1. Introduction

Owing to the increasing global demand for offshore oil and gas, the development and research of marine equipment have become increasingly popular. A single-point mooring system is one of the main techniques used for offshore oil terminals. Unlike the traditional duck, the single-point mooring system employs “point” mooring system. Hence, the very large crude carrier (VLCC) can be moored to it and directly operated at sea. Currently, the catenary anchor leg mooring system (CALM) is the most widely used in single-point mooring systems.

Due to its low initial investment and high efficiency, many companies have competitively developed CALM. The design of the mooring configuration and analysis of the strength of anchor chains have always been the focus of research in CALM. The efficient design of the configuration of the mooring anchor chain and analysis of its dynamic response characteristics is key to the preliminary design of the CALM. In addition, the variety of anchor chain lengths and tension angle arrangements has increased the difficulty of the configuration design. To meet engineering requirements and specifications, engineers base the preliminary design of the CALM on previous engineering experience. Mooring anchor chain design involves many parameters and usually requires considerable computational time and cost; however, the final result is sometimes not ideal. It is not easy to quickly and effectively evaluate the rationality of design parameters. Therefore, a rapid optimization design framework for the CALM is essential.

Felix-Gonzalez et al. [

1] established a fully symmetrical and bilaterally symmetric two-dimensional static equivalent mooring system model. The root mean square error of equivalent model displacement and root mean square error of numerical model displacement are taken as objective functions, and the genetic algorithm is used to optimize. Shafieefar et al. [

2] proposed a program to optimize the mooring design of floating platforms to reduce the dynamic response of floating platforms. Aqdam et al. [

3] established a radial neural network for the damage diagnosis of mooring lines, considering the uncertainty of the mooring line boundary of floating structures. Thomsen et al. [

4] used an approximation model to determine the mooring parameters that affect the mooring cost and find a cheap and reliable mooring solution. Sun et al. [

5] optimized the cable length and used the breakage strength of the anchor chains as a constraint condition to minimize the longitudinal and transverse values in each wave direction of floating production storage and offloading (FPSO) and obtained more reasonable design parameters. Yetkin et al. [

6] used the simulation results of mooring tensions and tanker displacements for the four-point tanker-buoy mooring system to train the ANN structure and created an algorithm to obtain quick predictions. Pillai et al. [

7] optimized a mooring system design using a random forest-based surrogate model-assisted multi-objective genetic algorithm. Bruno da Fonseca Monteiro et al. [

8] used Particle Swarm to obtain a solution for the mooring system radius. Girón et al. [

9] summarized the mooring design method and pointed out the optimization objectives of a mooring system. Li et al. [

10] applied Kriging metamodels as surrogates for the responses of time-domain simulations and used a gradient-based search algorithm to find the optimal solutions by exploring the design space. Gumley et al. [

11] used metocean and GPS data from an FPSO to train a model using Kriging and neural network methods, and the identified mooring system change was used to predict a mooring line failure. Christiansen N H et al. [

12] raised a hybrid method for fatigue analysis to balance the accuracy and time consumption due to more sea states for floating offshore platforms anchored by mooring lines. Saad A M et al. [

13] used neural networks to detect mooring line failure in near real-time based on measured motion to predict spread moored FSPO motion.

In a detailed mooring system analysis, many parameters must be obtained through experiments or finite element calculations, all of which require considerable computation cost and time. In optimizing the approximation model, this method can effectively reduce the number of sample points to obtain higher model accuracy, saving considerable time and cost. Sasena et al. [

14] adopted a SuperEGO algorithm suitable for adaptive sampling to optimize the approximation model. Hao [

15] developed a set of adaptive anchor box optimization algorithms to optimize the kriging model and iteratively solved the problems caused by a large range of design variables. Tian et al. [

16] selected competitive sample points to optimize the approximation model based on specific criteria, thereby significantly improving the model calculation efficiency; however, the model accuracy slightly decreased. Hao et al. [

15] reduced the design variable space by setting an adaptive function and improving optimization efficiency.

