Pore Pressure Response and Dissipation of Piezocone Test in Shallow Silty Soil of Yellow River Delta

Abstract

:1. Introduction

2. Characteristics of Silts and Silty Clays

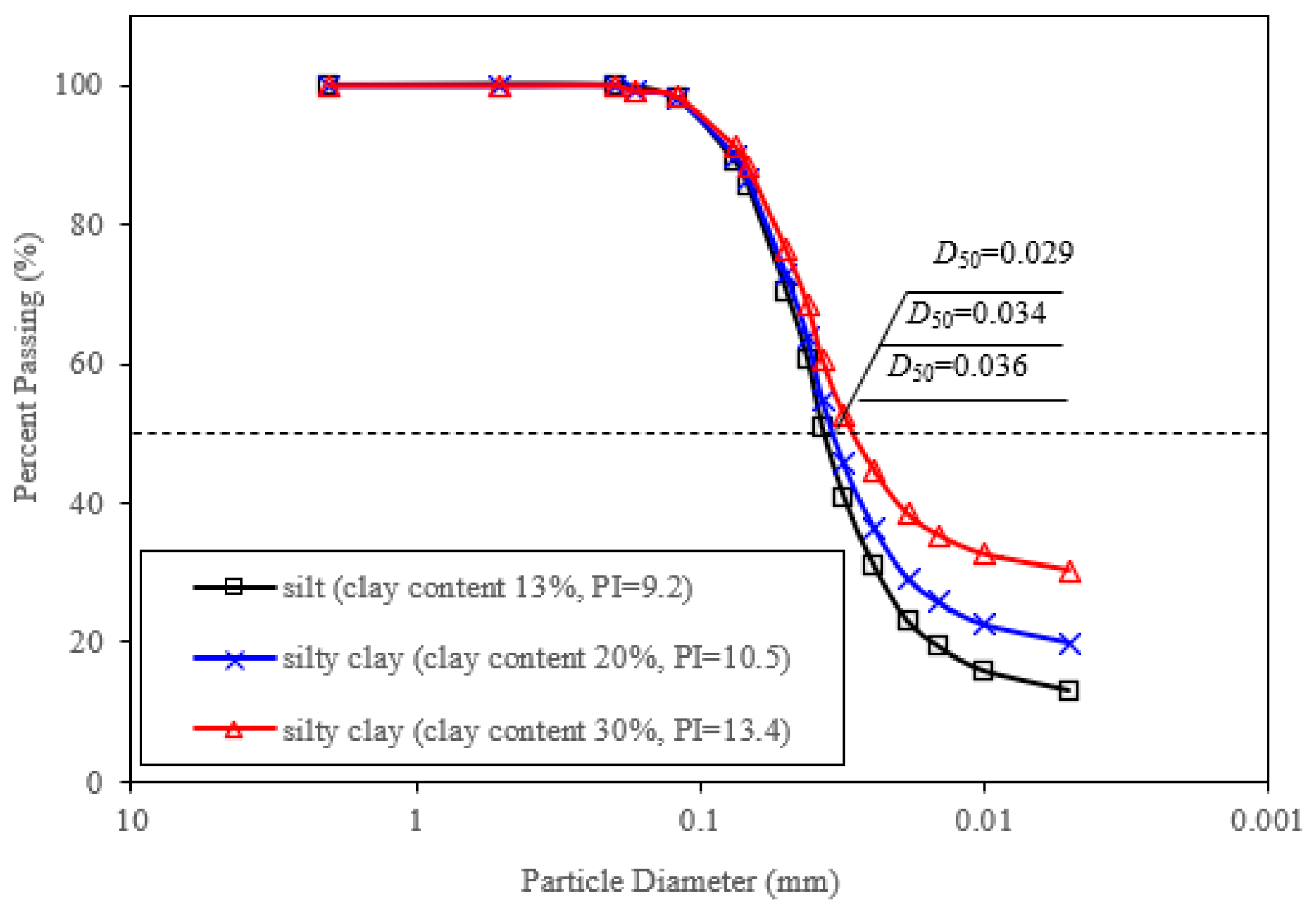

2.1. Particle Size Distribution of Silt and Silty Clays

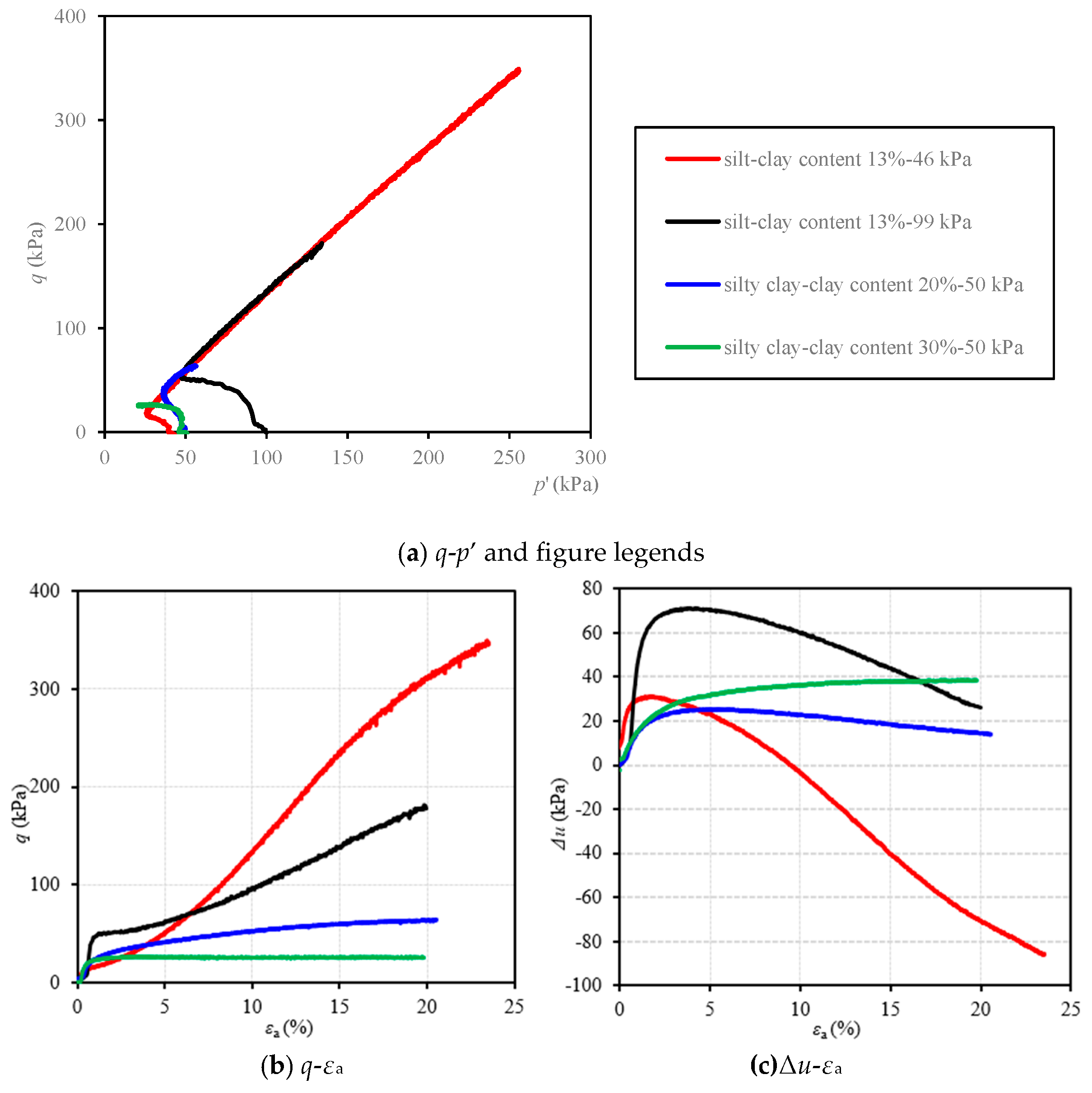

2.2. Triaxial Test Results

