1. Introduction

Sustainable development encompasses the three basic pillars of activity that ensure environmental, economic, and social development. Maritime or port logistics [

1] is also moving in this direction, seeking to organize multimodal transportation in an environmentally sustainable manner, with the lowest possible greenhouse gas (GHG) emissions, at economically acceptable prices, and with an employee-friendly work environment. The greatest emphasis is on the environmental dimension [

2], although socio-economic aspects are important for the sustainable operation of the port and terminal systems, as well as maritime and land transport sectors [

3].

UNCTAD [

4] highlights the importance of sustainable development of the maritime industry, which is currently under great pressure from global supply chains regarding the speed of deliveries and transport prices. Due to the decrease in the number of Container Lines (CL) or through integration or acquisitions, the supply of maritime container services is shrinking more and more. The latter strengthens the market position of CLs, but Matsuda et al. [

5] point out that there is no monopoly situation in the market. Prices for maritime container transport surged in late 2020 and then in the second quarter of 2021, reaching approximately 14,000 USD/FEU (Forty Equivalent Unit) in 2022 on the main maritime route between Asia and Europe. In the first half of 2020, prices for container services from Asia to Europe were almost ten times lower [

6]. In the mentioned period, the reliability of maritime services also decreased significantly.

At the beginning of 2020, the highest reliability was achieved by Denmark’s Maersk, with 46.9%, which Hamburg Sud followed with 42.8% and MSC with 30.7% [

7]. Before the COVID-19 pandemic outbreak in 2019, CL reached a reliability of over 80% [

8]. The irregular vessel arrivals at ports have affected the optimal operation of ports and container terminals. Queues for available berths are increasing, and the time to pick up the container at the terminal is getting longer. The total transit time of goods, including port logistics, has grown over the last two years, which has a negative impact on the sustainable operation of supply chains. The volumes of goods to be delivered are increasing, putting a strain on the liquidity of goods owners. Therefore, the aspect of economic sustainability is questionable. The negative impact on environmental sustainability should also be considered, as ships emit GHG emissions into the atmosphere even if they wait several days for a berth without performing basic transportation activities. Delays can lead to an increase in voyage speed, which negatively impacts GHG emissions. A 10% reduction in voyage speed reduces fuel consumption and emissions by nearly one-third [

9]. Multiple handling of full containers in terminals also leads to energy inefficiency and additional pollution due to long idle times [

10].

The COVID-19 pandemic certainly had the greatest impact on the above changes. In the beginning, the regular supply of semi-finished raw materials was crippled. As infections and deaths increased, preventive measures were initiated globally to contain the pandemic. Production facility closures and supply delays resulted in higher demand for cargo space during the relatively short period of a temporary decline in infection numbers in the summer months of 2020 and 2021. There was excess demand relative to production and supply capacity [

11]. The precautionary closure of some ports in Asia in 2021 due to the pandemic resulted in long queues outside ports and hundreds of ships at anchorages outside ports. As a result, shipping space availability, ocean freight growth, and lead time prolongation have come under additional pressure. Companies are, therefore, faced with supply chain restructuring and changes in distribution channels [

12]. Durugbo et al. [

13] point out that shortening supply chains and the search for resources in the local environment will further impact port logistics.

The ports of the northern Adriatic are strongly involved in global overseas supply chains. The volume of goods from Asian ports is increasing year-by-year, so the supply chains through the ports have certainly suffered from the negative consequences of the COVID-19 pandemic. This study aims to investigate the impact of the COVID-19 pandemic on the sustainable operation of port logistics and supply chains through the ports of the northern Adriatic Sea and to determine how logistics service providers (LSPs) have adapted to the changed way of working. The basic research hypothesis (H0) is that the COVID-19 pandemic strongly impacted the operation of port logistics in the selected ports of the northern Adriatic. The auxiliary hypothesis (H1) aims to identify the LSPs’ adjustments in sustainable operations and states that LSPs introduced a new way of working for efficient and sustainable port logistics.

