A K-Means Clustering Algorithm to Determine Representative Operational Profiles of a Ship Using AIS Data

Abstract

:1. Introduction

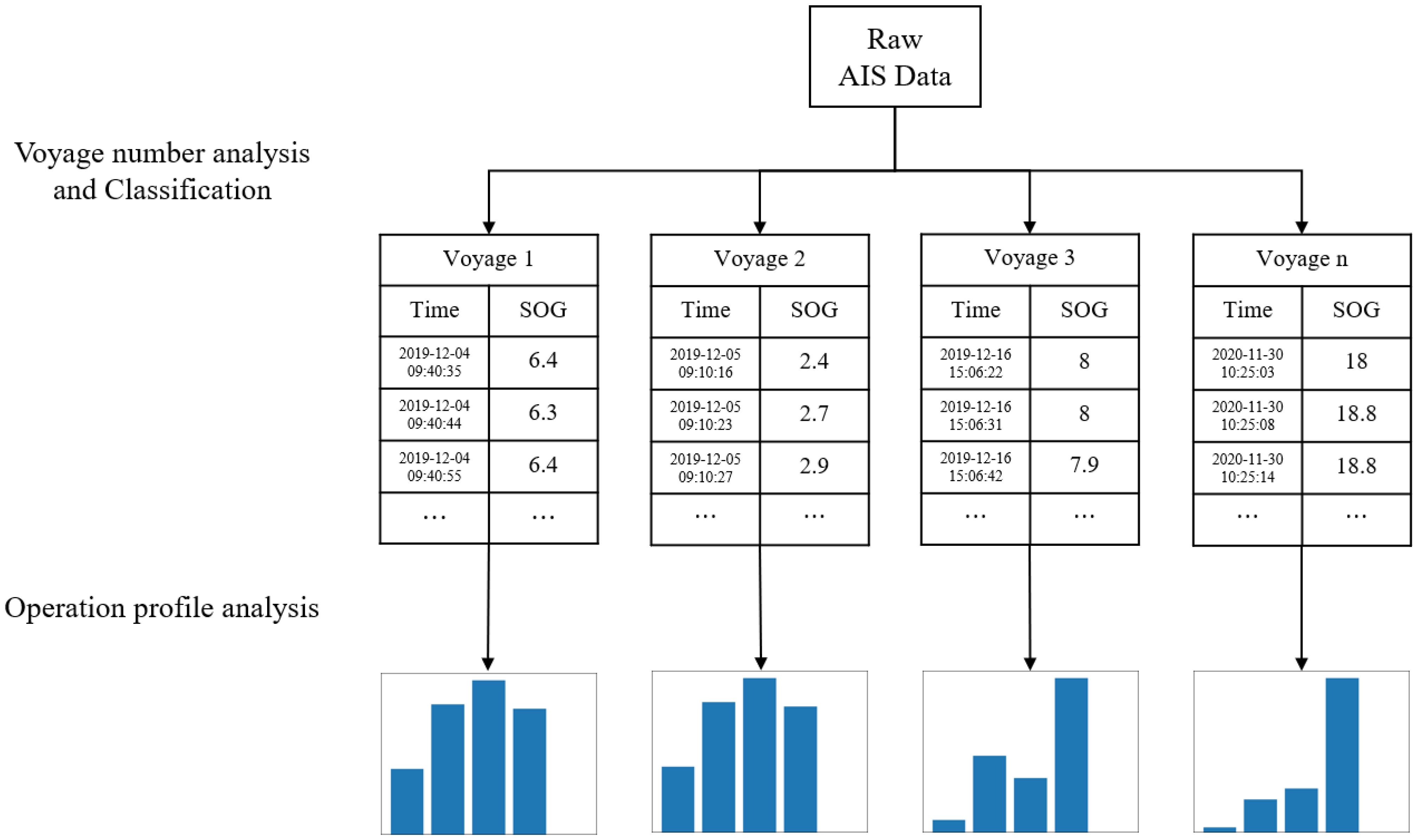

2. Data Preparation

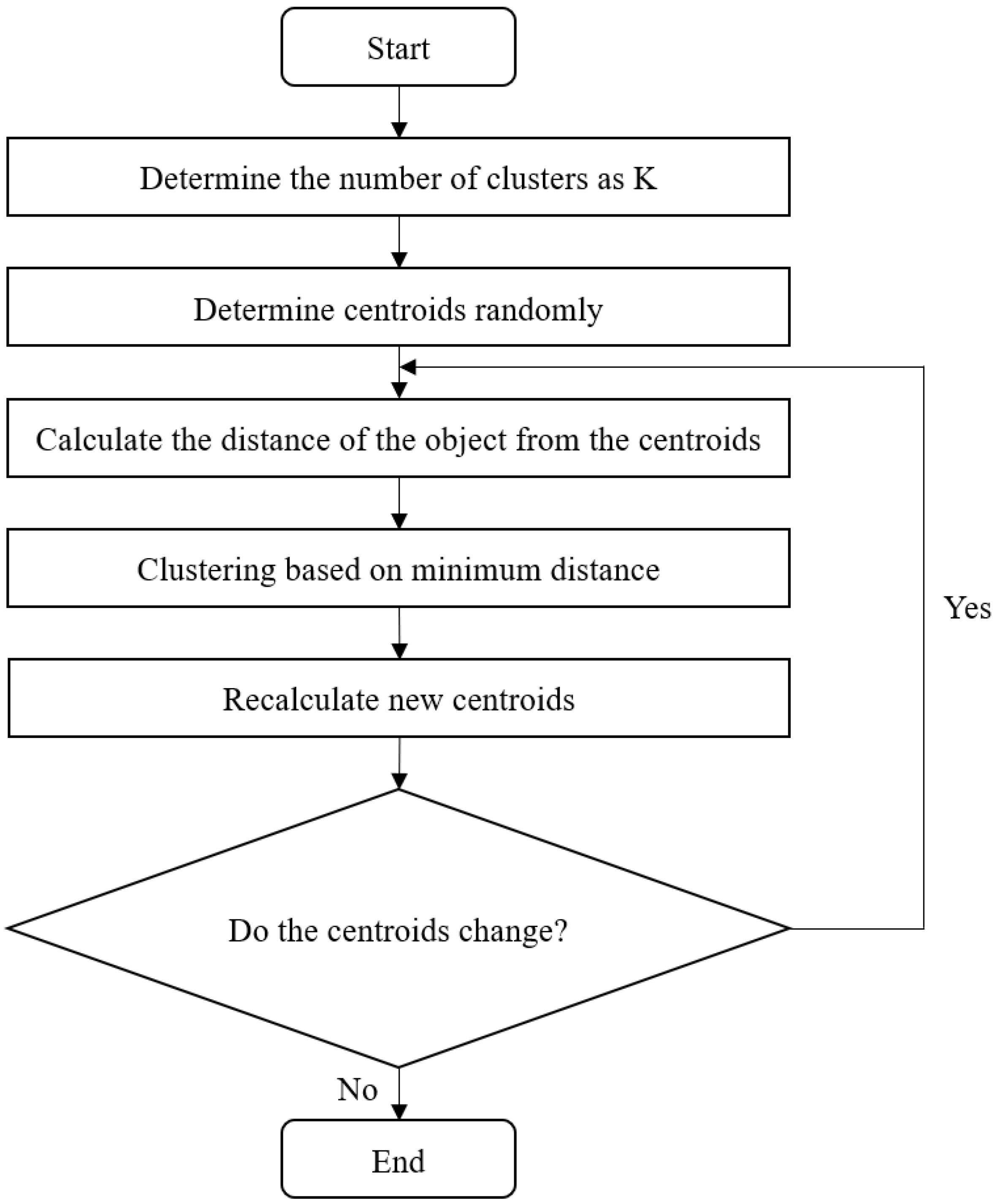

3. K-Means Clustering Algorithm

