Hybrid Mechanical Vapor Compression and Membrane Distillation System: Concept and Analysis

Abstract

1. Introduction

2. Process Description

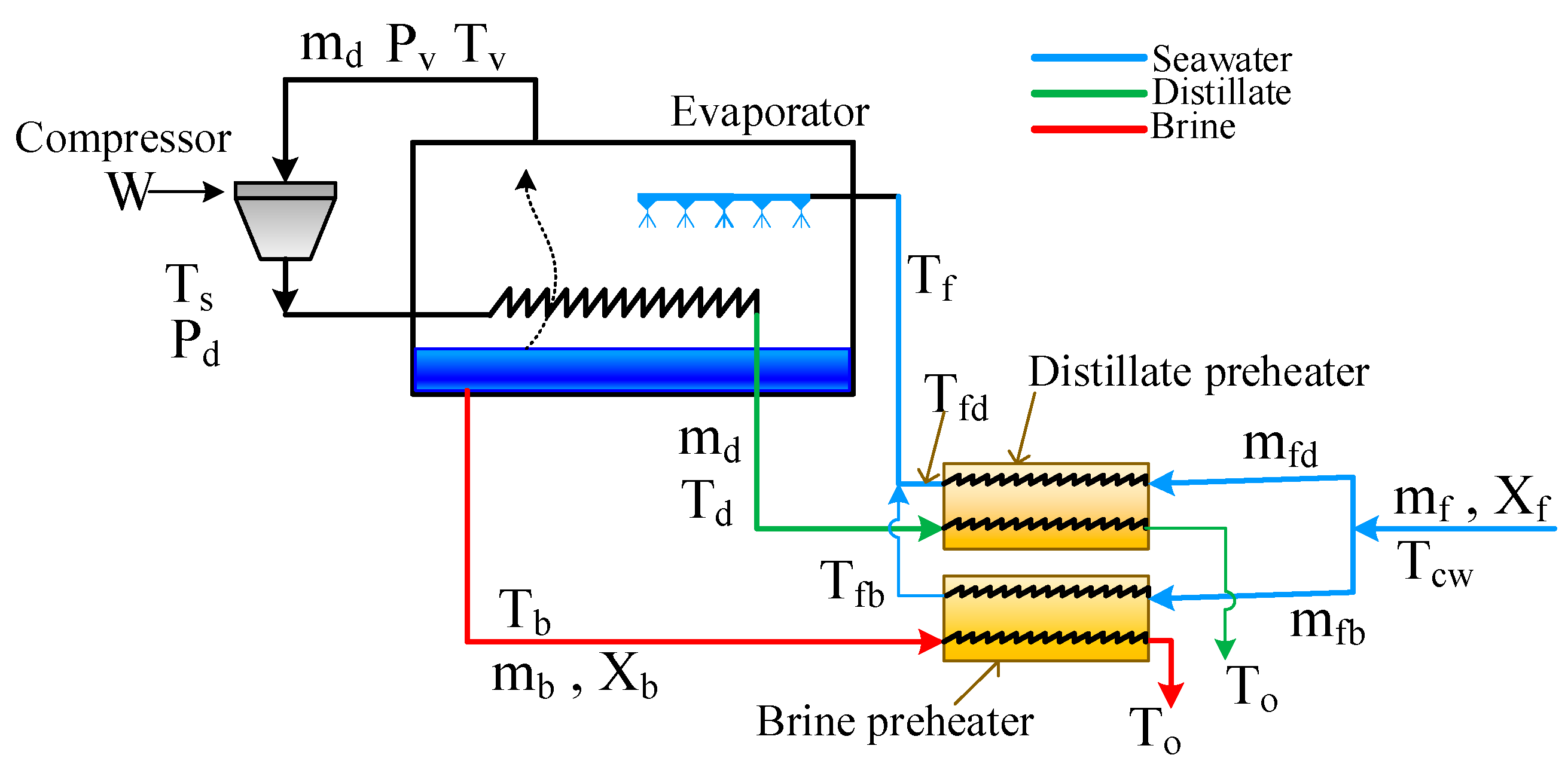

2.1. Mechanical Vapor Compression

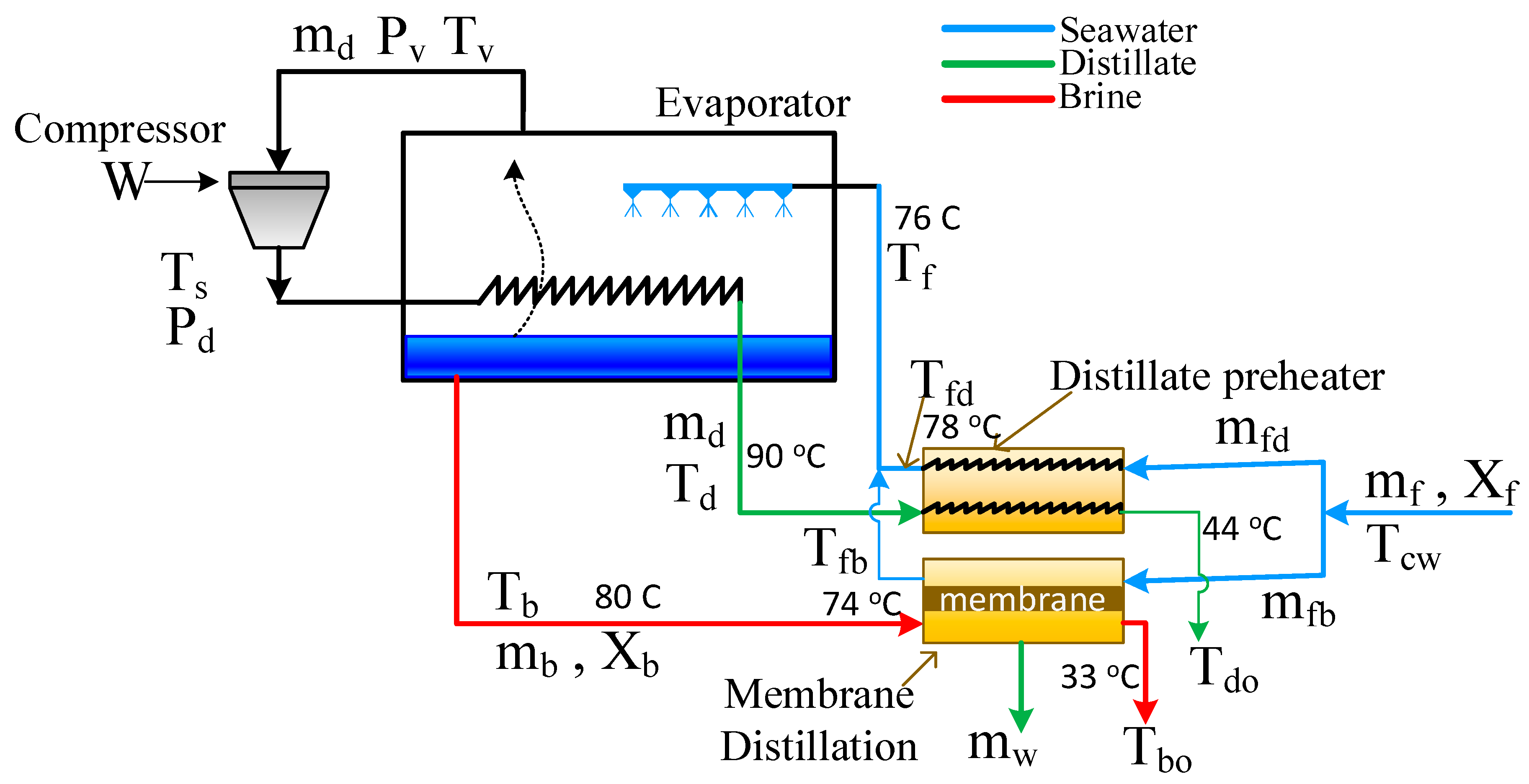

2.2. The Hybrid System

3. Simulation Procedure

3.1. Algorithm A1

- Using Equations (1) and (2), find mb and mf.

- Using Equation (7), find the isentropic compressor work. Using Equation (8) and the preassigned compressor efficiency, find the actual work and Ts.

- Using Equations (3) and (6), find Tf and To iteratively.

- Compute the normalized transfer area using Equations (10)–(15).

3.2. Algorithm A2

- Using Equations (1) and (2) find mb and mf.

- Assume a value for Td

- Given the heat exchanger efficiency solve the following heat balance to find Tf and To:

- For the distillate preheater find:

- For the brine preheater find:

- Compute the weighted average feed temperature:

- Using Equation (7), find the isentropic compressor work. Using Equation (8) and the preassigned compressor efficiency, find the actual work and Ts.

- Check the equality given by Equation (6); if it is satisfied, stop the iteration.

- Otherwise, update Td and repeat steps 3 to 5.