While previous studies focused mainly on identifying port adaptations to emergencies in port logistics during the COVID-19 pandemic, our study focuses on understanding changes and sustainable measures that LSPs implemented for the smooth flow of logistics chains through ports while ensuring a safe working environment for employees. Notteboom and Haralambides [

14] point out the need for such studies to be conducted by the research community to understand port governance and port logistics development in the post-pandemic era. The study results provide meaningful conclusions about rapid changes in port logistics operations under emergency medical and operational conditions that will have long-term impacts on the industry. The study enriches existing knowledge on the impact of the COVID-19 pandemic on port operations and serves as a basis for further action to ensure sustainable development.

2. Port Logistics during the COVID-19 Pandemic

In the early 2020s, the COVID-19 pandemic spread and crippled the Asian market, and later, the rest of the world, including the European market. China very quickly and effectively contained the spread of the COVID-19 virus, allowing local factories to resume normal operations. At the same time, in Europe, the virus substantially impacted the economy and triggered important responses at the national and European levels [

15]. Countries responded differently with measures to close public life, a functioning economy, crossing borders, and measures tailored to social groups [

16]. Supply chains were threatened by the closure of production facilities, ports, and warehouses. Labor shortages due to infections or preventive decisions by employers slowed workflows, communications, and logistics processes. Mena et al. [

17] argue that COVID-19 demonstrated how vulnerable supply chains are in times of crisis, and at the same time, some industries are more resilient to certain market conditions.

From a micro-logistics perspective, it is important to point out the problems in providing all the resources needed for business operations, which in many cases led to bankruptcy and the cessation of operations [

18]. Business risks increased significantly during the pandemic, and LSP selection was one of the main risks during the COVID-19 pandemic [

19]. The latter had a significant impact on the supply chain [

12,

13] and, at the same time, on the financial performance of logistics companies [

20]. In their research findings, Hilmola et al. [

21] point out that most of the companies studied had to increase their inventories of raw materials and semi-finished products to ensure smooth operations and faced an extraordinary increase in transportation costs. Tsai et al. [

11] note that the COVID-19 pandemic affected the supply of certain semi-finished products, particularly microchips and electronics, further complicating the operation of global supply chains and changing the priority of maritime and air transportation. According to Kutsenko et al. [

22], these two modes of transport had the greatest negative impact.

The socially sustainable aspect of the impact of the COVID-19 pandemic must also be considered from the perspective of work organization. The decline in orders triggered a wave of layoffs in various industries [

23]. The absence of employees from work due to the ordered quarantine forced companies to look for alternative remote work methods. The number of employees in the transportation and logistics industry who regularly work from home has increased. According to Dorofeev’s [

24] research, this led to many new circumstances in companies’ process operations as problems arose with Internet access, remote access to computer programs, protection of sensitive data, etc. Many companies in the transportation and logistics industry quickly adapted to the new way of working, some of which are still in use. It allows companies to reduce the cost of transporting employees to work while presenting themselves as employee-friendly employers.

The COVID-19 pandemic has had an impact on pollution. With the forced shutdown of the economy due to measures to prevent the spread of the virus, pollution from transportation has decreased [

25,

26,

27]. Similar positive effects of economic crises on GHG reduction are highlighted by Nocera et al. [

28], as the volume of transport use decreases along with investments in transport infrastructure and transport systems. Similarly, the past decade’s economic crisis impacted the reduction in GHG emissions [

29]. However, the gradual easing of the epidemiological situation and the general stagnation of international trade for several months led to the rapid start-up of industries and the need to transport large quantities of raw materials and products, which negatively affected the cost of carbon emissions [

30]. Speed of delivery and price of transportation took precedence over environmental friendliness of transportation, moving transportation operations away from the established green agenda.

