The Effect of a Flexible Electrode on the Electro Deformability of an Actuating Unit of a MDI-Polyurethane Composite Fiber Membrane Filled with BaTiO3

Abstract

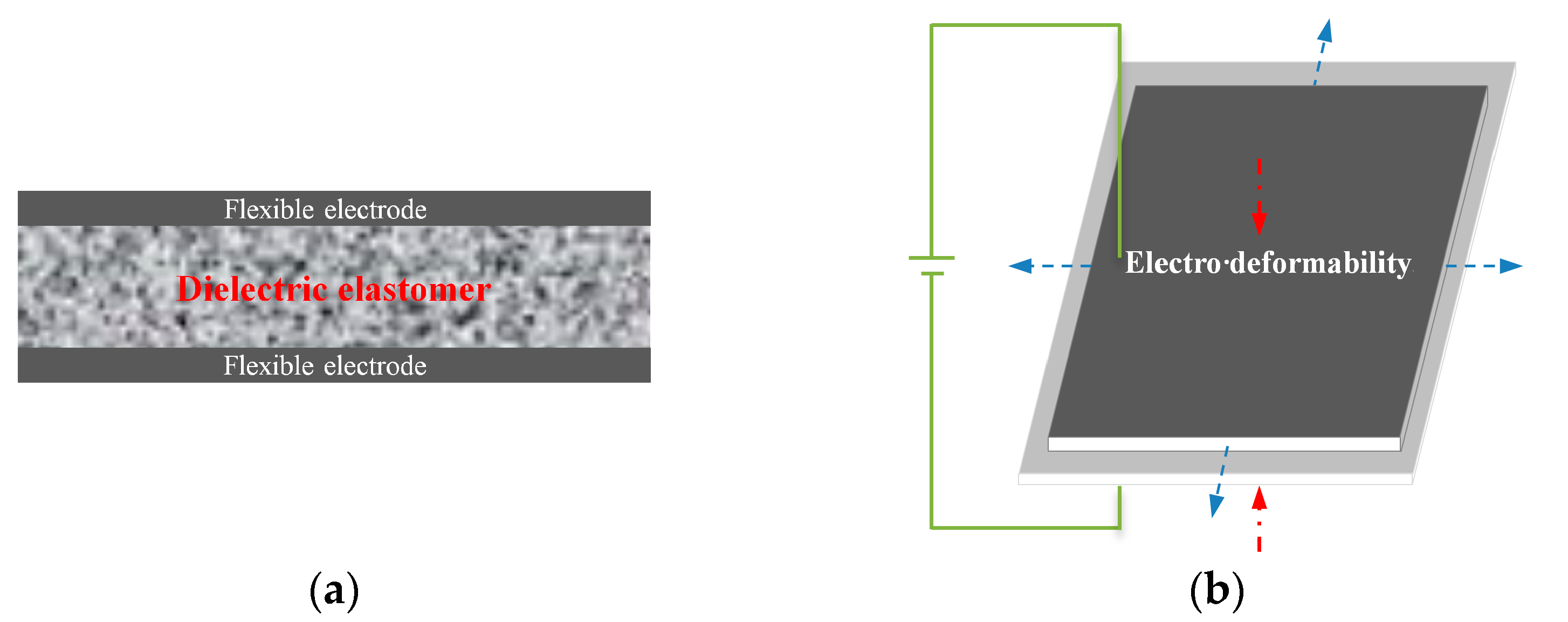

:1. Introduction