4. Results and Discussion

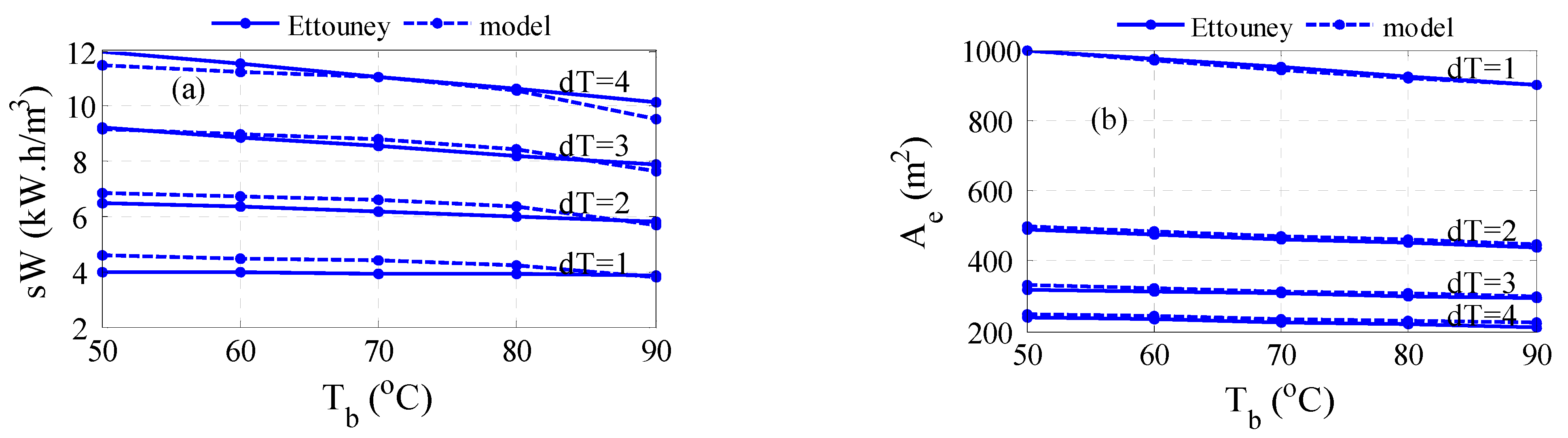

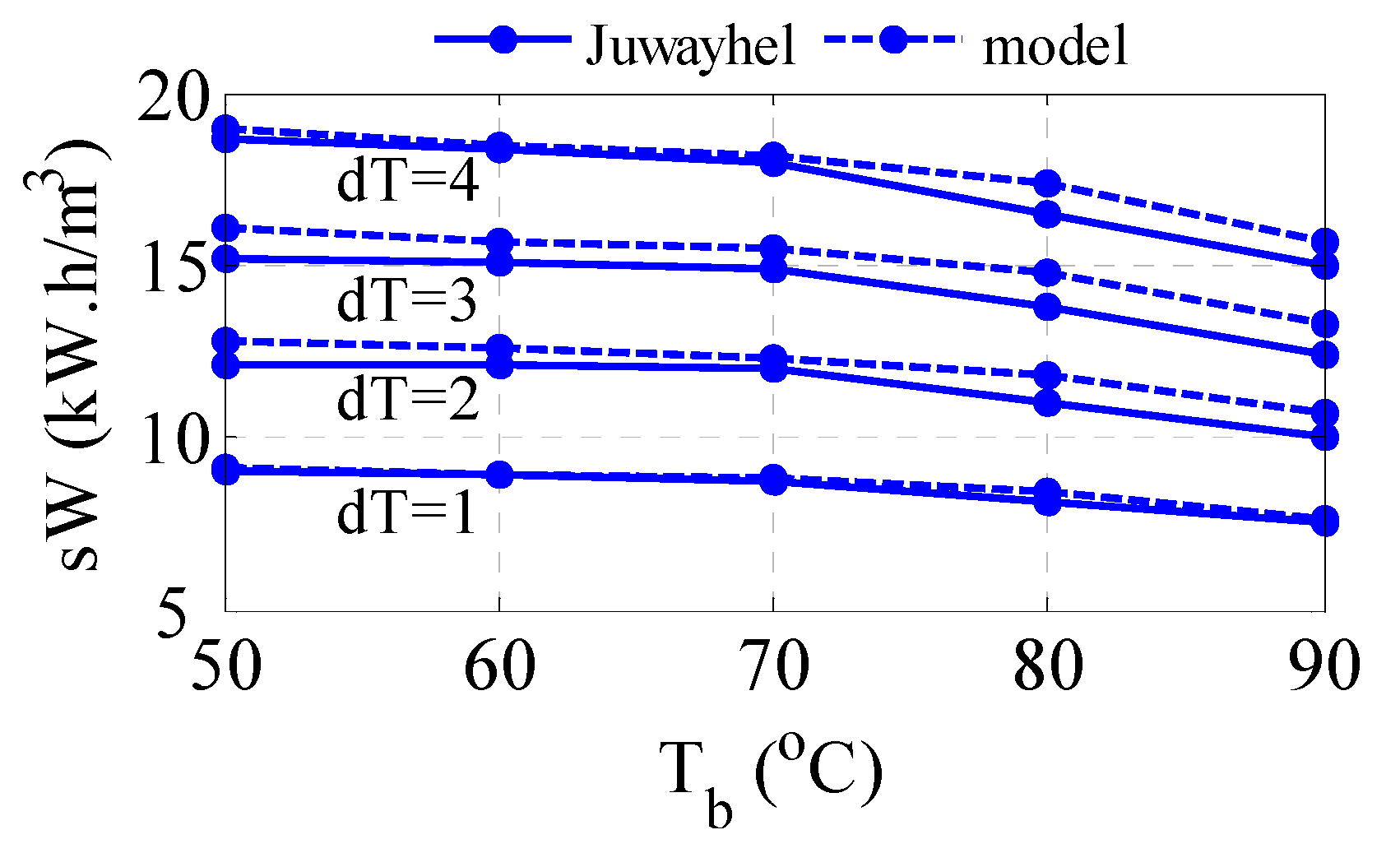

4.1. Model Validation

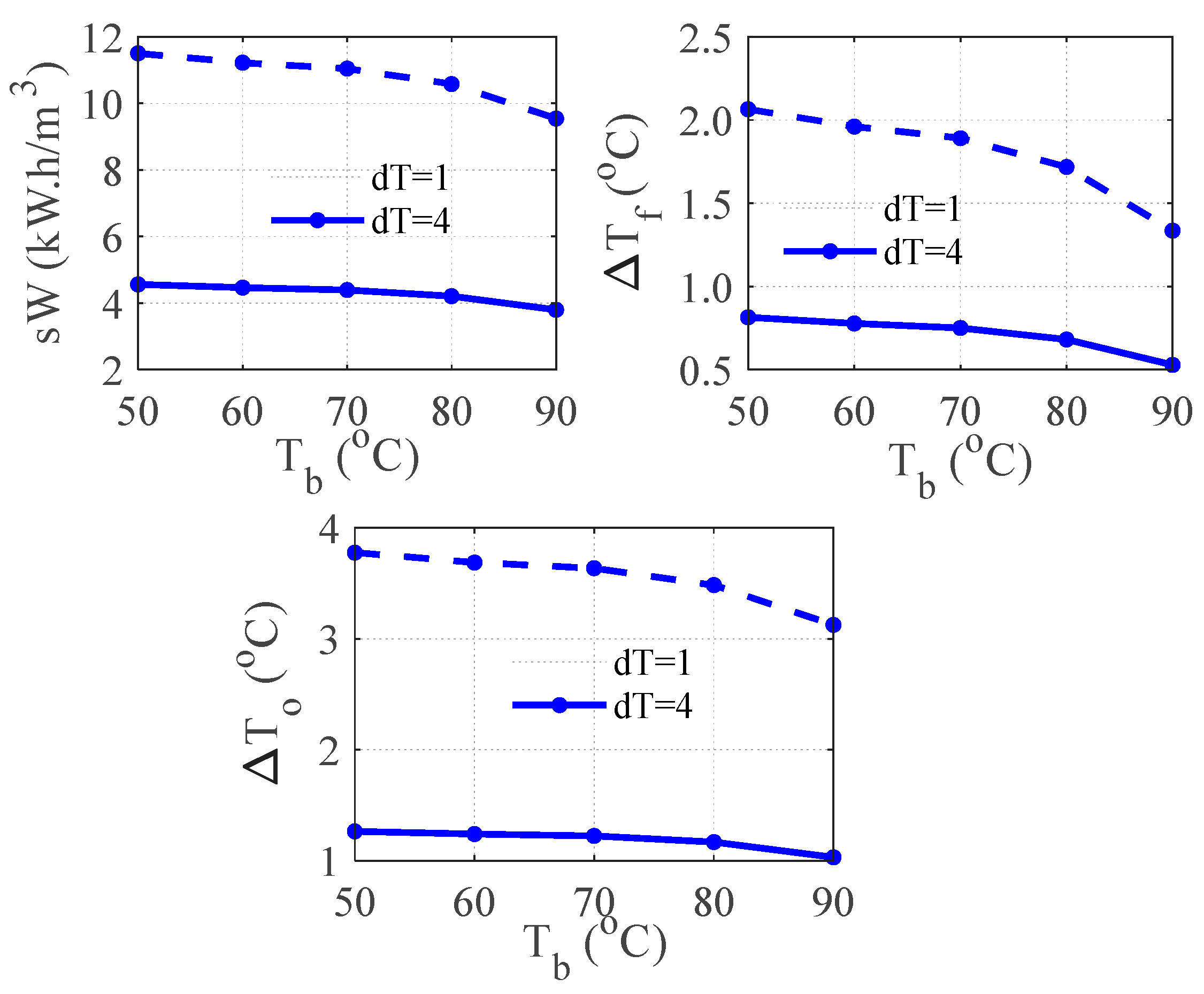

4.2. Preheater Analysis of the Standalone MVC

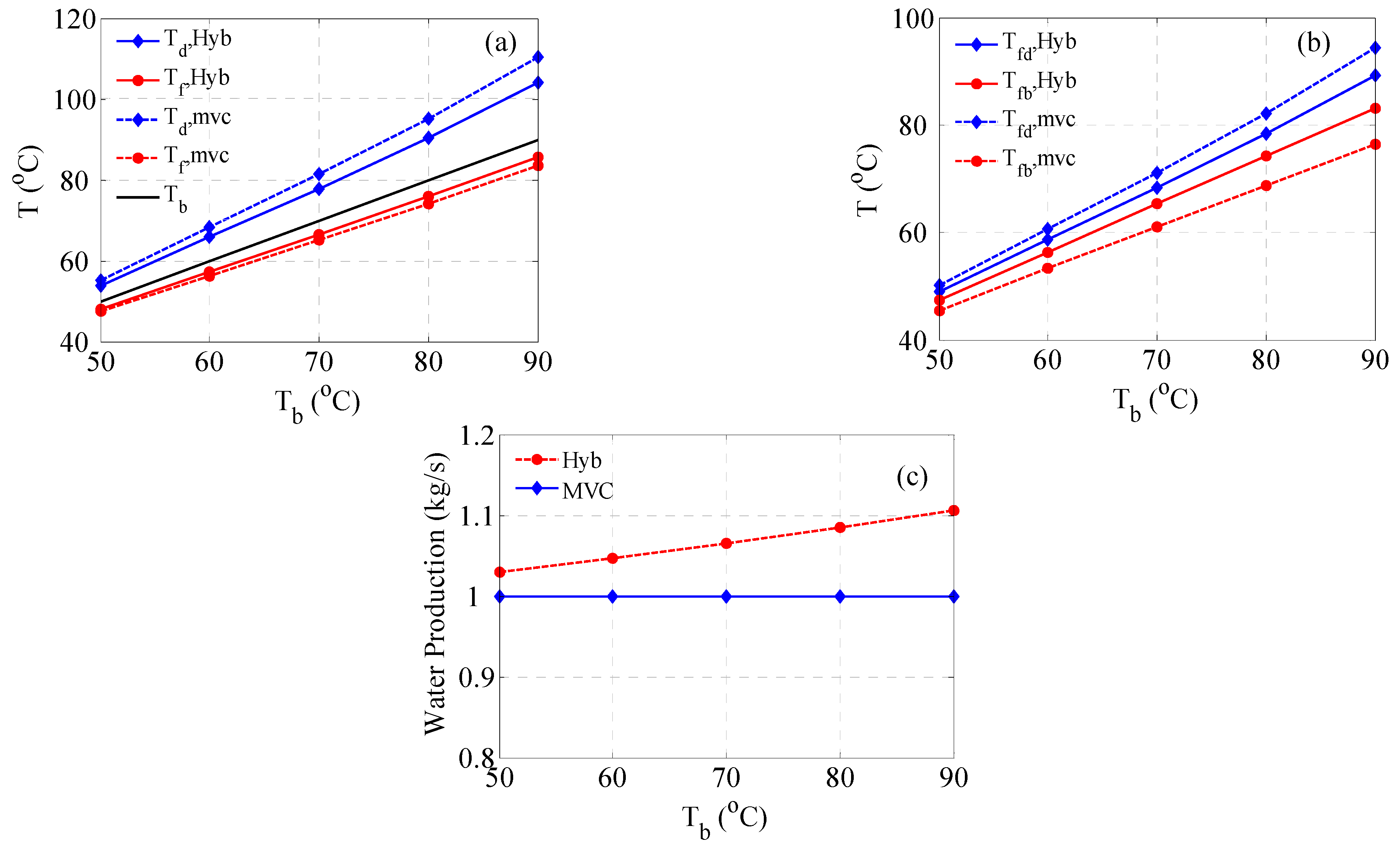

4.3. Comparison of the Hybrid System with MVC

4.4. Effect of the Heat Exchanger Efficiency

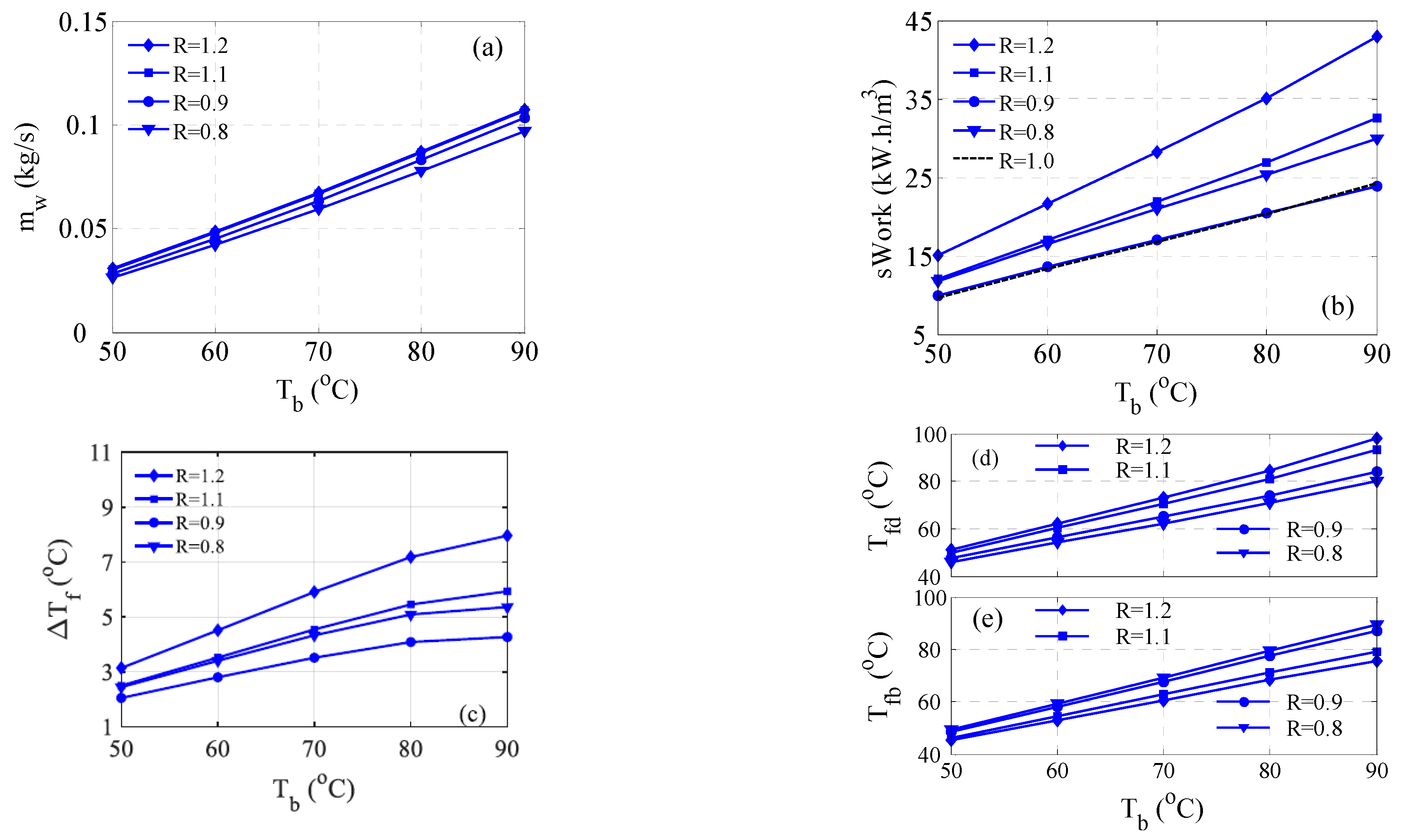

4.5. Effect of the Flow Rate Ratio

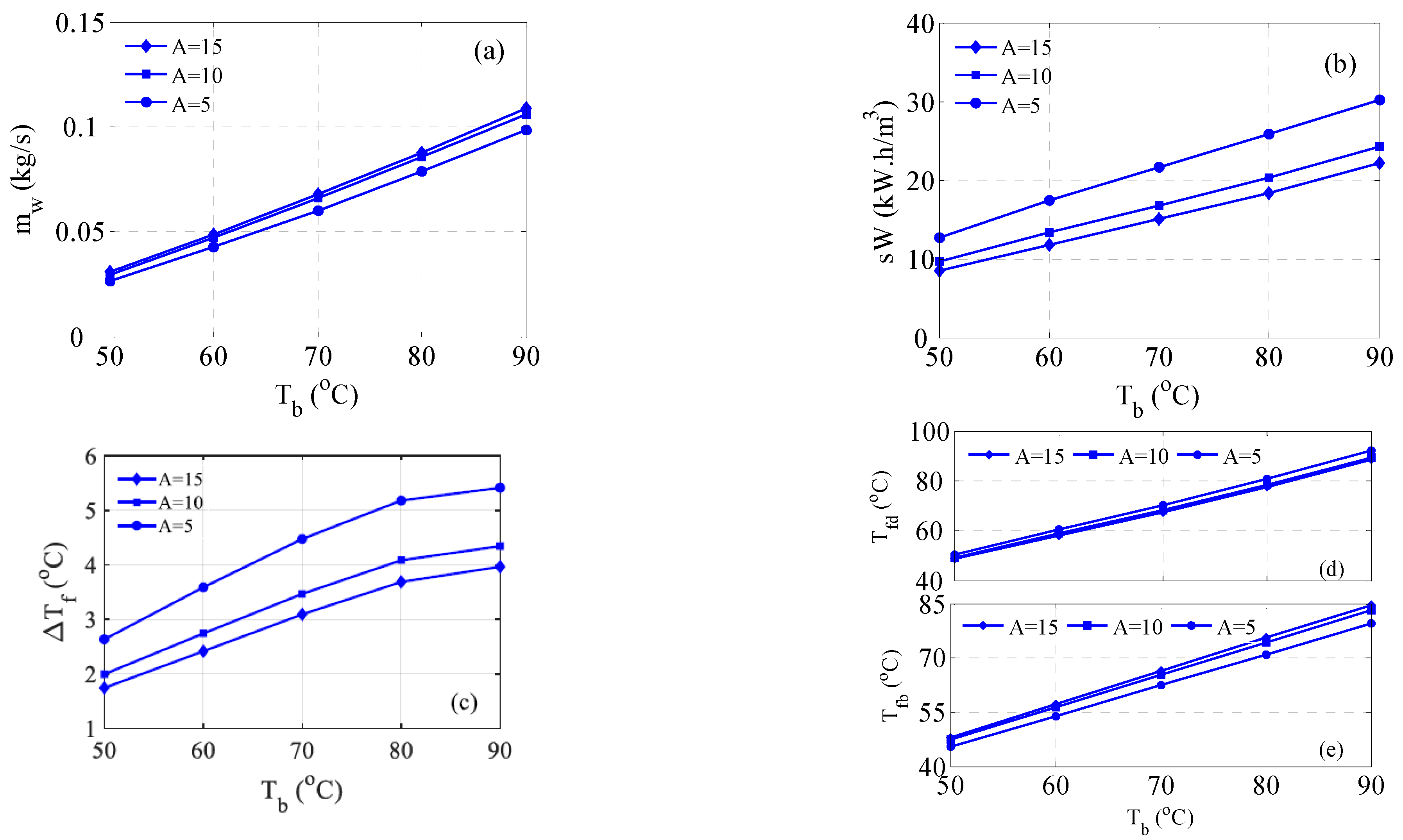

4.6. Effect of the Membrane Length

4.7. Performance of Modified Hybrid Structure

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Nomenclature

| Amd | MD surface area area, m2 |

| Ab | Brine preheater surface area, m2 |

| Ad | Distillate preheater surface area, n2 |

| Ae | Evaporator surface area, m2 |

| At | Total surface area, m2 |

| BPE | Boiling point elevation, C |

| Cm | Permeability coefficient, kg/m2s Pa |

| Knudsen mass flux coefficient, kg/m2s Pa | |

| Moléculaire diffusion mass flux coefficient, kg/m2s Pa | |

| Transition mass flux coefficient, kg/m2s Pa | |

| Cp | Heat capacity, J/kg K |

| de | collision diameter of the water vapor and air, m2 |

| hv | Latent heat of vaporization for MD, J/kg |

| hf, hp, hm | Feed, permeate, and membrane heat transfer coefficient, W/m2 K |

| Enthalpy of vapor at , kJ/kg | |

| Enthalpy of superheated steam at , kJ/kg | |

| Jw | Mass flux, kg/m2 h |

| kB | Boltzmann constant |

| km | Membrane conductivity, W/m K |

| ks | Solid phase thermal conductivity, W/m.K |

| kg | Gas phase thermal conductivity, W/m.K |

