Hierarchical Optimization of Oil Spill Response Vessels in Cases of Accidental Pollution of Bays and Coves

Abstract

:1. Introduction

2. Maritime Spill Accidents and Oils Behaviour in the Marine Environment

3. Materials and Methods

- The minimum number of response ships involved in the operation,

- The shortest operation duration (includes collection only).

- The amount (volume) of pollution;

- Data on available response ships, i.e., for each ship. the following is known:

- Maximum capacity (m3);

- Collection rate (m3/h).

- Ship capacity (m3);

- Collection rate (m3/h).

- 3.

- Distance from the oil slick (km);

- 4.

- Average sailing speed (km/h);

- 5.

- Price of participation in the operation (EUR/h).

- Minimum total duration of the operation (includes the start and duration of collection);

- Minimum cost of participating in the operation (includes travel and collection).

4. Verification of Models and Results

5. Discussion

6. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Appendix A. Pseudocodes

| Algorithm A1: Strategy 1 | ||||

| Input: Matrix of response ships data A (A has n rows, where n is number of available ships; the columns are as follows: A[:, 1] (the first column of A)—ship capacity in m3; A[:, 2] (the second column of A)—oil collection rate in m3/h); volume of pollution: P in m3. | ||||

| Output: Number of optimal scenarios k; matrix of optimal scenarios M (M has k rows and n columns; M[i,j]—quantity of pollution assigned to ship j in solution i), matrix of duration for each scenario: T (T has k rows and n columns, T[i,j]—duration of operation of ship j in scenario i); duration of operation T_min. | ||||

| 1 | Initialization: M is the matrix of all possible solutions (M has binary entries, 2n−1 rows and n columns, M[i, j] = 0 means that ship j is not assigned and M[i, j] = 1 means that ship j is assigned in the i-th solution.); k = 2n−1. | |||

| Stage 1: Elimination of scenarios with insufficient capacity | ||||

| 2 | for i = 1, 2,…, k do: | |||

| 3 | if the dot product of M[i, :] and A[:, 1] (the total capacity of ships in the i-th scenario) is less than P | |||

| 4 | Remove row i from matrix M | |||

| 5 | end if | |||

| 6 | end for | |||

| 7 | k = number of rows of matrix M | |||

| Stage 2: Minimizing the number of ships in the scenario | ||||

| 8 | Initialization: s_min = n … number of rows of A, i.e., number of available ships | |||

| 9 | for i = 1,2,…,k do: | |||

| 10 | s =sum(M[i, :]) … number of ships involved in scenario i | |||

| 11 | if s_min > s | |||

| 12 | s_min = s | |||

| 13 | end if | |||

| 14 | end for | |||

| 15 | for i = 1,2,…,k do: | |||

| 16 | if s_min < sum(M[i, :]) | |||

| 17 | Remove row i from matrix M | |||

| 18 | end if | |||

| 19 | end for | |||

| 20 | k = number of rows of matrix M | |||

| Stage 3: Job allocation given the total duration of the operation | ||||

| 21 | Initialization: T = kxn nul-matrix; T_min = 0 | |||

| 22 | for i = 1,2,…,k | |||

| 23 | cap = elementwise product of A[:, 1] and M[i, :] … vector of maximum capacities of the i-th scenario | |||

| 24 | c =sum(cap) … total maximum capacity of the i-th scenario | |||

| 25 | dur = elementwise quotient of A[:, 1] and A[:, 2] multiplied elementwise with the M[i, :] … the duration vector of full capacity collection of all ships participating in the operation according to scenario i | |||

| 26 | j_0 = argmax(dur) … index corresponding to the vessel that has the longest individual duration of maximum capacity collection in i-th scenario | |||

| 27 | for j = 1, 2, …, n do: | |||

| 28 | if j≠ j_0 | |||

| 29 | M[i, j] = cap[j] … Update the i-th row of the matrix M so that instead of each unit, except the one corresponding to the ship j_0, it is replaced with the maximum capacity of that ship. | |||

| 30 | T[i, j] = dur[j] … Update the i-th row of the matrix T so that instead of each unit, except the one corresponding to the ship j_0, it is replaced with the full capacity collection duration for that ship. | |||

| 31 | otherwise if j = j_0 | |||

| 32 | M[i, j] = cap[j]–(c–P) … Update value in the i-th row of matrix M corresponding to ship j_0 with the remaining volume of pollution. | |||

| 33 | T[i, j] = M[i, j]/A[j, 2] … Update value in the i-th row of matrix T corresponding to ship j_0 with the duration of the collection of the allocated volume of pollution according to the corresponding value in the matrix M. | |||

