Hybrid Optimized Fuzzy Pitch Controller of a Floating Wind Turbine with Fatigue Analysis

Abstract

1. Introduction

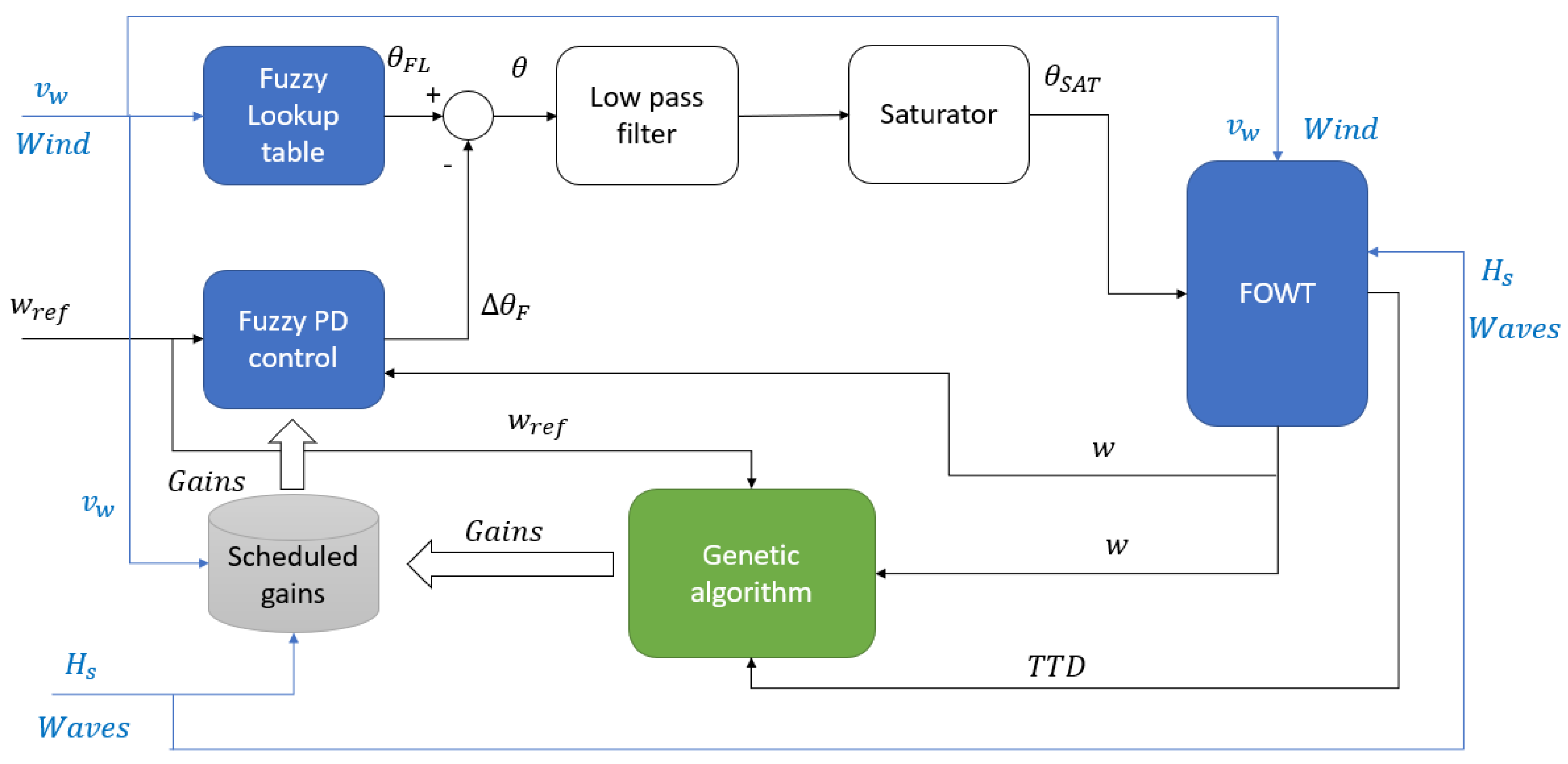

- An intelligent hybrid controller of the blade angle of a barge-type FOWT has been proposed. The control architecture combines a gain scheduling incremental proportional–derivative (PD) fuzzy controller and a fuzzy implementation of the wind speed–pitch relationship. As far as we know, this control scheme for collective pitch control of an FOWT is novel.

- The controller is tuned by a genetic algorithm, which allows definition of a fitness function that includes both maintaining the output power to its maximum value and the reduction of the vibrations of the floating structure. The error of the rotor speed and the tower top displacement have been used in this cost function.

