Chloride Ingress Resistance, Microstructure and Mechanical Properties of Lightweight Mortars with Natural Cork and Expanded Clay Prepared Using Sustainable Blended Cements

Abstract

:1. Introduction

2. Materials and Methods

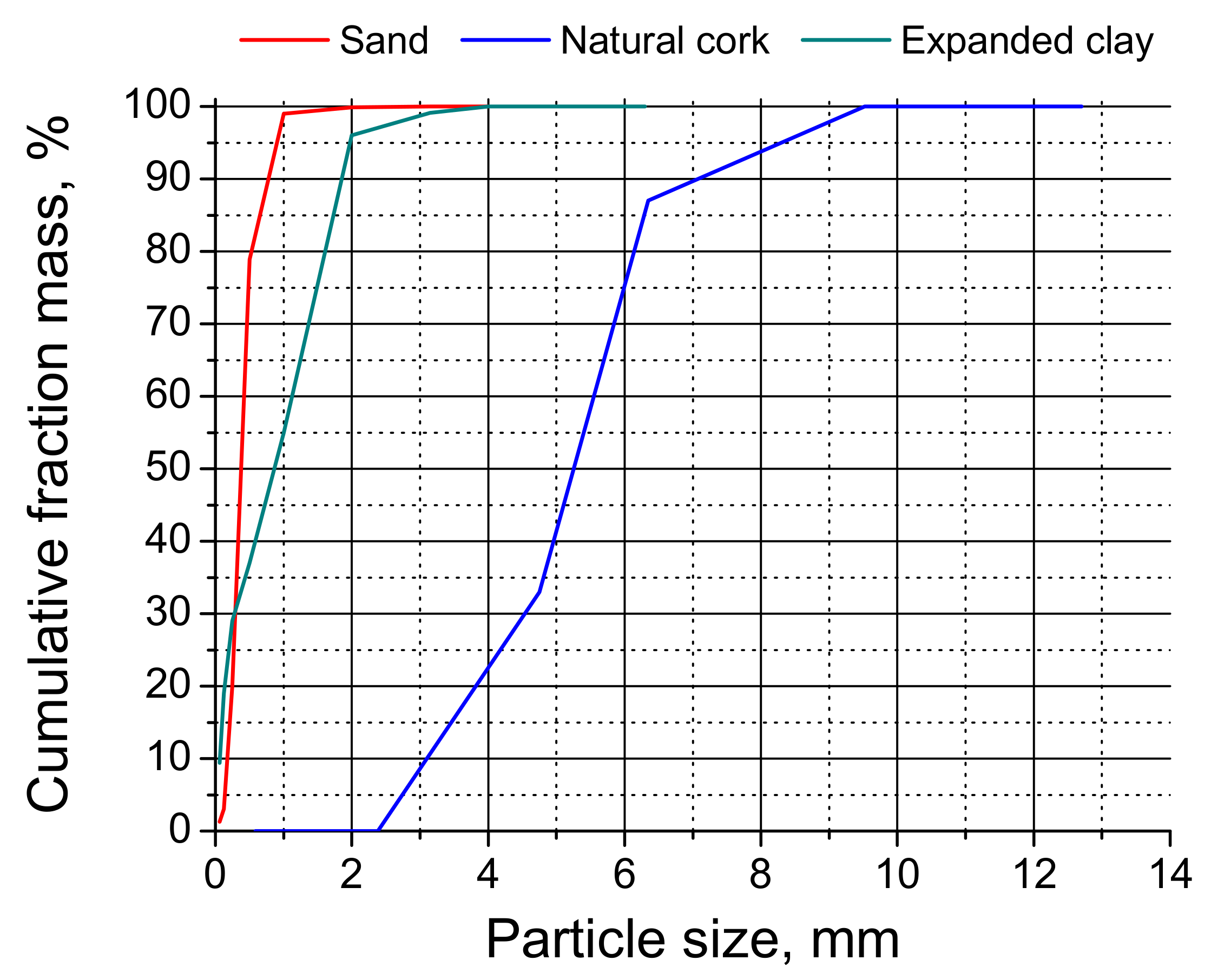

2.1. Materials and Sample Preparation

2.2. Mercury Intrusion Porosimetry

2.3. Forced Migration Test

2.4. Mechanical Strengths

3. Results and Discussion