| 34 | end for | |||

| 35 | t =max(T[i, :]) … duration of the operation in scenario i | |||

| 36 | if i = 1 | |||

| 37 | T_min = t | |||

| 38 | otherwise if T_min > t | |||

| 39 | T_min = t | |||

| 40 | end if | |||

| 41 | end for | |||

| Stage 4: Extracting the solutions with minimal duration | ||||

| 42 | for i = 1, 2,…, k do: | |||

| 43 | if T_min < max(T[i, :]) | |||

| 44 | Remove row i from matrix M | |||

| 45 | Remove row i from matrix T | |||

| 46 | end if | |||

| 47 | end for | |||

| 48 | k = number of rows of matrix M | |||

| Algorithm A2: Strategy 2a | ||||

| Input: Matrix of ship data A (A has n rows, where n is number of available ships; the columns are as follows: A[:, 1] (the first column of A)—ship capacity in m3; A[:, 2] (the second column of A)—oil collection rate in m3/h; A[:, 3] (the third column of A)—distance from pollution in km; A[:, 4] (the fourth column of A)—average sailing speed in km/h; A[:, 5] (the fifth column of A)—price of participation in the operation in EUR/h); volume of pollution: P in m3. | ||||

| Output: Number of optimal scenarios k; matrix of optimal scenarios M (M has k rows and n columns; M[i,j]—quantity of pollution assigned to ship j in solution i), matrix of duration for each scenario: T (T has k rows and n columns, T[i,j]—duration of operation of ship j in scenario i); duration of operation: T_min, matrix of cost for each scenario: C (C has k rows and n columns, T[i,j]—cost of operation of ship j in scenario i); total cost of operation: C_min. | ||||

| 1 | Initialization: M is the matrix of all possible solutions (M has binary entries, 2n−1 rows and n columns, M[I,j] = 0 means that ship j is not assigned and M[i,j] = 1 means that ship j is assigned in the i-th solution.); k = 2n−1. | |||

| Stage 1: Elimination of scenarios with insufficient capacity | ||||

| 2 | for i = 1, 2,…, k do: | |||

| 3 | if the dot product of M[i, :] and A[:, 1] (the total capacity of ships in the i-th scenario) is less than P | |||

| 4 | Remove row i from matrix M | |||

| 5 | end if | |||

| 6 | end for | |||

| 7 | k = number of rows of matrix M | |||

| Stage 2: Removing redundancies | ||||

| 8 | for i = 1, 2,…, k do: | |||

| 9 | d = elementwise product of M[i, :] and A[:, 0] in which all zeros have been removed … capacity vector of ships in scenario i | |||

| 10 | d_min =min(d) … the minimum capacity of an individual ship in the scenario i | |||

| 11 | d_tot =sum(d) … total capacity in the scenario i | |||

| 12 | if d_tot–d_min >= P | |||

| 13 | Remove row i from matrix M | |||

| 14 | end if | |||

| 15 | end for | |||

| 16 | k = number of rows of matrix M | |||

| Stage 3: Job allocation and duration minimization | ||||

| 17 | Initialization: T = kxn nul-matrix; T_min = 0, C = kxn nul-matrix | |||

| 18 | for i = 1, 2, …, k | |||

| 19 | cap = elementwise product of A[:, 1] and M[i, :] … vector of maximum capacities of the i-th scenario | |||

| 20 | cap_tot =sum(cap) … total maximum capacity of the i-th scenario | |||

| 21 | a = elementwise quotient of A[:, 3] and, A[:,4] multiplied elementwise by M[i, :] … arrival duration vector for ships in scenario i | |||

| 22 | col = elementwise quotient of A[:, 1] and A[:, 2] multiplied elementwise with the M[i, :] … the duration vector of full capacity collection of all ships participating in the operation according to scenario i | |||

| 23 | dur = a + col … total duration vector for ships in scenario i | |||

| 24 | j_0 = argmax(dur) … index corresponding to the vessel that has the longest individual total duration in i-th scenario | |||

| 25 | for j = 1, 2, …, n do: | |||

| 26 | if j≠ j_0 | |||

| 27 | M[i, j] = cap[j] … Update the i-th row of the matrix M so that instead of each unit, except the one corresponding to the ship j_0, it is replaced with the maximum capacity of that ship. | |||

| 28 | T[i, j] = dur[j] … Update the i-th row of the matrix T so that instead of each unit, except the one corresponding to the ship j_0, it is replaced with the total duration for that ship. | |||

| 29 | C[i, j] = (dur[j] + a[j]) * A[j, 5] … Update the i-th row of the matrix C so that instead of each unit, except the one corresponding to the ship j_0, it is replaced with the total cost for that ship. | |||

| 30 | otherwise if j = j_0 | |||

| 31 | M[i, j] = cap[j]–(cap_tot–P) … Update value in the i-th row of matrix M corresponding to ship j_0 with the remaining volume of pollution. | |||

| 32 | T[i, j] = a[j] + M[i, j]/A[j, 2] … Update value in the i-th row of matrix T corresponding to ship j_0 with the duration of the arrival and collection of the allocated volume of pollution according to the corresponding value in the matrix M. | |||

| 33 | C[i, j] = (T[i, j] + a[j]) * A[j, 5] … Update value in the i-th row of matrix C corresponding to ship j_0 with the total cost of arrival, departure and collection of the allocated volume of pollution according to the corresponding value in the matrix M. | |||