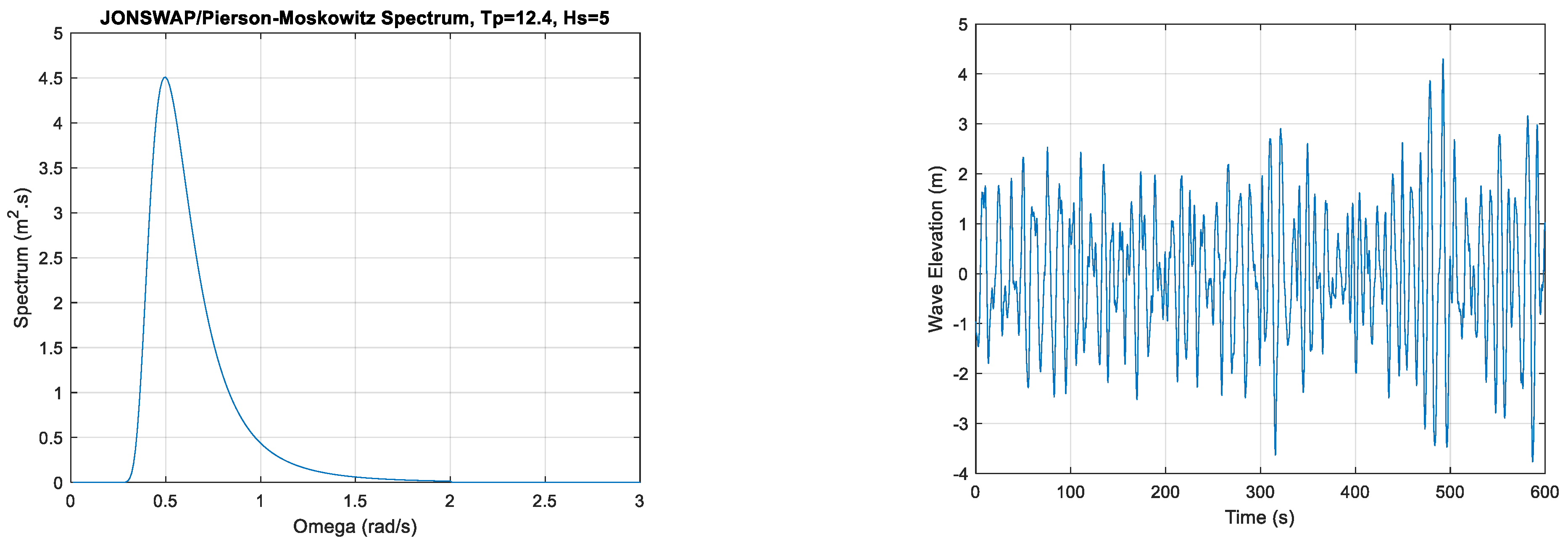

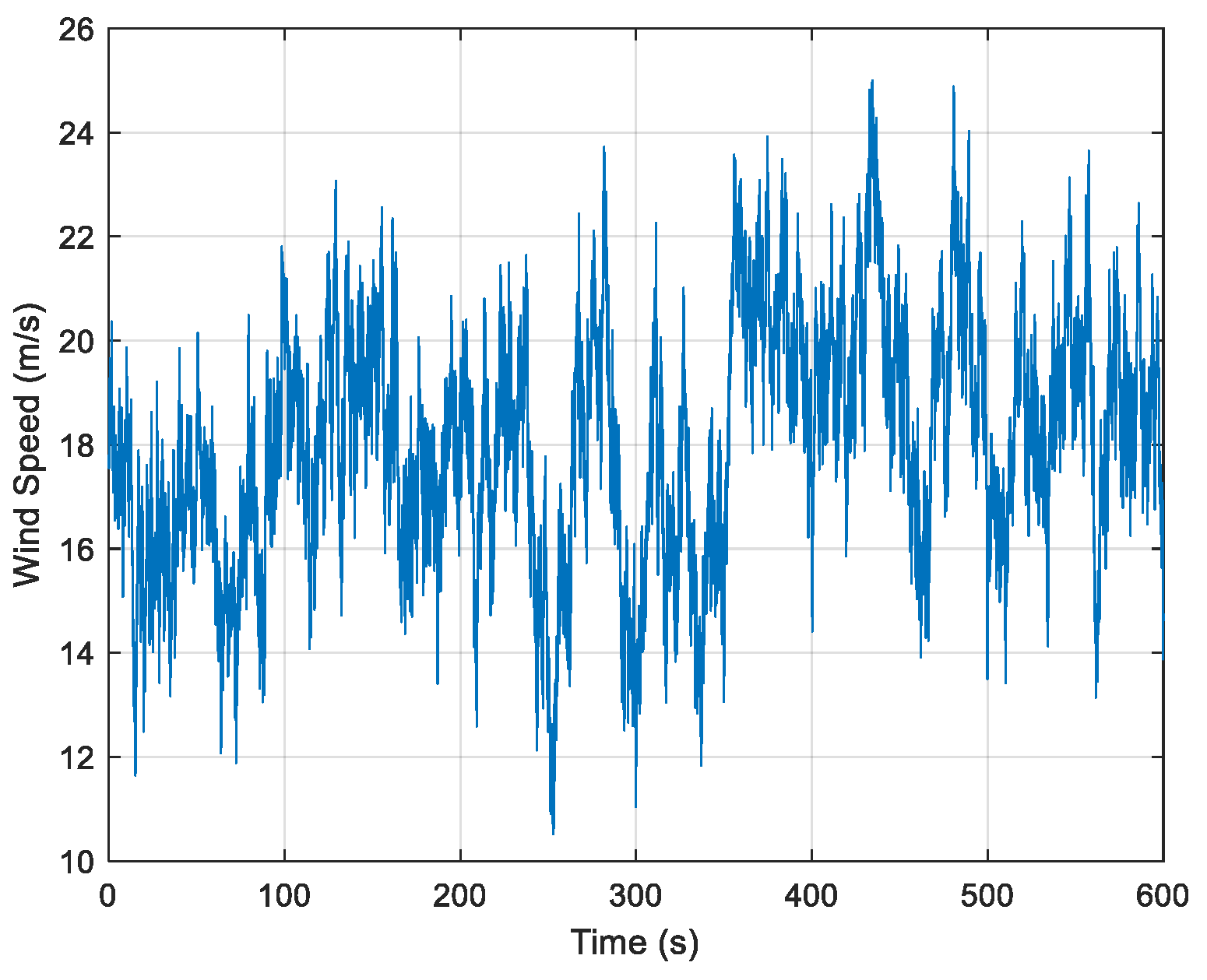

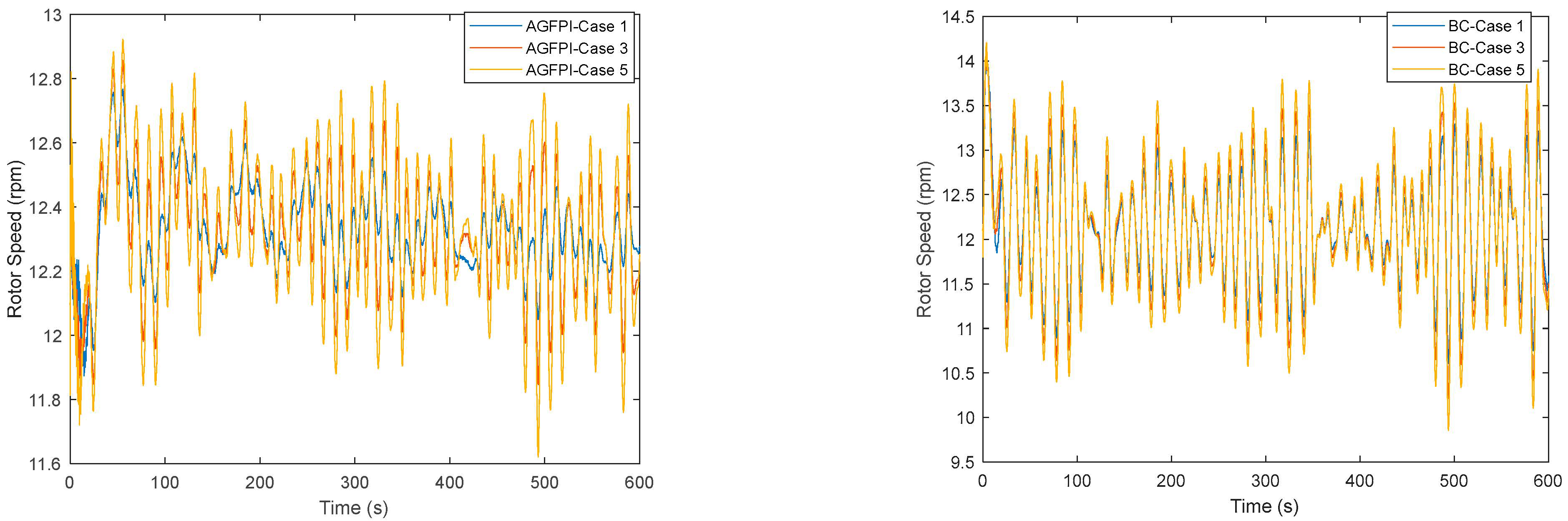

- To ensure the correct behavior under different wind speeds and wave heights, the controller is adjusted for different operation conditions.

