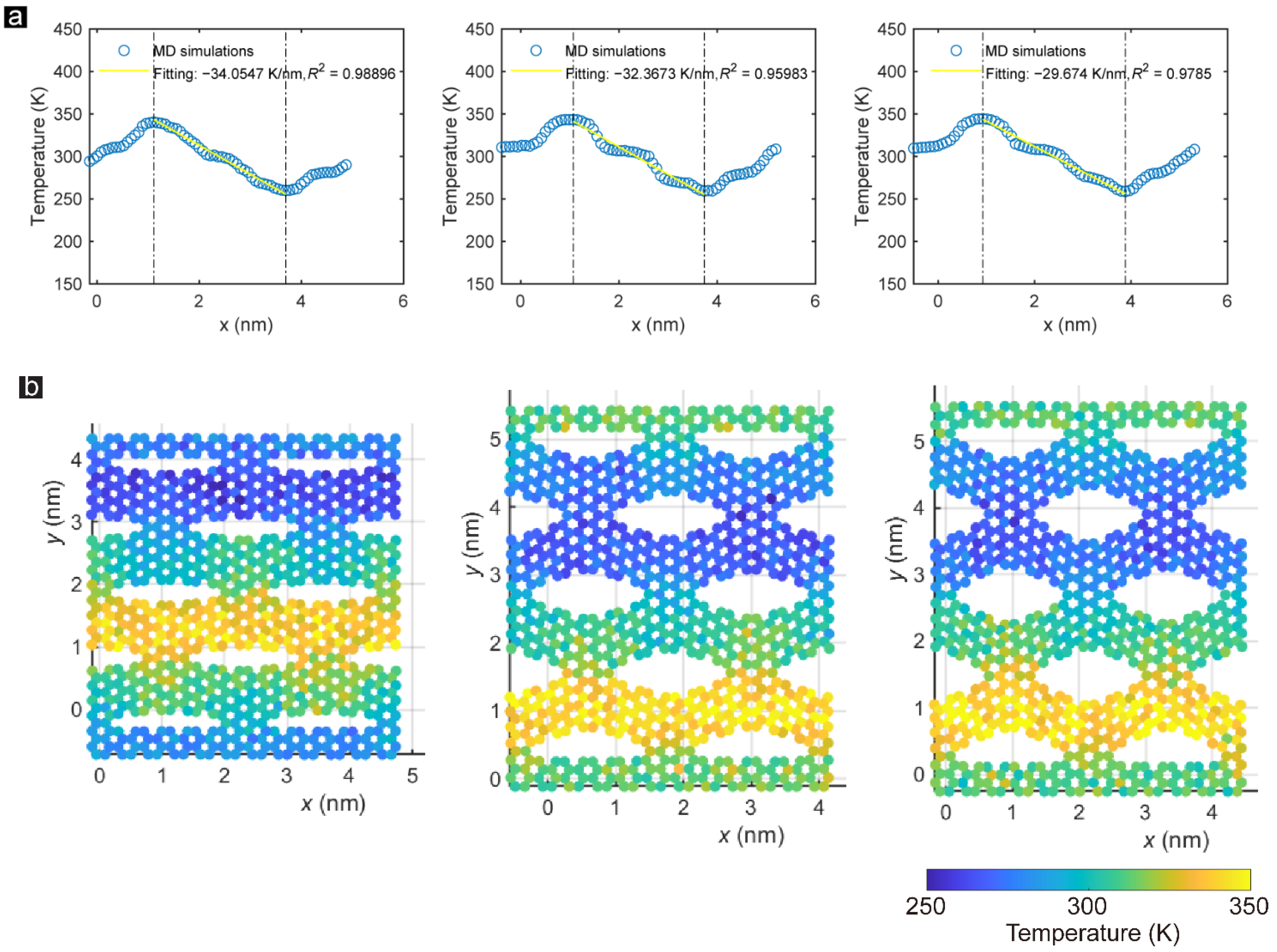

3.2. Heat Transfer Direction Effects

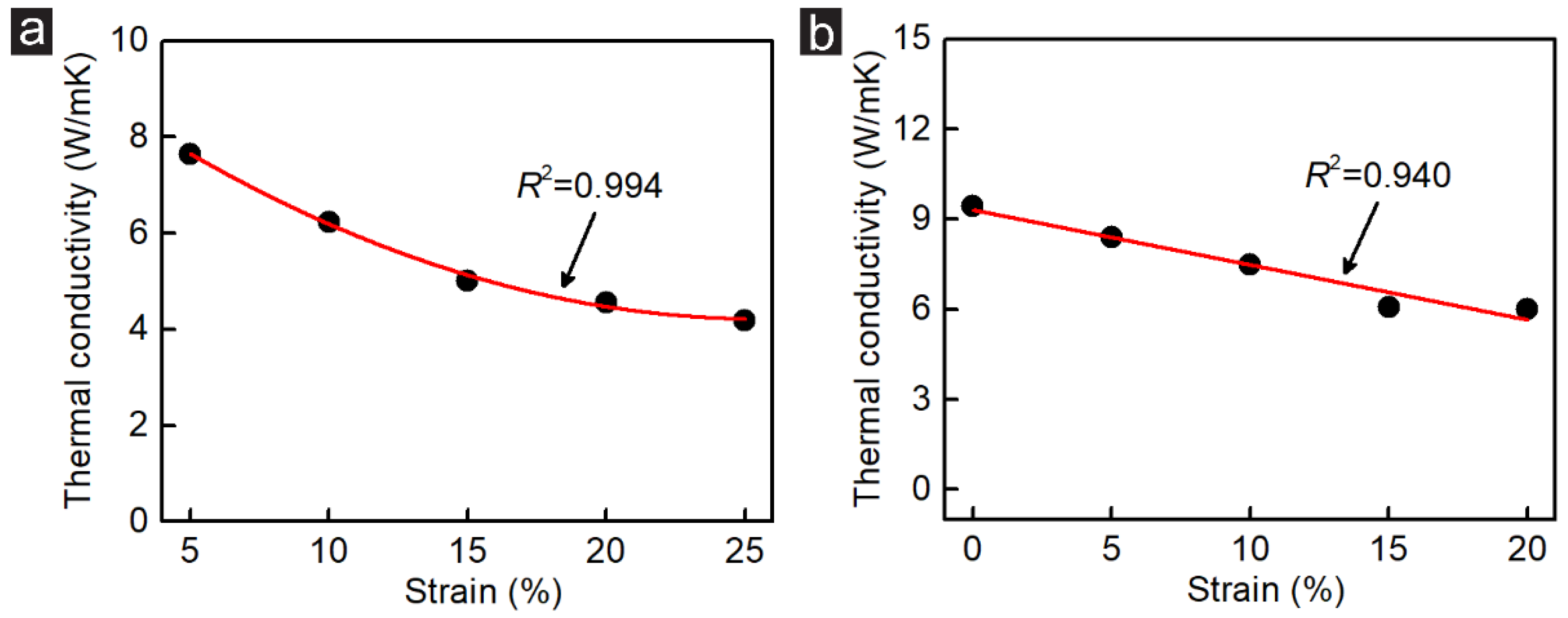

3.3. Tensile Strain Effects

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Yang, G.; Zhu, C.; Du, D.; Zhu, J.; Lin, Y. Graphene-like two-dimensional layered nanomaterials: Applications in biosensors and nanomedicine. Nanoscale 2015, 7, 14217–14231. [Google Scholar] [CrossRef] [PubMed]

- Ma, J.; Ping, D.; Dong, X. Recent developments of graphene oxide-based membranes: A review. Membranes 2017, 7, 52. [Google Scholar] [CrossRef] [PubMed]

- Muzzi, C.; Gotzias, A.; Fontananova, E.; Tocci, E. Stability of Graphene Oxide Composite Membranes in an Aqueous Environment from a Molecular Point of View. Appl. Sci. 2022, 12, 3460. [Google Scholar] [CrossRef]

