Collaborative Optimization of Yard Crane Deployment and Inbound Truck Arrivals with Vessel-Dependent Time Windows

Abstract

:1. Introduction

2. Problem Formulation

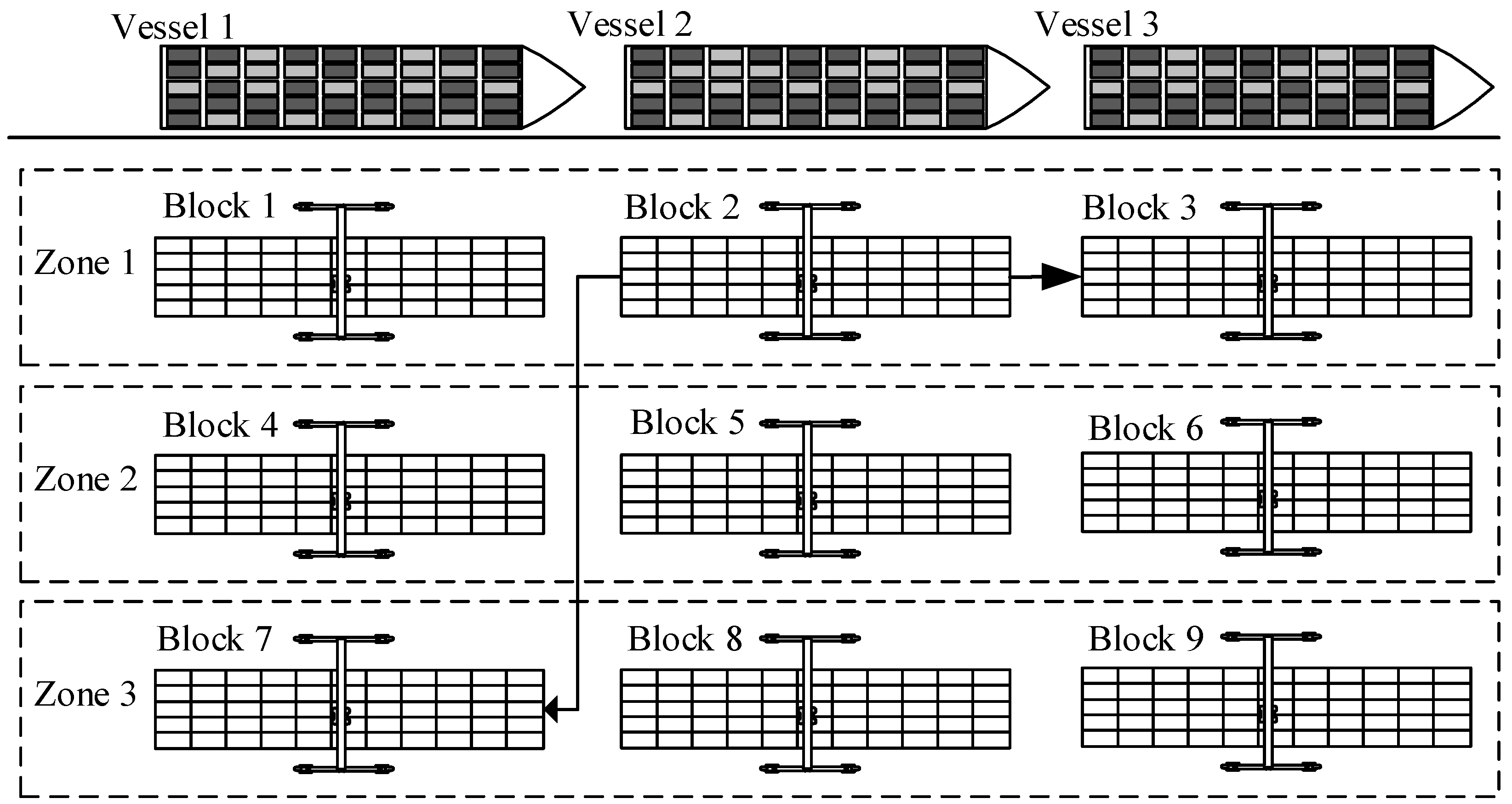

2.1. Problem Description and Assumptions

2.2. Vessel Dependent Time Windows

2.3. Container Yard Operation and RTGC Deployment

2.4. Assumptions and Notations

2.4.1. Assumptions

- Most international container carriers offer regular weekly service, so we assign the optimal time window to truck entries related to each vessel that will arrive within a planning horizon of one week.

