Abstract

A coil structure that is compatible with the structure of the autonomous underwater vehicles (AUVs) and preventing the rotational misalignment is proposed for stabilizing the output power of a wireless power transfer (WPT) system. The transmitting coil and the receiving coil are wound on the structure of the energy base station and the AUV in a spiral tube type, respectively. This arrangement not only guarantees a constant mutual inductance when the AUV rotates, but it also maintains the efficient transmission of energy when the receiving coil is conformal with the AUV by optimizing the size of the magnetic core and the distance between the coil and the metal structure. The performance of the proposed coil structure is experimentally evaluated by building an inductor–capacitor–capacitor series (LCC-S)-compensated WPT prototype. It was found that the system can stably deliver a 2 kW power with a dc–dc efficiency of 92.7%.

1. Introduction

AUVs can replace divers in sunken ship salvage, deep-water exploration, underwater cable laying, and other operations and construction, so it is widely used in civil and military fields [1]. In order to achieve long-distance navigation and wider operation range, energy supply is an important constraint. The AUVs powered by battery usually use watertight connectors to charge after insertion or directly replace the battery, which obviously limits the autonomous operation ability of AUVs [2]. Recently, WPT technology has been favored because it can achieve power supply without physical connection [3,4]. Microwave WPT [5], laser WPT [6], and inductive WPT [7] technology have been widely used in different fields. The inductive WPT technology can also achieve energy transmission when the equipment is not aligned with the energy base station [8]. Therefore, it is a promising choice in the working scene where it is difficult to use wired power supply. Inductive WPT systems usually generate alternating current to form an alternating magnetic field around the transmitting coil, and achieve the energy exchange between the transmitting coil and the receiving coil through the alternating magnetic field. Compensation networks, such as series–series (S-S) [9], LCC-S [10], double-sided LCC [11], etc., are usually used for efficient power transmission. In order to improve the stability of the energy transmission, it is necessary to optimize the design of the coils [12,13].

Due to the particularity of the water environment, AUVs will inevitably be disturbed by water flow, which will change the coupling between the receiving coil of AUVs and the transmitting coil of energy base station dynamically. The change of the mutual inductance between the coils will cause the fluctuation of transmission power and reduce transmission efficiency [2,14]. For the rotary AUVs, the water environment will not only make the vehicle rotate, but it will also make the vehicle deviate from the energy base station in any direction. In addition, the water resistance characteristics of different shapes of AUVs are also different. If the installation of the WPT equipment does not change the shape of AUVs, it will not affect the resistance characteristics. Therefore, the compatibility between the WPT equipment and the structure of AUVs should also be fully considered.

In the work of Cheng [15], a semiclosed structure is proposed for underwater WPT; the shaking of the AUV can be restrained while reducing the magnetic field leakage by fully aligning the protruding part of the AUV with the concave part of the mother ship. Although this method perfectly solves the problem of disturbance in the charging process, it is very challenging to achieve accurate alignment in the underwater environment. A docking station is built to recover and charge AUVs [16]. The rotational misalignment can be overcome by installing a pair of coaxial coils on the recovery cage and the AUV. This kind of structure can overcome the rotation misalignment, but it will protrude on the vehicle, which is not conformal to the AUV. A receiving coil structure composed of two reverse wound coils is proposed in [2]. The two reverse-wound coils can be fully decoupled and guarantee the mutual inductance between the receiving coil and the transmitting coil constant within a certain range. Therefore, it has the ability against rotational misalignment. However, when processing the coil, it is difficult to obtain a group of circular magnetic sheets for winding the coil, so the coil structure can only be constructed with a rectangular magnetic core, which will lead to a certain degree of fluctuation of the mutual inductance and, hence, affect the ability to prevent the rotational misalignment.

In practice, the hull of the AUV is usually made of metal materials, and the loss will be increased when the coil is close to the metal materials. As the solutions proposed in [15,16], the coil structure protrudes to the outside of the AUV shell to reduce the influence of the metal materials on the transmission power or efficiency. The additional protruding part on the AUV will change the water-resistance characteristics of the vehicle. In this paper, a novel coil structure is proposed. The ability of preventing the rotational misalignment is achieved by installing a pair of coaxial coils in the AUV and the recovery cage. In addition, the compatibility between the wireless charging equipment and the AUV structure is also fully considered. The influence of the arrangement of the magnetic core and the distance between the coil and metal on the quality factor of the coil is analyzed in detail. The sensitivity of the structure to radial and axial eccentricity is also evaluated.

The organization of this paper is as follows. The structure and design procedure of the coils are given in Section 2. The selection of the thickness of the magnetic core and the optimal distance between the coil and the metal structure are derived by the finite element analysis (FEA) simulation. In Section 3, the principle prototype is built to evaluate the performance of the proposed coil structure, including variation of mutual inductance with rotational misalignment, the stability of transmission power, and transmission efficiency. Finally, the conclusions are summarized in Section 4.

