Application of Deep Neural Network to Predict the High-Cycle Fatigue Life of AISI 1045 Steel Coated by Industrial Coatings

Abstract

:1. Introduction

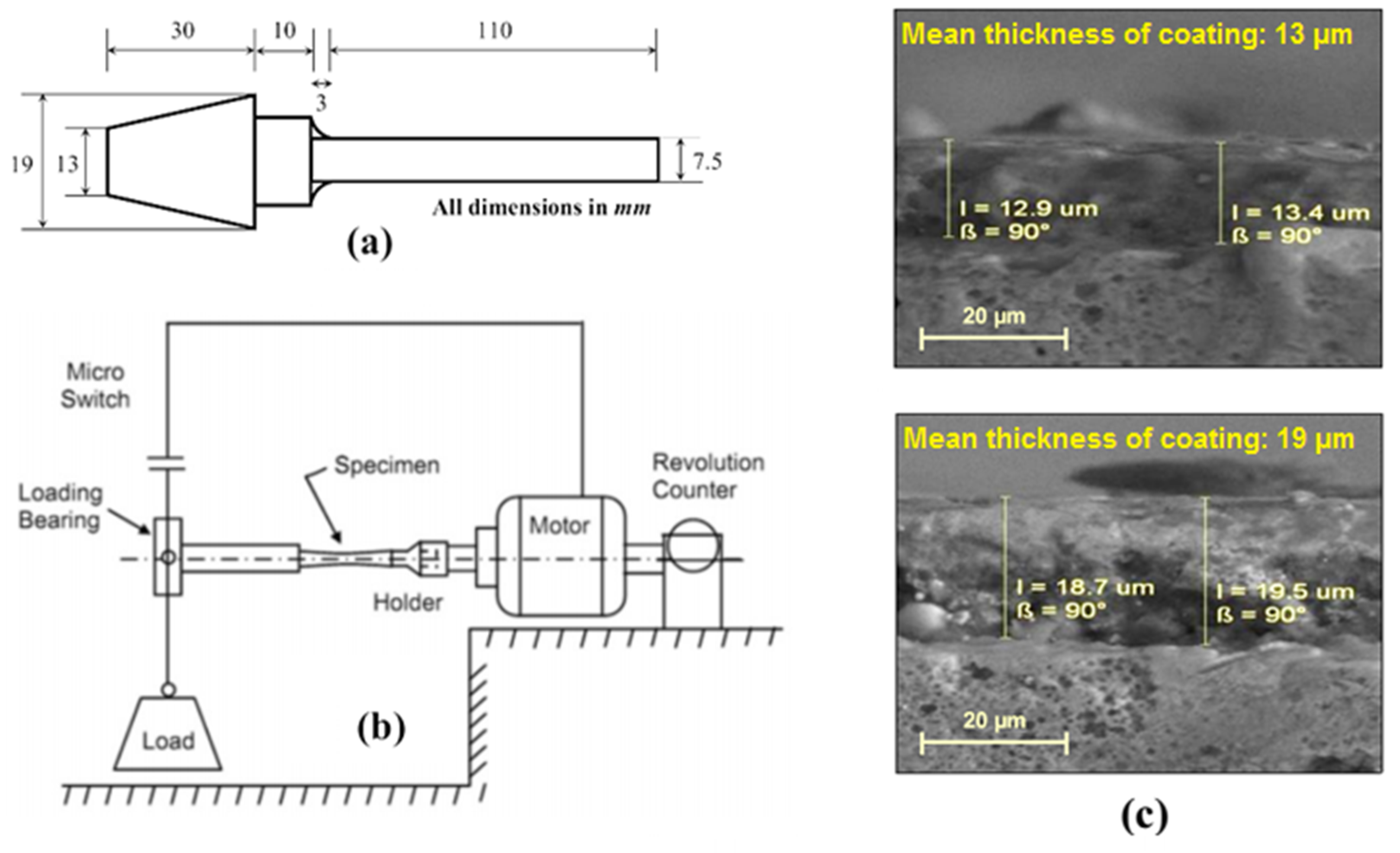