| 34 | end for | |||

| 35 | t =max(T[i, :]) … duration of the operation in scenario i | |||

| 36 | if i = 1 | |||

| 37 | T_min = t | |||

| 38 | otherwise if T_min > t | |||

| 39 | T_min = t | |||

| 40 | end if | |||

| 41 | for i = 1, 2,…, k do: | |||

| 42 | if T_min < max(T[i, :]) | |||

| 43 | Remove row i from matrix M | |||

| 44 | Remove row i from matrix T | |||

| 45 | Remove row i from matrix C | |||

| 46 | end if | |||

| 47 | end for | |||

| 48 | k = number of rows of matrix M | |||

| Stage 4: Cost minimization | ||||

| 49 | Initialization: C_min = 0 | |||

| 50 | for i = 1, 2,…, k do: | |||

| 51 | c =sum(C[i, :]) … total cost of the operation in scenario i | |||

| 52 | if i = 1 | |||

| 53 | C_min = c | |||

| 54 | otherwise if C_min > c | |||

| 55 | C_min = c | |||

| 56 | end if | |||

| 57 | end for | |||

| 58 | for i = 1, 2,…, k do: | |||

| 59 | if C_min < sum(C[i, :]) | |||

| 60 | Remove row i from matrix C | |||

| 61 | Remove row i from matrix M | |||

| 62 | Remove row i from matrix T | |||

| 63 | end if | |||

| 64 | end for | |||

| 65 | k = number of rows of matrix M | |||

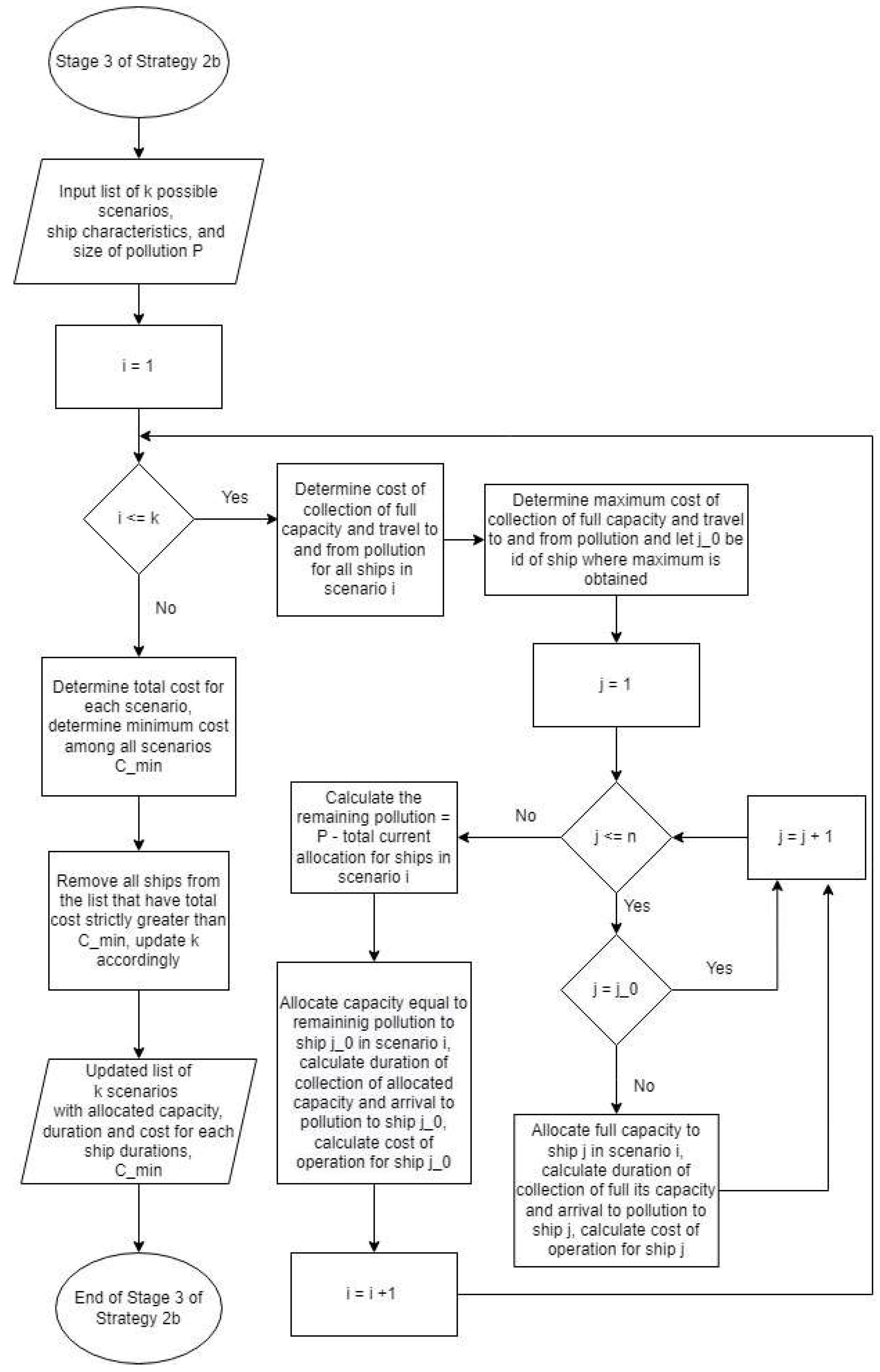

| Algorithm A3: Strategy 2b | ||||

| Input: Matrix of ship data A (A has n rows, where n is number of available ships; the columns are as follows: A[:, 1] (the first column of A)—ship capacity in m3; A[:, 2] (the second column of A)—oil collection rate in m3/h; A[:, 3] (the third column of A)—distance from pollution in km; A[:, 4] (the fourth column of A)—average sailing speed in km/h; A[:, 5] (the fifth column of A)—price of participation in the operation in EUR/h); volume of pollution: P in m3. | ||||

| Output: Number of optimal scenarios k; matrix of optimal scenarios M (M has k rows and n columns; M[I,j]—quantity of pollution assigned to ship j in solution i), matrix of duration for each scenario: T (T has k rows and n columns, T[i,j]—duration of operation of ship j in scenario i); duration of operation: T_min, matrix of cost for each scenario: C (C has k rows and n columns, T[i,j]—cost of operation of ship j in scenario i); total cost of operation: C_min. | ||||

| 1 | Initialization: M is the matrix of all possible solutions (M has binary entries, 2n-1 rows and n columns, M[I,j] = 0 means that ship j is not assigned and M[i,j] = 1 means that ship j is assigned in the i-th solution.); k = 2n-1. | |||

| Stage 1: Elimination of scenarios with insufficient capacity | ||||

| 2 | for i = 1, 2,…, k do: | |||

| 3 | if the dot product of M[i, :] and A[:, 1] (the total capacity of ships in the i-th scenario) is less than P | |||

| 4 | Remove row i from matrix M | |||