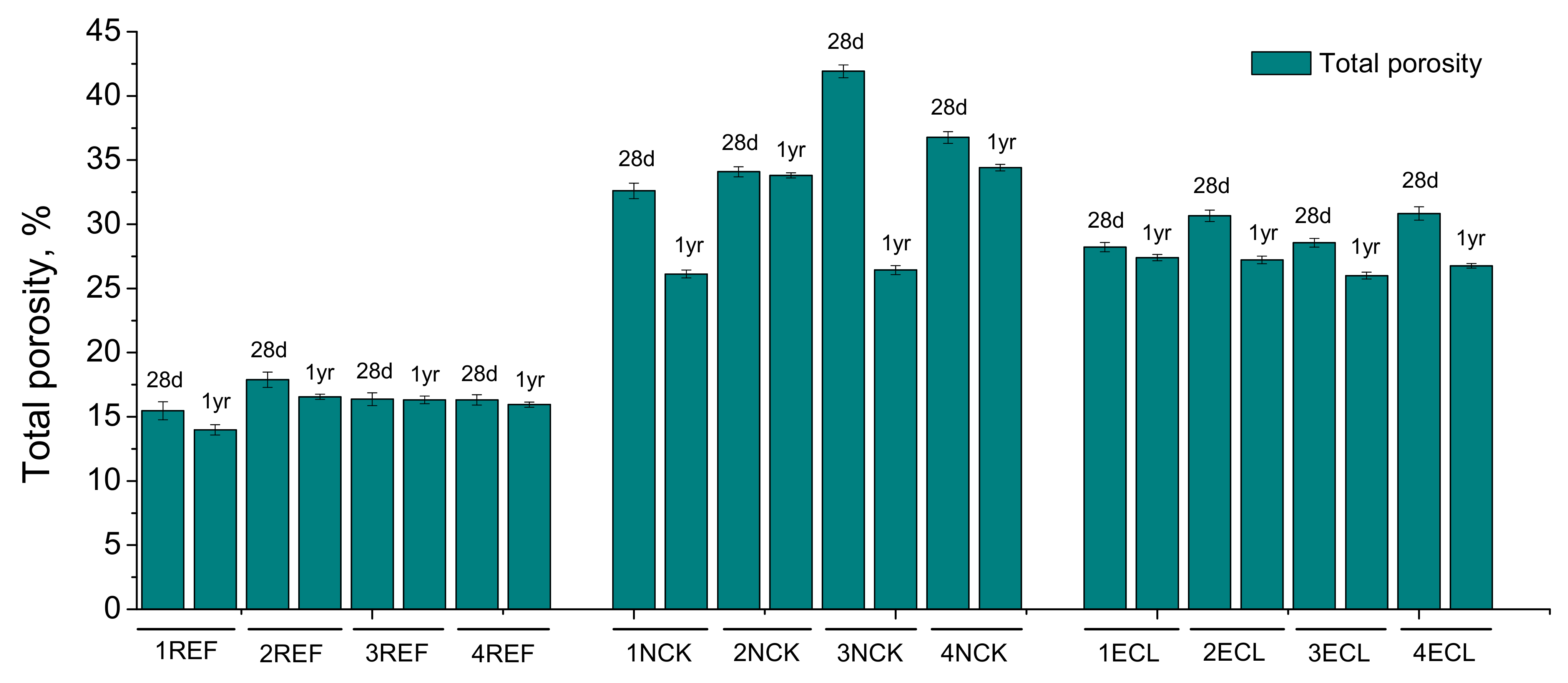

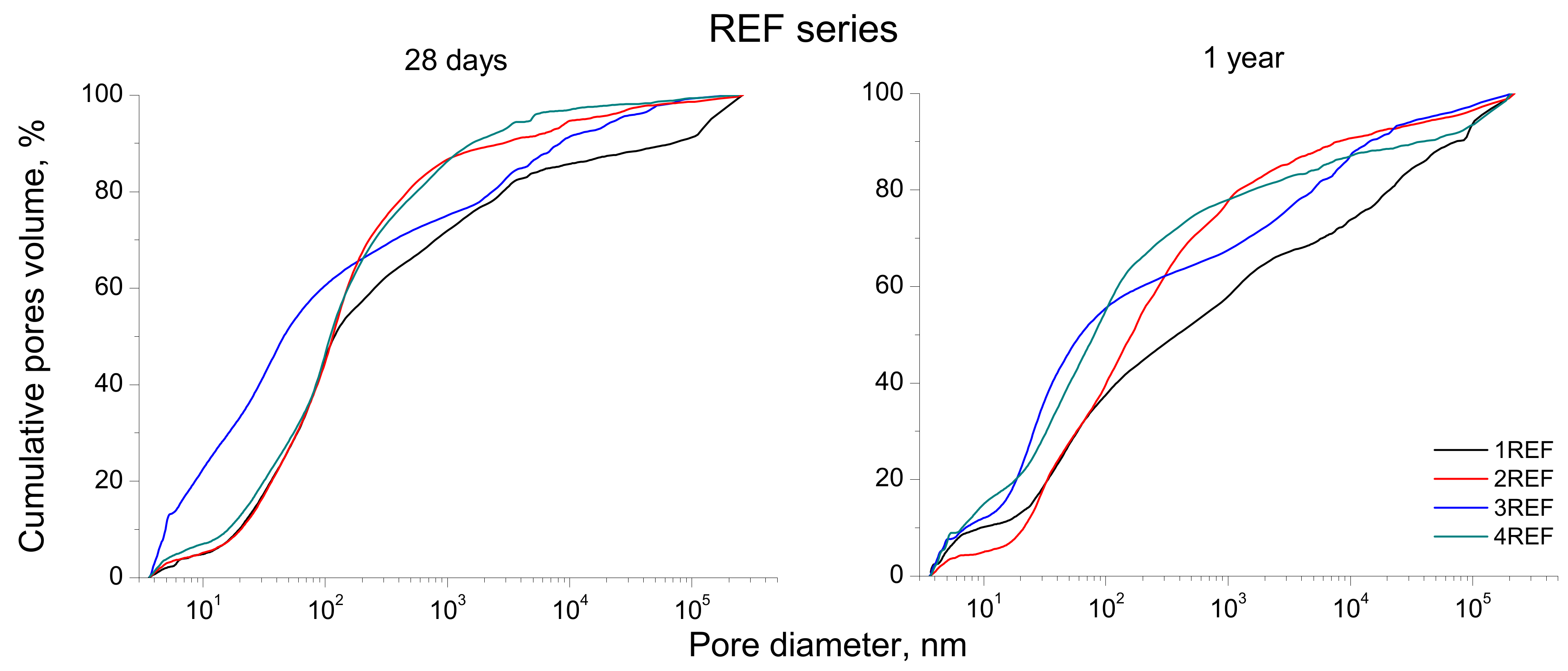

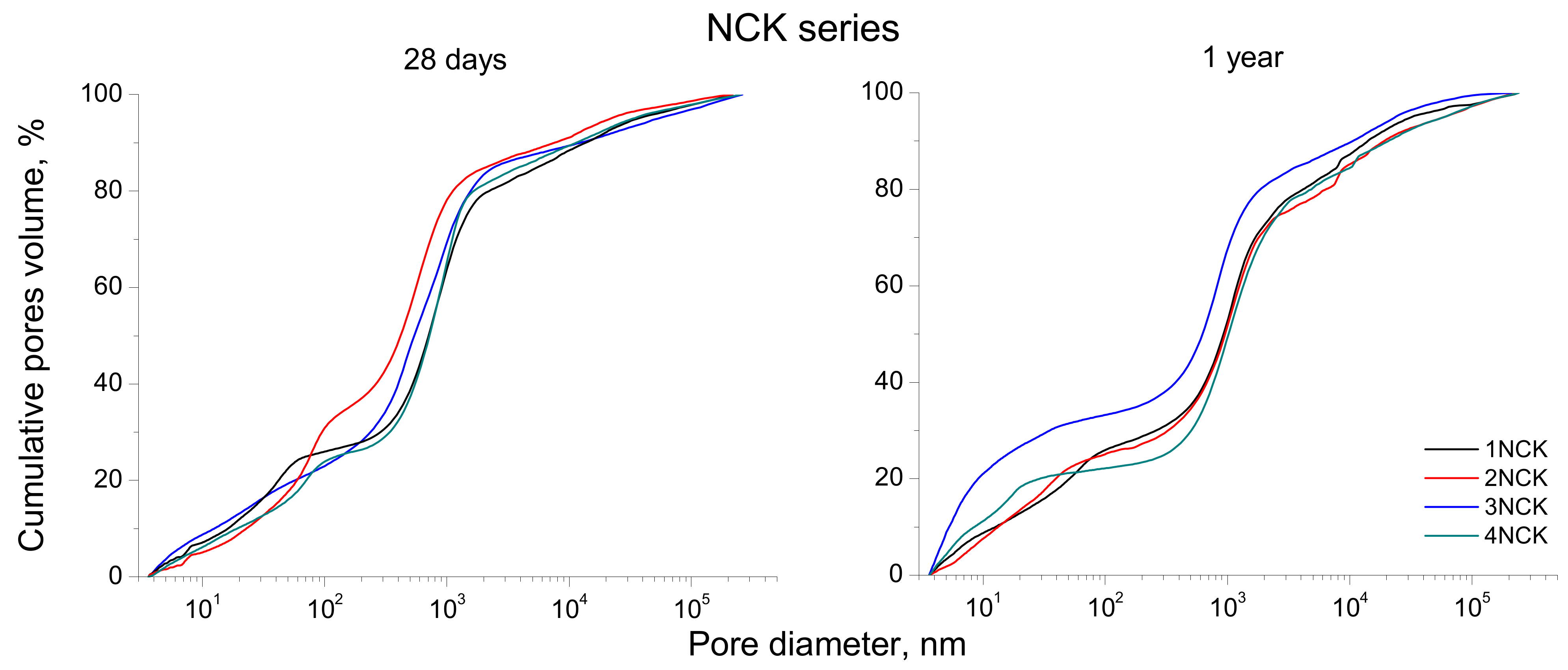

3.1. Mercury Intrusion Porosimetry

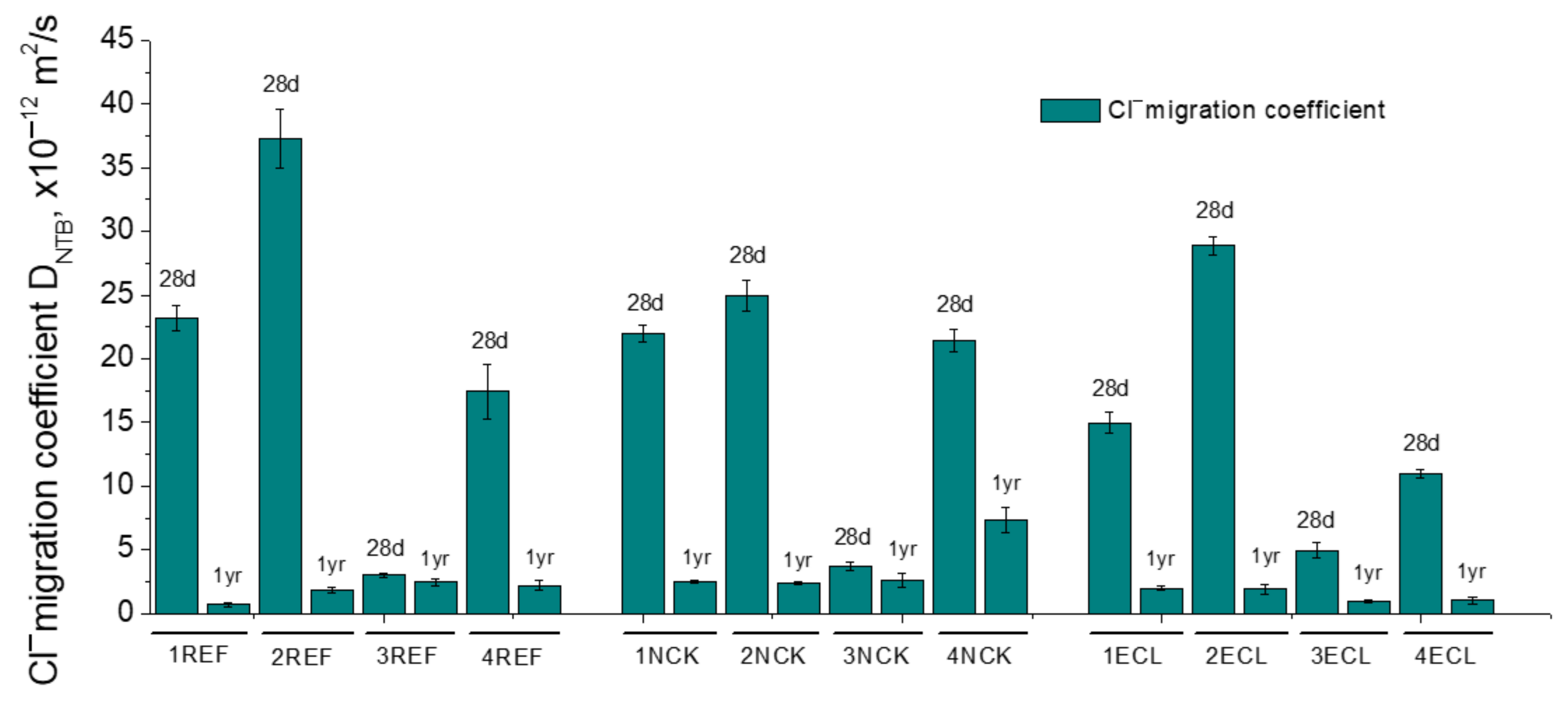

3.2. Non-Steady-State Chloride Migration Coefficient

3.3. Mechanical Strengths

4. Conclusions

- The lowest total porosity in the long term was generally obtained for reference mortars without lightweight aggregates. The total porosity differences