2. Experimental Study

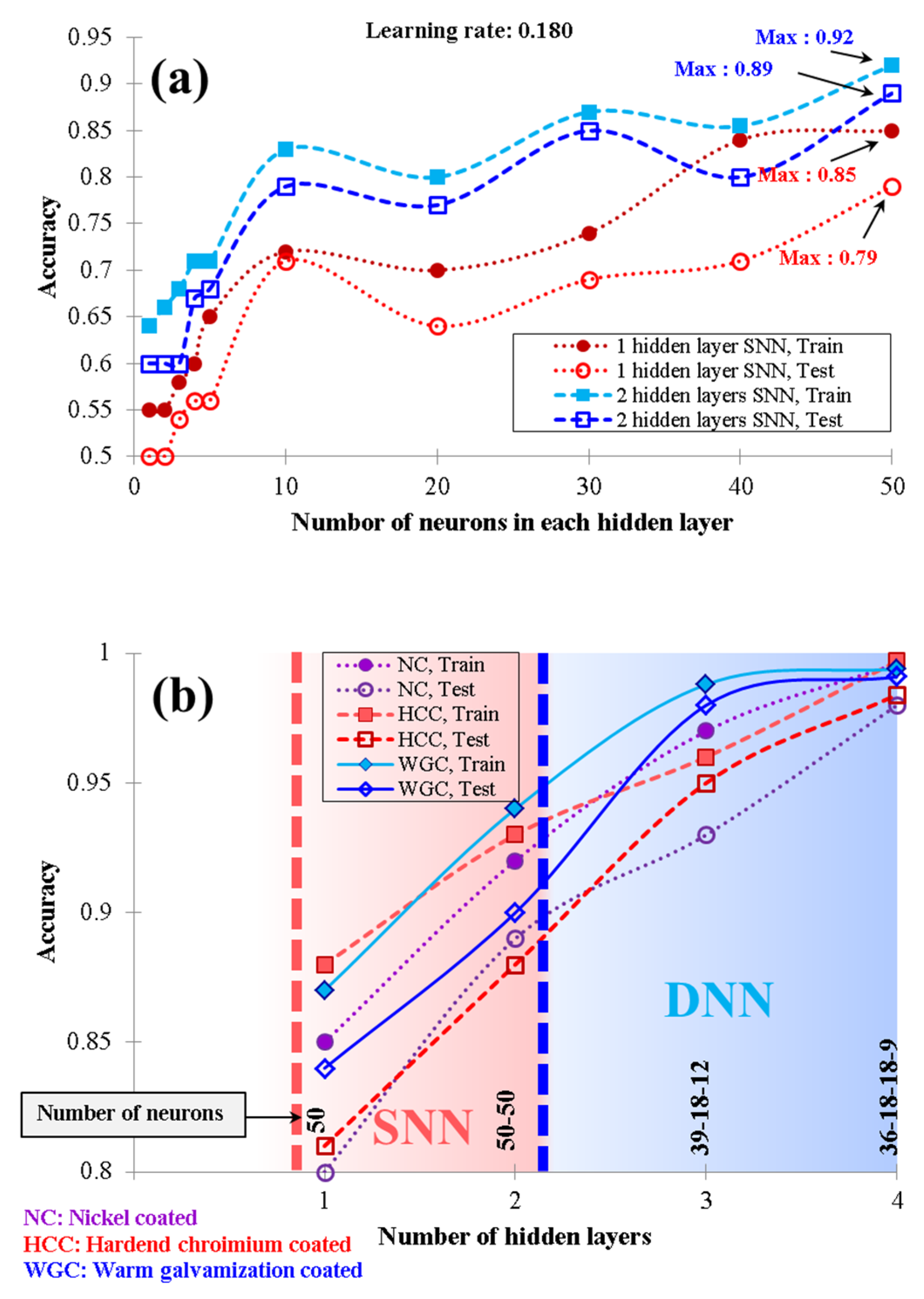

3. Deep Neural Network

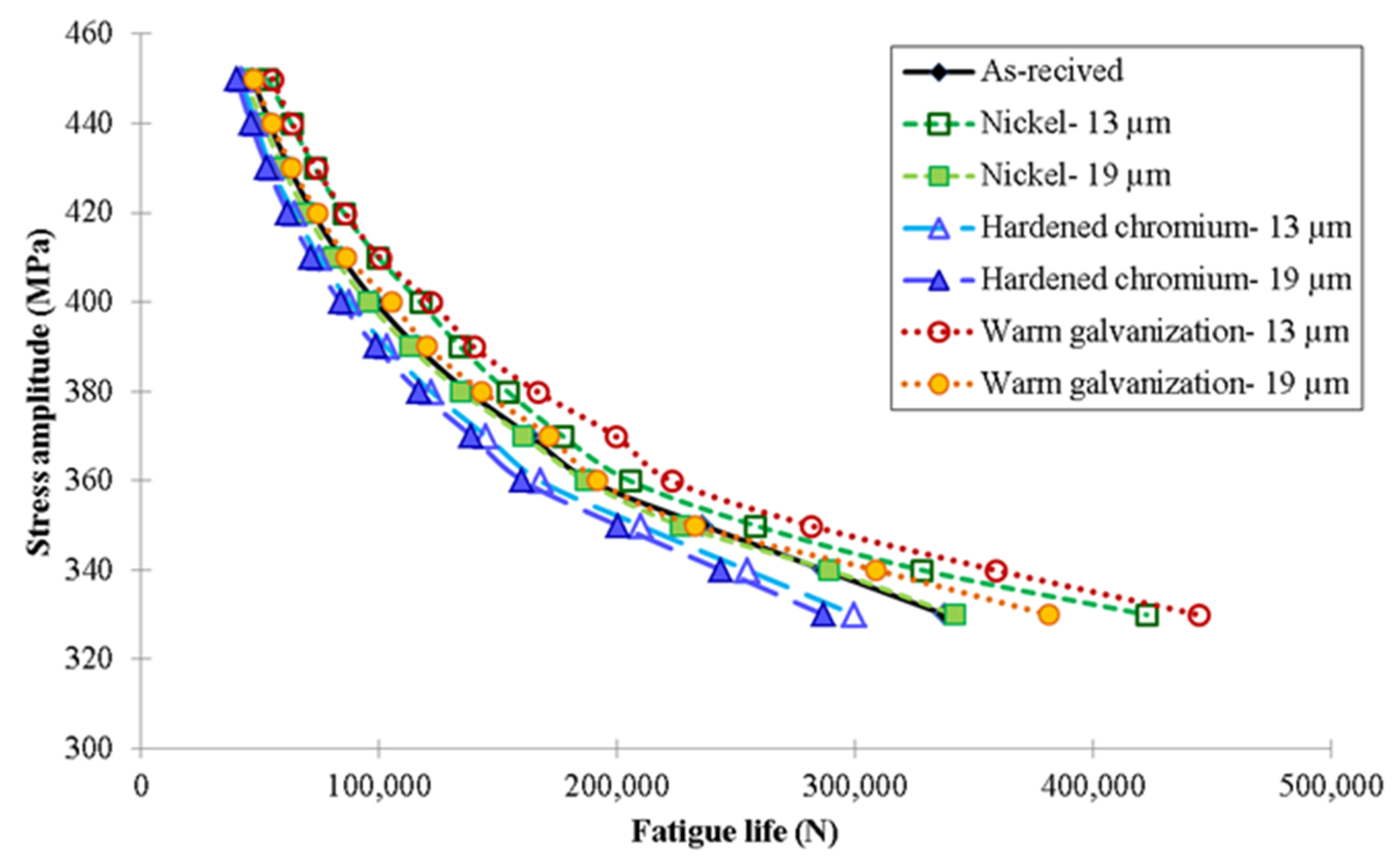

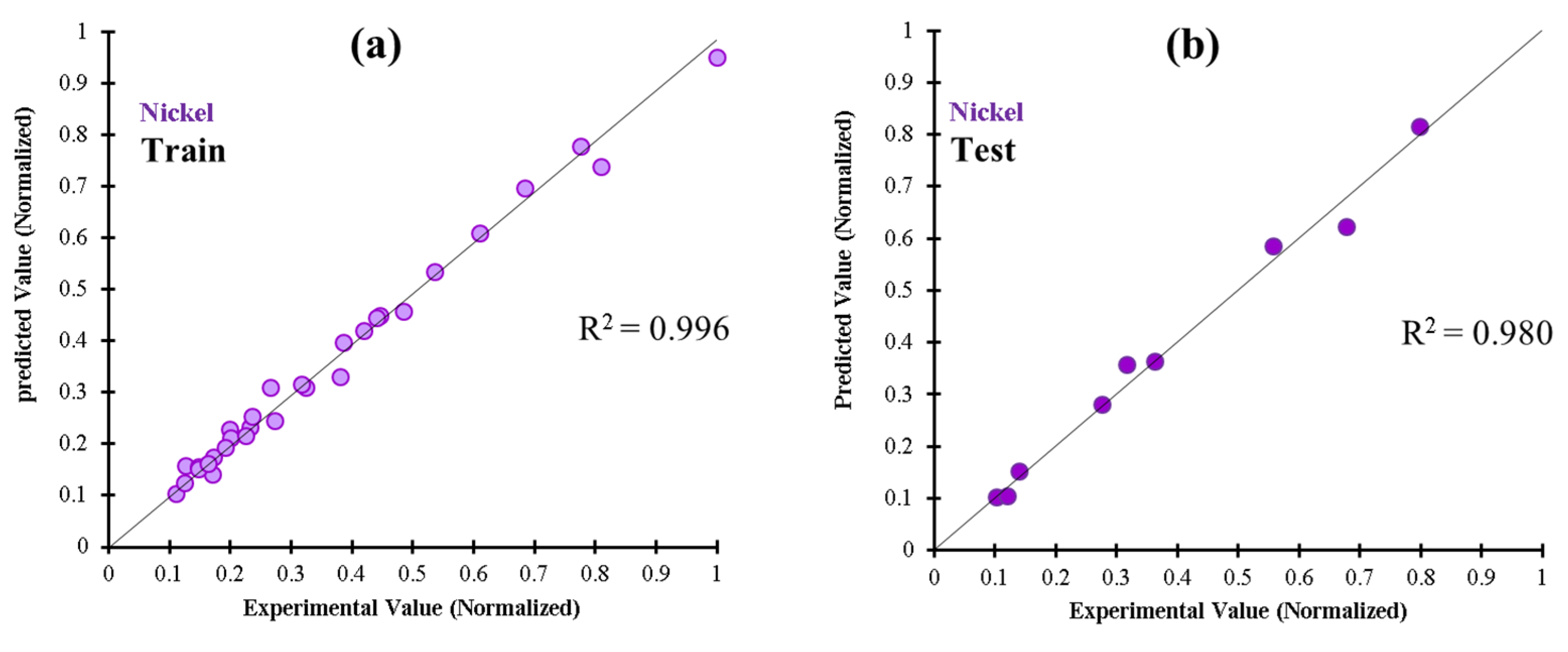

