Analysis and Experimental Study on Water Vapor Partial Pressure in the Membrane Distillation Process

Abstract

:1. Introduction

2. Materials and Methods

2.1. Vapor-Liquid Equilibrium State

2.2. Standard Measurement of Water Vapor Saturation Pressure

2.3. The Saturation Pressure of the Aqueous Solution

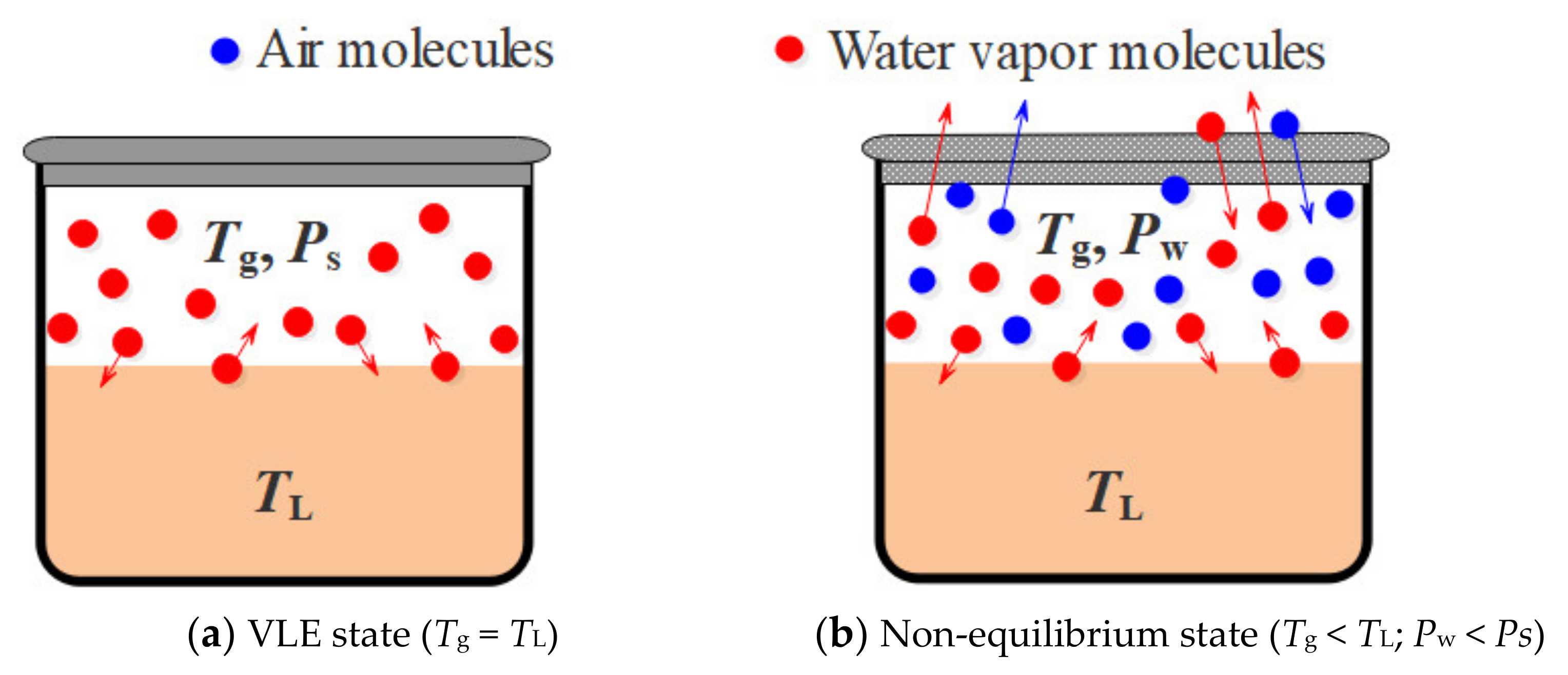

2.4. Non-Equilibrium State in Membrane Distillation

3. Experiments

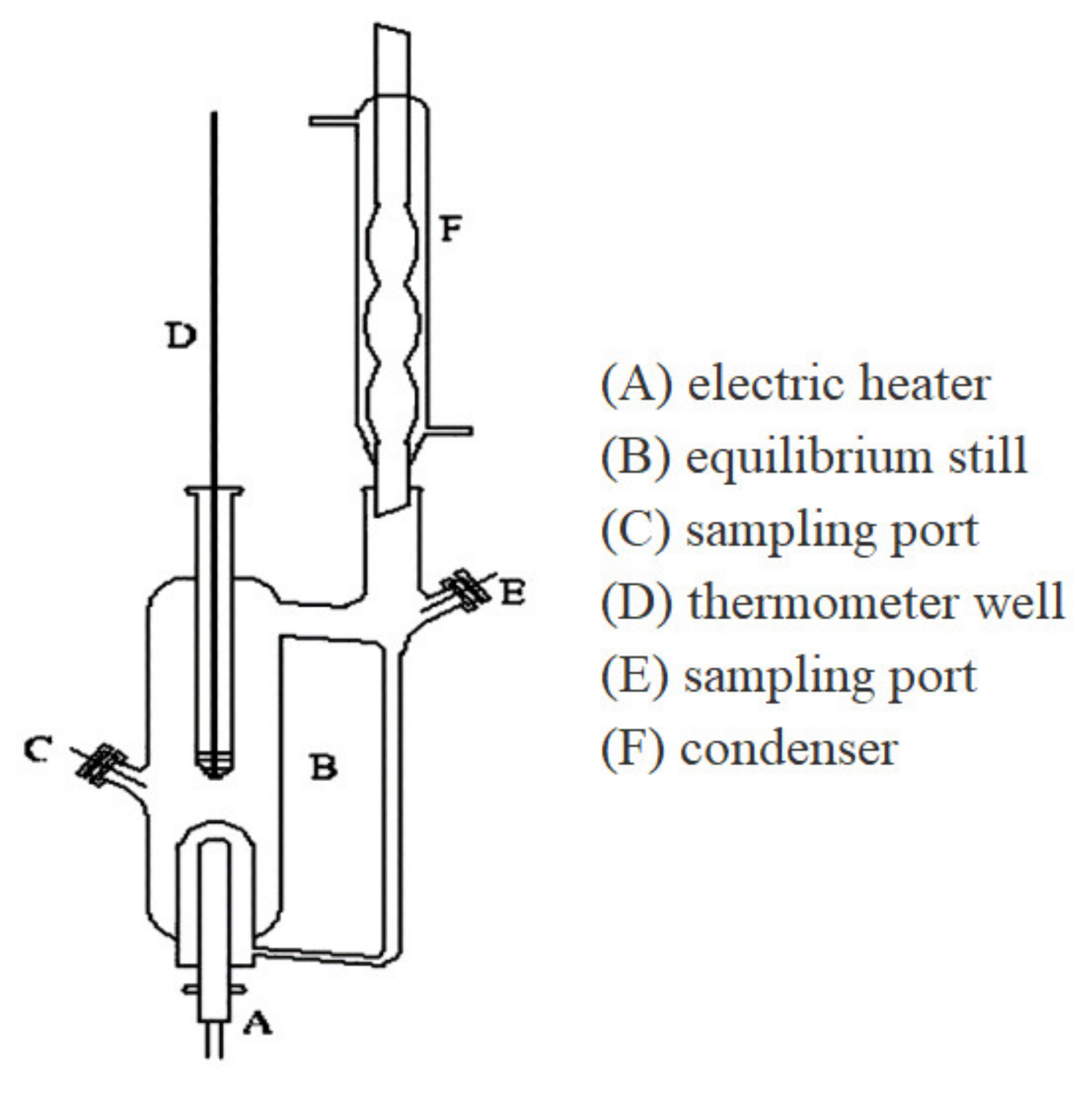

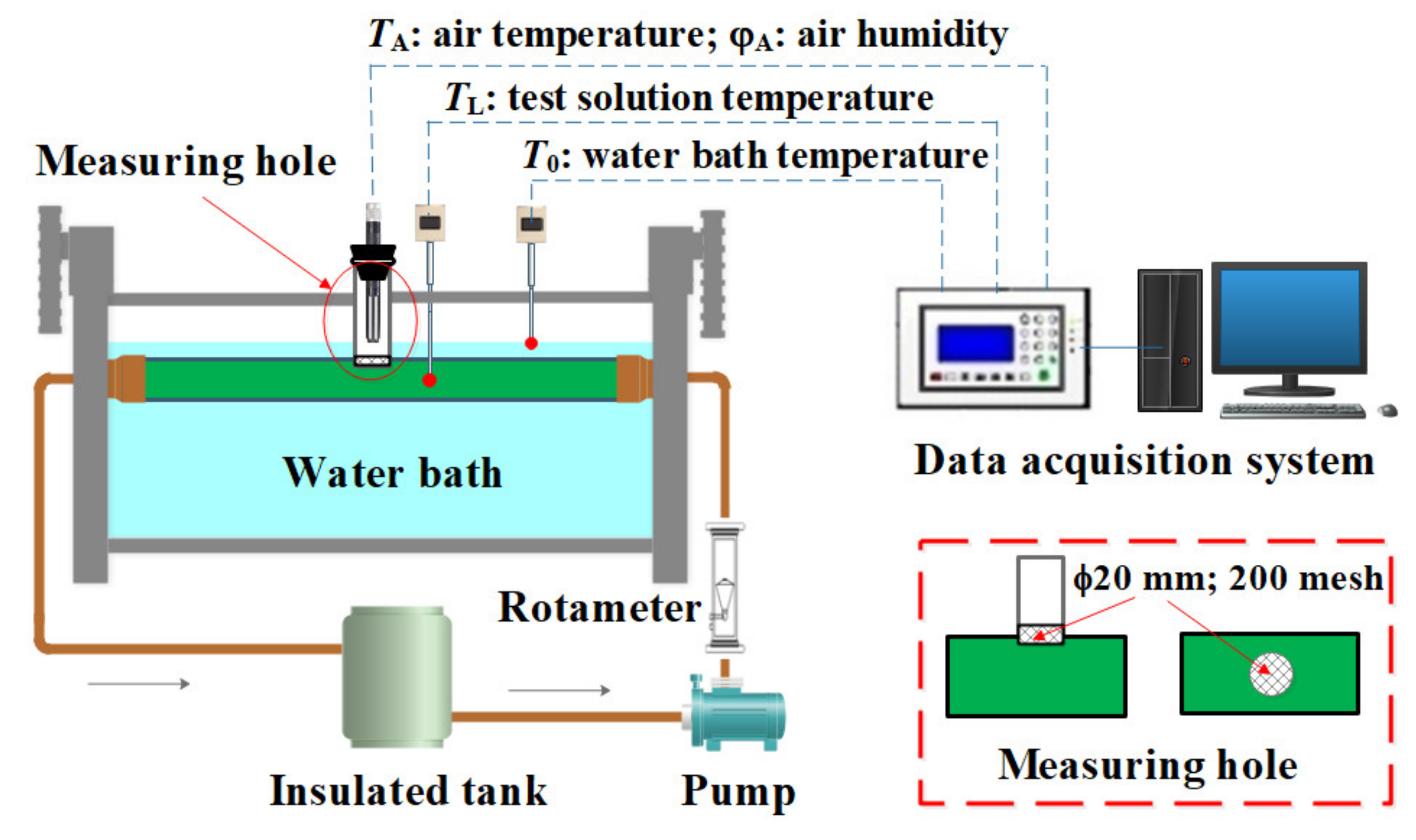

3.1. Method

3.2. Uncertainty Analysis of the Experimental Measurements

3.3. Test Results and Discussion

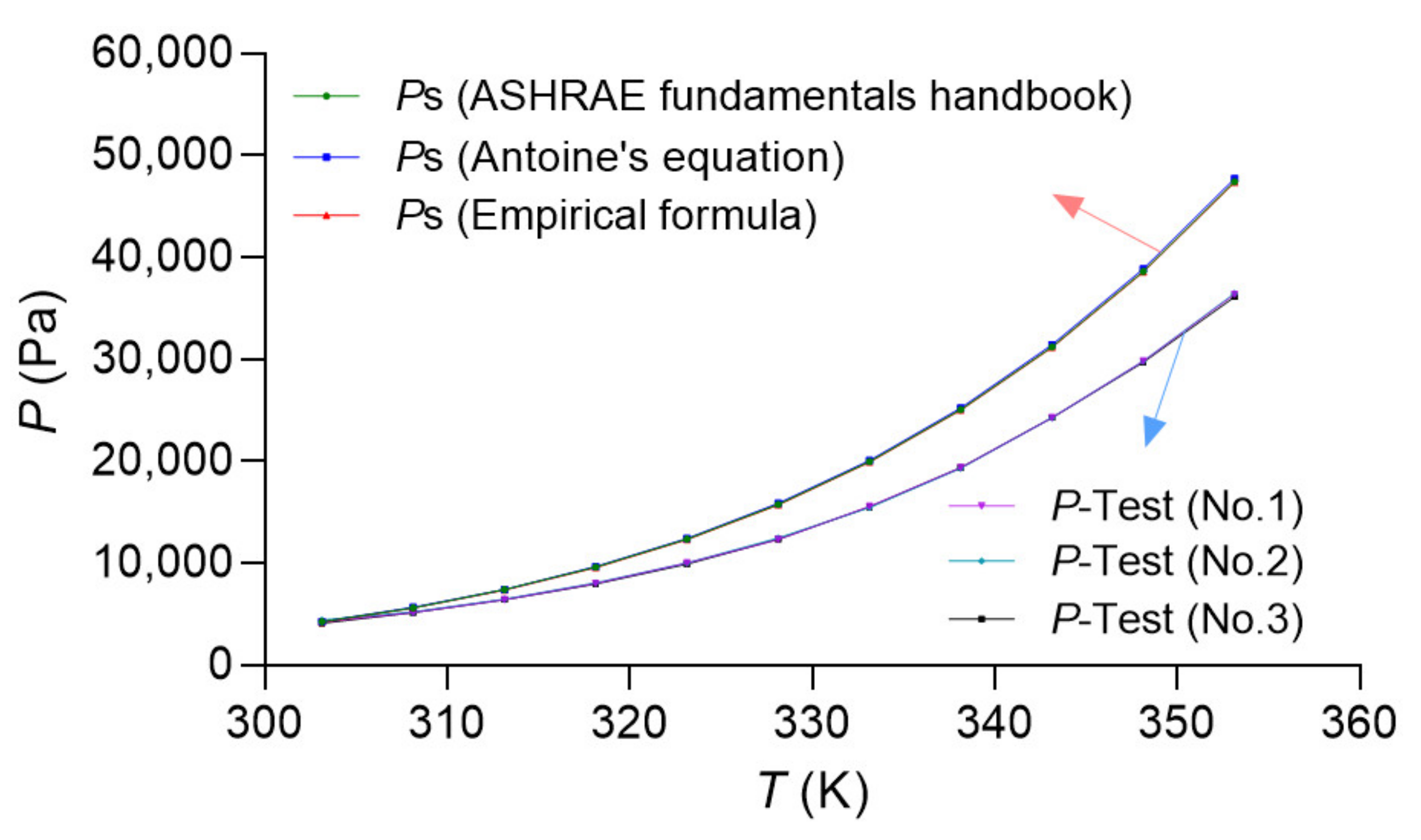

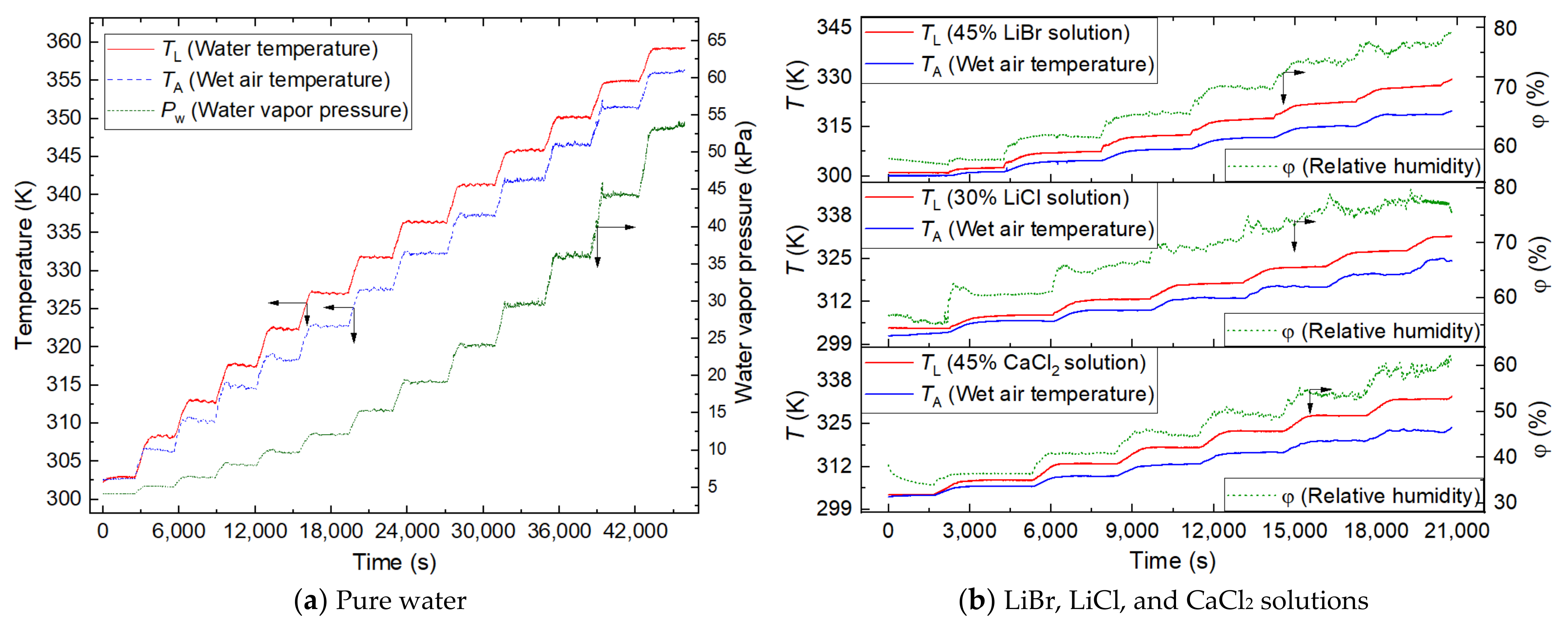

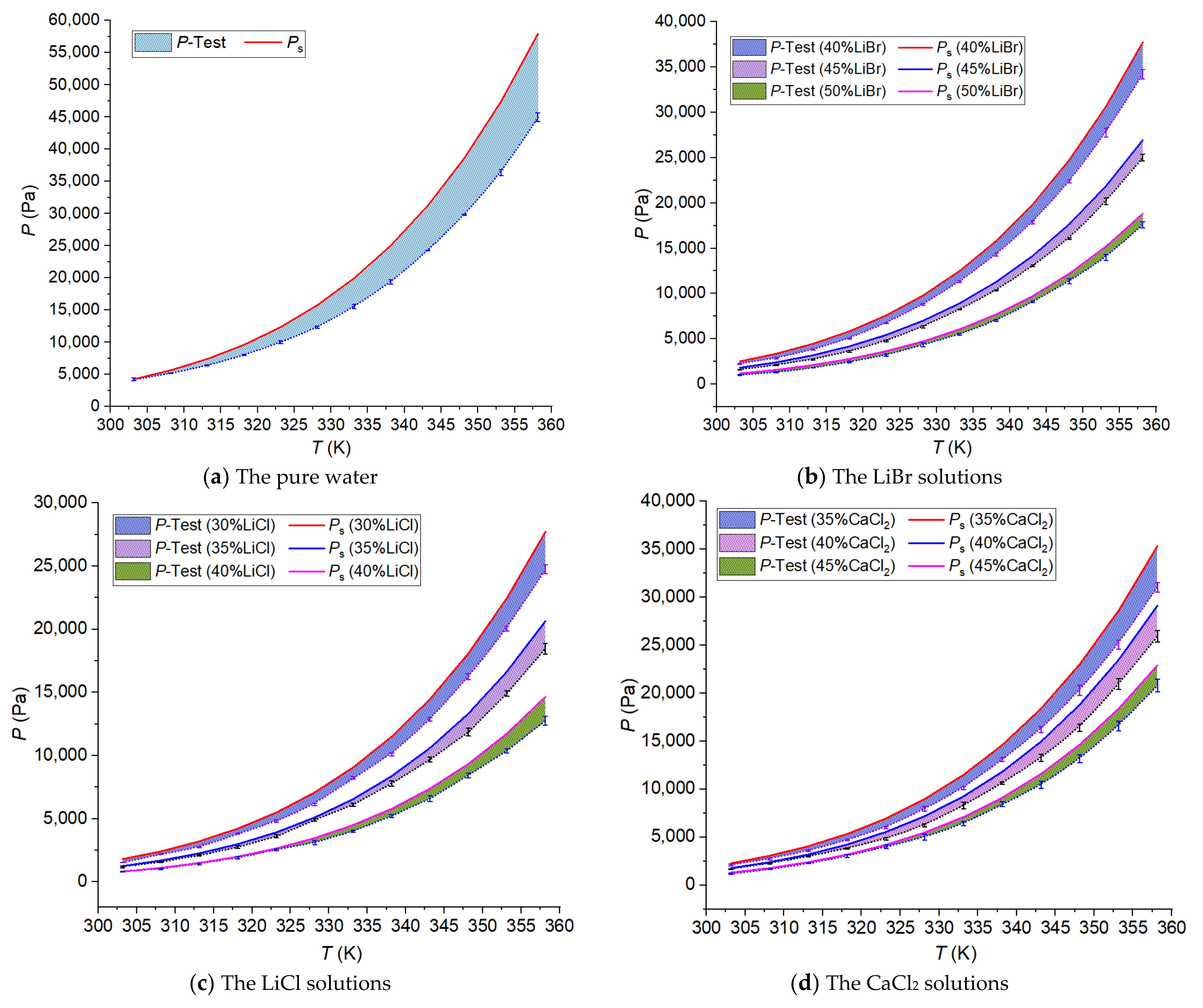

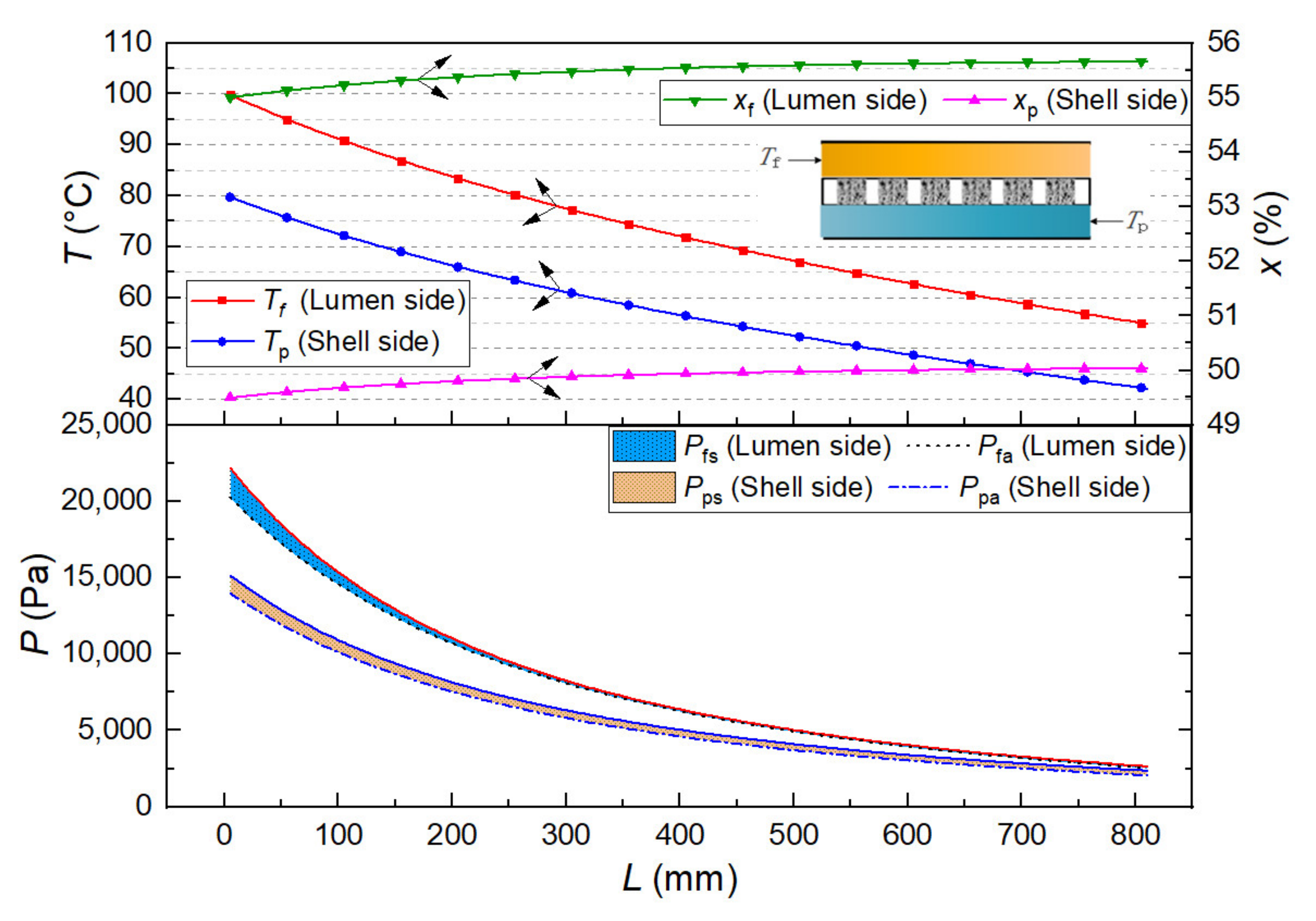

3.3.1. Test Results

3.3.2. Results Comparison

3.3.3. Discussion

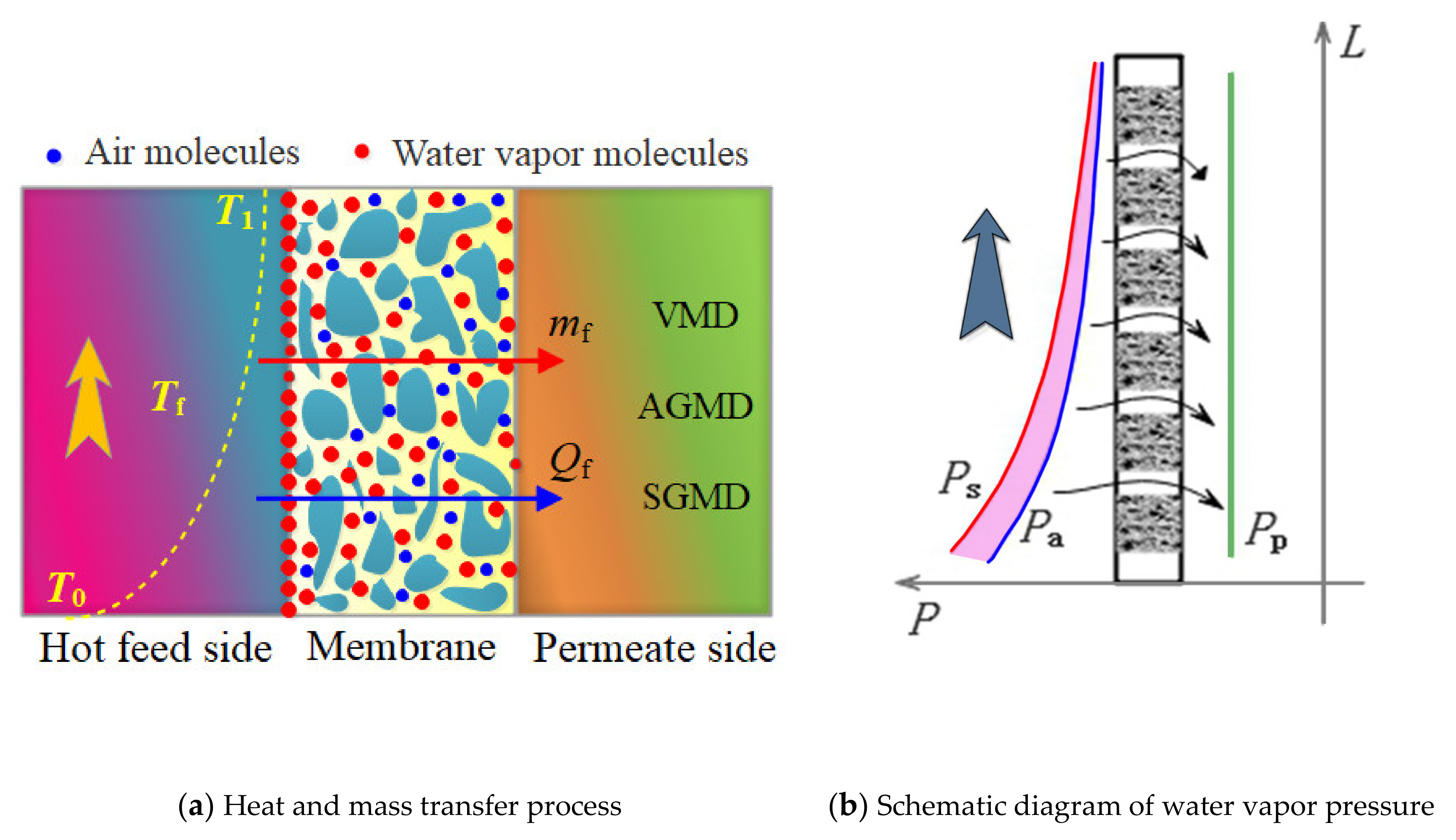

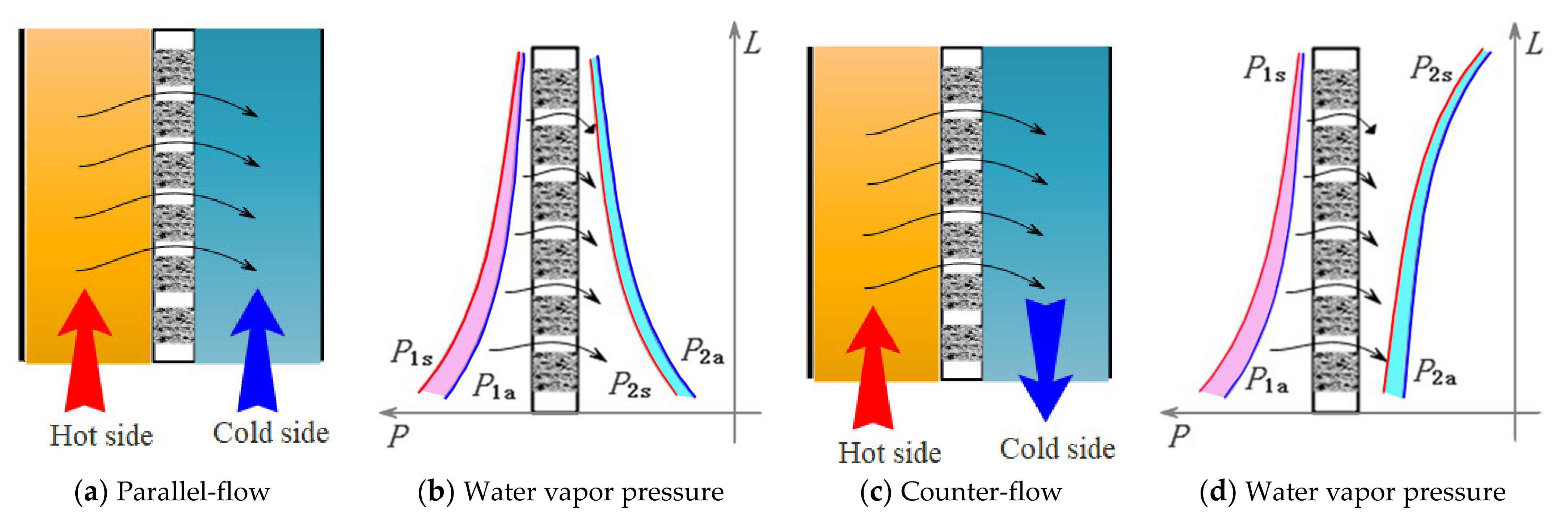

4. The Water Vapor Pressure in the Membrane Distillation Process