The highlighted points of the COVID-19 pandemic had important impacts on port logistics, which different authors analyzed. Notteboom and Haralambides [

14] expose that all stakeholders in the port ecosystem were affected by economic, social, institutional, and environmental shocks caused by the COVID-19 pandemic. Port authorities have been very active in responding to the decline in cargo and ship calls. The decrease in the latter was as high as between 20 and 30% in 2020 [

31]. Zhang et al. [

32] find a very close correlation between the speed of the pandemic’s spread and the decline in dry bulk, container, and liquid bulk cargoes, which resulted in rapid and mostly negative impacts on port logistics. Notteboom et al. [

33] also point to a close relationship between the decline in supply chain activity and the operations of container terminals and shipping companies. Terminal operators respond quickly to changes by adapting their processes and seeking leaner operations. Mańkowska et al. [

34] also emphasize the need for tactical adaptation by terminal operators, who are forced to seek new terminal management strategies under the pressure of the epidemic. Similarly, the issue of terminal capacity during a pandemic is addressed by Russell et al. [

35], who emphasize the importance of infrastructure flexibility for the efficient operation of port logistics. Additionally, Merk et al. [

36] analyze the impact of the COVID-19 pandemic on the operation of ports and container shipping companies and note that the consequences are also pronounced in the post-pandemic period. During the pandemic, there were changes in the business of CL, which faced lower occupancy of vessel capacity, and in their vertical integration. In the comprehensive treatment and understanding of the adaptation of port logistics during the COVID-19 pandemic, there is a lack of studies in the field of impacts on the operation of LSPs, which are the generator of logistics flows through selected ports and coordinate successive operational activities along the logistics chains.

The operation of LSPs during the pandemic is discussed by Gultekin et al. [

37] and Herold et al. [

38], but not specifically about companies that are part of the port ecosystem. The authors note that during the pandemic, LSPs were exposed to high risks of fluctuations in logistics chains, which affected employee management and communication. Similarly, Dovbischuk [

39] deals with logistics companies, namely their response to the lack of maritime services, delivery limitations, etc. LSPs respond quickly to changes, especially where there is a higher level of innovation and internal involvement of employees. Rokicki et al. [

40] analyzed the performance of LSPs during the pandemic in Poland, while Ahmedova [

41] analyzed transport companies in Bulgaria. Both analyses highlight the importance of the development of digitization within LSPs and the effective management of human resources during the pandemic. Choi [

18] also specifically points out the digitization of operations in managing logistics systems and the importance of sudden changes for higher risks in the effective realization of logistics services.

Even if there are studies on the impact of the COVID-19 pandemic on port logistics, we note that there is a lack of studies in the field of the adaptation of freight forwarding or LSPs to the changed circumstances in port logistics. Thus, our study covers a specific gap for a comprehensive understanding of changes in port logistics, with additional emphasis on the sustainable operation of LSPs during the pandemic.

3. Research and Methodology

This study focuses on a specific area of global supply chains, namely port logistics. Port logistics includes the organization of maritime transportation, transshipment, and land transportation of goods or containers from the port to the consignee. Within port logistics, the research is limited to the adaptation of forwarding and logistics companies to the emergency conditions of the COVID-19 pandemic. Geographically, this study is limited to the area of the northern Adriatic Sea, with a special focus on port logistics through the ports of Koper (Slovenia) and Rijeka (Croatia). The geographical location of this study coincides with the situation during the COVID-19 pandemic when supply chains pursued the shortest transport routes for the delivery of essential goods for the supply of people. The transport route between China and the northern Adriatic offers the shortest sea connection to supply central European markets. As a result, we can assume that the impacts on changes in port logistics were more pronounced. The two ports were chosen because similar maritime container services are offered there and because the logistics companies located in Koper also offer maritime logistics services in the port of Rijeka.