2. Experimental Techniques

2.1. The Main Raw Materials

2.2. The Main Devices

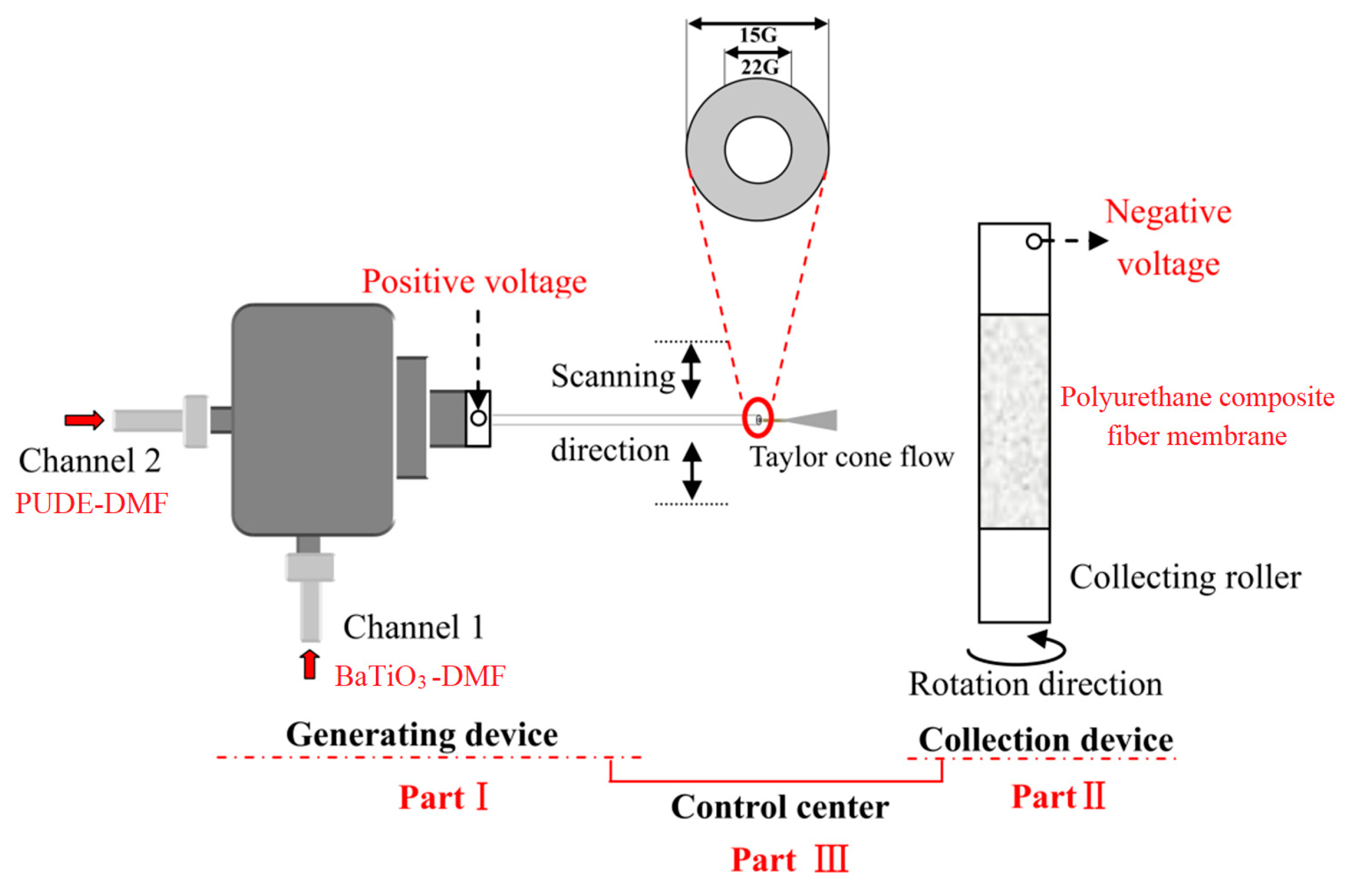

2.3. Experimental Procedure

- (1)

- Preparation of polyurethane composite fiber membrane filled with BaTiO3

- (2)

