Use of Chitosan as Copper Binder in the Continuous Electrochemical Reduction of CO2 to Ethylene in Alkaline Medium

Abstract

:1. Introduction

2. Materials and Methods

2.1. Electrode Preparation

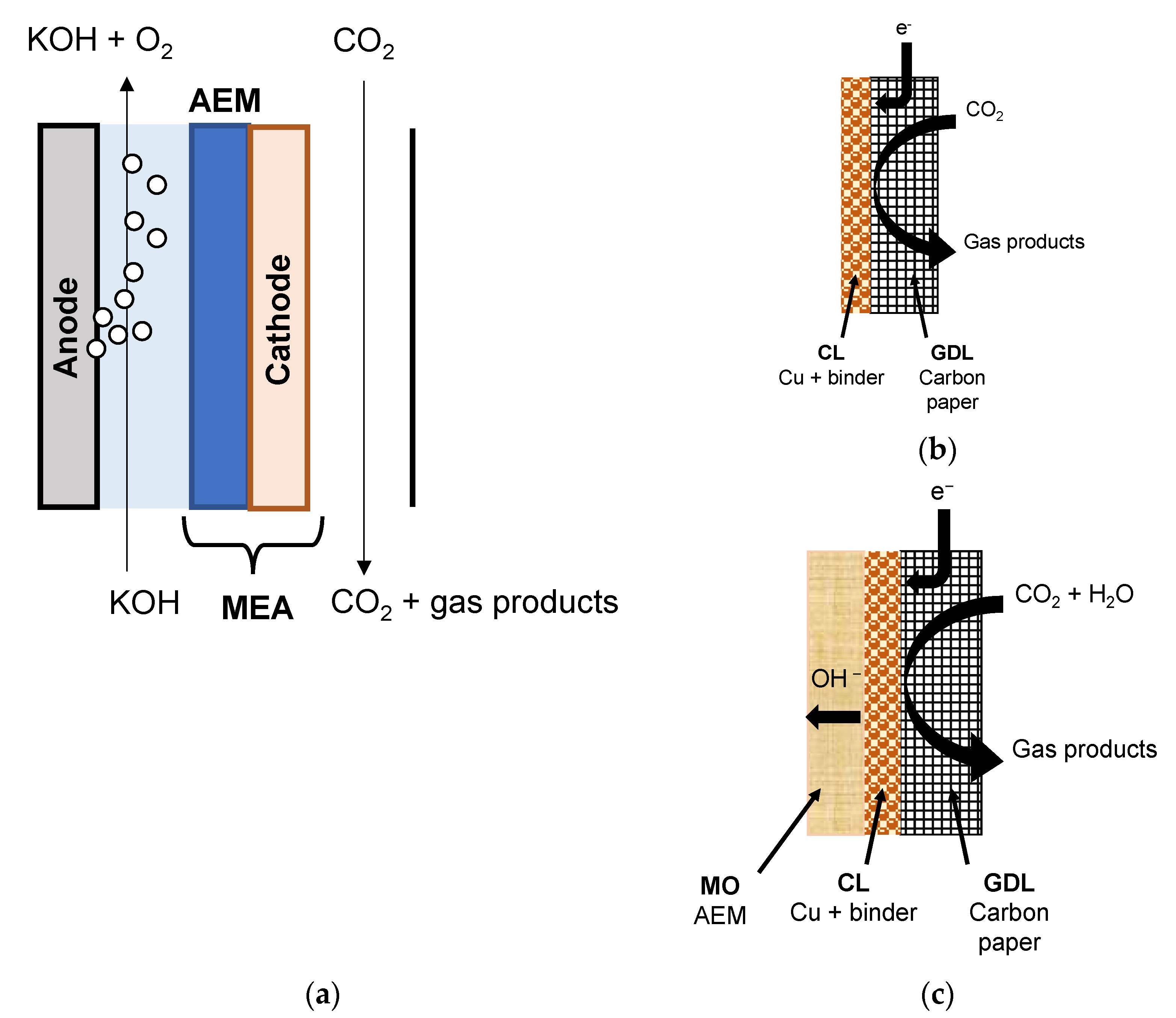

2.2. CO2R Experiments in Filter-Press Cell

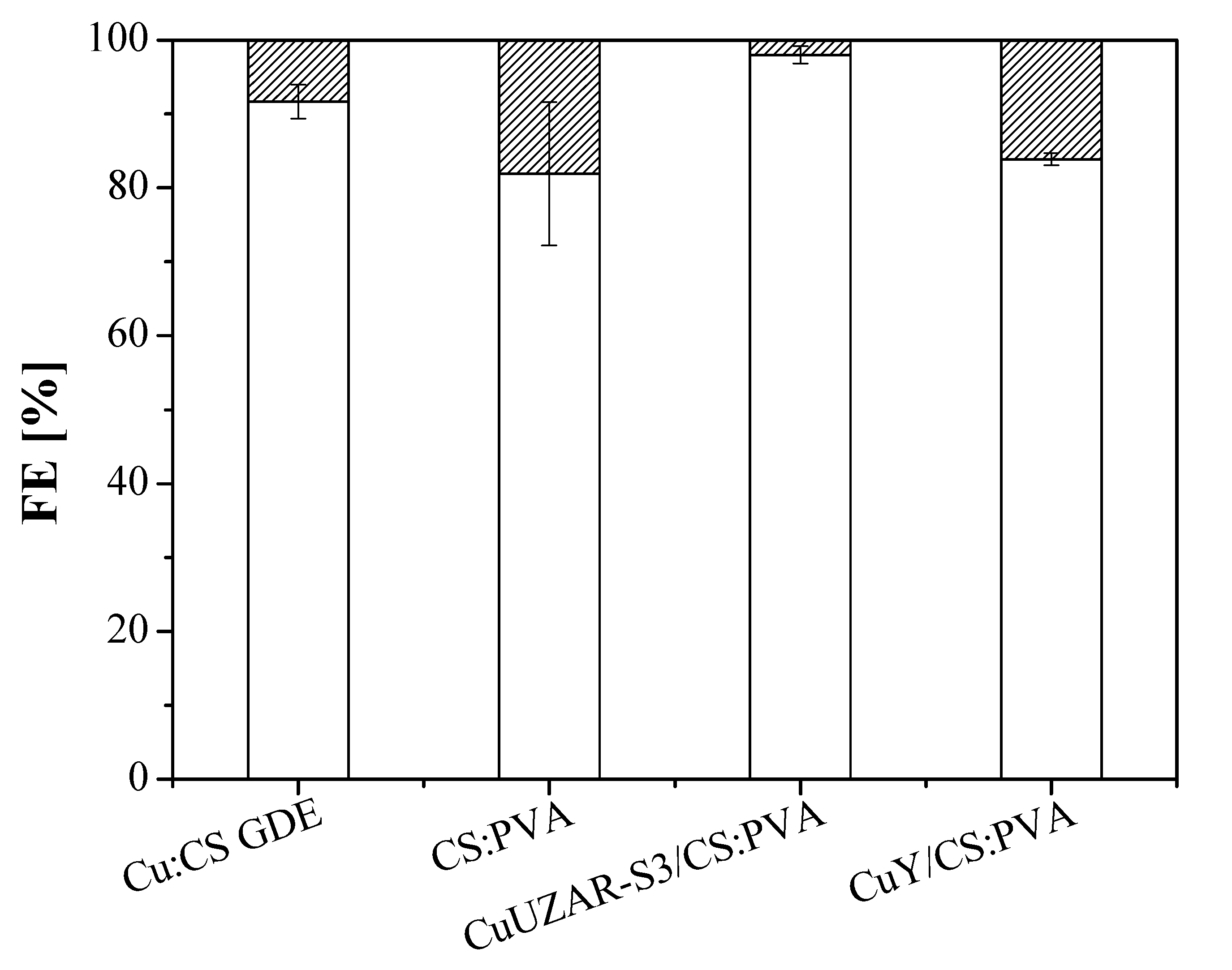

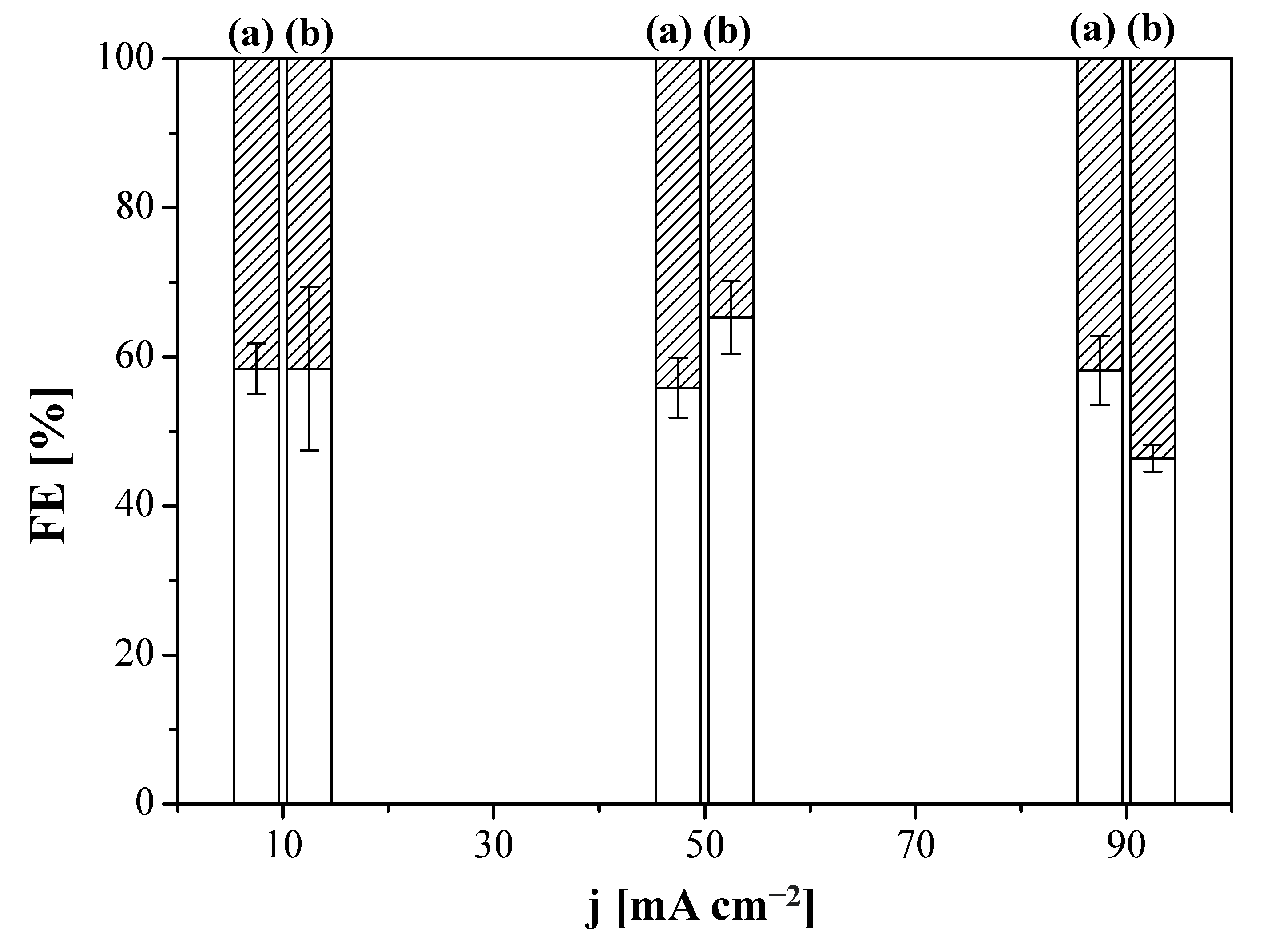

3. Results and Discussion

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Ioannou, I.; D’Angelo, S.C.; Martín, A.J.; Pérez-Ramírez, J.; Guillén-Gosálbez, G. Hybridization of Fossil- and CO2-Based Routes for Ethylene Production Using Renewable Energy. ChemSusChem 2020, 13, 6370–6380. [Google Scholar] [CrossRef] [PubMed]

- Rumayor, M.; Dominguez-Ramos, A.; Irabien, A. Environmental and Economic Assessment of the Formic Acid Electrochemical Manufacture Using Carbon Dioxide: Influence of the Electrode Lifetime. Sustain. Prod. Consum. 2019, 18, 72–82. [Google Scholar] [CrossRef]