2. Structure and Design Procedure of Proposed Coils

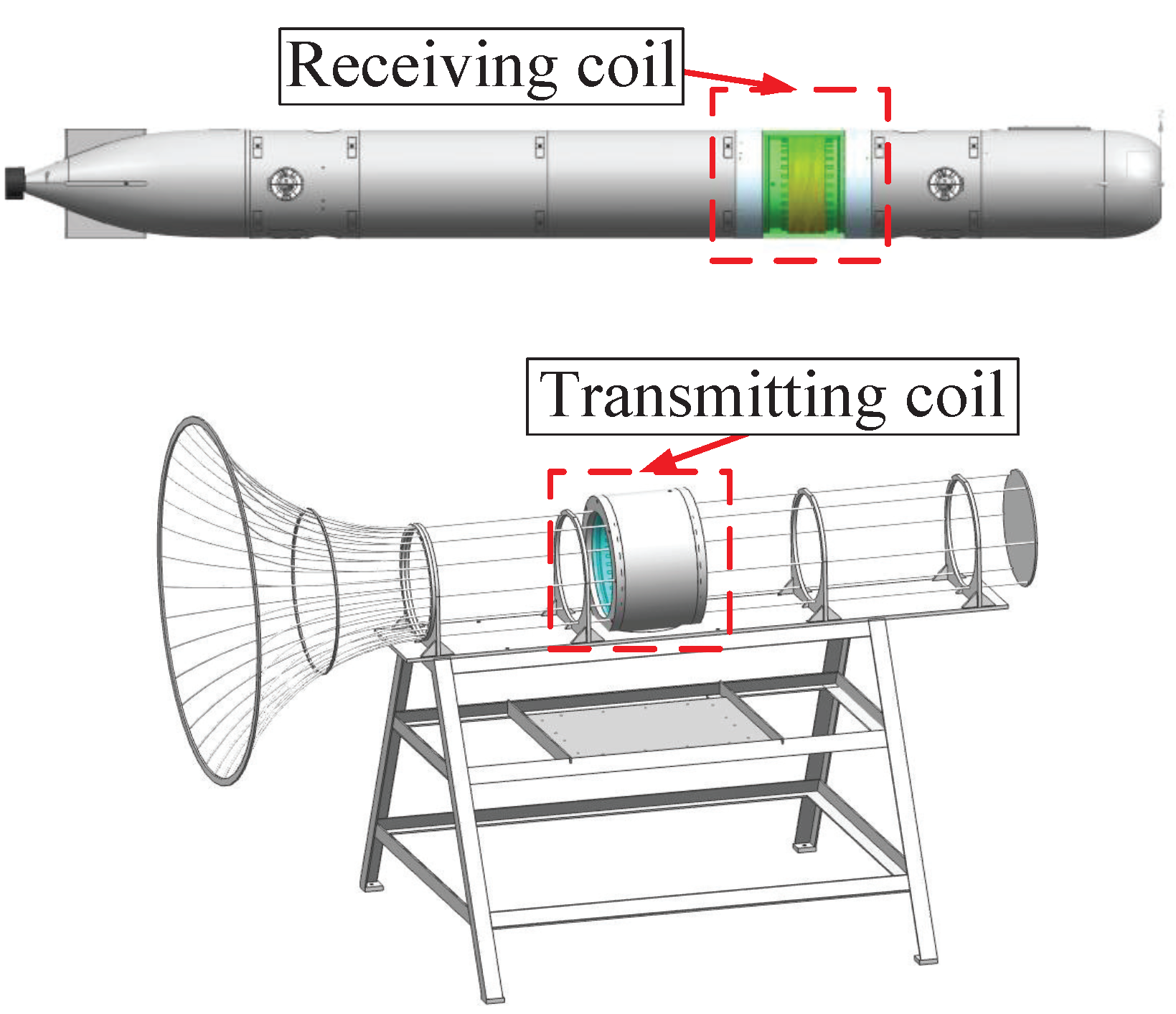

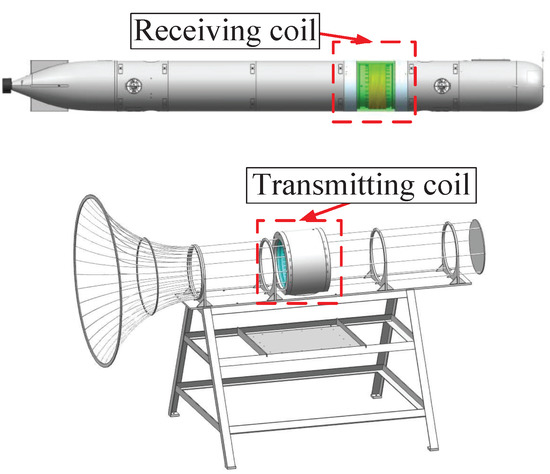

Figure 1 depicts a typical wireless charging mode for AUVs. The electric energy-transmitting device can be placed on the support plate of the structure, and the transmitting coil is installed coaxially with the trumpet-shaped structure. The receiving coil and related circuits are placed in a separate structure, which is completely conformal with the AUV, so it does not affect the water-resistance characteristics of the AUV. When the power of the AUV is insufficient, it can drive to the inside of the trumpet-shaped structure to realize power supply. When the AUV is to be charged, the transmitting coil is driven by the alternating current generated by the energy-transmitting base station to generate the alternating magnetic field, and the receiving coil converts the alternating magnetic field into electric energy, so as to achieve the wireless transmission of electric energy. The opening at the front end of this trumpet-shaped structure is large, which serves to conduct the AUV to the inside. The diameter of the rear end is slightly larger than that of the AUV, which is used to restrict the range of radial eccentricity. There is a baffle at the rear end to block the AUV, and also to limit the range of axial movement of the AUV.

Figure 1.

A typical wireless charging mode for AUVs.