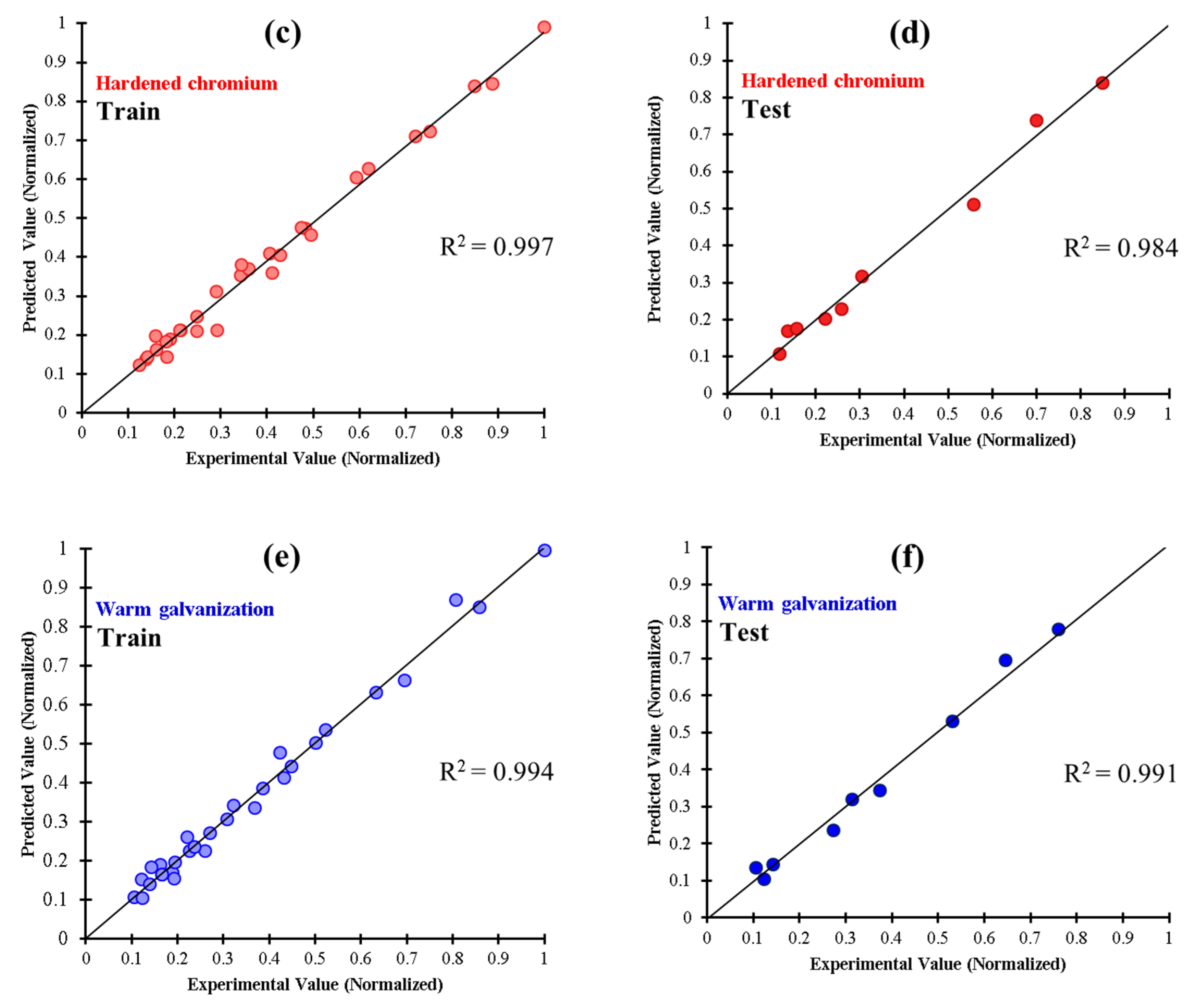

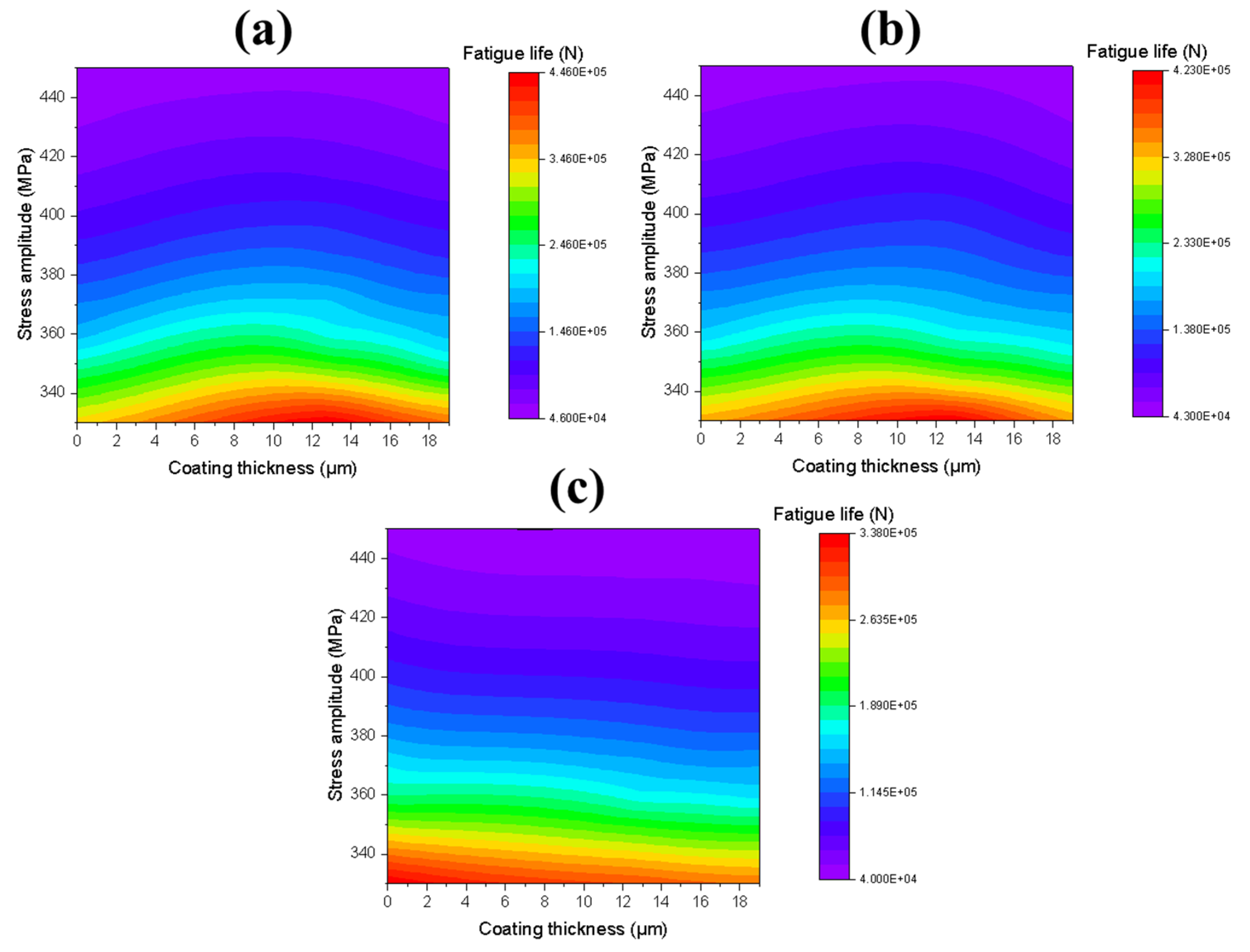

4. Results and Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Amiri, N.; Shaterabadi, M.; Reza Kashyzadeh, K.; Chizari, M. A Comprehensive Review on Design, Monitoring, and Failure in Fixed Offshore Platforms. J. Mar. Sci. Eng. 2021, 9, 1349. [Google Scholar] [CrossRef]