- The proportions of truck flows of each vessel headed to a yard destination (specific blocks) remain constant over the entire planning horizon.

- In order to facilitate the ship loading process, outbound containers shall be stacked in the container yard before the corresponding vessels are berthed. This means that VDTWs are affected by the berth plan. In order to simplify the problem, berth allocation is not considered. It is only assumed that the ending point of each vessel’s time window should be earlier than the corresponding vessel’s expected time of arrival. Readers interested in berth allocation can refer to [35].

- In order to reduce traffic blockages, an RTGC can only move once at most during each RTGC deployment shift.

- To simplify the problem, the model also assumes that if an RTGC needs to be moved, it should be moved at the beginning of the deployment shifts.

2.4.2. Notations

- Indices

- : index of vessels, , where is the number of vessels that will arrive within a planning horizon

- : index of periods, , where the planning horizon is divided into P periods, each of which has a duration of hours

- : index of RTGC deployment shifts, , where the planning horizon is divided into RTGC deployment shifts, each of which has a duration of hours. The RTGC can be redeployed for each shift

- : index of time intervals, where the planning horizon is decomposed into T time intervals

- : index of gate lane, , where is the number of gate lanes

- : index of yard block, , where is the number of yard blocks

- 2.

- Input parameters

- : planning horizon (day)

- : the number of time intervals included in each period,

- : the number of time intervals included in each RTGC deployment shift,

- : the expected time of arrival of vessel

- : the estimated time of departure of vessel

- : 0–1 variable which judges whether the vessel has left the port during the appointment period . If vessel has dispatched at the beginning of period , , otherwise . If the start time of the planning horizon is 0, the period refers to the time range . Therefore,

- : outbound container volume of vessel (natural container)

- : the average loading rate of inbound trucks (natural containers /truck)

- : The proportions of outbound containers of vessel headed to block

- Zj: the set of vessels whose outbound containers are stored at block

- : the service rate of one gate lane at time interval (trucks/ interval)

- : the service rate of one RTGC at time interval (natural container/ interval)

- : the coefficient of variation of service time distribution of one RTGC

- : the minimum length of time window

- : the maximum storage capacity of block

- : set of blocks that RTGC at yard block cannot be transferred to/from. Due to the fact that RTGCs cannot cross each other, RTGC transferring from block to block cannot stride across other blocks

- : set of blocks that cannot transfer RTGC to other blocks at RTGC deployment shift . When the workload of one block is greater than 0, RTGCs deployed in the block cannot be transferred to other blocks

- : travelling time of RTGC from block to block (h)

- : initialize workload of block at the beginning of the planning horizon (h)

- : the number of RTGCs in block at the beginning of the planning horizon

- 3.

- Derived variables

- : arrival ratio of inbound trucks in period for vessel

- : the number of trucks arriving at terminal gate in period for vessel

- : arrival flow rate at terminal gate at time interval

- : the average number of trucks waiting in queue at terminal gate at time interval

- : actual discharge rate of terminal gate at time interval

- : the capacity utilization rate of the gate lane at time interval

- : arrival flow rate of vessel at time interval

- : arrival flow rate at yard block at time interval

- : the average number of trucks waiting in queue at yard block at time interval

- : actual discharge rate of yard block at time interval

- : the capacity utilization rate of RTGC at yard block at time interval

- : the number of RTGCs transferred from block and have been deployed at block before time interval

- : the number of RTGCs have been deployed to block at time interval

- : the workload underflow in block after RTGC deployment shift (h)

- : the workload overflow in block after RTGC deployment shift (h)

- 4.

- Decision variables

- : the starting period of time window for vessel

- : the ending period of time window for vessel

- : the number of RTGCs moving from block to block at the beginning of RTGC deployment shift , when , these RTGCs stay in the same block during RTGC deployment shift .

2.5. Mathematic Model

2.5.1. Upper Level Problem of Vessel-Dependent Time Window Optimization

- Objective function

- 2.

