Optimized Design of the Carrier Structure of an Autonomous Glide Marine Seismometer

Abstract

:1. Introduction

2. Materials and Methods

2.1. Design Indicators and Working Modalities

- (1)

- Surface stage

- (2)

- Glide down stage

- (3)

- Signal acquisition stage

- (4)

- Ascending stage

- (5)

- Communication stage

2.2. Design Solutions for Carrier Profiles and Pressure-Resistant Structures

3. Pressure-Resistant Shell Design

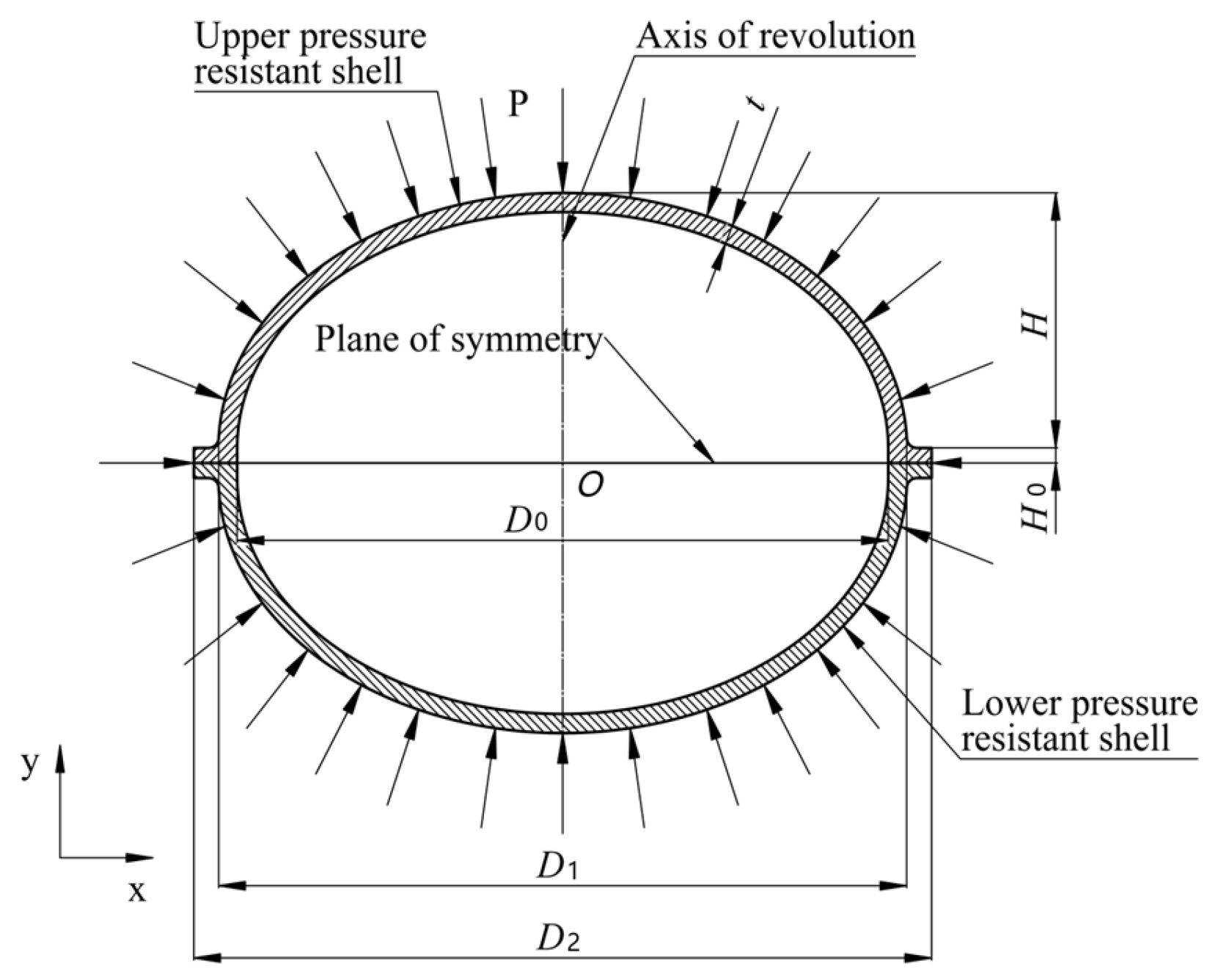

3.1. Structural Form and Material Selection

3.2. Base Material Thickness Calculation and Design

3.3. Stress Calculation and Check

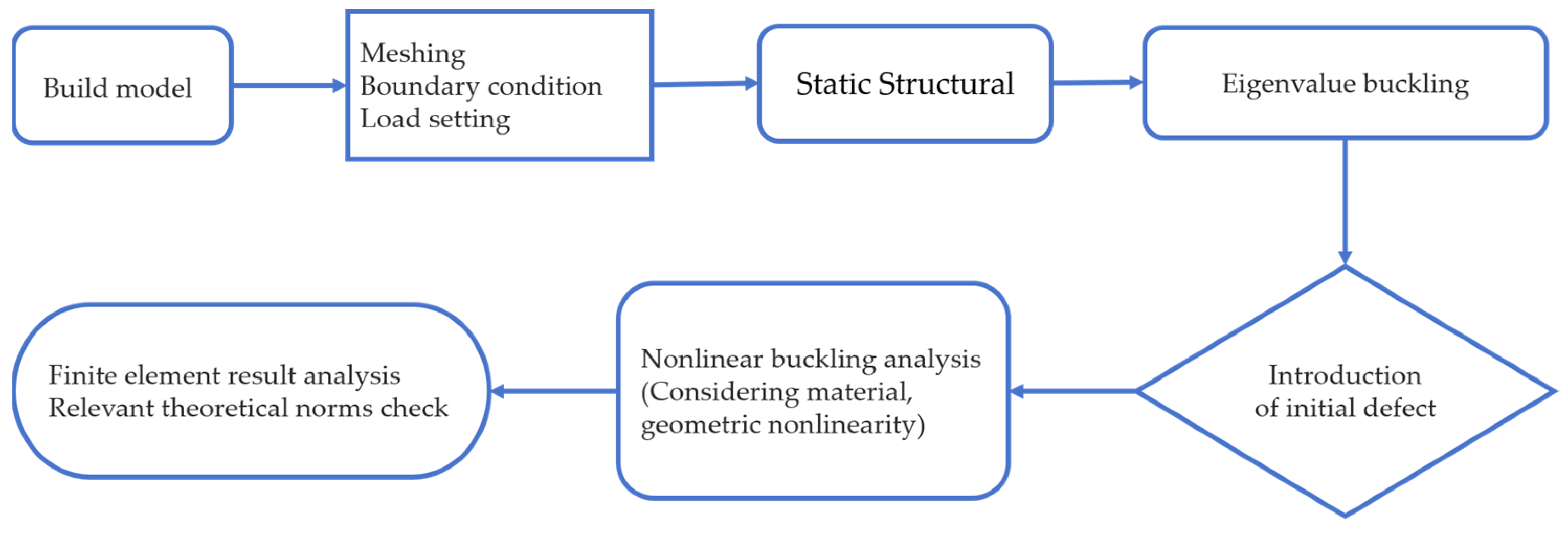