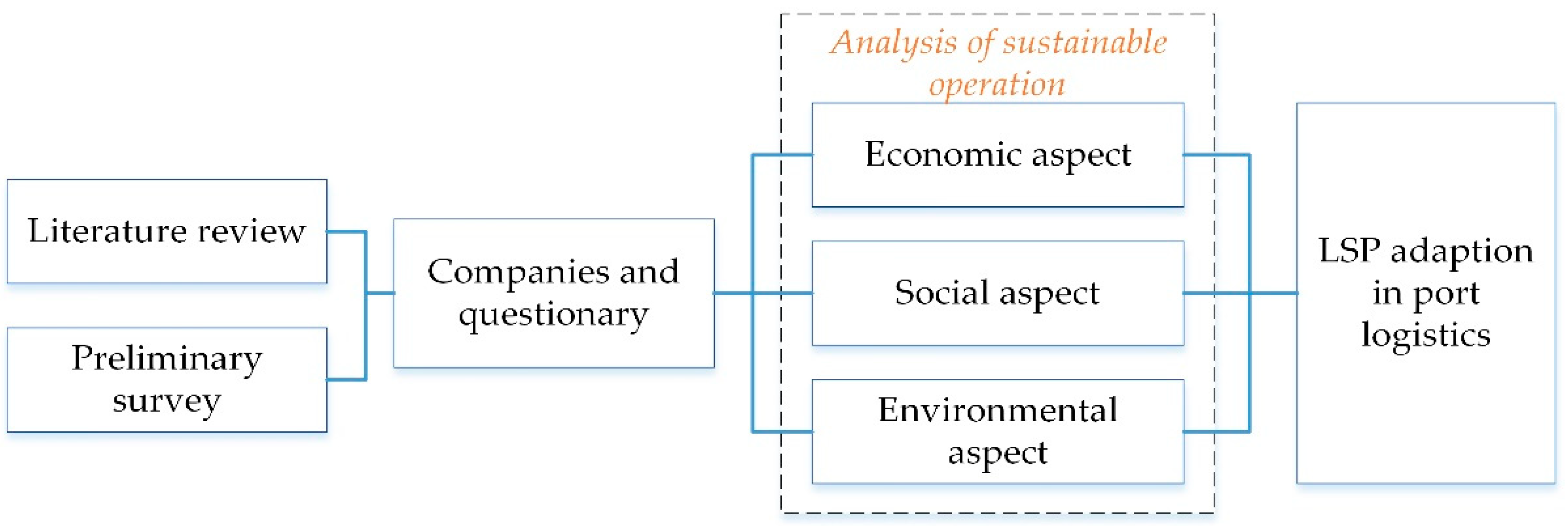

This study includes an analysis of LSPs’ opinions on implemented changes and the sustainable operation of port logistics during the COVID-19 pandemic and consists of three steps (

Figure 1). First, a review of the literature and a preliminary meeting with key LSPs were conducted to understand the starting points of changes in port logistics. In the second step, LSPs were identified, and a structured questionnaire was prepared. Based on three aspects of the sustainable approach, findings on adapting LSPs to new ways of working in port logistics are formulated.

Altogether, 90 logistics companies, including shipping agencies that provide port logistics and hinterland transport, were contacted via email and social platforms (LinkedIn). Of these, 45% are regional LSPs, and the rest represent global logistics companies’ offices. Regarding the number of employees, 60% are companies with more than 200 employees. The companies were asked to provide responses to the survey, published in the online tool 1ka.si. As many as 91.1% of the companies accessed the survey page. A total of 38 companies (42.22%) participated in the survey and answered six sets of questions. The entire survey was completed by 30 companies or 33.33% of all contacted companies. The survey was conducted in February and March 2022.

A structured questionnaire was prepared based on a literature review and preliminary discussions with five larger and more important LSPs in terms of volume of business through selected ports, highlighting the biggest problems and adaptations of business operations during the COVID-19 pandemic. The companies also warned about the range of answers they are willing to give so that they do not reveal commercially sensitive data. Consequently, the questionnaire includes sets of questions covering three key areas for the sustainable operation of port logistics during the COVID-19 pandemic. The economic aspect covers the specific sub-area and elements of price access to overseas container transportation, the availability of transportation, and the time element of transportation execution. The environmental aspect of transportation is examined in terms of the degree of focus on environmentally friendly transportation before and during the COVID-19 pandemic and the extent to which green transportation is chosen in relation to other elements, such as price, time, safety, and reliability. The social aspect of port logistics implementation is examined in terms of the company’s commitment to employees: their safety, absence from work, ability to work from home, and the cost aspect to employees.