between the series with natural cork and with expanded clay were not high, depending on the binder used.

- The series with natural cork showed a lower refinement of the microstructure compared with the reference mortars and those with expanded clay. Furthermore, it was observed that the pore size distributions of the natural cork mortars in the short term were mainly affected by the aggregate, with the binder having less influence.

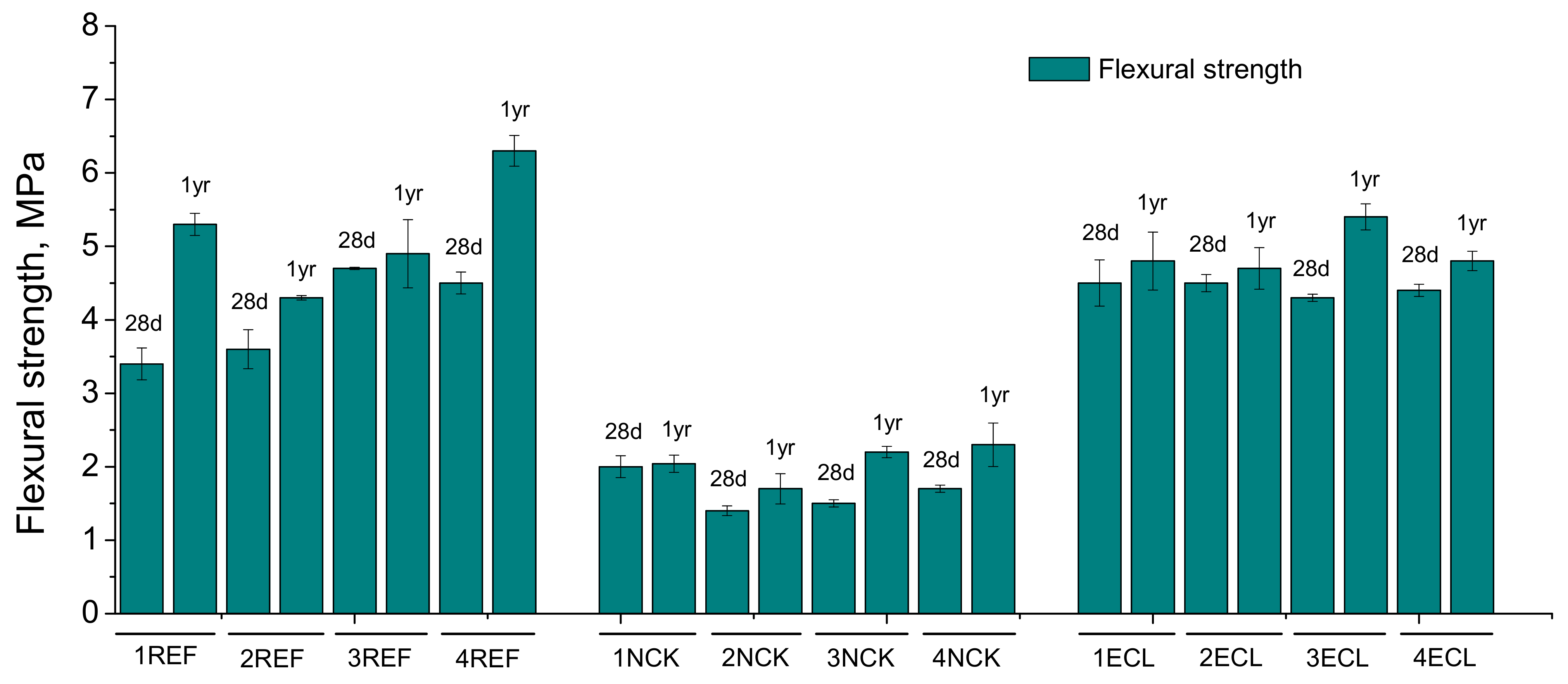

- A decrease in the total porosity and rise in the refinement of pores with time were observed for most of the mortar series studied, independently of the aggregate used. This evolution of the microstructure would improve the other parameters analyzed, resulting in a lessening with the hardening time of the non-steady-state chloride migration coefficient and a rise in the mechanical strengths.