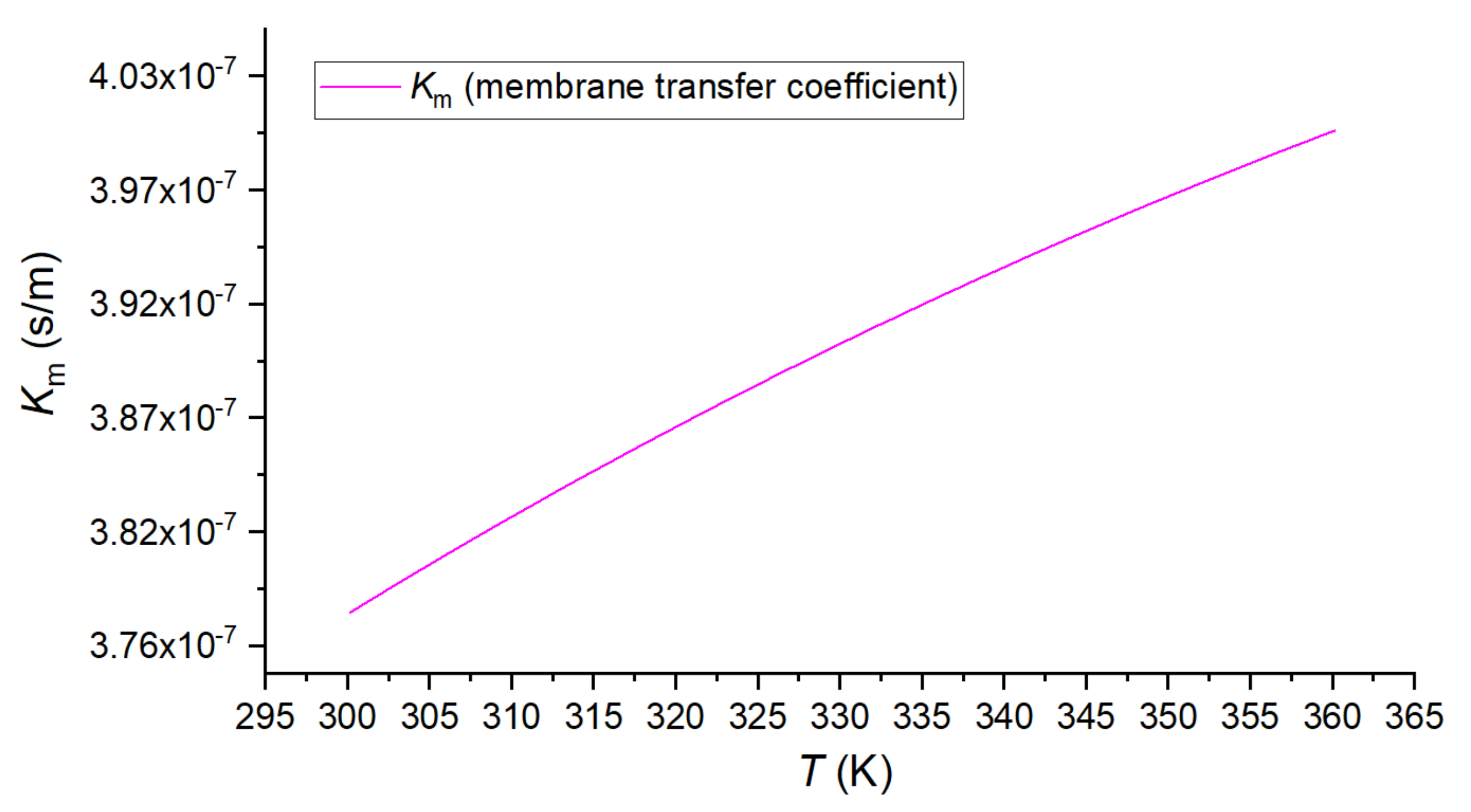

4.1. The Membrane Transfer Coefficient Km

4.2. The VMD, AGMD, and SGMD Process

4.3. The DCMD Process

4.4. Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Boubakri, A.; Bouguecha, S.A.; Hafiane, A. Box-Behnken design assisted by theoretical mass and heat transfer using for multi-responses optimization of membrane distillation process. Chem. Pap. 2021, 75, 6009–6024. [Google Scholar] [CrossRef]

- Liu, J.; Li, X.; Zhang, W.; Li, B.; Liu, C. Superhydrophobic-slip surface based heat and mass transfer mechanism in vacuum membrane distillation. J. Membr. Sci. 2020, 614, 118505. [Google Scholar] [CrossRef]

- Yang, X.; Duke, M.; Zhang, J.H.; Li, J.D. Modeling of heat and mass transfer in vacuum membrane distillation for ammonia separation. Sep. Purif. Technol. 2019, 224, 121–131. [Google Scholar] [CrossRef]

- Thomas, N.; Sreedhar, N.; Al-Ketan, O.; Rowshan, R.; Abu Al-Rub, R.K.; Arafat, H. 3D printed triply periodic minimal surfaces as spacers for enhanced heat and mass transfer in membrane distillation. Desalination 2018, 443, 256–271. [Google Scholar] [CrossRef]

