Cellulose Nanofiber-Assisted Dispersion of Halloysite Nanotubes via Silane Coupling Agent-Reinforced Starch–PVA Biodegradable Composite Membrane

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Preparation of KH560 and KH570 Modified CNF/HNTs

2.3. Preparation of Starch–PVA Composite Membranes

2.4. Characterization

2.4.1. Scanning Electron Microscopy (SEM)

2.4.2. Fourier Transform Infrared Spectroscopy (FTIR)

2.4.3. X-ray Diffraction Test (XRD)

2.4.4. Thermogravimetric Analyzer Test (TGA) and Differential Scanning Calorimetry (DSC)

2.4.5. Water Resistance Properties

2.4.6. Mechanical Properties

2.4.7. Statistical Analysis

3. Results and Discussion

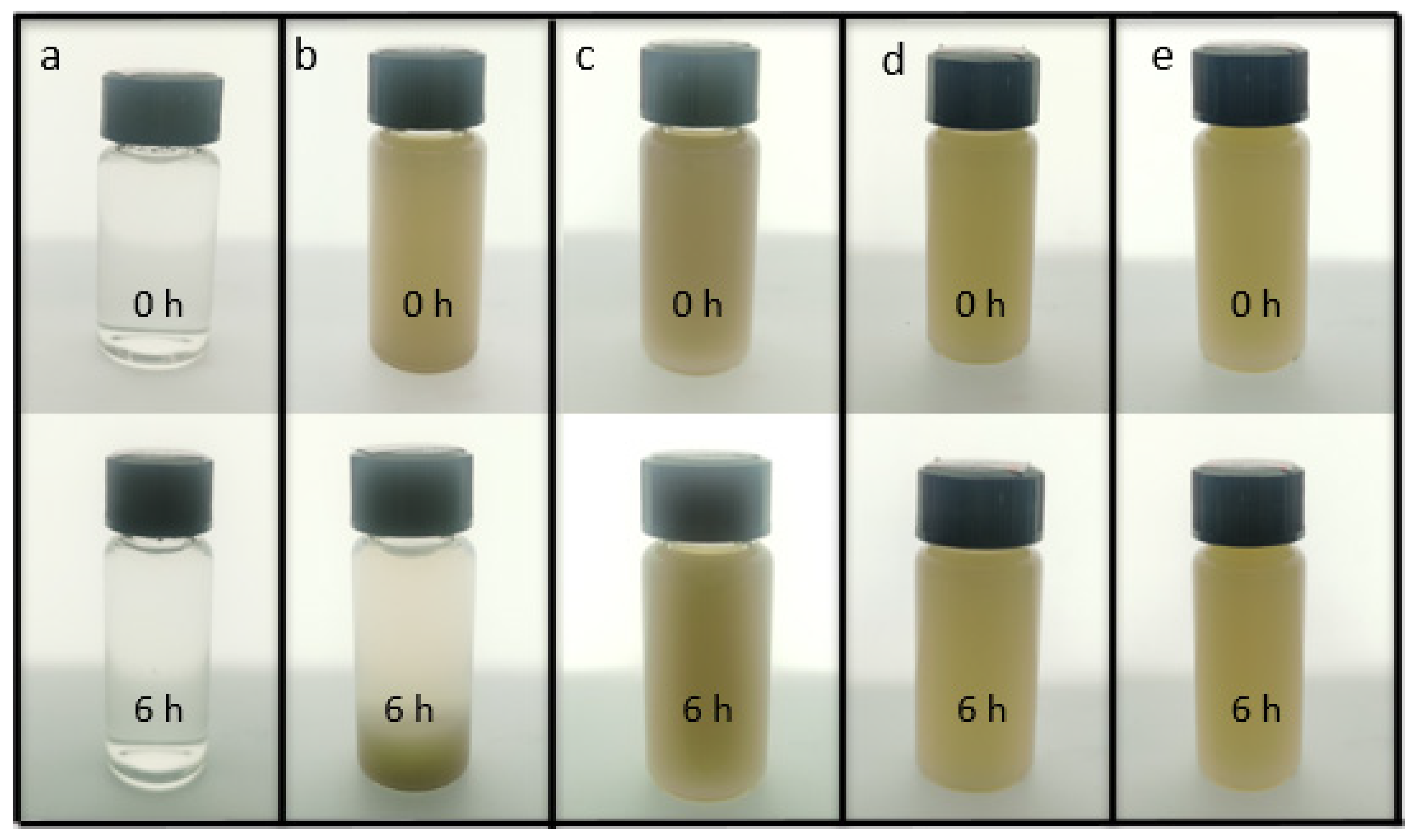

3.1. CNF Disperse HNTs

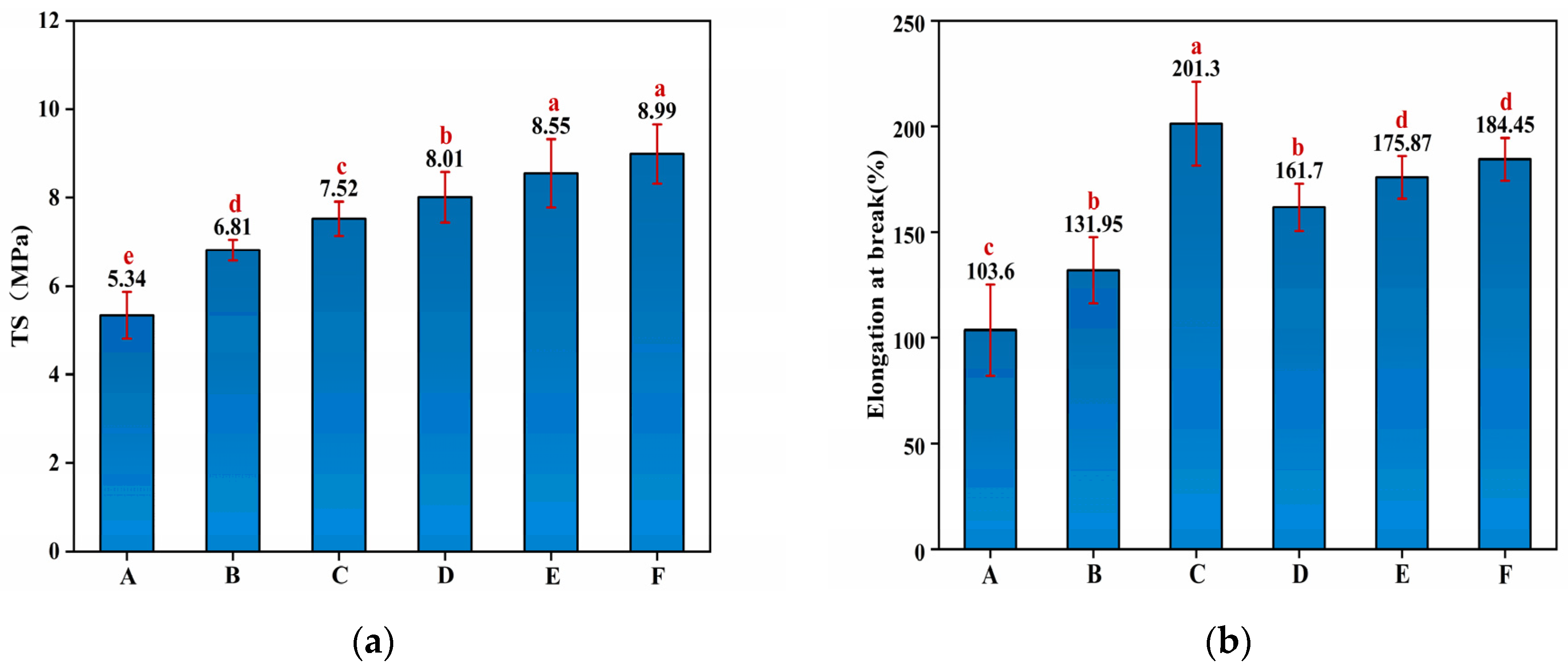

3.2. Mechanical Properties Analysis

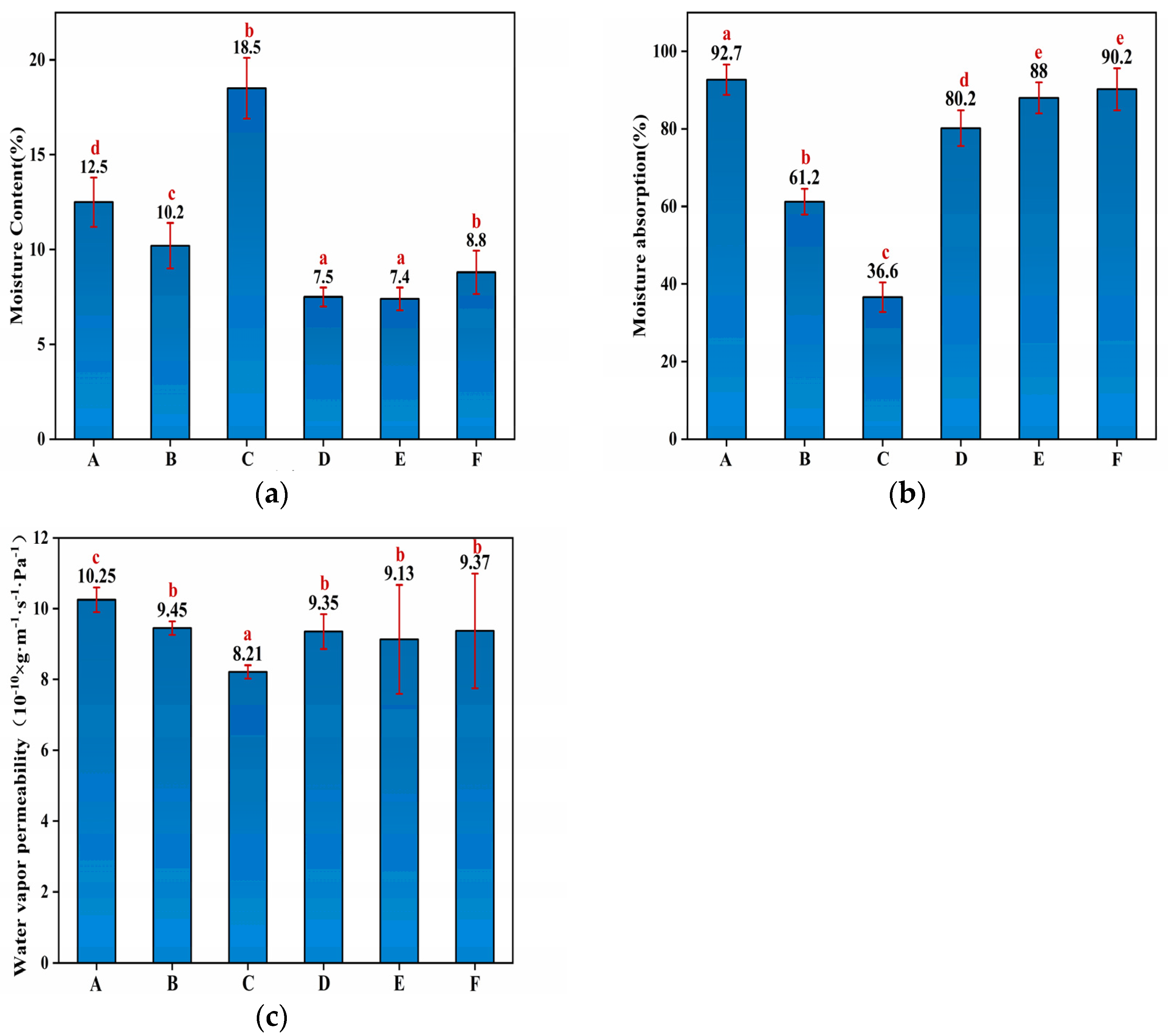

3.3. Water Resistance Properties of Starch–PVA Composite Membrane