| kn | Knudsen number |

| l | Channel height, m |

| LMDT | Logarithmic mean temperature difference |

| Distillate mass rate for MVC, kg/s | |

| MVC brine flow rate, kg/s | |

| Seawater intake rate, kg/s | |

| Seawater stream fed to brine preheater/MD unit, kg/s | |

| Seawater stream fed to distillate preheater, kg/s | |

| distillate mass rate for MD, kg/s | |

| Total distillate mass rate, kg/s | |

| Mw | Molecular weight |

| Nu | Nusselt Number |

| P1, P2 | Vapor pressure at feed and permeate membrane surfaces, Pa |

| P | Average membrane interface pressure, Pa |

| Pa | Entrapped air pressure, Pa |

| PD | Membrane pressure multiplied by diffusivity, Pa.m2/s |

| Pr | Prandtl number |

| Vapor pressure at , Pa | |

| Vapor pressure at , Pa | |

| Evaporator and condenser heat load, kJ/s | |

| Preheater heat load, kJ/s | |

| r | Membrane pore size, m |

| R | Ideal gas constant, also flow rate ratio |

| Re | Reynold Number |

| Specific total surface area, m2/(kg/s) | |

| Specific compressor work, kWh⋅m−3 | |

| Th, Tc | Feed (hot) and permeate (cold) temperature, K |

| Thb, Tcb | Feed (hot) and permeate (cold) bulk temperature, K |

| Thm, Tcm | Feed and permeate membrane temperature, K |

| Seawater temperature exiting brine preheater, C | |

| Seawater temperature exiting brine preheater, C | |

| T | The average temperature at the membrane interface, K |

| MVC feed temperature, C | |

| Distillate temperature, C | |

| Temperature of the superheated steam, C | |

| Vapor temperature, C | |