- Chen, Y.; Li, J.; Li, T.; Zhang, L.; Meng, F. Recent advances in graphene-based films for electromagnetic interference shielding: Review and future prospects. Carbon 2021, 180, 163–184. [Google Scholar] [CrossRef]

- Wang, J.; Mu, X.; Sun, M.; Mu, T. Optoelectronic properties and applications of graphene-based hybrid nanomaterials and van der Waals heterostructures. Appl. Mater. Today 2019, 16, 1–20. [Google Scholar] [CrossRef]

- Song, H.; Zhang, X.; Liu, Y.; Su, Z. Developing Graphene-Based Nanohybrids for Electrochemical Sensing. Chem. Rec. 2019, 19, 534–549. [Google Scholar] [CrossRef] [PubMed]

- Zhang, Q.; Zhou, J.; Chen, Z.; Xu, C.; Tang, W.; Yang, G.; Lai, C.; Xu, Q.; Yang, J.; Peng, C. Direct ink writing of moldable electrochemical energy storage devices: Ongoing progress, challenges, and prospects. Adv. Eng. Mater. 2021, 23, 2100068. [Google Scholar] [CrossRef]

- Cao, B.-Y.; Yao, W.-J.; Ye, Z.-Q. Networked nanoconstrictions: An effective route to tuning the thermal transport properties of graphene. Carbon 2016, 96, 711–719. [Google Scholar] [CrossRef]

- Kim, J.; Eum, J.-H.; Kang, J.; Kwon, O.; Kim, H.; Kim, D.W. Tuning the hierarchical pore structure of graphene oxide through dual thermal activation for high-performance supercapacitor. Sci. Rep. 2021, 11, 2063. [Google Scholar] [CrossRef]

- Wei, N.; Xu, L.; Wang, H.-Q.; Zheng, J.-C. Strain engineering of thermal conductivity in graphene sheets and nanoribbons: A demonstration of magic flexibility. Nanotechnology 2011, 22, 105705. [Google Scholar] [CrossRef]

- Fang, T.-H.; Lee, Z.-W.; Chang, W.-J.; Huang, C.-C. Determining porosity effect on the thermal conductivity of single-layer graphene using a molecular dynamics simulation. Phys. E Low Dimens. Syst. Nanostructures 2019, 106, 90–94. [Google Scholar] [CrossRef]

- Yousefi, F.; Khoeini, F.; Rajabpour, A. Thermal conductivity and thermal rectification of nanoporous graphene: A molecular dynamics simulation. Int. J. Heat Mass Transf. 2020, 146, 118884. [Google Scholar] [CrossRef]

- Varghese, S.S.; Lonkar, S.; Singh, K.; Swaminathan, S.; Abdala, A. Recent advances in graphene based gas sensors. Sens. Actuators B Chem. 2015, 218, 160–183. [Google Scholar] [CrossRef]

- Kagan, C.R.; Fernandez, L.E.; Gogotsi, Y.; Hammond, P.T.; Hersam, M.C.; Nel, A.E.; Penner, R.M.; Willson, C.G.; Weiss, P.S. Nano day: Celebrating the next decade of nanoscience and nanotechnology. ACS Nano 2016, 10, 9093–9103. [Google Scholar] [CrossRef] [PubMed]

- Nam, Y.-T.; Kang, J.-H.; Jang, J.-D.; Bae, J.-H.; Jung, H.-T.; Kim, D.-W. Recent developments in nanoporous graphene membranes for organic solvent nanofiltration: A short review. Membranes 2021, 11, 793. [Google Scholar] [CrossRef]

- Zhang, Y.; Cheng, Y.; Pei, Q.; Wang, C.; Xiang, Y. Thermal conductivity of defective graphene. Phys. Lett. A 2012, 376, 3668–3672. [Google Scholar] [CrossRef]

- Mortazavi, B.; Ahzi, S. Thermal conductivity and tensile response of defective graphene: A molecular dynamics study. Carbon 2013, 63, 460–470. [Google Scholar] [CrossRef]