- The binder used in the mortars played an important role in the results of the nonsteady-state chloride migration coefficient, especially at 28 days. It is remarkable that the studied mortars with natural cork showed similar or slightly higher migration coefficients than the reference and expanded clay mortars for each one of the binders studied at 1 year.

- Both the compressive and flexural strengths were greatly influenced by the type of aggregate. The mortars with natural cork had lower mechanical strengths than the reference series and those prepared with expanded clay, for all the studied binders.

- For each one of the aggregates studied, at the initial ages, the mortars with slag overall showed higher microstructure refinement, a lower chloride migration coefficient and greater compressive strength compared with the other studied binders.

- In view of the results obtained, it is noteworthy to underline the adequate long-term performance of the studied mortars with natural cork in relation to chloride ingress resistance, and in comparison with a standardized and commonly used lightweight aggregate, such as expanded clay. This adequate chloride ingress resistance, combined with the low mechanical strengths produced by the incorporation of natural cork, would recommend the possible use of this lightweight aggregate in non-structural cement-based materials for civil engineering works exposed to maritime environments. Furthermore, the use of binders with active additions, and especially blast-furnace slag, overall improved the behavior of mortars with natural cork at later ages.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Hammond, G.P.; Jones, C.I. Embodied energy and carbon in construction materials. Proc. Inst. Civ. Eng. Energy 2008, 161, 87–98. [Google Scholar] [CrossRef]

- Qualharini, E.L.; Oscar, L.H.C.; Silva, M.R.D. Rehabilitation of buildings as an alternative to sustainability in Brazilian constructions. Open Eng. 2019, 9, 139–143. [Google Scholar] [CrossRef]

- Mália, M.; de Brito, J.; Pinheiro, M.D.; Bravo, M. Construction and demolition waste indicators. Waste Manag. Res. 2013, 31, 241–255. [Google Scholar] [CrossRef]

- de Brito, J.; Kurda, R. The past and future of sustainable concrete: A critical review and new strategies on cement-based materials. J. Clean. Prod. 2021, 281, 123558. [Google Scholar] [CrossRef]

- Almutairi, A.L.; Tayeh, B.A.; Adesina, A.; Isleem, H.F.; Zeyad, A.M. Potential applications of geopolymer concrete in construction: A review. Case Stud. Constr. Mater. 2021, 15, e00733. [Google Scholar] [CrossRef]

- Fraj, A.B.; Idir, R. Concrete based on recycled aggregates—Recycling and environmental analysis: A case study of paris’ region. Constr. Build. Mater. 2017, 157, 952–964. [Google Scholar] [CrossRef]

- Puthussery, J.V.; Kumar, R.; Garg, A. Evaluation of recycled concrete aggregates for their suitability in construction activities: An experimental study. Waste Manag. 2017, 60, 270–276. [Google Scholar] [CrossRef] [PubMed]

- Nikbin, I.M.; Aliaghazadeh, M.; Charkhtab, S.; Fathollahpour, A. Environmental impacts and mechanical properties of lightweight concrete containing bauxite residue (red mud). J. Clean. Prod. 2016, 172, 2683–2694. [Google Scholar] [CrossRef]

- Teixeira, E.R.; Camões, A.; Branco, F.G. Synergetic effect of biomass fly ash on improvement of high-volume coal fly ash concrete properties. Constr. Build. Mater. 2022, 314, 125680. [Google Scholar] [CrossRef]

- Fonseca, T.V.; dos Anjos, M.A.S.; Ferreira, R.L.S.; Branco, F.G.; Pereira, L. Evaluation of self-compacting concretes produced with ternary and quaternary blends of different SCM and hydrated-lime. Constr. Build. Mater. 2022, 320, 126235. [Google Scholar] [CrossRef]

- Malhotra, V.M. Fly ash, slag, silica fume, and rice-husk ash in concrete. A review. Concr. Int. 1993, 15, 23–28. [Google Scholar]

- Wang, A.; Zhang, C.; Sun, W. Fly ash effects. Cem. Concr. Res. 2004, 34, 2057–2060. [Google Scholar] [CrossRef]

- Kupwade-Patil, K.; Palkovic, S.D.; Bumajdad, A.; Soriano, C.; Büyüköztürk, O. Use of silica fume and natural volcanic ash as a replacement to Portland cement: Micro and pore structural investigation using NMR, XRD, FTIR and X-ray microtomography. Constr. Build. Mater. 2018, 158, 574–590. [Google Scholar] [CrossRef]

- Elaqra, H.; Rustom, R. Effect of using glass powder as cement replacement on rheological and mechanical properties of cement paste. Constr. Build. Mater. 2018, 179, 326–335. [Google Scholar] [CrossRef]

- Kamali, M.; Ghahremaninezhad, A. Effect of glass powders on the mechanical and durability properties of cementitious materials. Constr. Build. Mater. 2015, 98, 407–416. [Google Scholar] [CrossRef]