- Yu, H.; Yang, X.; Wang, R.; Fane, A.G. Analysis of heat and mass transfer by CFD for performance enhancement in direct contact membrane distillation. J. Membr. Sci. 2012, 405, 38–47. [Google Scholar] [CrossRef]

- Chen, T.-C.; Ho, C.-D.; Yeh, H.-M. Theoretical modeling and experimental analysis of direct contact membrane distillation. J. Membr. Sci. 2009, 330, 279–287. [Google Scholar] [CrossRef]

- Diban, N.; Voinea, O.C.; Urtiaga, A.; Ortiz, I. Vacuum membrane distillation of the main pear aroma compound: Experimental study and mass transfer modeling. J. Membr. Sci. 2009, 326, 64–75. [Google Scholar] [CrossRef]

- Soni, V.; Abildskov, J.; Jonsson, G.; Gani, R. A general model for membrane-based separation processes. Comput. Chem. Eng. 2009, 33, 644–659. [Google Scholar] [CrossRef]

- Ding, Z.; Ma, R.; Fane, A.G. A new model for mass transfer in direct contact membrane distillation. Desalination 2003, 151, 217–227. [Google Scholar] [CrossRef]

- Alkhudhiri, A.; Darwish, N.; Hilal, N. Membrane distillation: A comprehensive review. Desalination 2012, 287, 2–18. [Google Scholar] [CrossRef]

- Khayet, M. Membranes and theoretical modeling of membrane distillation: A review. Adv. Colloid Interface Sci. 2011, 164, 56–88. [Google Scholar] [CrossRef]

- Liu, X.; Qu, M.; Liu, X.; Wang, L. Membrane-based liquid desiccant air dehumidification: A comprehensive review on materials, components, systems and performances. Renew. Sustain. Energy Rev. 2019, 110, 444–466. [Google Scholar] [CrossRef]

- Qtaishat, M.; Matsuura, T.; Kruczek, B.; Khayet, M. Heat and mass transfer analysis in direct contact membrane distillation. Desalination 2008, 219, 272–292. [Google Scholar] [CrossRef]

- May, P.M.; Rowland, D. Thermodynamic Modeling of Aqueous Electrolyte Systems: Current Status. J. Chem. Eng. Data 2017, 62, 2481–2495. [Google Scholar] [CrossRef]