The first part of the survey examines which role port logistics companies experience the most problems with related to the COVID-19 pandemic. The second part of the survey asks which problems LSPs encounter most often. Companies choose from six previously formulated statements (no issues, problems with space, problems with drivers, problems with transportation price, problems with coordination of transport, problems with cooperation with the terminal). The third section examines the quantitative change in the challenges of implementing port logistics during the COVID-19 pandemic. The companies evaluate the percentage changes compared to the pre-pandemic situation. The fourth section aims to identify changes in work processes and employee support. Companies quantitatively rate changes in employee work practices using a seven-point scale. The fifth and comprehensive section examines the environmental orientation of port logistics during the COVID-19 pandemic. Companies rank transportation components according to the needs of goods owners and compare green transportation to transportation time, price, safety, and reliability components. The companies also evaluate the importance of green container transportation in organizing overseas transportation before and during the COVID-19 pandemic.

4. Results

This study’s results highlight the changes in sustainable port logistics during the COVID-19 pandemic. As expected, in the organization of maritime transport, LSPs have the most problems with the successive use of different means of transportation in complex intermodal chains. No less than 89% of the companies have the most problems with maritime transport, and 11% have the most issues with the organization of road transport of containerized goods. Space problems or access to a means of transport affect 94% of companies in maritime transport. Similar problems are experienced by 44% of companies in road transport and 33% of companies in organizing rail transport. Companies that also manage air transport of shipments for their customers face similar challenges in 22% of cases. No less than 96% of LSPs have problems finding drivers for road transport. The results are somewhat expected, as the studies by Brooks et al. [

42] and Sperry et al. [

43] also highlight the problems faced by road transport companies during the pandemic. Only 4% of the companies reported staffing problems in maritime and rail transport. The increase in transportation prices due to the pandemic has affected the activity of LSPs, as 90% of the participating companies have problems with maritime prices. The latter result is expected, as studies point to problems with the rapid increase in sea freight rates [

31,

44]. Price problems in road transport were highlighted by 48% of the companies. Prices in rail transport are not a challenge for LSPs, as only one company pointed out such problems. The impact of price pressures and difficulties in obtaining loading space is often reflected in the difficulty of coordinating subsequent shipments in combined or intermodal transport.

A total of 78% of companies pointed to problems with consecutive shipments in maritime transport, while 48% of companies have issues coordinating shipments in road transport. Due to the complexity of intermodal transportation, as many as 37% of companies have problems coordinating rail transport. The second set of questions provides information about LSPs’ issues with the work and responsiveness of the port or terminal. For the largest percentage, 93% of the companies, the problems with container terminal operations are mainly reflected in the lower efficiency of maritime transport and land transport to a lesser extent. The same is shown by Coulinane in Haralambides [

31], as container ships waited for free berths and, thus, became floating warehouses. For 38% of LSPs, the lower efficiency of port or terminal operations is reflected in suboptimal road transport management, and for only 24% of companies in poor rail transport organization.

Undoubtedly, the negative consequences of the COVID-19 pandemic are reflected throughout the supply chain [

45]. This situation is also confirmed by the survey data, as 97% of companies point to the time extension of supply chains. Of these, 28% of companies claim that times increased by 30%, while 25% believe that times have increased by 20% and 40%, respectively. Only a quarter, or 26%, of the companies surveyed, said that supply chains requiring port logistics have lengthened by 50% or more. The obtained results are much better compared to the results of the ISM survey, according to which supply chain times at the global level even doubled [

46].