- Constraint for time windows

- 3.

- Constraints for queuing process at terminal gate

- 4.

- Constraints for queuing process at container yard

2.5.2. Lower Level Problem of RTGC Deployment

- 1.

- Objective function

- 2.

- Constraint for RTGC deployment

3. Synchronous Optimization Algorithm for Yard Crane Deployment and VDTWs Arrangement

3.1. Encoding and Decoding Strategy

3.2. Population Initialization

3.3. Fitness Value Evaluation

3.4. Perturbation Strategies

- Experience-based phase

- 2.

- Others’-based phase

- 3.

- Group thinking-based phase

- 4.

- Leader-based phase

- 5.

- Innovation-based phase

3.5. Selection Strategy

4. Numerical Experiments and Analysis

4.1. Algorithm Performance Verification

4.1.1. Lower Bound Analysis

4.1.2. Algorithms Comparison

4.2. Optimization Result

4.3. Comparative Analysis of Different Optimization Strategies

4.4. Sensitive Analysis

4.4.1. The Total Number of RTGCs Deployed

4.4.2. The Length of RTGC Deployment Shift

4.4.3. Initial Occupancy of Container Yard

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Appendix A. Kernel Distribution Function Estimator for the Estimation of Truck Arrivals Distribution Pattern in a Time Window

| Transfer Time * (Min) | Block No. | |||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | 11 | 12 | 13 | 14 | 15 | 16 | 17 | 18 | 19 | ||

| 1 | 0 | 20 | 25 | 10 | 20 | 30 | M | M | M | M | M | M | M | M | M | M | M | M | M | |

| Block No. | 2 | 20 | 0 | 20 | 20 | 10 | 25 | M | M | M | M | M | M | M | M | M | M | M | M | M |