| Temperature exiting preheaters, C | |

| Seawater intake temperature, C | |

| U | Overall heat transfer coefficient, W/m2K |

| Vapor specific volume, m3/kg | |

| Feed and brine salinity, ppm | |

| W | Actual Compressor work, kW |

| Adiabatic compressor work, kW | |

| Greek letters | |

| h | Compressor efficiency |

| Heat exchanger efficiency | |

| τ | tortuosity |

| ρ | Water density, kg/m3 |

| δ | Membrane thickness |

| ε | porosity |

| g | Heat capacity ratio |

| λ | Mean free path, m |

| ld | Latent heat at , kJ/kg |

| lv | Latent heat at , kJ/kg |

Appendix A

- Given the bulk temperature at both sides of the MD membrane () the local heat transfer coefficients () are calculated from the Nusselt number as follows [37]:

- 2.

- Set

- 3.

- Calculate the vapor pressure at the membrane interface using [36]:

- 4.

- Knowing the membrane characteristics and the average membrane temperature, i.e., , the membrane coefficient Cm can be estimated utilizing the correlation in [50] according to the designated mechanism:

- Knudsen flow mechanism, kn > 1:

- Molecular diffusion mechanism, kn<0.01:

- Knudsen-molecular diffusion transition mechanism, 0.01 < kn < 1:

- 5.

- Calculate the latent heat of vaporization at the average membrane temperature using [49]:

- 6.

- Calculate the mass flux using:

- 7.

- Compute the overall heat transfer coefficient using [11]:

- 8.

- At equilibrium, the heat convection from the hot side to the membrane interface and heat convection from the membrane interface to the cold side are equal. Hence the following conditions hold [50]:

