Abstract

With the rising consumption of oil resources, major oil companies around the world have increasingly engaged in offshore oil exploration and development, and offshore oil resources have accounted for an increasing proportion. Offshore oil engineering projects are capital intensive, and the development of offshore oil fields faces a tough battle, especially in a period of low oil prices. Thus, a comprehensive evaluation model is highly needed to help assess economic benefits and provide meaningful and valuable information for operators and investors to make sensible decisions. This study firstly proposed a realistic and integrated evaluation model for offshore oil development based on actual historical project data. This evaluation model incorporated modules from the underwater system to the platform system and processes from oil reservoir extraction to oil, gas and water treatment. The uncertain parameters in the evaluation process are dealt with by sensitivity analysis and Monte Carlo simulation. The proposed model is applied to a typical offshore oil development project in Bohai Bay, China. The results reveal that the recovery factor and oil price have the greatest impact on the economic benefits. In the case of deterministic analysis, the breakeven oil price of the project is 40.59 USD/bbl. After considering the uncertainty of project parameters, the higher the oil price, the greater the probability of NPV > 0. When the oil price is higher than 70 USD/bbl, even with uncertain project parameters, the probability of NPV > 0 can still be as high as 97.39%.

1. Introduction

1.1. Background

With the continuous growth of global demand for oil resources and the gradual reduction of onshore oil resources, more and more countries and oil companies are turning their attention to the ocean. Numerous offshore oil field projects have been developed in the Middle East, the North Sea, Brazil, the Gulf of Mexico, the Caspian Sea, etc., and the production and proven reserves of global offshore oil resources have steadily increased [1]. Since the year 2000, offshore oil fields have produced 30% of the world’s oil production [2]. Taking the offshore oil fields around the Federal Gulf of Mexico as an example, offshore oil production accounted for approximately 15% of total crude oil production in America in 2020 [3]. In the New Policies Scenario, the International Energy Agency (IEA) predicts offshore oil production will grow from 26.4 million bbl/d in the year 2016 to 27.4 million bbl/d in the year 2040. Tapping huge offshore oil resources will be vital to meeting future energy demand around the world. Therefore, the development and production of offshore oil resources have gradually become a key research topic in the oil industry [4].

Despite the abundance of offshore oil resources, offshore projects still face many challenges [5]. The lack of geological data, especially in deep-sea oil fields, is not conducive to the identification and estimation of oil reserves. Special marine environments, such as waves and currents, ridges, and slopes, bring more stringent technical requirements to exploration and construction. The complex characteristics of offshore oil reservoirs, especially for high-coagulation, high-viscosity, and high-waxy crude oil, bring safety problems to the processes of oil and gas gathering and transportation. Therefore, the development and production of offshore oil resources are riskier and more costly projects than onshore projects [6]. The largest offshore project in Australia called the Gorgon project, cost more than 57 billion USD, more than double the estimated cost [1]. The cost of project investment determines whether an offshore field is worth exploiting. The economic evaluation of the project is a critical subject for the industry to ensure its profitability [7]. In addition, the prospect of offshore oil is also shaken by the shale revolution, the rise of renewables, and the fall in oil prices [8]. Under the various pressures of the changing market and policy environment, there is an urgent need to improve the efficiency and economics of offshore oil projects. How to carry out an effective economic evaluation of offshore oil development projects under the condition of low oil prices is a top priority, which is also the research topic of this paper.

1.2. Related Works

Oil and gas field development projects are capital intensive [9]. Mastering the cost structure of the project and establishing the corresponding economic evaluation model are the key steps in the development of offshore oil resources. To the best of our knowledge, there is currently no relevant model integrating various modules for a more comprehensive economic evaluation of offshore oil projects. A literature search shows that scholars have only researched economic evaluation or cost optimization on a specific submodule of an offshore oil project. Many scholars have conducted studies on the optimal design of oil and gas production systems from the viewpoints of submarine pipeline routes [10], manifold placement and pipeline layout [11], pressure equipment placement [12], floating and subsea layouts [13] and gathering system [14]. These studies aim to reduce the investment cost and risk of the project from the design and layout of the oil and gas gathering pipeline network. Gao et al. [15] built a multi-period mixed integer nonlinear programming (MINLP) model to consider both well operation and flow assurance. The optimal objective is to minimize the total operation cost, including well production state, polymer flooding, flow assurance, and so on. Allahyarzadeh-Bidgoli et al. [16] took the minimum energy consumption as the objective function, established an oil treatment process model based on HYSYS, and solved seven optimal process operating parameters through genetic algorithms. The work of Veloso et al. [17] and the work of Reis and Gallo [18] both optimized the energy consumption of heat exchange-related processes on floating production storage and offloading (FPSO) from the perspective of the Rankine cycle. Kim et al. [19] built an economic evaluation model of mono ethylene glycol (MEG) injection and regeneration process for oil FPSO based on NPC (net present cost), which includes capital investment and operating costs. In the study of Cruz et al. [20], new primary cooling for deepwater offshore platforms was proposed based on deep seawater intake at 4 °C from depths around 900 m, reducing the outlet temperature of intercoolers to 12 °C. In the optimal design of oil and gas production and gathering systems, in addition to improving economic benefits, some studies also focus on improving the environmental benefits of the system [21,22]. The economic analysis of the above studies focuses on the individual module level rather than the project level. Due to this limitation, existing economic models associated with offshore oil development cannot adequately assess the economic viability of projects.

In terms of economic feasibility analysis of other similar oil resource development, many scholars have established models to conduct technical and economic evaluations of projects, which can provide stronger support for project decision making. Currently, the most popular economic evaluation models are the net present value (NPV) model and the internal rate of return (IRR) model. Based on a great number of actual historical data in Canada, Rui et al. [23] built an economic evaluation model for oil sands development with Steam-Assisted Gravity Drainage (SAGD) technology. The model consists of six submodules and considers the effect of steam oil ratio, flowline length, true vertical depth, recovery factors and so on. The proposed model helps to analyze the economic benefits of the oil sands project with SAGD technology in a relatively complete manner. Based on Jeff’s model [24] and Sawhney’s model [25], Saini et al. [26] built a reservoir scoping model coupled with economic analysis for heavy oil reservoirs in a pseudo-SAGD mode. This model helps users predict specific scenarios and rank the impact of different variables on project viability. For the evaluation of the carbon dioxide enhanced oil recovery (EOR) project, Wei et al. [27] proposed a hybrid techno-economic method for the evaluation of storage resources and economic feasibility, which includes a performance model and a cost model for economic evaluation and sensitivity analysis. In addition, Jiang et al. [28] developed an integrated technical-economic model for economic potential and greenhouse gas (GHG) emission analysis based on historical data from about 40 field projects. The NPV of six scenarios was calculated for different design requirements. Due to the ambiguity of the knowledge of the oil reservoir and the uncertainty of the development environment, the reliability of some deterministic evaluations is not high. Therefore, some researchers have further analyzed the uncertain factors in the project evaluation [29]. Sensitivity analysis, scenario analysis, and Monte Carlo simulation are often used to analyze the impact of uncertain factors on project economics [30].