A major factor in lengthening supply chains during the COVID-19 pandemic has been heavily congested ports. Overall, 38% of companies reported a 20% increase in container dwell time at the terminal. One-fifth of companies (19%) identified a 30% increase in container dwell time at the port, while 13% believe container dwell time increased tremendously by 40% or even more than 50% (

Figure 2).

Logistics companies are faced with the problem of high prices and the acceptance of price increases by the owners of the goods. Based on previous transport contracts, no less than 34% of the companies have to inform their customers about a more than 50% price increase. A quarter of the companies have to increase prices to customers by 40%, and 16% of the companies have problems with a price increase by one-third. Only 13% of companies need to increase prices to customers by 20%, and 9% of companies by 10% of the previously agreed price. An increase in warehouse prices by between 20 and 30% was confirmed by 72% of the companies. Only 16% of the companies have not yet had to accept an increase in warehouse prices. The remaining 12% of LSPs were confronted with an increase in prices for storing goods and containers by more than 30%. The opinions of logistics companies differ when evaluating the share of energy prices in the transport and logistics prices increase.

The majority, 57% of the companies, believe that the share of energy prices impacted the increase in transport and logistics prices from 10% to 30%. As many as 22% of the companies believe that more than 50% of price increases are related to energy prices. The price increase is also reflected in the lack of available cargo storage space. A good third (34%) of companies have major problems with a lack of storage space at 20%. A slightly higher proportion (37%) of companies have more than 30% of major issues with storage space compared to the pre-pandemic situation (

Figure 2).

Limited communication between parties often generates price, space, and time problems [

47]. CL is certainly the most important stakeholder in port logistics; thus, their communication should be very responsive and efficient. Companies estimate that communication with them has worsened or become more difficult compared to the pre-pandemic period. The largest percentage of companies (28%) believe that communication has been further exacerbated by more than 50%. It is followed by 19% of companies who believe communication with CL has worsened by 20%, and only 16% of companies believe communication has remained the same as before the pandemic. Given the deterioration in communication between port logistics stakeholders, we examined whether CLs adapted during the COVID-19 pandemic by digitizing communication and documentation processes. Most companies (44%) believe there have been no changes during the pandemic. Just slightly under a third of companies (28%) saw an improvement of 10%, and 13% of companies saw a gain of 20% in communication with CLs through introducing a higher level of digitization. The results are consistent with the study of Toygar et al. [

48], who point to the need for faster adaptation of CL’s digital communications. While the latter introduce changes, the pandemic has highlighted the need for the faster digitization of operations along logistics chains.

From the social point of view of the sustainable operation of LSPs, there were significant changes in workplaces and the work process organization. One-third of the companies had to increase the number of employees during the COVID-19 pandemic. Approximately a quarter (23%) of the companies increased their staff by 10%, while 10% of logistics companies increased their team by 20%. The vast majority, 65% of companies, did not change the number of employees (

Figure 3). Companies have become much more attuned to the new way of working, which allows employees to work from home. As many as 74% of the companies surveyed have introduced such a work process. A high proportion among the LSPs studied is expected because the companies mainly provide administrative and sales support as part of port logistics. According to a study by Herold et al. [

38], working from home is lower among companies that mainly provide long-distance transportation, warehousing, and distribution. These companies have also decreased their staff or introduced half-time work due to reduced orders. In our study, almost one-third (29%) of companies have used teleworking from home for half of their staff. Moreover, 23% and 16% of companies organized such work for 20% and 30% of employees, respectively. In 6% of companies, only 10% of employees work from home.

Companies have also adapted their programs and processes to support the changes in their work. The volume of remote meetings has increased sharply. No less than 48% of companies have increased such communication by 50% in their business and 39% of companies increased digital communication platforms by 20% or 30%. Only 6% of companies stayed with the same approach. Increased investment in the digitization of operational processes was confirmed by 65% of companies, much more than the results of a survey among transport companies conducted by Ahmedova [

41]. In each case, 16% of companies increased their input by 10% and more than 50%. Increased investments by 20% were made by 23% of companies, while 16% increased their assets by 30% or more (

Figure 3).