4. Stability Analysis of the Pressure-Resistant Shell

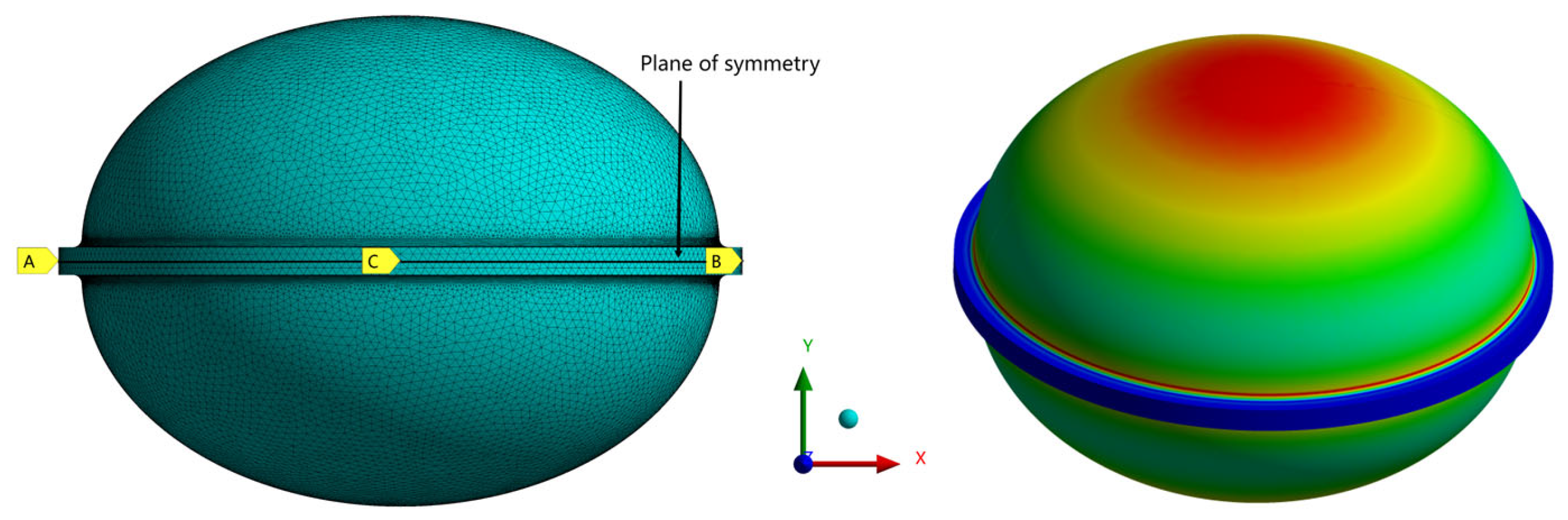

4.1. Finite-Element Analysis of Linear Buckling

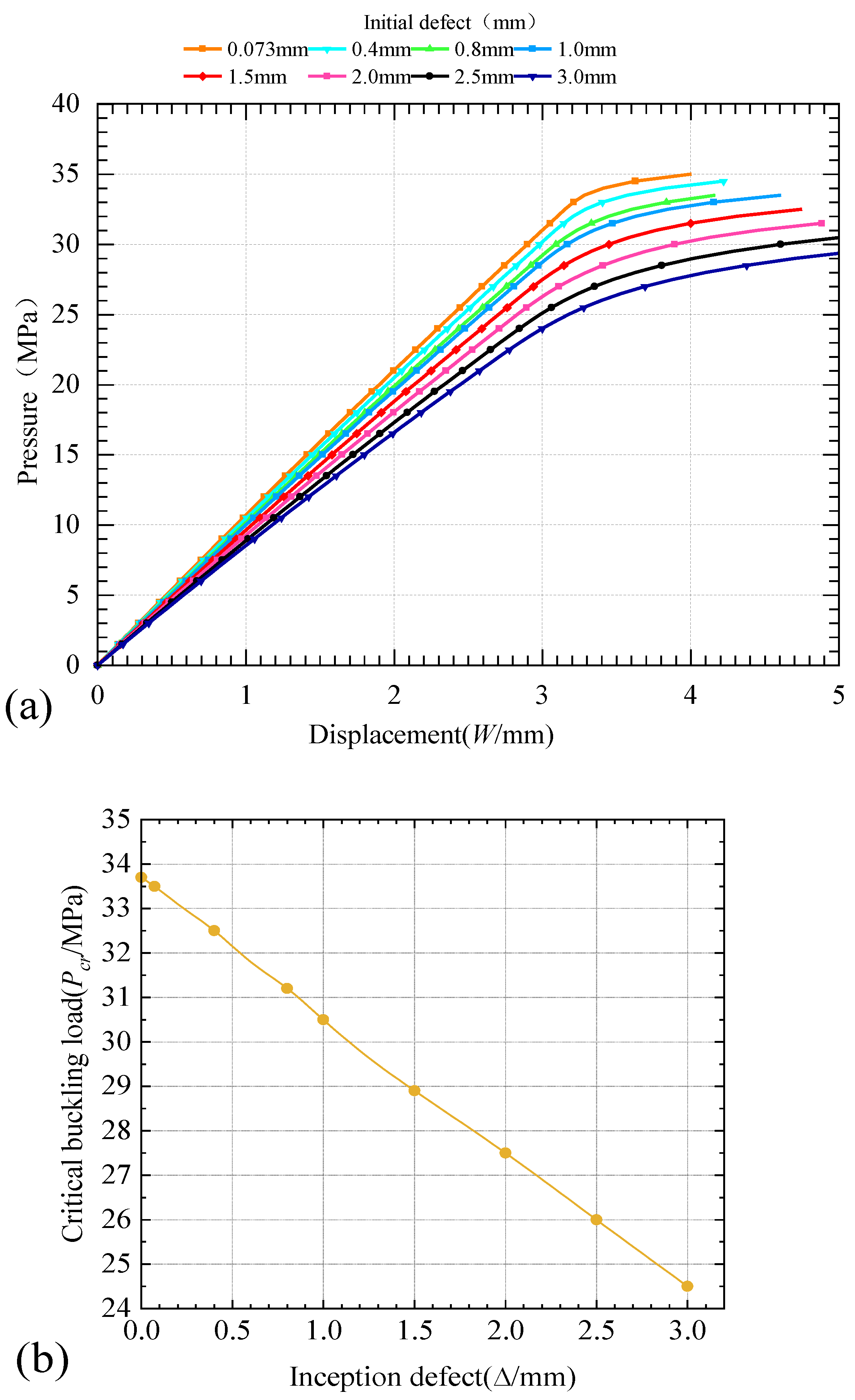

4.2. Nonlinear Flexion Analysis

4.3. Analysis of Results and Comparison

5. Discussion

- (1)

- This paper mainly discussed the AGMS’s design parameters and working mode. We accomplished the structural design of a pressure-resistant shell and performed strength analysis and checks. Our calculations affirmed that the design strength satisfied all essential criteria.

- (2)

- Ellipsoidal pressure-resistant compartments have limited examples, and varying theoretical formulas produce differing calculation results. Additionally, there was a lack of theoretical analyses for high-strength aluminum alloys utilized in deep-sea, pressure-resistant shells. To ensure structural stability, our design considered multiple reference standards and maintained a minimum stability strength value greater than the calculated strength. However, this approach may result in unnecessary weight, which we will optimize through experimentation in subsequent structural optimization studies.

- (3)

- Moving forward, our team will continue researching the pressure-resistant structure of the motorized marine seismometer, focusing on stability and sealing and conducting pressure tests on the pressure-resistant structure. Since the ellipsoid pressurization chamber has no spherical pressurization structural strength and the aluminum alloy is not ideal for corrosion resistance and in strength, we will consider other structural forms and materials in the future to further improve the working depth and service life of AMGS. We hope that our study will contribute to the observation of ocean networking.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Ding, W.W.; Huang, H.; Zhu, X.; Sun, G.; Niu, X. New mobile oceanic seismic recording system and its application in marine seismic exploration. J. Prog. Geophys. 2019, 34, 292–296. (In Chinese) [Google Scholar]