From the above literature, it can be concluded that the existing evaluation models related to offshore oil development are incomplete, and often only consider specific modules in the project. These methods can only achieve the purpose of reducing the economic investment as much as possible, but cannot carry out the overall economic evaluation of the overall project to achieve the purpose of avoiding investment risks. Although there have been similar economic evaluation methods for oil development based on the NPV model and the IRR model, the facilities of offshore oilfields are quite different, such as the underwater production system module and the platform upper chunk module. In addition, the input parameter of the evaluation models needs to be verified using actual data. We need to collect actual project data and analyze the impact of different factors on the project. These circumstances prevent us from transferring models, data, and conclusions directly from other project evaluation methods. Therefore, it is of great significance to develop customized evaluation methods for the quantitative economic evaluation of offshore oil development projects.

1.3. Contributions

Inspired by the above analysis, this paper puts forward a data-based integrated evaluation model for offshore oil development. The major data sources include the National Bureau of Statistics of China [31], field practice data, industry statistics, and technical literature [32,33,34]. Based on the actual project data of the oil field, the model can conduct economic evaluations on the development of offshore oil projects and provide data demonstration and theoretical support for decision makers on whether to invest in the project.

The contributions of this work are as follows:

(1) This paper firstly proposed an evaluation model supported by actual data from offshore oil field projects. The actual data will significantly improve the model’s applicability and reliability because all input parameters have reasonable values and realistic ranges.

(2) This evaluation model incorporated various modules for offshore oil development from the underwater system to the platform system and from oil reservoir extraction to oil, gas, and water treatment. Therefore, this model can perform the overall economic evaluation for an offshore oil development instead of a partial evaluation.

(3) A detailed case study is conducted to demonstrate the application of the integrated model, and the effect of major factors is quantified.

2. Offshore Oil Project Description

Offshore oil development is a huge and complicated engineering project. In recent years, offshore oil development has continued to advance to deep-sea oilfields. This kind of project far away from the mainland is a complex project integrating exploration, drilling, processing, storage, and transportation [35].

2.1. Offshore Oil Project Procedure

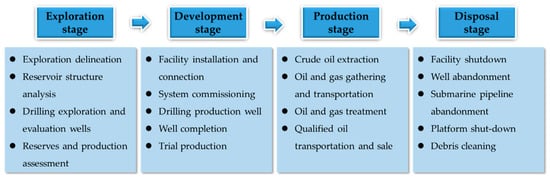

The offshore oil project includes four stages: the exploration stage, development stage, production stage, and disposal stage, as shown in Figure 1. The exploration stage mainly relies on geophysical technology to explore reserves by drilling appraisal wells. The development phase is mainly about the overall construction of the project to ensure smooth production. The production stage mainly involves the extraction of crude oil and its treatment, storage, and transportation. The abandonment stage refers to the disposal of production facilities after all production activities in the oilfield are stopped.

Figure 1.

Offshore oil project procedure.

In the exploration stage, geophysical technology is used to conduct exploration delineation and oil storage structure analysis in the target sea area, and then the reserves and the production of oil reservoirs can be assessed in detail by drilling exploration wells and evaluation wells. Thus, it can be preliminary determined whether the oil reservoir can be developed. This stage mainly provides geological parameters for offshore oil development, completes the formulation of the overall development plan, and prepares for the transition to the oil development stage. In terms of economic evaluation, whether the oil field will be developed or not in the future, the expenses in the exploration stage already exist, and it is regarded as a sunk cost. They are irrelevant to investment decisions in the future and do not need to be considered when performing economic evaluations. Therefore, this paper does not consider the influence of the cost of the exploration stage in the economic evaluation of offshore oil development projects.

When the exploration stage is completed, it will be transferred to the development stage according to the evaluation results of the exploration stage. This stage mainly completes the project construction and commissioning work, including jacket platform installation, submarine pipeline layout, cable laying, FPSO facility connection and so on. After system commissioning, if there is no fault, the production well can be drilled, the well completion operation can be carried out and trial production can be started. Due to the relatively small output and short duration of the trial production, the cost of the trial production stage is included in the production stage when performing the economic evaluation. The investment at this stage mainly includes investment in engineering facilities and drilling and completion costs. The investment in engineering facilities can be divided into underwater production facility investment, platform construction investment, and upper block facility investment.

After the completion of the development stage, it will enter the production stage. At this stage, crude oil is extracted from the reservoir through the built engineering facilities and transported to the target platform through the subsea gathering pipeline network and riser system for further production and treatment. After treatment, the qualified oil is exported for sale through shuttle cruise ships or submarine pipelines. In this stage, to ensure stable and safe production, it is necessary to invest in corresponding workover costs, equipment maintenance costs, chemical purchase and injection costs, energy consumption costs, and personnel welfare costs. The expenses incurred in the production process can be included in the operating expenses in the economic evaluation and are regarded as annual costs.

With continuous development, the output of the oil field decreases year by year, and it enters the middle and late stages of development and, finally, enters the disposal stage, which cannot generate economic benefits [36,37]. When the oil field reaches its end of life, all production facilities need to be dismantled and disposed of following relevant laws and regulations, which is also a reflection of the company’s environmental awareness [38]. The disposal process generally includes the following parts: facility shutdown, well abandonment, submarine pipeline abandonment, platform shutdown, debris cleaning and so on. At present, there are three conventional disposal methods: local abolition, off-site abolition, and conversion to other uses. Since disposal costs account for only a minor proportion of the total investment, they are ignored in the economic evaluation in this paper for simplification.

2.2. Offshore Oil Production Process

The production process of offshore oil is mainly divided into four steps: drilling and completion, gathering and transportation, treatment, storage, and transportation. After reservoir exploration, drilling and completion are performed. Formation crude oil is extracted from the reservoir through production wells, and the extracted oil is gathered and transported to the FPSO through the subsea oil gathering pipeline network and risers. The treatment on the platform includes oil, gas, and water separation, crude oil dehydration, natural gas dehydration, carbon dioxide and hydrogen sulfide removal for natural gas, oil and suspended solid removal for produced water and so on. Qualified oil is stored in storage tanks and is regularly exported by shuttle cruise ships or submarine pipelines. Natural gas is burned or reinjected or exported according to production requirements. Produced water is reinjected or discharged according to production requirements. A complete economic evaluation of an offshore oil project must include all production processes and take into account all investment and operating costs involved.

