Treatment of Flue Gas Desulfurization Wastewater by an Integrated Membrane-Based Process for Approaching Zero Liquid Discharge

Abstract

:1. Introduction

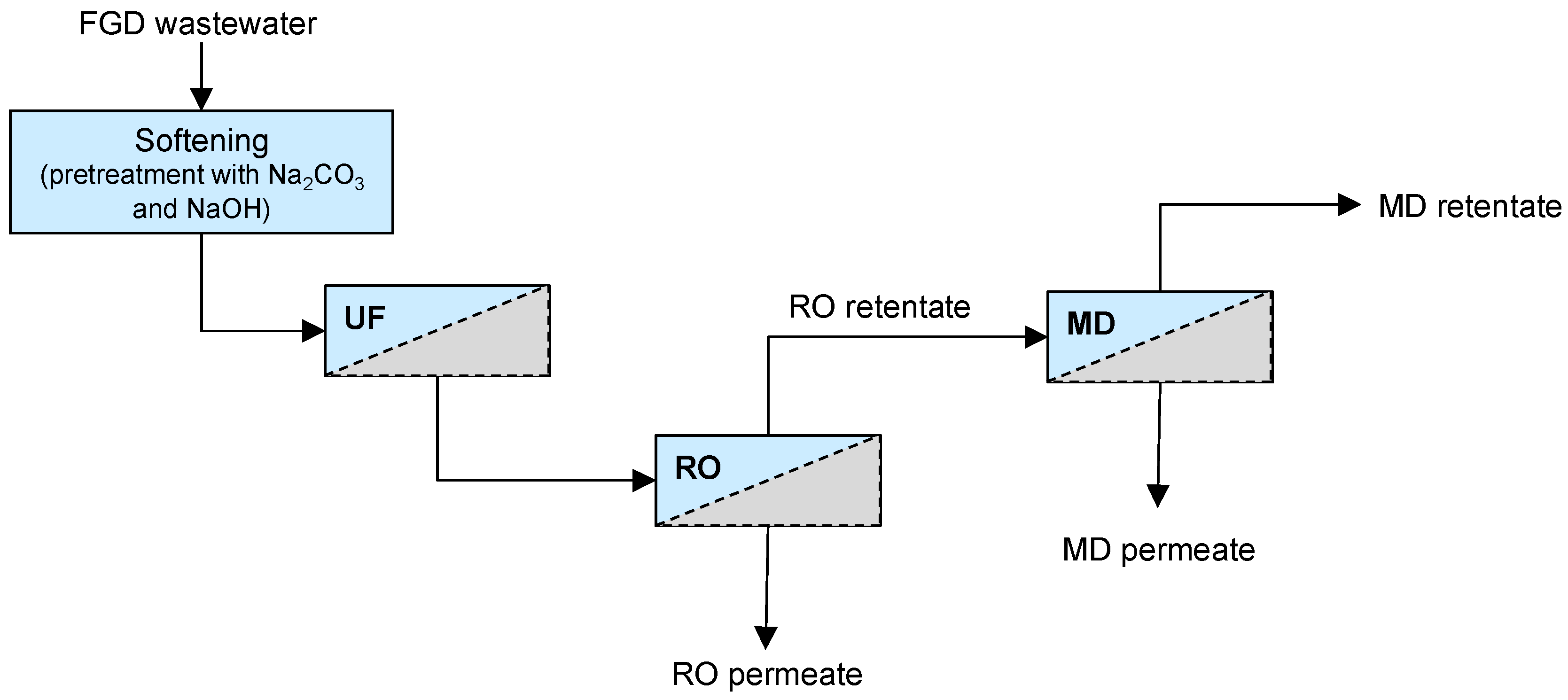

2. Materials and Methods

2.1. Pretreatment of FGD Wastewaters

2.2. RO and MD: Experimental Set-Up and Membranes