This study optimized platform mooring under the influence of environmental distribution forces and the tension and length of the mooring cables were optimized under the influence of the material and size of each mooring cable. To minimize the total sampling points, an approximation model is established to obtain a global solution roughly, and based on an adaptive sampling technique, a local solution is revised exactly. A combination of a genetic algorithm and a sequential quadratic programming method is utilized to optimize the approximation model to find a set of design parameters for the mooring anchor chains that maximize economic benefits under safety conditions.

The manuscript is structured as follows:

Section 3 and

Section 4 introduce the approximation model and optimization algorithm adopted in this study,

Section 5 discusses the adaptive sampling method based on the approximation model, and

Section 6 uses the above program framework to analyze specific examples and verify it with commercial software.

2. Problem Description

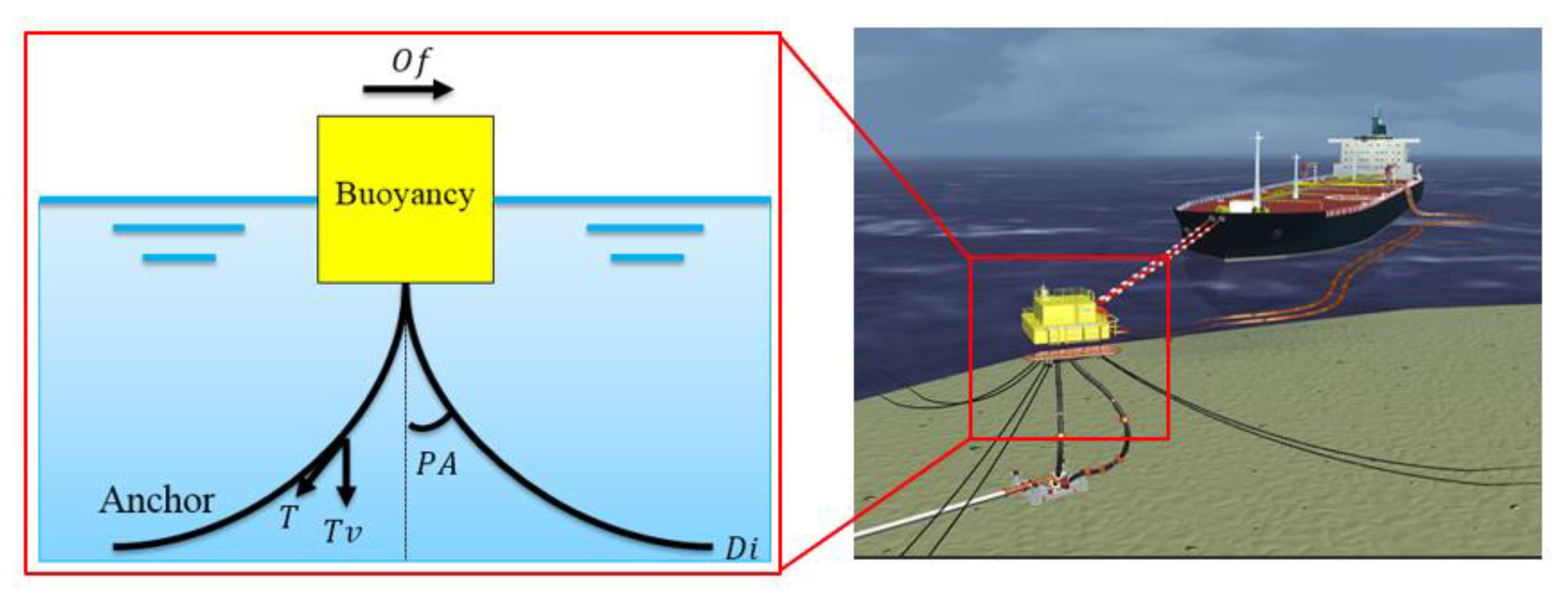

Figure 1 shows a schematic of the CALM, which consists of an upper buoyancy system and mooring chains. Under working conditions, the anchor chain is subjected to tensile forces, gravity, and buoyancy caused by the buoyancy system and seawater. A tanker is connected to the CALM buoy. The mooring ship in this study is a 300,000-ton large oil tanker with a scale of 320 m long, 60 m wide, and 30.5 m height. Considering that ballast draft and full load draft are typical loading conditions of mooring, CALM can replace the wharves to transfer crude oil from tanker to shore by pipelines. CALM has the advantage of less investment compared to wharves. However, it is complicated and tedious to choose a scheme with good mooring performance and economy, which brings challenges to mooring design. This study is to establish a program to quickly obtain an optimal mooring scheme to solve this problem.