3.4. Micromorphological Analysis of Composite Membranes

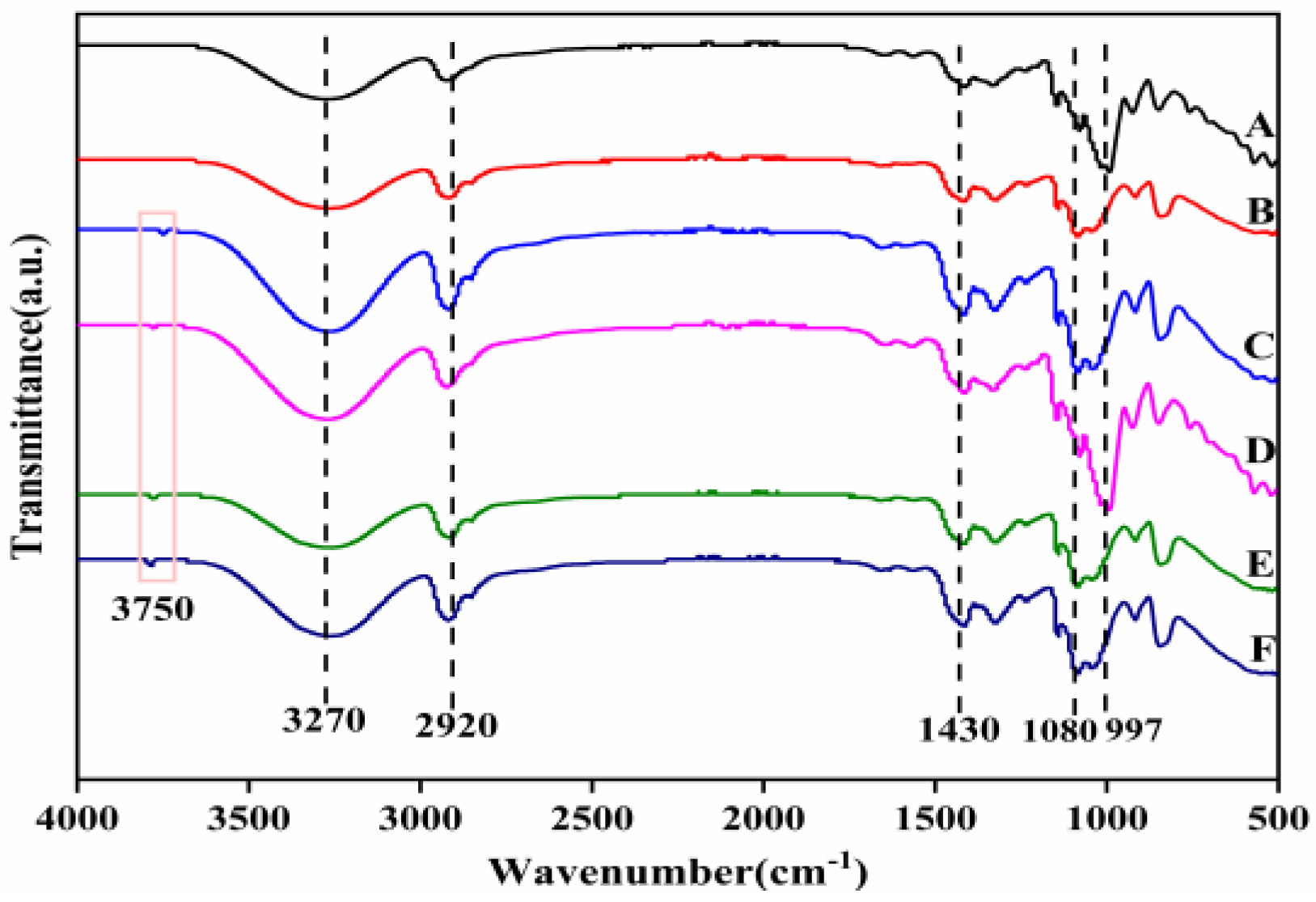

3.5. FTIR Analysis of Composite Membranes

3.6. XRD Analysis of Composite Membrane

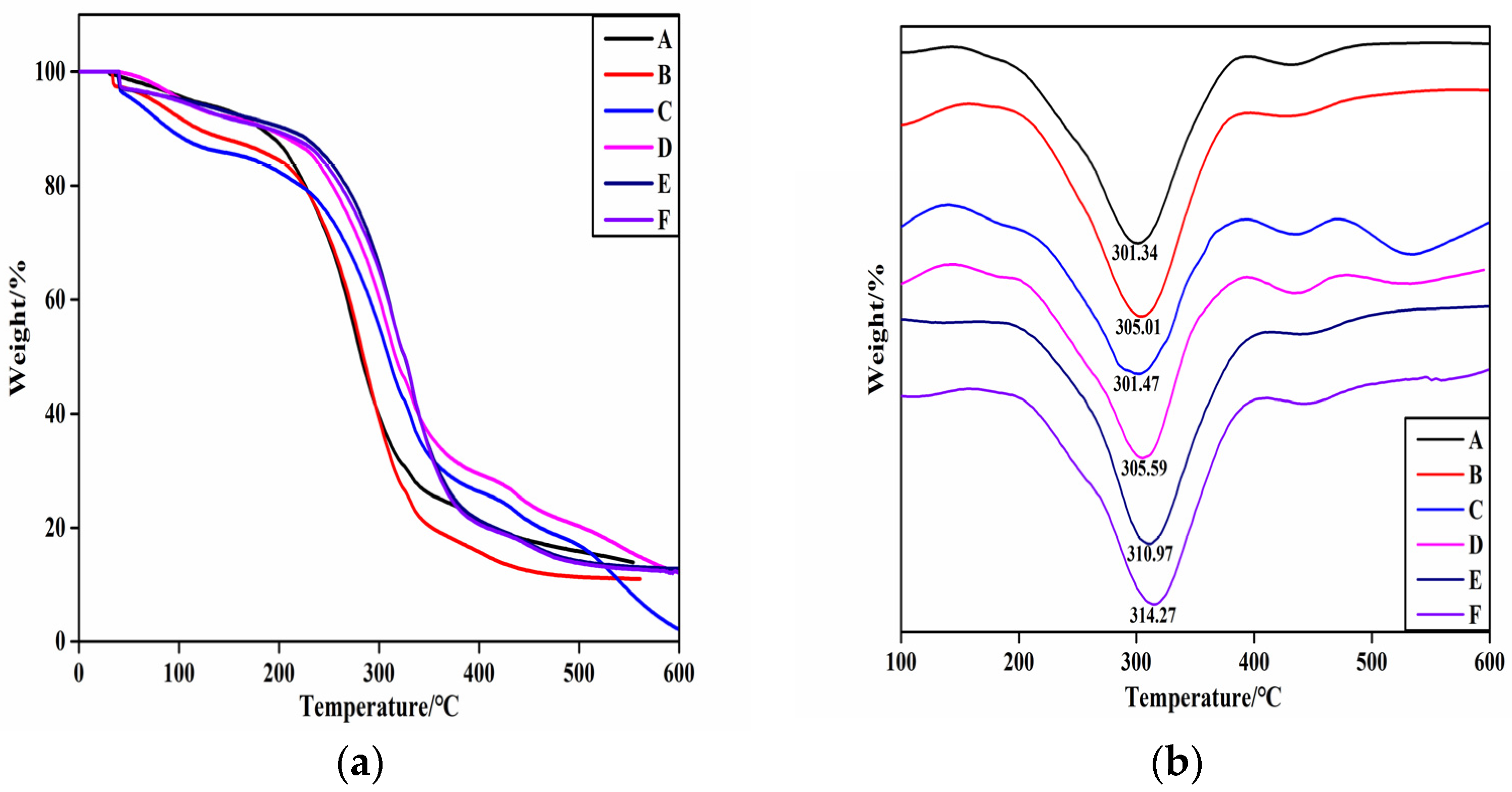

3.7. Thermal Performance of the HNTs/Starch–PVA Composite Membrane

3.8. DSC Studies of the HNTs/Starch–PVA Composite Membrane

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Conflicts of Interest

References

- Pacheco, M.S.; Barbieri, D.; da Silva, C.F.; de Moraes, M.A. A review on orally disintegrating membranes (ODFs) made from natural polymers such as pullulan, maltodextrin, starch, and others. Int. J. Biol. Macromol. 2021, 178, 504–513. [Google Scholar] [CrossRef] [PubMed]

- Prabhu, T.N.; Prashantha, K. A review on present status and future challenges of starch based polymer membranes and their composites in food packaging applications. Polym. Compos. 2018, 39, 2499–2522. [Google Scholar] [CrossRef]