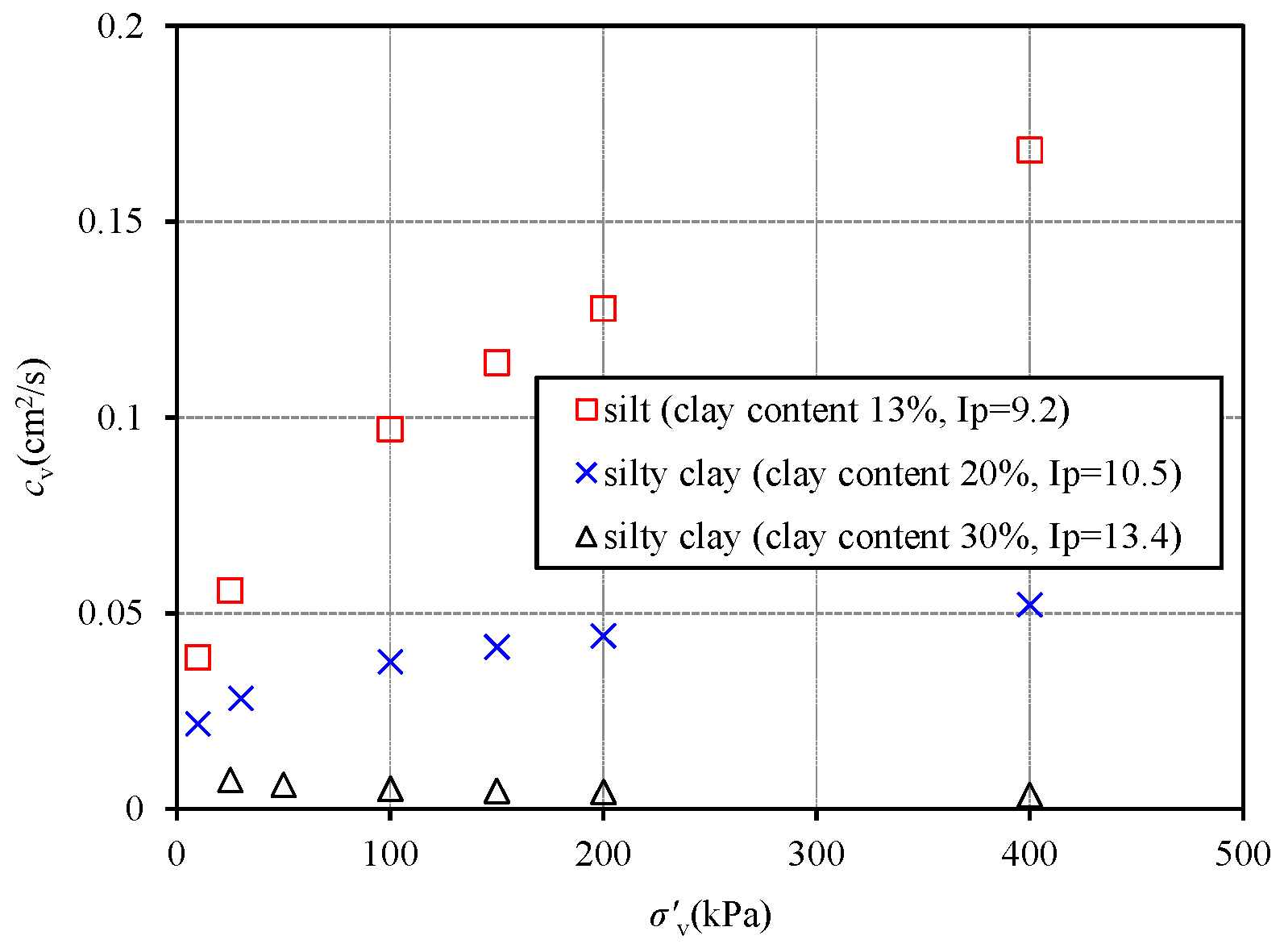

2.3. One-Dimensional Consolidation Test Results

2.4. Analysis of Mechanical Properties of Silty Soils

3. CPTu Penetration Analysis in Remolded Silty Clay under Shallow Stress

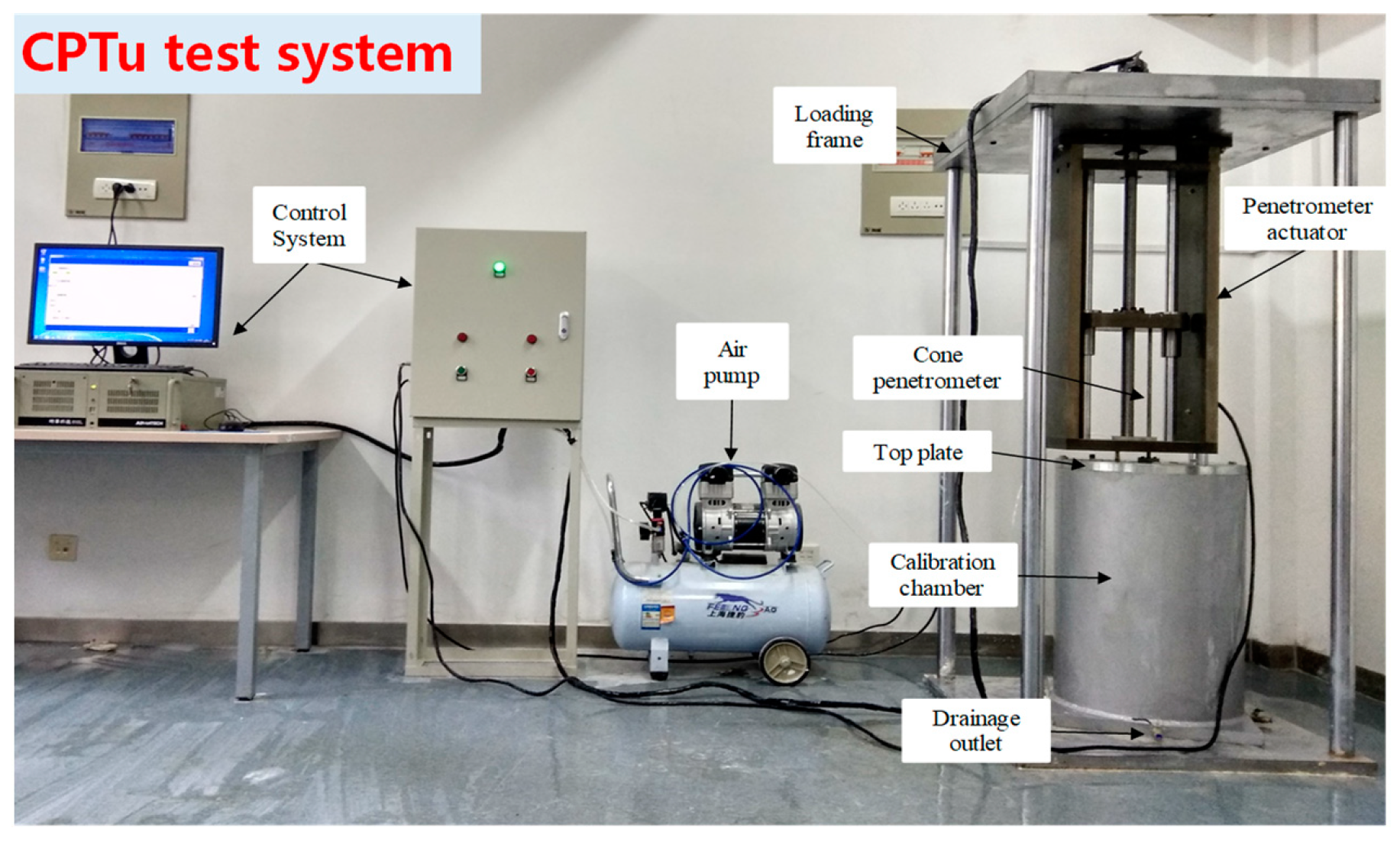

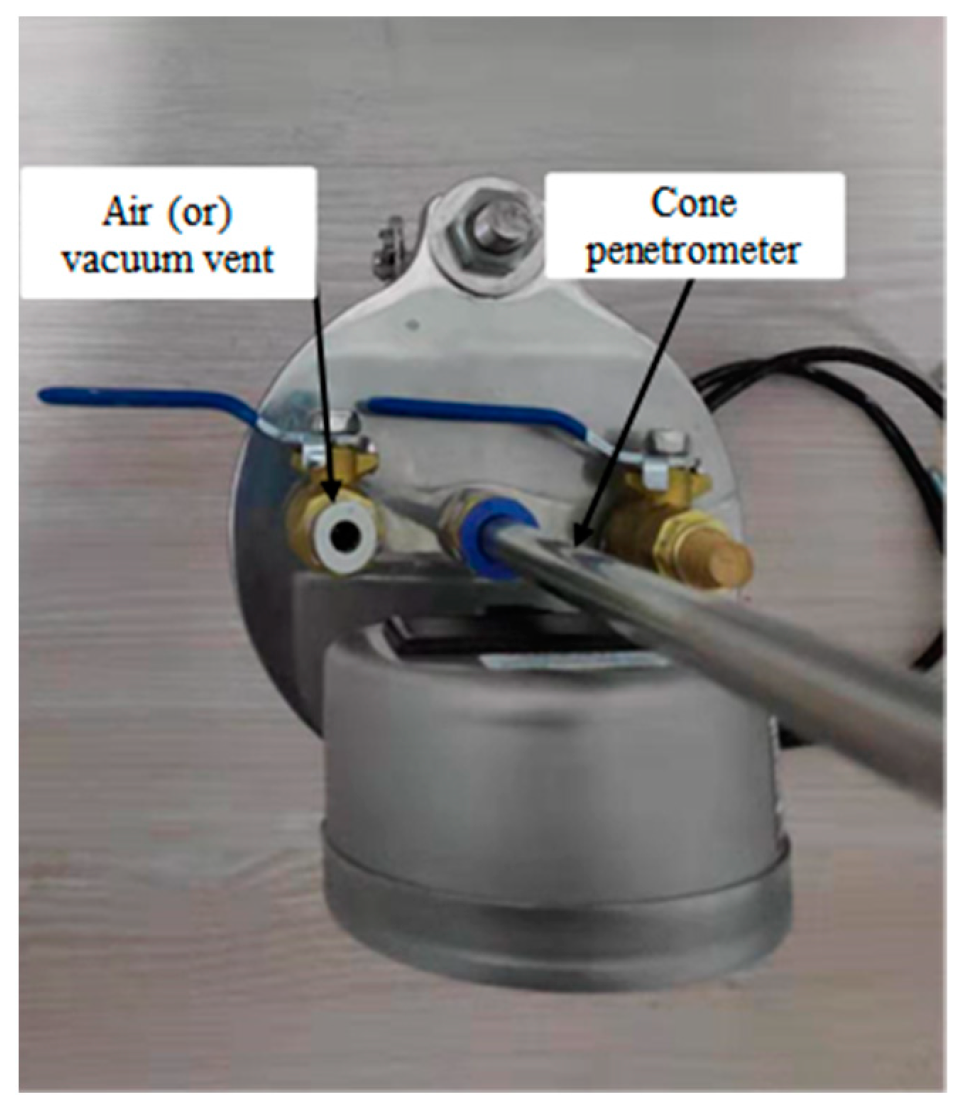

3.1. CPTu Test System

3.2. Test Plan