- Hello, Y.; Ogé, A.; Sukhovich, A.; Nolet, G. Modern mermaids: New floats image the deep Earth. EOS Trans. Am. Geophys. Union 2011, 92, 337–338. [Google Scholar] [CrossRef]

- Sukhovich, A.; Bonnieux, S.; Hello, Y.; Irisson, J.; Simons, F.J.; Nolet, G. Seismic monitoring in the oceans by autonomous floats. Nat. Commun. 2015, 6, 8027. [Google Scholar] [CrossRef]

- Jones, N. Global seismic network takes to the seas. Nature 2014, 507, 151. [Google Scholar] [CrossRef]

- Hao, T.Y.; You, Q.Y. Progress of homemade OBS and its application on ocean bottom structure survey. J. Geophys. 2011, 54, 3352–3361. (In Chinese) [Google Scholar]

- Wang, J.; Qiu, Y.; Yan, P. A joint investigation using OBS, multi-channel seismic and gravity data across the southwestern sub-basin of the South China Sea. J. Trop. Oceanogr. 2019, 38, 81–90. (In Chinese) [Google Scholar]

- Li, F.H.; Lu, Y.G.; Wang, H.B.; Guo, Y.G.; Zhang, F. Research Progress and Development Trend of Seafloor Observation Network. J. Bull. Chin. Acad. Sci. 2019, 34, 321–330. (In Chinese) [Google Scholar]

- Yin, L.; Li, Y.B.; Ma, J.G. Present status of marine observation technology. J. Ship Electron. Eng. 2013, 33, 4–7. (In Chinese) [Google Scholar]

- Zhu, J.J.; Sun, Z.X.; Lian, S.M.; Yin, J.P.; Li, Z.G. Review on cabled seafloor observatories in the world. J. Trop. Oceanogr. 2017, 36, 20–33. (In Chinese) [Google Scholar]

- Nolet, G.; Hello, Y.; Lee, S.V.; Bonnieux, S.; Ruiz, M.C.; Pazmino, N.A.; Deschamps, A.; Regnier, M.M.; Font, Y.; Chen, Y.J. Imaging the Galápagos mantle plume with an unconventional application of floating seismometers. J. Sci. Rep. 2019, 9, 1326. [Google Scholar] [CrossRef]

- Joubert, C.; Nolet, G.; Bonnieux, S.; Deschamps, A.; Dessa, J.X.; Hello, Y. P-Delays from Floating Seismometers (MERMAID), Part I: Data Processing. J. Seismol. Res. Lett. 2016, 87, 73–80. [Google Scholar] [CrossRef]

- Huang, H.; Zhang, C.; Ding, W.; Zhu, X.; Sun, G.; Wang, H. Design of the Depth Controller for a Floating Ocean Seismograph. J. Mar. Sci. Eng. 2020, 8, 166. [Google Scholar] [CrossRef]

- Wang, H.; Zhang, R.; Wang, G.; An, Y.; Jin, B. Quality control of Argo temperature and salinity observation profiles. J. Geophys. 2012, 55, 577–588. (In Chinese) [Google Scholar]

- Gould, W.J. From Swallow floats to Argo-the development of neutrally buoyant floats. J. Deep Sea Res. II 2005, 52, 529–543. [Google Scholar] [CrossRef]

- Rudnick, D.L.; Davis, R.; Eriksen, C.C.; Fratantoni, D.M. Underwater gliders for ocean research. J. Mar. Technol. Soc. J. 2004, 38, 73–84. [Google Scholar] [CrossRef]

- Liu, T. Analysis and Design of Deep-Sea Submersible Structures. Ph.D. Thesis, China Ship Scientific Research Center, Wuxi, China, 2001. Volume 2. (In Chinese). [Google Scholar]

- Shi, D.P.; Li, C.C. Structural Strength of Submersible; Shanghai Jiao Tong University Press: Shanghai, China, 1991; p. 6. [Google Scholar]

