Dynamic Characteristic Analysis of Centrifugal Pump Impeller Based on Fluid-Solid Coupling

Abstract

:1. Introduction

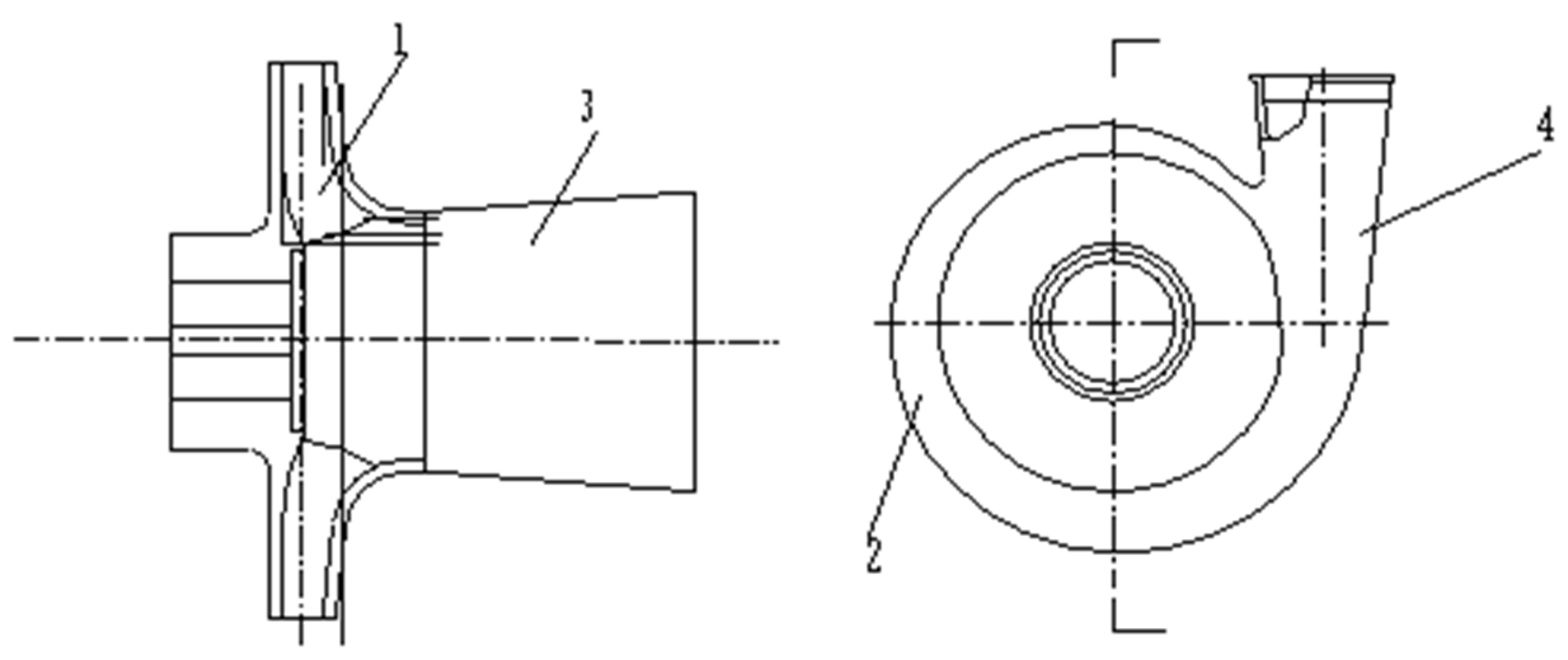

2. Fluid-Solid Coupling Theory of Centrifugal Pump

3. Dynamic Characteristics Analysis of Centrifugal Pump Impeller during Start-Up

3.1. Flomaster Simulation Experiment

3.2. Vibration Analysis of Impeller during Start-Up

4. Analysis of Unsteady Flow Induced Impeller Vibration

4.1. Steady State Radial Force Analysis

4.2. Impeller Vibration Analysis

4.2.1. Calculation and Analysis of Transient Radial Force

4.2.2. Harmonic Response Analysis

5. Conclusions

- (1)

- During the start-up process of centrifugal pump, the speed and flow do not reach the rated value instantaneously but experience the process of rapidly increasing first and then decreasing until reaching stability. During this period, the impeller vibration changes violently; the overall vibration amplitude increases and fluctuates stably at the amplitude of 0.01 mm. The speed and acceleration fluctuate violently and finally stabilizes within a range of fluctuation.

- (2)

- Under low flow condition 0.8 Q and high flow condition 1.2 Q and 1.5 Q, the radial force on the centrifugal pump impeller increases compared with the design flow Q, and the greater the deviation from the design flow, the greater the radial force.

- (3)

- In the unsteady numerical simulation of the centrifugal pump, the radial force changes periodically. Every rotation cycle, the transient radial force presents six peaks, which is consistent with the number of times that the blade sweeps through the volute tongue when the impeller rotates one cycle.