4. Results and Discussion

4.1. Data Processing Method

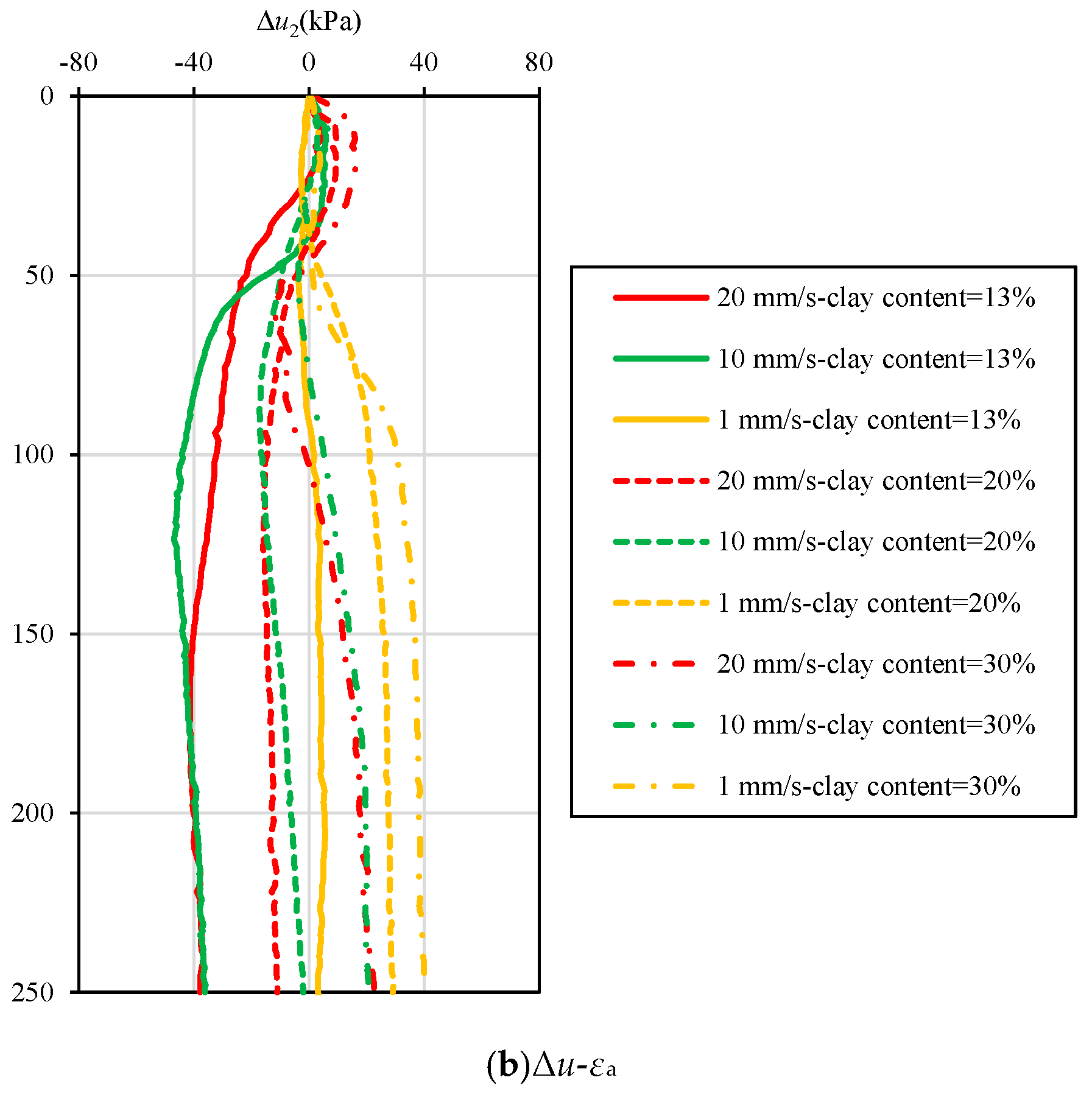

4.2. Penetration Resistance and Pore Pressure Results

4.3. Effect of penetration rate on Qt-Bq

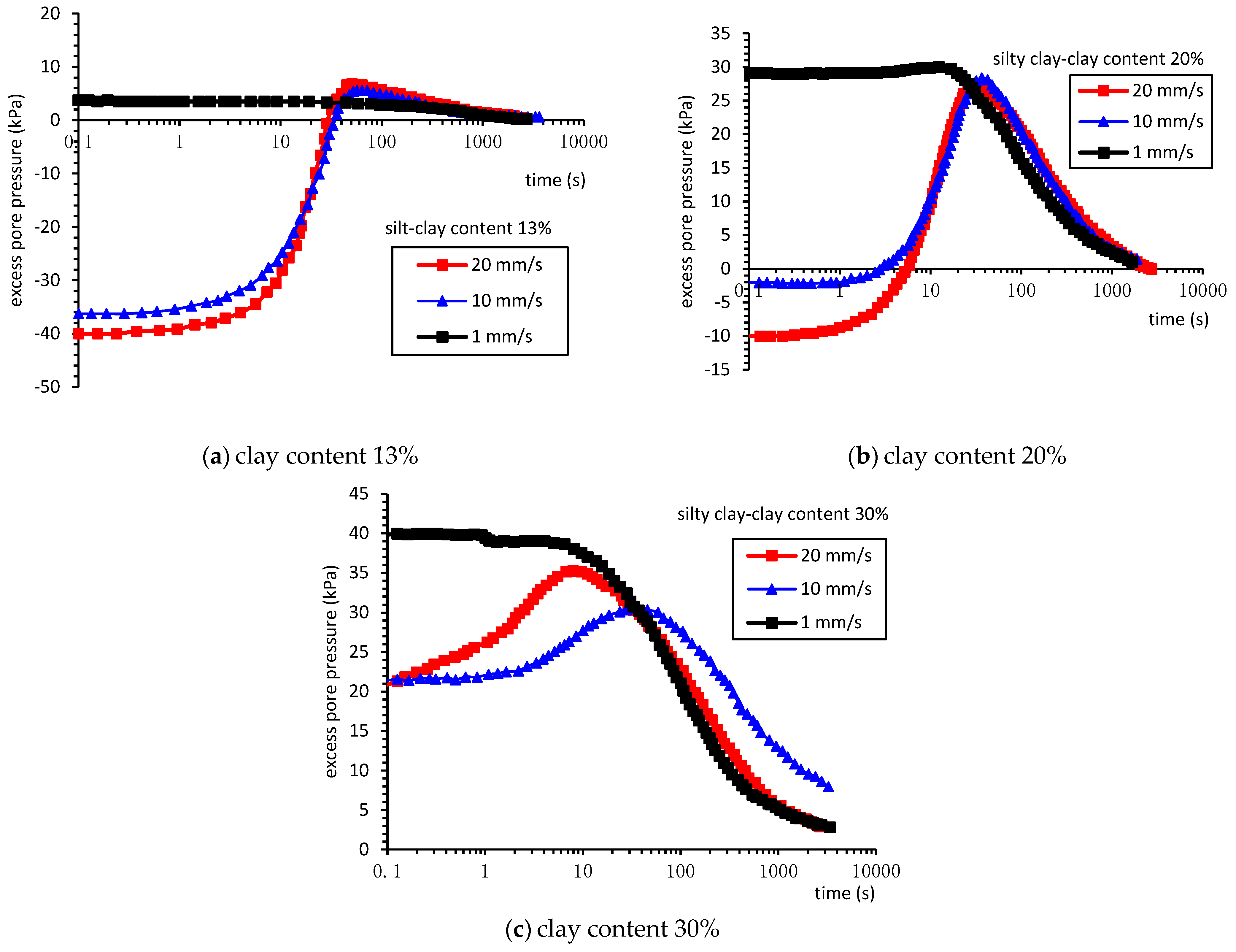

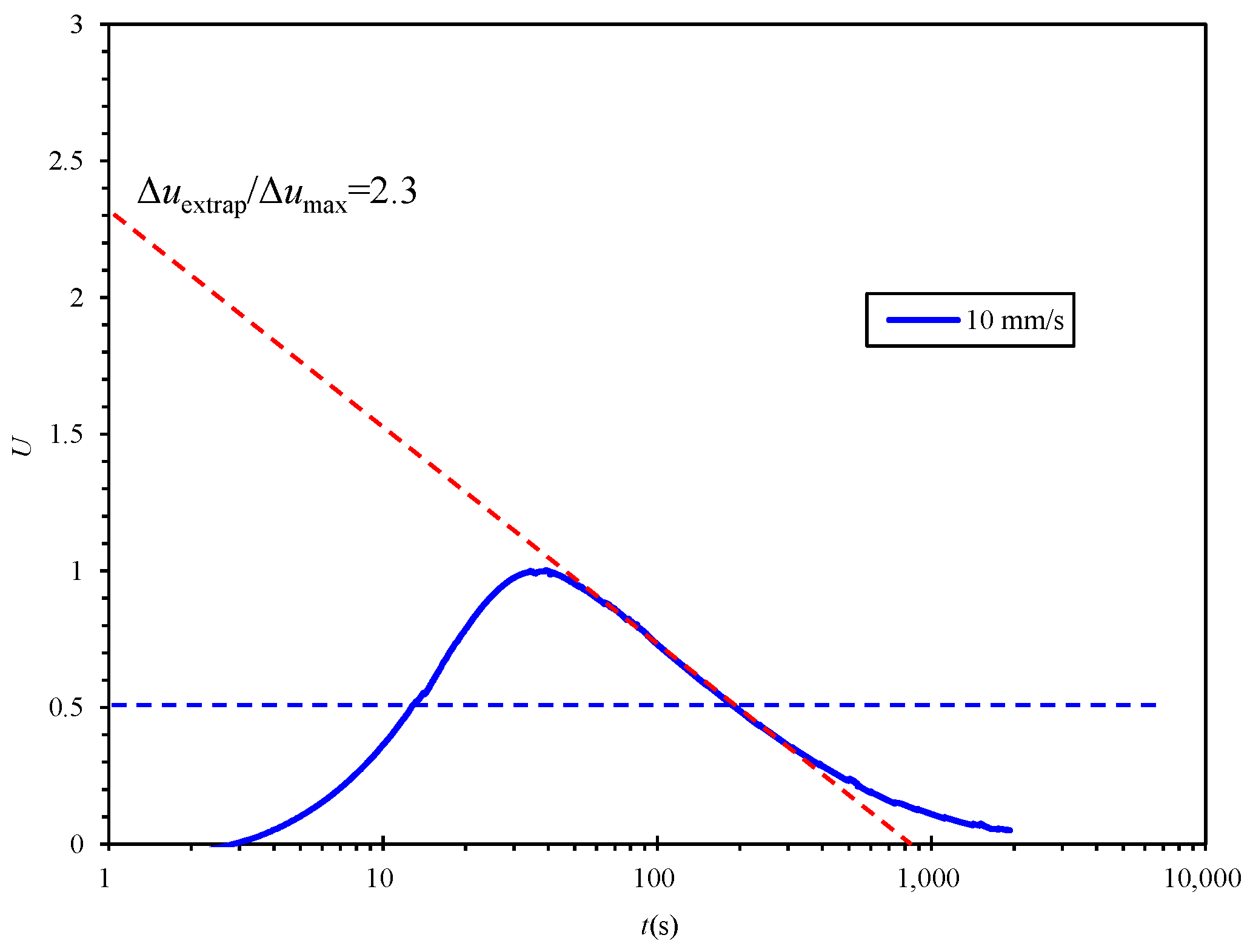

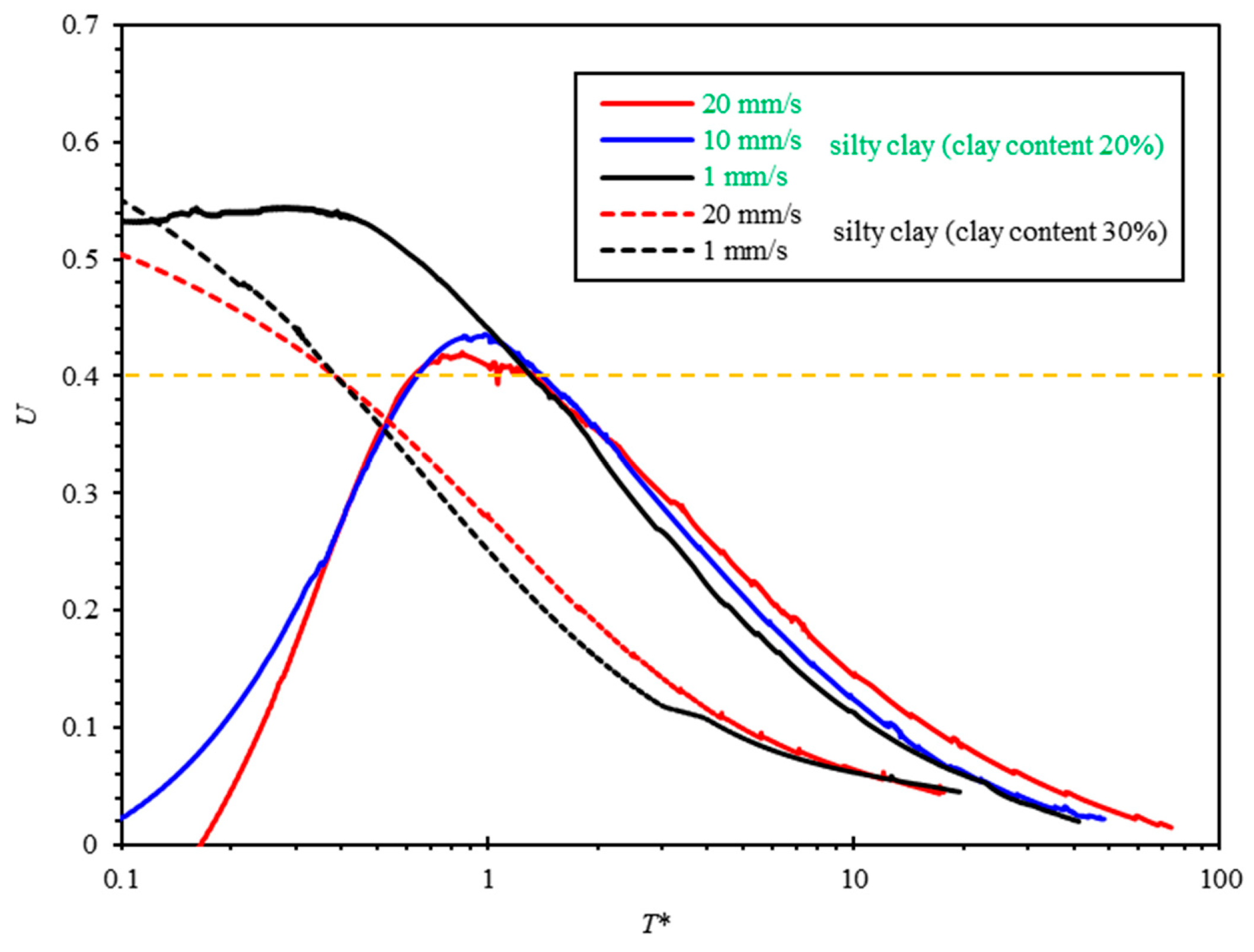

4.4. Pore Pressure Dissipation after Penetration