2.3. Offshore Oil Project Investment

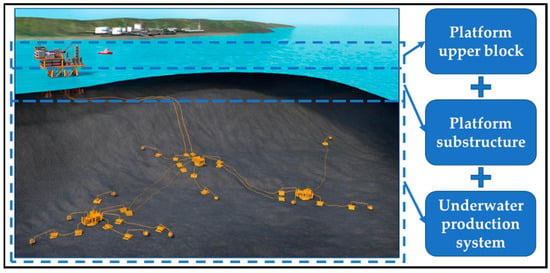

Offshore oil project investment can be divided into drilling and completion investment, underwater production system investment, platform substructure investment, and platform upper block investment according to the different development and production processes, as shown in Figure 2.

Figure 2.

Investment composition of an offshore oil project.

Drilling and completion costs are an important part of project investment, including drilling costs and completion costs. Offshore oil drilling and completion operations are generally carried out on drilling platforms or drilling ships, and the operation sites are located in the ocean and face relatively harsh natural environments. Due to the limited working space of the platform, the technical content of drilling and completion engineering in offshore oilfields is relatively high. At the same time, with the increasing awareness of marine environmental protection, offshore operations are also subject to relevant laws and regulations. Therefore, compared with onshore oil drilling and completion engineering, offshore engineering has higher technical requirements, more complex investment structures, and higher investment costs.

A typical underwater production system consists of underwater production equipment and control facilities. According to the function, it can be divided into a wellhead and Christmas tree system, manifold system and connection system, underwater control and umbilical cable system. Oil in the reservoir is collected into manifolds through underwater wellheads and “Christmas trees”, then collected and transported through terminal equipment on underwater pipelines and finally transported to surface facilities by risers.

Due to the unique operating environment of offshore oilfields, it is necessary to build a platform on the sea to place production facilities. A floating platform hull refers to the architectural structure of the platform, which is used to support and place the base structure of the well and upper block. Fixing the platform on the sea faces difficulties, such as wind and waves, ocean currents, water depth, and load-bearing. It is an indispensable part of the economic evaluation of offshore oil projects.

The platform upper block is divided into two functional modules according to the needs of production and life. The production module is mainly equipped with equipment related to oil, gas, and water treatment, and has functions such as oil, gas, and water separation and metering. The life module is mainly used to ensure the daily life of employees on the platform and is also the production command center.

3. Methodology

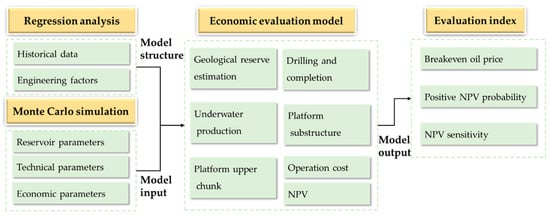

Based on the above analysis, this paper established a realistic and integrated evaluation method for offshore oil development based on actual historical project data, shown in Figure 3. Firstly, the engineering parameters/factors that affect the investment in offshore oilfield projects are summarized and screened by referring to the literature and investigating actual engineering cases. Next, historical project data are collected from the National Bureau of Statistics of China, field practice data, industry statistics, and technical literature for statistical analysis. According to the collected historical data, multiple regression analysis is used to fit the investment calculation submodel. The integrated economic evaluation model considers various components of the deep-sea oil project and includes seven submodels: the geological reserve estimation model, drilling and completion model, underwater production system model, platform substructure model, platform upper chunk model (new FPSO), operation cost model and NPV model. Finally, the proposed economic evaluation method is applied to the evaluation and analysis of actual engineering cases, and uncertainty analysis is carried out through Monte Carlo simulation.

Figure 3.

Diagram of the realistic and integrated evaluation method.

3.1. Regression Analysis

Investment in each part of an offshore oilfield project is influenced by a variety of factors. Screening the main factors and quantifying the impact of each factor on investment is a key step in this research. Based on historical project data, this research introduces multiple regression to fit the investment calculation submodel. In this way, the structure of the submodel can be determined, including model variable types (main factors) and model coefficients (influence degree). The data originate from the National Bureau of Statistics of China [31], field practice data, industry statistics, and technical literature [32,33,34]. The specific multiple regression method is shown in Appendix A. The regression analysis results are shown in the introduction of each submodel in Section 3.2.

3.2. Integrated Economic Evaluation Models

3.2.1. Geological Reserve Estimation Model

The geological reserve model is the basis of economic evaluation. It is used to evaluate the original oil storage of the target reservoir and can help calculate the recoverable reserves and the production of associated gas and produced water. The calculation result is the foundation for determining the number of wells, FPSO capacity, field life and so on. In this paper, the volume method is used to estimate the original oil storage of the target reservoir [39]. It is the most commonly used static method. It is measured by reservoir volume, oil saturation, and rock porosity. The specific geological reserve model is shown in Equations (1)–(4):

where N is the original oil storage [m3], A is the drainage area [m2], h is the net pay thickness [m], is the porosity, fraction, S is the oil saturation, fraction, B is the formation volume factor, Poil is the recoverable reserves [m3], RF is recovery factor, Pgas is the associated gas [m3], GOR is the gas and oil ratio, Pwater is the produced water [m3] and RW is water cut.

3.2.2. Drilling and Completion Model

Based on the project survey and literature review, three factors are identified as the main drivers affecting the cost of drilling and completion: well depth, water depth, and drilling cycle. The greater the well depth, the more difficult it is to drill. The greater the water depth of the target reservoir, the greater the difficulty of operation. These lead to higher requirements for drilling and completion technology and equipment, and the corresponding higher costs. Additionally, longer drilling cycles result in longer operation times and higher drilling costs. To describe the relationship between drilling and completion costs and the above factors, the project parameters of six wells were collected for regression analysis, as seen in Table 1. The expression of the drilling and completion model is shown in Equation (5):

where Cwell is the cost of drilling and completion [million USD], Dewater is the water depth [m], Dewell is the well depth [m] and Tdrilling is the drilling cycle. Estimates for each parameter are derived from historical project data and the regression model: β1 = 0.0111, β2 = 0.0006, β3 = 0.1069.