- Malekpour, H.; Ramnani, P.; Srinivasan, S.; Balasubramanian, G.; Nika, D.L.; Mulchandani, A.; Lake, R.K.; Balandin, A.A. Thermal conductivity of graphene with defects induced by electron beam irradiation. Nanoscale 2016, 8, 14608–14616. [Google Scholar] [CrossRef] [Green Version]

- Yu, H.-D.; Regulacio, M.D.; Ye, E.; Han, M.-Y. Chemical routes to top-down nanofabrication. Chem. Soc. Rev. 2013, 42, 6006–6018. [Google Scholar] [CrossRef]

- Dervin, S.; Dionysiou, D.D.; Pillai, S.C. 2D nanostructures for water purification: Graphene and beyond. Nanoscale 2016, 8, 15115–15131. [Google Scholar] [CrossRef]

- Song, J.; Zhang, Y. From two-dimensional to three-dimensional structures: A superior thermal-driven actuator with switchable deformation behavior. Chem. Eng. J. 2019, 360, 680–685. [Google Scholar] [CrossRef]

- Lei, X.; Nakatani, A.; Doi, Y.; Matsunaga, S. Bifurcation analysis of periodic kirigami structure with out-plane deformation. J. Soc. Mater. Sci. Jpn. 2018, 67, 202–207. [Google Scholar] [CrossRef] [Green Version]

- Ning, X.; Wang, X.; Zhang, Y.; Yu, X.; Choi, D.; Zheng, N.; Kim, D.S.; Huang, Y.; Zhang, Y.; Rogers, J.A. Assembly of advanced materials into 3D functional structures by methods inspired by origami and kirigami: A review. Adv. Mater. Interfaces 2018, 5, 1800284. [Google Scholar] [CrossRef] [Green Version]

- Brooks, A.K.; Chakravarty, S.; Ali, M.; Yadavalli, V.K. Kirigami-Inspired Biodesign for Applications in Healthcare. Adv. Mater. 2022, 34, 2109550. [Google Scholar] [CrossRef]

- Blees, M.K.; Barnard, A.W.; Rose, P.A.; Roberts, S.P.; McGill, K.L.; Huang, P.Y.; Ruyack, A.R.; Kevek, J.W.; Kobrin, B.; Muller, D.A. Graphene kirigami. Nature 2015, 524, 204–207. [Google Scholar] [CrossRef]

- Qi, Z.; Campbell, D.K.; Park, H.S. Atomistic simulations of tension-induced large deformation and stretchability in graphene kirigami. Phys. Rev. B 2014, 90, 245437. [Google Scholar] [CrossRef] [Green Version]

- Gao, Y.; Chen, S.; Chen, W.; Wang, W.; Duan, W. Graphene kirigami membrane with superior theoretical permeability and adjustable selection capability. Carbon 2021, 181, 398–407. [Google Scholar] [CrossRef]

- Wu, X.; Zhao, H.; Pei, J. Fabrication of nanopore in graphene by electron and ion beam irradiation: Influence of graphene thickness and substrate. Comput. Mater. Sci. 2015, 102, 258–266. [Google Scholar] [CrossRef]

- Chen, D.; Shao, L. Using irradiation-induced defects as pinning sites to minimize self-alignment in twisted bilayer graphene. Appl. Phys. Lett. 2021, 118, 151602. [Google Scholar] [CrossRef]

- Gao, Y.; Chen, W.; Liu, Y.; Wu, J.; Jing, H. Graphene kirigami as an ultra-permeable water desalination membrane. Carbon 2022, 195, 183–190. [Google Scholar] [CrossRef]

- Gao, Y.; Lu, S.; Chen, W.; Zhang, Z.; Gong, C. Study on the Shear Behaviour and Fracture Characteristic of Graphene Kirigami Membranes via Molecular Dynamics Simulation. Membranes 2022, 12, 886. [Google Scholar] [CrossRef] [PubMed]