To ensure the safe operation of the system, engineers must consider various conditions and limit the anchor chain pretension angle and buoyancy system offset within a certain range. The conditions contain environment—wind, current, and wave; tanker loading—full load and ballast or away from the buoy; and the mooring system—intact or one anchor line broken, involving many variables in mooring analysis, which will make the computation complex and time-consuming. Here, we give the optimization formula for the optimized anchor chain system in Equation (1). In the equations, the design objective is to minimize the cost

, the design variables are the anchor diameter

and pretension angle

, and the constraints are the buoyancy offset

, anchor chain tension safe factor

(the ratio of maximum chain tension and actual tension), fatigue damage

, and vertical force

. The list of all parameters are shown in

Table A2 of

Appendix A.

The constraint conditions are further refined as follows. It can be seen that the derivation of each constraint almost depends on a large amount of numerical calculation work. Since the calculation of these parameters is not the focus of this paper, the paper lists the constraints for the main variables.

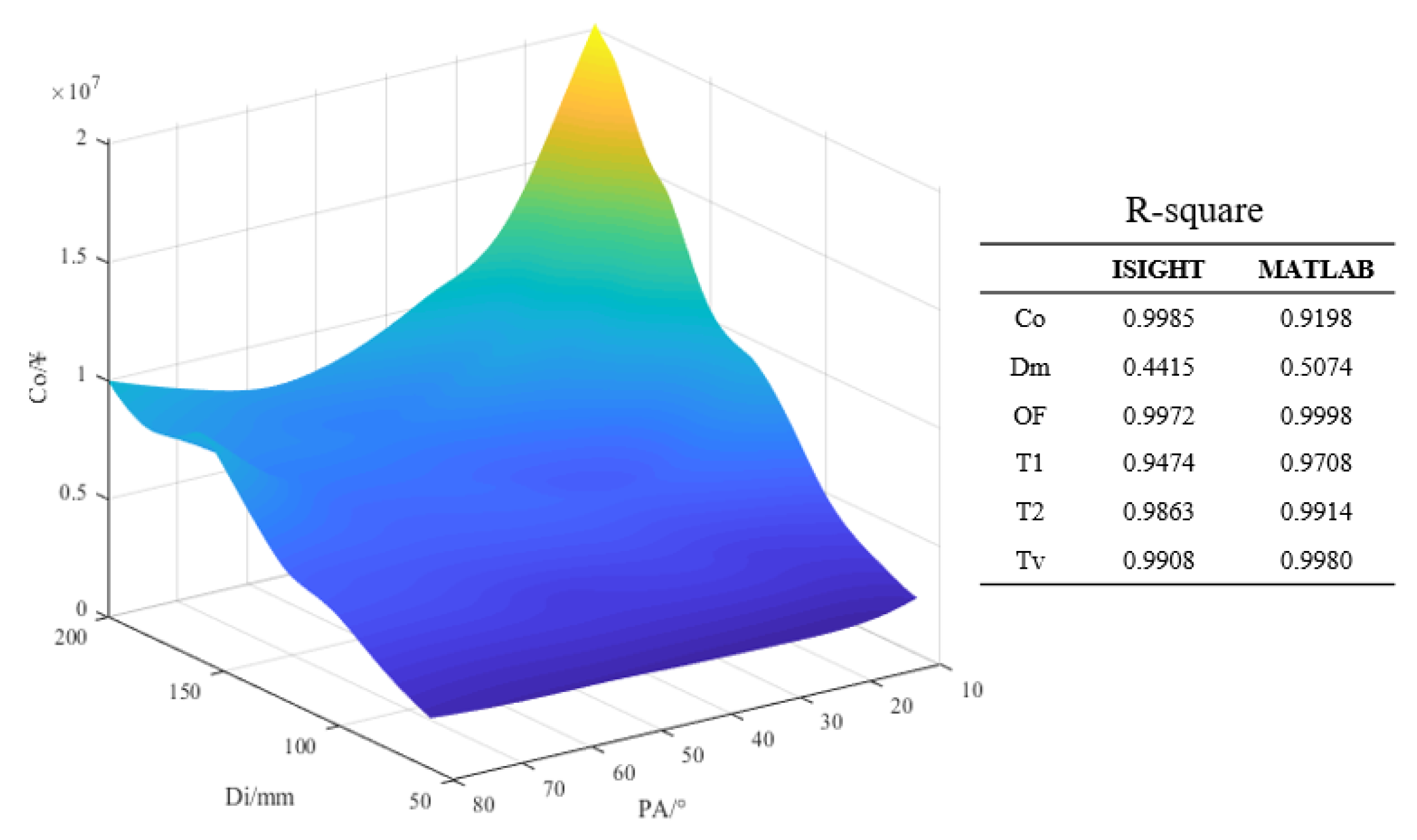

Because the anchor chain is slim, it usually exhibits large deformations. The wind and wave loads in a marine environment are simultaneous random loads. All of these factors cause fatigue damage. Traditionally, engineering design relies on experience and experiments to obtain optimal variables. However, this work relies on sample point data calculated by AQWA and uses MATLAB and ISIGHT to independently develop optimization programs to achieve a rapid automatic design of the anchor chains. The workflow is shown in

Figure 2.

3. Establishment of the Approximation Model

The essential feature of the approximation model is using the response values of the sample points in the numerical experiment to predict the response values of the unknown points in the design space. In other words, the sample data obtained from the experimental design were fitted to establish an approximate relationship between input and output parameters.

3.1. Design of Experiment

The experimental design is based on probability and mathematical statistics. Without prior knowledge, it studies how to efficiently and reasonably conduct experiments and effectively analyze and process the experimental design results. The number and quality of the experimental design samples directly affected the approximation model’s effectiveness for the real solution. If the number of samples is too small or not representative, it cannot reflect the mapping between the approximation model and the real solution. Too many samples cause overfitting, making it impossible to establish the correct mapping relationship.

In this study, the Latin hypercube sampling (LHS) method [

17,