Table 1.

Project parameters of six wells.

3.2.3. Underwater Production System Model

The investment composition of the underwater production system is extremely complex, but in general, all costs are related to the number of underwater wells, pipeline length, and pipeline diameter. Thus, the number of underwater wells, pipeline length, and pipeline diameter are selected as independent variables to develop the multiple regression model, as shown in Equation (6). In total, 24 sets of underwater production data are collected. Statistics show that the cost ranges from 491.40 million USD to 1407.10 million USD with an average of 809.30 million USD. The number of wells is between 5 and 15. The pipeline diameter is between 2 inches and 16 inches, and the pipeline length ranges from 10 km to 30 km with an average of 20 km.

where Cunderwater is the cost of the underwater production system [million USD], Lpipeline is the pipeline length [km], Dpipeline is the pipeline diameter [in] and Nwell is the number of wells. Estimates for each parameter are derived from historical project data and the regression model: β1 = 17.484, β2 = 2.912, β3 = 56.312.

3.2.4. Platform Substructure Model

The platform substructure mainly carries oil processing facilities and is not equipped with operators. Its investment cost is mainly affected by the water depth of the sea area and the weight and volume of treatment facilities on the upper block, while the weight and volume of treatment facilities depend on the treatment capacity. Therefore, in this module, this paper chooses water depth, oil storage capacity, and gas and water treatment volume as the independent variables for regression analysis, as shown in Equation (7). The cost ranges from 100 million USD to 1800 million USD with an average of 446.36 million USD. The oil storage capacity is between 88.25 million bbl and 2800 million bbl with an average of 1180.05 million bbl. The production of gas is between 4 mmscfd and 950 mmscf with an average of 147.49 mmscf, and the production of water is between 12 million bbl and 391 million bbl with an average of 96.25 million bbl. The water depth ranges from 26.82 m to 2200.05 m with an average of 592.03 m.

where Cplatform substructure is the cost of platform substructure [million USD], Soil is the oil storage capacity [million bbl], Pgas,day is the daily production of gas [mmscf], Pwater,day is the daily production of water [million bbl] and Dewater is the water depth [m]. Estimates for each parameter are derived from historical project data and the regression model: β1 = 0.1130, β2 = 0.3290, β3 = 2.6630, β4 = 0.0929.

3.2.5. Platform Upper Chunk Model

The platform upper chunk integrates production and life and is equipped with oil, gas, and water treatment facilities and public living facilities for employees. The principle of equipment configuration is to meet the demand for oil, gas, and water treatment. Thus, oil production and gas production are selected as the independent variables of regression analysis for the platform upper chunk model, as shown in Equation (8). Statistics show that the cost ranges from 782.32 million USD to 1813.92 million USD, with an average of 1265.53 million USD. The oil production is between 50 million bbl and 350 million bbl with an average of 202.78 million bbl, and the gas production is between 27 mmscf and 1850 mmscf with an average of 677.25 mmscf.

where Cplatform upper is the cost of platform upper chunk [million USD], Poil,day is the daily production of oil [million bbl] and Pgas,day is the daily production of gas [mmscf]. Estimates for each parameter are derived from historical project data and the regression model: β1 = 1.757, β2 = 0.490.

3.2.6. Operation Cost Model

Operation costs are the daily cost of maintaining normal production, which is complicated in composition, including fuel consumption, equipment maintenance, communication, insurance, environmental protection and so on. Operation costs are based on production demand and operation environment. Therefore, oil production, water depth, and distance from shore are selected as independent variables for regression analysis, as shown in Equation (9). Statistics show that the operation cost ranges from 4.63 USD/bbl to 7.93 USD/bbl with an average of 6.02 USD/bbl. The oil production is between 100 million bbl and 200 million bbl, with an average of 150 million bbl. The water depth ranges from 1500 m to 2500 m with an average of 2000 m. The distance from shore ranges from 100 m to 300 m with an average of 200 m.

where Coperation is the operation cost [USD/bbl], Dewater is the water depth [m], Poil,day is the daily production of oil [bbl] and Dis is the distance from shore [m]. Estimates for each parameter are derived from historical project data and the regression model: β1 = −0.029, β2 = 0.00034, β3 = 0.0016.

3.2.7. NPV Model

Based on the six submodels established above, the overall economic evaluation model of offshore oil development projects, namely the NPV model, is established. Referring to the research work of Rui et al. [23], project revenue comes from the sale of oil and gas. Project expenditures include project construction investment, operation costs, oil and gas royalty fee, and income tax. The NPV model is as follows in Equations (10)–(15):

where GRt is annual oil and gas sales revenue [million USD/year], Coil is the oil price [USD/bbl], Cgas is the gas price [USD/m3], Poil,t is annual oil production [million bbl/year], Pgas,t is annual gas production [million m3], ROt is oil and gas royalty fee [million USD/year], Rroyalty is royalty rate [%], NRt is annual operation profit [million USD/year], Cinvest,t is annual investment cost [million USD/year], Coperation,t is annual operation cost [million USD/year], TRt is the income tax rate [%], NCFt is annual net cash flow [million USD/year], NPV is the net present value [million USD] and r is the discounted rate [%].

4. Case Studies

An oil field development project in Bohai Bay, China is taken as a case for economic evaluation. The project is far from the mainland and is located in the deep sea. The new FPSO all-sea type is adopted as the development mode.

4.1. Basic Data

The distribution of the input parameters for the integrated model is given in Table 2. Input parameters include geological parameters, environmental parameters, technical parameters, and economic parameters. The base, minimum, and maximum of the input parameters are collected to reflect the uncertainty realistically. Monte Carlo simulation is used for uncertainty analysis. It is assumed that each uncertain parameter follows a triangular distribution.

Table 2.

Input parameters of the model.

4.2. Results and Discussion

4.2.1. Economic Benefit Analysis

Based on the oil price of 45 USD/bbl, the economic performance of the case is calculated using the proposed integrated economic evaluation model. It can be seen from Table 2 that the total investment in the offshore oil development project is 3066.62 million USD. The revenue is about 14,732.39 million USD, which can create a royalty fee of 1473.24 million USD and a tax of 882.74 million USD. The NPV of the project is 369.09 million USD, which means that the project can create economic benefits.

Considering the uncertainty of input parameters, it is found through Monte Carlo simulation that the economic evaluation results of the project will fluctuate within a relatively large range, as shown in Table 3. In the worst case, the NPV is only −1880.67 million USD, which is much less than 0, but in the best case, the NPV value can be as high as 7839.33 million USD, showing great economic potential. Therefore, it is very necessary to conduct uncertainty analysis and sensitivity analysis on the input parameters of the model to provide theoretical support for decision makers to effectively avoid risks.