- 9.

- If then stop the iteration, otherwise set and go back to step 3.

References

- Abid, M.B.; Wahab, R.A.; Abdelsalam, M.; Gzara, L.; Moujdin, I.A. Desalination technologies, membrane distillation, and electrospinning, an overview. Heliyon 2023, 9, e12810. [Google Scholar] [CrossRef] [PubMed]

- Ravi, J.; Othman, M.H.D.; Matsuura, T.; Bilad, M.R.i.; El-Badawy, T.; Aziz, F.; Ismail, A.; Rahman, M.A.; Jaafar, J. Polymeric membranes for desalination using membrane distillation: A review. Desalination 2020, 490, 114530. [Google Scholar] [CrossRef]

- Parker, W.P., Jr.; Kocher, J.D.; Menon, A.K. Brine concentration using air gap diffusion distillation: A performance model and cost comparison with membrane distillation for high salinity desalination. Desalination 2024, 580, 117560. [Google Scholar] [CrossRef]

- Yan, Z.; Jiang, Y.; Liu, L.; Li, Z.; Chen, X.; Xia, M.; Fan, G.; Ding, A. Membrane distillation for wastewater treatment: A mini Review. Water 2021, 13, 3480. [Google Scholar] [CrossRef]

- Criscuoli, A.; Drioli, E. Date juice concentration by vacuum membrane distillation. Sep. Purif. Technol. 2020, 251, 117301. [Google Scholar] [CrossRef]

- Boubakri, A.; Bouguecha, S.A.-T.; Hafiane, A. Membrane Distillation Process: Fundamentals, Applications, and Challenges; Intechopen: London, UK, 2024. [Google Scholar] [CrossRef]