- Thomas, M.D.A.; Scott, A.; Bremner, T.; Bilodeau, A.; Day, D. Performance of slag concrete in marine environment. ACI Mater. J. 2008, 105, 628–634. [Google Scholar]

- Faleschini, F.; Zanini, M.A.; Brunelli, K.; Pellegrino, C. Valorization of co-combustion fly ash in concrete production. Mater. Des. 2015, 85, 687–694. [Google Scholar] [CrossRef]

- Elahi, A.; Basheer, P.A.M.; Nanukuttan, S.V.; Khan, Q.U.Z. Mechanical and durability properties of high performance concretes containing supplementary cementitious materials. Constr. Build. Mater. 2010, 24, 292–299. [Google Scholar] [CrossRef]

- Ortega, J.M.; Albaladejo, A.; Pastor, J.L.; Sánchez, I.; Climent, M.A. Influence of using slag cement on the microstructure and durability related properties of cement grouts for micropiles. Constr. Build. Mater. 2013, 38, 84–93. [Google Scholar] [CrossRef]

- Khayat, K.H.; Yahia, A.; Sayed, M. Effect of supplementary cementitious materials on rheological properties, bleeding, and strength of structural grout. ACI Mater. J. 2008, 105, 585–593. [Google Scholar]

- Fernandez, A.; Alonso, M.C.; García-Calvo, J.L.; Lothenbach, B. Influence of the synergy between mineral additions and Portland cement in the physical-mechanical properties of ternary binders. Mater. Constr. 2016, 66, e097. [Google Scholar] [CrossRef]

- Bilek, V.; Fiala, C. Sustainability of concrete elements from concrete with ternary binders. In Sustainable Construction Materials and Technologies; Routledge: London, UK, 2013; Volume 2013. [Google Scholar]

- Anastasiou, E.; Georgiadis Filikas, K.; Stefanidou, M. Utilization of fine recycled aggregates in concrete with fly ash and steel slag. Constr. Build. Mater. 2014, 50, 154–161. [Google Scholar] [CrossRef]

- Papadakis, V.G. Effect of fly ash on Portland cement systems. Cem. Concr. Res. 1999, 29, 1727–1736. [Google Scholar] [CrossRef]

- Bouikni, A.; Swamy, R.N.; Bali, A. Durability properties of concrete containing 50% and 65% slag. Constr. Build. Mater. 2009, 23, 2836–2845. [Google Scholar] [CrossRef]

- Dadsetan, S.; Bai, J. Mechanical and microstructural properties of self-compacting concrete blended with metakaolin, ground granulated blast-furnace slag and fly ash. Constr. Build. Mater. 2017, 146, 658–667. [Google Scholar] [CrossRef]

- Wedding, P.; Manmohan, D.; Mehta, P. Influence of Pozzolanic, Slag, and Chemical Admixtures on Pore Size Distribution and Permeability of Hardened Cement Pastes. Cem. Concr. Aggreg. 1981, 3, 63. [Google Scholar] [CrossRef]

- Chindaprasirt, P.; Jaturapitakkul, C.; Sinsiri, T. Effect of fly ash fineness on compressive strength and pore size of blended cement paste. Cem. Concr. Compos. 2005, 27, 425–428. [Google Scholar] [CrossRef]

- Dhandapani, Y.; Santhanam, M.; Kaladharan, G.; Ramanathan, S. Towards ternary binders involving limestone additions—A review. Cem. Concr. Res. 2021, 143, 106396. [Google Scholar] [CrossRef]

- Hadji, T.; Guettala, S.; Quéneudec, M. Mix design of high performance concrete with different mineral additions. World J. Eng. 2021, 18, 767–779. [Google Scholar] [CrossRef]

- Marchetti, G.; Irassar, E.F.; Rahhal, V.F. Effects of packing density and water film thickness on fresh and hardened properties of ternary cement pastes. Adv. Cem. Res. 2020, 32, 444–455. [Google Scholar] [CrossRef]

- Branco, F.G.; Godinho, L. On the use of lightweight mortars for the minimization of impact sound transmission. Constr. Build. Mater. 2013, 45, 184–191. [Google Scholar] [CrossRef]

- Belgas, M.d.L.; Branco, F.G. Cork concrete mechanical behavior under high temperatures. Int. J. Hous. Sci. Its Appl. 2013, 37, 207–215. [Google Scholar]

- Souza, N.S.L.D.; Anjos, M.A.S.D.; Sá, M.D.V.V.A.D.; Farias, E.C.D.; Souza, M.M.D.; Branco, F.G.; Pereira, A. Evaluation of sugarcane bagasse ash for lightweight aggregates production. Constr. Build. Mater. 2021, 271, 121604. [Google Scholar] [CrossRef]

- Baroghel-Bouny, V. Water vapour sorption experiments on hardened cementitious materials. Cem. Concr. Res. 2007, 37, 414–437. [Google Scholar] [CrossRef]

- Poon, C.S.; Kou, S.C.; Lam, L. Compressive strength, chloride diffusivity and pore structure of high performance metakaolin and silica fume concrete. Constr. Build. Mater. 2006, 20, 858–865. [Google Scholar] [CrossRef]

- Gurdián, H.; García-Alcocel, E.; Baeza-Brotons, F.; Garcés, P.; Zornoza, E. Corrosion behavior of steel reinforcement in concrete with recycled aggregates, fly ash and spent cracking catalyst. Materials 2014, 7, 3176–3197. [Google Scholar] [CrossRef]