The environmental sustainability pillar in port logistics was reviewed using a ranking of elements of companies’ decisions in organizing transportation. Among the elements of price, time, safety, reliability, and environmentally friendly mode of transport, no LSP chose the last element. Almost half of the companies (48%) chose the element of reliability (

Figure 4). In second place was the element of time (30% of companies), followed by the element of price (13%). Only 3% of the companies chose the element of safety. Companies also made suggestions for important details, e.g., 3% of the companies believe that accessibility of transportation equipment is important, and 3% assume that it is necessary to consider all the elements and adapt them to the very different needs of the customers. Companies were specifically asked whether a greener mode of transportation is more or less important than before the COVID-19 pandemic. Companies defined importance on a scale of −10 to +10. One-third of companies (32%) believe the importance of greener modes has remained unchanged, while 23% of logistics companies believe it has worsened. Of these, 14% of companies rated the significance with a value of −10 and 9% with a value of −7. 14% of LSPs state that the importance has increased (value 4), while 5% of companies agree with the greatest change with a rating of 6. The median score among the surveyed companies is −0.5 points, which means that the green approach to transportation planning in port logistics is considered slightly less than before the COVID-19 pandemic.

5. Discussion

The study results reveal changes in the sustainable operation of port logistics in selected ports during the COVID-19 pandemic. LSPs can see changes in all three key areas, economic and social, as well as the environmental performance of transport services. They have the most problems with maritime transport, as indicated by 89% of respondents, where the greatest issues are with space and accessibility of transport means (94% of companies). In addition, 44% of companies have similar problems with road transport, where companies also have many issues with the availability of drivers (as many as 96% of logistics companies surveyed). Issues with prices for international transport are also significant. No less than 90% of national and international logistics companies have problems with prices in maritime transport, and 48% of companies with costs in road transport. The prices of energy products undoubtedly influenced the increase in prices, but the indirect effects of the longer dwell time of containers in terminals, ships at anchorages, and problems with carriers and means of transport are also significant. All these factors had a substantial impact on the lengthening of supply chains. An extension of more than 40% of the normal lead time in the supply chains is confirmed by more than 40% of logistics companies, which is less than the globally perceived prolongation [

46]. It can be concluded that the implementation of logistics routes through the northern Adriatic was more successful than other maritime routes and that the stakeholders in the port logistics ecosystem successfully responded to the consequences of the pandemic.

The social aspect of sustainable management in port logistics is highlighted by the research findings as an important factor in the changing nature of sustainable management of the workforce. Undoubtedly, employees are under great pressure to communicate with the owners of the goods, to whom they must adequately communicate the rising prices, cargo space problems, and availability of transportation. This difficulty, which is 30% higher than before the COVID-19 pandemic, is perceived by more than half of the logistics companies operating through the ports of Koper and Rijeka (

Figure 5). The impact of the COVID-19 pandemic on employees is very pronounced and is also reflected in the absence of employees from the traditional workplace. Such work organization leads to a lack of communication and the joint management of difficult situations in port logistics. The results of the study highlight the difficulties in communicating with CLs, as more than 50% of the companies estimate these difficulties to be 30% higher than before the pandemic (

Figure 5). In addition, employees have to use new software tools to conduct remote meetings, although they receive very little training. No less than 90% of companies introduced such a way of working during the COVID-19 pandemic. As also highlighted in other studies [

48,

49], the shipping sector needs to digitize faster and involve as many stakeholders as possible in the chain’s digitalization. By this, the pressure on ports can be effectively reduced, and consequently, the efficiency of port logistics increases.