| 5 | end if | |||

| 6 | end for | |||

| 7 | k = number of rows of matrix M | |||

| Stage 2: Removing redundancies | ||||

| 8 | for i = 1, 2,…, k do: | |||

| 9 | d = elementwise product of M[i, :] and A[:, 0] in which all zeros have been removed … capacity vector of ships in scenario i | |||

| 10 | d_min =min(d) … the minimum capacity of an individual ship in the scenario i | |||

| 11 | d_tot =min(d) … total capacity in the scenario i | |||

| 12 | if d_tot–d_min >= P | |||

| 13 | Remove row i from matrix M | |||

| 14 | end if | |||

| 15 | end for | |||

| 16 | k = number of rows of matrix M | |||

| Stage 3: Job allocation and cost minimization | ||||

| 17 | Initialization: T = kxn nul-matrix; C_min = 0, C = kxn nul-matrix | |||

| 18 | for i = 1, 2, …, k | |||

| 19 | cap = elementwise product of A[:, 1] and M[i, :] … vector of maximum capacities of the i-th scenario | |||

| 20 | cap_tot =sum(cap) … total maximum capacity of the i-th scenario | |||

| 21 | a = elementwise quotient of A[:, 3], A[:,4] multiplied elementwise by M[i, :] … arrival duration vector for ships in scenario i | |||

| 22 | col = elementwise quotient of A[:, 1] and A[:, 2] multiplied elementwise with the M[i, :] … the duration vector of full capacity collection of all ships participating in the operation according to scenario i | |||

| 23 | cost = elementwise product of (a*2 + col) and A[:, 5] … total cost vector for ships in scenario i | |||

| 24 | j_0 = argmax(cost) … index corresponding to the vessel that has the largest individual total cost in i-th scenario | |||

| 25 | for j = 1, 2, …, n do: | |||

| 26 | if j≠ j_0 | |||

| 27 | M[i, j] = cap[j] … Update the i-th row of the matrix M so that instead of each unit, except the one corresponding to the ship j_0, it is replaced with the maximum capacity of that ship. | |||

| 28 | T[i, j] = a[j] + col[j] … Update the i-th row of the matrix T so that instead of each unit, except the one corresponding to the ship j_0, it is replaced with the total duration for that ship. | |||

| 29 | C[i, j] = cost[j] … Update the i-th row of the matrix C so that instead of each unit, except the one corresponding to the ship j_0, it is replaced with the total cost for that ship. | |||

| 30 | otherwise if j = j_0 | |||

| 31 | M[i, j] = cap[j]–(cap_tot–P) … Update value in the i-th row of matrix M corresponding to ship j_0 with the remaining volume of pollution. | |||

| 32 | T[i, j] = a[j] + M[i, j]/A[j, 2] … Update value in the i-th row of matrix T corresponding to ship j_0 with the duration of the arrival and collection of the allocated volume of pollution according to the corresponding value in the matrix M. | |||