18] was used to sample the design variables. This method can evenly distribute sample points into the design space and does not have overlapping sample points in small neighborhoods. The main advantage of the LHS is that the generated sample points represent all parts of the vector space, and knowing the problem’s dimensions is unnecessary.

3.2. Radial Basis Function (RBF)

At present, approximation models include the response surface method, Kriging method, and radial basis function method with a high nonlinear mapping capability. Because the optimization problem of mooring anchor chains involves relatively high nonlinearity, the radial basis function method (RBF) [

19,

20] is adopted in this study.

The RBF model uses the distance between the measured and sample points as the independent basis functions and is constructed using linear weighting. It can approximate continuous or discrete functions with arbitrary precision. The RBF model consists of three layers: the input, hidden, and output layers. Each node of the hidden layer uses a Gaussian function (Equation (2)) as the radial basis function; that is, the data transformation from the input layer to the hidden layer is nonlinear. After the radial basis functions are determined, the results of these functions are weighted and linearly summed to obtain the output value of the RBF neural network (Equation (3)), as shown in

Figure 3.

Here, represents the design variable, represents the central point, represents the distance between the sample and measured points, represents the radial function, and represents the weight factor.

5. Adaptive Sampling

The adaptive experimental design obtains relevant information through early sampling to guide later sampling. This method can be used for approximation-model optimization. Because this study’s sample point acquisition must be obtained by AQWA calculation, the calculation time of each group of sample points is approximately 2 h. Therefore, we consider the adaptive function method proposed by Hao et al. [

15] to reduce the design space and avoid spending much time updating the approximation model, as shown in

Figure 5.

In the formula, represents the first-step optimization value of the -th variable, represents the initial value of the -th variable, and represents the upper and lower limits of the -th variable.

In the second optimization step, the sample point distribution can be determined using the function

. The sampling interval function

is used to describe the sampling interval of the design variable in the adaptation, see

Figure 5. For the

function, the sampling interval of the variable is set to decrease from the center to the optimization value of the first step. Variables with optimization results close to the upper and lower limits in the first step are considered monotonic with the optimization goal and do not participate in sampling. Based on the above principles, the adaptive function

can be selected independently. When the form of

is determined, the sampling interval of the design variable can be expressed as

.