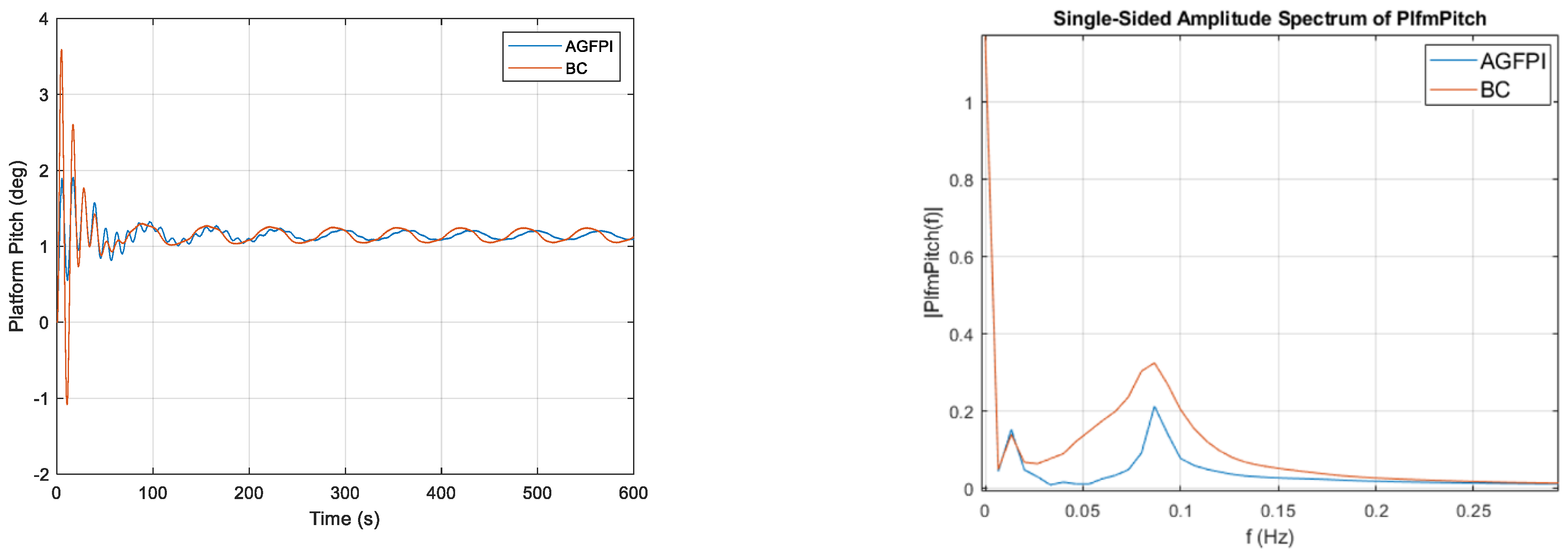

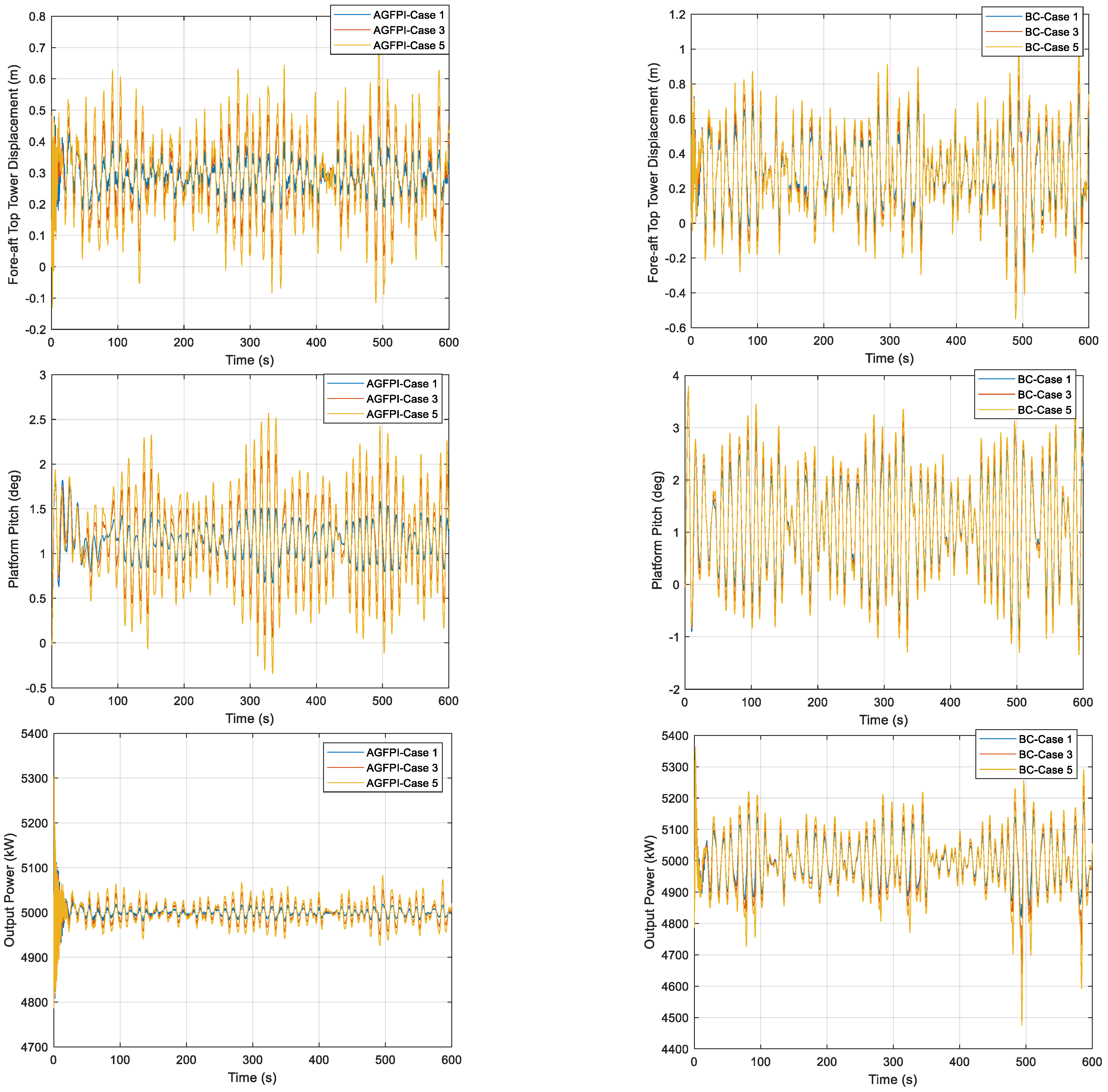

- This hybrid intelligent control strategy has been validated and compared with the baseline controller embedded in wind turbine simulation software Fatigue, Aerodynamics, Structures, and Turbulence (FAST) by the National Renewable Energy Laboratory (NREL). The intelligent approach gives smaller power error, fewer vibrations (regarding tower displacement and platform pitch) and lower damage equivalent load (DEL) estimated by the rainflow counting technique.