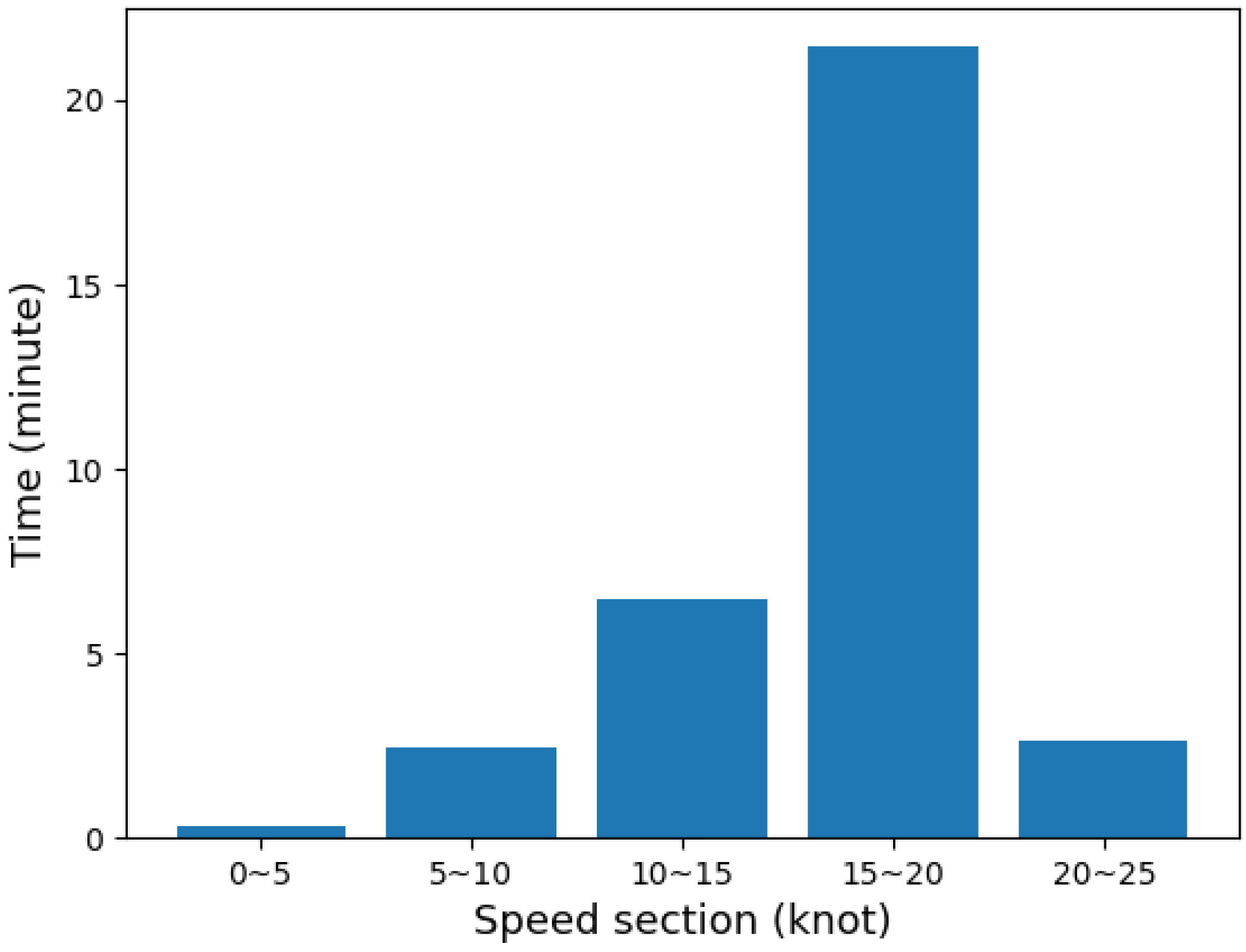

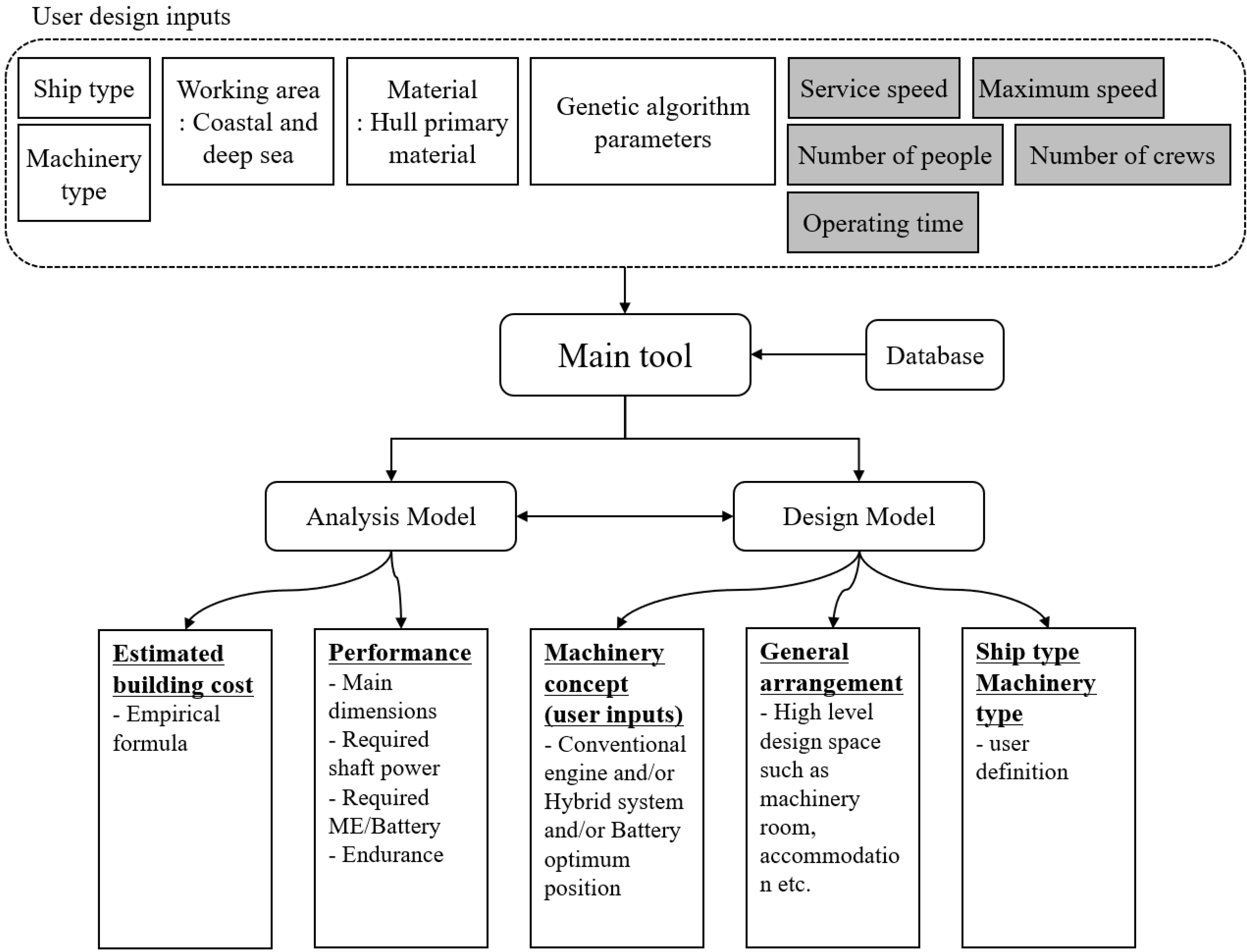

4. Case Study

4.1. Description of the Case

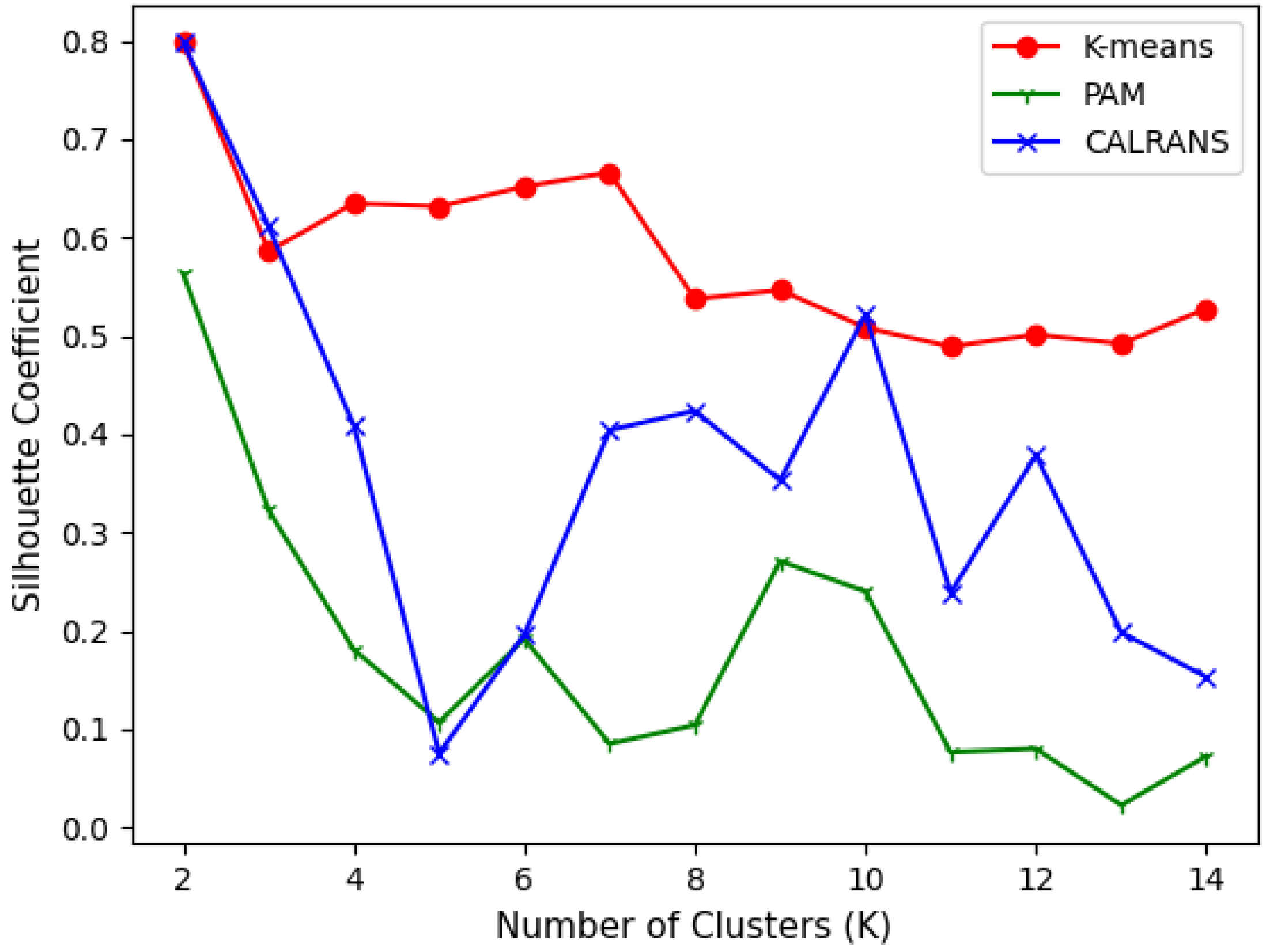