- Li, J.; Zhou, W.; Fan, S.; Xiao, Z.; Liu, Y.; Liu, J.; Qiu, B.; Wang, Y. Bioethanol production in vacuum membrane distillation bioreactor by permeate fractional condensation and mechanical vapor compression with polytetrafluoroethylene (PTFE) membrane. Bioresour. Technol. 2018, 268, 708–714. [Google Scholar] [CrossRef]

- Stillwell, A.S.; Webber, M.E. Predicting the specific energy consumption of reverse osmosis desalination. Water 2016, 8, 601. [Google Scholar] [CrossRef]

- Criscuoli, A.; Carnevale, M.C.; Drioli, E. Evaluation of energy requirements in membrane distillation. Chem. Eng. Process. Process Intensif. 2008, 47, 1098–1105. [Google Scholar] [CrossRef]

- Najib, A.; Orfi, J.; Ali, E.; Saleh, J. Thermodynamics analysis of a direct contact membrane distillation with/without heat recovery based on experimental data. Desalination 2019, 466, 52–67. [Google Scholar] [CrossRef]

- Gude, V.G. Energy storage for desalination processes powered by renewable energy and waste heat sources. Appl. Energy 2015, 137, 877–898. [Google Scholar] [CrossRef]

- Camacho, L.M.; Dumée, L.; Zhang, J.; Li, J.-d.; Duke, M.; Gomez, J.; Gray, S. Advances in membrane distillation for water desalination and purification applications. Water 2013, 5, 94–196. [Google Scholar] [CrossRef]

- Eke, J.; Yusuf, A.; Giwa, A.; Sodiq, A. The global status of desalination: An assessment of current desalination technologies, plants and capacity. Desalination 2020, 495, 114633. [Google Scholar] [CrossRef]

- Goosen, M.F.; Mahmoudi, H.; Ghaffour, N. Today’s and future challenges in applications of renewable energy technologies for desalination. Crit. Rev. Environ. Sci. Technol. 2014, 44, 929–999. [Google Scholar] [CrossRef]