2. Related Works

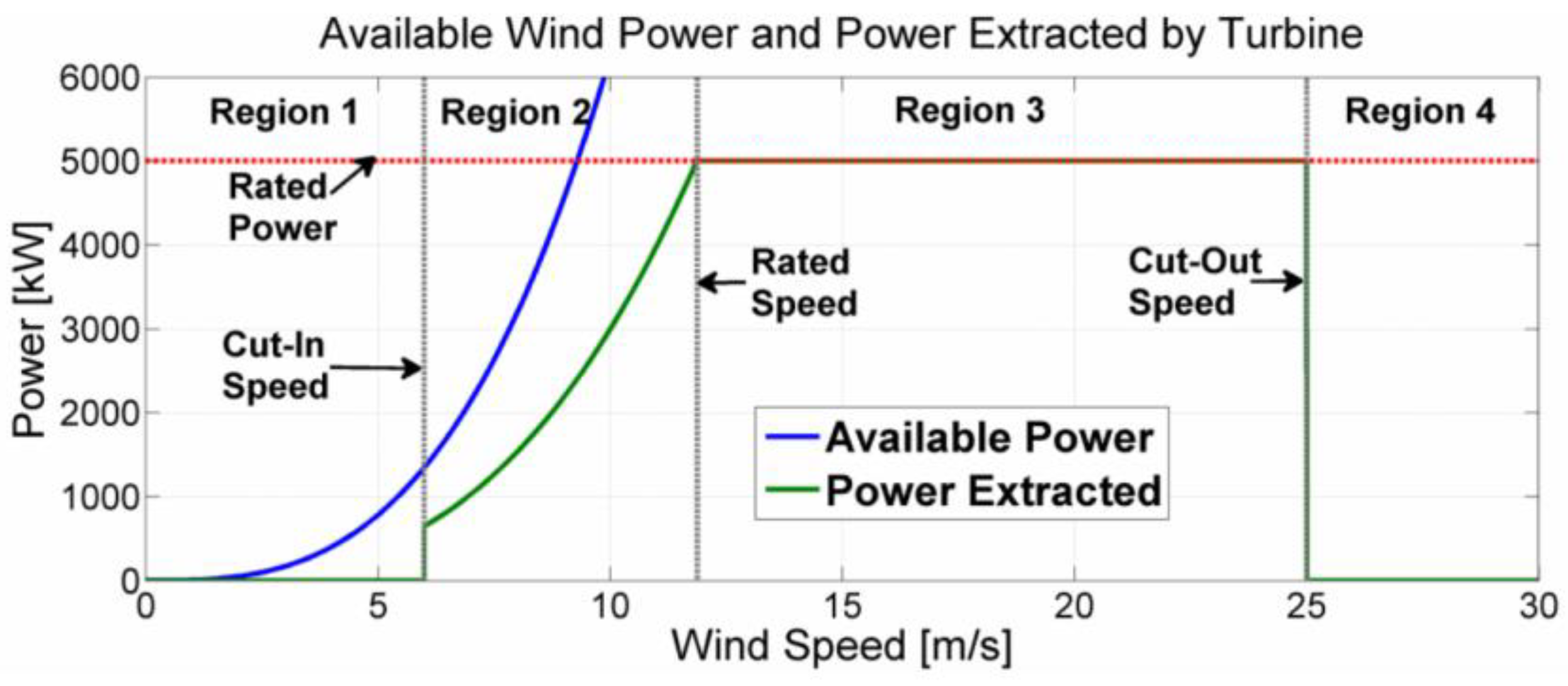

3. FOWT Power Equations

4. Methodology

- If is negative and is negative, then Δ is −5.

- If is negative and is zero, then Δ is −2.5.

- If is negative and is positive, then Δ is 0.

- If is zero and is negative, then Δ is −2.5.

- If is zero and is zero, then Δ is 0.

- If is zero and is positive, then Δ is 2.5.

- If is positive and is negative, then Δ is 0.

- If is positive and is zero, then Δ is 2.5.

- If is positive and is positive, then Δ is 5.