- Li, J.; Polka, H.-M.; Gmehling, J. A gE model for single and mixed solvent electrolyte systems: 1. Model and results for strong electrolytes. Fluid Phase Equilibria 1994, 94, 89–114. [Google Scholar] [CrossRef]

- Xu, X.; Hu, Y.; Wang, X.; Wu, L. Experimental and Modeling of Vapor–Liquid Equilibria for Mixed Electrolyte Solution Systems. J. Chem. Eng. Data 2016, 61, 2311–2320. [Google Scholar] [CrossRef]

- Xu, X.; Hu, Y.; Wu, L.; Zhang, S. Experimental and Modeling of Vapor–Liquid Equilibria for Electrolyte Solution Systems. J. Chem. Eng. Data 2014, 59, 3741–3748. [Google Scholar] [CrossRef]

- Kretzschmar, H.J.; Cooper, J.R.; Dittmann, A.; Friend, D.G.; Gallagher, J.S.; Knobloch, K.; Mares, R.; Miyagawa, K.; Stocker, I.; Trubenbach, J.; et al. Supplementary backward equations for pressure as a function of enthalpy and entropy p(h, s) to the industrial formulation IAPWS-IF97 for water and steam. J. Eng. Gas Turbines Power-Trans. Asme 2006, 128, 702–713. [Google Scholar] [CrossRef]

- Wagner, W.; Rukes, B. IAPWS-IF97: The new industrial formulation. Brennst. -Warme-Kraft 1998, 50, 42–47. [Google Scholar]

- Daen, J.A. Lange’s Handbook of Chemistry; McGraw-Hill Inc.: New York, NY, USA, 1999. [Google Scholar]

- Kujawa, J.; Kujawski, W. Driving force and activation energy in air-gap membrane distillation process. Chem. Pap. 2015, 69, 1438–1444. [Google Scholar] [CrossRef]

- Lee, J.-G.; Lee, E.-J.; Jeong, S.; Guo, J.; An, A.K.; Guo, H.; Kim, J.; Leiknes, T.; Ghaffour, N. Theoretical modeling and experimental validation of transport and separation properties of carbon nanotube electrospun membrane distillation. J. Membr. Sci. 2017, 526, 395–408. [Google Scholar] [CrossRef]

- Liu, J.; Wang, Q.; Shan, H.; Guo, H.; Li, B. Surface hydrophobicity based heat and mass transfer mechanism in membrane distillation. J. Membr. Sci. 2019, 580, 275–288. [Google Scholar] [CrossRef]

- Liu, J.; Liu, M.; Guo, H.; Zhang, W.; Xu, K.; Li, B. Mass transfer in hollow fiber vacuum membrane distillation process based on membrane structure. J. Membr. Sci. 2017, 532, 115–123. [Google Scholar] [CrossRef]