2.3. Analytical Measurements

3. Results and Discussion

3.1. Pretreatment of FGD Wastewaters

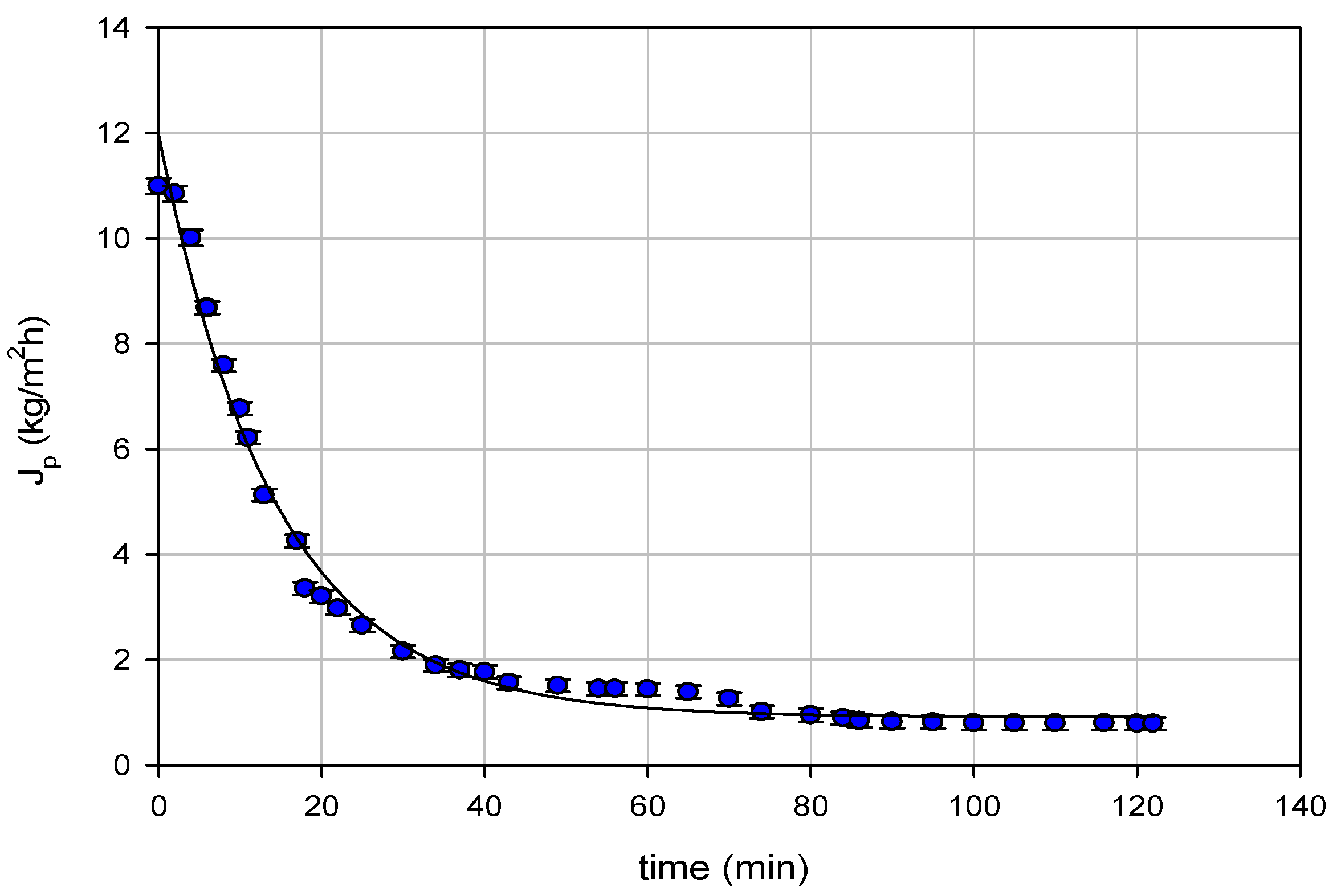

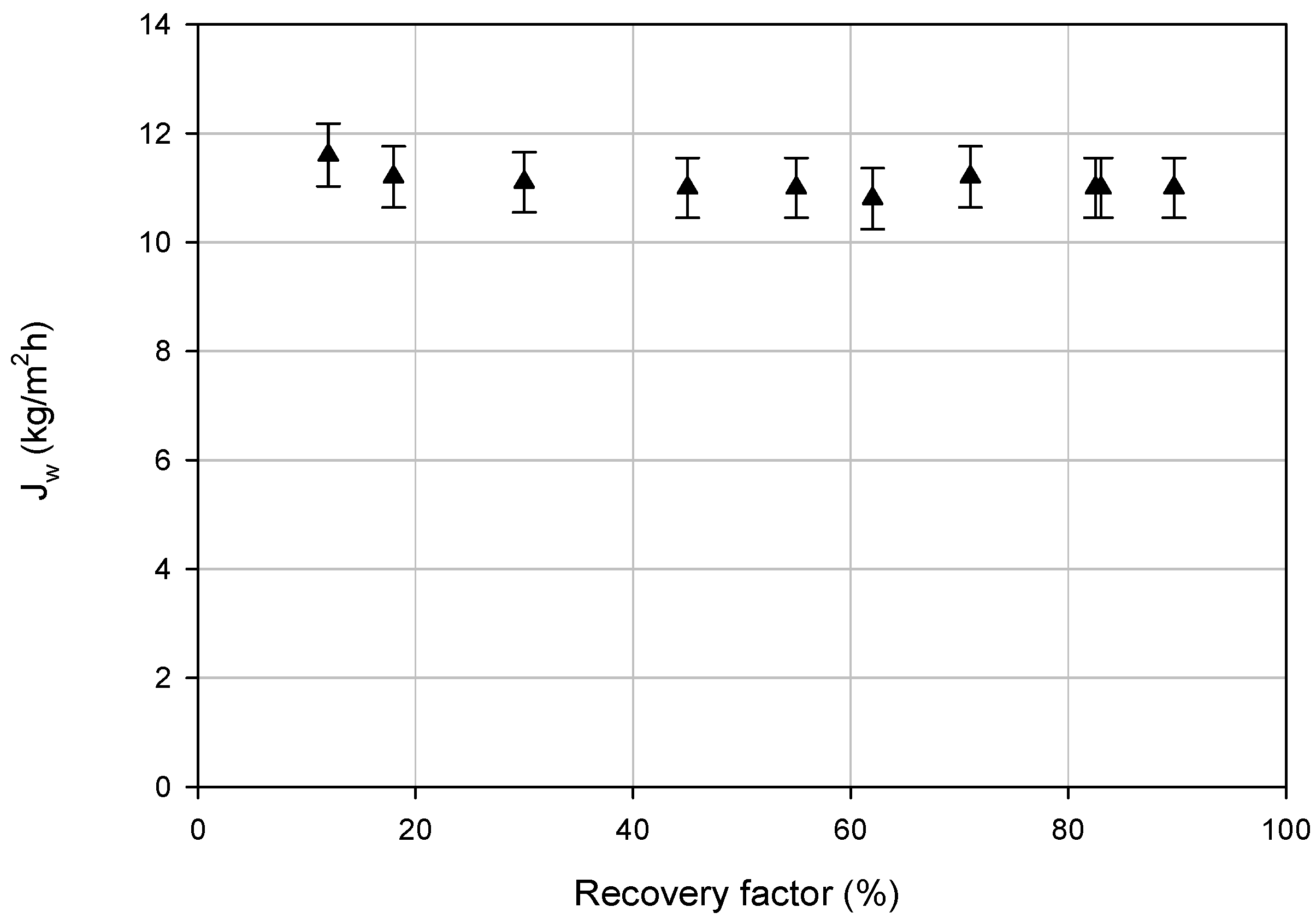

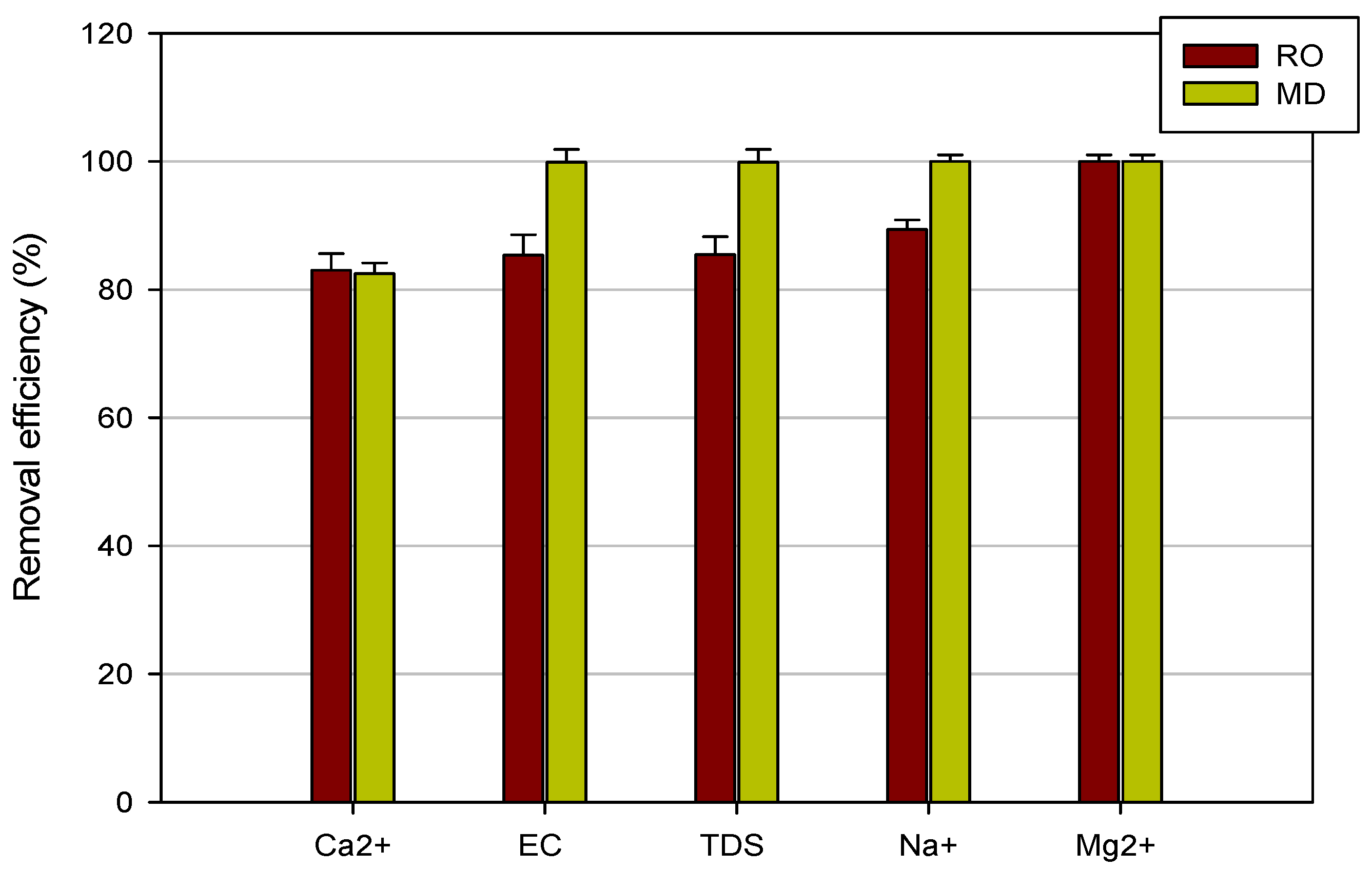

3.2. Reverse Osmosis and Membrane Distillation Performance

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Cheremisinoff, N.P. Pollution Control Handbook for Oil and Gas Engineering; Scrivener Publishing LLC: Salem, MA, USA, 2016; pp. 503–511. [Google Scholar]

- Chu, P. Technical Manual: Guidance for Assessing Wastewater Impacts of FGD Scrubbers; EPRI Report#1013313; Electric Power Research Institute: Palo Alto, CA, USA, 2006. [Google Scholar]

- USEPA. Steam Electric Power Generating Point Source Category: Final Detailed Study Report; EPA 821-R-09-008; USEPA: Washington, DC, USA, 2009. Available online: https://www.epa.gov/sites/production/files/2015-06/documents/steam-electric_detailed_study_report_2009.pdf (accessed on 26 November 2018).