- Pappijn, C.A.R.; Ruitenbeek, M.; Reyniers, M.F.; Van Geem, K.M. Challenges and Opportunities of Carbon Capture and Utilization: Electrochemical Conversion of CO2 to Ethylene. Front. Earth Sci. 2020, 8, 557466. [Google Scholar] [CrossRef]

- Aresta, M.; Dibenedetto, A. Carbon Recycling Through CO2-Conversion for Stepping toward a Cyclic-C Economy. A Perspective. Front. Energy Res. 2020, 8, 159. [Google Scholar] [CrossRef]

- Fan, Q.; Zhang, M.; Jia, M.; Liu, S.; Qiu, J.; Sun, Z. Electrochemical CO2 Reduction to C2+ Species: Heterogeneous Electrocatalysts, Reaction Pathways, and Optimization Strategies. Mater. Today Energy 2018, 10, 280–301. [Google Scholar] [CrossRef]

- Pătru, A.; Binninger, T.; Pribyl, B.; Schmidt, T.J. Design Principles of Bipolar Electrochemical Co-Electrolysis Cells for Efficient Reduction of Carbon Dioxide from Gas Phase at Low Temperature. J. Electrochem. Soc. 2019, 166, F34–F43. [Google Scholar] [CrossRef]

- Nitopi, S.; Bertheussen, E.; Scott, S.B.; Liu, X.; Engstfeld, A.K.; Horch, S.; Seger, B.; Stephens, I.E.L.; Chan, K.; Hahn, C.; et al. Progress and Perspectives of Electrochemical CO2 Reduction on Copper in Aqueous Electrolyte. Chem. Rev. 2019, 119, 7610–7672. [Google Scholar] [CrossRef]

- Tufa, R.A.; Chanda, D.; Ma, M.; Aili, D.; Demissie, T.B.; Vaes, J.; Li, Q.; Liu, S.; Pant, D. Towards Highly Efficient Electrochemical CO2 Reduction: Cell Designs, Membranes and Electrocatalysts. Appl. Energy 2020, 277, 115557. [Google Scholar] [CrossRef]

- Hori, Y. Electrochemical CO2 Reduction on Metal Electrodes. In Modern Aspects of Electrochemistry; Vayenas, C., Ed.; Springer: New York, NY, USA, 2008; pp. 89–189. [Google Scholar]

- Ma, S.; Sadakiyo, M.; Luo, R.; Heima, M.; Yamauchi, M.; Kenis, P.J.A. One-Step Electrosynthesis of Ethylene and Ethanol from CO2 in an Alkaline Electrolyzer. J. Power Sources 2016, 301, 219–228. [Google Scholar] [CrossRef]

- Aeshala, L.M.; Rahman, S.U.; Verma, A. Effect of Solid Polymer Electrolyte on Electrochemical Reduction of CO2. Sep. Purif. Technol. 2012, 94, 131–137. [Google Scholar] [CrossRef]

- Ren, D.; Deng, Y.; Handoko, A.D.; Chen, C.S.; Malkhandi, S.; Yeo, B.S. Selective Electrochemical Reduction of Carbon Dioxide to Ethylene and Ethanol on Copper(I) Oxide Catalysts. ACS Catal. 2015, 5, 2814–2821. [Google Scholar] [CrossRef]

- De Luna, P.; Quintero-Bermudez, R.; DInh, C.T.; Ross, M.B.; Bushuyev, O.S.; Todorović, P.; Regier, T.; Kelley, S.O.; Yang, P.; Sargent, E.H. Catalyst Electro-Redeposition Controls Morphology and Oxidation State for Selective Carbon Dioxide Reduction. Nat. Catal. 2018, 1, 103–110. [Google Scholar] [CrossRef]

- Lv, J.J.; Jouny, M.; Luc, W.; Zhu, W.; Zhu, J.J.; Jiao, F. A Highly Porous Copper Electrocatalyst for Carbon Dioxide Reduction. Adv. Mater. 2018, 30, 1803111. [Google Scholar] [CrossRef] [PubMed]

- Min, S.; Yang, X.; Lu, A.Y.; Tseng, C.C.; Hedhili, M.N.; Li, L.J.; Huang, K.W. Low Overpotential and High Current CO2 Reduction with Surface Reconstructed Cu Foam Electrodes. Nano Energy 2016, 27, 121–129. [Google Scholar] [CrossRef]

- Wang, Y.; Shen, H.; Livi, K.J.T.; Raciti, D.; Zong, H.; Gregg, J.; Onadeko, M.; Wan, Y.; Watson, A.; Wang, C. Copper Nanocubes for CO2 Reduction in Gas Diffusion Electrodes. Nano Lett. 2019, 19, 8461–8468. [Google Scholar] [CrossRef]

- Reller, C.; Krause, R.; Volkova, E.; Schmid, B.; Neubauer, S.; Rucki, A.; Schuster, M.; Schmid, G. Selective Electroreduction of CO2 toward Ethylene on Nano Dendritic Copper Catalysts at High Current Density. Adv. Energy Mater. 2017, 7, 1602114. [Google Scholar] [CrossRef]

- Merino-Garcia, I.; Albo, J.; Irabien, A. Tailoring Gas-Phase CO2 Electroreduction Selectivity to Hydrocarbons at Cu Nanoparticles. Nanotechnology 2018, 29, 014001. [Google Scholar] [CrossRef]

- Marepally, B.C.; Ampelli, C.; Genovese, C.; Tavella, F.; Veyre, L.; Quadrelli, E.A.; Perathoner, S.; Centi, G. Role of Small Cu Nanoparticles in the Behaviour of Nanocarbon-Based Electrodes for the Electrocatalytic Reduction of CO2. J. CO2 Util. 2017, 21, 534–542. [Google Scholar] [CrossRef]

- Gutiérrez-Guerra, N.; Moreno-López, L.; Serrano-Ruiz, J.C.; Valverde, J.L.; de Lucas-Consuegra, A. Gas Phase Electrocatalytic Conversion of CO2 to Syn-Fuels on Cu Based Catalysts-Electrodes. Appl. Catal. B Environ. 2016, 188, 272–282. [Google Scholar] [CrossRef]