- Gotzias, A.; Charalambopoulou, G.; Steriotis, T. On the orientation of N2 and CO2 molecules adsorbed in slit pore models with oxidised graphitic surface. Mol. Simul. 2016, 42, 186–195. [Google Scholar] [CrossRef]

- Chen, W.Q.; Sedighi, M.; Jivkov, A.P. Thermo-osmosis in hydrophilic nanochannels: Mechanism and size effect. Nanoscale 2021, 13, 1696–1716. [Google Scholar] [CrossRef] [PubMed]

- Hu, J.; Ruan, X.; Chen, Y.P. Thermal conductivity and thermal rectification in graphene nanoribbons: A molecular dynamics study. Nano Lett. 2009, 9, 2730–2735. [Google Scholar] [CrossRef] [Green Version]

- Dehaghani, M.Z.; Farzadian, O.; Kostas, K.V.; Molaei, F.; Spitas, C.; Mashhadzadeh, A.H. Theoretical study of heat transfer across biphenylene/h-BN superlattice nanoribbons. Phys. E Low Dimens. Syst. Nanostruct. 2022, 144, 115411. [Google Scholar] [CrossRef]

- Farzadian, O.; Dehaghani, M.Z.; Kostas, K.V.; Mashhadzadeh, A.H.; Spitas, C. A theoretical insight into phonon heat transport in graphene/biphenylene superlattice nanoribbons: A molecular dynamic study. Nanotechnology 2022, 33, 355705. [Google Scholar] [CrossRef]

- Schneider, T.; Stoll, E. Molecular-dynamics study of a three-dimensional one-component model for distortive phase transitions. Phys. Rev. B 1978, 17, 1302. [Google Scholar] [CrossRef]

- Brenner, D.W.; Shenderova, O.A.; Harrison, J.A.; Stuart, S.J.; Ni, B.; Sinnott, S.B. A second-generation reactive empirical bond order (REBO) potential energy expression for hydrocarbons. J. Phys. Condens. Matter 2002, 14, 783. [Google Scholar] [CrossRef] [Green Version]

- Lindsay, L.; Broido, D. Optimized Tersoff and Brenner empirical potential parameters for lattice dynamics and phonon thermal transport in carbon nanotubes and graphene. Phys. Rev. B 2010, 81, 205441. [Google Scholar] [CrossRef] [Green Version]

- Chen, S.; Wu, Q.; Mishra, C.; Kang, J.; Zhang, H.; Cho, K.; Cai, W.; Balandin, A.A.; Ruoff, R.S. Thermal conductivity of isotopically modified graphene. Nat. Mater. 2012, 11, 203–207. [Google Scholar] [CrossRef]

- Lin, C.-J.; Lin, I.; Tuan, W.-H. Effect of graphene concentration on thermal properties of alumina–graphene composites formed using spark plasma sintering. J. Mater. Sci. 2017, 52, 1759–1766. [Google Scholar] [CrossRef]

- Pereira, L.F.C.; Mortazavi, B.; Makaremi, M.; Rabczuk, T. Anisotropic thermal conductivity and mechanical properties of phagraphene: A molecular dynamics study. RSC Adv. 2016, 6, 57773–57779. [Google Scholar] [CrossRef] [Green Version]

- Kumar, A.; Sharma, K.; Dixit, A.R. A review of the mechanical and thermal properties of graphene and its hybrid polymer nanocomposites for structural applications. J. Mater. Sci. 2019, 54, 5992–6026. [Google Scholar] [CrossRef]

| Sample | L (Å) | W (Å) | DD (%) |

|---|---|---|---|

| ZZ_1_1 | 18.46 | 8.52 | 11.59 |

| ZZ_1_2 | 16.01 | 8.52 | 9.96 |

| ZZ_1_3 | 13.55 | 8.52 | 8.33 |

| ZZ_1_4 | 11.09 | 8.52 | 6.07 |

| ZZ_2_1 | 16.01 | 2.84 | 19.92 |

| ZZ_2_2 | 16.01 | 4.26 | 14.94 |

| ZZ_2_3 | 16.01 | 7.10 | 12.4 |

| AC_3_1 | 19.88 | 4.92 | 8.13 |

| AC_3_2 | 17.04 | 2.46 | 8.54 |

| AC_3_3 | 19.88 | 2.46 | 9.76 |

| AC_3_4 | 21.30 | 2.46 | 10.97 |

| Sample | Heat Flux (J/m2·ns) | Temperature Gradient (K/nm) | Thermal Conductivity (W/mK) |