- Abdelkareem, M.A.; Assad, M.; Sayed, E.T.; Soudan, B. Recent progress in the use of renewable energy sources to power water desalination plants. Desalination 2018, 444, 178. [Google Scholar] [CrossRef]

- Alkaisi, A.; Mossad, R.; Sharifian-Barforoush, A. A review of the water desalination systems integrated with renewable energy. Energy Procedia 2017, 110, 268–274. [Google Scholar] [CrossRef]

- Nafey, A.; Fath, H.; Mabrouk, A. Thermo-economic investigation of multi effect evaporation (MEE) and hybrid multi effect evaporation—Multi stage flash (MEE-MSF) systems. Desalination 2006, 201, 241–254. [Google Scholar] [CrossRef]

- Ali, E.; Orfi, J.; AlAnsary, H.; Lee, J.-G.; Alpatova, A.; Ghaffour, N. Integration of multi effect evaporation and membrane distillation desalination processes for enhanced performance and recovery ratios. Desalination 2020, 493, 114619. [Google Scholar] [CrossRef]

- Curto, D.; Franzitta, V.; Guercio, A. A review of the water desalination technologies. Appl. Sci. 2021, 11, 670. [Google Scholar] [CrossRef]

- Si, Z.; Han, D.; Song, Y.; Chen, J.; Luo, L.; Li, R. Experimental investigation on a combined system of vacuum membrane distillation and mechanical vapor recompression. Chem. Eng. Process.-Process Intensif. 2019, 139, 172–182. [Google Scholar] [CrossRef]

- Farsi, A.; Dincer, I. Development and evaluation of an integrated MED/membrane desalination system. Desalination 2019, 463, 55–68. [Google Scholar] [CrossRef]

- Manesh, M.K.; Ghalami, H.; Amidpour, M.; Hamedi, M. Optimal coupling of site utility steam network with MED-RO desalination through total site analysis and exergoeconomic optimization. Desalination 2013, 316, 42–52. [Google Scholar] [CrossRef]

- Son, H.S.; Shahzad, M.W.; Ghaffour, N.; Ng, K.C. Pilot studies on synergetic impacts of energy utilization in hybrid desalination system: Multi-effect distillation and adsorption cycle (MED-AD). Desalination 2020, 477, 114266. [Google Scholar] [CrossRef]

- Shen, J.; Xing, Z.; Wang, X.; He, Z. Analysis of a single-effect mechanical vapor compression desalination system using water injected twin screw compressors. Desalination 2014, 333, 146–153. [Google Scholar] [CrossRef]

- Zhou, Y.; Shi, C.; Dong, G. Analysis of a mechanical vapor recompression wastewater distillation system. Desalination 2014, 353, 91–97. [Google Scholar] [CrossRef]

- Rostamzadeh, H. A new pre-concentration scheme for brine treatment of MED-MVC desalination plants towards low-liquid discharge (LLD) with multiple self-superheating. Energy 2021, 225, 120224. [Google Scholar] [CrossRef]

- Randon, A.; Rech, S.; Lazzaretto, A. Brine management: Techno-economic analysis of a mechanical vapor compression energy system for a near-zero liquid discharge application. Int. J. Thermodyn. 2020, 23, 128–137. [Google Scholar] [CrossRef]

- Schwantes, R.; Chavan, K.; Winter, D.; Felsmann, C.; Pfafferott, J. Techno-economic comparison of membrane distillation and MVC in a zero liquid discharge application. Desalination 2018, 428, 50–68. [Google Scholar] [CrossRef]

- Mabrouk, A.; Nafey, A.; Fath, H. Analysis of a new design of a multi-stage flash–mechanical vapor compression desalination process. Desalination 2007, 204, 482–500. [Google Scholar] [CrossRef]

- Fernández-López, C.; Viedma, A.; Herrero, R.; Kaiser, A. Seawater integrated desalination plant without brine discharge and powered by renewable energy systems. Desalination 2009, 235, 179–198. [Google Scholar] [CrossRef]

- Makanjuola, O.; Lalia, B.; Janajreh, I.; Hashaikeh, R. Numerical and experimental investigation of thermoelectric materials in direct contact membrane distillation. Energy Convers. Manag. 2022, 267, 115880. [Google Scholar] [CrossRef]

- Bibi, W.; Asif, M.; Iqbal, F.; Rabbi, J. Hybrid vacuum membrane distillation-multi effect distillation (VMD-MED) system for reducing specific energy consumption in desalination. Desalination Water Treat. 2024, 317, 100064. [Google Scholar] [CrossRef]

- Wu, L.; Zheng, Z.; Zhang, D.; Zhang, Y.; Zhang, B.; Tang, Z. Optimization of design and operational parameters of hybrid MED-RO desalination system via modelling, simulation and engineering application. Results Eng. 2024, 24, 103253. [Google Scholar] [CrossRef]

- Rostami, S.; Ghiasirad, H.; Rostamzadeh, H.; Kalan, A.S.; Maleki, A. A wind turbine driven hybrid HDH-MED-MVC desalination system towards minimal liquid discharge. S. Afr. J. Chem. Eng. 2023, 44, 356–369. [Google Scholar] [CrossRef]

- Swaminathan, J.; Nayar, K.G.; Lienhard, J.H., V. Mechanical vapor compression—Membrane distillation hybrids for reduced specific energy consumption. Desalination Water Treat. 2016, 57, 26507–26517. [Google Scholar] [CrossRef]

- Lawal, D.U.; Khalifa, A.E. Flux prediction in direct contact membrane distillation. Int. J. Mater. Mech. Manuf. 2014, 2, 302–308. [Google Scholar] [CrossRef]

- Alkhudhiri, A.; Darwish, N.; Hilal, N. Membrane distillation: A comprehensive review. Desalination 2012, 287, 2–18. [Google Scholar] [CrossRef]

- Zhang, Z.; Lokare, O.R.; Gusa, A.V.; Vidic, R.D. Pretreatment of brackish water reverse osmosis (BWRO) concentrate to enhance water recovery in inland desalination plants by direct contact membrane distillation (DCMD). Desalination 2021, 508, 115050. [Google Scholar] [CrossRef]

- Panagopoulos, A.; Haralambous, K.-J. Minimal Liquid Discharge (MLD) and Zero Liquid Discharge (ZLD) strategies for wastewater management and resource recovery–Analysis, challenges and prospects. J. Environ. Chem. Eng. 2020, 8, 104418. [Google Scholar] [CrossRef]

- Ettouney, H.; El-Dessouky, H.; Al-Roumi, Y. Analysis of mechanical vapour compression desalination process. Int. J. Energy Res. 1999, 23, 431–451. [Google Scholar] [CrossRef]