- Shang, L.; Lv, X.; Shen, H.; Shao, Z.; Zheng, G. Selective Carbon Dioxide Electroreduction to Ethylene and Ethanol by Core-Shell Copper/Cuprous Oxide. J. Colloid Interface Sci. 2019, 552, 426–431. [Google Scholar] [CrossRef]

- Han, Z.; Kortlever, R.; Chen, H.Y.; Peters, J.C.; Agapie, T. CO2 Reduction Selective for C≥2 Products on Polycrystalline Copper with N-Substituted Pyridinium Additives. ACS Cent. Sci. 2017, 3, 853–859. [Google Scholar] [CrossRef] [PubMed]

- Todoroki, N.; Yokota, N.; Nakahata, S.; Nakamura, H.; Wadayama, T. Electrochemical Reduction of CO2 on Ni- and Pt-Epitaxially Grown Cu(111) Surfaces. Electrocatalysis 2016, 7, 97–103. [Google Scholar] [CrossRef]

- Hoang, T.T.H.; Verma, S.; Ma, S.; Fister, T.T.; Timoshenko, J.; Frenkel, A.I.; Kenis, P.J.A.; Gewirth, A.A. Nanoporous Copper-Silver Alloys by Additive-Controlled Electrodeposition for the Selective Electroreduction of CO2 to Ethylene and Ethanol. J. Am. Chem. Soc. 2018, 140, 5791–5797. [Google Scholar] [CrossRef]

- Huo, S.; Weng, Z.; Wu, Z.; Zhong, Y.; Wu, Y.; Fang, J.; Wang, H. Coupled Metal/Oxide Catalysts with Tunable Product Selectivity for Electrocatalytic CO2 Reduction. ACS Appl. Mater. Interfaces 2017, 9, 28519–28526. [Google Scholar] [CrossRef]

- Merino-Garcia, I.; Albo, J.; Solla-Gullón, J.; Montiel, V.; Irabien, A. Cu Oxide/ZnO-Based Surfaces for a Selective Ethylene Production from Gas-Phase CO2 Electroconversion. J. CO2 Util. 2019, 31, 135–142. [Google Scholar] [CrossRef]

- Huang, Y.; Deng, Y.; Handoko, A.D.; Goh, G.K.L.; Yeo, B.S. Rational Design of Sulfur-Doped Copper Catalysts for the Selective Electroreduction of Carbon Dioxide to Formate. ChemSusChem 2018, 11, 320–326. [Google Scholar] [CrossRef] [PubMed]

- Birdja, Y.Y.; Shen, J.; Koper, M.T.M. Influence of the Metal Center of Metalloprotoporphyrins on the Electrocatalytic CO2 Reduction to Formic Acid. Catal. Today 2017, 288, 37–47. [Google Scholar] [CrossRef]

- Komatsu, S.; Tanaka, M.; Okumura, A.; Kungi, A. Preparation of Cu-Solid Polymer Electrolyte Composite Electrodes and Application to Gas-Phase Electrochemical Reduction of CO2. Electrochim. Acta 1995, 40, 745–753. [Google Scholar] [CrossRef]

- Song, Y.; Peng, R.; Hensley, D.K.; Bonnesen, P.V.; Liang, L.; Wu, Z.; Meyer, H.M.; Chi, M.; Ma, C.; Sumpter, B.G.; et al. High-Selectivity Electrochemical Conversion of CO2 to Ethanol Using a Copper Nanoparticle/N-Doped Graphene Electrode. ChemistrySelect 2016, 1, 6055–6061. [Google Scholar] [CrossRef]

- Periasamy, A.P.; Ravindranath, R.; Senthil Kumar, S.M.; Wu, W.P.; Jian, T.R.; Chang, H.T. Facet- and Structure-Dependent Catalytic Activity of Cuprous Oxide/Polypyrrole Particles towards the Efficient Reduction of Carbon Dioxide to Methanol. Nanoscale 2018, 10, 11869–11880. [Google Scholar] [CrossRef]

- Kim, C.; Bui, J.C.; Luo, X.; Cooper, J.K.; Kusoglu, A.; Weber, A.Z.; Bell, A.T. Tailored Catalyst Microenvironments for CO2 Electroreduction to Multicarbon Products on Copper Using Bilayer Ionomer Coatings. Nat. Energy 2021, 6, 1026–1034. [Google Scholar] [CrossRef]

- Chang, Q.; Lee, J.H.; Liu, Y.; Xie, Z.; Hwang, S.; Marinkovic, N.S.; Park, A.-H.A.; Kattel, S.; Chen, J.G. Electrochemical CO2 Reduction Reaction over Cu Nanoparticles with Tunable Activity and Selectivity Mediated by Functional Groups in Polymeric Binder. JACS Au 2022, 2, 214–222. [Google Scholar] [CrossRef] [PubMed]

- Vennekötter, J.B.; Scheuermann, T.; Sengpiel, R.; Wessling, M. The Electrolyte Matters: Stable Systems for High Rate Electrochemical CO2 Reduction. J. CO2 Util. 2019, 32, 202–213. [Google Scholar] [CrossRef]

- Weekes, D.M.; Salvatore, D.A.; Reyes, A.; Huang, A.; Berlinguette, C.P. Electrolytic CO2 Reduction in a Flow Cell. Acc. Chem. Res. 2018, 51, 910–918. [Google Scholar] [CrossRef] [PubMed]

- Higgins, D.; Hahn, C.; Xiang, C.; Jaramillo, T.F.; Weber, A.Z. Gas-Diffusion Electrodes for Carbon Dioxide Reduction: A New Paradigm. ACS Energy Lett. 2019, 4, 317–324. [Google Scholar] [CrossRef]

- Merino-Garcia, I.; Alvarez-Guerra, E.; Albo, J.; Irabien, A. Electrochemical Membrane Reactors for the Utilisation of Carbon Dioxide. Chem. Eng. J. 2016, 305, 104–120. [Google Scholar] [CrossRef]

- Gabardo, C.M.; Seifitokaldani, A.; Edwards, J.P.; Dinh, C.T.; Burdyny, T.; Kibria, M.G.; O’Brien, C.P.; Sargent, E.H.; Sinton, D. Combined High Alkalinity and Pressurization Enable Efficient CO2 Electroreduction to CO. Energy Environ. Sci. 2018, 11, 2531–2539. [Google Scholar] [CrossRef]