| 33 | C[i, j] = (T[i, j] + a[j]) * A[j, 5] … Update value in the i-th row of matrix C corresponding to ship j_0 with the total cost of arrival, departure and collection of the allocated volume of pollution according to the corresponding value in the matrix M. | |||

| 34 | end for | |||

| 35 | c =sum(T[i, :]) … total cost of the operation in scenario i | |||

| 36 | if i = 1 | |||

| 37 | C_min = c | |||

| 38 | otherwise if C_min > c | |||

| 39 | C_min = c | |||

| 40 | end if | |||

| 41 | for i = 1, 2,…, k do: | |||

| 42 | if C_min < sum(C[i, :]) | |||

| 43 | Remove row i from matrix M | |||

| 44 | Remove row i from matrix T | |||

| 45 | Remove row i from matrix C | |||

| 46 | end if | |||

| 47 | end for | |||

| 48 | k = number of rows of matrix M | |||

| Stage 4: Operation duration minimization | ||||

| 49 | Initialization: T_min = 0 | |||

| 50 | for i = 1, 2,…, k do: | |||

| 51 | t =max(T[i, :]) … duration of the operation in scenario i | |||

| 52 | if i = 1 | |||

| 53 | T_min = t | |||

| 54 | otherwise if T_min > t | |||

| 55 | T_min = t | |||

| 56 | end if | |||

| 57 | end for | |||

| 58 | for i = 1, 2,…, k do: | |||

| 59 | if T_min < max(T[i, :]) | |||

| 60 | Remove row i from matrix C | |||

| 61 | Remove row i from matrix M | |||

| 62 | Remove row i from matrix T | |||

| 63 | end if | |||

| 64 | end for | |||

| 65 | k = number of rows of matrix M | |||

References

- Fratila, A.; Gavril, I.; Nita, S.; Hrebenciuc, A. The Importance of Maritime Transport for Economic Growth in the European Union: A Panel Data Analysis. Sustainability 2021, 13, 7961. [Google Scholar] [CrossRef]

- Zhang, Q.; Wen, Y.; Han, D.; Zhang, F.; Xiao, C. Construction of knowledge graph of maritime dangerous goods based on IMDG code. Int. J. Eng. Technol. 2020, 2020, 361–365. [Google Scholar] [CrossRef]

- Review of Maritime Transport. 2021. Available online: https://unctad.org/system/files/official-document/rmt2021_en_0.pdf (accessed on 11 February 2022).

- Jagerbrand, A.; Brutemark, A.; Sveden, J.; Gren, I. Review on the Environmental Impacts of Shipping on Aquatic and Nearshore Ecosystems. Sci. Total Environ. 2019, 695, 133637. [Google Scholar] [CrossRef] [PubMed]

- Protocol on Preparedness, Response and Co-Operation to Pollution Incidents by Hazardous and Noxious Substances. 2000. Available online: https://disasterlaw.ifrc.org/sites/default/files/media/disaster_law/2020-08/I627EN.pdf (accessed on 25 February 2022).

- EPA, Understanding Oil Spills and Oil Spill Response. Available online: https://www.epa.gov/sites/default/files/2018-01/documents/ospguide99.pdf (accessed on 3 April 2022).

- Lazuga, K.; Gucma, L.; Perkovic, M. The Model of Optimal Allocation of Maritime Oil Spill Combat Ships. Sustainability 2018, 10, 2321. [Google Scholar] [CrossRef] [Green Version]

- Dorčić, I. The Basic of Cleaning Oil Pollution, 1st ed.; INA Development and Research: Zagreb, Croatia, 1987; pp. 1–3. [Google Scholar]

- Dhaka, A.; Chattopadhyay, P. A Review on Physical Remediation Techniques for Treatment of Marine Oil Spills. J. Environ. Manag. 2021, 288, 112428. [Google Scholar] [CrossRef]

- Etkin, D.; Nedwed, T. Effectiveness of Mechanical Eecovery for Large Offshore oil spills. Mar. Pollut. Bull. 2021, 163, 111848. [Google Scholar] [CrossRef]

- Vetere, A.; Profrock, D.; Schrade, W. Qualitative and Quantitative Evaluation of Sulfur-Containing Compound Types in Heavy Crude Oil and its Fractions. Energy Fuels 2021, 35, 8723–8732. [Google Scholar] [CrossRef]

- IMO Model Courses–First Responders. Available online: https://www.imo.org/en/OurWork/Environment/Pages/IMO-OPRC-Model-Courses.aspx (accessed on 10 April 2022).