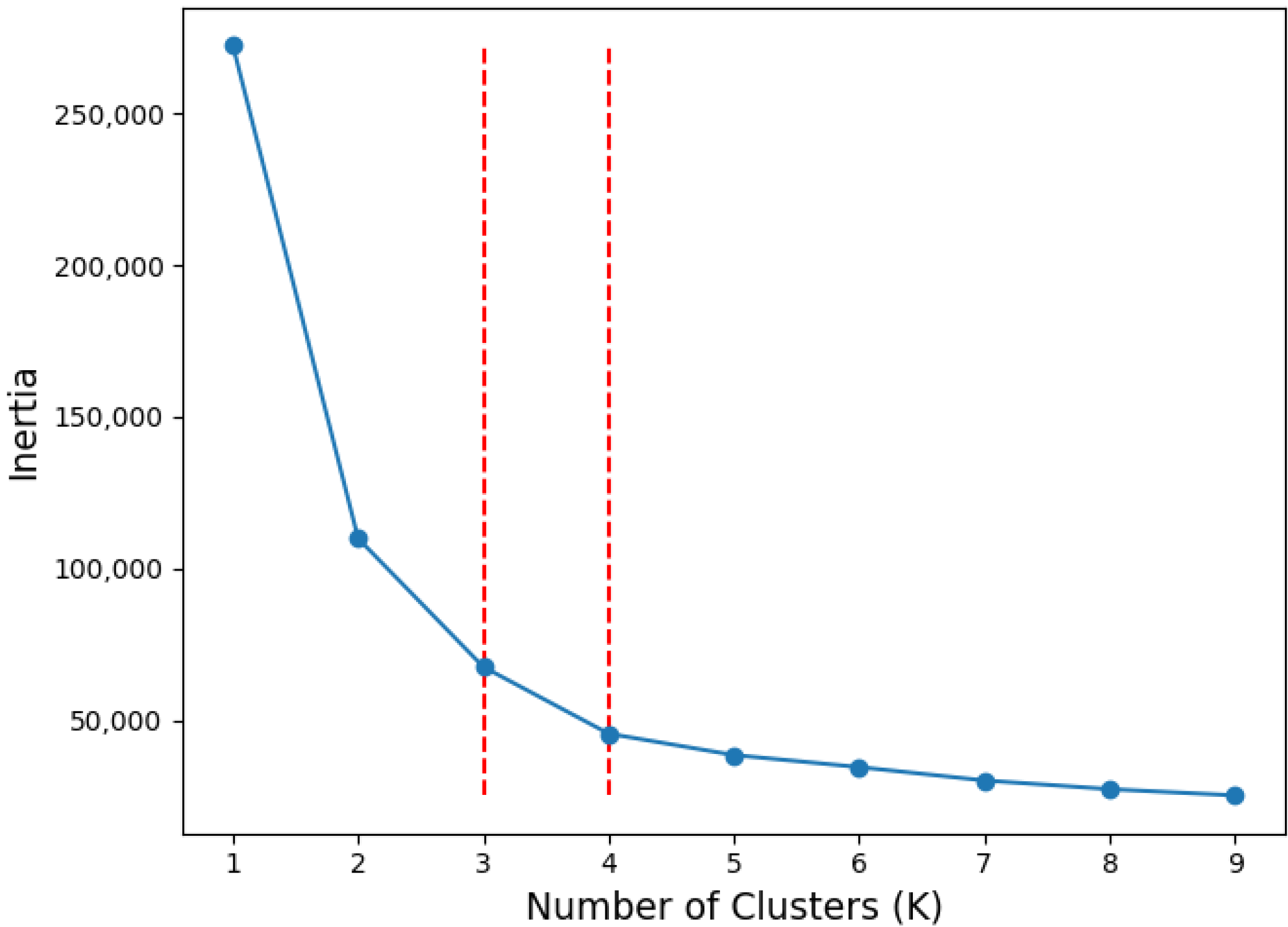

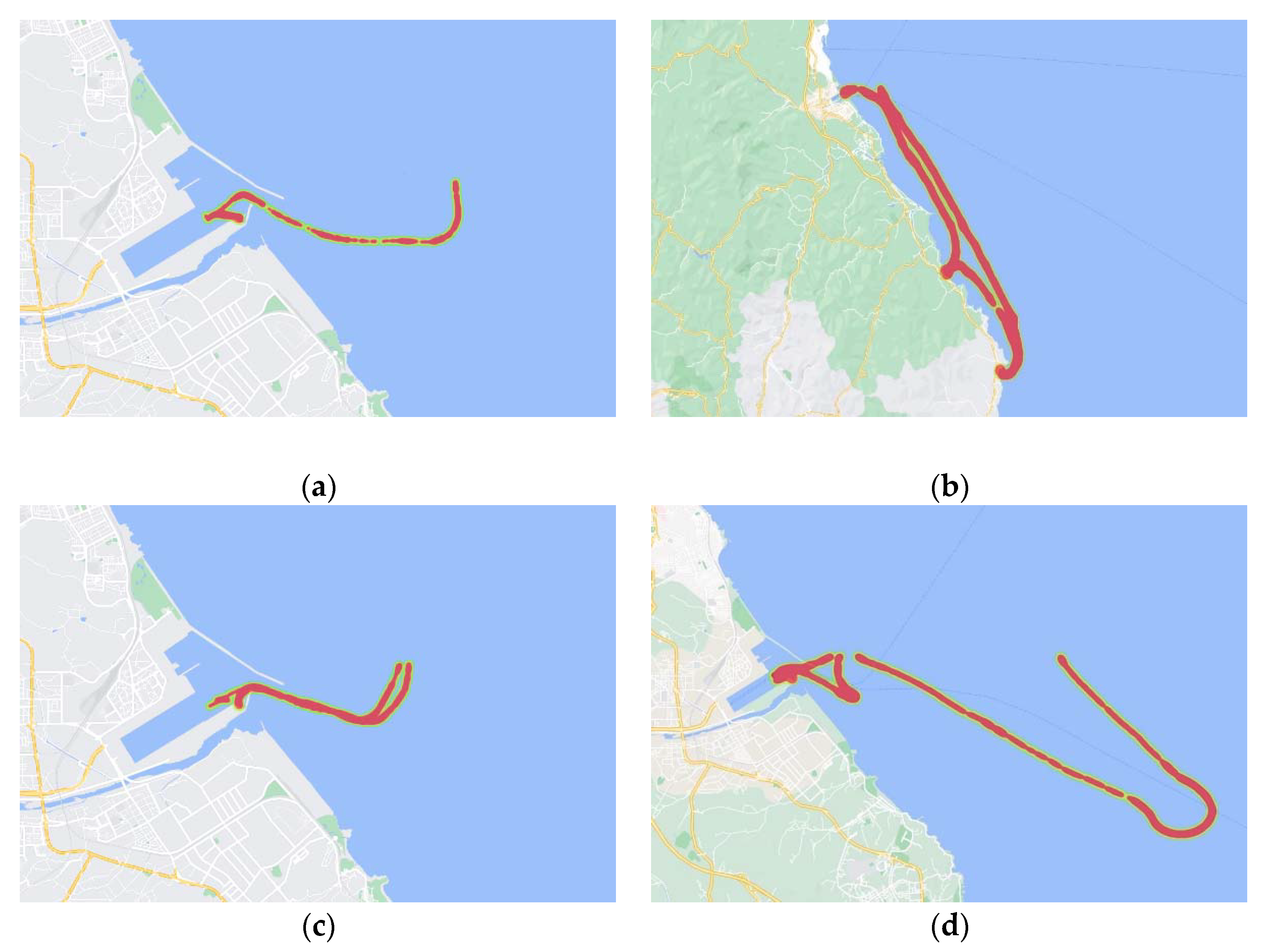

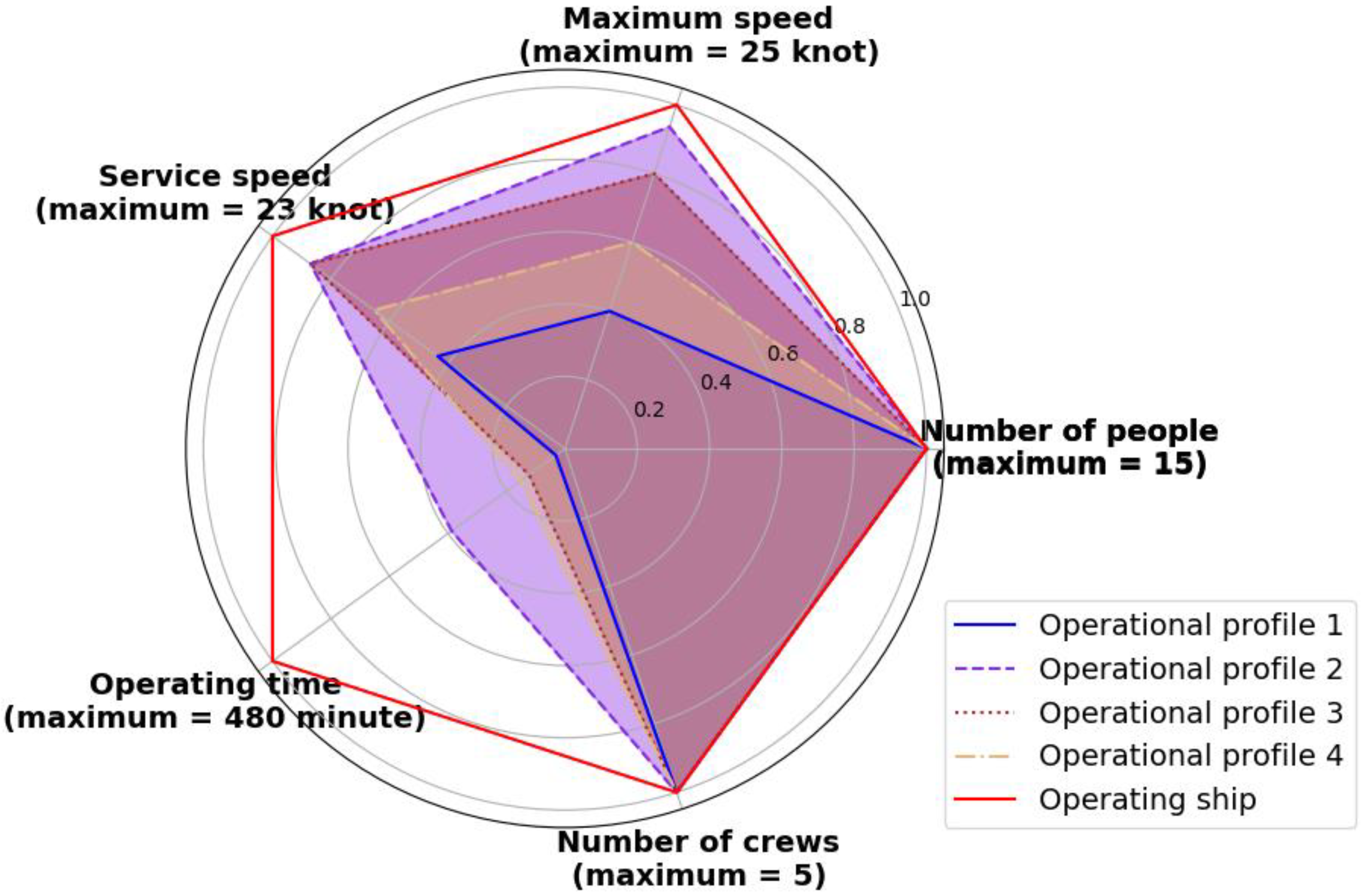

4.2. Application of the K-Means Clustering Algorithm

5. Conclusions and Future Work

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Xiao, F.; Ligteringen, H.; van Gulijk, C.; Ale, B. Comparison study on AIS data of ship traffic behavior. Ocean. Eng. 2015, 95, 84–93. [Google Scholar] [CrossRef]