- García de Arquer, F.P.; Dinh, C.T.; Ozden, A.; Wicks, J.; McCallum, C.; Kirmani, A.R.; Nam, D.H.; Gabardo, C.; Seifitokaldani, A.; Wang, X.; et al. CO2 Electrolysis to Multicarbon Products at Activities Greater than 1 A cm−2. Science 2020, 367, 661–666. [Google Scholar] [CrossRef]

- Gabardo, C.M.; O’Brien, C.P.; Edwards, J.P.; McCallum, C.; Xu, Y.; Dinh, C.T.; Li, J.; Sargent, E.H.; Sinton, D. Continuous Carbon Dioxide Electroreduction to Concentrated Multi-Carbon Products Using a Membrane Electrode Assembly. Joule 2019, 3, 2777–2791. [Google Scholar] [CrossRef]

- Chen, X.; Chen, J.; Alghoraibi, N.M.; Henckel, D.A.; Zhang, R.; Nwabara, U.O.; Madsen, K.E.; Kenis, P.J.A.; Zimmerman, S.C.; Gewirth, A.A. Electrochemical CO2-to-Ethylene Conversion on Polyamine-Incorporated Cu Electrodes. Nat. Catal. 2021, 4, 20–27. [Google Scholar] [CrossRef]

- Zhuang, T.T.; Liang, Z.Q.; Seifitokaldani, A.; Li, Y.; De Luna, P.; Burdyny, T.; Che, F.; Meng, F.; Min, Y.; Quintero-Bermudez, R.; et al. Steering Post-C-C Coupling Selectivity Enables High Efficiency Electroreduction of Carbon Dioxide to Multi-Carbon Alcohols. Nat. Catal. 2018, 1, 421–428. [Google Scholar] [CrossRef]

- Ozden, A.; Wang, Y.; Li, F.; Luo, M.; Sisler, J.; Thevenon, A.; Rosas-Hernández, A.; Burdyny, T.; Lum, Y.; Yadegari, H.; et al. Cascade CO2 Electroreduction Enables Efficient Carbonate-Free Production of Ethylene. Joule 2021, 5, 706–719. [Google Scholar] [CrossRef]

- Müller, J.; Zhegur, A.; Krewer, U.; Varcoe, J.R.; Dekel, D.R. Practical Ex-Situ Technique to Measure the Chemical Stability of Anion-Exchange Membranes under Conditions Simulating the Fuel Cell Environment. ACS Mater. Lett. 2020, 2, 168–173. [Google Scholar] [CrossRef] [PubMed]

- Yang, K.; Kas, R.; Smith, W.A. In Situ Infrared Spectroscopy Reveals Persistent Alkalinity near Electrode Surfaces during CO2 Electroreduction. J. Am. Chem. Soc. 2019, 141, 15891–15900. [Google Scholar] [CrossRef] [PubMed]

- Aeshala, L.M.; Uppaluri, R.G.; Verma, A. Effect of Cationic and Anionic Solid Polymer Electrolyte on Direct Electrochemical Reduction of Gaseous CO2 to Fuel. J. CO2 Util. 2013, 3–4, 49–55. [Google Scholar] [CrossRef]

- Gunasekara, I.; Lee, M.; Abbott, D.; Mukerjee, S. Mass Transport and Oxygen Reduction Kinetics at an Anion Exchange Membrane Interface: Microelectrode Studies on Effect of Carbonate Exchange. ECS Electrochem. Lett. 2012, 1, 24–27. [Google Scholar] [CrossRef]

- Kutz, R.B.; Chen, Q.; Yang, H.; Sajjad, S.D.; Liu, Z.; Masel, I.R. Sustainion Imidazolium-Functionalized Polymers for Carbon Dioxide Electrolysis. Energy Technol. 2017, 5, 929–936. [Google Scholar] [CrossRef]

- Yin, Z.; Peng, H.; Wei, X.; Zhou, H.; Gong, J.; Huai, M.; Xiao, L.; Wang, G.; Lu, J.; Zhuang, L. An Alkaline Polymer Electrolyte CO2 Electrolyzer Operated with Pure Water. Energy Environ. Sci. 2019, 12, 2455–2462. [Google Scholar] [CrossRef]

- Novalin, T.; Pan, D.; Lindbergh, G.; Lagergren, C.; Jannasch, P.; Lindström, R.W. Electrochemical Performance of Poly(Arylene Piperidinium) Membranes and Ionomers in Anion Exchange Membrane Fuel Cells. J. Power Sources 2021, 507, 230287. [Google Scholar] [CrossRef]

- Chu, J.Y.; Lee, K.H.; Kim, A.R.; Yoo, D.J. Graphene-Mediated Organic-Inorganic Composites with Improved Hydroxide Conductivity and Outstanding Alkaline Stability for Anion Exchange Membranes. Compos. Part B Eng. 2019, 164, 324–332. [Google Scholar] [CrossRef]

- Nwabara, U.O.; Hernandez, A.D.; Henckel, D.A.; Chen, X.; Cofell, E.R.; De-Heer, M.P.; Verma, S.; Gewirth, A.A.; Kenis, P.J.A. Binder-Focused Approaches to Improve the Stability of Cathodes for CO2 Electroreduction. ACS Appl. Energy Mater. 2021, 4, 5175–5186. [Google Scholar] [CrossRef]

- Liu, Z.; Masel, R.I.; Chen, Q.; Kutz, R.; Yang, H.; Lewinski, K.; Kaplun, M.; Luopa, S.; Lutz, D.R. Electrochemical Generation of Syngas from Water and Carbon Dioxide at Industrially Important Rates. J. CO2 Util. 2016, 15, 50–56. [Google Scholar] [CrossRef]

- Koshy, D.M.; Akhade, S.A.; Shugar, A.; Abiose, K.; Shi, J.; Liang, S.; Oakdale, J.S.; Weitzner, S.E.; Varley, J.B.; Duoss, E.B.; et al. Chemical Modifications of Ag Catalyst Surfaces with Imidazolium Ionomers Modulate H2 Evolution Rates during Electrochemical CO2 Reduction. J. Am. Chem. Soc. 2021, 143, 14712–14725. [Google Scholar] [CrossRef] [PubMed]