Table 3.

The outcome of the integrated economic evaluation model.

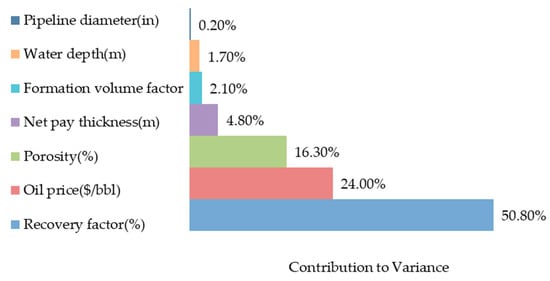

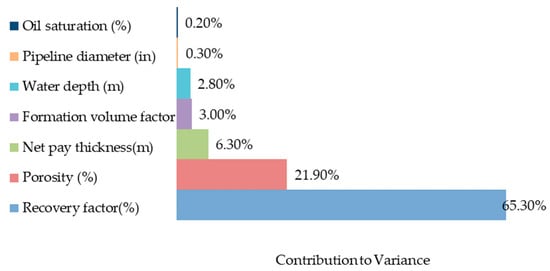

4.2.2. Sensitivity Analysis of All Parameters

The impact of uncertain factors in project development has a greater impact on the economic evaluation, and may even cause the economic evaluation results to be opposite. Therefore, it is necessary to extract and analyze the uncertain factors involved in the project development process to improve the robustness of economic evaluation. In this study, the Monte Carlo simulation method is used for sensitivity analysis to analyze the influence of uncertain input parameters on NPV. The results are shown in Figure 4. In the figure, the importance of all input parameters is ranked according to the contribution variance, followed by recovery factor, oil price, porosity, net pay thickness, formation volume factor, water depth, and pipeline diameter.

Figure 4.

Sensitivity analysis of all parameters.

In total, 50.80% of the NPV variation is caused by the uncertainty of the recovery factor, and 24.00% of the NPV variation is caused by the uncertainty of oil price. The remaining 25.2% is due to porosity, net pay thickness, formation volume factor, water depth, and pipeline diameter. These show that oil production and oil price are important factors in determining whether the project is economically viable. The output of the project is constrained by both internal and external factors. Among them, reservoir parameters are internal factors such as porosity, net pay thickness, and formation volume factor. The recovery factor is an external factor, determined by the mining technology. The oil price is determined by the market and is a factor beyond the control of policymakers. To avoid decision-making risks as much as possible, it is necessary to further analyze the specific impact of the oil price and the impact of other important parameters based on possible oil prices on the economic evaluation.

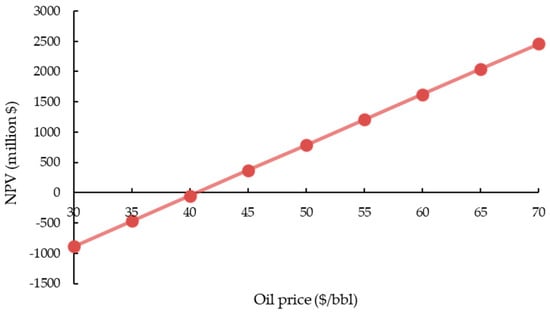

4.2.3. Sensitivity Analysis of Oil Price

Sensitivity analysis shows that the oil price is an important external factor affecting the economic benefit of offshore oil development projects. Especially in the context of the low oil price, the level of oil price determines the profitability of oilfield projects to a large extent. This paper chooses NPV as the key performance indicator for project economic evaluation. NPV = 0 is the key node of economic evaluation. If the NPV is positive, it means that the project is profitable, and investment in the project will be considered. Otherwise, the project cannot create economic value, and investment in the project will not be considered. The relationship between the NPV and oil prices is shown in Figure 5. When oil prices rise from 30 USD/barrel to 70 USD/barrel, the NPV increases from −886.48 million USD to 2461.70 million USD. For this offshore oilfield project, the oil price of 40.59 USD/bbl is identified as the breakeven oil price, which is the oil price when NPV = 0. This means that for this project, when the oil price is greater than 40.59 USD/bbl, the project can create economic benefits and investment can be considered.

Figure 5.

NPV under different oil prices (without considering uncertainty).

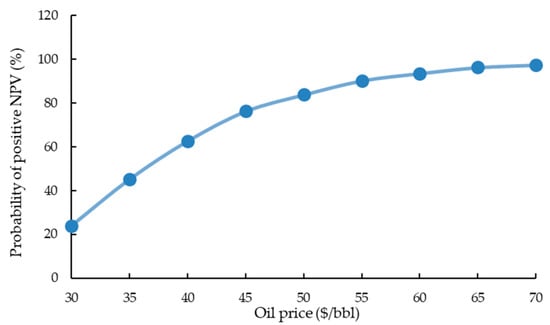

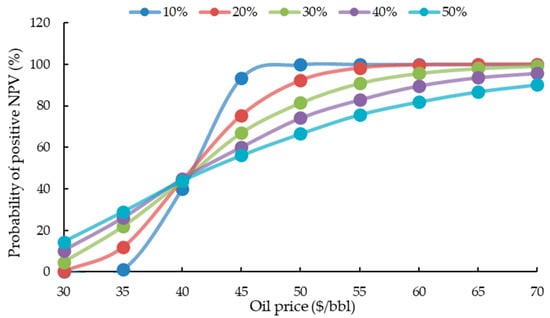

The above analysis of the oil price is carried out using the base of other parameters and does not take into account the uncertainty of other parameters. Then, considering the uncertainty of other parameters, Monte Carlo simulation is applied to analyze the probability of NPV > 0 under different oil prices (Figure 6). As can be seen from the figure, the probability of NPV > 0 increases as oil prices rise. When the oil price is above 70 USD/bbl, the probability of a positive NPV is 97.39%, and when the oil price is below 30 USD/bbl, the probability of a positive NPV is 23.98%. The results indicate that when the oil price is higher than 70 USD/bbl, this offshore oilfield project will be economically feasible, but when the oil price is lower than 30 USD/bbl, the project has a great risk of being unprofitable, and investors need to make a prudent decision.

Figure 6.

Probability of positive NPV under different oil prices (considering uncertainty).