There are also noticeable changes in implementing the third pillar of the sustainable operation of port logistics in the northern Adriatic. The organization of the logistics chain is primarily aimed at ensuring the highest possible reliability of transport, as it has more than halved in the maritime container industry during the COVID-19 pandemic. Time and price are also important, while the most environmentally friendly mode of transportation is not among the decision priorities of logistics companies. Compared to the pre-COVID-19 pandemic, the importance of a green way of transport has decreased among LSPs in the northern Adriatic, but the change is less pronounced compared to other analyzed elements. Changes that would reduce the importance of the green mode by more than 30% were expressed by 14.5% of companies.

The results indicate important changes in the sustainable operation of port logistics in the northern Adriatic region. It should be noted that the results are directly dependent on the characteristics of the operation of port logistics in the northern Adriatic, such as container services, number of LSPs, size of the container terminal and its throughput, number of road carriers, the volume of train connections to Central Europe, etc. Research on changes in sustainable port logistics in other regions should be adapted to the above circumstances. Consequently, different results can be obtained depending on the level of operational work, the involvement of stakeholders in complex intermodal transport chains, and the level of digitalization. Moreover, port logistics faces important technical and technological changes shaping the sector’s further development and employees’ involvement in operational processes. Permanent changes are to be expected, brought about by the digitalization of operational processes and the different systematization of work. Such changes may also have negative consequences, such as poor communication, knowledge and information transfer, shifting costs to employees working from home, etc.

The results provide a detailed overview of changes in the European intermodal node on the important Asia–Southern Europe intermodal maritime corridor and a good starting point for a more comprehensive global view of changes in port logistics. Therefore, it is necessary to consider the results regionally and search for commonalities for general changes in the functioning of port logistics and between LSPs with further regionally focused research. Such research is planned for future project work by delineating the impacts caused by the COVID-19 pandemic and the general evolution of port logistics.

6. Conclusions

The COVID-19 pandemic has had a tremendous impact on the functioning of economies around the world. The effect on supply chains is still being felt as the virus, while no longer as deadly, is still spreading. The negative consequences can be seen in congestion at ports and terminals, ships waiting at anchorage for a free berth, high transportation prices, and general uncertainty about timely deliveries. Port logistics aim to mitigate the negative impact on supply chains but has been severely affected by the pandemic. This is also reflected in the activities of logistics companies. The results of the study make it clear that there will be significant changes in the sustainable operations of the companies, which will certainly have longer-term consequences. From the economic perspective of sustainable supply chain activities, there are substantial changes in logistics and transportation prices. Some companies cannot afford these costs, which affects the liquidity of operations and the reliability of supply chains. There are also changes in the social aspects of sustainable port logistics, especially in logistics companies. The study results show regional changes in operational processes, organization, and working methods, as well as the internal and external communication of the companies. The requirements for on-time and reliable transportation have eclipsed environmental priorities regarding a more environmentally friendly way of overseas transportation. Thus, this study’s results confirm the basic research hypothesis (H0) that the COVID-19 pandemic strongly impacted maritime logistics operations in the ports of the northern Adriatic. The data analysis also confirms the auxiliary hypothesis (H1) that LSPs moderately changed their working approaches for efficient and sustainable port logistics. Namely, LSPs have adapted elements of all three pillars of sustainable port logistics to external economic, security, and health influences. In some areas, the changes will be permanent. These include changes in delivery locations, which will move closer to consumption locations. This will shorten delivery times, lower transportation costs, and reduce risks to supply security. On the social side of sustainable employee engagement, we can expect more widespread and accelerated digitization of workflows, working from home, more virtual remote business meetings, and new approaches to managing the risks of employee absenteeism. As for the environmental strategy, the reduced focus on greener transportation will likely be temporary and will return once port logistics return to normal. Indeed, processes to use greener propulsion and reduce the carbon footprint of the maritime industry will continue.

This study’s results add new understandings to the existing knowledge on the impact of the COVID-19 pandemic on sustainable supply chains, particularly on port logistics in the observed region. The findings are particularly relevant regarding how companies adapt to the new market and workforce demands and how this translates into changes in sustainable port logistics.