- Imdakm, A.O.; Matsuura, T. Simulation of heat and mass transfer in direct contact membrane distillation (MD): The effect of membrane physical properties. J. Membr. Sci. 2005, 262, 117–128. [Google Scholar] [CrossRef]

- Alklaibi, A.M.; Lior, N. Heat and mass transfer resistance analysis of membrane distillation. J. Membr. Sci. 2006, 282, 362–369. [Google Scholar] [CrossRef]

- Bui, V.A.; Vu, L.T.T.; Nguyen, M.H. Modelling the simultaneous heat and mass transfer of direct contact membrane distillation in hollow fibre modules. J. Membr. Sci. 2010, 353, 85–93. [Google Scholar] [CrossRef]

- Ismail, M.S.; Mohamed, A.M.; Poggio, D.; Pourkashanian, M. Direct contact membrane distillation: A sensitivity analysis and an outlook on membrane effective thermal conductivity. J. Membr. Sci. 2021, 624, 119035. [Google Scholar] [CrossRef]

- Said, I.A.; Chomiak, T.; Floyd, J.; Li, Q. Sweeping gas membrane distillation (SGMD) for wastewater treatment, concentration, and desalination: A comprehensive review. Chem. Eng. Processing-Process Intensif. 2020, 153, 107960. [Google Scholar] [CrossRef]

- William, E.A., Jr.; James, S.C. Thermophysical Properties of Fluid Systems. In NIST Chemistry WebBook, NIST Standard Reference Database Number 69; Linstrom, P.J., Mallard, W.G., Eds.; National Institute of Standards and Technology: Gaithersburg, MD, USA; p. 20899. Available online: https://doi.org/10.18434/T4D303 (accessed on 29 July 2022).

- Yaws, C.L. Yaws’ Handbook of Vapor Pressure: Antoine Coefficients; Gulf Publishing: Houston, TX, USA, 2007; ISBN 1-933762-10-1. [Google Scholar]

- Huang, J.; Li, J.; Gmehling, J. Prediction of solubilities of salts, osmotic coefficients and vapor–liquid equilibria for single and mixed solvent electrolyte systems using the LIQUAC model. Fluid Phase Equilibria 2009, 275, 8–20. [Google Scholar] [CrossRef]

- Wang, H.; Chen, H.; Chen, W.; Sun, H.; Xu, X. Vapor–Liquid Equilibrium Study of LiBr + H2O and LiBr + CaCl2 + H2O Systems. Front. Chem. 2020, 7, 890. [Google Scholar] [CrossRef]

- Xu, X.; Wang, Y.; Sun, X.; Zhou, Y. Vapor–Liquid Equilibria Study of the LiCl + CaCl2 + H2O System. ACS Omega 2019, 4, 4390–4396. [Google Scholar] [CrossRef]

- Saul, A.; Wagner, W. A Fundamental Equation for Water Covering the Range from the Melting Line to 1273 K at Pressures up to 25,000 MPa. J. Phys. Chem. Ref. Data 1989, 18, 1537–1564. [Google Scholar] [CrossRef]

- Wagner, W.; Pruss, A. The IAPWS Formulation 1995 for the Thermodynamic Properties of Ordinary Water Substance for General and Scientific Use. J. Phys. Chem. Ref. Data 2002, 31, 387–535. [Google Scholar] [CrossRef]

- Kunz, O.; Wagner, W. The GERG-2008 Wide-Range Equation of State for Natural Gases and Other Mixtures: An Expansion of GERG-2004. J. Chem. Eng. Data 2012, 57, 3032–3091. [Google Scholar] [CrossRef]

- Wisniak, J. Historical development of the vapor pressure equation from dalton to antoine. J. Phase Equilibria 2001, 22, 622. [Google Scholar] [CrossRef]

- Khalifa, A.; Ahmad, H.; Antar, M.; Laoui, T.; Khayet, M. Experimental and theoretical investigations on water desalination using direct contact membrane distillation. Desalination 2017, 404, 22–34. [Google Scholar] [CrossRef]

- Bouguecha, S.; Chouikh, R.; Dhahbi, M. Numerical study of the coupled heat and mass transfer in membrane distillation. Desalination 2003, 152, 245–252. [Google Scholar] [CrossRef]

- Huang, J.; Tang, T.Q.; He, Y.R. Numerical Simulation Study on the Mass and Heat Transfer in the Self-Heating Membrane Distillation Process. Ind. Eng. Chem. Res. 2021, 60, 12663–12674. [Google Scholar] [CrossRef]

- Orfi, J.; Loussif, N.; Davies, P.A. Heat and mass transfer in membrane distillation used for desalination with slip flow. Desalination 2016, 381, 135–142. [Google Scholar] [CrossRef]

- Wu, C.R.; Li, Z.G.; Zhang, J.H.; Jia, Y.; Gao, Q.J.; Lu, X.L. Study on the heat and mass transfer in air-bubbling enhanced vacuum membrane distillation. Desalination 2015, 373, 16–26. [Google Scholar] [CrossRef]

- Andrjesdottir, O.; Ong, C.L.; Nabavi, M.; Paredes, S.; Khalil, A.S.G.; Michel, B.; Poulikakos, D. An experimentally optimized model for heat and mass transfer in direct contact membrane distillation. Int. J. Heat Mass Transf. 2013, 66, 855–867. [Google Scholar] [CrossRef]

- Yu, H.; Yang, X.; Wang, R.; Fane, A.G. Numerical simulation of heat and mass transfer in direct membrane distillation in a hollow fiber module with laminar flow. J. Membr. Sci. 2011, 384, 107–116. [Google Scholar] [CrossRef]

- Ashrae. Thermophysical Properties of Refrigerants: 2017 ASHRAE Handbook: Fundamentals; ASHRAE: Atlanta, GA, USA, 2017. [Google Scholar]

- He, W.; Yu, P.; Hu, Z.; Lv, S.; Qin, M.; Yu, C. Experimental Study and Performance Analysis of a Portable Atmospheric Water Generator. Energies 2020, 13, 73. [Google Scholar] [CrossRef]

- Chua, H.T.; Toh, H.K.; Malek, A.; Ng, K.C.; Srinivasan, K. Improved thermodynamic property fields of LiBr–H2O solution. Int. J. Refrig. 2000, 23, 412–429. [Google Scholar] [CrossRef]

- Kaita, Y. Thermodynamic properties of lithium bromide–water solutions at high temperatures. Int. J. Refrig. 2001, 24, 374–390. [Google Scholar] [CrossRef]

- Pátek, J.; Klomfar, J. A computationally effective formulation of the thermodynamic properties of LiBr–H2O solutions from 273 to 500 K over full composition range. Int. J. Refrig. 2006, 29, 566–578. [Google Scholar] [CrossRef]

- Yuan, Z.; Herold, K. Thermodynamic Properties of Aqueous Lithium Bromide Using a Multiproperty Free Energy Correlation. HVACR Res. 2005, 11, 377–393. [Google Scholar] [CrossRef]

- Patil, K.R.; Tripathi, A.D.; Pathak, G.; Katti, S.S. Thermodynamic properties of aqueous electrolyte solutions. 1. Vapor pressure of aqueous solutions of lithium chloride, lithium bromide, and lithium iodide. J. Chem. Eng. Data 1990, 35, 166–168. [Google Scholar] [CrossRef]