- Kwon, S.-J.; Lee, H.-S.; Karthick, S.; Saraswathy, V.; Yang, H.-M. Long-term corrosion performance of blended cement concrete in the marine environment—A real-time study. Constr. Build. Mater. 2017, 154, 349–360. [Google Scholar] [CrossRef]

- Vázquez, K.; Rodríguez, R.R.; Esteban, M.D. Corrosion Prediction Models in the Reinforcement of Concrete Structures of Offshore Wind Farms. J. Mar. Sci. Eng. 2022, 10, 185. [Google Scholar] [CrossRef]

- Ju, X.; Wu, L.; Liu, M.; Jiang, H.; Zhang, W. Modelling of Chloride Concentration Profiles in Concrete by the Consideration of Concrete Material Factors under Marine Tidal Environment. J. Mar. Sci. Eng. 2022, 10, 917. [Google Scholar] [CrossRef]

- EN 1992-1-1; Eurocode 2: Design of Concrete Structures—Part 1-1: General Rules and Rules for Buildings. European Committee for Standardization: Brussels, Belgium, 2004.

- EN 197-1:2011; Cement—Part 1: Composition, specifications and conformity criteria for common cements. European Committee for Standardization: Brussels, Belgium, 2011; p. 30.

- Branco, F.G.; Tadeu, A.; Belgas, M.d.L. Can cork be used as a concrete aggregate? Int. J. Hous. Sci. Its Appl. 2007, 31, 1–11. [Google Scholar]

- Diamond, S. Mercury porosimetry. Cem. Concr. Res. 2000, 30, 1517–1525. [Google Scholar] [CrossRef]

- Ouellet, S.; Bussière, B.; Aubertin, M.; Benzaazoua, M. Microstructural evolution of cemented paste backfill: Mercury intrusion porosimetry test results. Cem. Concr. Res. 2007, 37, 1654–1665. [Google Scholar] [CrossRef]

- Horpibulsuk, S.; Rachan, R.; Chinkulkijniwat, A.; Raksachon, Y.; Suddeepong, A. Analysis of strength development in cement-stabilized silty clay from microstructural considerations. Constr. Build. Mater. 2010, 24, 2011–2021. [Google Scholar] [CrossRef]

- Ho, L.S.; Nakarai, K.; Duc, M.; Kouby, A.L.; Maachi, A.; Sasaki, T. Analysis of strength development in cement-treated soils under different curing conditions through microstructural and chemical investigations. Constr. Build. Mater. 2018, 166, 634–646. [Google Scholar] [CrossRef]

- Horpibulsuk, S.; Rachan, R.; Raksachon, Y. Role of fly ash on strength and microstructure development in blended cement stabilized silty clay. Soils Found. 2009, 49, 85–98. [Google Scholar] [CrossRef]

- Yu, Z.; Ye, G. The pore structure of cement paste blended with fly ash. Constr. Build. Mater. 2013, 45, 30–35. [Google Scholar] [CrossRef]

- NT Build 492; Concrete, Mortar and Cement-Based Repair Materials: Chloride Migration Coefficient from Non-Steady-State Migration Experiments. Nordtest: Oslo, Norway, 1999; p. 8.

- EN 1015-11:1999; Methods of test for mortar for masonry—Part 11: Determination of flexural and compressive strength of hardened mortar. European Committee for Standardization: Brussels, Belgium, 1999; p. 16.

- Adhikary, S.K.; Rudžionis, Ž.; Tučkutė, S. Characterization of novel lightweight self-compacting cement composites with incorporated expanded glass, aerogel, zeolite and fly ash. Case Stud. Constr. Mater. 2022, 16, e00879. [Google Scholar] [CrossRef]

- Bijen, J. Benefits of slag and fly ash. Constr. Build. Mater. 1996, 10, 309–314. [Google Scholar] [CrossRef]

- Ibáñez-Gosálvez, J.; Real-Herraiz, T.; Ortega, J.M. Microstructure, durability and mechanical properties of mortars prepared using ternary binders with addition of slag, fly ash and limestone. Appl. Sci. 2021, 11, 6388. [Google Scholar] [CrossRef]

- Ortega, J.M.; Sánchez, I.; Climent, M.A. Impedance spectroscopy study of the effect of environmental conditions in the microstructure development of OPC and slag cement mortars. Arch. Civ. Mech. Eng. 2015, 15, 569–583. [Google Scholar] [CrossRef]

- Escalante-García, J.I.; Sharp, J.H. Effect of temperature on the hydration of the main clinker phases in Portland cements: Part I, neat cements. Cem. Concr. Res. 1998, 28, 1245–1257. [Google Scholar] [CrossRef]

- Escalante-García, J.I.; Sharp, J.H. Effect of temperature on the hydration of the main clinker phasesin Portland cements: Part II, blended cements. Cem. Concr. Res. 1998, 28, 1259–1274. [Google Scholar] [CrossRef]

- Meddah, M.S.; Lmbachiya, M.C.; Dhir, R.K. Potential use of binary and composite limestone cements in concrete production. Constr. Build. Mater. 2014, 58, 193–205. [Google Scholar] [CrossRef]

- Duan, P.; Shui, Z.; Chen, W.; Shen, C. Effects of metakaolin, silica fume and slag on pore structure, interfacial transition zone and compressive strength of concrete. Constr. Build. Mater. 2013, 44, 1–6. [Google Scholar] [CrossRef]