- Abdollahnia, H.; Hadi, M.; Elizei, A.; Kashyzadeh, K.R. Multiaxial Fatigue Life Assessment of Integral Concrete Bridge with a Real-Scale and Complicated Geometry Due to the Simultaneous Effects of Temperature Variations and Sea Waves Clash. J. Mar. Sci. Eng. 2021, 9, 1433. [Google Scholar] [CrossRef]

- Makhlouf, A.S.H. Handbook of Smart Coatings for Materials Protection; Woodhead Publishing: Cambridge, UK, 2014; ISBN 9780857096883. [Google Scholar]

- Maleki, E.; Bagherifard, S.; Bandini, M.; Guagliano, M. Surface post-treatments for metal additive manufacturing: Progress, challenges, and opportunities. Addit. Manuf. 2021, 37, 101619. [Google Scholar] [CrossRef]

- Maleki, E.; Maleki, N.; Fattahi, A.; Unal, O.; Guagliano, M.; Bagherifard, S. Mechanical characterization and interfacial enzymatic activity of AISI 316L stainless steel after surface nanocrystallization. Surf. Coat. Technol. 2021, 405, 126729. [Google Scholar] [CrossRef]

- Unal, O.; Maleki, E.; Varol, R. Effect of severe shot peening and ultra-low temperature plasma nitriding on Ti-6Al-4V alloy. Vacuum 2018, 150, 69–78. [Google Scholar] [CrossRef]

- Maleki, E.; Unal, O.; Reza Kashyzadeh, K. Efficiency Analysis of Shot Peening Parameters on Variations of Hardness, Grain Size and Residual Stress via Taguchi Approach. Met. Mater. Int. 2019, 25, 1436–1447. [Google Scholar] [CrossRef]

- Maleki, E.; Unal, O.; Kashyzadeh, K.R.K.R. Effects of conventional, severe, over, and re-shot peening processes on the fatigue behavior of mild carbon steel. Surf. Coat. Technol. 2018, 344, 62–74. [Google Scholar] [CrossRef]

- Amanov, A.; Karimbaev, R.; Maleki, E.; Unal, O.; Pyun, Y.S.Y.-S.; Amanov, T. Effect of combined shot peening and ultrasonic nanocrystal surface modification processes on the fatigue performance of AISI 304. Surf. Coat. Technol. 2019, 358, 695–705. [Google Scholar] [CrossRef]

- Hashemi, B.; Rezaee Yazdi, M.; Azar, V. The wear and corrosion resistance of shot peened-nitrided 316L austenitic stainless steel. Mater. Des. 2011, 32, 3287–3292. [Google Scholar] [CrossRef]

- Maleki, E.; Bagherifard, S.; Unal, O.; Bandini, M.; Farrahi, G.H.; Guagliano, M. Introducing gradient severe shot peening as a novel mechanical surface treatment. Sci. Rep. 2021, 11, 22035. [Google Scholar] [CrossRef] [PubMed]

- Maleki, E.; Unal, O.; Guagliano, M.; Bagherifard, S. The effects of shot peening, laser shock peening and ultrasonic nanocrystal surface modification on the fatigue strength of Inconel 718. Mater. Sci. Eng. A 2021, 810, 141029. [Google Scholar] [CrossRef]

- Maleki, E.; Unal, O.; Reza Kashyzadeh, K. Influences of Shot Peening Parameters on Mechanical Properties and Fatigue Behavior of 316 L Steel: Experimental, Taguchi Method and Response Surface Methodology. Met. Mater. Int. 2021, 27, 4418–4440. [Google Scholar] [CrossRef]

- Unal, O.; Maleki, E.; Karademir, I.; Husem, F.; Efe, Y.; Das, T. Effects of conventional shot peening, severe shot peening, re-shot peening and precised grinding operations on fatigue performance of AISI 1050 railway axle steel. Int. J. Fatigue 2022, 155, 106613. [Google Scholar] [CrossRef]

- Nikam, V.V.; Reddy, R.G.; Collins, S.R.; Williams, P.C.; Schiroky, G.H.; Henrich, G.W. Corrosion resistant low temperature carburized SS 316 as bipolar plate material for PEMFC application. Electrochim. Acta 2008, 53, 2743–2750. [Google Scholar] [CrossRef]

- Martin, F.J.; Natishan, P.M.; Lemieux, E.J.; Newbauer, T.M.; Rayne, R.J.; Bayles, R.A.; Kahn, H.; Michal, G.M.; Ernst, F.; Heuer, A.H. Enhanced corrosion resistance of stainless steel carburized at low temperature. Proc. Metall. Mater. Trans. A Phys. Metall. Mater. Sci. 2009, 40, 1805–1810. [Google Scholar] [CrossRef]

- Sharghi-Moshtaghin, R.; Kahn, H.; Ge, Y.; Gu, X.; Martin, F.J.; Natishan, P.M.; Rayne, R.J.; Michal, G.M.; Ernst, F.; Heuer, A.H. Low-temperature carburization of the ni-base superalloy IN718: Improvements in surface hardness and crevice corrosion resistance. Metall. Mater. Trans. A Phys. Metall. Mater. Sci. 2010, 41, 2022–2032. [Google Scholar] [CrossRef]

- Balaraju, J.N.; Sankara Narayanan, T.S.N.; Seshadri, S.K. Evaluation of the corrosion resistance of electroless Ni-P and Ni-P composite coatings by electrochemical impedance spectroscopy. J. Solid State Electrochem. 2001, 5, 334–338. [Google Scholar] [CrossRef] [Green Version]