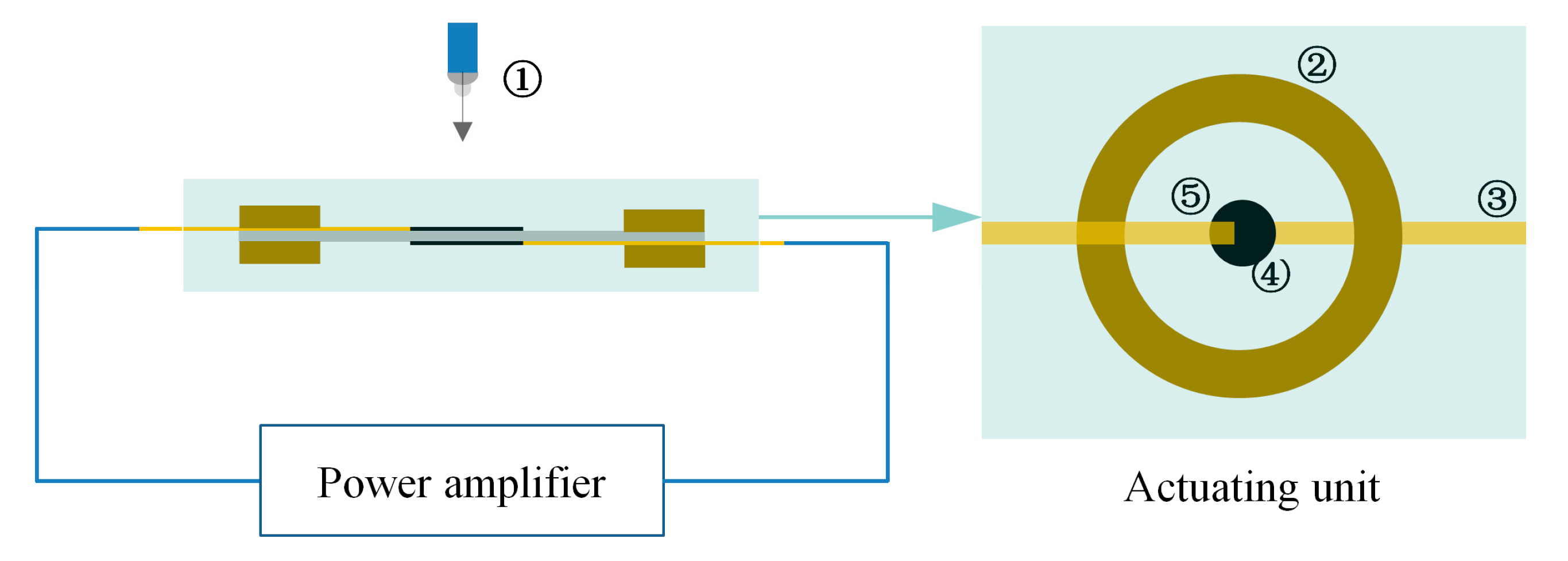

- Packaging of polyurethane composite fiber membrane actuating unit

2.4. Testing Methods

- (1)

- Micro morphology characterization

- (2)

- Electro deformability test

3. Experimental Results

3.1. Micro Morphology of Fiber Membrane and Arrangement State of BaTiO3

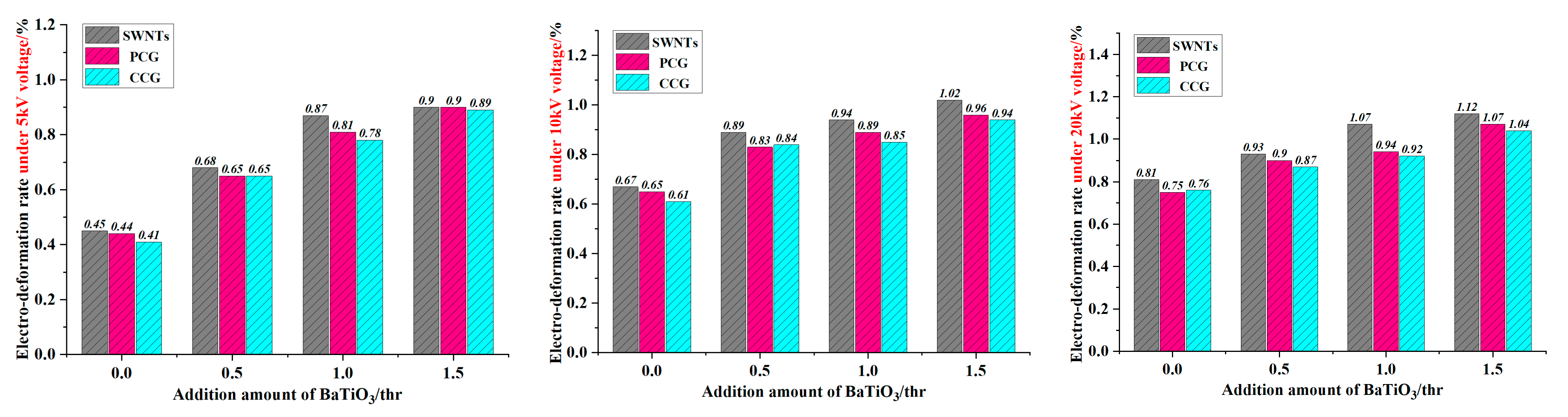

3.2. Electro Deformability of the Fiber Membrane Actuating Unit

- (1)

- Effect of flexible electrode on electro deformability of fiber membrane

- (2)

- Effect of coating methods of SWNTs electrode on electro deformability of the actuating unit

4. Conclusions

- (1)

- For the polyurethane dielectric composite fiber membrane of this system, the electro deformability of the actuating unit encapsulated with the SWNT flexible electrode is higher than that coated with PCG and CCG electrode. When the loading voltage is 20 kV, the performance of the SWNT electrode is better by 13.8% than that of PCG and CCG.