- Zhu, J.M. Design of Submersible; Shanghai Jiaotong University Press: Shanghai, China, 1992. [Google Scholar]

- Zhang, Y.; Lai, C.L.; He, W.P.; Liu, Y. Review of materials selection and application of submersible pressure hull structure. J. Ship Sci. Technol. 2022, 44, 1–6. (In Chinese) [Google Scholar] [CrossRef]

- Turner, S.E. Underwater implosion of glass spheres. J. Acoust. Soc. Am. 2007, 121, 844–852. [Google Scholar] [CrossRef]

- Luo, S.; Li, Y.; Wang, W. Development and prospects of non-metallic submersible pressure hull. Chin. J. Ship Res. 2020, 15, 9–18. (In Chinese) [Google Scholar]

- YST479-2005; General Industrial Aluminum and Aluminum Alloy Forgings. National Nonferrous Metals Standardization Technical Committee: China.

- GB 150. 1~150. 4—2011. S. Pressure Vessel, China. National Standard of the People’s Republic of China. Available online: https://members.wto.org/crnattachments/2011/tbt/CHN/11_1135_00_et.pdf (accessed on 1 June 2022).

- China Classification Society. Rules for Classification of Diving Systems And Submersibles; People’s Communications Press: Beijing, China, 2018; pp. 9+22–47. Available online: https://www.ccs.org.cn/ccswzen/articleDetail?id=201910000000003438 (accessed on 1 June 2022).

- Zhang, J.; Wang, W.; Wang, F.; Tang, W.; Cui, W.; Wang, W. Elastic buckling of externally pressurized Cassini oval shells with various shape indices. Thin-Walled Struct. 2018, 122, 83–89. [Google Scholar] [CrossRef]

- Jansen, E. The Influence of Initial Geometric Imperfections on Composite Shell Stability and Vibrations. In Stability and Vibrations of Thin Walled Composite Structures; Abramovich, H., Ed.; Woodhead Publishing: Vienna, Austria, 2017; pp. 509–548. [Google Scholar]

- Wagner, H.N.R.; Niewohner, G.; Pototzky, A.; Huhne, C. On the imperfection sensitivity and design of tori-spherical shells under external pressure. J. Int. Press. Vessel Pip. 2021, 191, 104321. [Google Scholar] [CrossRef]

- Zhou, C.T. Elastic-Plastic Stability Theory of Thin Shells; National Defense Industry Press: Beijing, China, 1979; pp. 1–125. [Google Scholar]

- Chen, T.Y.; Chen, B.Z. Mechanics of Elastic Thin Shells, 1st ed.; Huazhong Institute of Technology Press: Hubei, China, 1983; pp. 177–241. [Google Scholar]

- Renhua, W.; Minghua, Y.; Zili, W. Ultimate strength analysis of pressure spherical hull of manned deep-ocean submersibles. J. Jiangsu Univ. Sci. Technol. Nat. Sci. Ed. 2006, 20, 1–5. (In Chinese) [Google Scholar]

- Renhua, W.A.; Minghua, Y.U.; Liangbi, L.I. Influence of initial deflection on plastic stability of manned deep-sea submersible’s pressure sphere hull. J. Ocean. Eng. 2005, 23, 111–115. (In Chinese) [Google Scholar]

- Narayana, Y.V.; Gunda, J.B.; Reddy, P.R.; Markandeya, R. Non-linear Buckling and Post-buckling Analysis of Cylindrical Shells Subjected to Axial Compressive Loads: A Study on Imperfection Sensitivity. Nonlinear Eng. 2013, 2, 83–95. [Google Scholar] [CrossRef]

- Germanischer Lloyd Aktiengesellschaft. Rules for Classification and Construction, 1-Ship Technology, 5-Underwater Technology, 2-Manned Submersibles. S. Sweden: Germanischer Lloyd Aktiengesellschaft in 2009 (GL). 2009. Available online: https://sea.edu/wp-content/uploads/2022/02/Guidelines_for_Design_and_Contruction_of_Large_Modern_Yacht_Rigs.pdf (accessed on 5 June 2022).