4.2.4. Sensitivity Analysis of Parameters under Low Oil Price

In recent years, affected by political, economic, market, and other factors, international oil prices have continued to decline. Especially under the influence of the current COVID-19 pandemic, the international oil price situation is not optimistic. This requires decision makers to fully understand the factors affecting project development in the context of low oil prices to guide decision making. Based on the low oil price of 40 USD/bbl, this paper uses Monte Carlo simulation to analyze the impact of the uncertainty of the reservoir parameters, environmental parameters, and technical parameters on the economic benefits of the project, as shown in Figure 7. It can be seen from the figure that the recovery factor is still the most important, accounting for 65.30%, followed by reservoir geological parameters (porosity, net pay thickness, and formation volume factor). It is worth noting that the water depth also has a great impact on the economic benefits of the project. Technical parameters, such as pipeline diameter, also have a certain influence. This shows that in the context of low oil prices, how to improve reservoir recovery is still the key to ensuring economic benefits. In the face of a low oil price market, increasing production is still the most effective strategy to ensure the economic viability of the project. In addition, low oil prices will lead to more factors, such as pipeline diameter affecting the economics of the project. Therefore, decision makers also need to reduce project construction investment as much as possible to reduce investment risks.

Figure 7.

Sensitivity analysis of parameters under low oil price.

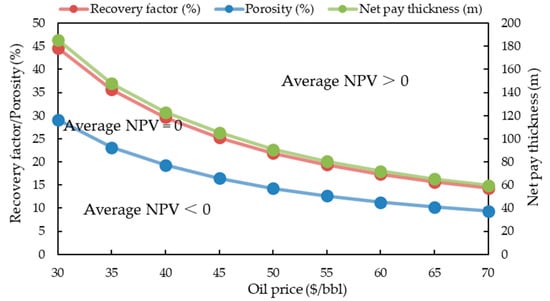

The following takes the top three factors (recovery factor, porosity and net pay thickness) with the greatest influence as the research object, and analyzes their key profit curves under different oil price ranges from 30 USD/bbl to 70 USD/bbl. Changes in the above three parameters are controlled while maintaining the uncertainty of other parameters. The goal is to find the value of each parameter corresponding to different oil prices when the NPV average is equal to 0. The simulation results of key profit curves are shown in Figure 8. In the figure, taking NPV average = 0 as the dividing line, the left side of the curve represents that the NPV average is less than 0, and the right side of the curve represents that the NPV average is greater than 0. For the recovery factor, lower oil prices bring higher requirements for recovery. When the oil price is as low as 40 USD/bbl, the recovery factor is at least 29.65% to guarantee an average NPV of 0. This means that the recovery factor must be at least 29.65% to have a greater probability of obtaining considerable economic value. As the oil price rises, the expected economic benefits can be achieved even with a lower recovery factor. When the oil price is as high as USD70/bbl, and the recovery rate is greater than 14.32%, the probability of obtaining economic returns is greater. Similarly, when the oil price is as low as 40 USD/bbl, the porosity needs to be greater than 19.32% and the net pay thickness needs to be greater than 123 m to ensure that the project has a greater possibility of obtaining economic benefits. When the oil price is as high as 70 USD/bbl, the porosity only needs to be greater than 9.34% and the net pay thickness only needs to be greater than 59.7 m to ensure that the project has a greater possibility of obtaining economic benefits.

Figure 8.

Key profit curves of reservoir parameters.

4.2.5. Influence of Parameter Uncertainty under Different Oil Prices

To further analyze the influence of parameter uncertainty on project economics, we adjust the fluctuation range of parameters. The wider the fluctuation range of the parameter, the greater the uncertainty of the parameter. By Monte Carlo Simulation, the probability of positive NPV as oil prices change under different fluctuation ranges of parameters is calculated. The influence of parameter uncertainty on NPV is shown in Figure 9. In Figure 9, the ordinate is the probability that the project’s NPV is greater than 0. Different legends reflect the fluctuation range of uncertain parameters; 10% means that the uncertain parameter changes within 10% of the reference value. As can be seen from the figure, in the case of low oil prices, parameter uncertainty has a favorable impact on the economic evaluation of the project. Greater parameter uncertainty brings a greater probability of positive NPV. As oil prices rise, the influence of parameter uncertainty gradually changes. In the case of higher oil prices, the increase in parameter uncertainty will reduce the probability of positive NPV. This is because low oil prices will reduce the probability of positive NPV, while the uncertainty of other parameters may increase NPV in this case. When the oil price rises to 40 USD/bbl, the oil price began to show economic potential, and the uncertainty of other parameters began to show more adverse effects. In addition, it is found that even if the project is affected by the uncertainty of other parameters, the impact of oil prices on project economics is still crucial. As oil prices rise, the impact of parameter uncertainty gradually decreases. When the oil price is higher than 65 USD/bbl, the influence of parameter uncertainty slows down with the change in oil price and the probability of positive NPV even approaches 100% with the fluctuation range of 10%, 20%, and 30%.

Figure 9.

Probability of positive NPV under different oil prices (considering fluctuation range).

5. Conclusions

Based on actual historical project data, this paper develops a realistic and integrated economic evaluation model for offshore oil development projects, including drilling and completion module, underwater production system module, platform substructure module and platform upper chunk module. Monte Carlo simulation is used to analyze the impact of oil prices, reservoir parameters, environmental parameters, and technical parameters on the economic benefits of offshore oil projects, providing support for investors to avoid risks.

(1) Through regression analysis, the quantitative relationship between the main parameters and costs in each submodule is given, and the integrated evaluation model of offshore oil development projects is established to guide investment decisions.

(2) In the project evaluation of the case, the four most influential factors are the recovery factor, oil price, porosity, and net pay thickness, and their uncertainty brings about 95.9% of NPV variation. The recovery factor and oil price are the most important factors affecting project economics. In the case of low oil prices, investors should focus on how to enhance oil recovery and minimize construction investment.

(3) Based on sensitivity analysis, this paper focuses on the impact of oil prices. In the case of deterministic analysis, the breakeven oil price of the project is 40.59 USD/bbl. When the oil price is as low as 30 USD/bbl, the probability of NPV > 0 is extremely low, about 23.98%, but when the oil price is higher than 70 USD/bbl, the probability of NPV > 0 is as high as 97.39%, showing great economic potential. In addition, when the oil price is higher than 70 USD/bbl, the economic benefit of the project will be less affected by parameter uncertainty, and it will show a very high probability of profitability. These data can provide decision support for the preliminary investment evaluation of the project.

In summary, this integrated model can provide decision makers with realistic and confident results for investing in offshore oil development projects to reduce investment risk. The proposed model is general, but the quantity and quality of historical project data greatly affect the accuracy and reliability of the project’s economic evaluation. For different types of offshore oil fields, the model submodules should be updated according to their characteristics, and the cost calculation models of the submodules with higher applicability should be fitted based on specific historical data.

