Transient Performance of Gas-Engine-Based Power System on Ships: An Overview of Modeling, Optimization, and Applications

Abstract

:1. Introduction

2. Transient Performance of Current Gas Engine Power System on Ships

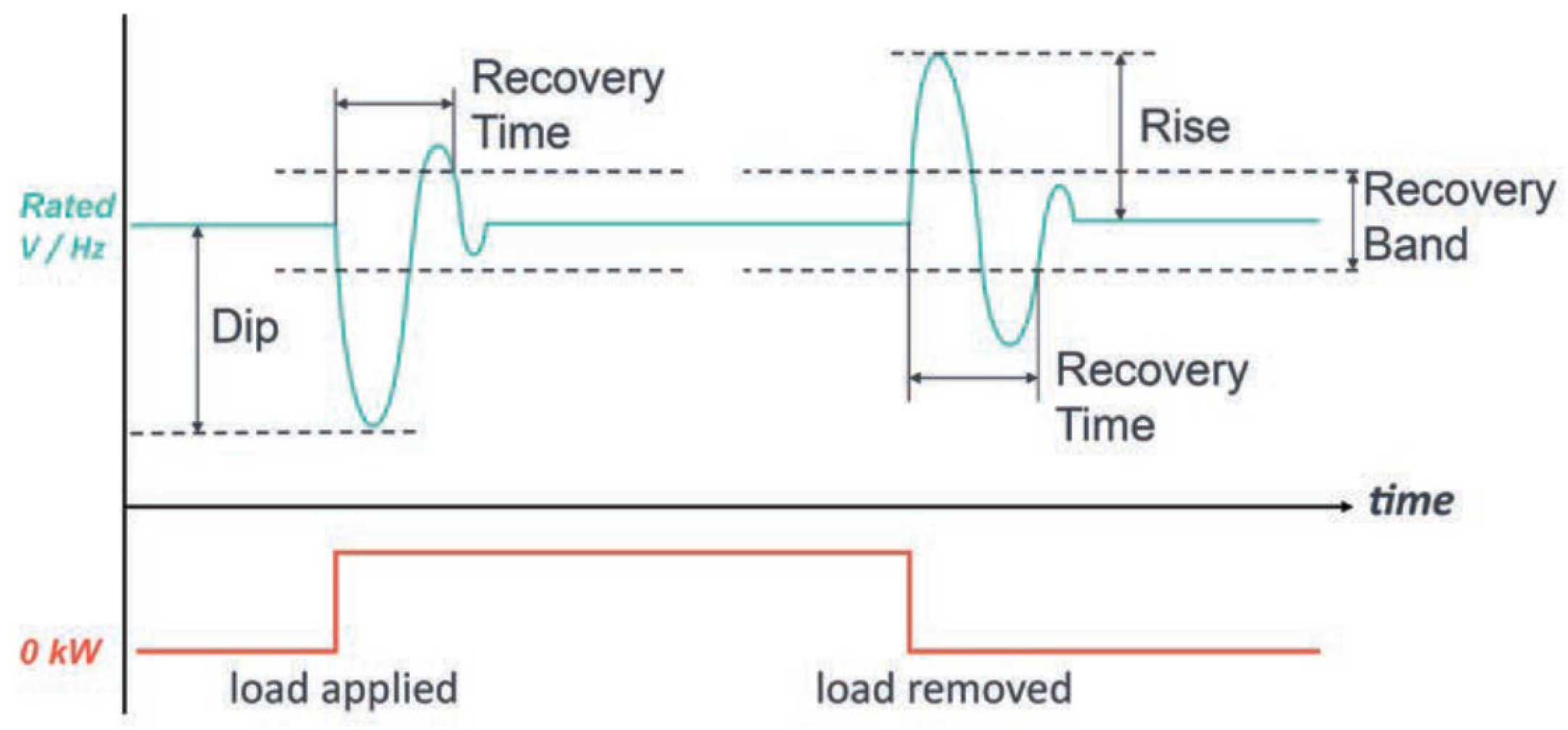