- Mcvaugh, J.; Wall, W.T. Optimization of heavy metals wastewater treatment effluent quality versus sludge treatment. In Proceedings of the 31st Industrial Waste Conference, Purdue University, Lafayette, IN, USA, 22–26 March 1976; pp. 17–25. [Google Scholar]

- Blowes, D.W.; Ptacek, C.J.; Benner, S.G.; McRae, C.W.T.; Bennett, T.A.; Puls, R.W. Treatment of inorganic contaminants using permeable reactive barriers. J. Contam. Hydrol. 2000, 45, 123–137. [Google Scholar] [CrossRef]

- Morrison, S.J.; Metzler, D.R.; Dwyer, B.P. Removal of As, Mn, Mo, Se, U, V and Zn from groundwater by zero-valent iron in a passive treatment cell: Reaction progress modeling. J. Contam. Hydrol. 2002, 56, 99–116. [Google Scholar] [CrossRef]

- Huang, Y.H.; Zhang, T.C.; Shea, P.J.; Comfort, S.D. Effects of oxide coating and selected cations on nitrate reduction by iron metal. J. Environ. Qual. 2003, 32, 1306–1315. [Google Scholar] [CrossRef] [PubMed]

- Wilkin, R.T.; McNeil, M.S. Laboratory evaluation of zero-valent iron to treat water impacted by acid mine drainage. Chemosphere 2003, 53, 715–725. [Google Scholar] [CrossRef]

- Shokes, T.E.; Moller, G. Removal of dissolved heavy metals from acid rock drainage using iron metal. Environ. Sci. Technol. 1999, 33, 282–287. [Google Scholar] [CrossRef]

- EPRI. Selenium Removal by Iron Cementation from a Coal-Fired Power Plant Flue-Gas Desulfurization Wastewater in a Continuous Flow System—A Pilot Study; EPRI Report#1017956; Electric Power Research Institute: Palo Alto, CA, USA, 2009. [Google Scholar]

- NAMC. Review of Available Technologies for the Removal of Selenium from Water; Technical Report; North America Metals Council: Washington, DC, USA, 2010; Available online: http://www.namc.org/docs/00062756.PDF (accessed on 10 July 2018).

- Huang, Y.H.; Peddi, P.K.; Tang, C.; Zeng, H.; Teng, X. Hybrid zero-valent iron process for removing heavy metals and nitrate from flue-gas-desulfurization wastewater. Sep. Purif. Technol. 2013, 118, 690–698. [Google Scholar] [CrossRef]

- Scherer, M.M.; Richter, S.; Valentine, R.L.; Alvarez, P.J. Chemistry and microbiology of permeable reactive barriers for in situ groundwater cleanup. Crit. Rev. Environ. Sci. Technol. 2000, 30, 363–411. [Google Scholar] [CrossRef]

- Enoch, G.D.; Van Den Broeke, W.F.; Spiering, W. Removal of heavy metals and suspended solids from wastewater from wet lime (stone)-gypson flue gas desulphurization plants by means of hydrophobic and hydrophilic crossflow microfiltration membranes. J. Membr. Sci. 1994, 87, 191–198. [Google Scholar] [CrossRef]

- Liu, C.; Farooq, K.; Doll, B.; Venkatadri, R. Economical and reliable mercury reduction in refinery and power plant discharge wastewater with robust microfiltration membrane technology. Desalin. Water Treat. 2013, 51, 4980–4986. [Google Scholar] [CrossRef]

- Yin, N.; Liu, F.; Zhong, Z.; Xing, W. Integrated membrane process for the treatment of desulfurization wastewater. Ind. Eng. Chem. Res. 2010, 49, 3337–3341. [Google Scholar] [CrossRef]

- Fritzmann, C.; Lowenberg, J.; Wintgens, T.; Melin, T. State-of-the-art of reverse osmosis desalination. Desalination 2007, 216, 1–76. [Google Scholar] [CrossRef]

- Liu, H.Y.; Wang, J.L. Treatment of radioactive wastewater using direct contact membrane distillation. J. Hazard. Mater. 2013, 261, 307–315. [Google Scholar] [CrossRef] [PubMed]

- Kezia, K.; Lee, J.; Weeks, M.; Kentish, S. Direct contact membrane distillation for the concentration of saline dairy effluent. Water Res. 2015, 81, 167–177. [Google Scholar] [CrossRef] [PubMed]

- Macedonio, F.; Ali, A.; Poerio, T.; El-Sayed, E.; Drioli, E.; Abdel-Jawad, M. Direct contact membrane distillation for treatment of oilfield produced water. Sep. Purif. Technol. 2014, 126, 69–81. [Google Scholar] [CrossRef]