- Wilfer, P.B.; Giridaran, G.; Jeevahan, J.J.; Joseph, G.B.; Kumar, G.S.; Thykattuserry, N.J. Effect of starch type on the membrane properties of native starch based edible membranes. Mater. Today Proc. 2021, 44, 3903–3907. [Google Scholar] [CrossRef]

- Sadegh-Hassani, F.; Mohammadi Nafchi, A. Preparation and characterization of bionanocomposite membranes based on potato starch/halloysite nanoclay. Int. J. Biol. Macromol. 2014, 67, 458–462. [Google Scholar] [CrossRef]

- Van Long, N.N.; Joly, C.; Dantigny, P. Active packaging with antifungal activities. Int. J. Food Microbiol. 2016, 220, 73–90. [Google Scholar] [CrossRef] [PubMed]

- Zhu, Z.F.; Wang, M.; Li, W. Starch maleation and sulfosuccinylation to alleviate the intrinsic drawback of brittleness of cornstarch membrane for warp sizing. Fibers Polym. 2015, 16, 1890–1897. [Google Scholar] [CrossRef]

- Riyajan, S.A.; Chantawee, K. Cassava starch composite based membranes for encapsulated neem: Effect of carboxylated styrene-butadiene rubber coating. Food Packag. Shelf Life 2020, 23, 100438. [Google Scholar] [CrossRef]

- Sharma, V.; Kaur, M.; Sandhu, K.S.; Nain, V.; Janghu, S. Physicochemical and rheological properties of cross-linked litchi kernel starch and its application in development of bio-membranes. Starch-Stärke 2021, 73, 2100049. [Google Scholar] [CrossRef]

- Ordonez, R.; Atares, L.; Chiralt, A. Physicochemical and antimicrobial properties of cassava starch membranes with ferulic or cinnamic acid. LWT-Food Sci. Technol. 2021, 144, 1–8. [Google Scholar] [CrossRef]

- Yan, X.X.; Diao, M.X.; Yu, Y.L.; Gao, F.; Wang, E.L.; Wang, Z.Z.; Zhang, T.H. Influence of esterification and ultrasound treatment on formation and properties of starch nanoparticles and their impact as a filler on chitosan based membranes characteristics. Int. J. Biol. Macromol. 2021, 179, 154–160. [Google Scholar] [CrossRef]

- Liu, P.F.; Gao, W.; Zhang, X.L.; Wang, B.; Zou, F.X.; Yu, B.; Lu, L.; Fang, Y.S.; Wu, Z.Z.; Yuan, C.; et al. Effects of ultrasonication on the properties of maize starch/stearic acid/sodium carboxymethyl cellulose composite membrane. Ultrason. Sonochem. 2021, 72, 105447. [Google Scholar] [CrossRef] [PubMed]

- Sani, I.K.; Geshlaghi, S.P.; Pirsa, S.; Asdagh, A. Composite membrane based on potato starch/apple peel pectin/ZrO2 nanoparticles/microencapsulated Zataria multiflora essential oil; Investigation of physicochemical properties and use in quail meat packaging. Food Hydrocoll. 2021, 117, 106719. [Google Scholar] [CrossRef]

- Wu, S.L.; Wang, W.T.; Zhang, R.; Zhai, X.S.; Hou, H.X. Preparation and characterization of biodegradable trilayer membranes based on starch and polyester. Int. J. Biol. Macromol. 2021, 183, 1058–1066. [Google Scholar] [CrossRef] [PubMed]