2.1. Industrial Requirements for the Transient Performance of Marine Gas Engines

2.2. Dynamic Performance for Various Types of Gas Engines

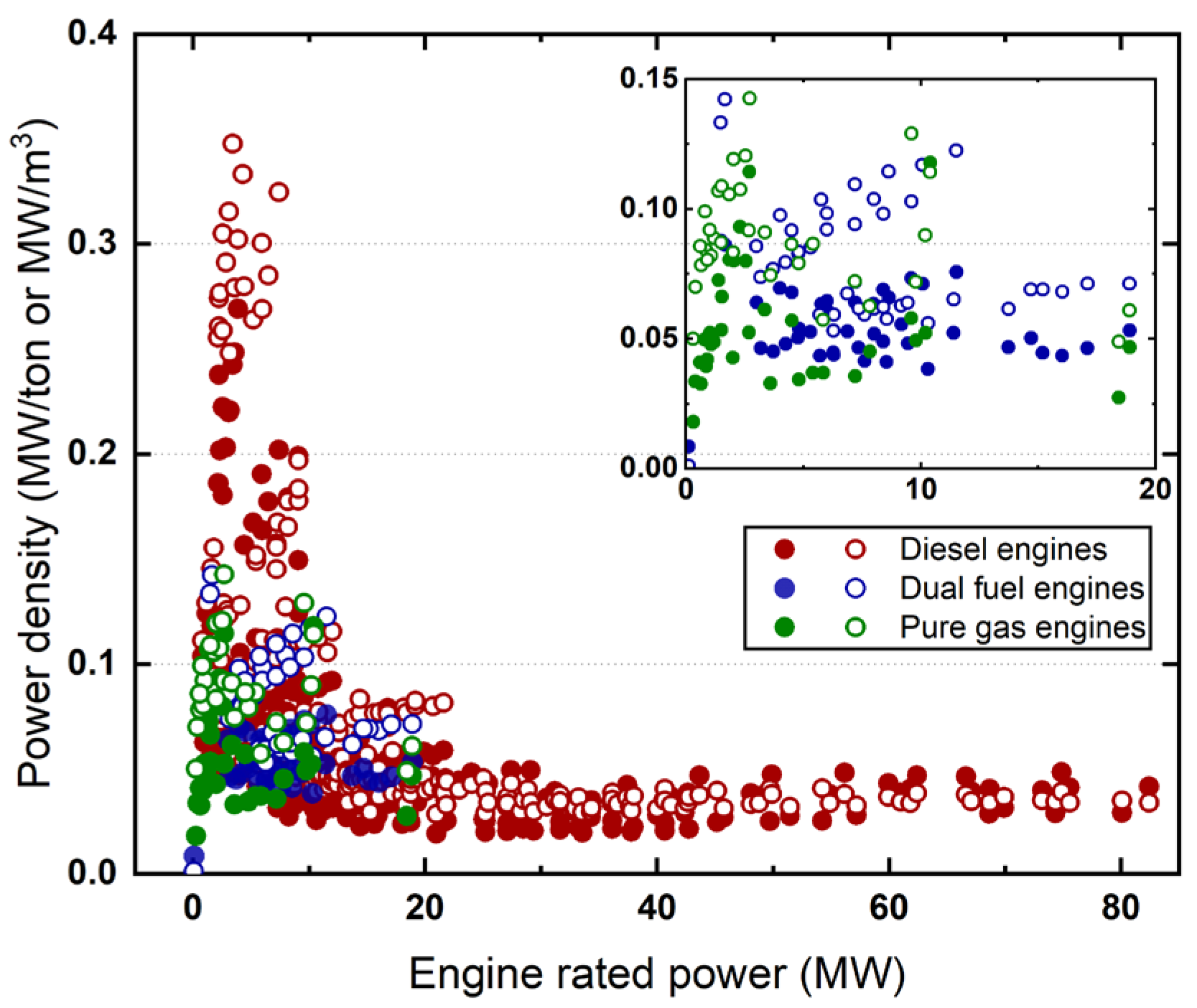

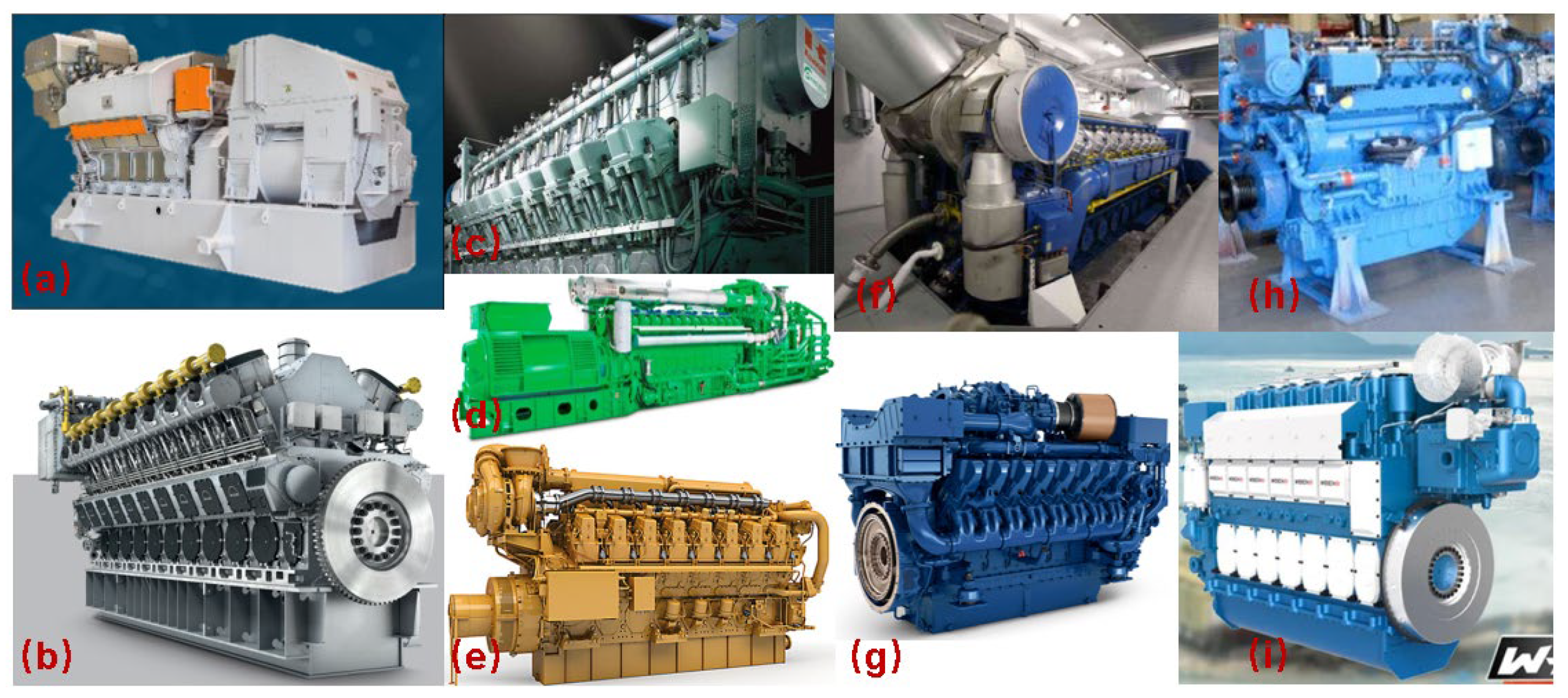

2.3. Available Gas Engines in Marine Applications

- LBSI engine, medium–high speed (0.5–8 MW);

- LPDF engine, four-stroke medium speed (1–18 MW);

- LPDF engine, two-stroke low speed (5–63 MW);

- HPDF engine, two-stroke low speed (>2.5 MW).