- Esposito, D.V. Membrane-Coated Electrocatalysts—An Alternative Approach to Achieving Stable and Tunable Electrocatalysis. ACS Catal. 2018, 8, 457–465. [Google Scholar] [CrossRef]

- Liu, Y.; Leung, K.Y.; Michaud, S.E.; Soucy, T.L.; McCrory, C.C.L. Controlled Substrate Transport to Electrocatalyst Active Sites for Enhanced Selectivity in the Carbon Dioxide Reduction Reaction. Comments Inorg. Chem. 2019, 39, 242–269. [Google Scholar] [CrossRef]

- Dutta, A.; Rahaman, M.; Luedi, N.C.; Mohos, M.; Broekmann, P. Morphology Matters: Tuning the Product Distribution of CO2 Electroreduction on Oxide-Derived Cu Foam Catalysts. ACS Catal. 2016, 6, 3804–3814. [Google Scholar] [CrossRef]

- Berggren, M.; Malliaras, G.G. How Conducting Polymer Electrodes Operate. Science 2019, 364, 233–234. [Google Scholar] [CrossRef]

- Pham, T.H.M.; Zhang, J.; Li, M.; Shen, T.H.; Ko, Y.; Tileli, V.; Luo, W.; Züttel, A. Enhanced Electrocatalytic CO2 Reduction to C2+ Products by Adjusting the Local Reaction Environment with Polymer Binders. Adv. Energy Mater. 2022, 12, 2103663. [Google Scholar] [CrossRef]

- Ahn, S.; Klyukin, K.; Wakeham, R.J.; Rudd, J.A.; Lewis, A.R.; Alexander, S.; Carla, F.; Alexandrov, V.; Andreoli, E. Poly-Amide Modified Copper Foam Electrodes for Enhanced Electrochemical Reduction of Carbon Dioxide. ACS Catal. 2018, 8, 4132–4142. [Google Scholar] [CrossRef]

- Ma, J.; Sahai, Y. Chitosan Biopolymer for Fuel Cell Applications. Carbohydr. Polym. 2013, 92, 955–975. [Google Scholar] [CrossRef]

- Wang, J.; Zhao, Y.; Hou, W.; Geng, J.; Xiao, L.; Wu, H.; Jiang, Z. Simultaneously Enhanced Methanol Barrier and Proton Conductive Properties of Phosphorylated Titanate Nanotubes Embedded Nanocomposite Membranes. J. Power Sources 2010, 195, 1015–1023. [Google Scholar] [CrossRef]

- García-Cruz, L.; Casado-Coterillo, C.; Irabien, Á.; Montiel, V.; Iniesta, J. Performance Assessment of a Polymer Electrolyte Membrane Electrochemical Reactor under Alkaline Conditions—A Case Study with the Electrooxidation of Alcohols. Electrochim. Acta 2016, 206, 165–175. [Google Scholar] [CrossRef]

- Vaghari, H.; Jafarizadeh-Malmiri, H.; Berenjian, A.; Anarjan, N. Recent Advances in Application of Chitosan in Fuel Cells. Sustain. Chem. Process. 2013, 1, 16. [Google Scholar] [CrossRef]

- Maiti, J.; Kakati, N.; Lee, S.H.; Jee, S.H.; Viswanathan, B.; Yoon, Y.S. Where Do Poly(Vinyl Alcohol) Based Membranes Stand in Relation to Nafion® for Direct Methanol Fuel Cell Applications? J. Power Sources 2012, 216, 48–66. [Google Scholar] [CrossRef]

- García-Cruz, L.; Casado-Coterillo, C.; Iniesta, J.; Montiel, V.; Irabien, Á. Chitosan: Poly (Vinyl) Alcohol Composite Alkaline Membrane Incorporating Organic Ionomers and Layered Silicate Materials into a PEM Electrochemical Reactor. J. Memb. Sci. 2016, 498, 395–407. [Google Scholar] [CrossRef]

- Marcos-Madrazo, A.; Casado-Coterillo, C.; García-Cruz, L.; Iniesta, J.; Simonelli, L.; Sebastián, V.; Encabo-Berzosa, M.d.M.; Arruebo, M.; Irabien, Á. Preparation and Identification of Optimal Synthesis Conditions for a Novel Alkaline Anion-Exchange Membrane. Polymers 2018, 10, 913. [Google Scholar] [CrossRef]

- Marcos-Madrazo, A.; Casado-Coterillo, C.; Irabien, Á. Sustainable Membrane-Coated Electrodes for CO2 Electroreduction to Methanol in Alkaline Media. ChemElectroChem 2019, 6, 5273–5282. [Google Scholar] [CrossRef]

- Larrazábal, G.O.; Martín, A.J.; Pérez-Ramírez, J. Building Blocks for High Performance in Electrocatalytic CO2 Reduction: Materials, Optimization Strategies, and Device Engineering. J. Phys. Chem. Lett. 2017, 8, 3933–3944. [Google Scholar] [CrossRef]

- Lv, W.; Zhou, J.; Bei, J.; Zhang, R.; Wang, L.; Xu, Q.; Wang, W. Electrodeposition of Nano-Sized Bismuth on Copper Foil as Electrocatalyst for Reduction of CO2 to Formate. Appl. Surf. Sci. 2017, 393, 191–196. [Google Scholar] [CrossRef]

- Díaz-Sainz, G.; Alvarez-Guerra, M.; Solla-Gullón, J.; García-Cruz, L.; Montiel, V.; Irabien, A. CO2 Electroreduction to Formate: Continuous Single-Pass Operation in a Filter-Press Reactor at High Current Densities Using Bi Gas Diffusion Electrodes. J. CO2 Util. 2019, 34, 12–19. [Google Scholar] [CrossRef]

- Yang, H.; Kaczur, J.J.; Sajjad, S.D.; Masel, R.I. Electrochemical Conversion of CO2 to Formic Acid Utilizing SustainionTM Membranes. J. CO2 Util. 2017, 20, 208–217. [Google Scholar] [CrossRef]

- O’Brien, C.P.; Miao, R.K.; Liu, S.; Xu, Y.; Lee, G.; Robb, A.; Huang, J.E.; Xie, K.; Bertens, K.; Gabardo, C.M.; et al. Single Pass CO2 Conversion Exceeding 85% in the Electrosynthesis of Multicarbon Products via Local CO2 Regeneration. ACS Energy Lett. 2021, 6, 2952–2959. [Google Scholar] [CrossRef]

