1. Introduction

One of the concepts considered for propelling high-speed underwater vehicles (e.g., cruising at 150–250 knots) is the water-breathing ramjet. The fundamental physical principle, on which the water-breathing ramjet is based, is the high stagnation pressure of water at high velocities. The elevated stagnation pressure enables introducing water into the motor, due to the vehicle’s motion, without the necessity of actively operated devices (pumps). The water ingested may be used as a source of inert fluid to increase the mass flow rate, thus increasing the thrust and the overall impulse produced by the motor for a given quantity of propellant. Additionally, the water may also be used as an oxidizer to oxidize water-reactive fuel components, thus enabling a reduction in the amount of oxidizer carried onboard, a valuable quality in volume-limited vehicles. In general, the introduction of water from the surroundings can substantially increase the energetic performance, enabling an increased range and operating time without changing the amount of on-board propellant.

Various metals are known for their exothermic reaction with water and are considered additives to solid-propellant ramjets [

1,

2,

3,

4,

5], as water-reactive fuel components, to increase the specific impulse and the thrust of the propulsion unit.

Table 1 displays the theoretical properties of the water–metal reaction of selected metals. The data in

Table 1 were computed by calculating the change in the heat of formation between the reactants and products of the stoichiometric reaction of the specific metal with water (additional parameters of the water-metallic reaction of the metals listed in the table can be found in Ref. [

6]). It is apparent from

Table 1 that the water–beryllium reaction releases the largest amount of heat per unit mass of metal, yet due to the toxicity of beryllium and its combustion products, utilizing beryllium is impractical. Volumetrically, second to beryllium is boron, which theoretically demonstrates a highly energetic reaction with water; however, achieving a quality combustion efficiency with boron is challenging due to peculiar features, such as the retarding effect of the low melting temperature and the high boiling point of its oxide. Although quite energetic volumetrically, zirconium is not widely considered due to its relatively low gravimetric figure as well as safety concerns. Hence, in practice, aluminum and magnesium are considered for inclusion in the fuel grains of the marine ramjet as hydro-reactive additives. Aluminum has a higher heat of reaction with water, whereas magnesium is more reactive with water, which, in practice, may lead to a better reaction efficiency, compensating for its lower heat of reaction.

Works performed in the field have mainly focused on different aspects of solid-propellant, water-breathing ramjets, such as evaluating optimal operating conditions and maximal theoretical performance [

7,

8,

9,

10,

11], combustion properties of different propellants and fuels tailored for a water-breathing operation [

1,

2,

3,

4,

5], and static firing tests [

12,

13] as well as other aspects [

14]. Previous research conducted by these authors [

15,

16] suggested considering the use of a ducted, hybrid, ram-rocket-based water-breathing ramjet. The hybrid motor employs a propellant consisting of an oxidizer and fuel stored at different phases, typically liquid oxidizer and solid fuel. In addition to the notable advantages of hybrid propellants regarding controllability and safety [

17], the hybrid configuration enables a wide choice of strong oxidizers that may enable the achievement of superior performance relative to marine solid-propellant ramjets. The general architecture of a hybrid-propellant, water-breathing ram-rocket is presented in