- Weiwei, J.; Wei, A.; Yupeng, Z.; Zhaoyu, Q. Research on Scheduling Optimization of Marine Oil Spill Emergency Vessels. Aquat. Procedia 2015, 3, 35–40. [Google Scholar] [CrossRef]

- Li, S.; Grifoll, M.; Estrada, M.; Zheng, P.; Feng, H. Optimization on Emergency Materials Dispatching Considering the Characteristics of Integraded Emergency Response for Large-Scale Marine Oil Spills. J. Mar. Sci. Eng. 2019, 7, 214. [Google Scholar] [CrossRef] [Green Version]

- Ye, X.; Chen, B.; Li, P.; Jing, L.; Zeng, G. A Simulations-based Multi-agent Particle Swarm Optimization Approach for Supporting Dynamic Decision Making in Marine Oil Spill Response. Ocean Coast. Manag. 2019, 172, 128–136. [Google Scholar] [CrossRef]

- Ye, X.; Chen, B.; Lee, K.; Storesund, R.; Li, P.; Kang, Q. An Emergency Response System by Dynamic Simulation and Enhanced Particle Swarm Optimization and Application for a Marine Oil Spill Accident. J. Clean. Prod. 2021, 287, 126591. [Google Scholar] [CrossRef]

- Tijan, E.; Jović, M.; Aksentijević, S.; Pucihar, A. Digital Transformation in the Maritime Transport Sector. Technol. Forecast. Soc. Change. 2021, 170, 120879. [Google Scholar] [CrossRef]

- Peša, I.; Ross, C. Extractive Industries and the Environment: Production, Pollution, and Protest in Global History. Extr. Ind. Soc. 2021, 8, 100933. [Google Scholar] [CrossRef]

- Fingas, M. Remote Sensing for Marine Management. In World Seas: An Environmental Evaluation, 2nd ed.; Ecological Issues and Environmental Impacts; Elsevier: Amsterdam, The Netherlands, 2019; Volume 3, pp. 103–119. [Google Scholar]

- Keramea, P.; Kokkos, N.; Gikas, G.; Sylaios, G. Operational Modeling of North Aegean Oil Spills Forced by Real-Time Met-Ocen Forecast. J. Mar. Sci. Eng. 2022, 10, 411. [Google Scholar] [CrossRef]

- Zerebecki, R.; Heck, K.; Valentine, J. Biodiversity Influences the Effects of Oil Disturbance on Coastal Ecosystems. Ecol. Evol. 2022, 12, 23–28. [Google Scholar] [CrossRef]

- ITOPF. Available online: https://www.itopf.org/knowledge-resources/data-statistics/statistics/ (accessed on 14 April 2022).

- Ulker, D.; Burak, S.; Balas, L.; Caglar, N. Mathematical Modeling of Oil Spill Weathering Processes for Contingency Planning in Izmit Bay. Reg. Stud. Mar. Sci. 2022, 50, 102155. [Google Scholar] [CrossRef]

- Silva, I.A.; Almeida, F.C.; Souza, T.C.; Bezerra, K.G.; Durval, I.J.; Converti, A.; Sarubbo, L.A. Oil Spills: Impacts and Perspectives of Treatment Technologies with Focus on the Use of Green Surfactants. Environ Monit Assess. 2022, 194, 143. [Google Scholar] [CrossRef]

- Cano, J.; Loza, J.; Guida, P.; Roberts, W.; Chejne, F.; Sarathy, S.; Im, G. Evaporation, break-up, and Pyrolysis of Multicomponent Arabian Light Crude Oil Droplets at Various Temperatures. Int. J. Heat Mass Transf. 2022, 183, 103–106. [Google Scholar]

- Majid, D.; Farahani, D.; Zheng, Y. The Formulation, Development and Application of Oil Dispersants. J. Mar. Sci. Eng. 2022, 10, 425. [Google Scholar]

- Alade, I.; Oyedeji, M.; Rahman, M.; Saleh, T. Predicting the Density of Carbon-based Nanomaterials in Diesel Oil Through Computational Intelligence Methods. J. Therm. Anal. Calorim. 2022, 10, 425. [Google Scholar] [CrossRef]

- Gao, X.; Dong, P.; Cui, J.; Gao, Q. Prediction Model for the Viscosity of Heavy Oil Diluted with Light Oil Using Machine Learning Techniques. Energies 2022, 15, 2297. [Google Scholar] [CrossRef]

- Krivoshchekov, S.; Kochnev, A.; Vyatkin, K. The Development of Forecasting Technique for Cyclic Steam Stimulation Technology Effectiveness in Near–Wellbore Area. Fluids 2022, 7, 64. [Google Scholar] [CrossRef]

- Chacon-Patino, M.; Nelson, J.; Rogel, E.; Hench, K.; Poirier, L.; Lopez-Linares, F.; Ovalles, C. Vanadium and Nickel Distributions in Selective-separated n-heptane Asphaltenes of Heavy Crude Oils. Fuel 2022, 312, 23–28. [Google Scholar] [CrossRef]

- El-Gayar, D.; Khodary, M.; Abdel-Aziz, H.; Khalil, M. Effect of Disk Skimmer Material and Oil Viscosity on Oil Spill Recovery. Water Air Soil Pollut. 2021, 232, 193. [Google Scholar] [CrossRef]