- Li, L.; Wang, R.; Yu, M.; Wang, Z. Nonlinear Finite Element Analysis of Pressurized Spherical Shell for Manned Deep Submersible. J. Shipbuild. China 2005, 46, 11–18. (In Chinese) [Google Scholar]

- Barathan, V.; Rajamohan, V. Nonlinear buckling analysis of a semi-elliptical dome: Numerical and experimental investigations. J. Thin-Walled Struct. 2022, 171, 108708. [Google Scholar] [CrossRef]

- Wang, X.S. Pressure Vessel; East China University of Science and Technology Press: Shanghai, China, 2018; p. 107. [Google Scholar]

| Items | Symbols/Units | Parameter |

|---|---|---|

| Model shape | / | spheroidicity |

| The ratio of the length axis | / | 1.38 |

| External diameter | 700 | |

| Modulus of elasticity | 71,000 | |

| Poisson ratio | 0.33 | |

| Limit of proportionality | σp/MPa | 300 |

| Yield strength | 440 | |

| Tensile strength | 500 |

| t/mm | 19 | 20 | 21 |

|---|---|---|---|

| C | 0.036 | 0.0372 | 0.0392 |

| CS | 0.385 | 0.373 | 0.355 |

| CZ | 0.9378 | 0.94 | 0.959 |

| Pj/Mpa | 25 | 25 | 25 |

| Pe/Mpa | 77.29 | 82.53 | 91.65 |

| Pcr/Mpa | 27.905 | 28.92 | 31.20 |

| The Flexion Mode Order | Grid Buckling Factor | Elastic Instability Force (MPa) |

|---|---|---|

| 1 | 5.2569 | 156.4225 |

| 2 | 5.2605 | 156.5123 |

| 3 | 5.4482 | 161.205 |

| 4 | 5.4485 | 161.2125 |

| 5 | 5.4686 | 161.715 |

| 6 | 5.469 | 161.725 |

| 7 | 6.0304 | 175.76 |

| 8 | 6.0383 | 175.9575 |

| Computational Method | Pj (MPa) | Pcr (MPa) |

|---|---|---|

| Kármán–Tsien formula | 25 | 40.12 |

| The experimental mean value of Kármán–Tsien formula [36] | 25 | 27.47 |

| CCS | 25 | 27.905 |

| GL standard | 25 | 34.41 |

| Taylor pool formula | 25 | 35.19 |

| Linear flexion (corrected by CCS) | 25 | 56.477 |

| Nonlinear flexion | 25 | 33.5 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, K.; Zhu, X.; Qin, H.; Hou, F. Optimized Design of the Carrier Structure of an Autonomous Glide Marine Seismometer. J. Mar. Sci. Eng. 2023, 11, 2124. https://doi.org/10.3390/jmse11112124

Li K, Zhu X, Qin H, Hou F. Optimized Design of the Carrier Structure of an Autonomous Glide Marine Seismometer. Journal of Marine Science and Engineering. 2023; 11(11):2124. https://doi.org/10.3390/jmse11112124

Chicago/Turabian StyleLi, Kun, Xinke Zhu, Huawei Qin, and Fei Hou. 2023. "Optimized Design of the Carrier Structure of an Autonomous Glide Marine Seismometer" Journal of Marine Science and Engineering 11, no. 11: 2124. https://doi.org/10.3390/jmse11112124

APA StyleLi, K., Zhu, X., Qin, H., & Hou, F. (2023). Optimized Design of the Carrier Structure of an Autonomous Glide Marine Seismometer. Journal of Marine Science and Engineering, 11(11), 2124. https://doi.org/10.3390/jmse11112124