- Quist-Jensen, C.A.; Macedonio, F.; Horbez, D.; Drioli, E. Reclamation of sodium sulfate from industrial wastewater by using membrane distillation and membrane crystallization. Desalination 2017, 401, 112–119. [Google Scholar] [CrossRef]

- Chafidz, A.; Kerme, E.D.; Wazeer, I.; Khalid, Y.; Ajbar, A.; Al-Zahrani, S.M. Design and fabrication of a portable and hybrid solar-powered membrane distillation system. J. Clean. Prod. 2016, 133, 631–647. [Google Scholar] [CrossRef]

- Eykens, L.; Hitsov, I.; De Sitter, K.; Dotremont, C.; Pinoy, L.; Nopens, I.; Van Der Bruggen, B. Influence of membrane thickness and process conditions on direct contact membrane distillation at different salinities. J. Membr. Sci. 2016, 498, 353–364. [Google Scholar] [CrossRef] [Green Version]

- Koschikowski, J.; Wieghaus, M.; Rommel, M. Solar thermal-driven desalination plants based on membrane distillation. Desalination 2003, 156, 295–304. [Google Scholar] [CrossRef]

- Jia, D.; Wang, J. Treatment of flue gas desulfurization wastewater with near-zero liquid discharge by nanofiltration-membrane distillation process. Sep. Sci. Technol. 2018, 53, 146–153. [Google Scholar] [CrossRef]

- Conidi, C.; Macedonio, F.; Argurio, P.; Cassano, A.; Drioli, E. Performance of reverse osmosis membranes in the treatment of flue-gas desulfurization (FGD) wastewaters. Environments 2018, 5, 71. [Google Scholar] [CrossRef]

- Li, Q.; Song, J.; Yu, H.; Li, Z.K.; Pan, X.H.; Yang, B. Investigating the microstructures and surface features of seawater RO membranes and the dependencies of fouling resistance performances. Desalination 2014, 352, 109–117. [Google Scholar] [CrossRef]

- Lee, S.; Lee, E.; Elimelech, M.; Hong, S. Membrane characterization by dynamic hysteresis: Measurements, mechanisms, and implications for membrane fouling. J. Membr. Sci. 2011, 366, 17–24. [Google Scholar] [CrossRef]

- Ali, A.; Criscuoli, A.; Macedonio, F.; Argurio, P.; Figoli, A.; Drioli, E. Direct contact membrane distillation for treatment of wastewater for cooling tower in power industry. H2 Open J. 2018, 1, 57–68. [Google Scholar] [CrossRef]

- Sim, L.N.; Chong, T.H.; Taheri, A.H.; Sim, S.T.V.; Lai, L.; Krantz, W.B.; Fane, A.G. A review of fouling indices and monitoring techniques for reverse osmosis. Desalination 2018, 434, 169–188. [Google Scholar] [CrossRef]

- Shirazi, S.; Lin, C.J.; Chen, D. Inorganic fouling of pressure-driven membrane processes—A critical review. Desalination 2010, 250, 236–248. [Google Scholar] [CrossRef]

- Filloux, E.; Wang, J.; Pidou, M.; Gernjak, W.; Yuan, Z. Biofouling and scaling control of reverse osmosis membrane using one-step cleaning-potential of acidified nitrite solution as an agent. J. Membr. Sci. 2015, 495, 276–283. [Google Scholar] [CrossRef] [Green Version]