- Mou, J.M.; van der Tak, C.; Ligteringen, H. Study on collision avoidance in busy waterways by using AIS Data. Ocean. Eng. 2010, 37, 483–490. [Google Scholar] [CrossRef]

- Tsou, M.-C. Online analysis process on automatic identification system data warehouse for application in vessel traffic service. Proc. Inst. Mech. Eng. M J. Eng. Marit. Environ. 2016, 230, 199–215. [Google Scholar] [CrossRef]

- Breithaupt, S.A.; Copping, A.; Tagestad, J.; Whiting, J. Maritime route delineation using AIS data from the Atlantic coast of the US. J. Navig. 2017, 70, 379–394. [Google Scholar] [CrossRef]

- Dobrkovic, A.; Iacob, M.-E.; van Hillegersberg, J. Maritime pattern extraction from AIS data using a genetic algorithm. In Proceedings of the 2016 IEEE International Conference on Data Science and Advanced Analytics (DSAA), Montreal, QC, Canada, 17–19 October 2016; pp. 642–651. [Google Scholar]

- Mazzarella, F.; Arguedas, V.F.; Vespe, M. Knowledge-based vessel position prediction using historical AIS data. In Proceedings of the 2015 Sensor Data Fusion: Trends, Solutions, Applications (SDF), Bonn, Germany, 6–8 October 2015; pp. 1–6. [Google Scholar]

- Ristic, B.; la Scala, B.; Morelande, M.; Gordon, N. Statistical analysis of motion patterns in AIS data: Anomaly detection and motion prediction. In Proceedings of the 2008 11th International Conference on Information Fusion, Cologne, Germany, 30 June–3 July 2008; pp. 1–7. [Google Scholar]

- Kim, S.-H.; Roh, M.-I.; Oh, M.-J.; Park, S.-W.; Kim, I.-I. Estimation of ship operational efficiency from AIS data using big data technology. Int. J. Nav. Archit. Ocean Eng. 2020, 12, 440–454. [Google Scholar] [CrossRef]

- Rong, H.; Teixeira, A.P.; Guedes Soares, C. Data Mining Approach to Shipping Route Characterization and Anomaly Detection Based on AIS Data. Ocean. Eng. 2020, 198, 106936. [Google Scholar] [CrossRef]

- Silveira, P.A.M.; Teixeira, A.P.; Soares, C.G. Use of AIS Data to Characterise Marine Traffic Patterns and Ship Collision Risk off the Coast of Portugal. J. Navig. 2013, 66, 879–898. [Google Scholar] [CrossRef]

- Murray, B.; Perera, L.P. A Dual Linear Autoencoder Approach for Vessel Trajectory Prediction Using Historical AIS Data. Ocean. Eng. 2020, 209, 107478. [Google Scholar] [CrossRef]

- Reusser, C.A.; Pérez Osses, J.R. Challenges for zero-emissions ship. J. Mar. Sci. Eng. 2021, 9, 1042. [Google Scholar] [CrossRef]

- Kim, K.; Roh, G.; Kim, W.; Chun, K. A preliminary study on an alternative ship propulsion system fueled by ammonia: Environmental and economic assessments. J. Mar. Sci. Eng. 2020, 8, 183. [Google Scholar] [CrossRef] [Green Version]

- Hansen, J.F.; Wendt, F. History and state of the art in commercial electric ship propulsion, integrated power systems, and future trends. Proc. IEEE 2015, 103, 2229–2242. [Google Scholar] [CrossRef]

- Sulligoi, G.; Vicenzutti, A.; Menis, R. All-electric ship design: From electrical propulsion to integrated electrical and electronic power systems. IEEE Trans. Transp. Electrif. 2016, 2, 507–521. [Google Scholar] [CrossRef]

- Shakeri, N.; Zadeh, M.; Nielsen, J.B. Hydrogen fuel cells for ship electric propulsion: Moving toward greener ships. IEEE Electrif. Mag. 2020, 8, 27–43. [Google Scholar] [CrossRef]

- Harati-Mokhtari, A.; Wall, A.; Brooks, P.; Wang, J. Automatic Identification System (AIS): Data reliability and human error implications. J. Navig. 2007, 60, 373–389. [Google Scholar] [CrossRef]

- MacQueen, J. Some methods for classification and analysis of multivariate observations. In Proceedings of the Fifth Berkeley Symposium on Mathematical Statistics and Probability, Berkeley, CA, USA, 7 January 1967; pp. 281–297. [Google Scholar]

- Zheng, B.; Chen, J.; Xia, S.; Jin, Y. Data analysis of vessel traffic flow using clustering algorithms. In Proceedings of the 2008 International Conference on Intelligent Computation Technology and Automation (ICICTA), Changsha, China, 20–22 October 2008; pp. 243–246. [Google Scholar]

- Affandi, A.; Sumpeno, S. Clustering spatial temporal distribution of fishing vessel based LON VMS data using K-means. In Proceedings of the 2020 3rd International Conference on Information and Communications Technology (ICOIACT), Yogyakarta, Indonesia, 24–25 November 2020; pp. 1–6. [Google Scholar]