- Trinh, B.M.; Chang, C.C.; Mekonnen, T.H. Facile fabrication of thermoplastic starch/poly (lactic acid) multilayer membranes with superior gas and moisture barrier properties. Polymer 2021, 223, 123679. [Google Scholar] [CrossRef]

- Hernandez-Garcia, E.; Vargas, M.; Chiralt, A. Thermoprocessed starch-polyester bilayer membranes as affected by the addition of gellan or xanthan gum. Food Hydrocoll. 2021, 113, 106509. [Google Scholar] [CrossRef]

- Tang, H.L.; Xiong, H.G.; Tang, S.W.; Zou, P. A starch-based biodegradable membrane modified by nano silicon dioxide. J. Appl. Polym. Sci. 2009, 113, 34–40. [Google Scholar] [CrossRef]

- Mohan, T.P.; Kanny, K. Thermoforming studies of corn starch-derived biopolymer membrane filled with nanoclays. J. Plast. Membr. Sheeting 2016, 32, 163–188. [Google Scholar] [CrossRef]

- Belibi, P.C.; Daou, T.J.; Ndjaka, J.M.B.; Michelin, L.; Brendlé, J.; Nsom, B.; Durand, B. Tensile and water barrier properties of cassava starch composite membranes reinforced by synthetic zeolite and beidellite. J. Food Eng. 2013, 115, 339–346. [Google Scholar] [CrossRef]

- Gou, Z.Q. The synergistic reinforcing effects of nano-diamond and chitosan-grafted MWNTs in starch membranes. Starch-Stärke 2021, 73, 2000277. [Google Scholar] [CrossRef]

- Devi, N.; Dutta, J. Development and in vitro characterization of chitosan/starch/halloysite nanotubes ternary nanocomposite membranes. Int. J. Biol. Macromol. 2019, 127, 222–231. [Google Scholar] [CrossRef]

- Noshirvani, N.; Ghanbarzadeh, B.; Fasihi, B.; Almasi, H. Starch-PVA nanocomposite membrane incorporated with cellulose nanocrystals and MMT: A comparative study. Int. J. Food Eng. 2016, 12, 37–48. [Google Scholar] [CrossRef]

- Ortega, F.; Arce, V.B.; Garcia, M.A. Nanocomposite starch-based membranes containing silver nanoparticles synthesized with lemon juice as reducing and stabilizing agent. Carbohydr. Polym. 2021, 252, 117208. [Google Scholar] [CrossRef] [PubMed]

- Chen, X.H.; Zhou, L.Y.; Pan, X.M.; Hu, J.H.; Hu, Y.X.; Wei, S.S. Effect of different compatibilizers on the mechanical and thermal properties of starch/polypropylene blends. J. Appl. Polym. Sci. 2016, 133. [Google Scholar] [CrossRef]

- Yang, L.; Xie, M.Z.; Fang, J.X.; Zhang, T.Y.; Wang, X.M.; Chen, L.P. Effect of additives on properties of cross-linked carboxymethyl starch/polyvinyl alcohol composite membranes. J. Appl. Polym. Sci. 2022, 139, 51546. [Google Scholar] [CrossRef]

- Patil, S.; Bharimalla, A.K.; Mahapatra, A.; Dhakane-Lad, J.; Arputharaj, A.; Kumar, M.; Raja, A.S.M.; Kambli, N. Effect of polymer blending on mechanical and barrier properties of starch-polyvinyl alcohol based biodegradable composite membranes. Food Biosci. 2021, 44, 101352. [Google Scholar] [CrossRef]

- Abdullah, Z.W.; Dong, Y. Biodegradable and water resistant poly(vinyl) alcohol (PVA)/starch (ST)/glycerol (GL)/halloysite nanotube (HNT) nanocomposite membranes for sustainable food packaging. Front. Mater. 2019, 6, 58. [Google Scholar] [CrossRef] [Green Version]

- Sarifuddin, N.; Ismail, H.; Ahmad, Z. Influence of halloysite nanotubes hybridized with kenaf core fibers on the physical and mechanical properties of low density polyethylene/thermoplastic sago starch blends. Polym.-Plast. Technol. Eng. 2014, 53, 107–115. [Google Scholar] [CrossRef] [Green Version]

- He, Y.Q.; Kong, W.N.; Wang, W.C.; Liu, T.L.; Liu, Y.; Gong, Q.J.; Gao, J.P. Modified natural halloysite/potato starch composite membranes. Carbohydr. Polym. 2012, 87, 2706–2711. [Google Scholar] [CrossRef]

- Lazzara, G.; Cavallaro, G.; Panchal, A.; Fakhrullin, R.; Stavitskaya, A.; Vinokurov, V.; Lvov, Y. An assembly of organic-inorganic composites using halloysite clay nanotubes. Curr. Opin. Colloid Interface Sci. 2018, 35, 42–50. [Google Scholar] [CrossRef]