- Chaudhari, S.K.; Patil, K.R. Thermodynamic Properties of Aqueous Solutions of Lithium Chloride. Phys. Chem. Liq. 2002, 40, 317–325. [Google Scholar] [CrossRef]

- Conde, M.R. Properties of aqueous solutions of lithium and calcium chlorides: Formulations for use in air conditioning equipment design. Int. J. Therm. Sci. 2004, 43, 367–382. [Google Scholar] [CrossRef]

- Patil, K.R.; Tripathi, A.D.; Pathak, G.; Katti, S.S. Thermodynamic properties of aqueous electrolyte solutions. 2. Vapor pressure of aqueous solutions of sodium bromide, sodium iodide, potassium chloride, potassium bromide, potassium iodide, rubidium chloride, cesium chloride, cesium bromide, cesium iodide, magnesium chloride, calcium chloride, calcium bromide, calcium iodide, strontium chloride, strontium bromide, strontium iodide, barium chloride, and barium bromide. J. Chem. Eng. Data 1991, 36, 225–230. [Google Scholar] [CrossRef]

- Ertas, A.; Anderson, E.E.; Kiris, I. Properties of a new liquid desiccant solution—Lithium chloride and calcium chloride mixture. Sol. Energy 1992, 49, 205–212. [Google Scholar] [CrossRef]

- Wang, Z.; Cui, F.; Wang, G.; Feng, S.; Zhao, M.; Gu, Z. Analysis of DCMD-Based Hollow Fiber Membrane Heat Exchanger. J. Chem. Eng. Jpn. 2013, 46, 573–582. [Google Scholar] [CrossRef]

- Wang, Z.; Gu, Z.; Feng, S.; Li, Y. Applications of membrane distillation technology in energy transformation process-basis and prospect. Chin. Sci. Bull. 2009, 54, 2766–2780. [Google Scholar] [CrossRef]

- Legg, R. Chapter 1—Properties of Humid Air. In Air Conditioning System Design; Legg, R., Ed.; Butterworth-Heinemann: Oxford, UK, 2017; pp. 1–28. [Google Scholar]

- Lisboa, K.M.; de Souza, J.R.B.; Naveira-Cotta, C.P.; Cotta, R.M. Heat and mass transfer in hollow-fiber modules for direct contact membrane distillation: Integral transforms solution and parametric analysis. Int. Commun. Heat Mass Transf. 2019, 109, 7. [Google Scholar] [CrossRef]

- Salem, M.S.; El-shazly, A.H.; Nady, N.; Elmarghany, M.R.; Shouman, M.A.; Sabry, M.N. 3-D numerical investigation on commercial PTFE membranes for membrane distillation: Effect of inlet conditions on heat and mass transfer. Case Stud. Therm. Eng. 2019, 13, 7. [Google Scholar] [CrossRef]

- Salmon, I.R.; Janssens, R.; Luis, P. Mass and heat transfer study in osmotic membrane distillation crystallization for CO2 valorization as sodium carbonate. Sep. Purif. Technol. 2017, 176, 173–183. [Google Scholar] [CrossRef]

- Liu, J.; Wang, Q.; Han, L.; Li, B.A. Simulation of heat and mass transfer with cross-flow hollow fiber vacuum membrane distillation: The influence of fiber arrangement. Chem. Eng. Res. Des. 2017, 119, 12–22. [Google Scholar] [CrossRef]

- Charfi, K.; Khayet, M.; Safi, M.J. Numerical simulation and experimental studies on heat and mass transfer using sweeping gas membrane distillation. Desalination 2010, 259, 84–96. [Google Scholar] [CrossRef]

- Phattaranawik, J.; Jiraratananon, R.; Fane, A.G. Effect of pore size distribution and air flux on mass transport in direct contact membrane distillation. J. Membr. Sci. 2003, 215, 75–85. [Google Scholar] [CrossRef]

- Wang, Z.S.; Gu, Z.L.; Feng, S.Y.; Li, Y. Application of vacuum membrane distillation to lithium bromide absorption refrigeration system. Int. J. Refrig. -Rev. Int. Du Froid 2009, 32, 1587–1596. [Google Scholar] [CrossRef]

- Wang, Z.; Feng, S.; Li, Y.; Gu, Z. Simulation of heat and mass transfer in solution heat exchanger with hollow fiber membrane. J. Xi’an Jiaotong Univ. 2009, 43, 36–41. [Google Scholar]

| Reference | Calculation Formula | |

|---|---|---|

| Antoine equation [38,39,40,41,42,43,44,45] | (3) | |

| ASHRAE Fundamentals Handbook [46] | (4) | |

| A1 = −5.8002206 × 103; A2 = 1.3914993; A3 = −4.8640239 × 10−2; | ||

| A4 = 4.1764768 × 10−5; A5 = −1.4452093 × 10−8; A6 = 6.5459673 | ||

| The empirical formula [47] | (5) | |

| i | 0 | 1 | 2 | 3 |

|---|---|---|---|---|

| Ai | −2.00755 | 1.69760 × 10−1 | −3.133362 × 10−3 | 1.97668 × 10−5 |

| Bi | 1.24937 × 102 | −7.71649 | 1.52286 × 10−1 | −7.9509 × 10−4 |

| C = 7.05; D = −1.59649 × 103; E = −1.040955 × 105 | ||||

| π0 | π1 | π2 | π3 | π4 | π5 |

| 0.28/0.31 * | 4.3/3.698 * | 0.6/0.6 * | 0.21/0.231 * | 5.1/4.584 * | 0.49/0.49 * |

| π6 | π7 | π8 | π9 | Tc | Pc |

| 0.362/0.478 * | −4.75/−5.2 * | −0.4/−0.4 * | 0.03/0.018 * | 647.3 K | 22,090 kPa |

| a | b | c | d | e | f |

| −7.85823 | 1.83991 | −11.7811 | 22.6705 | −15.9393 | 1.77516 |

| Parameters | TA [°C]/Pt100/A | φA [%Rh]/Hygrometer HT-1 |

|---|---|---|

| Bias limit | ±0.2 | ±0.8 |

| 0.115 | 0.462 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, Z.; Jia, Z.; Li, R.; Gao, Q.; Gu, Z. Analysis and Experimental Study on Water Vapor Partial Pressure in the Membrane Distillation Process. Membranes 2022, 12, 802. https://doi.org/10.3390/membranes12080802

Wang Z, Jia Z, Li R, Gao Q, Gu Z. Analysis and Experimental Study on Water Vapor Partial Pressure in the Membrane Distillation Process. Membranes. 2022; 12(8):802. https://doi.org/10.3390/membranes12080802

Chicago/Turabian StyleWang, Zanshe, Zhaoying Jia, Ran Li, Qi Gao, and Zhaolin Gu. 2022. "Analysis and Experimental Study on Water Vapor Partial Pressure in the Membrane Distillation Process" Membranes 12, no. 8: 802. https://doi.org/10.3390/membranes12080802

APA StyleWang, Z., Jia, Z., Li, R., Gao, Q., & Gu, Z. (2022). Analysis and Experimental Study on Water Vapor Partial Pressure in the Membrane Distillation Process. Membranes, 12(8), 802. https://doi.org/10.3390/membranes12080802