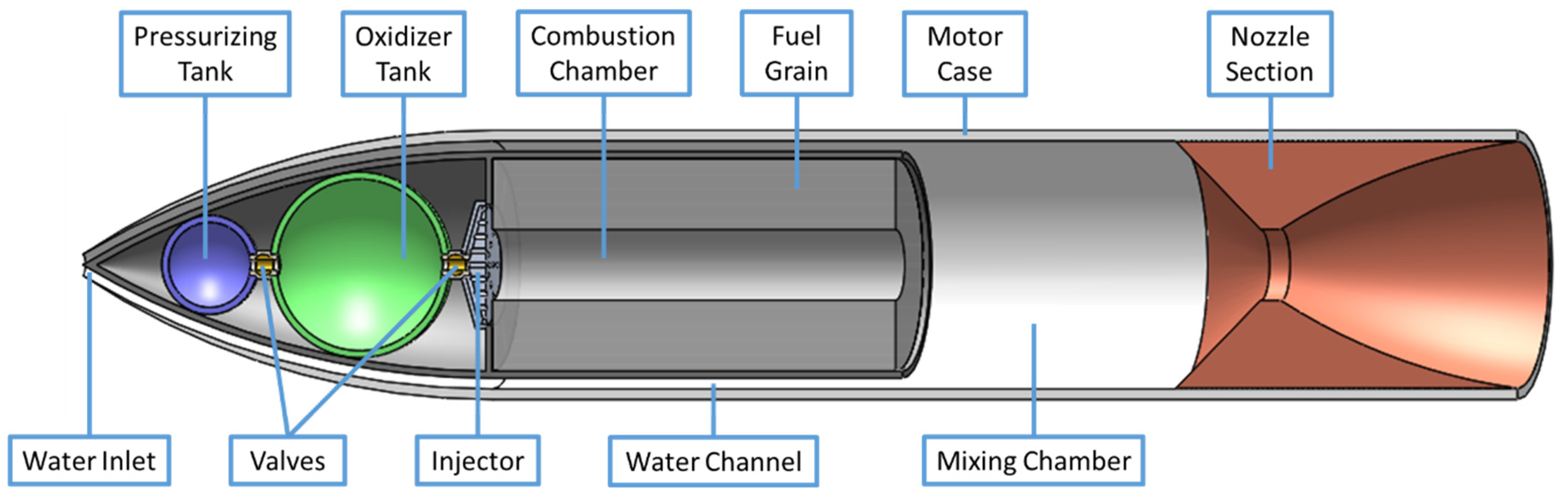

Figure 1.

However, to the best of our knowledge, except for the research conducted by these authors, no work has been conducted on evaluating or testing the performance of a marine hybrid-propellant ramjet that contains hydro-reactive ingredients within the fuel grain.

The objective of this work was to both theoretically and experimentally study the influence on combustion characteristics and energetic performance of the addition of aluminum and magnesium particles to the solid fuel grain of a marine hybrid-propellant, water-breathing ramjet.

2. Methods

To test the performance of a marine hydro-reactive, fuel-rich, hybrid-propellant ramjet, numerous static firing tests have been performed alongside the use of a theoretical model to predict the maximal possible performance at the conditions tested experimentally. The specific impulse (

), defined as the thrust divided by the weight flow rate of propellant consumed in order to produce the thrust, was the key measure in evaluating the energetic performance of propellant compositions and operating conditions. Static firing tests were conducted to determine the specific impulse achieved by the addition of aluminum and magnesium to a polyester fuel grain; the oxidizer used in all cases was gaseous oxygen (in addition to the water from a pressurized water tank, introduced during the combustion). The fuel grains were manufactured by mixing aluminum particles with a typical size of 15–20 microns (as shown in

Figure 2) and/or coarser magnesium particles with a typical size of 70–80 microns (as shown in

Figure 3) within an erco

® E-7 unsaturated orthophthalic polyester resin together with 1% (of the polyester weight) of hardener (methyl ethyl ketone peroxide), and 1% (of the total weight) 100-150 micron flakes of expandable graphite (Graphit Kropfmühl ES 100 C10) for flame stabilization. The fuel–resin mixture was then casted into an acrylonitrile butadiene styrene (ABS) 3D printed mold, which later, after the fuel hardening, was dissolved in acetone. A photograph of one of the fuel grains before and after firing is shown in

Figure 4. The composition of the polyester used was determined by a chemical analysis to be approximately

C42H41O10 (see

Table 1 in Ref. [

16]). The different hydro-reactive, fuel-rich compositions examined in this work are listed in

Table 2. Several static firing tests were conducted with each metallized composition, in addition to experiments with plain, non-metallized polymer (polyester) that we reported earlier [

16]. There was a desire to also manufacture fuel grains containing 50% of hydro-reactive fuel components; however, it was challenging to properly mix such viscus compositions. Thus, the maximal mass fraction of hydro-reactive metal particles in the tested fuel grains was 46%.