| 3 | 25 | 20 | 0 | 25 | 20 | 20 | M | M | M | M | M | M | M | M | M | M | M | M | M | |

| 4 | 10 | 20 | 25 | 0 | 20 | 30 | 10 | 20 | 30 | M | M | M | M | M | M | M | M | M | M | |

| 5 | 20 | 10 | 20 | 20 | 0 | 25 | 20 | 10 | 25 | M | M | M | M | M | M | M | M | M | M | |

| 6 | 30 | 25 | 20 | 30 | 25 | 0 | 30 | 25 | 10 | M | M | M | M | M | M | M | M | M | M | |

| 7 | M | M | M | 10 | 20 | 30 | 0 | 20 | 30 | 20 | 25 | 30 | 35 | 50 | M | M | M | M | M | |

| 8 | M | M | M | 20 | 10 | 25 | 20 | 0 | 25 | 10 | 20 | 25 | 30 | 45 | M | M | M | M | M | |

| 9 | M | M | M | 30 | 25 | 10 | 30 | 25 | 0 | 25 | 20 | 10 | 20 | 35 | M | M | M | M | M | |

| 10 | M | M | M | M | M | M | 20 | 10 | 25 | 0 | 20 | 25 | 30 | 45 | 10 | 20 | 25 | 30 | M | |

| 11 | M | M | M | M | M | M | 25 | 20 | 20 | 20 | 0 | 20 | 25 | 40 | 20 | 10 | 20 | 25 | M | |

| 12 | M | M | M | M | M | M | 30 | 25 | 10 | 25 | 20 | 0 | 20 | 35 | 25 | 20 | 10 | 20 | M | |

| 13 | M | M | M | M | M | M | 35 | 30 | 20 | 30 | 25 | 20 | 0 | 30 | 30 | 25 | 20 | 10 | M | |

| 14 | M | M | M | M | M | M | 50 | 45 | 35 | 45 | 40 | 35 | 30 | 0 | 45 | 40 | 35 | 30 | M | |

| 15 | M | M | M | M | M | M | M | M | M | 10 | 20 | 25 | 30 | 45 | 0 | 20 | 25 | 30 | 55 | |

| 16 | M | M | M | M | M | M | M | M | M | 20 | 10 | 20 | 25 | 40 | 20 | 0 | 20 | 25 | 50 | |

| 17 | M | M | M | M | M | M | M | M | M | 25 | 20 | 10 | 20 | 35 | 25 | 20 | 0 | 20 | 45 | |

| 18 | M | M | M | M | M | M | M | M | M | 30 | 25 | 20 | 10 | 30 | 30 | 25 | 20 | 0 | 40 | |

| 19 | M | M | M | M | M | M | M | M | M | M | M | M | M | M | 55 | 50 | 45 | 40 | 0 | |

| Vessel No. | Block No. | ||||

|---|---|---|---|---|---|

| 1 | 439 | 18 | 34 | 14 | 1 |

| 2 | 324 | 20 | 33 | 12 | 1 |

| 3 | 86 | 20 | 32 | 11 | 1 |

| 4 | 273 | 32 | 48 | 7 | 1 |

| 5 | 247 | 32 | 50 | 16 | 1 |

| 6 | 229 | 32 | 55 | 15 | 0.59 |

| 16 | 0.41 | ||||

| 7 | 86 | 40 | 61 | 2 | 1 |

| 8 | 204 | 46 | 61 | 4 | 1 |

| 9 | 107 | 52 | 63 | 4 | 1 |

| 10 | 233 | 62 | 79 | 12 | 0.53 |

| 17 | 0.47 | ||||

| 11 | 150 | 64 | 80 | 3 | 0.57 |

| 5 | 0.43 | ||||

| 12 | 77 | 62 | 73 | 19 | 1 |

| 13 | 155 | 62 | 79 | 10 | 1 |

| 14 | 146 | 66 | 80 | 17 | 1 |

| 15 | 92 | 70 | 85 | 5 | 1 |

| 16 | 227 | 76 | 89 | 11 | 1 |

| 17 | 253 | 84 | 96 | 8 | 1 |

| 18 | 94 | 88 | 102 | 1 | 1 |

| 19 | 214 | 102 | 114 | 18 | 1 |

| 20 | 109 | 138 | 155 | 8 | 1 |

| 21 | 410 | 154 | 168 | 11 | 0.38 |

| 16 | 0.62 | ||||

| 22 | 158 | 120 | 150 | 6 | 1 |

| 23 | 202 | 132 | 158 | 13 | 1 |

| 24 | 171 | 140 | 154 | 11 | 1 |

| 25 | 333 | 140 | 154 | 17 | 1 |

| 26 | 149 | 142 | 157 | 10 | 1 |

| 27 | 60 | 140 | 157 | 14 | 1 |

| 28 | 201 | 152 | 168 | 3 | 0.22 |

| 9 | 0.78 | ||||

| 29 | 169 | 140 | 168 | 4 | 1 |

| 30 | 127 | 154 | 168 | 7 | 1 |

| 31 | 105 | 156 | 166 | 14 | 1 |

| 32 | 285 | 154 | 171 | 10 | 0.54 |

| 13 | 0.46 | ||||

| 33 | 76 | 152 | 176 | 15 | 1 |

| 34 | 132 | 162 | 174 | 2 | 1 |

| 35 | 287 | 162 | 178 | 1 | 0.56 |

| 3 | 0.44 | ||||

| 36 | 78 | 166 | 184 | 4 | 1 |

| 37 | 377 | 168 | 192 | 16 | 0.48 |

| 18 | 0.52 | ||||

| 38 | 80 | 186 | 206 | 16 | 1 |

| 39 | 53 | 168 | 188 | 2 | 1 |

| 40 | 110 | 178 | 190 | 9 | 1 |

References

- Wan, C.; Yan, X.; Zhang, D.; Qu, Z.; Yang, Z. An advanced fuzzy Bayesian-based FMEA approach for assessing maritime supply chain risks. Transp. Res. Part E Logist. Transp. Rev. 2019, 125, 222–240. [Google Scholar] [CrossRef]

- Chen, X.; Zhou, X.; List, G.F. Using time-varying tolls to optimize truck arrivals at ports. Transp. Res. E-Log. 2011, 47, 965–982. [Google Scholar] [CrossRef]

- Container Shipping—Statistics & Facts. Available online: https://www.statista.com/topics/1367/container-shipping/ (accessed on 2 November 2018).