3. Advanced Methods to Enhance Transient Performance

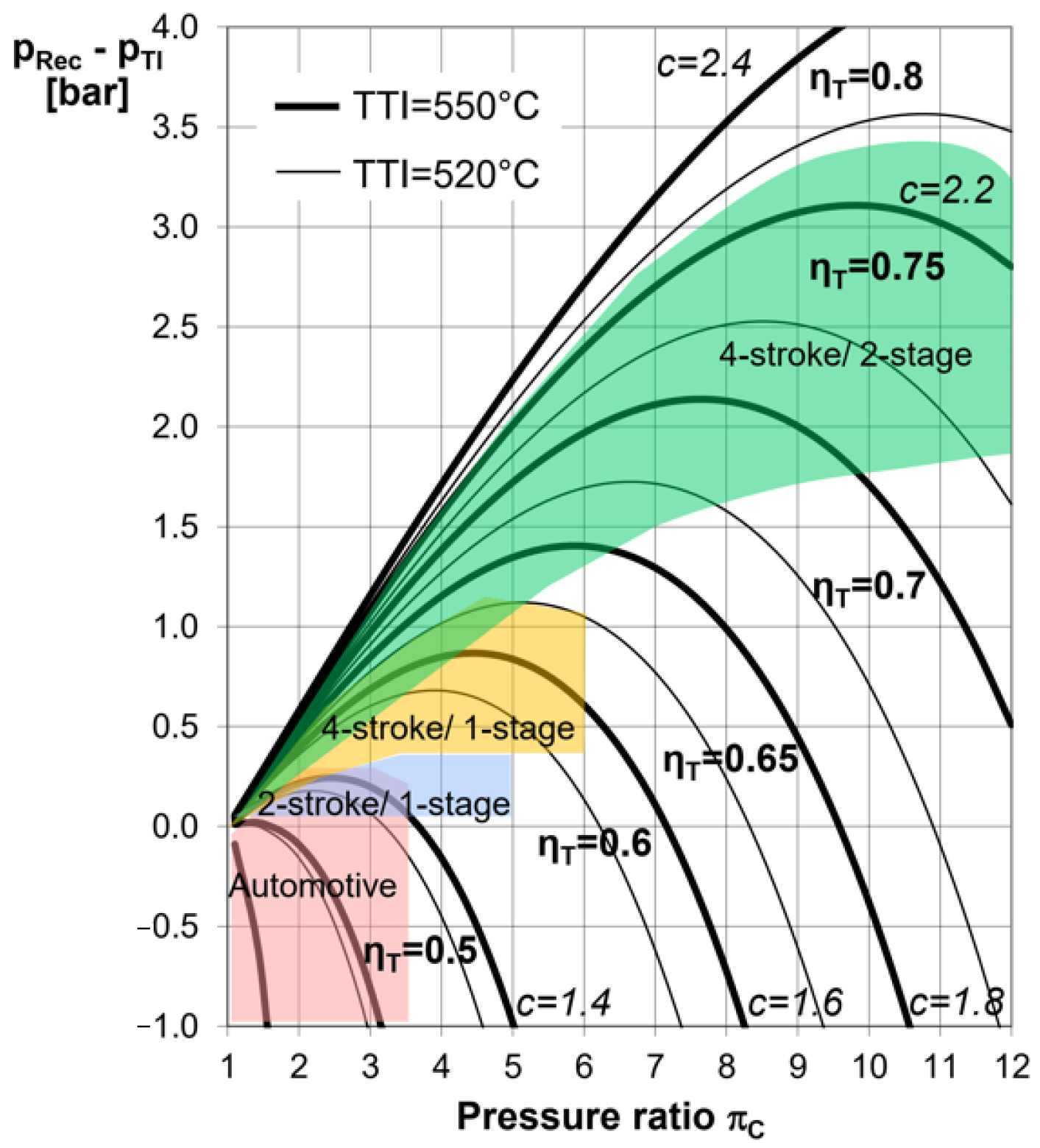

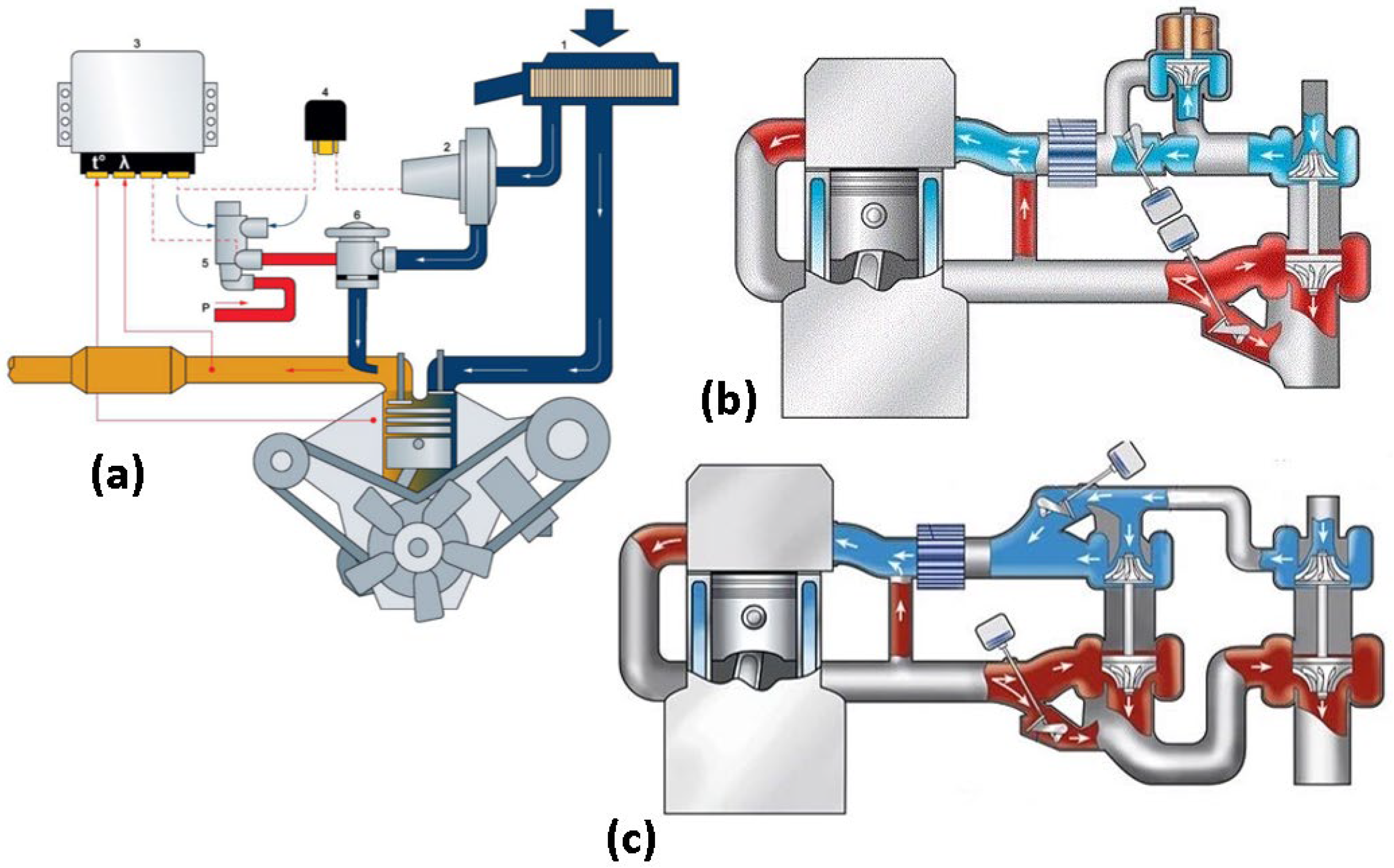