The calculation of the theoretical specific impulse for the different fuel compositions listed above in

Table 2 was completed with the aid of the Computer Program for Calculation of Complex Chemical Equilibrium Compositions and Applications (CEA) [

18] for oxidizer to fuel mass ratios (O/F) in the range of 0.5–3 and water–propellant mass ratios (W/P) in the range of 0–3, according to the method presented in length in Ref. [

16] (in the Theoretical Model section). The governing equation used in this method is derived from the following equation that yields the thrust produced by the ramjet:

where

= thrust;

= exhaust mass flow rate;

= exhaust jet velocity;

= incoming water mass flow rate;

= vehicle velocity;

= exhaust jet static pressure;

= ambient pressure.

For optimal operation, an adapted nozzle is used, namely

=

, and the thrust equation obtains the form:

The specific impulse, by the definition mentioned above, may be calculated:

where

= specific impulse;

= propellant mass flow rate;

= standard gravity acceleration.

Two parameters that are widely used to characterize the rocket motors are the characteristic velocity,

, which is a measure of the combustor performance, and the adapted nozzle thrust coefficient,

, which is used to evaluate the maximum possible nozzle performance and enable us to obtain the governing equation used in our approach (assuming adapted nozzle, namely full expansion to the ambient pressure):

where

= water–propellant mass ratio;

= characteristic velocity;

= adapted nozzle thrust coefficient.

It should be mentioned that when large quantities of water are added, the product’s temperature in some cases might decrease below the temperature of condensation (boiling) of water (i.e., 557K at 1000 psia (69 bar)), which may lead to an incorrect calculation of CEA; thus, theoretical results obtained at those conditions have been ignored. It should also be addressed that all the theoretical calculations were carried out with CEA, which does not take into account the two-phase flow effects, internal drag, heat loses, and other effects that are expected in practice to lead to reduced performance.

The influence of external underwater forces on the performance of a hybrid propulsor has not been taken into account in this work but have been investigated by [

10,

19] in regard to the ratio between the drag to the thrust produced by the motor.

The experimental method used in this work was identical to that used and described in Ref. [

16] (in the Experimental Setup section), including dimensions, measuring methods, gauges, time sequence, etc.; however, the fuel grains used for this investigation were slightly shorter, 95–190 mm, because of the higher density of the fuel due to the increased density of the hydro-reactive fuel particles. However, for clarification, the main parameters are summarized here. A general layout of the experimental setup can be seen in the photograph presented in

Figure 5. During the firing test, oxygen was streamed down the central port of the cylindrical fuel grain, enabling the fuel to burn. The combustion products exiting the fuel grain then entered a mixing chamber located downstream, at which water was introduced to enable secondary combustion of the hydro-reactive fuel with the water, along with vaporizing additional water to augment the thrust produced by the motor. Throughout the experiment, flow rates of both the oxygen and the water were measured and logged alongside the thrust produced by the motor and the combustion pressure for further analysis. The operating sequence of each firing test began by flushing the motor with oxygen for 2 s prior to ignition. Then, the motor was operated for 4 s without water to achieve a steady condition and to enable measuring the performance of the motor without water. Next, water was introduced for 4 additional seconds to quantify the performance of the water-breathing motor. Finally, the water line was closed, and the motor continued to operate for 4 additional seconds, after which the oxygen line was also closed and the experiment terminated. Additionally, since each experiment was conducted at slightly different conditions, adjustment to the equivalent standard specific impulse (corresponding to a standard chamber pressure of 1000 psia (69 bar)) was conducted to enable comparison of experiments on a common basis. Such stagnation pressure would be achieved when cruising at approximately 115 m/s at sea level. Although the CEA theoretical prediction was used only to predict performance obtained at water–propellant ratios smaller than 3 (due to water condensation at larger ratios), for the 20% aluminum fuel composition, the experimental investigation covered a broader range of O/F ratios, between 1 and 4.5.