- El-Dessouky, H.T.; Ettouney, H.M. Fundamentals of Salt Water Desalination; Elsevier: Amsterdam, The Netherlands, 2002. [Google Scholar]

- Ali, E.; Orfi, J.; Najib, A. Assessing the thermal efficiency of brackish water desalination by membrane distillation using exergy analysis. Arab. J. Sci. Eng. 2018, 43, 2413–2424. [Google Scholar] [CrossRef]

- Najib, A.; Orfi, J.; Ali, E.; Ajbar, A.; Boumaaza, M.; Alhumaizi, K. Performance analysis of cascaded membrane distillation arrangements for desalination of brackish water. Desalination Water Treat. 2017, 76, 19–29. [Google Scholar] [CrossRef]

- Orfi, J.; Najib, A.; Ali, E.; Ajbar, A.; AlMatrafi, M.; Boumaaza, M.; Alhumaizi, K. Membrane distillation and reverse osmosis based desalination driven by geothermal energy sources. Desalination Water Treat. 2017, 76, 40–52. [Google Scholar] [CrossRef]

- Ali, E.; Orfi, J. An experimentally calibrated model for heat and mass transfer in full-scale direct contact membrane distillation. Desalination Water Treat. 2018, 116, 1–18. [Google Scholar] [CrossRef]

- Swaminathan, J.; Chung, H.; Warsinger, D. Membrnae Distillation Model Based on Heat exchanger Theory and Configuration Comparison. Applied Energy. 2016, 184, 491–505. [Google Scholar] [CrossRef]

- Triki, Z.; Bouaziz, M.; Boumaza, M. Performance and cost evaluation of an autonomous solar vacuum membrane distillation desalination plant. Desalination Water Treat. 2017, 73, 107–120. [Google Scholar] [CrossRef]

- Al-Juwayhel, F.; El-Dessouky, H.; Ettouney, H. Analysis of single-effect evaporator desalination systems combined with vapor compression heat pumps. Desalination 1997, 114, 253–275. [Google Scholar] [CrossRef]

- Fard, A.K.; Manawi, Y.M.; Rhadfi, T.; Mahmoud, K.A.; Khraisheh, M.; Benyahia, F. Synoptic analysis of direct contact membrane distillation performance in Qatar: A case study. Desalination 2015, 360, 97–107. [Google Scholar] [CrossRef]

- Nakoa, K.; Date, A.; Akbarzadeh, A. A research on water desalination using membrane distillation. Desalination Water Treat. 2015, 56, 2618–2630. [Google Scholar] [CrossRef]

- Summers, E.K.; Arafat, H.A. Energy efficiency comparison of single-stage membrane distillation (MD) desalination cycles in different configurations. Desalination 2012, 290, 54–66. [Google Scholar] [CrossRef]

- Swaminathan, J.; Chung, H.W.; Warsinger, D.M. Energy efficiency of membrane distillation up to high salinity: Evaluating critical system size and optimal membrane thickness. Appl. Energy 2018, 211, 715–734. [Google Scholar] [CrossRef]

- He, F.; Gilron, J.; Sirkar, K.K. High water recovery in direct contact membrane distillation using a series of cascades. Desalination 2013, 323, 48–54. [Google Scholar] [CrossRef]

- Ali, A.; Tsai, J.-H.; Tung, K.-L.; Drioli, E.; Macedonio, F. Designing and optimization of continuous direct contact membrane distillation process. Desalination 2018, 426, 97–107. [Google Scholar] [CrossRef]

- Guan, G.; Yang, X.; Wang, R.; Fane, A.G. Evaluation of heat utilization in membrane distillation desalination system integrated with heat recovery. Desalination 2015, 366, 80–93. [Google Scholar] [CrossRef]

- Winter, D. Membrane Distillation: A Thermodynamic, Technological and Economic Analysis; Shaker Verlag: Aachen, Germany, 2015. [Google Scholar]

- Lin, S.; Yip, N.Y.; Elimelech, M. Direct contact membrane distillation with heat recovery: Thermodynamic insights from module scale modeling. J. Membr. Sci. 2014, 453, 498–515. [Google Scholar] [CrossRef]

- Naidu, G.; Jeong, S.; Vigneswaran, S. Influence of feed/permeate velocity on scaling development in a direct contact membrane distillation. Sep. Purif. Technol. 2014, 125, 291–300. [Google Scholar] [CrossRef]

- Ali, E. Novel structures of direct contact membrane distillation for brackish water desalination using distributed feed flow. Desalination 2022, 540, 116000. [Google Scholar] [CrossRef]

- Winter, D.; Koschikowski, J.; Wieghaus, M. Desalination using membrane distillation: Experimental studies on full scale spiral wound modules. J. Membr. Sci. 2011, 375, 104–112. [Google Scholar] [CrossRef]

| Parameter | Value |

|---|---|

| md | 1 kg/s |

| BPR | 1 °C |

| Tcw | 30 °C |

| Xf | 42,000 ppm |

| Xb | 70,000 ppm |

| h | 0.76 |

| g | 1.42 |

| Cpv | 1.884 kJ/kg.K |

| Parameter | Value |

|---|---|

| Effective surface area | 10 m2 |

| Membrane thickness | 230 mm |

| Channel length | 14 m |

| Channel height | 0.7 m |

| Pore diameter | 0.2 mm |

| Channel gap | 0.2 mm |

| Porosity | 0.8 |

| Entry pressure | 4.1 bar |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ali, E.; Orfi, J.; Mokraoui, S. Hybrid Mechanical Vapor Compression and Membrane Distillation System: Concept and Analysis. Membranes 2025, 15, 69. https://doi.org/10.3390/membranes15030069

Ali E, Orfi J, Mokraoui S. Hybrid Mechanical Vapor Compression and Membrane Distillation System: Concept and Analysis. Membranes. 2025; 15(3):69. https://doi.org/10.3390/membranes15030069

Chicago/Turabian StyleAli, Emad, Jamel Orfi, and Salim Mokraoui. 2025. "Hybrid Mechanical Vapor Compression and Membrane Distillation System: Concept and Analysis" Membranes 15, no. 3: 69. https://doi.org/10.3390/membranes15030069

APA StyleAli, E., Orfi, J., & Mokraoui, S. (2025). Hybrid Mechanical Vapor Compression and Membrane Distillation System: Concept and Analysis. Membranes, 15(3), 69. https://doi.org/10.3390/membranes15030069