2.1. Proposed Coil Structure

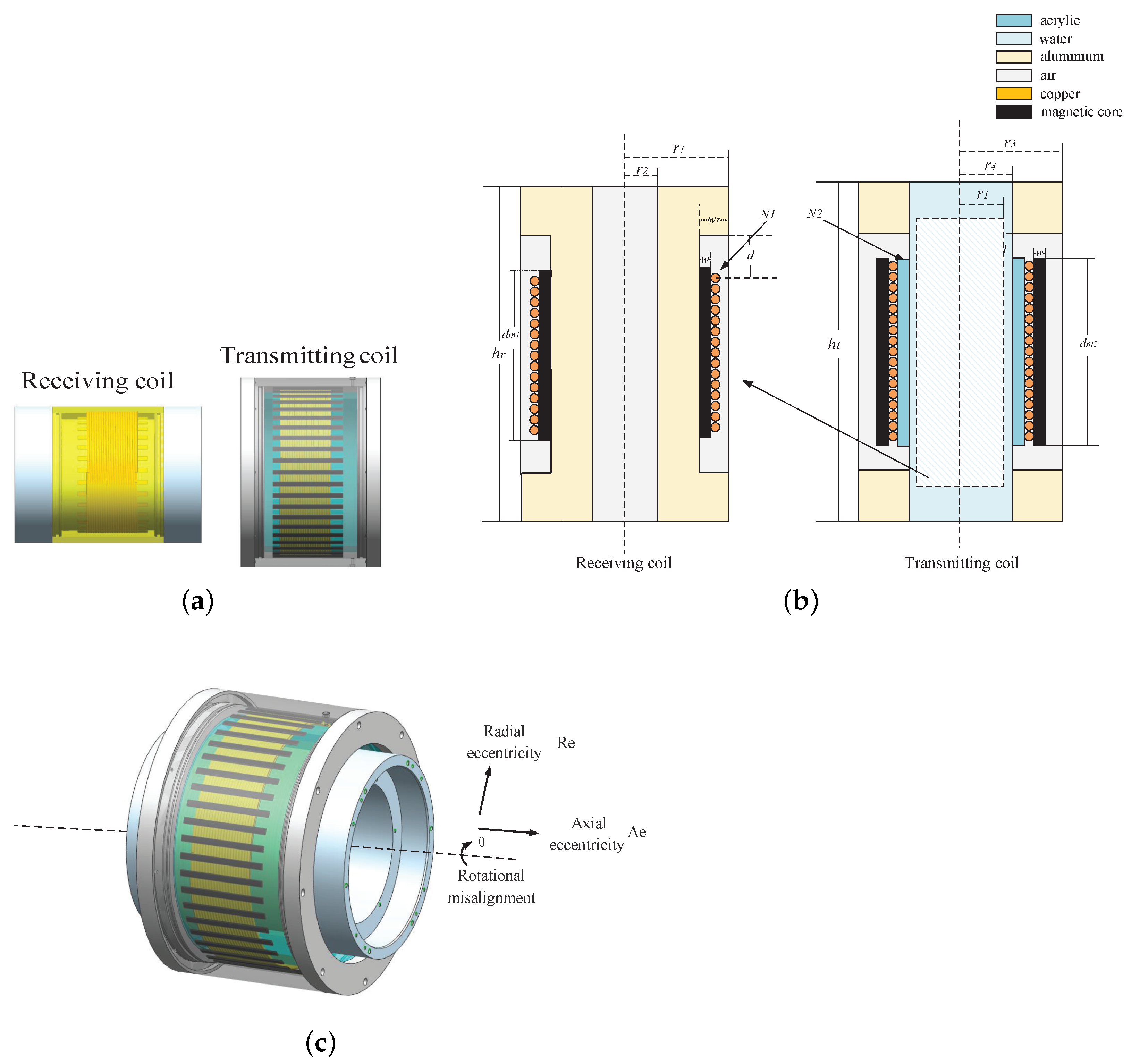

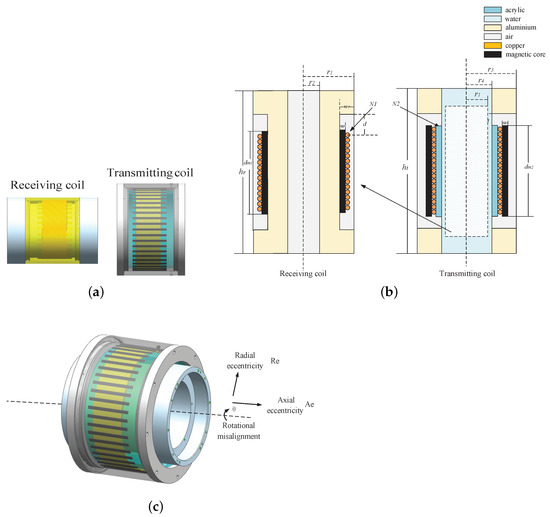

The proposed transmitting coil structure is shown in Figure 2, which mainly includes the insulated frame for winding coil, metal structure for connecting with trumpet-shaped structure, magnetic core, and litz wire. A litz wire with 0.1 mm × 1000 strands is chosen in order to reduce the AC resistance of the coil. The coil is closely wound on the insulated frame with equal turn spacing. The insulated frame is made of acrylic material, which plays a role in supporting the shape of the coil. In order to improve the structural strength of the coil and the reliability of connection with the trumpet-shaped structure considering that the structure usually needs to bear the pressure of water, both sides of the acrylic frame are, respectively, fixed with a metal structure, and then installed on the trumpet-shaped structure as a whole. A layer of soft magnetic material is laid on the coil for confining the magnetic field near the coil to increase the coupling between the primary coil and the secondary coil as much as possible. The magnetic material layer is built by standard-sized low-cost ferrite sheets (PC44) [17]. The dimensions of the ferrite sheets are 90 mm × 11 mm × 5 mm. The compatibility with the structure of the AUV and the influence on resistance characteristics of the AUV should be considered since the receiving coil structure needs to be directly installed on the AUV. Considering the requirements of pressure-bearing capacity and electromagnetic compatibility of the AUV, the frame used for winding the receiving coil does not adopt the same insulation structure as the transmitting coil, but mills the outer surface of the aluminum alloy cylindrical hollow structure with a thickness of 20 mm. A layer of soft magnetic material is laid on the metal surface to separate the metal from the litz wire, and the coil is wound along the circumference on the soft magnetic material. The litz wire and soft magnetic material are the same as that used for winding the transmitting coil. In this way, the magnetic field can be limited to the side of the magnetic core close to the litz wire such that the electric field induced by the coil to the metal shell could be reduced. On the other hand, it can also avoid interfering with the electronic subsystem inside the AUV during high-power wireless power supply through the shielding effect of the metal shell.

Figure 2.

(a) Schematic diagram of the coil structure. (b) Simulation model of the coil structure. (c) The definition of the eccentricity.