| Membrane Type | SWC-2540 |

| Membrane Material | Composite polyamide |

| Configuration | Spiral-wound |

| Salt Rejection (%) | 99.4 (minimum 99.0) |

| pH Operating Range | 2–11 |

| Max. Operating Temperature (°C) | 45 |

| Max. Operating Pressure (bar) | 69 |

| Membrane Surface Area (m2) | 2.34 |

| Water Permeability (kg/m2hbar) | 1.77 a |

| Zeta Potential (mV) | −21.2 at pH 7 b |

| Contact Angle | 96.05 ± 4.35 c |

| Membrane Material | Polyethyelene-oleophobic (PE-O) |

| Configuration | Flat sheet |

| Active Module Length | 50 cm |

| Membrane Area | 0.05 m2 |

| Mean Pore Size | 0.3 μm |

| Porosity | 80% |

| Membrane Thickness | 76 μm |

| Liquid Entry Pressure (LEP) | >4 bar |

| Contact Angle | >118° |

| MD Feed Solution | RO brine |

| TFeed, in, °C | 69 ± 0.1 |

| TPermeate, in, °C | 28 ± 0.3 |

| Feed Flow Rate, l/min | 0.5 |

| Permeate Flow Rate, l/min | 0.4 |

| Parameter | Sample | Overall Removal (%) | ||

|---|---|---|---|---|

| Raw Water | After Softening | After UF | ||

| Ca2+ (ppm) | 384.4 ± 4.8 | 39.16 ± 2.1 | 38.13 ± 2.1 | 90.00 |

| Mg2+ (ppm) | 289.9 ± 2.6 | 62.5 ± 0.5 | 62.4 ± 0.1 | 78.84 |

| Na+ (g/L) | 7.28 ± 0.6 | 7.0 ± 0.14 | 7.0 ± 0.3 | 3.84 |

| EC (mS/cm) | 33.6 ± 2.1 | 32.5 ± 1.2 | 31.1 ± 1.7 | 7.44 |

| TDS (g/L) | 16.9 ± 0.6 | 15.7 ± 0.8 | 14.62 ± 1.2 | 13.49 |

| TOC (mg/L) | - | 90.12 ± 0.90 | 33.80 ± 0.34 | 62.50 |

| pH | 6.7 ± 0.1 | 6.55 ± 0.2 | 6.8 ± 0.1 | - |

| Sample | Ca2+ (ppm) | Mg2+ (ppm) | Na+ (g/L) | EC (mS/cm) | TDS (g/L) | pH |

|---|---|---|---|---|---|---|

| Feed RO | 40.1 ± 0.8 | 67.4 ± 1.3 | 6.9 ± 0.1 | 34.7 ± 0.7 | 17.4 ± 0.9 | 7.53 ± 0.4 |

| Permeate RO | 6.9 ± 0.4 | n.d. | 0.70 ± 0.01 | 5.08 ± 0.10 | 2.53 ± 0.10 | 7.12 ± 0.14 |

| Retentate RO | 92.7 ± 1.8 | 175.1 ± 3.5 | 15.9 ± 0.3 | 69.4 ± 1.4 | 35.8 ± 0.7 | 7.78 ± 0.15 |

| Permeate MD | 16.22 ± 0.32 | n.d. | n.d. | 0.080 ± 0.001 | 0.040 ± 0.001 | 6.37 ± 0.13 |

| Retentate MD | 286.64 ± 5.37 | 539.8 ± 10.8 | 4.9 ± 0.1 | 158.3 ± 3.1 | 78.8 ± 1.6 | 8.15 ± 0.16 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Conidi, C.; Macedonio, F.; Ali, A.; Cassano, A.; Criscuoli, A.; Argurio, P.; Drioli, E. Treatment of Flue Gas Desulfurization Wastewater by an Integrated Membrane-Based Process for Approaching Zero Liquid Discharge. Membranes 2018, 8, 117. https://doi.org/10.3390/membranes8040117

Conidi C, Macedonio F, Ali A, Cassano A, Criscuoli A, Argurio P, Drioli E. Treatment of Flue Gas Desulfurization Wastewater by an Integrated Membrane-Based Process for Approaching Zero Liquid Discharge. Membranes. 2018; 8(4):117. https://doi.org/10.3390/membranes8040117

Chicago/Turabian StyleConidi, Carmela, Francesca Macedonio, Aamer Ali, Alfredo Cassano, Alessandra Criscuoli, Pietro Argurio, and Enrico Drioli. 2018. "Treatment of Flue Gas Desulfurization Wastewater by an Integrated Membrane-Based Process for Approaching Zero Liquid Discharge" Membranes 8, no. 4: 117. https://doi.org/10.3390/membranes8040117

APA StyleConidi, C., Macedonio, F., Ali, A., Cassano, A., Criscuoli, A., Argurio, P., & Drioli, E. (2018). Treatment of Flue Gas Desulfurization Wastewater by an Integrated Membrane-Based Process for Approaching Zero Liquid Discharge. Membranes, 8(4), 117. https://doi.org/10.3390/membranes8040117