- Wang, Y.; Shen, Z.; Li, Y.; Niu, J. Electrochemical Properties of the Erbium-Chitosan-Fluorine-Modified PbO2 Electrode for the Degradation of 2,4-Dichlorophenol in Aqueous Solution. Chemosphere 2010, 79, 987–996. [Google Scholar] [CrossRef] [PubMed]

- de Sousa, L.; Harmoko, C.; Benes, N.; Mul, G. Optimizing the Ink Formulation for Preparation of Cu-Based Gas Diffusion Electrodes Yielding Ethylene in Electroreduction of CO2. ACS ES&T Eng. 2021, 1, 1649–1658. [Google Scholar] [CrossRef]

- Li, J.; Chang, K.; Zhang, H.; He, M.; Goddard, W.A.; Chen, J.G.; Cheng, M.J.; Lu, Q. Effectively Increased Efficiency for Electroreduction of Carbon Monoxide Using Supported Polycrystalline Copper Powder Electrocatalysts. ACS Catal. 2019, 9, 4709–4718. [Google Scholar] [CrossRef]

- Bui, J.C.; Kim, C.; Weber, A.Z.; Bell, A.T. Dynamic boundary layer simulation of pulsed CO2 electrolysis on a copper catalyst. ACS Energy Lett. 2021, 6, 1181–1188. [Google Scholar] [CrossRef]

- Tatin, A.; Comminges, C.; Kokoh, B.; Costentin, C.; Robert, M.; Savéant, J.M. Efficient Electrolyzer for CO2 Splitting in Neutral Water Using Earth-Abundant Materials. Proc. Natl. Acad. Sci. USA 2016, 113, 5526–5529. [Google Scholar] [CrossRef]

- Jeong, S.; Ohto, T.; Nishiuchi, T.; Nagata, Y.; Fujita, J.; Ito, Y. Polyethylene Glycol Covered Sn Catalysts Accelerate the Formation Rate of Formate by Carbon Dioxide Reduction. ACS Catal. 2021, 11, 9962–9969. [Google Scholar] [CrossRef]

- Casado-Coterillo, C.; Fernández-Barquín, A.; Zornoza, B.; Téllez, C.; Coronas, J.; Irabien, Á. Synthesis and Characterisation of MOF/Ionic Liquid/Chitosan Mixed Matrix Membranes for CO2/N2 Separation. RSC Adv. 2015, 5, 102350–102361. [Google Scholar] [CrossRef]

- Casado-Coterillo, C.; Garea, A.; Irabien, Á. Effect of Water and Organic Pollutant in CO2/CH4 Separation Using Hydrophilic and Hydrophobic Composite Membranes. Membranes 2020, 10, 405. [Google Scholar] [CrossRef]

- Wang, L.; Nitopi, S.A.; Bertheussen, E.; Orazov, M.; Morales-Guio, C.G.; Liu, X.; Higgins, D.C.; Chan, K.; Nørskov, J.K.; Hahn, C.; et al. Electrochemical Carbon Monoxide Reduction on Polycrystalline Copper: Effects of Potential, Pressure, and PH on Selectivity toward Multicarbon and Oxygenated Products. ACS Catal. 2018, 8, 7445–7454. [Google Scholar] [CrossRef]

- Choi, W.; Park, S.; Jung, W.; Won, D.H.; Na, J.; Hwang, Y.J. Origin of Hydrogen Incorporated into Ethylene during Electrochemical CO2 Reduction in Membrane Electrode Assembly. ACS Energy Lett. 2022, 7, 939–945. [Google Scholar] [CrossRef]

- Hoang, T.T.H.; Ma, S.; Gold, J.I.; Kenis, P.J.A.; Gewirth, A.A. Nanoporous Copper Films by Additive-Controlled Electrodeposition: CO2 Reduction Catalysis. ACS Catal. 2017, 7, 3313–3321. [Google Scholar] [CrossRef]

- Wang, Y.; Wang, Z.; Dinh, C.T.; Li, J.; Ozden, A.; Golam Kibria, M.; Seifitokaldani, A.; Tan, C.S.; Gabardo, C.M.; Luo, M.; et al. Catalyst synthesis under CO2 electroreduction favours faceting and promotes renewable fuels electrosynthesis. Nat. Catal. 2020, 3, 98–106. [Google Scholar] [CrossRef]

- Li, Y.C.; Wang, Z.; Yuan, T.; Nam, D.H.; Luo, M.; Wicks, J.; Chen, B.; Li, J.; Li, F.; De Arquer, F.P.G.; et al. Binding Site Diversity Promotes CO2 Electroreduction to Ethanol. J. Am. Chem. Soc. 2019, 141, 8584–8591. [Google Scholar] [CrossRef] [PubMed]

- Dinh, C.T.; Burdyny, T.; Kibria, G.; Seifitokaldani, A.; Gabardo, C.M.; Pelayo García De Arquer, F.; Kiani, A.; Edwards, J.P.; De Luna, P.; Bushuyev, O.S.; et al. CO2 electroreduction to ethylene via hydroxide-mediated copper catalysis at an abrupt interface. Science 2018, 360, 783–787. [Google Scholar] [CrossRef]

- Ma, S.; Sadakiyo, M.; Heim, M.; Luo, R.; Haasch, R.T.; Gold, J.I.; Yamauchi, M.; Kenis, P.J.A. Electroreduction of carbon dioxide to hydrocarbons using bimetallic Cu-Pd catalysts with different mixing patterns. J. Am. Chem. Soc. 2017, 139, 47–50. [Google Scholar] [CrossRef]

- Zhi, W.Y.; Liu, Y.T.; Shan, S.L.; Jiang, C.J.; Wang, H.; Lu, J.X. Efficient electroreduction of CO2 to C2-C3products on Cu/Cu2O@N-doped graphene. J. CO2 Util. 2021, 50, 101594. [Google Scholar] [CrossRef]

- Li, J.; Ozden, A.; Wan, M.; Hu, Y.; Li, F.; Wang, Y.; Zamani, R.R.; Ren, D.; Wang, Z.; Xu, Y.; et al. Silica-copper catalyst interfaces enable carbon-carbon coupling towards ethylene electrosynthesis. Nat. Commun. 2021, 12, 2808. [Google Scholar] [CrossRef]