- Soni, B.; Hassan, E.B.; Mahmoud, B. Chemical isolation and characterization of different cellulose nanofibers from cotton stalks. Carbohydr. Polym. 2015, 134, 581–589. [Google Scholar] [CrossRef]

- De Almeida, T.S.; Barretti, B.R.V.; Ito, V.C.; Malucelli, L.; Da Silva Carvalho Filho, M.A.; Demiate, I.M.; Pinheiro, L.A.; Lacerda, L.G. Thermal, morphological, and mechanical properties of regular and waxy maize starch membranes reinforced with cellulose nanofibers (CNF). Mater. Res.-Ibero-Am. J. Mater. 2020, 23. [Google Scholar] [CrossRef]

- Qin, Z.; Mo, L.; Liao, M.; He, H.; Sun, J. Preparation and characterization of soy protein isolate-based nanocomposite membranes with cellulose nanofibers and nano-silica via silane grafting. Polymers 2019, 11, 1835. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Fazeli, M.; Keley, M.; Biazar, E. Preparation and characterization of starch-based composite membranes reinforced by cellulose nanofibers. Int. J. Biol. Macromol. 2018, 116, 272–280. [Google Scholar] [CrossRef] [PubMed]

- Jose, J.; Al-Harthi, M.A.; AlMa’adeed, M.A.A.; Dakua, J.B.; De, S.K. Effect of graphene loading on thermomechanical properties of poly(vinyl alcohol)/starch blend. J. Appl. Polym. Sci. 2015, 132. [Google Scholar] [CrossRef]

- Zhang, S.F.; Xia, C.L.; Dong, Y.M.; Yan, Y.T.; Li, J.Z.; Shi, S.Q.; Cai, L.P. Soy protein isolate-based membranes reinforced by surface modified cellulose nanocrystal. Ind. Crop. Prod. 2016, 80, 207–213. [Google Scholar] [CrossRef]

- Gutiérrez, T.J.; Tapia, M.S.; Pérez, E.; Famá, L. Structural and mechanical properties of edible membranes made from native and modified cush-cush yam and cassava starch. Food Hydrocoll. 2015, 45, 211–217. [Google Scholar] [CrossRef]

- Panaitescu, D.M.; Frone, A.N.; Ghiurea, M.; Chiulan, I. Influence of storage conditions on starch/PVA membranes containing cellulose nanofibers. Ind. Crop. Prod. 2015, 70, 170–177. [Google Scholar] [CrossRef]

- Aguirre-Loredo, R.Y.; Rodríguez-Hernández, A.I.; Morales-Sánchez, E.; Gómez-Aldapa, C.A.; Velazquez, G. Effect of equilibrium moisture content on barrier, mechanical and thermal properties of chitosan membranes. Food Chem. 2016, 196, 560–566. [Google Scholar] [CrossRef]

- Khalil, H.P.S.A.; Yap, S.W.; Tye, Y.Y.; Tahir, P.M.; Rizal, S.; Fazita, M.R.N. Effects of corn starch and Kappaphycus alvarezii seaweed blend concentration on the optical, mechanical, and water vapor barrier properties of composite membranes. Bioresources 2018, 13, 1157–1173. [Google Scholar]

- Cano, A.; Fortunati, E.; Cháfer, M.; González-Martínez, C.; Chiralt, A.; Kenny, J.M. Effect of cellulose nanocrystals on the properties of pea starch–poly(vinyl alcohol) blend membranes. J. Mater. Sci. 2015, 50, 6979–6992. [Google Scholar] [CrossRef] [Green Version]

- Hu, D.Y.; Wang, L.J. Physical and antibacterial properties of polyvinyl alcohol membranes reinforced with quaternized cellulose. J. Appl. Polym. Sci. 2016, 133. [Google Scholar] [CrossRef]

- Kang, H.J.; Liu, X.R.; Zhang, S.F.; Li, J.Z. Functionalization of halloysite nanotubes (HNTs) via mussel-inspired surface modification and silane grafting for HNTs/soy protein isolate nanocomposite membrane preparation. RSC Adv. 2017, 7, 24140–24148. [Google Scholar] [CrossRef] [Green Version]

- Meira, S.M.M.; Zehetmeyer, G.; Scheibel, J.M.; Werner, J.O.; Brandelli, A. Starch-halloysite nanocomposites containing nisin: Characterization and inhibition of Listeria monocytogenes in soft cheese. LWT-Food Sci. Technol. 2016, 68, 226–234. [Google Scholar] [CrossRef]

- Mansour, G.; Zoumaki, M.; Marinopoulou, A.; Raphaelides, S.N.; Tzetzis, D.; Zoumakis, N. Investigation on the effects of glycerol and clay contents on the structure and mechanical properties of maize starch nanocomposite membranes. Starch-Stärke 2020, 72, 1900166. [Google Scholar] [CrossRef]