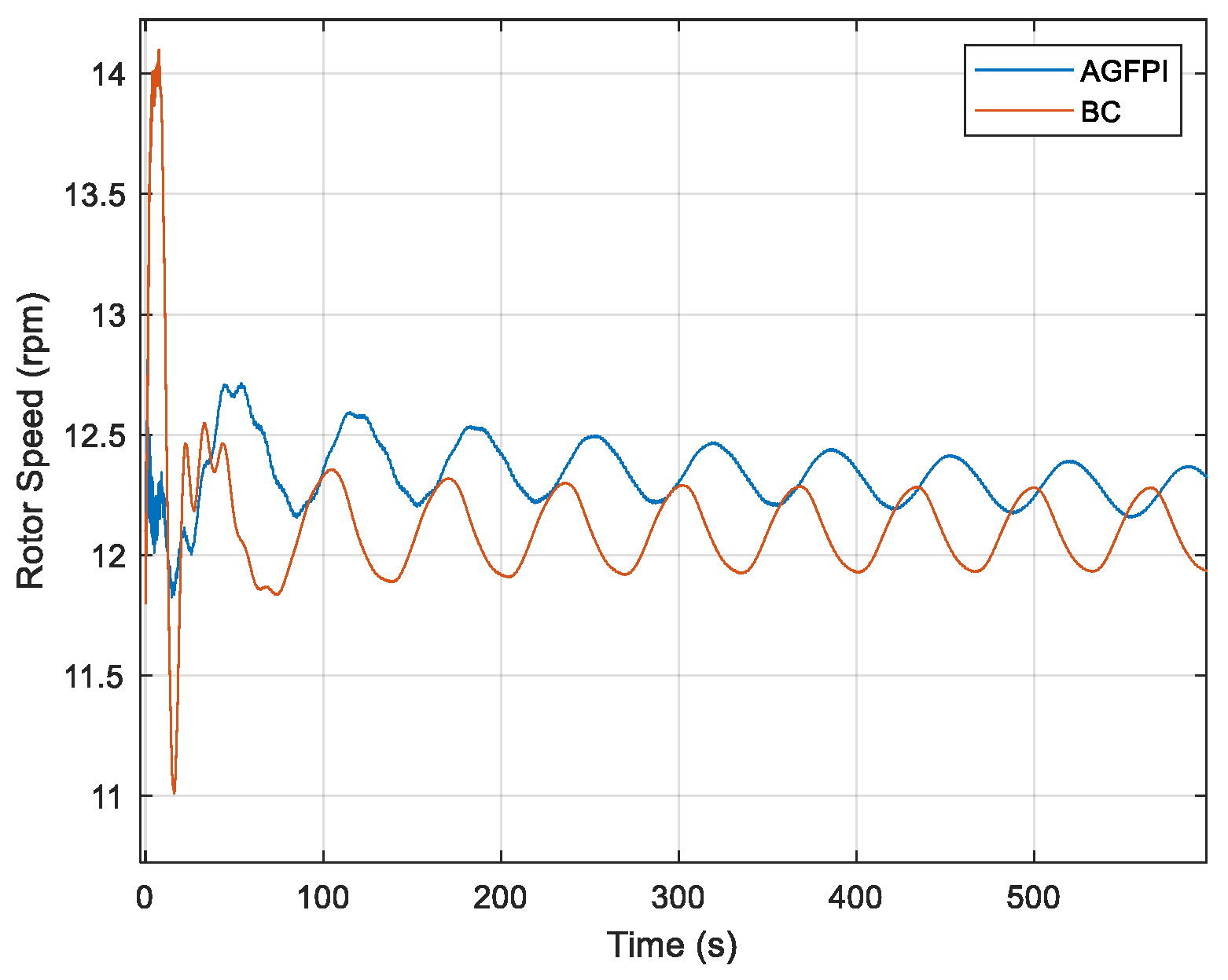

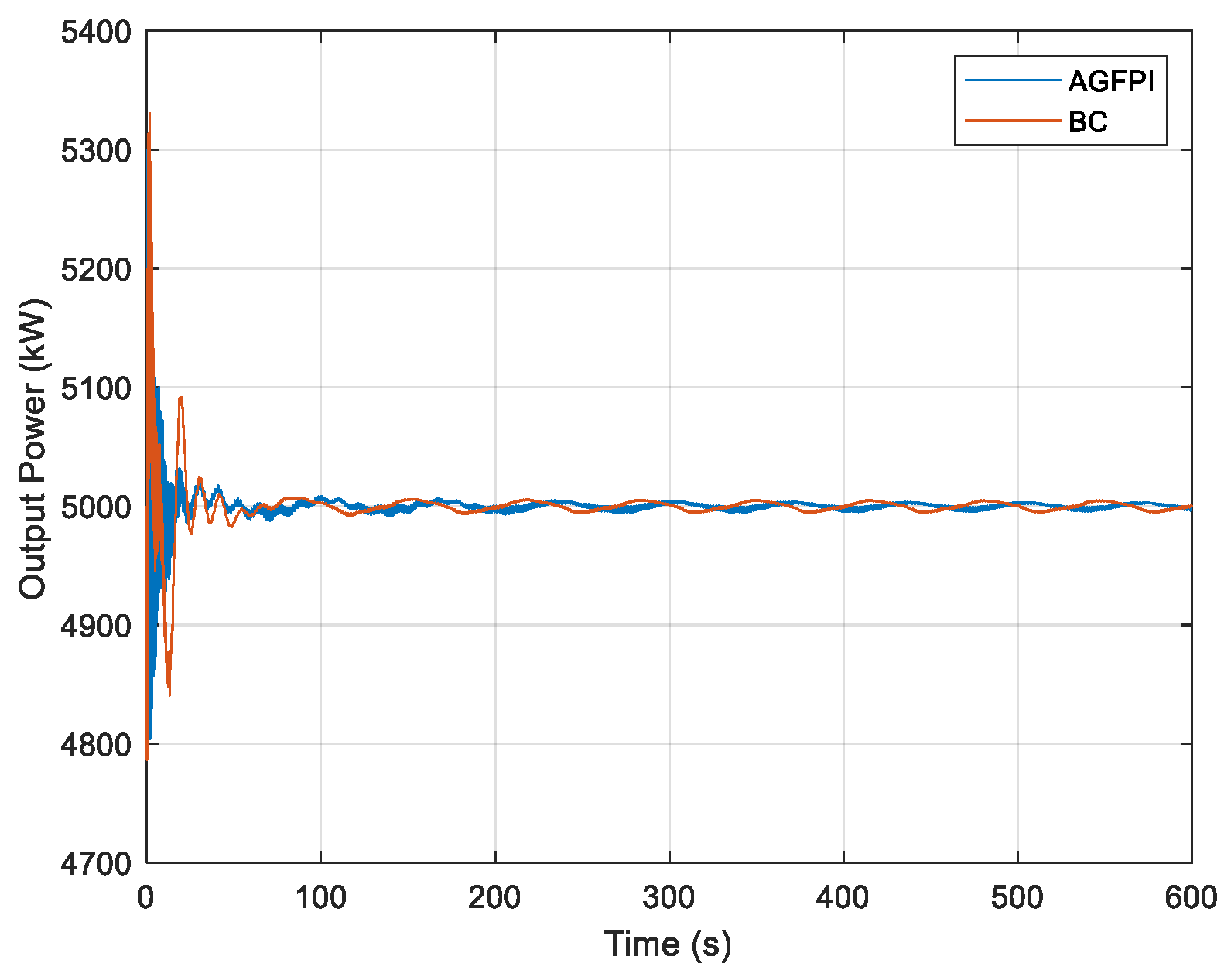

5. Simulation Results and Discussion

5.1. Performance without Waves

5.2. Performance with Waves

6. Conclusions and Future Works

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Conflicts of Interest

References

- Gomes, I.L.; Melício, R.; Mendes, V.M.; Pousinho, H.M. Wind power with energy storage arbitrage in day-ahead market by a stochastic MILP approach. Log. J. IGPL 2020, 28, 570–582. [Google Scholar] [CrossRef]

- Javadinasab Hormozabad, S.; Gutierrez Soto, M.; Adeli, H. Integrating structural control, health monitoring, and energy harvesting for smart cities. Expert Syst. 2021, 38, e12845. [Google Scholar] [CrossRef]

- Mikati, M.; Santos, M.; Armenta, C. Modelado y simulación de un sistema conjunto de energía solar y eólica para analizar su dependencia de la red eléctrica. Rev. Iberoam. De Automática E Inf. Ind. 2012, 9, 267–281. [Google Scholar] [CrossRef]

- Villoslada, D.; Santos, M.; Tomás-Rodríguez, M. General methodology for the identification of reduced dynamic models of barge-type floating wind turbines. Energies 2021, 14, 3902. [Google Scholar] [CrossRef]

- Tomás-Rodríguez, M.; Santos, M. Modelling and control of floating offshore wind turbines. Rev. Iberoam. De Automática E Inf. Ind. 2019, 16, 381–390. [Google Scholar] [CrossRef]

- Sierra-García, J.E.; Santos, M. Redes neuronales y aprendizaje por refuerzo en el control de turbinas eólicas. Rev. Iberoam. De Automática E Inf. Ind. 2021, 18, 327–335. [Google Scholar] [CrossRef]

- Serrano-Barreto, C.; Santos, M. Intelligent fuzzy optimized control for energy extraction in large wind turbines. In International Conference on Intelligent Data Engineering and Automated Learning; Springer: Cham, Switzerland, 2020; pp. 269–276. [Google Scholar]

- Jove, E.; González-Cava, J.M.; Casteleiro-Roca, J.L.; Alaiz-Moretón, H.; Baruque, B.; Leitão, P.; Pérez, J.A.M.; Calvo-Rolle, J.L. An intelligent system for harmonic distortions detection in wind generator power electronic devices. Neurocomputing 2021, 456, 609–621. [Google Scholar] [CrossRef]

- Sierra-García, J.E.; Santos, M. Performance analysis of a wind turbine pitch neurocontroller with unsupervised learning. Complexity 2020, 2020, 4681767. [Google Scholar] [CrossRef]