- (4)

- The time domain signal is transformed into the frequency domain signal to obtain the vibration peak at 101.67 Hz and 610 Hz, which are the fundamental frequency of the impeller and the blade passing frequency, respectively. Under the design condition, the dynamic influence of radial force on the impeller structure is the smallest, and it has a relatively large influence under the non-design condition. This is consistent with the variation relationship between radial force and flow of centrifugal pump. Under the design flow, the radial force is the smallest, and the greater the deviation from the design flow, the greater the radial force.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Adu-Poku, K.A.; Zhang, F.; Appiah, D.; Chen, K.; Osman, F.K.; Acheaw, E. Study on the inner flow mechanisms and unsteady force distribution of side channel pump. Proc. Inst. Mech. Eng. Part A J. Power Energy 2022. [Google Scholar] [CrossRef]

- Jin, F.; Tao, R.; Wei, Z.; Wu, Y.; Xiao, R. Investigation of the axial force on a varying-speed centrifugal pump impeller. Proc. Inst. Mech. Eng. Part A J. Power Energy 2021, 236, 714–726. [Google Scholar] [CrossRef]

- Pavesi, G.; Cavazzini, G.; Ardizzon, G. Time-frequency characterization of the unsteady phenomena in a centrifugal pump. Int. J. Heat Fluid Flow 2008, 29, 1527–1540. [Google Scholar] [CrossRef]

- Yuan, S.Q.; Ni, Y.Y.; Pan, Z.Y.; Yuan, J.P. Unsteady Turbulent Simulation and Pressure Fluctuation Analysis for Centrifugal Pumps. Chin. J. Mech. Eng. 2009, 22, 64–69. [Google Scholar] [CrossRef]

- Abdolahnejad, E.; Moghimi, M.; Derakhshan, S. Experimental and numerical investigation of slip factor reduction in centrifugal slurry pump. J. Braz. Soc. Mech. Sci. Eng. 2021, 43, 179. [Google Scholar] [CrossRef]

- Derakhshan, S.; Pourmahdavi, M.; Abdolahnejad, E.; Reihani, A.; Ojaghi, A. Numerical shape optimization of a centrifugal pump impeller using artificial bee colony algorithm. Comput. Fluids 2013, 81, 145–151. [Google Scholar] [CrossRef]

- Ge, Z.; He, D.; Huang, R.; Zuo, J.; Luo, X. Application of CFD-PBM coupling model for analysis of gas-liquid distribution characteristics in centrifugal pump. J. Pet. Sci. Eng. 2020, 194, 107518. [Google Scholar] [CrossRef]

- Gu, Y.; Liu, N.; Mou, J.; Zhou, P.; Qian, H.; Dai, D. Study on solid-liquid two-phase flow characteristics of centrifugal pump impeller with non-smooth surface. Adv. Mech. Eng. 2019, 11, 1687814019848269. [Google Scholar] [CrossRef]

- Hermez, M.Y.; Jawad, B.A.; Liu, L.; Fernandez, V.; Yee, K.; Oklejas, E. Comparison of inlet curved disk arrangements for suppression of recirculation in centrifugal pump impellers. In Proceedings of the ASME International Mechanical Engineering Congress and Exposition (IMECE2016), Phoenix, AZ, USA, 11–17 November 2017. [Google Scholar]

- Ji, L.; Li, W.; Shi, W.; Agarwal, R.K. Application of Wray-Agarwal Turbulence Model in Flow Simulation of a Centrifugal Pump With Semispiral Suction Chamber. J. Fluids Eng.-Trans. ASME 2021, 143, 031203. [Google Scholar] [CrossRef]

- Jia, X.; Chu, Q.; Zhang, L.; Zhu, Z. Experimental Study on Operational Stability of Centrifugal Pumps of Varying Impeller Types Based on External Characteristic, Pressure Pulsation and Vibration Characteristic Tests. Front. Energy Res. 2022, 10, 246. [Google Scholar] [CrossRef]

- Jianci, Z.; Baoling, C.U.I.; Yi, L.I.; Zuchao, Z.H.U.; Ying, C. Optimum design system of low-specific open-impeller high-speed centrifugal pump. Chin. J. Mech. Eng. 2006, 42, 19–23. [Google Scholar]

- Khoeini, D.; Shirani, E. Influences of Diffuser Vanes Parameters and Impeller Micro Grooves Depth on the Vertically Suspended Centrifugal Pump Performance. J. Mech. 2019, 35, 735–746. [Google Scholar] [CrossRef]

- Kuang, R.; Zhang, Z.; Wang, S.; Chen, X. Effect of hub inclination angle on internal and external characteristics of centrifugal pump impellers. Aip Adv. 2021, 11, 025043. [Google Scholar] [CrossRef]