- Jayakumar, A.; Heera, K.V.; Sumi, T.S.; Joseph, M.; Mathew, S.; Praveen, G.; Nair, I.C.; Radhakrishnan, E.K. Starch-PVA composite membranes with zinc-oxide nanoparticles and phytochemicals as intelligent pH sensing wraps for food packaging application. Int. J. Biol. Macromol. 2019, 136, 395–403. [Google Scholar] [CrossRef]

- Ali, M.A.S.S.; Jimat, D.N.; Nawawi, W.M.F.W.; Sulaiman, S. Antibacterial, mechanical and thermal properties of PVA/starch composite membrane reinforced with cellulose nanofiber of sugarcane bagasse. Arab. J. Sci. Eng. 2021. [Google Scholar] [CrossRef]

- Cavallaro, G.; Lazzara, G.; Milioto, S. Sustainable nanocomposites based on halloysite nanotubes and pectin/polyethylene glycol blend. Polym. Degrad. Stab. 2013, 98, 2529–2536. [Google Scholar] [CrossRef] [Green Version]

- Kumar, A.; Chouhan, D.K.; Alegaonkar, P.S.; Patro, T.U. Graphene-like nanocarbon: An effective nanofiller for improving the mechanical and thermal properties of polymer at low weight fractions. Compos. Sci. Technol. 2016, 127, 79. [Google Scholar] [CrossRef]

| Code | 5% Starch Solutions | 5% PVA Solutions | 1% Nanofillers Solution |

|---|---|---|---|

| A | 20 g | 10 g | - |

| B | 20 g | 10 g | 7.5 g HNTs |

| C | 20 g | 10 g | 7.5 g CNF |

| D | 20 g | 10 g | 7.5 g HNTs-CNF |

| E | 20 g | 10 g | 7.5 g HNTs-KH560-CNF |

| F | 20 g | 10 g | 7.5 g HNTs-KH570-CNF |

| Code | Angle 2θ/° | d/Å | Degree of Crystallinity |

|---|---|---|---|

| A | 19.750° | 4.4915 | 39.44% |

| B | 19.980° | 4.4403 | 38.18% |

| C | 19.860° | 4.4668 | 43.86% |

| D | 19.790° | 4.4825 | 41.45% |

| E | 19.990° | 4.4381 | 47.93% |

| F | 19.890° | 4.4602 | 40.37% |

| Code | Cooling | Heating | ||||||

|---|---|---|---|---|---|---|---|---|

| Tc1 (°C) | Tc2 (°C) | Hc (W/g) | Tg (°C) | Tm1 (°C) | Tm2 (°C) | Hm (W/g) | X (%) | |

| A | 161 | 192.7 | 11.48 | 100.8 | 210.1 | 213.6 | 8.742 | 60.08 |

| B | 156.7 | 193.5 | 15.02 | 88.7 | 205.9 | 216.8 | 6.308 | 43.35 |

| C | 170.2 | 193.9 | 14.94 | 111.5 | 210.1 | 220.9 | 6.03 | 41.44 |

| D | 165.4 | 192.8 | 19.57 | 104.9 | 214.6 | 217.6 | 7.91 | 54.36 |

| E | 163.2 | 192.8 | 15.77 | 107.9 | 209.9 | 217.3 | 12.89 | 88.59 |

| F | 170.6 | 194.8 | 15.32 | 105.1 | 208.4 | 220.3 | 10.18 | 69.96 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, H.; Yang, J.; Feng, X.; Qin, Z. Cellulose Nanofiber-Assisted Dispersion of Halloysite Nanotubes via Silane Coupling Agent-Reinforced Starch–PVA Biodegradable Composite Membrane. Membranes 2022, 12, 169. https://doi.org/10.3390/membranes12020169

Li H, Yang J, Feng X, Qin Z. Cellulose Nanofiber-Assisted Dispersion of Halloysite Nanotubes via Silane Coupling Agent-Reinforced Starch–PVA Biodegradable Composite Membrane. Membranes. 2022; 12(2):169. https://doi.org/10.3390/membranes12020169

Chicago/Turabian StyleLi, Han, Jisheng Yang, Xiaoqiong Feng, and Zhiyong Qin. 2022. "Cellulose Nanofiber-Assisted Dispersion of Halloysite Nanotubes via Silane Coupling Agent-Reinforced Starch–PVA Biodegradable Composite Membrane" Membranes 12, no. 2: 169. https://doi.org/10.3390/membranes12020169

APA StyleLi, H., Yang, J., Feng, X., & Qin, Z. (2022). Cellulose Nanofiber-Assisted Dispersion of Halloysite Nanotubes via Silane Coupling Agent-Reinforced Starch–PVA Biodegradable Composite Membrane. Membranes, 12(2), 169. https://doi.org/10.3390/membranes12020169