- (2)

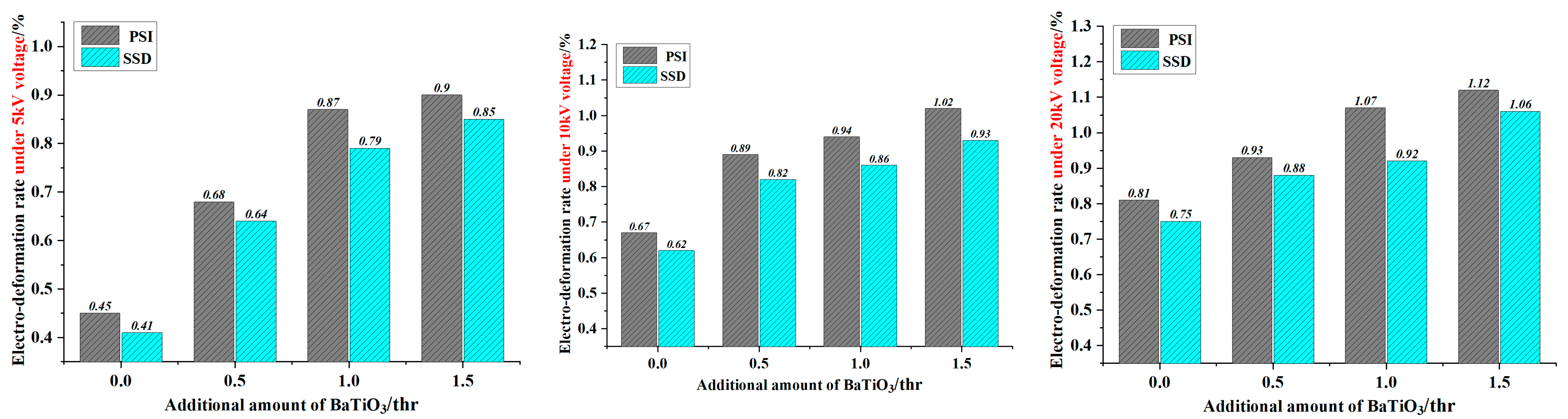

- For the flexible electrode based on SWNTs coating, the electro deformability of the actuating unit is better using the PSI method than that of the SSD.

- (3)

- In the future, the influence of the types of carbon nanotubes on the electro deformation ability of the fiber membrane materials in this system should be studied. In addition, it will be very meaningful to explore the microscopic synergistic effect between carbon nanotubes and fiber membrane and the change law of electrodes when voltage is applied.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Franke, M.; Ehrenhofer, A.; Lahiri, S.; Henke, E.F.M.; Richter, A. Dielectric Elastomer Actuator Driven Soft Robotic Structures with Bioinspired Skeletal and Muscular Reinforcement. Front. Robot. AI 2020, 7, 510757. [Google Scholar] [CrossRef] [PubMed]

- Shankar, R.; Ghosh, T.K.; Spontak, R.J. Dielectric elastomer as next-generation polymeric actuators. Soft Matter 2007, 3, 1116–1129. [Google Scholar] [CrossRef] [PubMed]

- Cristina, P. Polyurethane Elastomers; Springer: Berlin/Heidelberg, Germany, 2011. [Google Scholar]

- Chen, T.; Qiu, J.H.; Zhu, K.J.; Li, J.H. Electro-mechanical performance of polyurethane dielectric elastomer flexible micro-actuator composite modified with titanium dioxide-graphene hybrid fillers. Mater. Des. 2016, 90, 1069–1076. [Google Scholar] [CrossRef]

- Tomer, V.; Randall, C.A.; Polizos, G.; Kostelnick, J.; Manias, E. High and low-field dielectric characteristics of dielectrophoretically aligned ceramic/polymer nanocomposites. J. Appl. Phys. 2008, 103, 34115. [Google Scholar] [CrossRef]

- Akram, M.; Javed, A.; Rizvi, T.Z. Dielectric Properties of Industrial Polymer Composite Materials. Turk. J. Phys. 2005, 29, 355–362. [Google Scholar]