3.1. Air Path System Development

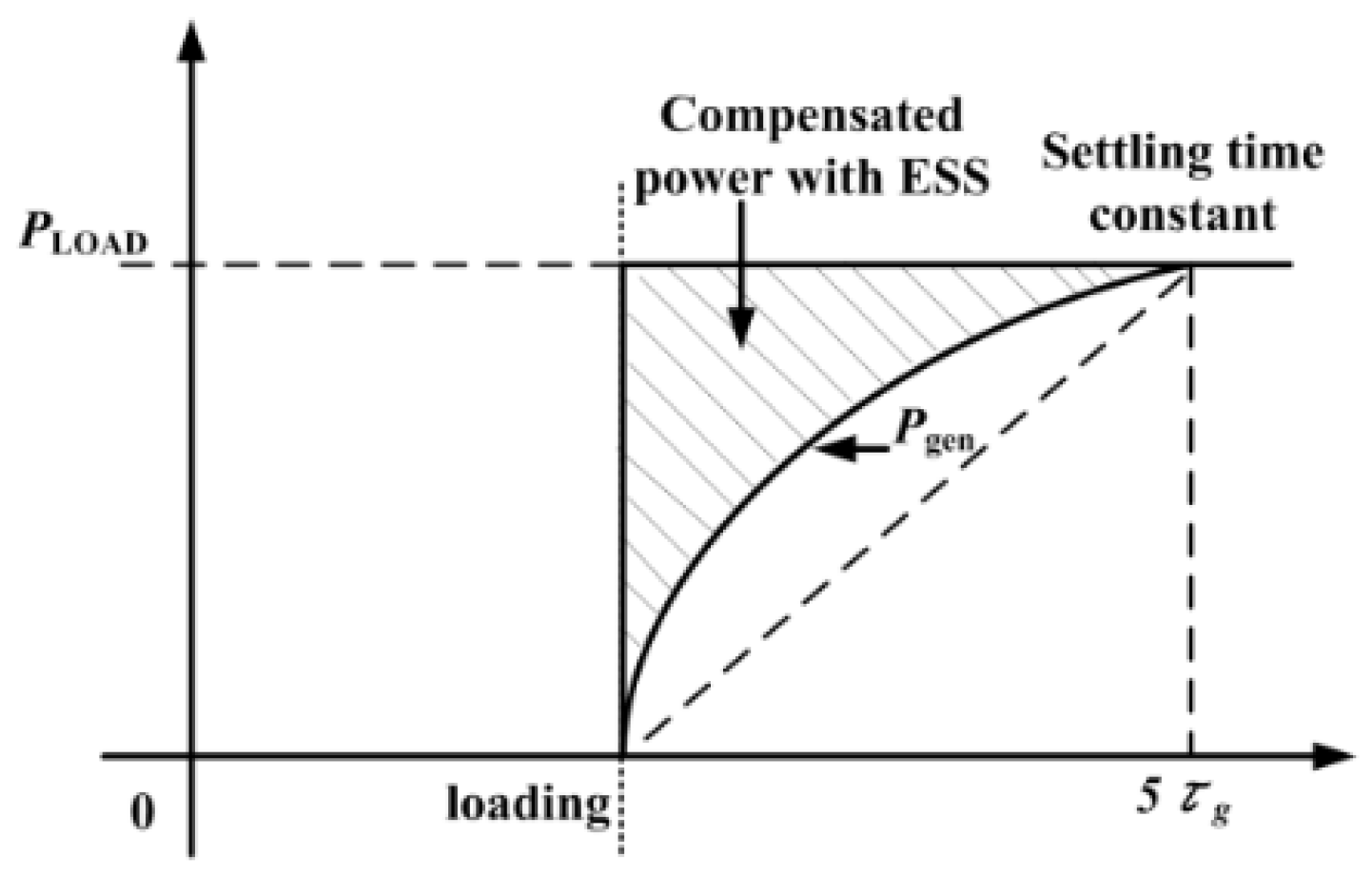

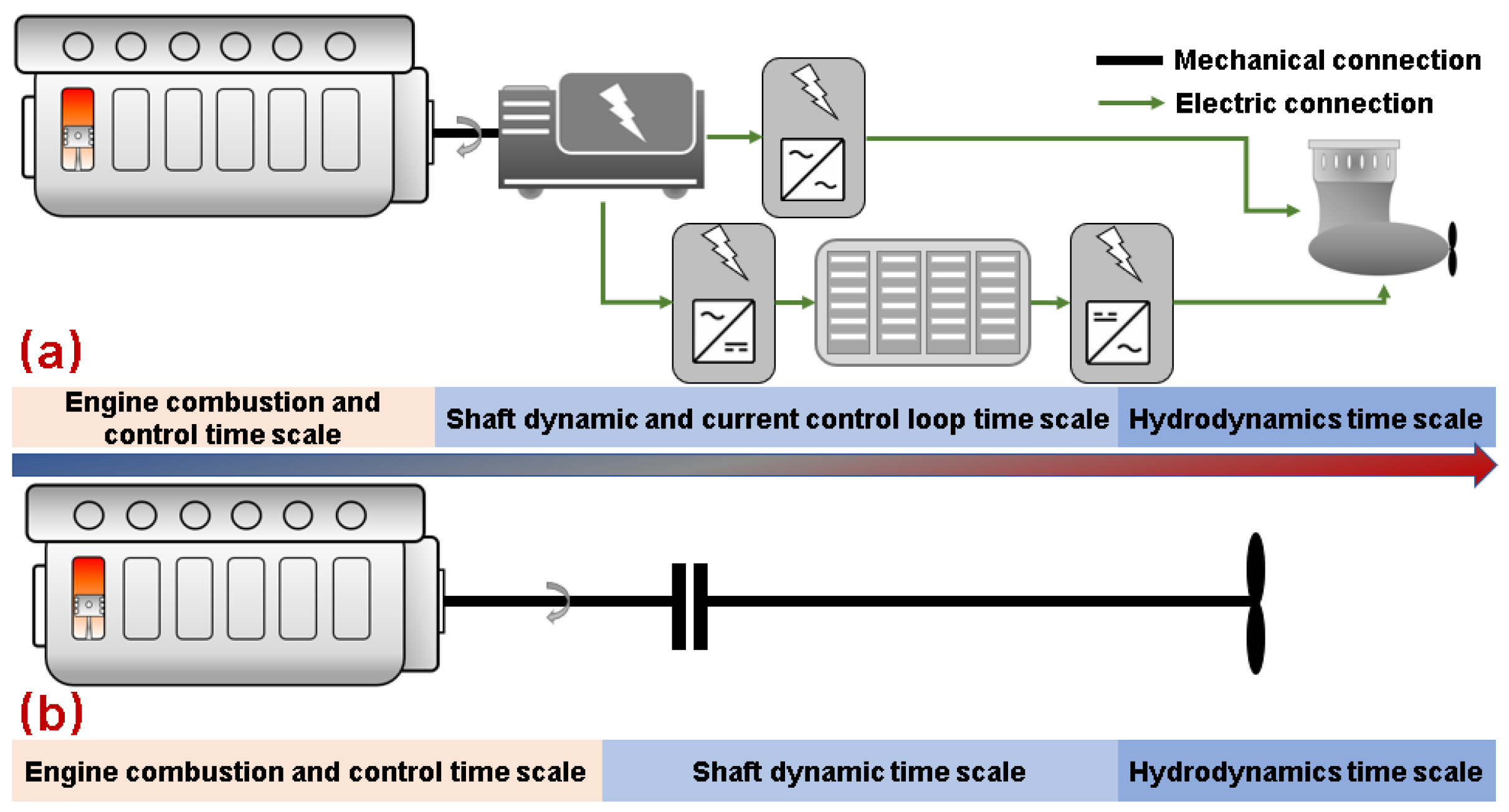