- Mieczyńska, M.; Czarnowski, I. K-means clustering for SAT-AIS data analysis. WMU J. Marit. Aff. 2021, 20, 377–400. [Google Scholar] [CrossRef]

- Gan, S.; Liang, S.; Li, K.; Deng, J.; Cheng, T. Ship trajectory prediction for intelligent traffic management using clustering and ANN. In Proceedings of the 2016 UKACC 11th International Conference on Control (CONTROL), Belfast, UK, 31 August–2 September 2016; pp. 1–6. [Google Scholar]

- Liu, L.; Zhang, Y.; Hu, Y.; Wang, Y.; Sun, J.; Dong, X. A hybrid-clustering model of ship trajectories for maritime traffic patterns analysis in port area. J. Mar. Sci. Eng. 2022, 10, 342. [Google Scholar] [CrossRef]

- Pham, D.T.; Dimov, S.S.; Nguyen, C.D. Selection of K in K-means clustering. Proc. Inst. Mech. Eng. C J. Mech. Eng. Sci. 2005, 219, 103–119. [Google Scholar] [CrossRef]

- Yuan, C.; Yang, H. Research on K-value selection method of K-means clustering algorithm. J 2019, 2, 226–235. [Google Scholar] [CrossRef]

- Kodinariya, T.M.; Makwana, P.R. Review on determining number of cluster in K-means clustering. Int. J. Adv. Res. Comput. Sci. Manag. Stud. 2013, 1, 90–95. [Google Scholar]

- Xu, D.; Tian, Y. A comprehensive survey of clustering algorithms. Ann. Data. Sci. 2015, 2, 165–193. [Google Scholar] [CrossRef]

- Kaufman, L.; Rousseeuw, P.J. Finding Groups in Data: An Introduction to Cluster Analysis; John Wiley & Sons: Hoboken, NJ, USA, 2009; Volume 344. [Google Scholar]

- Ng, R.T.; Han, J. CLARANS: A method for clustering objects for spatial data mining. IEEE Trans. Knowl. Data Eng. 2002, 14, 1003–1016. [Google Scholar] [CrossRef] [Green Version]

| Static Information | Dynamic Information | Voyage Related Information |

|---|---|---|

| IMO and maritime mobile service identity number | ship’s position | destination and estimated time of arrival |

| call sign and name | time in universal time coordinated (UTC) | type of cargo |

| type of vessel | course over ground | ship’s draught |

| length and beam | speed over ground (SOG) | route plan-waypoints |

| ··· | ··· | ··· |

| Dimension | Value | Dimension | Value | Dimension | Value |

|---|---|---|---|---|---|

| Length (m) | 23.8 | Power (kW) | 2189 | Operating time (min) | 480 |

| Breadth (m) | 4.8 | GT (t) | 40 | Number of people (p.p.l) | 15 |

| Depth (m) | 2.3 | Maximum speed (knot) | 25 | Number of crew (p.p.l) | 5 |

| Draft (m) | 1.2 | Service speed (knot) | 23 |

| Dimension | Value | Dimension | Value | Dimension | Value |

|---|---|---|---|---|---|

| Length (m) | 25.7 | GT (t) | 57.1 | Operating time (min) | 186 |

| Breadth (m) | 5.5 | Battery capacity (kW·h) | 2997 | Number of people (p.p.l) | 15 |

| Depth (m) | 2.0 | Cost (USD M) | 5.08 | Number of crew (p.p.l) | 5 |

| Draft (m) | 1.0 | Maximum speed (knot) | 23.4 | ||

| Power (kW) | 1007 | Service speed (knot) | 20 |

| Dimension | Value | Dimension | Value | Dimension | Value |

|---|---|---|---|---|---|

| Length (m) | 40.9 | GT (t) | 177.7 | Operating time (min) | 480 |

| Breadth (m) | 6.0 | Battery capacity (kW·h) | 8536 | Number of people (p.p.l) | 15 |

| Depth (m) | 3.0 | Cost (USD M) | 10.51 | Number of crew (p.p.l) | 5 |

| Draft (m) | 2.0 | Maximum speed (knot) | 25 | ||

| Power (kW) | 1272 | Service speed (knot) | 23 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Park, J.; Choi, M. A K-Means Clustering Algorithm to Determine Representative Operational Profiles of a Ship Using AIS Data. J. Mar. Sci. Eng. 2022, 10, 1245. https://doi.org/10.3390/jmse10091245

Park J, Choi M. A K-Means Clustering Algorithm to Determine Representative Operational Profiles of a Ship Using AIS Data. Journal of Marine Science and Engineering. 2022; 10(9):1245. https://doi.org/10.3390/jmse10091245

Chicago/Turabian StylePark, Jongseo, and Minjoo Choi. 2022. "A K-Means Clustering Algorithm to Determine Representative Operational Profiles of a Ship Using AIS Data" Journal of Marine Science and Engineering 10, no. 9: 1245. https://doi.org/10.3390/jmse10091245

APA StylePark, J., & Choi, M. (2022). A K-Means Clustering Algorithm to Determine Representative Operational Profiles of a Ship Using AIS Data. Journal of Marine Science and Engineering, 10(9), 1245. https://doi.org/10.3390/jmse10091245