2.2. Magnetic Core Consideration

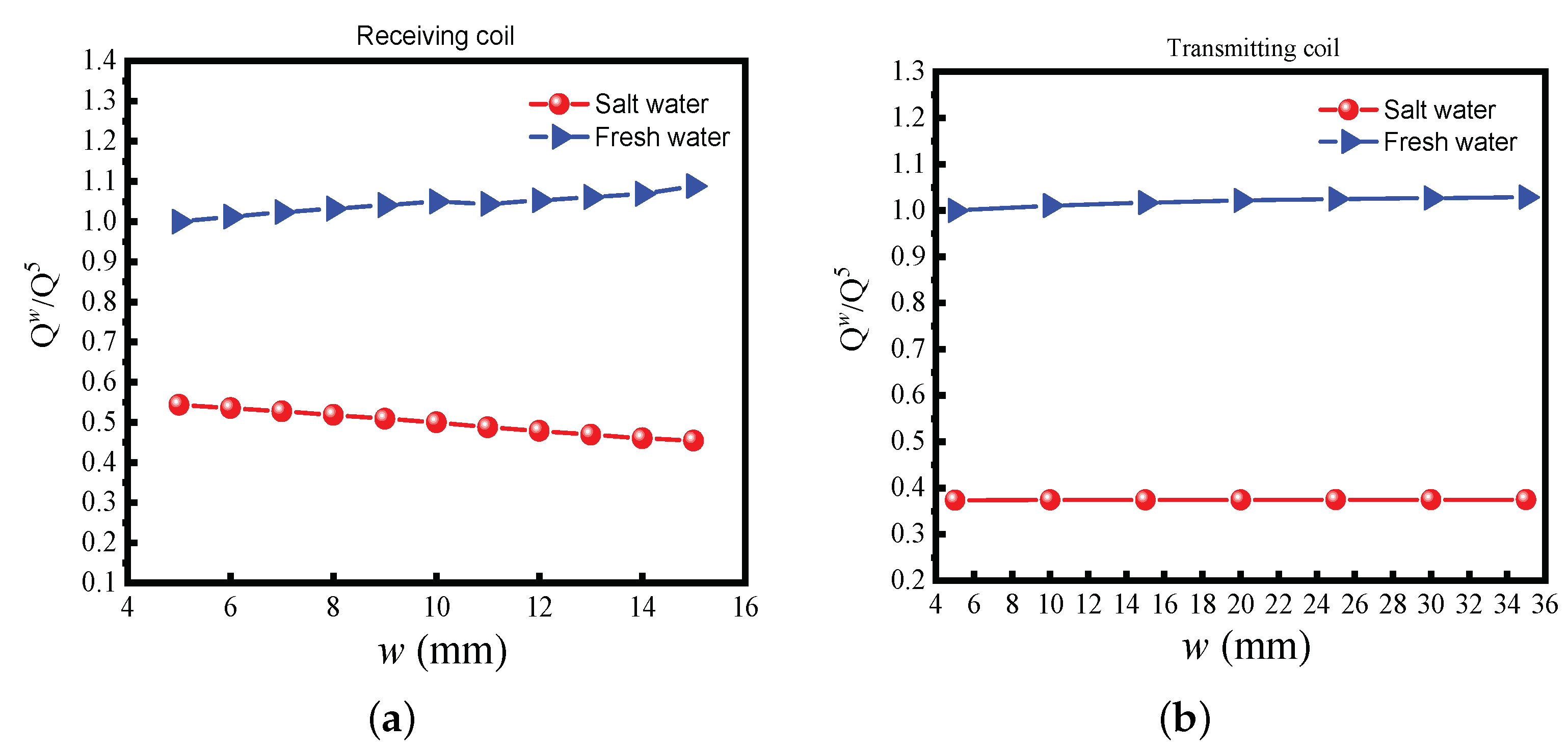

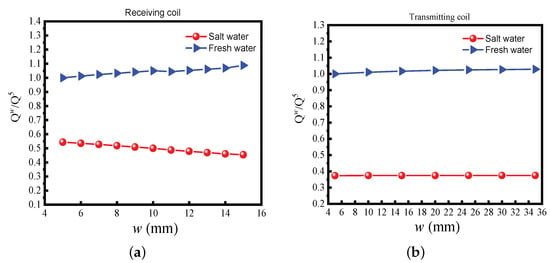

The magnetic cores in the structures are mainly used to restrict the magnetic field near the coil and reduce the leakage of the magnetic field to metal and water, which are built by commercial standard ferrite sheets. Placing the magnetic sheets next to the coil can restrict the magnetic field to the interior of the magnetic material. An air gap is implemented between the magnetic sheets to reduce the equivalent permeability of the magnetic cores and avoid magnetic saturation. Although the influence law of magnetic cores on coil can be estimated by building an equivalent circuit, both transmitting coil and receiving coil structures are complex with electromagnetic boundary conditions. A finite element analysis (FEA) simulation is often used to obtain relatively accurate results. Therefore, the calculation of the parameters is directly obtained by FEA simulation based on COMSOL [18]. High quality factor of a coil is conducive to high-efficiency energy transmission from the perspective of ensuring efficient power transmission [19]. Therefore, the quality factor of the coil is taken as the evaluation index of the influence of magnetic core on the overall performance of the structure. Although there are also methods to improve the quality factor through the optimization of the number of turns and turn spacing of the coil, the main purpose of this paper is to achieve high-efficiency power transmission while considering the conformal between the coil and AUVs. Therefore, the conventional coil wound with equal turn spacing is taken as an example. The simulation parameters are tabulated in Table 1. Figure 3 shows the influence of the magnetic core with different thickness w on the quality factor of the coil. For the convenience of comparison, we normalize the results of different thicknesses w with those of the single-layer magnetic core when the structure is immersed in fresh water. Obviously, when the coil structure is immersed in the salt water, its quality factor will be greatly reduced. From Figure 3, it can also be seen that increasing the thickness w of the magnetic core of the transmitting coil has little change on the quality factor of the coil. This is because the permeability of the magnetic core is much higher than that of the air, and the thickness of 5 mm is enough to restrict the magnetic field near the coil. The quality factor of the receiving coil increases with the increase of the thickness of the magnetic cores when the structure is immersed in the fresh water. However, there is an opposite trend when the fresh water is replaced by the salt water. Increasing the thickness of the magnetic core can indeed increase the distance between the coil and the metal shell, it also reduces the distance between the coil and the outer surface of the structure. When the water near the outer surface is the salt water, salt water will cause additional losses in the coil. Considering that the AUV is basically used in seawater, only one layer of magnetic sheet is placed next to the transmitting coil and the receiving coil.

Table 1.

Parameters description.

Figure 3.

Variation of the normalized quality factor of the coils with thickness w of the magnetic core. The conductivity of the fresh water is S/m, and the conductivity of the salt water is S/m. (a) Receiving coil. (b) Transmitting coil.

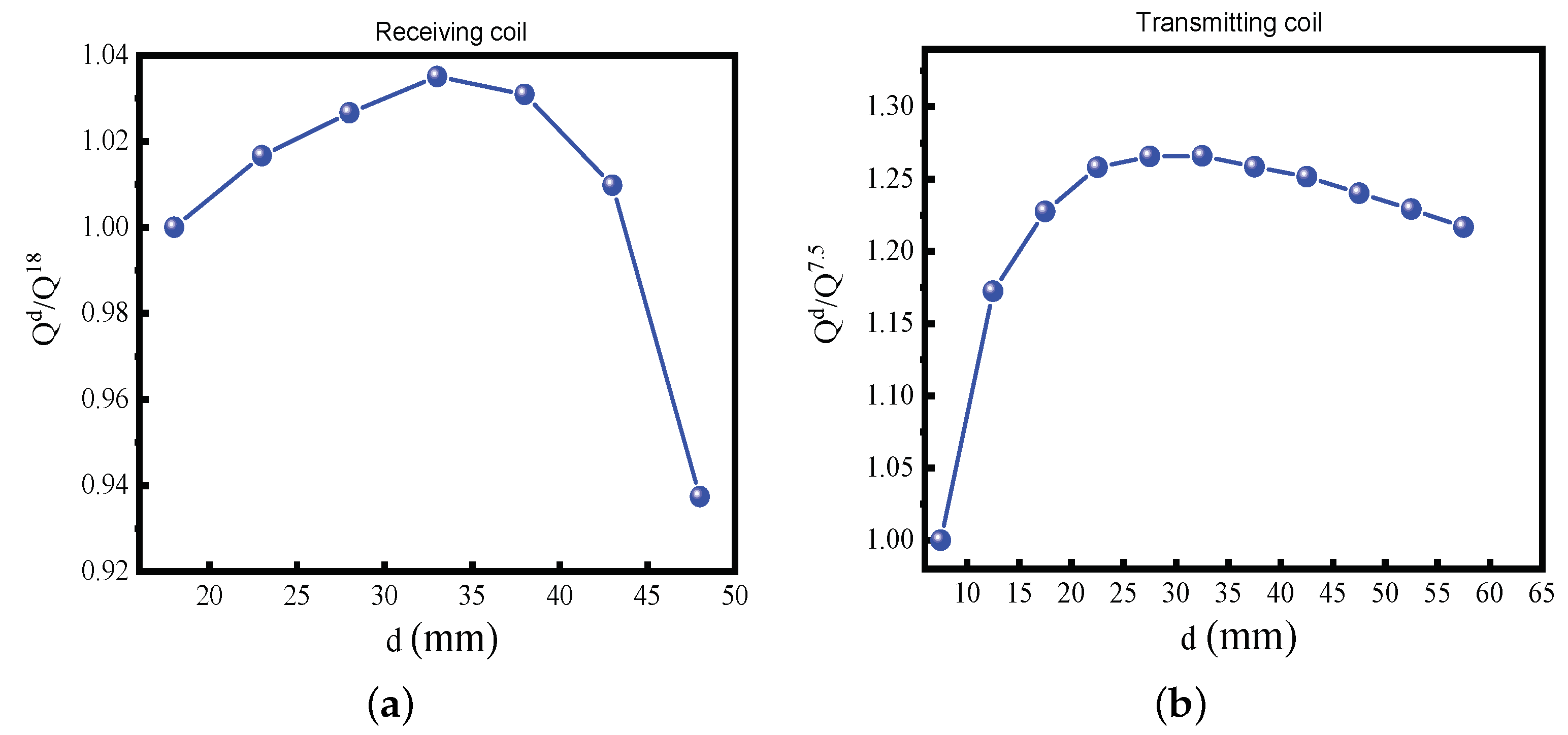

2.3. Influence of Metals on Both Sides of the Coil

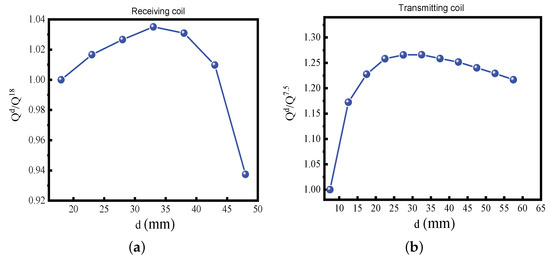

In order to increase the mechanical strength of the connection between the coil structure and other parts, both sides of the coil structure are made of metal materials. By placing a magnetic core near the coil, the distribution of the surrounding magnetic field can be changed, and the nearby metal medium will also affect the distribution of the magnetic field and the electrical parameters of the coil. We also use the FEA method to analyze the influence of the distance d between the coil and the metal structures on both sides on the quality factor of the coil. Similarly, we normalized the results to the quality factor when the magnetic core is next to the metal. The distances d are 18 mm and 7.5 mm when the magnetic core is next to the metal, respectively. As shown in Figure 4, it can be seen that there is an optimal distance between the coil and the metal for both transmitting coil and receiving coil, which makes the quality factor of the coil relatively highest. With the increase of d, the quality factor of the coil first increases and then decreases, which is the result of the joint action of water medium, metal shell, and magnetic materials.