- Ono, S.; Tsuge, H.; Nishi, Y.; Hirano, S.I. Improvement of corrosion resistance of metals by an environmentally friendly silica coating method. J. Sol-Gel Sci. Technol. 2004, 29, 147–153. [Google Scholar] [CrossRef]

- Li, G.; Zhang, L.; Cai, F.; Yang, Y.; Wang, Q.; Zhang, S. Characterization and corrosion behaviors of TiN/TiAlN multilayer coatings by ion source enhanced hybrid arc ion plating. Surf. Coat. Technol. 2019, 366, 355–365. [Google Scholar] [CrossRef]

- Tang, P.T.; Watanabet, T.; Andersen, J.E.T.; Bech-Nielsen, G. Improved corrosion resistance of pulse plated nickel through crystallisation control. J. Appl. Electrochem. 1995, 25, 347–352. [Google Scholar] [CrossRef]

- Kashyzadeh, K.R.; Arghavan, A. Study of the effect of different industrial coating with microscale thickness on the CK45 steel by experimental and finite element methods. Strength Mater. 2013, 45, 748–757. [Google Scholar] [CrossRef]

- Bagherifard, S.; Beretta, N.; Monti, S.; Riccio, M.; Bandini, M.; Guagliano, M. On the fatigue strength enhancement of additive manufactured AlSi10Mg parts by mechanical and thermal post-processing. Mater. Des. 2018, 145, 28–41. [Google Scholar] [CrossRef]

- Maleki, E.; Bagherifard, S.; Razavi, S.M.J.; Riccio, M.; Bandini, M.; du Plessis, A.; Berto, F.; Guagliano, M. Fatigue behaviour of notched laser powder bed fusion AlSi10Mg after thermal and mechanical surface post-processing. Mater. Sci. Eng. A 2022, 829, 142145. [Google Scholar] [CrossRef]

- Maleki, E.; Bagherifard, S.; Sabouri, F.; Bandini, M.; Guagliano, M. Hybrid thermal, mechanical and chemical surface post-treatments for improved fatigue behavior of laser powder bed fusion AlSi10Mg samples with notched geometry. Surf. Coat. Technol. 2021, 430, 127962. [Google Scholar] [CrossRef]

- Razavi, S.M.J.; Van Hooreweder, B.; Berto, F. Effect of build thickness and geometry on quasi-static and fatigue behavior of Ti-6Al-4V produced by Electron Beam Melting. Addit. Manuf. 2020, 36, 101426. [Google Scholar] [CrossRef]

- Solberg, K.; Berto, F. Notch-defect interaction in additively manufactured Inconel 718. Int. J. Fatigue 2019, 122, 35–45. [Google Scholar] [CrossRef]

- Kahlin, M.; Ansell, H.; Moverare, J.J. Fatigue behaviour of notched additive manufactured Ti6Al4V with as-built surfaces. Int. J. Fatigue 2017, 101, 51–60. [Google Scholar] [CrossRef]

- Nicoletto, G. INFLUENCE OF ROUGH AS-BUILT SURFACES ON SMOOTH AND NOTCHED FATIGUE BEHAVIOR OF L-PBF AlSi10Mg. Addit. Manuf. 2020, 34, 101251. [Google Scholar] [CrossRef]

- Uzan, N.E.; Ramati, S.; Shneck, R.; Frage, N.; Yeheskel, O. On the effect of shot-peening on fatigue resistance of AlSi10Mg specimens fabricated by additive manufacturing using selective laser melting (AM-SLM). Addit. Manuf. 2018, 21, 458–464. [Google Scholar] [CrossRef]

- Maleki, E.; Unal, O.; Bandini, M.; Guagliano, M.; Bagherifard, S. Individual and synergistic effects of thermal and mechanical surface post-treatments on wear and corrosion behavior of laser powder bed fusion AlSi10Mg. J. Mater. Process. Technol. 2021, 302, 117479. [Google Scholar] [CrossRef]

- Maleki, E.; Bagherifard, S.; Sabouri, F.; Guagliano, M. Effects of hybrid post-treatments on fatigue behaviour of notched LPBF AlSi10Mg: Experimental and deep learning approaches. Procedia Struct. Integr. 2021, 34, 141–153. [Google Scholar] [CrossRef]

- Genna, S.; Ucciardello, N. A thermographic technique for in-plane thermal diffusivity measurement of electroplated coatings. Opt. Laser Technol. 2019, 113, 338–344. [Google Scholar] [CrossRef]

- Arghavan, A.; Kashyzadeh, K.R.; Asfarjani, A.A. Investigating effect of industrial coatings on fatigue damage. Proc. Appl. Mech. Mater. 2011, 87, 230–237. [Google Scholar] [CrossRef]

- Weldon, D.G. Failure Analysis of Paints and Coatings: Revised Edition; Wiley: Hoboken, NJ, USA, 2009; ISBN 9780470697535. [Google Scholar]

- Karger-Kocsis, J. Paints, coatings and solvents. Compos. Sci. Technol. 1994, 51, 613–614. [Google Scholar] [CrossRef]

- Zadeh, M.K.; Yeganeh, M.; Shoushtari, M.T.; Esmaeilkhanian, A. Corrosion performance of polypyrrole-coated metals: A review of perspectives and recent advances. Synth. Met. 2021, 274, 116723. [Google Scholar] [CrossRef]

- Cha, S.C.; Erdemir, A. Coating Technology for Vehicle Applications; Springer: New York, NY, USA, 2015; ISBN 9783319147710. [Google Scholar]