|---|---|---|---|

| ZZ_1_1 | 235.8 (245.2) | 33.4 (34.0) | 7.1 (7.2) |

| ZZ_1_2 | 327.1 (322.6) | 30.3 (30.4) | 10.8 (10.6) |

| ZZ_1_3 | 357.0 (356.6) | 27.9 (27.8) | 12.8 (12.8) |

| ZZ_1_4 | 435.2 (439.1) | 24.7 (24.7) | 17.6 (17.8) |

| ZZ_2_1 | 128.7 (128.4) | 38.9 (39.3) | 3.3 (3.3) |

| ZZ_2_2 | 216.0 (222.4) | 35.9 (36.1) | 6.0 (6.2) |

| ZZ_2_3 | 272.7 (264.8) | 32.6 (31.9) | 8.4 (8.3) |

| AC_3_1 | 317.0 (314.5) | 33.6 (33.7) | 9.4 (9.3) |

| AC_3_2 | 287.4 (283.1) | 34.5 (34.7) | 8.3 (8.2) |

| AC_3_3 | 264.5 (265.9) | 35.9 (36.1) | 7.4 (7.4) |

| AC_3_4 | 184.6 (177.6) | 39.3 (38.2) | 4.7 (4.6) |

| ZZ_1_1_5% | 243.9 (235.8) | 31.9 (31.4) | 7.7 (7.5) |

| ZZ_1_1_10% | 193.3 (199.8) | 31.0 (32.9) | 6.2 (6.1) |

| ZZ_1_1_15% | 154.2 (153.0) | 30.7 (30.4) | 5.0 (5.0) |

| ZZ_1_1_20% | 142.0 (135.9) | 31.1 (29.0) | 4.6 (4.7) |

| ZZ_1_1_25% | 120.2 (117.2) | 28.7 (28.4) | 4.2 (4.1) |

| AC_3_1_5% | 285.7 (268.4) | 34.1 (30.9) | 8.4 (8.7) |

| AC_3_1_10% | 240.6 (223.4) | 32.4 (29.7) | 7.5 (7.5) |

| AC_3_1_15% | 196.3 (188.9) | 32.4 (32.0) | 6.1 (5.9) |

| AC_3_1_20% | 178.4 (184.9) | 29.7 (31.8) | 6.0 (5.8) |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Gao, Y.; Lu, S.; Chen, W.; Zhang, J.; Feng, C.; Liu, Y. Controlling the Thermal Conductivity of Monolayer Graphene with Kirigami Structure. Membranes 2022, 12, 1128. https://doi.org/10.3390/membranes12111128

Gao Y, Lu S, Chen W, Zhang J, Feng C, Liu Y. Controlling the Thermal Conductivity of Monolayer Graphene with Kirigami Structure. Membranes. 2022; 12(11):1128. https://doi.org/10.3390/membranes12111128

Chicago/Turabian StyleGao, Yuan, Shuaijie Lu, Weiqiang Chen, Jinyuan Zhang, Chundi Feng, and Yanming Liu. 2022. "Controlling the Thermal Conductivity of Monolayer Graphene with Kirigami Structure" Membranes 12, no. 11: 1128. https://doi.org/10.3390/membranes12111128

APA StyleGao, Y., Lu, S., Chen, W., Zhang, J., Feng, C., & Liu, Y. (2022). Controlling the Thermal Conductivity of Monolayer Graphene with Kirigami Structure. Membranes, 12(11), 1128. https://doi.org/10.3390/membranes12111128