- Salma Rima, U.; Beier, N. Effects of Seasonal Weathering on Dewatering and Strength of an Oil Sands Tailings Deposit. Can. Geotech. J. 2022, 59, 145–151. [Google Scholar]

- Bacosa, H.; Ancla, S.; Loui, C.; Russel, J. From Surface Water to the Deep Sea: A Review on Factors Affecting the Biodegradation of Spilled Oil in Marine Environment. J. Mar. Sci. Eng. 2022, 10, 426. [Google Scholar] [CrossRef]

- Hass Freeman, D.; Ward, C. Sunlight-driven Dissolution is a Major Fate of Oil at Sea. Sci. Adv. 2022, 8, 42–43. [Google Scholar] [CrossRef]

- Allahabady, A.; Yousefi, Z.; Tahamtan, R.; Sharif, Z. Measurement of BTEX (Benzene, Toluene, Ethylbenzene and Xylene) Concertation at Gas Stations. Environ. Eng. Manag. J. 2022, 9, 23–31. [Google Scholar]

- You, Y.; Liu, C.; Hu, Q.; Zhang, S.; Wang, C. Response Surface Methodology to Optimize Ultrasonic-Assisted Extraction of Crude Oil from Oily Sludge. Pet. Sci. Technol. 2022, 40, 15–18. [Google Scholar] [CrossRef]

- Yamada, K.; Yagishita, K.; Sato, K. Dispersion States of Lecithin-Soybean Oil Mixtures in Water. Colloid. Polym. Sci. 2022, 300, 95–102. [Google Scholar] [CrossRef]

- Zhang, X.; Ni, W.; Sun, L. Fatigue Analysis of the Oil Offloading Lines in FPSO System Under Wave and Current Loads. J. Mar. Sci. Eng. 2022, 10, 225. [Google Scholar] [CrossRef]

- Manivel, R.; Sivakumar, R. Boat Type Oil Recovery Skimmers. Mater. Today Proc. 2020, 21, 470–473. [Google Scholar] [CrossRef]

- Song, J.; Lu, Y.; Luo, J.; Huang, S.; Wang, L.; Xu, W.; Parkin, I.P. Barrel-Shaped Oil Skimmer Designed for Collection of Oil from Spills. Adv. Mater. Interfaces 2015, 2, 1500350. [Google Scholar] [CrossRef]

- Herbst, L. Fishing for Oil. IEEE Spectr. 2020, 57, 36–50. [Google Scholar] [CrossRef]

- Revollo, N.; Delrieux, A. Vessel and Oil Spill Early Detection Using COSMO Satellite Imagery. SPIE Remote Sens. 2017, 2017, 1042203. [Google Scholar]

- Fedrizzia, T.; Ciania, Y.; Lorenzina, F.; Cantorea, T.; Gasperinia, P.; Demichelis, F. Fast Mutual Exclusivity Algorithm Nominates Potential Synthetic Lethal Gene Pairs Through Brute Force Matrix Product Computations. Comput. Struct. Biotechnol. J. 2021, 19, 4394–4403. [Google Scholar] [CrossRef]

| Order of Criteria | Strategy 2a | Strategy 2b |

|---|---|---|

| 1. | Minimum total duration | Minimum cost |

| 2. | Minimum cost | Minimum total duration |

| Ship ID | Ship Capacity (m3) | Oil Collection Rate (m3/h) |

|---|---|---|

| 1 | 10 | 1 |

| 2 | 12 | 1 |

| 3 | 16 | 1 |

| 4 | 20 | 1 |

| Ship ID | 1 | 2 | 3 | 4 | |

|---|---|---|---|---|---|

| Scenario | |||||

| 1 | 0 | 0 | 1 | 1 | |

| 2 | 0 | 1 | 0 | 1 | |

| 3 | 0 | 1 | 1 | 0 | |

| 4 | 0 | 1 | 1 | 1 | |

| 5 | 1 | 0 | 0 | 1 | |

| 6 | 1 | 0 | 1 | 0 | |

| 7 | 1 | 0 | 1 | 1 | |

| 8 | 1 | 1 | 0 | 1 | |

| 9 | 1 | 1 | 1 | 0 | |

| 10 | 1 | 1 | 1 | 1 | |

| Ship ID | 1 | 2 | 3 | 4 | |

|---|---|---|---|---|---|

| Scenario | |||||

| 1 | 0 | 0 | 1 | 1 | |

| 2 | 0 | 1 | 0 | 1 | |

| 3 | 0 | 1 | 1 | 0 | |

| 5 | 1 | 0 | 0 | 1 | |

| 6 | 1 | 0 | 1 | 0 | |

| Ship ID | 1 | 2 | 3 | 4 | |

|---|---|---|---|---|---|

| Scenario | |||||

| 1 | 0 | 0 | 16 | 9 | |

| 2 | 0 | 12 | 0 | 13 | |

| 3 | 0 | 12 | 13 | 0 | |

| 5 | 10 | 0 | 0 | 15 | |

| 6 | 10 | 0 | 15 | 0 | |

| Ship ID | 1 | 2 | 3 | 4 | |

|---|---|---|---|---|---|

| Scenario | |||||

| 1 | 0 | 0 | 16 | 9 | |

| 2 | 0 | 12 | 0 | 13 | |

| 3 | 0 | 12 | 13 | 0 | |

| 5 | 10 | 0 | 0 | 15 | |

| 6 | 10 | 0 | 15 | 0 | |

| Ship ID | Ship Capacity (m3) | Oil Collection Rate (m3/h) | Distance From Pollution (km) | Average Sailing Speed (km/h) | Price of Participation in the Operation (EUR/h*) |