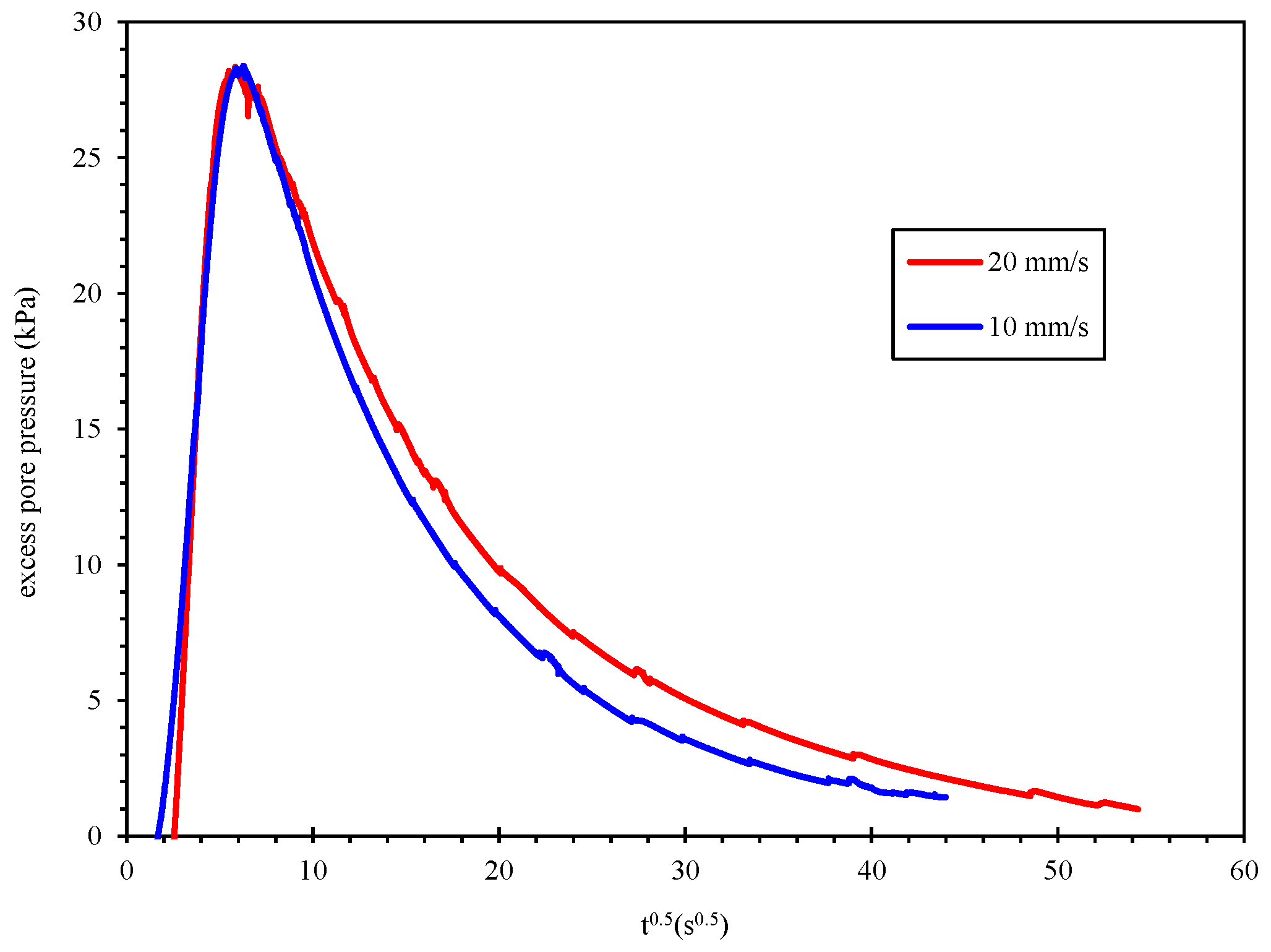

4.5. Selection Method of Modified Theoretical Time Factor T* for Consolidation Coefficient Inversion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Acknowledgments

Conflicts of Interest

References

- Feng, X.L.; Lin, L.; Zhuang, Z.Y.; Pan, S.C. The relationship between geotechnical parameters and sedimentary environment of soil layers since holocene in modern Huanghe subaqueous delta. Coast Eng. 1999, 18, 1–7. (In Chinese) [Google Scholar]

- Jia, Y.G.; Shan, H.X.; Yang, X.J.; Meng, X.M.; Chang, F.Q.; Zheng, J.W. Sediment Dynamics and Geologic Hazards in the Estuary of Yellow River, China; Science Press: Beijing, China, 2011. (In Chinese) [Google Scholar]

- Cui, J.G. Analysis and measures of submarine pipeline fracture in Chengdao Oilfield. Corros. Prot. Petrochem. Ind. 2011, 28, 3. (In Chinese) [Google Scholar]

- ASTM D5778-07; Standard Test Method for Electronic Friction Cone and Piezocone Penetration Testing of Soils. ASTM International: West Conshohocken, PA, USA, 2007.