- Li, J.; Wang, X.; Wang, Y.; Wang, W.; Chen, B.; Chen, X. Effects of a Combination Impeller on the Flow Field and External Performance of an Aero-Fuel Centrifugal Pump. Energies 2020, 13, 919. [Google Scholar] [CrossRef] [Green Version]

- Shi, X.; Lu, J.; Zhao, L. Investigations on the influence of tandem blades on inner flow and performance characteristics of centrifugal pump. Proc. Inst. Mech. Eng. Part E J. Process Mech. Eng. 2020, 234, 46–55. [Google Scholar] [CrossRef]

- Lu, J.; Luo, Z.; Chen, Q.; Liu, X.; Zhu, B. Study on Pressure Pulsation Induced by Cavitation at the Tongue of the Volute in a Centrifugal Pump. Arab. J. Sci. Eng. 2022. [Google Scholar] [CrossRef]

- Quan, H.; Cheng, J.; Guo, Y.; Kang, L.; Peng, G. Influence of Screw Centrifugal Inducer on Internal Flow Structure of Vortex Pump. J. Fluids Eng.-Trans. ASME 2020, 142, 091203. [Google Scholar] [CrossRef]

- Wu, X.; Sun, X.; Tan, M.; Liu, H. Research on operating characteristics of a centrifugal pump with broken impeller. Adv. Mech. Eng. 2021, 13, 16878140211049951. [Google Scholar] [CrossRef]

- Wang, L.; Lu, J.; Liao, W.; Guo, P.; Zhu, G.; Luo, X. Numerical investigation on vibration and pressure fluctuation characteristics in a centrifugal pump under low flow rate. Proc. Inst. Mech. Eng. Part C J. Mech. Eng. Sci. 2021, 235, 3888–3899. [Google Scholar] [CrossRef]

- Wu, C.; Li, Q.; Zheng, F.; Wu, P.; Yang, S.; Ye, H.; Huang, B.; Wu, D. Improve of Unsteady Pressure Pulsation Based on Jet-Wake Suppression for a Low Specific Centrifugal Pump. J. Fluids Eng.-Trans. ASME 2021, 143, 111202. [Google Scholar] [CrossRef]

- Yuan, J.; Shi, J.; Fu, Y.; Chen, H.; Lu, R.; Hou, X. Analysis of Fluid-Structure Coupling Dynamic Characteristics of Centrifugal Pump Rotor System. Energies 2022, 15, 2133. [Google Scholar] [CrossRef]

- Adamkowski, A.; Henke, A.; Lewandowski, M. Resonance of torsional vibrations of centrifugal pump shafts due to cavitation erosion of pump impellers. Eng. Fail. Anal. 2016, 70, 56–72. [Google Scholar] [CrossRef]

- Song, Y.; Fan, H.; Huang, Z. Study on radial force characteristics of double-suction centrifugal pumps with different impeller arrangements under cavitation condition. Proc. Inst. Mech. Eng. Part A J. Power Energy 2021, 235, 421–431. [Google Scholar] [CrossRef]

- Jaiswal, A.K.; Rehman, A.U.; Paul, A.R.; Jain, A. Detection of Cavitation through Acoustic Generation in Centrifugal Pump Impeller. J. Appl. Fluid Mech. 2019, 12, 1103–1113. [Google Scholar] [CrossRef]

- Cui, B.; Li, X.; Rao, K.; Jia, X.; Nie, X. Analysis of unsteady radial forces of multistage centrifugal pump with double volute. Eng. Comput. 2018, 35, 1500–1511. [Google Scholar] [CrossRef]

- Nan, G.; Chen, E.; Yang, A. Dynamic characteristics of centrifugal pump induced by fluid and motor excitation forces. J. Vibroengineering 2015, 17, 3909–3918. [Google Scholar]

| Parameter | Value |

|---|---|

| Young’s modulus/GPa | 96 |

| Density/(kg/m3) | 4620 |

| Poisson’s ratio | 0.36 |

| Yield strength/Mpa | 800 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, Y.; Su, H.; Wang, Y.; Jiang, W.; Zhu, Q. Dynamic Characteristic Analysis of Centrifugal Pump Impeller Based on Fluid-Solid Coupling. J. Mar. Sci. Eng. 2022, 10, 880. https://doi.org/10.3390/jmse10070880

Li Y, Su H, Wang Y, Jiang W, Zhu Q. Dynamic Characteristic Analysis of Centrifugal Pump Impeller Based on Fluid-Solid Coupling. Journal of Marine Science and Engineering. 2022; 10(7):880. https://doi.org/10.3390/jmse10070880

Chicago/Turabian StyleLi, Yufang, Hongli Su, Yanwei Wang, Wei Jiang, and Qipei Zhu. 2022. "Dynamic Characteristic Analysis of Centrifugal Pump Impeller Based on Fluid-Solid Coupling" Journal of Marine Science and Engineering 10, no. 7: 880. https://doi.org/10.3390/jmse10070880