- Kovářík, O.; Haušild, P.; Čapek, J.; Medřický, J.; Siegl, J.; Mušálek, R.; Pala, Z.; Curry, N.; Björklund, S. Resonance bending fatigue testing with simultaneous damping measurement and its application on layered coatings. Proc. Int. J. Fatigue 2016, 82, 300–309. [Google Scholar] [CrossRef]

- Yang, X.; Li, S.; Qi, H. Effect of MCrAlY coating on the low-cycle fatigue behavior of a directionally solidified nickel-base superalloy at different temperatures. Int. J. Fatigue 2015, 75, 126–134. [Google Scholar] [CrossRef]

- Maleki, E. Artificial neural networks application for modeling of friction stir welding effects on mechanical properties of 7075-T6 aluminum alloy. Proc. IOP Conf. Ser. Mater. Sci. Eng. 2015, 103, 012034. [Google Scholar] [CrossRef]

- Maleki, N.; Kashanian, S.; Maleki, E.; Nazari, M. A novel enzyme based biosensor for catechol detection in water samples using artificial neural network. Biochem. Eng. J. 2017, 128, 1–11. [Google Scholar] [CrossRef]

- Maleki, E.; Unal, O. Optimization of Shot Peening Effective Parameters on Surface Hardness Improvement. Met. Mater. Int. 2020, 27, 3173–3185. [Google Scholar] [CrossRef]

- Jahanshahi, M.; Maleki, E.; Ghiami, A. On the efficiency of artificial neural networks for plastic analysis of planar frames in comparison with genetic algorithms and ant colony systems. Neural Comput. Appl. 2016, 28, 3209–3227. [Google Scholar] [CrossRef]

- Maleki, E.; Unal, O.; Reza Kashyzadeh, K. Fatigue behavior prediction and analysis of shot peened mild carbon steels. Int. J. Fatigue 2018, 116, 48–67. [Google Scholar] [CrossRef]

- Kong, Y.S.; Abdullah, S.; Schramm, D.; Omar, M.Z.; Haris, S.M. Optimization of spring fatigue life prediction model for vehicle ride using hybrid multi-layer perceptron artificial neural networks. Mech. Syst. Signal Process. 2019, 122, 597–621. [Google Scholar] [CrossRef]

- Maleki, E.; Kashyzadeh, K.R.R. Effects of the hardened nickel coating on the fatigue behavior of CK45 steel: Experimental, finite element method, and artificial neural network modeling. Iran. J. Mater. Sci. Eng. 2017, 14, 81–99. [Google Scholar] [CrossRef]

- Maleki, E.; Unal, O. Fatigue limit prediction and analysis of nano-structured AISI 304 steel by severe shot peening via ANN. Eng. Comput. 2020, 37, 2663–2678. [Google Scholar] [CrossRef]

- Sbarufatti, C.; Manes, A.; Giglio, M. Performance optimization of a diagnostic system based upon a simulated strain field for fatigue damage characterization. Mech. Syst. Signal Process. 2013, 40, 667–690. [Google Scholar] [CrossRef]

- Fathalla, E.; Tanaka, Y.; Maekawa, K. Remaining fatigue life assessment of in-service road bridge decks based upon artificial neural networks. Eng. Struct. 2018, 171, 602–616. [Google Scholar] [CrossRef]

- Jimenez-Martinez, M.; Alfaro-Ponce, M. Fatigue damage effect approach by artificial neural network. Int. J. Fatigue 2019, 124, 42–47. [Google Scholar] [CrossRef]

- Venkatesh, V.; Rack, H.J. Neural network approach to elevated temperature creep-fatigue life prediction. Int. J. Fatigue 1999, 21, 225–234. [Google Scholar] [CrossRef]

- Vassilopoulos, A.P.; Georgopoulos, E.F.; Dionysopoulos, V. Artificial neural networks in spectrum fatigue life prediction of composite materials. Int. J. Fatigue 2007, 29, 20–29. [Google Scholar] [CrossRef]

- Figueira Pujol, J.C.; Andrade Pinto, J.M. A neural network approach to fatigue life prediction. Int. J. Fatigue 2011, 33, 313–322. [Google Scholar] [CrossRef]

- Barbosa, J.F.; Correia, J.A.F.O.; Júnior, R.C.S.F.; de Esus, A.M.P. Fatigue life prediction of metallic materials considering mean stress effects by means of an artificial neural network. Int. J. Fatigue 2020, 135, 105527. [Google Scholar] [CrossRef]

- Abdalla, J.A.; Hawileh, R. Modeling and simulation of low-cycle fatigue life of steel reinforcing bars using artificial neural network. Proc. J. Frankl. Inst. 2011, 348, 1393–1403. [Google Scholar] [CrossRef]

- Amiri, N.; Farrahi, G.H.; Kashyzadeh, K.R.; Chizari, M. Applications of ultrasonic testing and machine learning methods to predict the static & fatigue behavior of spot-welded joints. J. Manuf. Process. 2020, 52, 26–34. [Google Scholar] [CrossRef]

- Cervera, M.; Barbat, G.B.; Chiumenti, M.; Wu, J.Y. A Comparative Review of XFEM, Mixed FEM and Phase-Field Models for Quasi-brittle Cracking. Arch. Comput. Methods Eng. 2021, 1–75. [Google Scholar] [CrossRef]

- Pandey, V.B.; Singh, I.V.; Mishra, B.K.; Ahmad, S.; Venugopal Rao, A.; Kumar, V. A new framework based on continuum damage mechanics and XFEM for high cycle fatigue crack growth simulations. Eng. Fract. Mech. 2019, 206, 172–200. [Google Scholar] [CrossRef]

- Bui, T.Q.; Hu, X. A review of phase-field models, fundamentals and their applications to composite laminates. Eng. Fract. Mech. 2021, 248, 107705. [Google Scholar] [CrossRef]