- Çakır, Ö.; Aköz, F. Effect of curing conditions on the mortars with and without GGBFS. Constr. Build. Mater. 2008, 22, 308–314. [Google Scholar] [CrossRef]

- Nochaiya, T.; Wongkeo, W.; Chaipanich, A. Utilization of fly ash with silica fume and properties of Portland cement–fly ash–silica fume concrete. Fuel 2010, 89, 768–774. [Google Scholar] [CrossRef]

- Erdem, T.K.; Kirca, O. Use of binary and ternary blends in high strength concrete. Constr. Build. Mater. 2008, 22, 1477–1483. [Google Scholar] [CrossRef]

- Tsakiridis, P.E.; Agatzini-Leonardou, S.; Oustadakis, P. Red mud addition in the raw meal for the production of Portland cement clinker. J. Hazard. Mater. 2004, 116, 103–110. [Google Scholar] [CrossRef]

- Detwiler, R.J.; Fapohunda, C.A.; Natale, J. Use of supplementary cementing materials to increase the resistance to chloride ion penetration of concretes cured at elevated temperatures. ACI Mater. J. 1994, 91, 63–66. [Google Scholar]

- Moon, H.Y.; Kim, H.S.; Choi, D.S. Relationship between average pore diameter and chloride diffusivity in various concretes. Constr. Build. Mater. 2006, 20, 725–732. [Google Scholar] [CrossRef]

- Geiseler, J.; Kollo, H.; Lang, E. Influence of blast furnace cements on durability of concrete structures. ACI Mater. J. 1995, 92, 252–257. [Google Scholar]

- Jain, J.A.; Neithalath, N. Chloride transport in fly ash and glass powder modified concretes—Influence of test methods on microstructure. Cem. Concr. Compos. 2010, 32, 148–156. [Google Scholar] [CrossRef]

- Leng, F.; Feng, N.; Lu, X. An experimental study on the properties of resistance to diffusion of chloride ions of fly ash and blast furnace slag concrete. Cem. Concr. Res. 2000, 30, 989–992. [Google Scholar] [CrossRef]

- Brás, A.; Leal, M.; Faria, P. Cement-cork mortars for thermal bridges correction. Comparison with cement-EPS mortars performance. Constr. Build. Mater. 2013, 49, 315–327. [Google Scholar] [CrossRef]

- Demirboğa, R. Thermal conductivity and compressive strength of concrete incorporation with mineral admixtures. Build. Environ. 2007, 42, 2467–2471. [Google Scholar] [CrossRef]

| Designation | Binder | Aggregate (Percentage in Volume) | |||

|---|---|---|---|---|---|

| Cement Type [42] | Addition (Percentage in Weight) | Sand | Natural Cork | Expanded Clay | |

| 1REF | CEM I 42.5 R | - | 100% | - | - |

| 2REF | CEM II/B-L 32.5 N | Limestone (21–35%) | 100% | - | - |

| 3REF | CEM III/B 32.5 N/SR | Blast-furnace slag (70%) | 100% | - | - |

| 4REF | Equiv. to CEM II/A-V | Fly ash (20%) | 100% | - | - |

| 1NCK | CEM I 42.5 R | - | 50% | 50% | - |

| 2NCK | CEM II/B-L 32.5 N | Limestone (21–35%) | 50% | 50% | - |

| 3NCK | CEM III/B 32.5 N/SR | Blast-furnace slag (70%) | 50% | 50% | - |

| 4NCK | Equiv. to CEM II/A-V | Fly ash (20%) | 50% | 50% | - |

| 1ECL | CEM I 42.5 R | - | 50% | - | 50% |

| 2ECL | CEM II/B-L 32.5 N | Limestone (21–35%) | 50% | - | 50% |

| 3ECL | CEM III/B 32.5 N/SR | Blast-furnace slag (70%) | 50% | - | 50% |

| 4ECL | Equiv. to CEM II/A-V | Fly ash (20%) | 50% | - | 50% |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ortega, J.M.; Branco, F.G.; Pereira, L.; Marques, L. Chloride Ingress Resistance, Microstructure and Mechanical Properties of Lightweight Mortars with Natural Cork and Expanded Clay Prepared Using Sustainable Blended Cements. J. Mar. Sci. Eng. 2022, 10, 1174. https://doi.org/10.3390/jmse10091174

Ortega JM, Branco FG, Pereira L, Marques L. Chloride Ingress Resistance, Microstructure and Mechanical Properties of Lightweight Mortars with Natural Cork and Expanded Clay Prepared Using Sustainable Blended Cements. Journal of Marine Science and Engineering. 2022; 10(9):1174. https://doi.org/10.3390/jmse10091174

Chicago/Turabian StyleOrtega, José Marcos, Fernando G. Branco, Luís Pereira, and Luís Marques. 2022. "Chloride Ingress Resistance, Microstructure and Mechanical Properties of Lightweight Mortars with Natural Cork and Expanded Clay Prepared Using Sustainable Blended Cements" Journal of Marine Science and Engineering 10, no. 9: 1174. https://doi.org/10.3390/jmse10091174

APA StyleOrtega, J. M., Branco, F. G., Pereira, L., & Marques, L. (2022). Chloride Ingress Resistance, Microstructure and Mechanical Properties of Lightweight Mortars with Natural Cork and Expanded Clay Prepared Using Sustainable Blended Cements. Journal of Marine Science and Engineering, 10(9), 1174. https://doi.org/10.3390/jmse10091174