The heat released by the combustion process is influenced by the oxidizer–fuel ratio (O/F), which affects the maximal specific impulse that may be achieved. Therefore, the theoretical model was used to determine the optimal O/F for each fuel composition tested. All theoretical results presented below are for the O/F ratio at which maximal theoretical specific impulse is achieved (at optimal W/P ratio), and all experimental results are at an O/F within ±0.5 mass ratio of the theoretical optimal O/F mass ratio.

3. Results and Discussion

In total, 32 successful experiments have been conducted with fuel grains containing 20% or 30% of aluminum or 30% of magnesium, as well as more with a non-metallized fuel (polyester), as reported by these authors [

16]. By trial and error, it was discovered that the fuel grains heavily loaded with the hydro-reactive fuel (e.g., 46% magnesium or a mixture of 20% aluminum with 26% magnesium) demonstrated unstable combustion and low combustion efficiency, of no promise for practical applications. Therefore, the measurements logged during those firings were not taken into account when analyzing the results.

Figure 6 presents the equivalent standard specific impulse with fuel grains containing 20% of aluminum versus the water–propellant mass ratio as measured during a series of static firing tests and as predicted theoretically; a line representing an efficiency of 80% is also shown in the figure. For this composition, theoretically, the maximal specific impulse may be achieved at an O/F mass ratio of 1.9. It can be observed from

Figure 6 that the addition of water significantly increases the theoretical specific impulse to a maximum slightly above 515 s that is achieved when the W/P ratio is in the range of 2.2–2.8. Experimentally, good performance has been demonstrated with a typical efficiency of about 90% and a standard specific impulse as high as 470 s. The overall efficiency obtained with the metallized fuels was similar to the efficiency demonstrated during the combustion of the plain polymer (polyester) [

16]. It is encouraging because, in general, metallized fuels may show efficiency losses due to incomplete reaction, slag formation, and two-phase flow effects. As mentioned earlier, although the theoretical prediction focuses only on the range of W/P for which the water is in a gaseous phase, the range of the larger W/P was also experimentally examined. It is apparent from the figure that at W/P values for which the theoretical calculation predicts incomplete vaporization of water, a decrease in performance is measured.

Figure 7 presents the corresponding results for the fuel grains containing 30% aluminum. For this composition, theoretically, the maximal specific impulse may be achieved at an O/F mass ratio of 1.75. It can be understood from

Figure 7 that, theoretically, the addition of aluminum (relative to the previous case with 20%) increases the specific impulse to a value above 535 s for a W/P ratio between 2.3 and 3. However, it is observed that in practice, the addition of aluminum showed a negative effect, revealing a somewhat lower efficiency (mostly between 80% and 90%) and no benefit compared to the case of 20% aluminum. Furthermore, the combustion of these grains produced relatively large amounts of slag, causing some irregularities in the combustion behavior.

Figure 8 presents the parallel results for fuel grains containing 30% of magnesium. For this composition, theoretically, the maximal specific impulse may be achieved at an O/F mass ratio of 1.7. Theoretically, the composition with 30% magnesium should exhibit a similar performance to that containing 20% aluminum, with a maximal specific impulse of above 520 s for W/P in the range of 2.3–2.7. Interestingly, the high reactivity of magnesium contributes to a better combustion efficiency, enabling the 30% magnesium to experimentally achieve an equivalent standard specific impulse of roughly 485 s (above 90% efficiency) in several experiments. Additionally, the grains containing the 30% magnesium burned smoothly and exhibited higher regression rates.

Figure 9 presents a comparison between the different experimental and theoretical results obtained in this work for metal-containing fuels and additional results for pure polymeric fuel (polyester) exhibited in a previous work by these authors [

16]. It is noticeable from the figure that the addition of metals to the fuel grain improves performance significantly, both theoretically and experimentally. Additionally, the general trends discussed above are pronounced in this figure, as it is apparent that although, theoretically, the 30% magnesium may be inferior to the 30% aluminum, in practice, the 30% magnesium demonstrates superior performance due to the better efficiency.