- Rahman, M.; Ong, Z.C.; Chong, W.T.; Julai, S.; Ng, X.W. Wind turbine tower modeling and vibration control under different types of loads using ant colony optimized PID controller. Arab. J. Sci. Eng. 2019, 44, 707–720. [Google Scholar] [CrossRef]

- Song, Z.; Liu, J.; Hu, Y.; Cheng, Y.; Tan, F. Real-time performance analyses and optimal gain-scheduling control of offshore wind turbine under ice creep loads. IEEE Access 2019, 7, 181706–181720. [Google Scholar] [CrossRef]

- Lemmer, F.; Yu, W.; Schlipf, D.; Cheng, P.W. Robust gain scheduling baseline controller for floating offshore wind turbines. Wind. Energy 2020, 23, 17–30. [Google Scholar] [CrossRef]

- Wang, C.S.; Chiang, M.H. A novel pitch control system of a large wind turbine using two-degree-of-freedom motion control with feedback linearization control. Energies 2016, 9, 791. [Google Scholar] [CrossRef]

- Christiansen, S.; Knudsen, T.; Bak, T. Extended onshore control of a floating wind turbine with wave disturbance reduction. In Journal of Physics: Conference Series; IOP Publishing: Bristol, UK, 2014; Volume 555, p. 012018. [Google Scholar]

- Lemmer, F.; Schlipf, D.; Cheng, P.W. Control design methods for floating wind turbines for optimal disturbance rejection. In Journal of Physics: Conference Series; IOP Publishing: Bristol, UK, 2016; Volume 753, p. 092006. [Google Scholar]

- Bagherieh, O.; Nagamune, R. Gain-scheduling control of a floating offshore wind turbine above rated wind speed. Control Theory Technol. 2015, 13, 160–172. [Google Scholar] [CrossRef]

- Al-bayati, J.S.H.; Üstündağ, B.B. Hybrid intelligent technology for plant health using the fusion of evolutionary optimization and deep neural networks. Expert Syst. 2021, e12756. [Google Scholar] [CrossRef]

- Zouaidia, K.; Ghanemi, S.; Rais, M.S.; Bougueroua, L.; Katarzyna, W.W. Hybrid intelligent framework for one-day ahead wind speed forecasting. Neural Comput. Appl. 2021, 33, 16591–16608. [Google Scholar] [CrossRef]

- Chen, Y.L.; Liu, Y.P.; Sun, X.F. The active frequency control strategy of the wind power based on model predictive control. Complexity 2021, 2021, 8834234. [Google Scholar] [CrossRef]

- Djilali, L.; Badillo-Olvera, A.; Rios, Y.Y.; López-Beltrán, H.; Saihi, L. Neural high order sliding mode control for doubly fed induction generator based wind turbines. IEEE Lat. Am. Trans. 2021, 20, 223–232. [Google Scholar] [CrossRef]