Figure 4.

Variation of the normalized quality factor of the coils with the distance d between the coil and the metal structures on both sides. (a) Receiving coil. (b) Transmitting coil.

2.4. Evaluation of Shielding Effect

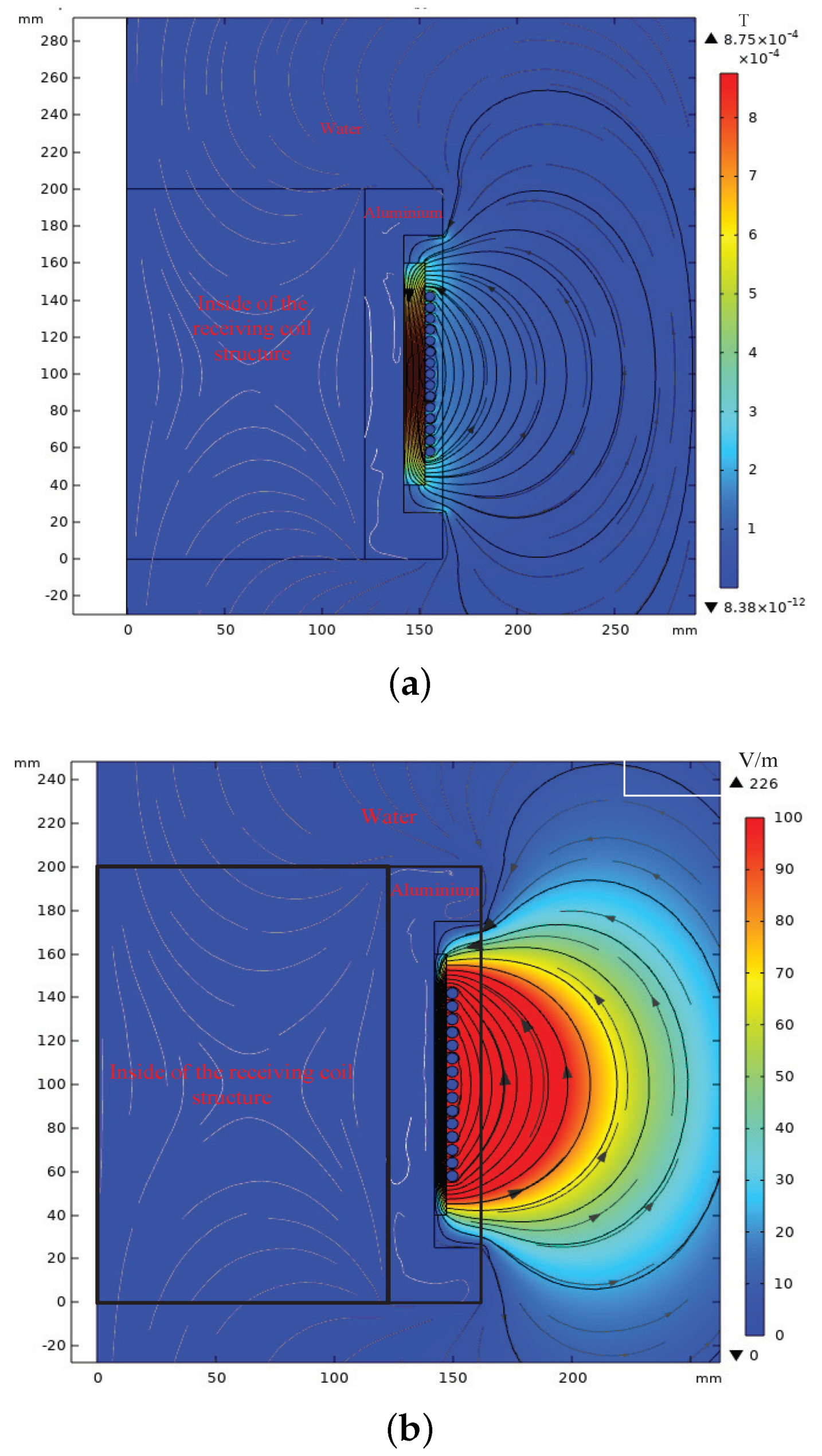

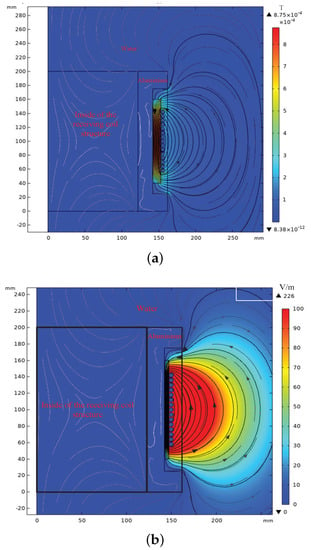

When the WPT system based on magnetic coupling transmits electric energy, an alternating magnetic field will be generated near the coil, and the alternating magnetic field will induce an alternating electric field, which will produce electromagnetic interference to the surrounding equipment. There are many pieces of electronic equipment inside the AUV, so the electromagnetic interference of the WPT system to the AUV must be considered. We also use the FEA method to evaluate the electromagnetic field distribution around the receiving coil. It can be seen from Figure 5 that the combination of the magnetic core and the metal material can prevent the electromagnetic field entering the interior of the coil structure. This is because the AUV and the coil structure form a closed metal shield. The magnetic core plays a role in restraining the magnetic field, and the metal shield can reduce the interference of the electric field.

Figure 5.

Electromagnetic field distribution of the receiving coil structure. (a) Magnetic field. (b) Electric field.