- Voyiadjis, G.Z.; Song, C.R. Determination of hydraulic conductivity using piezocone penetration test. Int. J. Geomech. 2003, 3, 217–224. [Google Scholar] [CrossRef]

- Lunne, T.; Robertson, P.K.; Powell, J.J.M. Cone-Penetration Testing in Geotechnical Practice; Spon Press: London, UK, 2001. [Google Scholar]

- Na, Y.; Choa, V.; Teh, C.I.; Chang, M.F. Geotechnical parameters of reclaimed sandfill from the cone penetration test. Can. Geotech. J. 2005, 42, 91–109. [Google Scholar] [CrossRef]

- Robertson, P.K.; Cabal, K.L. Guide to Cone Penetration Testing for Geotechnical Engineering; Gregg Drilling & Testing, Inc.: Signal Hill, CA, USA, 2012. [Google Scholar]

- Robertson, P.K. Soil classification using the cone penetration test. Can. Geotech. J. 1990, 27, 151–158. [Google Scholar] [CrossRef]

- Lu, Q.; Randolph, M.F.; Hu, Y.; Bugarski, I.C. A numerical study of cone penetration in clay. Geotechnique 2004, 54, 257–267. [Google Scholar] [CrossRef]

- Lunne, T.; Kleven, A. Role of CPT in north sea foundation engineering. Cone Penetration Test. Exp. ASCE 1981, 2, 76–107. [Google Scholar]

- Schneider, J.A.; Lehane, B.M.; Schnaid, F. Velocity effects on piezocone measurements in normally and over consolidated clays. Int. J. Phys. Model. Geotech. 2007, 7, 23–34. [Google Scholar] [CrossRef]

- Schneider, J.A.; Randolph, M.F.; Mayne, P.W.; Ramsey, N.R. Analysis of factors influencing soil classification using normalized piezocone tip resistance and pore pressure parameters. J. Geotech. Geoenviron. Eng. 2008, 134, 1569–1586. [Google Scholar] [CrossRef]

- Randolph, M.F.; Gaudin, C.; Gourvenec, S.; David, J.W.; Noel, B.; Mark, J.C. Recent advances in offshore geotechnics for deep water oil and gas developments. Ocean Eng. 2011, 38, 818–834. [Google Scholar] [CrossRef] [Green Version]

- DeJong, J.T.; Randolph, M.F. Influence of partial consolidation during cone penetration on estimated soil behavior type and pore pressure dissipation measurements. J. Geotech. Geoenviron. Eng. 2012, 138, 777–788. [Google Scholar] [CrossRef]

- Randolph, M.F.; Hope, S.F. Effect of cone velocity on cone resistance and excess pore pressures. In Proceedings of the Engineering Practice and Performance of Soft Deposits (IS-OSAKA 2004), Osaka, Japan, 1 January 2004; pp. 147–152. [Google Scholar]

- Silva, M.; White, D.; Bolton, M. An analytical study of the effect of penetration rate on piezocone tests in clay. Int. J. Numer. Anal. Methods Geomech. 2006, 30, 501–527. [Google Scholar] [CrossRef]

- Yi, J.T.; Goh, S.; Lee, F. A numerical study of cone penetration in fine-grained soils allowing for consolidation effects. Géotechnique 2012, 62, 707–719. [Google Scholar] [CrossRef]

- Mahmoodzadeh, H.; Randolph, M.F.; Wang, D. Numerical simulation of piezocone dissipation test in clays. Geotechnique 2014, 64, 657–666. [Google Scholar] [CrossRef]

- Jaeger, R.A.; DeJong, J.T.; Boulanger, R.W.; Low, H.E.; Randolph, M.F. Variable penetration rate CPT in an intermediate soil. In Proceedings of the 2nd International Symposium on Cone Penetration Testing, Huntington Beach, CA, USA, 9–11 May 2010. [Google Scholar]

- Suzuki, Y.; Lehane, B.M. Cone penetration at variable rates in kaolin–sand mixtures. Int. J. Phys. Model. Geotech. 2015, 15, 209–219. [Google Scholar] [CrossRef]

- Silva, M.F. Numerical and Physical Models of Rate Effects in Soil Penetration. Ph.D. Thesis, University of Cambridge, Cambridge, UK, 2005. [Google Scholar]

- Tonni, L.; Gottardi, G. Partial drainage effects in the interpretation of piezocone tests in Venetian silty soils. In Proceedings of the 17th International Conference on Soil Mechanics and Geotechnical Engineering, Alexandria, Egypt, 5–9 October 2009; pp. 1004–1007. [Google Scholar]

- Tonni, L.; Gottardi, G. Analysis and interpretation of piezocone data on the silty soils of the Venetian Lagoon (Treporti test site). Can. Geotech. J. 2011, 48, 616–633. [Google Scholar] [CrossRef]

- Price, A.B.; Boulanger, R.W.; DeJong, J.T. Centrifuge Modeling of Variable-Rate Cone Penetration in Low-Plasticity Silts. J. Geotech. Geoenviron. Eng. 2019, 145, 04019098. [Google Scholar] [CrossRef]

- Liu, H.J.; Lv, W.F.; Yang, J.J.; Wang, X.H. Effect of initial dry density and clay content on steady-state strength of silty soil in the Yellow River Delta. Chin. J. Geotech. Eng. 2009, 31, 1287–1291. [Google Scholar]

- Wang, H.; Liu, H.J.; Zhang, M.S. Characteristics of undrained strength of marine-silty soil under low stress and its application in analysis of shallow submarine landslide. Chin. J. Rock Mech. Eng. 2014, 33, 849–856. (In Chinese) [Google Scholar]

- Wang, S.; Luna, R.; Onyejekwe, S. Effect of initial consolidation condition on post-liquefaction undrained monotonic shear behavior of mississippi river valley silt. J. Geotech. Geoenviron. Eng. 2016, 142, 04015075. [Google Scholar] [CrossRef]

- Zhang, Y. Study on CPTU Soil Classification and Parameter Inversion Methods of Silty Layer in the Yellow River Delta. Ph.D.Thesis, Ocean University of China, Qingdao, China, 2020. [Google Scholar]

- GB50021-2018; Code for Investigation of Geotechnical Engineering. China Architecture & Building Press: Beijing, China, 2018.