- Asgharnia, A.; Jamali, A.; Shahnazi, R.; Maheri, A. Load mitigation of a class of 5-MW wind turbine with RBF neural network based fractional-order PID controller. ISA Trans. 2020, 96, 272–286. [Google Scholar] [CrossRef]

- Sierra-García, J.E.; Santos, M. Lookup table and neural network hybrid strategy for wind turbine pitch control. Sustainability 2021, 13, 3235. [Google Scholar] [CrossRef]

- Dong, Y.; Zhang, H.; Wang, C.; Zhou, X. Wind power forecasting based on stacking ensemble model, decomposition and intelligent optimization algorithm. Neurocomputing 2021, 462, 169–184. [Google Scholar] [CrossRef]

- Xie, J.; Zhang, H.; Liu, L.; Li, M.; Su, Y. Decomposition-Based Multistep Sea Wind Speed Forecasting Using Stacked Gated Recurrent Unit Improved by Residual Connections. Complexity 2021, 2021, 2727218. [Google Scholar] [CrossRef]

- Sui, A.; Qian, W. Intelligent grey forecasting model based on periodic aggregation generating operator and its application in forecasting clean energy. Expert Syst. 2022, 39, e12868. [Google Scholar] [CrossRef]

- Aparicio-Santos, J.; Hermosillo-Gómez, J.; Benitez-Pérez, H.; Alvarez-Icaza, L. Fuzzy controller to compensate comunication loads in real-time. Rev. Iberoam. De Automática E Inf. Ind. 2021, 18, 288–299. [Google Scholar] [CrossRef]

- Escaño, J.M.; Sánchez, A.J.; Ceballos, M.; Gallego, A.J.; Camacho, E.F. Neuro-fuzzy estimator, with complexity reduction, of the temperatures of a parabolic-trough solar field. Rev. Iberoam. De Automática E Inf. Ind. 2021, 18, 134–145. [Google Scholar] [CrossRef]

- Van, T.L.; Dang, N.K.; Doan, X.N.; Truong, T.H.; Minh, H.N. Adaptive fuzzy logic control to enhance pitch angle controller for variable-speed wind turbines. In Proceedings of the 2018 10th International Conference on Knowledge and Systems Engineering (KSE), Ho Chi Minh City, Vietnam, 1–3 November 2018; pp. 225–229. [Google Scholar]

- Sierra-Garcia, J.E.; Santos, M. Deep learning and fuzzy logic to implement a hybrid wind turbine pitch control. Neural Comput. Appl. 2021, 34, 10503–10517. [Google Scholar] [CrossRef]

- Kant, S.; Agarwal, D.; Shukla, P.K. A survey on fuzzy systems optimization using evolutionary algorithms and swarm intelligence. In Computer Vision and Robotics; Springer: Singapore, 2022; pp. 421–444. [Google Scholar]

- Adedeji, P.A.; Olatunji, O.O.; Madushele, N.; Ajayeoba, A.O. Soft computing in renewable energy system modeling. In Design, Analysis, and Applications of Renewable Energy Systems; Academic Press: Cambridge, MA, USA, 2021; pp. 79–102. [Google Scholar]

- Sahoo, D.K.; Sahu, R.K.; Sekhar, G.C.; Panda, S. A novel modified differential evolution algorithm optimized fuzzy proportional integral derivative controller for load frequency control with thyristor controlled series compensator. J. Electr. Syst. Inf. Technol. 2018, 5, 944–963. [Google Scholar] [CrossRef]

- Borni, A.; Bechouat, M.; Bessous, N.; Bouchakour, A.; Zaarour, L.; Zaghba, L. Comparative Study of P&O and Fuzzy MPPT Controllers and Their Optimization Using PSO and GA to Improve Wind Energy System. Int. J. Eng. Model. 2021, 34, 55–76. [Google Scholar]

- Sharma, S.; Tayal, V.K. Optimised controller design for frequency control of a wind turbine driven doubly fed induction generator. Int. J. Ambient. Energy 2022, 1–10. [Google Scholar] [CrossRef]

- Alaoui, C.; Saikouk, H.; Bakouri, A. MPPT Using Adaptive Genetic-Fuzzy Logic Control for Wind Power System. In International Conference on Digital Technologies and Applications; Springer: Cham, Switzerland, 2021; pp. 1787–1797. [Google Scholar]

- Adedeji, P.A.; Olatunji, O.O.; Madushele, N.; Jen, T.C. Evolutionary-based Hyperparameter Tuning in Machine Learning Models for Condition Monitoring in Wind Turbines–A Survey. In Proceedings of the 2021 IEEE 12th International Conference on Mechanical and Intelligent Manufacturing Technologies (ICMIMT), Cape Town, South Africa, 13–15 May 2021; pp. 254–258. [Google Scholar]

- Monkova, K.; Monka, P.P.; Hric, S.; Kozak, D.; Katinić, M.; Pavlenko, I.; Liaposchenko, O. Condition monitoring of Kaplan turbine bearings using vibro-diagnostics. Int. J. Mech. Eng. Robot. Res. 2020, 9, 1182–1188. [Google Scholar] [CrossRef]

- Mikati, M.; Santos, M.; Armenta, C. Electric grid dependence on the configuration of a small-scale wind and solar power hybrid system. Renew. Energy 2013, 57, 587–593. [Google Scholar] [CrossRef]

- López-Queija, J.; Robles, E.; Jugo, J.; Alonso-Quesada, S. Review of control technologies for floating offshore wind turbines. Renew. Sustain. Energy Rev. 2022, 167, 112787. [Google Scholar] [CrossRef]

- Network, M.R.I. Report on physical modelling methods for floating wind turbines. MARINET Rep. 2015. Available online: https://www.marinet2.eu/wp-content/uploads/2017/04/D2.20-Report-on-Physical-Modelling-Methods-for-Floating-Wind-Turbines-1.pdf (accessed on 10 November 2022).

- Jonkman, J.; Butterfield, S.; Musial, W.; Scott, G. Definition of a 5-MW Reference Wind Turbine for Offshore System Development (No. NREL/TP-500-38060); National Renewable Energy Lab. (NREL): Golden, CO, USA, 2009.