3. Experimental Verification and Discussion

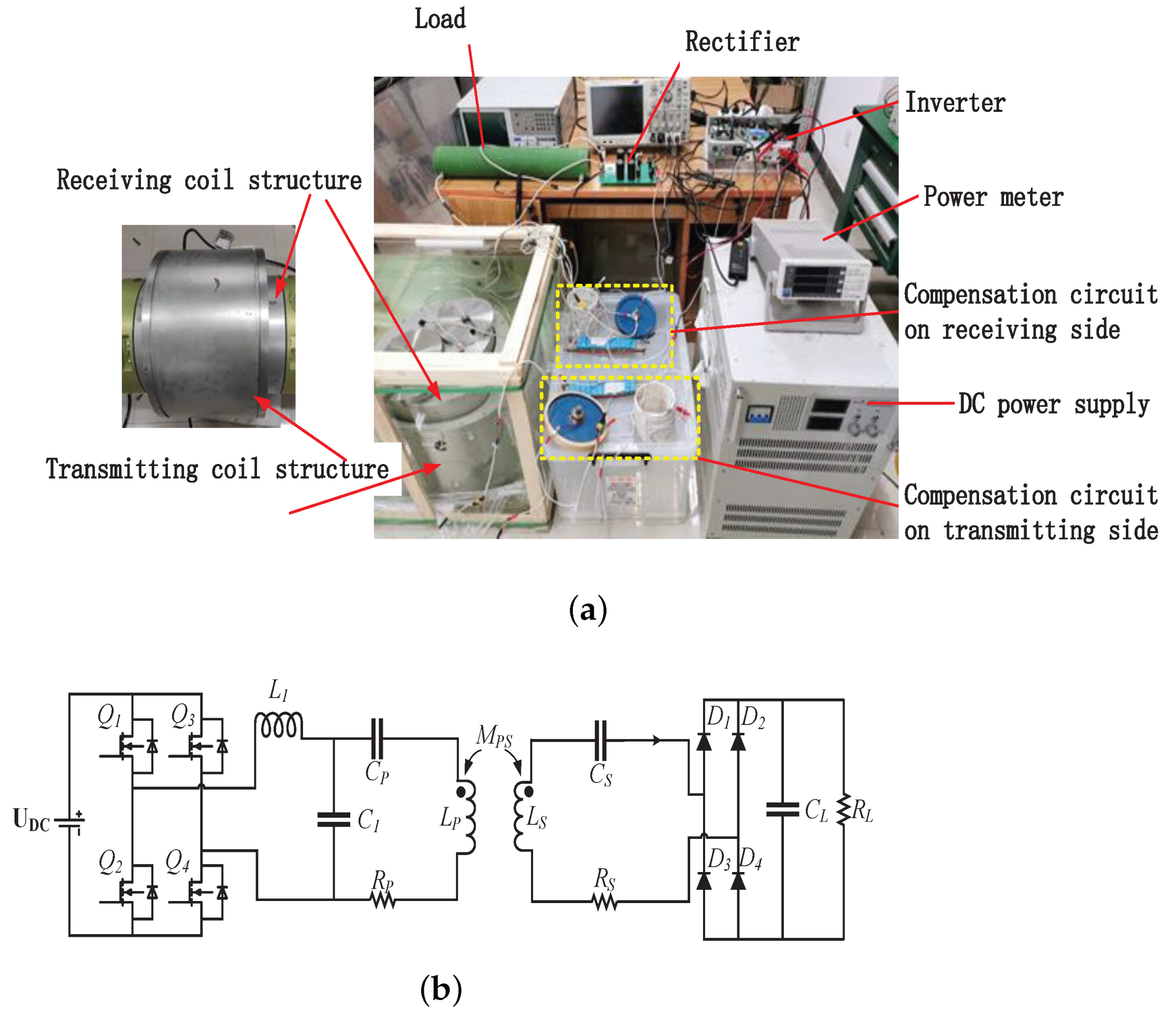

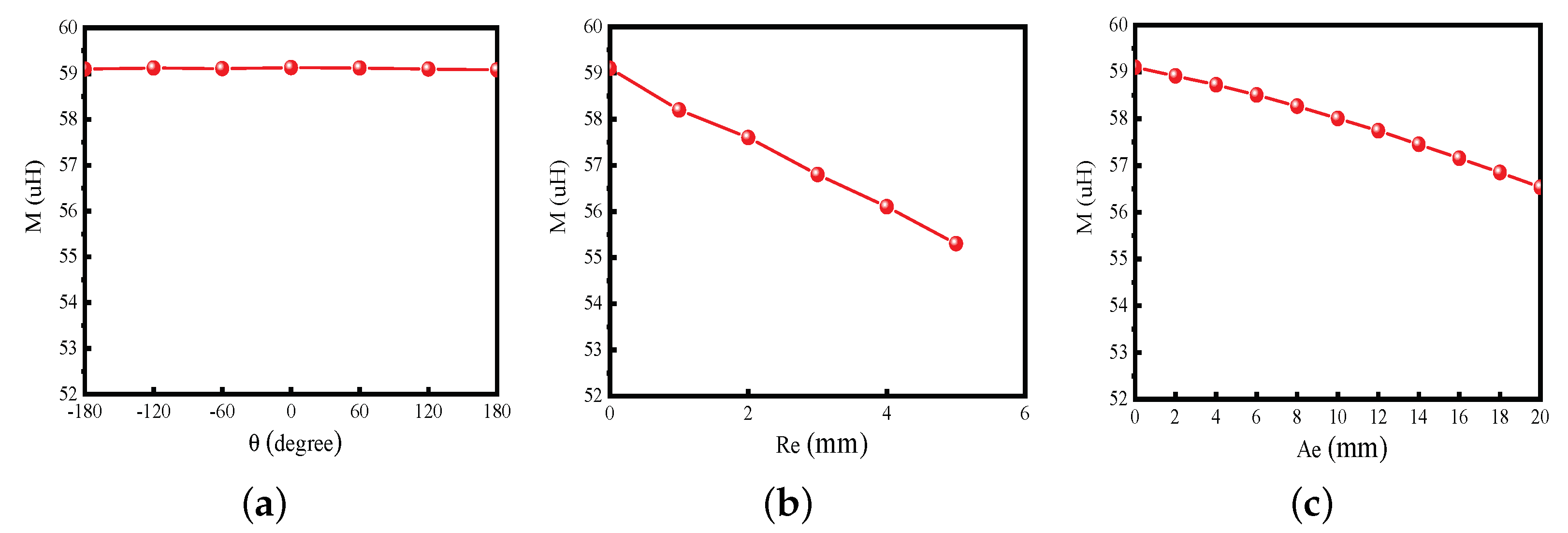

The picture of the prototype based on LCC-S-compensated topology is shown in Figure 6. The parameters of the WPT system are given in Table 2. Four SiC devices C3M0030090K are used to build a full-bridge inverter and four SiC didoes IDW30G65C5 are selected to build a full-wave rectifier. The transmitting and receiving coils are wound with litz wires, and the magnetic core is built by the standard-sized ferrite sheets (PC44). Two coil structures are placed in a water tank. Measurements have been performed by using the Wayne keer W6500B impedance analyzer to obtain the electrical parameters of the coil. The parameters of the prototype are measured as shown in Table 2. The measured self-inductance of transmitting coil is 152.7 uH, and the self-inductance of receiving coil is 123.3 uH. The AC resistance of transmitting and receiving coils is 1.22 Ω and 0.66 Ω, respectively. The mutual inductance of the coils is measured by the in-phase and the opposing-phase connections [20]. Figure 7 depicts the variation curve of the mutual inductance with rotational misalignment, radial, and axial eccentricity. As analyzed in the previous section, the mutual inductance of the spiral tube coil wound along the cylindrical structure hardly changes with rotational misalignment, but is sensitive to axial and radial eccentricity. In practice, in order to ensure full coupling between the coils and reduce magnetic leakage, the distance between the coils is usually kept within a few millimeters. Therefore, the mutual inductance change introduced by radial eccentricity will only fluctuate in a relatively small range in this case. Although the mutual inductance of this structure is also sensitive to axial eccentricity, it is less sensitive than radial eccentricity. In order to align the coils, the AUV usually clings to the tail baffle of the transmitting coil structure, which can also limit the axial eccentricity.

Figure 6.

(a) Picture of the prototype. (b) Schematic diagram of LCC-S-compensated topology.

Table 2.

Parameters of the prototype.

Figure 7.

The variation curve of mutual inductance with misalignments. (a) Rotational misalignment. (b) Radial eccentricity. (c) Axial eccentricity.