- Luo, M.; Wang, Z.; Li, Y.C.; Li, J.; Li, F.; Lum, Y.; Nam, D.H.; Chen, B.; Wicks, J.; Xu, A.; et al. Hydroxide promotes carbon dioxide electroreduction to ethanol on copper via tuning of adsorbed hydrogen. Nat. Commun. 2019, 10, 5814. [Google Scholar] [CrossRef]

- Ma, W.; Xie, S.; Liu, T.; Fan, Q.; Ye, J.; Sun, F.; Jiang, Z.; Zhang, Q.; Cheng, J.; Wang, Y. Electrocatalytic reduction of CO2 to ethylene and ethanol through hydrogen-assisted C–C coupling over fluorine-modified copper. Nat. Catal. 2020, 3, 478–487. [Google Scholar] [CrossRef]

- Brée, L.C.; Wessling, M.; Mitsos, A. Modular modeling of electrochemical reactors: Comparison of CO2-electolyzers. Comput. Chem. Eng. 2020, 139, 106890. [Google Scholar] [CrossRef]

- Yano, H.; Tanaka, T.; Nakayama, M.; Ogura, K. Selective electrochemical reduction of CO2 to ethylene at a three-phase interface on copper(I) halide-confined Cu-mesh electrodes in acidic solutions of potassium halides. J. Electroanal. Chem. 2004, 565, 287–293. [Google Scholar] [CrossRef]

| Catalyst/Cathode Type | (Ionic) Binding Type | Catalyst Loading (mg/cm2) | Membrane Overlayer | Reference | |

|---|---|---|---|---|---|

| Material Composition | Thickness (µm) | ||||

| Cu NP:CS/C | CS (1 wt.% in acetic acid/H2O) | 1.0 | - | - | [68] |

| CS:PVA/Cu NP/C | CS (1 wt.% in acetic acid/H2O) | 1.0 | CS:PVA | 52 ± 1.67 | [68] |

| CuUZAR-S3/CS:PVA/Cu-NP/C | CS (1 wt.% in acetic acid/H2O) | 1.0 | CuUZAR-S3/CS:PVA | 46 ± 0.51 | [68] |

| CuY/CS:PVA/Cu-NP/C | CS (1 wt.% in acetic acid/H2O) | 1.0 | CuY/CS:PVA | 47 ± 1.98 | [68] |

| Cu NP:S/C | Sustainion XA-9 (5 wt.% in ethanol) | 1.0 | - | - | This work |

| Cu NP:F/C | Fumion FAA-3 (10 wt.% in NMP) | 1.0 | - | - | This work |

| MEA Components | Anolyte | j (mA/cm2) | Ecat (V vs. RHE) | EE (C2H4) (%) | |

|---|---|---|---|---|---|

| Electrode | Membrane | ||||

| Cu:Fumion GDE | Fumatech FAA-3 (AEM) | 1 M KOH | 10 | 0.57 | 27.2 ± 0.7 |

| 50 | 0.83 | 20.4 ± 1.9 | |||

| 90 | 0.92 | 18.6 ± 0.6 | |||

| Cu:Sustainion 1 GDE | Sustainion X37 (AEM) | 1 M KOH | 10 | 0.48 | 55.2 ± 1.1 |

| 50 | 0.51 | 42.0 ± 1.2 | |||

| 90 | 0.62 | 33.0 ± 1.2 | |||

| Cu:CS GDE | Sustainion X37 (AEM) | 1 M KOH | 10 | 0.53 | 56.4 ± 2.3 |

| 50 | 0.55 | 41.0 ± 6.1 | |||

| 90 | 0.74 | 33.5 ± 2.4 | |||

| Cu:CS GDE | CS:PVA (AEM) | 1 M KOH | 10 | 0.94 | 10.7 ± 6.1 |

| 50 | 1.96 | 12.0 ± 1.0 | |||

| 90 | 2.43 | 10.3 ± 1.0 | |||

| Cu:CS GDE | CuY@CuUZAR-S3/ CS:PVA (AEM) | 1 M KOH | 10 | 1.32 | 23.4 ± 4.8 |

| 50 | 2.05 | 17.9 ± 1.3 | |||

| 90 | 2.78 | 8.90 ± 0.3 | |||

| MEA Components | Anolyte | J (mA cm−2) | Ecat (V vs. RHE) | EE (C2H4) (%) | |

|---|---|---|---|---|---|

| Electrode | Membrane | ||||

| CS:PVA/Cu/C MCE | Sustainion (AEM) | 1 M KOH | 10 | 1.26 | 27.8 ± 3.4 |

| CuUZAR-S3CS:PVA/Cu/C MCE | Sustainion (AEM) | 1 M KOH | 10 | 0.87 | 37.8 ± 0.4 |

| CuYCS:PVA/Cu/C MCE | Sustainion (AEM) | 1 M KOH | 10 | 0.96 | 13.3 ± 0.3 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Marcos-Madrazo, A.; Casado-Coterillo, C.; Iniesta, J.; Irabien, A. Use of Chitosan as Copper Binder in the Continuous Electrochemical Reduction of CO2 to Ethylene in Alkaline Medium. Membranes 2022, 12, 783. https://doi.org/10.3390/membranes12080783

Marcos-Madrazo A, Casado-Coterillo C, Iniesta J, Irabien A. Use of Chitosan as Copper Binder in the Continuous Electrochemical Reduction of CO2 to Ethylene in Alkaline Medium. Membranes. 2022; 12(8):783. https://doi.org/10.3390/membranes12080783

Chicago/Turabian StyleMarcos-Madrazo, Aitor, Clara Casado-Coterillo, Jesús Iniesta, and Angel Irabien. 2022. "Use of Chitosan as Copper Binder in the Continuous Electrochemical Reduction of CO2 to Ethylene in Alkaline Medium" Membranes 12, no. 8: 783. https://doi.org/10.3390/membranes12080783

APA StyleMarcos-Madrazo, A., Casado-Coterillo, C., Iniesta, J., & Irabien, A. (2022). Use of Chitosan as Copper Binder in the Continuous Electrochemical Reduction of CO2 to Ethylene in Alkaline Medium. Membranes, 12(8), 783. https://doi.org/10.3390/membranes12080783