- Lalla-Ruiz, E.; Expósito-Izquierdo, C.; Melián-Batista, B.; Moreno-Vega, J.M. A set-partitioning-based model for the berth allocation problem under time-dependent limitations. Eur. J. Oper. Res. 2016, 250, 1001–1012. [Google Scholar] [CrossRef]

- Ursavas, E.; Zhu, S.X. Optimal policies for the berth allocation problem under stochastic nature. Eur. J. Oper. Res. 2016, 255, 380–387. [Google Scholar] [CrossRef]

- Zhen, L.; Liang, Z.; Zhuge, D.; Lee, L.H.; Chew, E.P. Daily berth planning in a tidal port with channel flow control. Transp. Res. B Methodol. 2017, 106, 193–217. [Google Scholar] [CrossRef]

- Iris, C.; Pacino, D.; Ropke, S.; Larsen, A. Integrated berth allocation and quay crane assignment problem: Set partitioning models and computational results. Transp. Res. Part E Logist. Transp. Rev. 2015, 81, 75–97. [Google Scholar] [CrossRef] [Green Version]

- Iris, C.; Lam, J.S.L. Recoverable robustness in weekly berth and quay crane planning. Transp. Res. B Methodol. 2019, 122, 365–389. [Google Scholar] [CrossRef]

- Dulebenets, M.A. The vessel scheduling problem in a liner shipping route with heterogeneous fleet. Int. J. Civ. Eng. 2018, 16, 19–32. [Google Scholar] [CrossRef]

- Motono, I.; Furuichi, M.; Ninomiya, T.; Suzuki, S.; Fuse, M. Insightful observations on trailer queues at landside container terminal gates: What generates congestion at the gates? Res. Transp. Bus. Manag. 2016, 19, 118–131. [Google Scholar] [CrossRef]

- Giuliano, G.; O’Brien, T. Reducing port-related truck emissions: The terminal gate appointment system at the Ports of Los Angeles and Long Beach. Transp. Res. Part D Transp. Environ. 2007, 12, 460–473. [Google Scholar] [CrossRef]

- Zhao, W.; Goodchild, A.V. The impact of truck arrival information on container terminal rehandling. Transp. Res. Part E Logist. Transp. Rev. 2010, 46, 327–343. [Google Scholar]

- Ramírez-Nafarrate, A.; González-Ramírez, R.G.; Smith, N.R.; Guerra-Olivares, R.; Voss, S. Impact on yard efficiency of a truck appointment system for a port terminal. Ann. Oper. Res. 2017, 258, 195–216. [Google Scholar] [CrossRef]

- Zeng, Q.; Feng, Y.; Yang, Z. Integrated optimization of pickup sequence and container rehandling based on partial truck arrival information. Comput. Ind. Eng. 2019, 127, 366–382. [Google Scholar] [CrossRef]

- Huynh, N.; Walton, C.M. Robust Scheduling of Truck Arrivals at Marine Container Terminals. J. Transp. Eng. 2008, 134, 347–353. [Google Scholar] [CrossRef]

- Zhang, X.; Zeng, Q.; Chen, W. Optimization model for truck appointment in container terminals. Proc. Soc. Behav. Sci. 2013, 96, 1938–1947. [Google Scholar] [CrossRef] [Green Version]

- Chen, G.; Govindan, K.; Golias, M.M. Reducing truck emissions at container terminals in a low carbon economy: Proposal of a queueing-based bi-objective model for optimizing truck arrival pattern. Transp. Res. Part E Logist. Transp. Rev. 2013, 55, 3–22. [Google Scholar] [CrossRef]

- Phan, M.H.; Kim, K.H. Negotiating truck arrival times among trucking companies and a container terminal. Transp. Res. Part E Logist. Transp. Rev. 2015, 75, 132–144. [Google Scholar] [CrossRef]

- Phan, M.H.; Kim, K.H. Collaborative truck scheduling and appointments for trucking companies and container terminals. Transp. Res. B Methodol. 2016, 86, 37–50. [Google Scholar]

- Feng, Y.; Song, D.; Li, D.; Zeng, Q. The stochastic container relocation problem with flexible service policies. Transp. Res. B Methodol. 2020, 141, 116–163. [Google Scholar] [CrossRef]