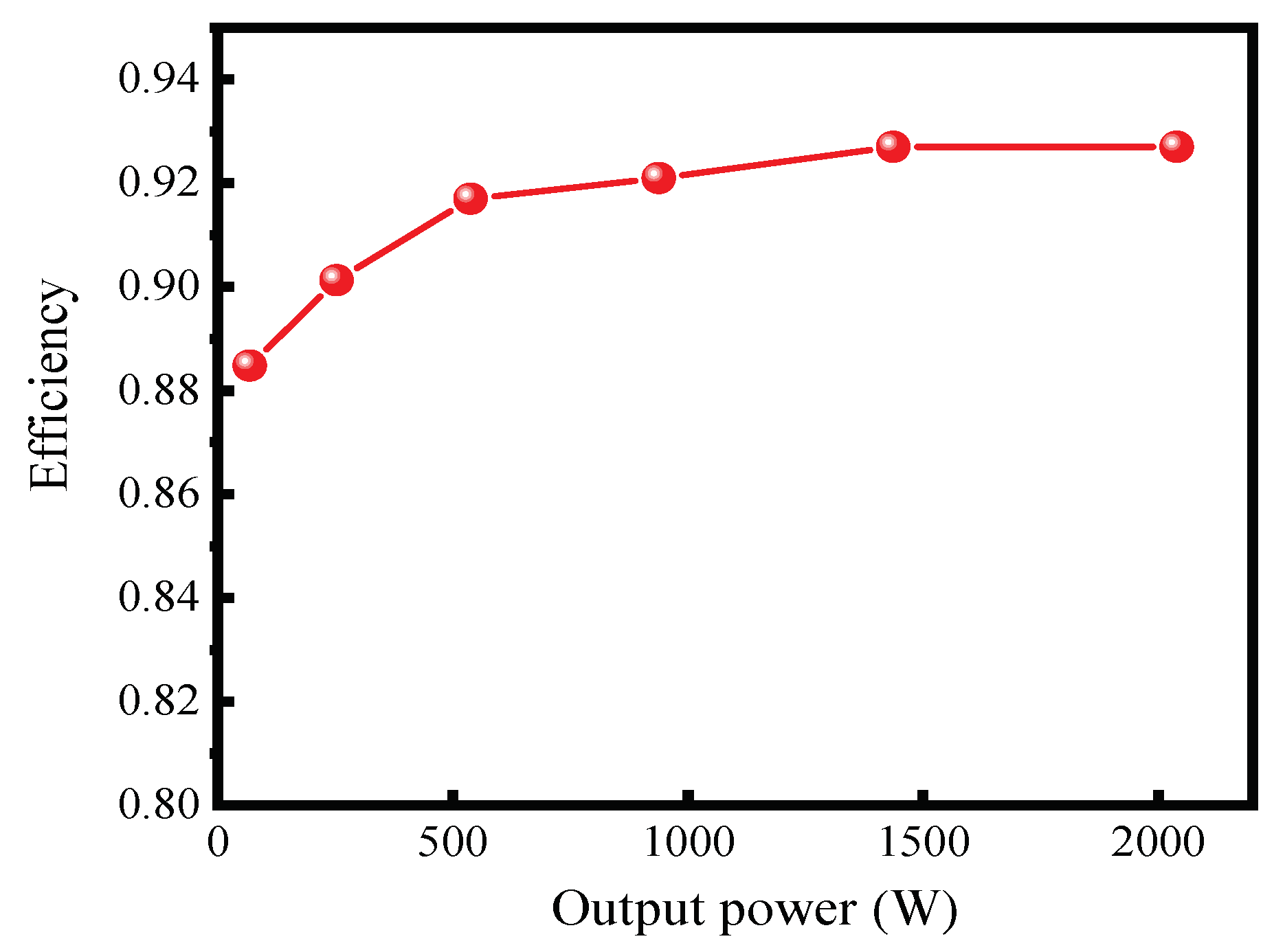

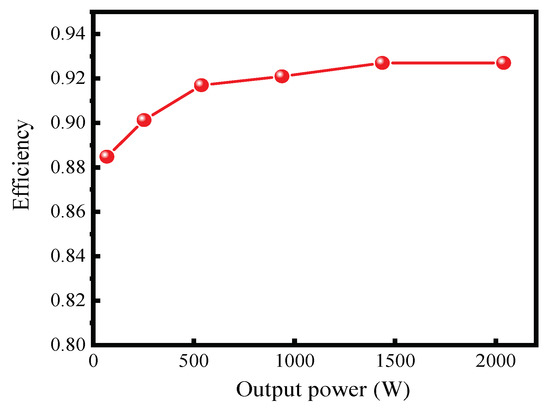

Efficiency is an important index to evaluate the WPT system, and the performance of the coil is the basis to achieve efficient power transmission. The efficiencies from 50 W to 2 kW output power are shown in Figure 8, and the peak efficiency is 92.7%. Obviously, although there are various conductive media around the structure of the receiving coil, this design, compatible with the structure of the AUV, can still maintain high power transmission efficiency.

Figure 8.

Variation of the efficiency with output power.

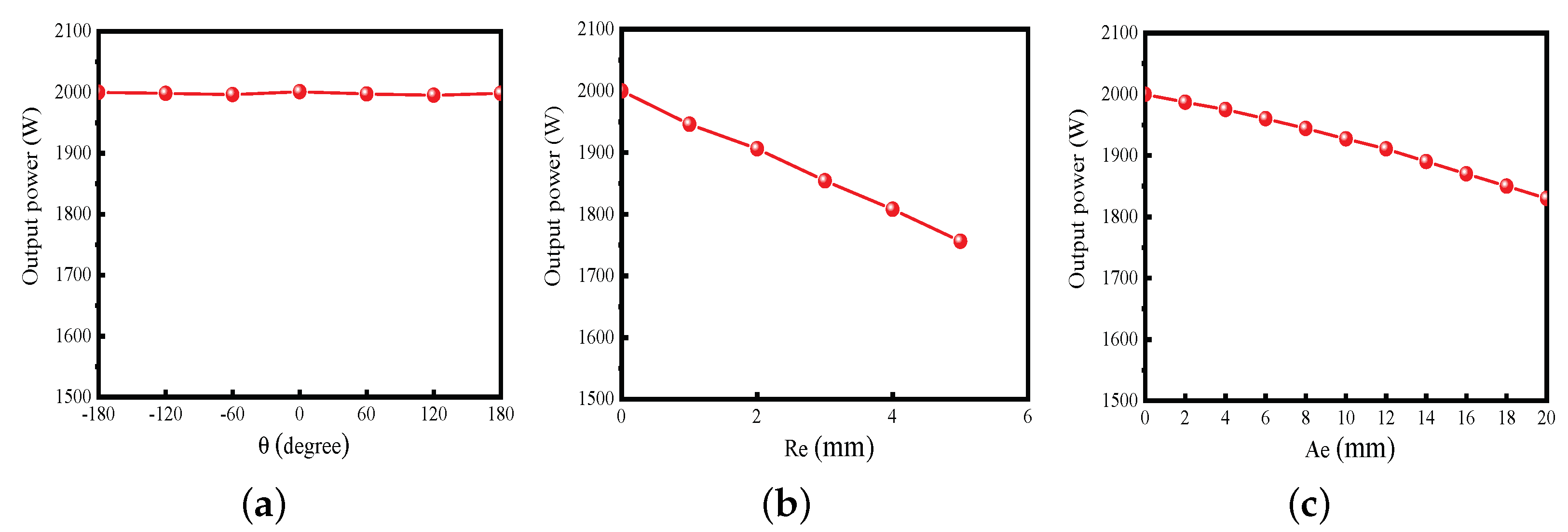

In order to evaluate the influence of rotational misalignment and eccentricity on the energy transmission of the proposed structure, we measured the influence of rotational misalignment and eccentricity on the output power by changing the position of the transmitting and receiving coil structure. The variation of output power with rotational misalignment and eccentricity are shown in Figure 9. It can be seen from the figure that the output power of the system is hardly affected by the rotational misalignment. Obviously, the radial eccentricity will cause the fluctuation of output power; when the eccentricity is 2 mm, the output power decreases by 5%, and when the eccentricity is 5 mm, the output power decreases by about 10%. Although the output power is also sensitive to axial eccentricity, it is less sensitive than radial eccentricity.