Author Contributions

Conceptualization, R.Q.; methodology, R.Q. and Q.Z.; validation, Z.L. and X.Y., and S.X.; investigation, R.Q., Q.Z., and B.W.; writing—original draft preparation, R.Q. and Q.Z.; writing—review and editing, Q.L. and B.W.; visualization, Q.L.; funding acquisition, B.W. All authors have read and agreed to the published version of the manuscript.

Funding

This work was funded by the Science Foundation of Zhejiang Ocean University [11025092122].

Informed Consent Statement

Not applicable.

Data Availability Statement

The data presented in this study are available on request from the corresponding author.

Acknowledgments

The authors are grateful to all study participants.

Conflicts of Interest

The authors declare no conflict of interest.

Appendix A. Regression Analysis

Regression analysis is a method of evaluating the relationship between two or more variables [40]. It can represent the important relationship between the dependent variable and the independent variable and the degree of influence of multiple independent variables on the dependent variable. In this study, reservoir parameters, environmental parameters and technical parameters of offshore oil projects are used as candidate independent variables, and project investment is used as dependent variables. Multiple linear regression analysis is applied for data analysis.

The basic model of multiple linear regression is as follows:

where yi is the dependent variable, xi is the independent variable, βi is the coefficient of the independent variable and εi is the estimation error, which is required to meet the following assumptions: the error term εi obeys a normal distribution; the expected value of the error term εi is zero, that is E(εi) = 0; the error term εi is not related to any observation value of the independent variable xi, namely COV(xi, εi) = 0. Additionally, it is required to meet the Gauss–Markov assumption. The specific expression is as follows:

The matrix expression of the above regression model is as follows:

Based on n sets of observations, the estimated values of the parameters in the regression model are calculated according to the principle of least squares. Therefore, the problem turns into finding a set of parameter estimates that minimize the residual sum of squares.

The overall investment of the project is classified according to its composition and divided into submodules. Through the above multiple linear regression method, based on the historical investment data, the cost calculation model of the submodule is fitted for subsequent economic analysis.

References

- Watson, S.M. Greenhouse gas emissions from offshore oil and gas activities—Relevance of the Paris Agreement, Law of the Sea, and Regional Seas Programmes. Ocean Coast. Manag. 2020, 185, 104942. [Google Scholar] [CrossRef]

- Rui, Z.; Li, C.; Peng, F.; Ling, K.; Chen, G.; Zhou, X.; Chang, H. Development of industry performance metrics for offshore oil and gas project. J. Nat. Gas Sci. Eng. 2017, 39, 44–53. [Google Scholar] [CrossRef]

- EIA. Oil and Petroleum Products Explained Offshore Oil and Gas; EIA: Washington, DC, USA, 2021. Available online: https://www.eia.gov/energyexplained/oil-and-petroleum-products/offshore-oil-and-gas-in-depth.php. (accessed on 9 March 2021).

- IEA. Offshore Energy Outlook; IEA: Paris, France, 2018; Available online: https://www.iea.org/reports/offshore-energy-outlook-2018. (accessed on 9 March 2021).

- Khan, F.; Ahmed, S.; Yang, M.; Hashemi, S.J.; Caines, S.; Rathnayaka, S.; Oldford, D. Safety challenges in harsh environments: Lessons learned. Process Safty Prog. 2014, 34, 191–195. [Google Scholar] [CrossRef]

- Rahman, M.S.; Khan, F.; Shaikh, A.; Ahmed, S.; Imtiaz, S. Development of risk model for marine logistics support to offshore oil and gas operations in remote and harsh environments. Ocean Eng. 2019, 174, 125–134. [Google Scholar] [CrossRef]

- Vidal, P.C.J.; González, M.O.A.; Vasconcelos, R.M.; Melo, D.C.; Ferreira, P.O.; Sampaio, P.G.V.; Silva, D.R. Decommissioning of offshore oil and gas platforms: A systematic literature review of factors involved in the process. Ocean Eng. 2022, 255, 111428. [Google Scholar] [CrossRef]

- Shi, X.; Variam, H.M.P. East Asia’s Gas-Market Failure and Distinctive Economics—A Case Study of Low Oil Prices. Appl. Energy 2017, 195, 800–809. [Google Scholar] [CrossRef]

- Wang, Y.; Estefen, S.F.; Lourenço, M.I.; Hong, C. Optimal Design and Scheduling for Offshore Oil-Field Development. Comput. Chem. Eng. 2019, 123, 300–316. [Google Scholar] [CrossRef]

- de Lucena, R.R.; Baioco, J.S.; de Lima, B.S.L.P.; Albrecht, C.H.; Jacob, B.P. Optimal Design of Submarine Pipeline Routes by Genetic Algorithm with Different Constraint Handling Techniques. Adv. Eng. Softw. 2014, 76, 110–124. [Google Scholar] [CrossRef]

- Rosa, V.R.; Camponogara, E.; Filho, V.J.M.F. Design Optimization of Oilfield Subsea Infrastructures with Manifold Placement and Pipeline Layout. Comput. Chem. Eng. 2018, 108, 163–178. [Google Scholar] [CrossRef]

- Hong, B.; Li, X.; Di, G.; Li, Y.; Liu, X.; Chen, S.; Gong, J. An Integrated MILP Method for Gathering Pipeline Networks Considering Hydraulic Characteristics. Chem. Eng. Res. Des. 2019, 152, 320–335. [Google Scholar] [CrossRef]

- Silva, L.M.R.; Soares, C.G. An Integrated Optimization of the Floating and Subsea Layouts. Ocean Eng. 2019, 191, 106557. [Google Scholar] [CrossRef]

- Wang, B.; Liang, Y.; Yuan, M.; Wang, J.; Zhang, H.; Li, X. Optimal Design of Oilfield Surface Pipeline Networks for the Cyclic Water Injection Development Method. J. Pet. Sci. Eng. 2018, 171, 1400–1408. [Google Scholar] [CrossRef]

- Gao, X.; Xie, Y.; Wang, S.; Wu, M.; Wang, Y.; Tan, C.; Zuo, X.; Chen, T. Offshore Oil Production Planning Optimization: An MINLP Model Considering Well Operation and Flow Assurance. Comput. Chem. Eng. 2020, 133, 106674. [Google Scholar] [CrossRef]