- Finnie, I.M.S.; Randolph, M.F. Punch-through and liquefaction induced failure of shallow foundations on calcareous sediments. In Proceedings of the 7th International Conference on the Behaviour of Offshore Structures, Boston, MA, USA, 1 January 1994; Volume 1, pp. 217–230. [Google Scholar]

- Ecemis, N.; Karaman, M. Influence of non-/low plastic fines on cone penetration and liquefaction resistance. Eng. Geol. 2014, 181, 48–57. [Google Scholar] [CrossRef] [Green Version]

- Chow, S.H.; Bienen, B.; Randolph, M.F. Rapid penetration of piezocones in sand. In Proceedings of the 4th International Symposium on Cone Penetration Testing (CPT’18), Delft, The Netherlands, 21–22 June 2018. [Google Scholar]

- Doan, L.V.; Lehane, B.M. CPT data in normally consolidated soils. Acta Geotech. 2021, 16, 2877–2885. [Google Scholar] [CrossRef]

- Schnaid, F.; Lehane, B.M.; Fahey, M. Characterization of unusual geomaterials. In Proceedings of the 2nd International Conference on Geotechnical and Geophysical Site Characterization (ISC-2), Rotterdam, The Netherlands, 19–22 September 2004; pp. 49–73. [Google Scholar]

- Houlsby, G.T.; Teh, C.I. Analysis of the Piezocone in Clay. In Proceedings of the International Symposium on Penetration Testing, Rotterdam, The Netherlands, 20–24 March 1988; pp. 777–783. [Google Scholar]

- Teh, C.I.; Houlsby, G.T. An analytical study of the cone penetration test in clay. Geotechnique 1991, 41, 17–34. [Google Scholar] [CrossRef]

- Mahmoodzadeh, H.; Randolph, M. Penetrometer Testing: Effect of partial consolidation on subsequent dissipation response. J. Geotech. Geoenviron. Eng. 2014, 140, 04014022. [Google Scholar] [CrossRef]

- Ong, D.; Sim, Y.S.; Leung, C.F. Performance of Field and Numerical Back-Analysis of Floating Stone Columns in Soft Clay Considering the Influence of Dilatancy. Int. J. Geomech. 2018, 18, 04018135. [Google Scholar] [CrossRef] [Green Version]

- Salazar, S.E.; Barnes, A.; Coffman, R.A. Development of an Internal Camera–Based Volume Determination System for Triaxial Testing. Geotech. Test. J. 2016, 39, 165–168. [Google Scholar] [CrossRef] [Green Version]

| No | Soil Type | σc (kPa) | e | qmax (kPa) | Δu (kPa) | Af |

|---|---|---|---|---|---|---|

| 1 | silt (clay content 13%) | 46.1 | 0.87 | 337 | −86.3 | −0.26 |

| 2 | silt (clay content 13%) | 99.2 | 0.82 | 177 | 26.4 | 0.15 |

| 3 | silty clay (clay content 20%) | 50 | 0.8 | 63 | 13.8 | 0.22 |

| 4 | silty clay (clay content 30%) | 50 | 0.81 | 25.4 | 38.3 | 1.51 |

| Consolidation degree | 20% | 30% | 40% | 50% | 60% | 70% | 80% |

| T* in CPTu shoulder | 0.038 | 0.078 | 0.142 | 0.245 | 0.439 | 0.804 | 1.600 |

| Soil Type | Drainage Condition (V) | σ’v (kPa) | e | ρ (g/cm3) | cv (cm2/s) | Ir (50 kPa) | Estimated t80(s) | ||

|---|---|---|---|---|---|---|---|---|---|

| v = 20 mm/s | v = 10 mm/s | v = 1 mm/s | |||||||

| silt (clay content 13%) | UD(53) | PD(26) | PD(2.6) | 30 | 0.87 | 1.97 | 0.06 | 54 | 81 |

| silty clay (clay content 20%) | UD(106) | UD(53) | PD(5.3) | 30 | 0.84 | 1.91 | 0.03 | 43 | 136 |

| silty clay (clay content 30%) | UD(457) | UD(228) | PD(23) | 30 | 0.86 | 1.88 | 0.007 | 37 | 590 |

| v (mm/s) | Silt (Clay Content 13%) (kPa) | Silty Clay (Clay Content 20%) (kPa) | Silty Clay (Clay Content 30%) (kPa) | ||||||

|---|---|---|---|---|---|---|---|---|---|

| Δumax | Δuinitial | qt | Δumax | Δuinitial | qt | Δumax | Δuinitial | qt | |

| 20 | 6.6 | −37.8 | 343.7 | 28.1 | −11.3 | 420.2 | 35.3 | 22.6 | 169.8 |

| 10 | 5.5 | −36.2 | 344.4 | 28.3 | −2.0 | 117.8 | 30.6 | 20.6 | 171.9 |

| 1 | 3.4 | 3.4 | 87.4 | 29.8 | 29.1 | 237.4 | 40.06 | 40.06 | 139.2 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, Y.; Feng, X.; Deng, S.; Ding, C.; Liu, T. Pore Pressure Response and Dissipation of Piezocone Test in Shallow Silty Soil of Yellow River Delta. J. Mar. Sci. Eng. 2022, 10, 255. https://doi.org/10.3390/jmse10020255

Zhang Y, Feng X, Deng S, Ding C, Liu T. Pore Pressure Response and Dissipation of Piezocone Test in Shallow Silty Soil of Yellow River Delta. Journal of Marine Science and Engineering. 2022; 10(2):255. https://doi.org/10.3390/jmse10020255

Chicago/Turabian StyleZhang, Yan, Xiuli Feng, Shenggui Deng, Chenhao Ding, and Tao Liu. 2022. "Pore Pressure Response and Dissipation of Piezocone Test in Shallow Silty Soil of Yellow River Delta" Journal of Marine Science and Engineering 10, no. 2: 255. https://doi.org/10.3390/jmse10020255