Figure 9.

The variation curve of the output power with misalignments. (a) Rotational misalignment. (b) Radial eccentricity. (c) Axial eccentricity.

The performance of the coil structure presented in [2,15,16] is comprehensively compared and tabulated in Table 3. The coil structure proposed in this paper is competitive in terms of its compatibility with the structure of AUVs and the ability against rotational misalignment. The stable output power and efficient energy transmission can be both achieved using the design method proposed in this paper.

Table 3.

Performance of existing WPTs for AUVs.

4. Conclusions

The coil structure not only prevents the rotational misalignment, but is also compatible with the AUV shapes that have been designed and experimentally tested. The size of the magnetic core and the distance between the coil and the metal structure are optimized by FEA simulation. The coaxial coils can guarantee the mutual inductance constant when the AUV rotates. The performance of the proposed coil structure is experimentally evaluated on an LCC-S-compensated WPT prototype. The results show that the performance of the coil structure is not affected by rotation, but is sensitive to radial and axial eccentricity. The prototype can achieve 92.7% efficiency at a 2 kW output power.

Author Contributions

Conceptualization, P.L. and T.G.; methodology, P.L. and Z.M.; software, P.L.; validation, P.L.; formal analysis, P.L., T.G. and Z.M.; investigation, P.L.; resources, P.L.; data curation, P.L.; writing—original draft, P.L.; writing—review and editing, P.L., Z.M. and T.G.; visualization, P.L.; supervision, Z.M., R.Z. and T.G.; project administration, Z.M. and T.G.; funding acquisition, Z.M. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by the National Natural Science Foundation of China, grant number 61572404.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Not applicable.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Marani, G.; Song, K.C.; Yuh, J. Underwater autonomous manipulation for intervention missions AUVs. Ocean. Eng. 2009, 36, 15–23. [Google Scholar] [CrossRef]

- Yan, Z.; Song, B.; Zhang, Y. A Rotation-Free Wireless Power Transfer System with Stable Output Power and Efficiency for Autonomous Underwater Vehicles. IEEE Trans. Power Electron. 2019, 34, 4005–4008. [Google Scholar] [CrossRef]

- Liang, B.; Mao, Z.; Zhang, K. Analysis and Optimal Design of a WPT Coupler for Underwater Vehicles Using Non-Dominated Sorting Genetic Algorithm. Appl. Sci. 2022, 12, 2015. [Google Scholar] [CrossRef]

- Zhang, Z.; Pang, H.; Georgiadis, A.; Cecati, C. Wireless Power Transfer-An Overview. IEEE Trans. Ind. Electron. 2019, 66, 1044–1058. [Google Scholar] [CrossRef]

- Wang, B.; Teo, K.H.; Nishino, T.; Yerazunis, W.; Barnwell, J.; Zhang, J. Experiments on wireless power transfer with metamaterials. Appl. Phys. Lett. 2011, 98, 254101. [Google Scholar] [CrossRef] [Green Version]

- Liu, Q.; Wu, J.; Xia, P.; Zhao, S.; Chen, W. Charging unplugged: Will distributed laser charging for mobile wireless power transfer work? IEEE Veh. Technol. Mag. 2016, 11, 36–45. [Google Scholar] [CrossRef]

- Kuperman, A. Additional two-capacitor basic compensation topologies for resonant inductive wpt links. IEEE Trans. Power Deliv. 2020, 35, 2568–2570. [Google Scholar] [CrossRef]

- Riehl, P.S.; Satyamoorthy, A.; Akram, H.; Yen, Y.C.; Yang, J.C.; Juan, B.; Lee, C.M.; Lin, F.C.; Muratov, V.; Plumb, W. Wireless power systems for mobile devices supporting inductive and resonant operating modes. IEEE Trans. Microw. Theory Tech. 2015, 63, 780–790. [Google Scholar] [CrossRef]

- Zhong, W.; Hui, S. Maximum energy efficiency operation of series-series resonant wireless power transfer systems using on-off keying modulation. IEEE Trans. Power Electron. 2017, 99, 1. [Google Scholar] [CrossRef]

- Ramezani, A.; Farhangi, S.; Iman-Eini, H.; Farhangi, B.; Rahimi, R.; Moradi, G.R. Optimized lcc-series compensated resonant network for stationary wireless ev chargers. IEEE Trans. Ind. Electron. 2019, 66, 2756. [Google Scholar] [CrossRef]

- Li, S.; Li, W.; Deng, J.; Nguyen, T.D.; Mi, C.C. A double-sided lcc compensation network and its tuning method for wireless power transfer. IEEE Trans. Veh. Technol. 2015, 64, 2261–2273. [Google Scholar] [CrossRef]

- Liu, P.; Gao, T.; Mao, Z. Optimization of Transfer Quality Factor of Limited-Size Coils for Series-Series Compensated Inductive Power Transfer System. Magnetochemistry 2022, 8, 30. [Google Scholar] [CrossRef]

- Fadhel, Y.B.; Bouattour, G.; Bouchaala, D.; Derbel, N.; Kanoun, O. Design optimization of spiral coils for textile applications by genetic algorithm. In Proceedings of the 18th International Multi-Conference on Systems, Signals and Devices (SSD), Monastir, Tunisia, 22–25 March 2021. [Google Scholar]

- Sampath, J.; Alphones, A.; Shimasaki, H. Coil design guidelines for high efficiency of wireless power transfer (WPT). In Proceedings of the 2016 IEEE Region 10 Conference, Singapore, 22–25 November 2016. [Google Scholar]

- Cheng, Z.Y.; Lei, Y.; Song, K.; Zhu, C.B. Design and Loss Analysis of Loosely Coupled Transformer for an Underwater High-Power Inductive Power Transfer System. IEEE Trans. Magn. 2015, 51. [Google Scholar] [CrossRef]

- Lin, M.; Li, D.; Yang, C. Design of an ICPT system for battery charging applied to underwater docking systems. Ocean. Eng. 2017, 145, 373–381. [Google Scholar] [CrossRef]

- Available online: https://www.digikey.com/en/products/detail/tdk-corporation/PC44PQ32-30Z-12/7424194 (accessed on 10 May 2022).

- Available online: https://www.comsol.com/ (accessed on 10 May 2022).

- Zhang, Y.; Zhao, Z.; Chen, K. Frequency Decrease Analysis of Resonant Wireless Power Transfer. IEEE Trans. Power Electron. 2013, 29, 1058–1063. [Google Scholar] [CrossRef]

- Liu, P.; Gao, T.; Mao, Z. Analysis of the Mutual Impedance of Coils Immersed in Water. Magnetochemistry 2021, 7, 113. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).