- Drakopoulos, S.X.; Patsidis, A.C.; Psarras, G.C. Epoxy-based/BaTiO3 nanodielectrics: Relaxation dynamics, charge transport and energy storage. Mater. Res. Bull. 2021, 145, 111537. [Google Scholar] [CrossRef]

- Panahi-Sarmad, M.; Zahiri, B.; Noroozi, M. Graphene-based composite for dielectric elastomer actuator: A comprehensive review. Sens. Actuators A Phys. 2019, 293, 222–241. [Google Scholar] [CrossRef]

- Ronald, E.P.; Roy, D.K.; Jose, P.J. Eletrostrction of polymer dielectrics with compliant electrodes as a means of actuation. Sens. Actuators A Phys. 1998, 64, 77–85. [Google Scholar]

- Sahu, R.K.; Saini, A.; Ahmad, D.; Patra, K.; Szpunar, J. Estimation and validation of maxwell stress of planar dielectric elastomer actuators. J. Mech. Sci. Technol. 2016, 30, 429–436. [Google Scholar] [CrossRef]

- Chen, T. Study on Electro Mechanical Properties of Polyurethane Dielectric Elastomer Composites; Nanjing University of Aeronautics and Astronautics: Nanjing, China, 2016. [Google Scholar]

- Wen, F.; Xu, Z.; Tan, S.B. Chemical Bonding-Induced Low Dielectric Loss and Low Conductivity in High-K Poly(vinylidenefluoride-trifluorethylene)/Graphene Nanosheets Nanocomposites. ACS Appl. Mater. Interfaces 2013, 5, 9411–9420. [Google Scholar] [CrossRef] [PubMed]

- Zhang, J.X.; Ma, J.C.; Zhang, L.Q.; Zong, C.Y.; Xu, A.H.; Zhang, Y.B.; Geng, B.; Zhang, S.X. Enhanced breakdown strength and suppressed dielectric loss of polymer nanocomposites with BaTiO3 fillers modified by fluoropolymer. RSC Adv. 2020, 10, 7065–7072. [Google Scholar] [CrossRef] [PubMed]

- Mohamed, I.M.A.; Dao, V.D.; Yasin, A.S.; Mousa, H.M.; Yassin, M.A.; Khan, M.Y.; Choi, H.S.; Barakat, N.A.M. Physicochemical and photo-electrochemical characterization of novel N-doped nanocomposite ZrO2/TiO2 photoanode towards technology of dye-sensitized solar cells. Mater. Charact. 2017, 127, 357–364. [Google Scholar] [CrossRef]

- Mesfin, A.K.; Fabian, I.E. Electrode Materials for Energy Storage and Conversion; CRC Press: Boca Raton, FL, USA, 2021. [Google Scholar]

- Lu, G.; Shuai, C.G.; Liu, Y.S.; Yang, X.; Hu, X.Y. Preparation and Dielectric Sensitivity of Polyurethane Composite Fiber Membrane Filled with BaTiO3. Membranes 2022, 12, 364. [Google Scholar] [CrossRef] [PubMed]

- Schroeder, V.; Savagatrup, S.; He, M.; Lin, S.; Swager, T.M. Carbon Nanotube Chemical Sensors. Chem. Rev. 2019, 119, 599–663. [Google Scholar] [CrossRef] [PubMed]

| Items | Manufactor |

|---|---|

| BaTiO3 (Particle size less than 1 μm) | China (Shanghai) Macklin Biochemcal Co., Ltd. |

| Polyether Diphenylmethane-4,4′-diisocyanate (MDI) polyurethane prepolymer (MDI-PUP) | China (Dongguan) polymerized rubber productsCo., Ltd. |

| Polyether polyol additive (PA) | China (Dongxu) Industry Manufacturing Co., Ltd. |

| 1,4-butanediol (BDO) | China (Wuhan) xiangjiutong Biotechnology Co., Ltd. |

| Single-walled carbon nanotubes (SWNTs) | China (Chengdu) Zhongke Shidai Naneng Co., Ltd. |

| Perfluoropolyether conductive grease (PCG) | China (Shenzhen) Songsen New Material Technology Co., Ltd. |

| Carbon conductive grease (CCG) | China (Shenzhen) Yuanzhuang Electronics Co., Ltd. |

| N. N-dimethylformamide (DMF) | China (Wuhan) xiangjiutong Biotechnology Co., Ltd. |