- Chen, G.; Yang, Z. Optimizing time windows for managing export container arrivals at Chinese container terminals. Int. J. Marit. Econ. 2010, 12, 111–126. [Google Scholar]

- Chen, G.; Govindan, K.; Yang, Z. Managing truck arrivals with time windows to alleviate gate congestion at container terminals. Int. J. Prod. Econ. 2013, 141, 179–188. [Google Scholar]

- Chen, G.; Jiang, L. Managing customer arrivals with time windows: A case of truck arrivals at a congested container terminal. Ann. Oper. Res. 2016, 244, 349–365. [Google Scholar] [CrossRef]

- Ma, M.; Fan, H.; Jiang, X.; Guo, Z. Truck arrivals scheduling with vessel dependent time windows to reduce carbon emissions. Sustainability 2019, 11, 1–26. [Google Scholar] [CrossRef] [Green Version]

- Qin, Z.; Li, W.; Xiong, X. Estimating wind speed probability distribution using kernel density method. Electr. Power Syst. Res. 2011, 81, 2139–2146. [Google Scholar] [CrossRef]

- Ma, M.; Fan, H.; Huang, J.; Kong, L.; Yue, L. Traffic demand forecasting model for container terminal based on non- parametric kernel density estimation. J. Dalian Marit. Univ. 2019, 45, 74–81. [Google Scholar]

- Kaan, O.; Ozlem, Y.T.; José, H.V. Evaluation of Impacts of Time-of-Day Pricing Initiative on Car and Truck Traffic: Port Authority of New York and New Jersey. Transp. Res. Rec. 2006, 1960, 48–56. [Google Scholar]

- Isbell, J.; Beckett, J.; Bok, S.; Ryan, T.J.; Swan, P.F.; Whicker, G.L.; Freund, D.; Adler, K.; Cambridge, J.W. National Cooperative Freight Research Program Report 11: Truck Drayage Productivity Guide; Transportation Research Board: Washington, DC, USA, 2011; pp. 49–52. [Google Scholar]

- Zhang, H.; Zhang, Q.; Chen, W. Bi-level programming model of truck congestion pricing at container terminals. J. Ambient Intell. Humaniz. Comput. 2017, 10, 385–394. [Google Scholar] [CrossRef]

- Zehendner, E.; Feillet, D. Benefits of a truck appointment system on the service quality of inland transport modes at a multimodal container terminal. Eur. J. Oper. Res. 2014, 235, 461–469. [Google Scholar] [CrossRef]

- Ma, M.; Fan, H.; Ji, M.; Guo, Z. Integrated Optimization of Truck Appointment for Export Containers and Crane Deployment in a Container Terminal. J. Transp. Syst. Eng. Inf. Technol. 2018, 18, 202–209. [Google Scholar]

- Li, N.; Chen, G.; Ng, M.; Talley, W.; Jin, Z. Optimized appointment scheduling for export container deliveries at marine terminals. Marit. Policy Manag. 2020, 47, 456–478. [Google Scholar] [CrossRef]

- Nadaraya, E.A. Some new estimates for distribution functions. Theory Probab. Appl. 1964, 9, 550–554. [Google Scholar] [CrossRef]

- Iris, C.; Christensen, J.; Pacino, D.; Ropke, S. Flexible ship loading problem with transfer vehicle assignment and scheduling. Transp. Res. B Methodol. 2018, 111, 113–134. [Google Scholar] [CrossRef] [Green Version]

- Iris, C.; Pacino, D.; Ropke, S. Improved formulations and an adaptive large neighborhood search heuristic for the integrated berth allocation and quay crane assignment problem. Transp. Res. Part E Logist. Transp. Rev. 2017, 105, 123–147. [Google Scholar] [CrossRef]

- Zhang, C.; Wan, Y.; Liu, J.; Linn, R.J. Dynamic crane deployment in container storage yards. Transp. Res. B Methodol. 2002, 36, 537–555. [Google Scholar] [CrossRef]

- Linn, R.; Liu, J.Y.; Wan, Y.W.; Zhang, C.Q.; Murty, K.G. Rubber tired gantry crane deployment for container yard operation. Comput. Ind. Eng. 2003, 45, 429–442. [Google Scholar] [CrossRef]