- Allahyarzadeh-Bidgoli, A.; Salviano, L.O.; Dezan, D.J.; de Oliveira Junior, S.; Yanagihara, J.I. Energy Optimization of an FPSO Operating in the Brazilian Pre-Salt Region. Energy 2018, 164, 390–399. [Google Scholar] [CrossRef]

- Veloso, T.G.C.; Sotomonte, C.A.R.; Coronado, C.J.R.; Nascimento, M.A.R. Multi-Objective Optimization and Exergetic Analysis of a Low-Grade Waste Heat Recovery ORC Application on a Brazilian FPSO. Energy Convers. Manag. 2018, 174, 537–551. [Google Scholar] [CrossRef]

- Reis, M.M.L.; Gallo, W.L.R. Study of Waste Heat Recovery Potential and Optimization of the Power Production by an Organic Rankine Cycle in an FPSO Unit. Energy Convers. Manag. 2018, 157, 409–422. [Google Scholar] [CrossRef]

- Kim, H.; Yoo, W.; Lim, Y.; Seo, Y. Economic Evaluation of MEG Injection and Regeneration Process for Oil FPSO. J. Pet. Sci. Eng. 2018, 164, 417–426. [Google Scholar] [CrossRef]

- de Andrade Cruz, M.; Araújo, O.D.Q.F.; de Medeiros, J.L. Deep Seawater Intake for Primary Cooling in Tropical Offshore Processing of Natural Gas with High Carbon Dioxide Content: Energy, Emissions and Economic Assessments. J. Nat. Gas Sci. Eng. 2018, 56, 193–211. [Google Scholar] [CrossRef]

- Wang, B.; Liang, Y.; Yuan, M. Water Transport System Optimisation in Oilfields: Environmental and Economic Benefits. J. Clean. Prod. 2019, 237, 117768. [Google Scholar] [CrossRef]

- Wang, B.; Liang, Y.; Zheng, T.; Yuan, M.; Zhang, H. Multi-Objective Site Selection Optimization of the Gas-Gathering Station Using NSGA-II. Process Saf. Environ. Prot. 2018, 119, 350–359. [Google Scholar] [CrossRef]

- Rui, Z.; Wang, X.; Zhang, Z.; Lu, J.; Chen, G.; Zhou, X.; Patil, S. A Realistic and Integrated Model for Evaluating Oil Sands Development with Steam Assisted Gravity Drainage Technology in Canada. Appl. Energy 2018, 213, 76–91. [Google Scholar] [CrossRef]

- Jeff, J. Steam Drive Model for Hand-Held Programmable Calculators. J. Pet. Technol. 1981, 33, 1583–1598. [Google Scholar]

- Sawhney, G.S.; Liebe, H.; Butler, R.M. Vertical Injection Wells For Sagd: A Practical Option Or Not? J. Can. Pet. Technol. 1995, 34, PETSOC-95-01-06. [Google Scholar] [CrossRef]

- Saini, D.; Jimenez, I.; Reedy, C.D.; Houghton, M. A Pseudo-SAGD Scoping Model for Evaluating Economic Viability of Heavy Oil Projects. J. Pet. Sci. Eng. 2016, 137, 125–133. [Google Scholar] [CrossRef]

- Wei, N.; Li, X.; Dahowski, R.T.; Davidson, C.L.; Liu, S.; Zha, Y. Economic Evaluation on CO2-EOR of Onshore Oil Fields in China. Int. J. Greenh. Gas Control 2015, 37, 170–181. [Google Scholar] [CrossRef]

- Jiang, J.; Rui, Z.; Hazlett, R.; Lu, J. An Integrated Technical-Economic Model for Evaluating CO2 Enhanced Oil Recovery Development. Appl. Energy 2019, 247, 190–211. [Google Scholar] [CrossRef]

- Mejean, A.; Hope, C. Modeling the costs of non-conventional oil: A case study of Canadian bitumen. Energy Policy 2008, 36, 4205–4216. [Google Scholar] [CrossRef]

- Giacchetta, G.; Leporini, M.; Marchetti, B. Economic and environmental analysis of a steam assisted gravity drainage (SAGD) facility for oil recovery from Canadian oil sands. Appl. Energy 2015, 142, 1–9. [Google Scholar] [CrossRef]

- National Bureau of Statistics of China, National Bureau of Statistics of China. Available online: http://data.stats.gov.cn/ (accessed on 3 February 2021).

- Chang, Y.; Wu, X.; Chen, G.; Ye, J.; Chen, B.; Xu, L.; Zhou, J.; Yin, Z.; Ren, K. Comprehensive risk assessment of deepwater drilling riser using fuzzy Petri net model. Process Saf. Environ. Prot. 2018, 117, 483–497. [Google Scholar] [CrossRef]

- Liu, M.; Wu, W.; Tang, D.; Ma, H.; Naess, A. Current profile analysis and extreme value prediction in the LH11-1 oil field of the South China Sea based on prototype monitoring. Ocean Eng. 2018, 153, 60–70. [Google Scholar] [CrossRef]

- Huang, W.; Gao, D. Analysis of drilling difficulty of extended-reach wells based on drilling limit theory. Pet. Sci. 2022, 19, 1099–1109. [Google Scholar] [CrossRef]

- Guedes, J.; Santos, P. Valuing an Offshore Oil Exploration and Production Project through Real Options Analysis. Energy Econ. 2016, 60, 377–386. [Google Scholar] [CrossRef]

- Wang, B.; Liang, Y.; Zheng, J.; Lei, T.; Yuan, M.; Zhang, H. A Methodology to Restructure a Pipeline System for an Oilfield in the Mid to Late Stages of Development. Comput. Chem. Eng. 2018, 115, 133–140. [Google Scholar] [CrossRef]

- Hamzah, B.A. International Rules on Decommissioning of Offshore Installations: Some Observations. Mar. Policy 2003, 27, 339–348. [Google Scholar] [CrossRef]

- Chandler, J.; White, D.; Techera, E.J.; Gourvenec, S.; Draper, S. Engineering and Legal Considerations for Decommissioning of Offshore Oil and Gas Infrastructure in Australia. Ocean Eng. 2017, 131, 338–347. [Google Scholar] [CrossRef]

- Caldwell, R.H.; Heather, D.I. How to evaluate hard to evaluate reserves. J. Pet. Technol. 1991, 43, 998–1000. [Google Scholar] [CrossRef]

- Di Leo, S.; Caramuta, P.; Curci, P.; Cosmi, C. Regression Analysis for Energy Demand Projection: An Application to TIMES-Basilicata and TIMES-Italy Energy Models. Energy 2020, 196, 117058. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).