| Ether (ET) | China (Wuhan) xiangjiutong Biotechnology Co., Ltd. |

| Instrument | Model | Manufactor |

|---|---|---|

| Vacuum drying oven | DZF-6050AB | China (Shanghai) Jingqi Co., Ltd. |

| Electrospinning apparatus | LT-Pro | China (Shenzhen) Tongli micro nano Co., Ltd. |

| Device | Model | Remarks |

|---|---|---|

| Scanning Electron Microscope | Zeiss Merlin | The signal sources were backscattered signal and secondary electron signal; the accelerating voltage was 20 kV. |

| Samples | 10 Hz | 100 Hz | Y/MPa | Dielectric Sensitivity Factor | |||

|---|---|---|---|---|---|---|---|

| ε1″ | Tanα1 | ε2″ | Tanα2 | β10Hz | β100Hz | ||

| DEM-BaTiO3/Blank | 14.362 | 0.198 | 4.905 | 0.097 | 2.15 | 6.68 | 2.28 |

| DEM-BaTiO3/0.5 thr | 18.037 | 0.157 | 5.583 | 0.126 | 2.31 | 7.81 | 2.42 |

| DEM-BaTiO3/1.0 thr | 26.623 | 0.263 | 9.964 | 0.145 | 2.65 | 10.05 | 3.76 |

| DEM-BaTiO3/1.5 thr | 41.915 | 0.416 | 12.125 | 0.109 | 3.18 | 13.18 | 3.81 |

| Items | 5 kV/% | 10 kV/% | 20 kV/% | ||||||

|---|---|---|---|---|---|---|---|---|---|

| SWNTs | PCG | CCG | SWNTs | PCG | CCG | SWNTs | PCG | CCG | |

| DEM-BaTiO3/Blank | 0.45 | 0.44 | 0.41 | 0.67 | 0.65 | 0.61 | 0.81 | 0.75 | 0.76 |

| DEM-BaTiO3/0.5 thr | 0.68 | 0.65 | 0.65 | 0.89 | 0.83 | 0.84 | 0.93 | 0.90 | 0.87 |

| DEM-BaTiO3/1.0 thr | 0.87 | 0.81 | 0.78 | 0.94 | 0.89 | 0.85 | 1.07 | 0.94 | 0.92 |

| DEM-BaTiO3/1.5 thr | 0.90 | 0.90 | 0.89 | 1.02 | 0.96 | 0.94 | 1.12 | 1.07 | 1.04 |

| Items | 5 kV/% | 10 kV/% | 20 kV/% | |||

|---|---|---|---|---|---|---|

| PSI | SSD | PSI | SSD | PSI | SSD | |

| DEM-BaTiO3/Blank | 0.45 | 0.41 | 0.67 | 0.62 | 0.81 | 0.75 |

| DEM-BaTiO3/0.5 thr | 0.68 | 0.64 | 0.89 | 0.82 | 0.93 | 0.88 |

| DEM-BaTiO3/1.0 thr | 0.87 | 0.79 | 0.94 | 0.86 | 1.07 | 0.92 |

| DEM-BaTiO3/1.5 thr | 0.90 | 0.85 | 1.02 | 0.93 | 1.12 | 1.06 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lu, G.; Shuai, C.; Liu, Y.; Yang, X.; Hu, X. The Effect of a Flexible Electrode on the Electro Deformability of an Actuating Unit of a MDI-Polyurethane Composite Fiber Membrane Filled with BaTiO3. Membranes 2022, 12, 878. https://doi.org/10.3390/membranes12090878

Lu G, Shuai C, Liu Y, Yang X, Hu X. The Effect of a Flexible Electrode on the Electro Deformability of an Actuating Unit of a MDI-Polyurethane Composite Fiber Membrane Filled with BaTiO3. Membranes. 2022; 12(9):878. https://doi.org/10.3390/membranes12090878

Chicago/Turabian StyleLu, Gang, Changgeng Shuai, Yinsong Liu, Xue Yang, and Xiaoyang Hu. 2022. "The Effect of a Flexible Electrode on the Electro Deformability of an Actuating Unit of a MDI-Polyurethane Composite Fiber Membrane Filled with BaTiO3" Membranes 12, no. 9: 878. https://doi.org/10.3390/membranes12090878

APA StyleLu, G., Shuai, C., Liu, Y., Yang, X., & Hu, X. (2022). The Effect of a Flexible Electrode on the Electro Deformability of an Actuating Unit of a MDI-Polyurethane Composite Fiber Membrane Filled with BaTiO3. Membranes, 12(9), 878. https://doi.org/10.3390/membranes12090878