|---|---|---|---|---|---|

| 1 | 10 | 1 | 1 | 1 | 1 |

| 2 | 12 | 1 | 1 | 1 | 2 |

| 3 | 16 | 1 | 1 | 1 | 1 |

| 4 | 20 | 1 | 1 | 1 | 1 |

| Ship ID | 1 | 2 | 3 | 4 | |

|---|---|---|---|---|---|

| Scenario | |||||

| 1 | 0 | 0 | 1 | 1 | |

| 2 | 0 | 1 | 0 | 1 | |

| 3 | 0 | 1 | 1 | 0 | |

| 4 | 0 | 1 | 1 | 1 | |

| 5 | 1 | 0 | 0 | 1 | |

| 6 | 1 | 0 | 1 | 0 | |

| 7 | 1 | 0 | 1 | 1 | |

| 8 | 1 | 1 | 0 | 1 | |

| 9 | 1 | 1 | 1 | 0 | |

| 10 | 1 | 1 | 1 | 1 | |

| Ship ID | 1 | 2 | 3 | 4 | |

|---|---|---|---|---|---|

| Scenario | |||||

| 1 | 0 | 0 | 1 | 1 | |

| 2 | 0 | 1 | 0 | 1 | |

| 3 | 0 | 1 | 1 | 0 | |

| 5 | 1 | 0 | 0 | 1 | |

| 6 | 1 | 0 | 1 | 0 | |

| Ship ID | 1 | 2 | 3 | 4 | |

|---|---|---|---|---|---|

| Scenario | |||||

| 2 | 0 | 12 | 0 | 13 | |

| 3 | 0 | 12 | 13 | 0 | |

| Ship ID | 1 | 2 | 3 | 4 | |

|---|---|---|---|---|---|

| Scenario | |||||

| 2 | 0 | 13 | 0 | 14 | |

| 3 | 0 | 13 | 14 | 0 | |

| Ship ID | 1 | 2 | 3 | 4 | |

|---|---|---|---|---|---|

| Scenario | |||||

| 2 | 0 | 28 | 0 | 15 | |

| 3 | 0 | 28 | 15 | 0 | |

| Ship ID | 1 | 2 | 3 | 4 | |

|---|---|---|---|---|---|

| Scenario | |||||

| 1 | 0 | 0 | 16 | 9 | |

| 5 | 10 | 0 | 0 | 15 | |

| 6 | 10 | 0 | 15 | 0 | |

| Ship ID | 1 | 2 | 3 | 4 | |

|---|---|---|---|---|---|

| Scenario | |||||

| 1 | 0 | 0 | 17 | 10 | |

| 5 | 11 | 0 | 0 | 16 | |

| 6 | 11 | 0 | 16 | 0 | |

| Ship ID | 1 | 2 | 3 | 4 | |

|---|---|---|---|---|---|

| Scenario | |||||

| 1 | 0 | 0 | 18 | 11 | |

| 5 | 12 | 0 | 0 | 17 | |

| 6 | 12 | 0 | 17 | 0 | |

| Ship ID | Ship Capacity (m3) | Oil Collection Rate (m3/h) | Distance from Pollution (km) | Average Sailing Speed (km/h) | Price of Participation in the Operation (EUR/h) |

|---|---|---|---|---|---|

| EKO 2000 | 10 | 6 | 10 | 18.52 | 500 |

| EKO 1 2000 | 10 | 6 | 15 | 18.52 | 500 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Đorđević, M.; Mohović, Đ.; Krišković, A.; Legović, T. Hierarchical Optimization of Oil Spill Response Vessels in Cases of Accidental Pollution of Bays and Coves. J. Mar. Sci. Eng. 2022, 10, 772. https://doi.org/10.3390/jmse10060772

Đorđević M, Mohović Đ, Krišković A, Legović T. Hierarchical Optimization of Oil Spill Response Vessels in Cases of Accidental Pollution of Bays and Coves. Journal of Marine Science and Engineering. 2022; 10(6):772. https://doi.org/10.3390/jmse10060772

Chicago/Turabian StyleĐorđević, Marko, Đani Mohović, Antoni Krišković, and Tarzan Legović. 2022. "Hierarchical Optimization of Oil Spill Response Vessels in Cases of Accidental Pollution of Bays and Coves" Journal of Marine Science and Engineering 10, no. 6: 772. https://doi.org/10.3390/jmse10060772