- Civelek, Z.; Lüy, M.; Çam, E.; Mamur, H. A new fuzzy logic proportional controller approach applied to individual pitch angle for wind turbine load mitigation. Renew. Energy 2017, 111, 708–717. [Google Scholar] [CrossRef]

- Global Optimization Toolbox, Matlab. 2022. Available online: https://es.mathworks.com/help/gads/getting-started-with-global-optimization-toolbox.html?s_tid=CRUX_lftnav (accessed on 10 November 2022).

- NREL National Wind Technology Center” NREL.gov. Available online: https://www.nrel.gov/wind/nwtc.html (accessed on 10 November 2022).

- IEC 61400-1. IEC 61400-1:2019 Wind Energy Generation Systems-Part 1: Design Requirements. 2019. Available online: https://www.une.org/encuentra-tu-norma/busca-tu-norma/iec?c=26423 (accessed on 10 November 2022).

- Sarkar, S.; Fitzgerald, B.; Basu, B. Individual blade pitch control of floating offshore wind turbines for load mitigation and power regulation. IEEE Trans. Control Syst. Technol. 2020, 29, 305–315. [Google Scholar] [CrossRef]

- Jonkman, J.M.; Buhl, M.L., Jr. Fast User’s Guide-Updated August 2005 (No. NREL/TP-500-38230); National Renewable Energy Lab. (NREL): Golden, CO, USA, 2005.

- Moskowitz, L. Estimates of the power spectrums for fully developed seas for wind speeds of 20 to 40 knots. J. Geophys. Res. 1964, 69, 5161–5179. [Google Scholar] [CrossRef]

- Li, Z.; Wen, B.; Dong, X.; Long, X.; Peng, Z. Effect of blade pitch control on dynamic characteristics of a floating offshore wind turbine under platform pitching motion. Ocean. Eng. 2021, 232, 109109. [Google Scholar] [CrossRef]

- Mei, X.; Xiong, M. Effects of second-order hydrodynamics on the dynamic responses and fatigue damage of a 15 mw floating offshore wind turbine. J. Mar. Sci. Eng. 2021, 9, 1232. [Google Scholar] [CrossRef]

- Downing, S.D.; Socie, D.F. Simple rainflow counting algorithms. Int. J. Fatigue 1982, 4, 31–40. [Google Scholar] [CrossRef]

| Symbol | Name | Units |

|---|---|---|

| Output power | W | |

| Air density | Kg/m3 | |

| Area swept by the blades | m2 | |

| Radius of the blade | m | |

| Power coefficient | - | |

| Tip speed ratio | - | |

| Wind velocity | m/s | |

| Rotor angular velocity | rad/s | |

| Angular velocity error | rad/s | |

| Angular velocity reference | rad/s | |

| Pitch angle reference before saturation | deg | |

| Pitch angle reference provided by the fuzzy lookup table | deg | |

| Pitch angle reference obtained with the fuzzy PD controller | deg | |

| Pitch angle reference after saturation | deg | |

| Fore–aft displacement of the tower top | m |

| Test Case Number | Average Wind Speed (m/s) | Wave Height Hs (m) |

|---|---|---|

| 1 | 13 | 1 |

| 2 | 15 | 2 |

| 3 | 17 | 3 |

| 4 | 19 | 4 |

| 5 | 21 | 5 |

| Optimization Case/Test Case | Case 1 | Case 2 | Case 3 | Case 4 | Case 5 |

|---|---|---|---|---|---|

| Case 1 | 0.0958 | 0.0989 | 0.1051 | 0.1106 | 0.1037 |

| Case 2 | 0.1013 | 0.0958 | 0.0987 | 0.1194 | 0.1258 |

| Case 3 | 0.1179 | 0.1088 | 0.0947 | 0.1104 | 0.1040 |

| Case 4 | 0.1071 | 0.1082 | 0.0978 | 0.0985 | 0.1029 |

| Case 5 | 0.1205 | 0.1185 | 0.1121 | 0.1085 | 0.0999 |

| Case Number | Suppression Rate (%) TTDspFA | Suppression Rate (%) Platform Pitch | Normalized Power RMSE |

|---|---|---|---|

| 1 | 23.01 | 33.75 | 0.22 |

| 2 | 10.22 | 25.32 | 0.39 |

| 3 | 5.25 | 15.34 | 0.58 |

| 4 | 7.10 | 19.21 | 0.49 |

| 5 | 6.92 | 19.31 | 0.41 |

| Case Number | Fatigue DEL AGFPI (kNm) | Fatigue DEL BC (kNm) | % Reduction |

|---|---|---|---|

| 1 | 1387 | 1538 | 9.82 |

| 2 | 1465 | 1598 | 8.32 |

| 3 | 1412 | 1605 | 12.02 |

| 4 | 1556 | 1618 | 3.83 |

| 5 | 1565 | 1633 | 4.16 |

| Case Number | Fatigue DEL AGFPI (kNm) | Fatigue DEL BC (kNm) | % Reduction |

|---|---|---|---|

| 1 | 5012 | 5237 | 4.30 |

| 2 | 5115 | 5266 | 2.87 |

| 3 | 5144 | 5301 | 2.96 |

| 4 | 5174 | 5322 | 2.78 |

| 5 | 5169 | 5313 | 2.71 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Serrano, C.; Sierra-Garcia, J.-E.; Santos, M. Hybrid Optimized Fuzzy Pitch Controller of a Floating Wind Turbine with Fatigue Analysis. J. Mar. Sci. Eng. 2022, 10, 1769. https://doi.org/10.3390/jmse10111769

Serrano C, Sierra-Garcia J-E, Santos M. Hybrid Optimized Fuzzy Pitch Controller of a Floating Wind Turbine with Fatigue Analysis. Journal of Marine Science and Engineering. 2022; 10(11):1769. https://doi.org/10.3390/jmse10111769

Chicago/Turabian StyleSerrano, Carlos, Jesus-Enrique Sierra-Garcia, and Matilde Santos. 2022. "Hybrid Optimized Fuzzy Pitch Controller of a Floating Wind Turbine with Fatigue Analysis" Journal of Marine Science and Engineering 10, no. 11: 1769. https://doi.org/10.3390/jmse10111769

APA StyleSerrano, C., Sierra-Garcia, J.-E., & Santos, M. (2022). Hybrid Optimized Fuzzy Pitch Controller of a Floating Wind Turbine with Fatigue Analysis. Journal of Marine Science and Engineering, 10(11), 1769. https://doi.org/10.3390/jmse10111769