- Lo, Y.S.; Borden, M.J.; Ravi-Chandar, K.; Landis, C.M. A phase-field model for fatigue crack growth. J. Mech. Phys. Solids 2019, 132, 103684. [Google Scholar] [CrossRef]

- Maleki, E.; Unal, O. Shot Peening Process Effects on Metallurgical and Mechanical Properties of 316 L Steel via: Experimental and Neural Network Modeling. Met. Mater. Int. 2019, 27, 262–276. [Google Scholar] [CrossRef]

- Maleki, E.; Bagherifard, S.; Guagliano, M. Application of artificial intelligence to optimize the process parameters effects on tensile properties of Ti-6Al-4V fabricated by laser powder-bed fusion. Int. J. Mech. Mater. Des. 2021, 1–24. [Google Scholar] [CrossRef]

- Feng, S.; Zhou, H.; Dong, H. Using deep neural network with small dataset to predict material defects. Mater. Des. 2019, 162, 300–310. [Google Scholar] [CrossRef]

- Maleki, E.; Unal, O.; Guagliano, M.; Bagherifard, S. Analysing the Fatigue Behaviour and Residual Stress Relaxation of Gradient Nano-structured 316L Steel Subjected to the Shot Peening via Deep Learning Approach. Met. Mater. Int. 2021, 28, 112–131. [Google Scholar] [CrossRef]

- Kalayci, C.B.; Karagoz, S.; Karakas, Ö. Soft computing methods for fatigue life estimation: A review of the current state and future trends. Fatigue Fract. Eng. Mater. Struct. 2020, 43, 2763–2785. [Google Scholar] [CrossRef]

- Abiodun, O.I.; Jantan, A.; Omolara, A.E.; Dada, K.V.; Mohamed, N.A.E.; Arshad, H. State-of-the-art in artificial neural network applications: A survey. Heliyon 2018, 4, e00938. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Tao, C.; Zhang, C.; Ji, H.; Qiu, J. Fatigue damage characterization for composite laminates using deep learning and laser ultrasonic. Compos. Part B Eng. 2021, 216, 108816. [Google Scholar] [CrossRef]

- Lee, H.; Lim, H.J.; Skinner, T.; Chattopadhyay, A.; Hall, A. Automated fatigue damage detection and classification technique for composite structures using Lamb waves and deep autoencoder. Mech. Syst. Signal Process. 2021, 163, 108148. [Google Scholar] [CrossRef]

- Rovinelli, A.; Sangid, M.D.; Proudhon, H.; Ludwig, W. Using machine learning and a data-driven approach to identify the small fatigue crack driving force in polycrystalline materials. Npj Comput. Mater. 2018, 4, 35. [Google Scholar] [CrossRef] [Green Version]

- Zhan, Z.; Li, H. Machine learning based fatigue life prediction with effects of additive manufacturing process parameters for printed SS 316L. Int. J. Fatigue 2021, 142, 10594. [Google Scholar] [CrossRef]

- Chen, J.; Liu, Y. Fatigue modeling using neural networks: A comprehensive review. Fatigue Fract. Eng. Mater. Struct. 2021. [Google Scholar] [CrossRef]

- Reza Kashyzadeh, K.; Maleki, E. Experimental Investigation and Artificial Neural Network Modeling of Warm Galvanization and Hardened Chromium Coatings Thickness Effects on Fatigue Life of AISI 1045 Carbon Steel. J. Fail. Anal. Prev. 2017, 17, 1276–1287. [Google Scholar] [CrossRef]

- Maleki, E.; Maleki, N. Artificial Neural Network Modeling of Pt/C Cathode Degradation in PEM Fuel Cells. J. Electron. Mater. 2016, 45, 3822–3834. [Google Scholar] [CrossRef]

- Maleki, E.; Mirzaali, M.J.; Guagliano, M.; Bagherifard, S. Analyzing the mechano-bactericidal effect of nano-patterned surfaces on different bacteria species. Surf. Coat. Technol. 2020, 408, 126782. [Google Scholar] [CrossRef]

- Maleki, E.; Unal, O.; Reza Kashyzadeh, K. Surface layer nanocrystallization of carbon steels subjected to severe shot peening: Analysis and optimization. Mater. Charact. 2019, 157, 109877. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Maleki, E.; Unal, O.; Seyedi Sahebari, S.M.; Reza Kashyzadeh, K.; Danilov, I. Application of Deep Neural Network to Predict the High-Cycle Fatigue Life of AISI 1045 Steel Coated by Industrial Coatings. J. Mar. Sci. Eng. 2022, 10, 128. https://doi.org/10.3390/jmse10020128

Maleki E, Unal O, Seyedi Sahebari SM, Reza Kashyzadeh K, Danilov I. Application of Deep Neural Network to Predict the High-Cycle Fatigue Life of AISI 1045 Steel Coated by Industrial Coatings. Journal of Marine Science and Engineering. 2022; 10(2):128. https://doi.org/10.3390/jmse10020128

Chicago/Turabian StyleMaleki, Erfan, Okan Unal, Seyed Mahmoud Seyedi Sahebari, Kazem Reza Kashyzadeh, and Igor Danilov. 2022. "Application of Deep Neural Network to Predict the High-Cycle Fatigue Life of AISI 1045 Steel Coated by Industrial Coatings" Journal of Marine Science and Engineering 10, no. 2: 128. https://doi.org/10.3390/jmse10020128

APA StyleMaleki, E., Unal, O., Seyedi Sahebari, S. M., Reza Kashyzadeh, K., & Danilov, I. (2022). Application of Deep Neural Network to Predict the High-Cycle Fatigue Life of AISI 1045 Steel Coated by Industrial Coatings. Journal of Marine Science and Engineering, 10(2), 128. https://doi.org/10.3390/jmse10020128