- Stewart, W.J. Probability, Markov chains, queues, and simulation. In The Mathematical Basis of Performance Modeling; Princeton University Press: Princeton, NJ, USA, 2009; pp. 560–562. [Google Scholar]

- Wang, G.; Ma, L.; Chen, J. A bilevel improved fruit fly optimization algorithm for the nonlinear bilevel programming problem. Knowl. Based Syst. 2017, 138, 113–123. [Google Scholar] [CrossRef]

- Zhang, Q.; Wang, R.; Yang, J.; Ding, K.; Li, Y.; Hu, J. Collective decision optimization algorithm: A new heuristic optimization method. Neurocomputing 2016, 221, 123–137. [Google Scholar] [CrossRef]

| Input Parameter | (Trucks/Interval) | (Natural Containers/Interval) | (h) | ||

|---|---|---|---|---|---|

| Value | 1.97 | 0.633 | 0.42687 | 6 | 1.4 |

| No. | Lower Bound | GA | HGA–CDO | ||||

|---|---|---|---|---|---|---|---|

| Objective Function Value | Objective Function Value | ||||||

| 1 | 20 | 20 | 1777.878 | 4304.512 | 142.12% | 2942.482 | 65.51% |

| 2 | 20 | 25 | 1777.878 | 4094.188 | 130.29% | 2741.636 | 54.21% |

| 3 | 20 | 30 | 1777.878 | 3810.618 | 114.34% | 2478.938 | 39.43% |

| 4 | 20 | 35 | 1777.878 | 3830.712 | 115.47% | 2383.667 | 34.07% |

| 5 | 30 | 20 | 3044.301 | 7136.629 | 134.43% | 4677.067 | 53.63% |

| 6 | 30 | 25 | 3044.301 | 6697.412 | 120.00% | 4593.616 | 50.89% |

| 7 | 30 | 30 | 3044.301 | 6308.744 | 107.23% | 4215.659 | 38.48% |

| 8 | 30 | 35 | 3044.301 | 6132.462 | 101.44% | 4042.178 | 32.78% |

| 9 | 40 | 20 | 4389.330 | 10,229.593 | 133.06% | 6934.286 | 57.98% |

| 10 | 40 | 25 | 4389.330 | 9852.538 | 124.47% | 6283.167 | 43.15% |

| 11 | 40 | 30 | 4389.330 | 8971.542 | 104.39% | 5965.620 | 35.91% |

| 12 | 40 | 35 | 4389.330 | 8225.870 | 87.41% | 5725.135 | 30.43% |

| W/O | VDTWO | RTGCD | SO_RTGCD_ VDTW | CO_RTGCD_VDTW | |

|---|---|---|---|---|---|

| The total number of trucks waiting at the terminal gate and container yard () | 122,888.87 | 9871.89 | 91,363.67 | 53,780.66 | 5979.756 |

| The total number of trucks waiting at the terminal gate () | 1587.68 | 706.37 | 1587.68 | 641.18 | 693.2 |

| The total number of trucks waiting at the container yard () | 121,301.19 | 9165.52 | 89,775.99 | 53,139.48 | 5286.55 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ma, M.; Zhao, W.; Fan, H.; Gong, Y. Collaborative Optimization of Yard Crane Deployment and Inbound Truck Arrivals with Vessel-Dependent Time Windows. J. Mar. Sci. Eng. 2022, 10, 1650. https://doi.org/10.3390/jmse10111650

Ma M, Zhao W, Fan H, Gong Y. Collaborative Optimization of Yard Crane Deployment and Inbound Truck Arrivals with Vessel-Dependent Time Windows. Journal of Marine Science and Engineering. 2022; 10(11):1650. https://doi.org/10.3390/jmse10111650

Chicago/Turabian StyleMa, Mengzhi, Wenting Zhao, Houming Fan, and Yu Gong. 2022. "Collaborative Optimization of Yard Crane Deployment and Inbound Truck Arrivals with Vessel-Dependent Time Windows" Journal of Marine Science and Engineering 10, no. 11: 1650. https://doi.org/10.3390/jmse10111650