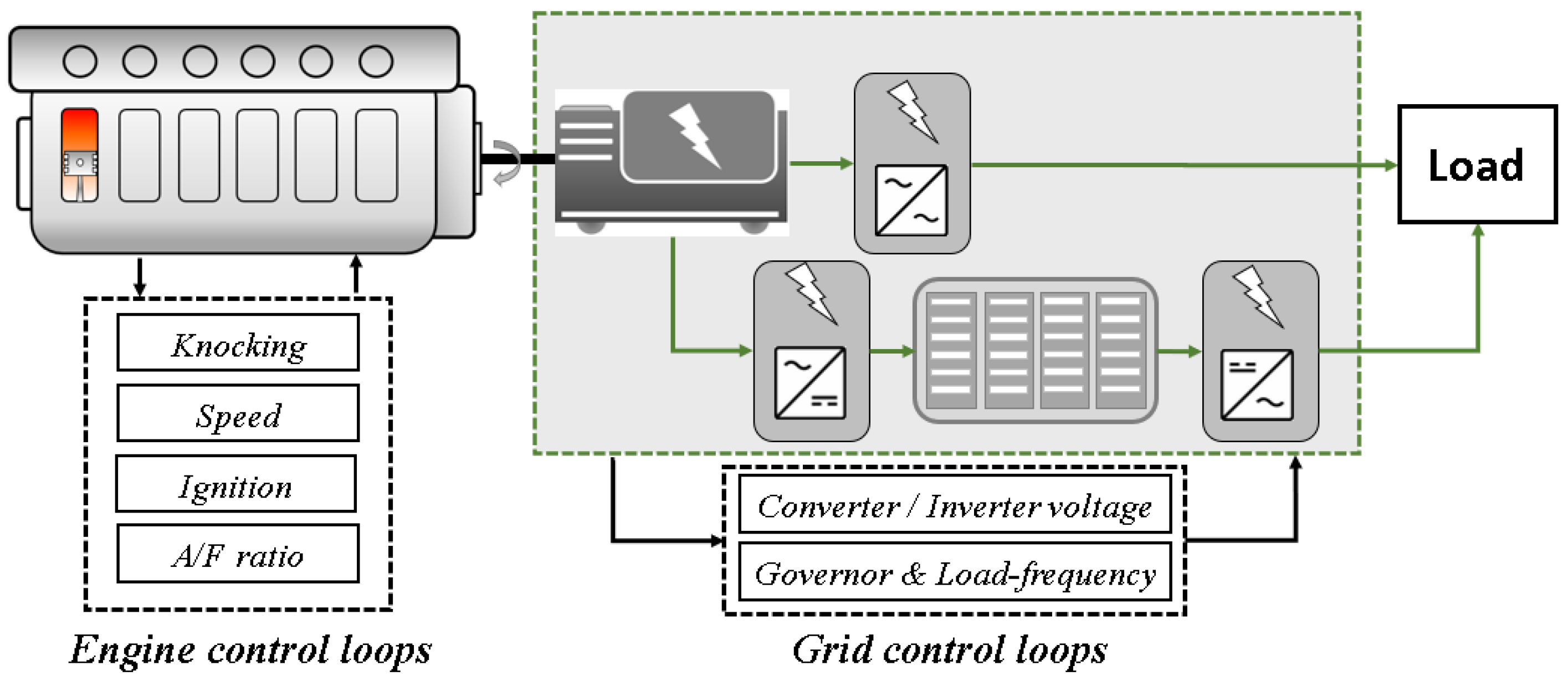

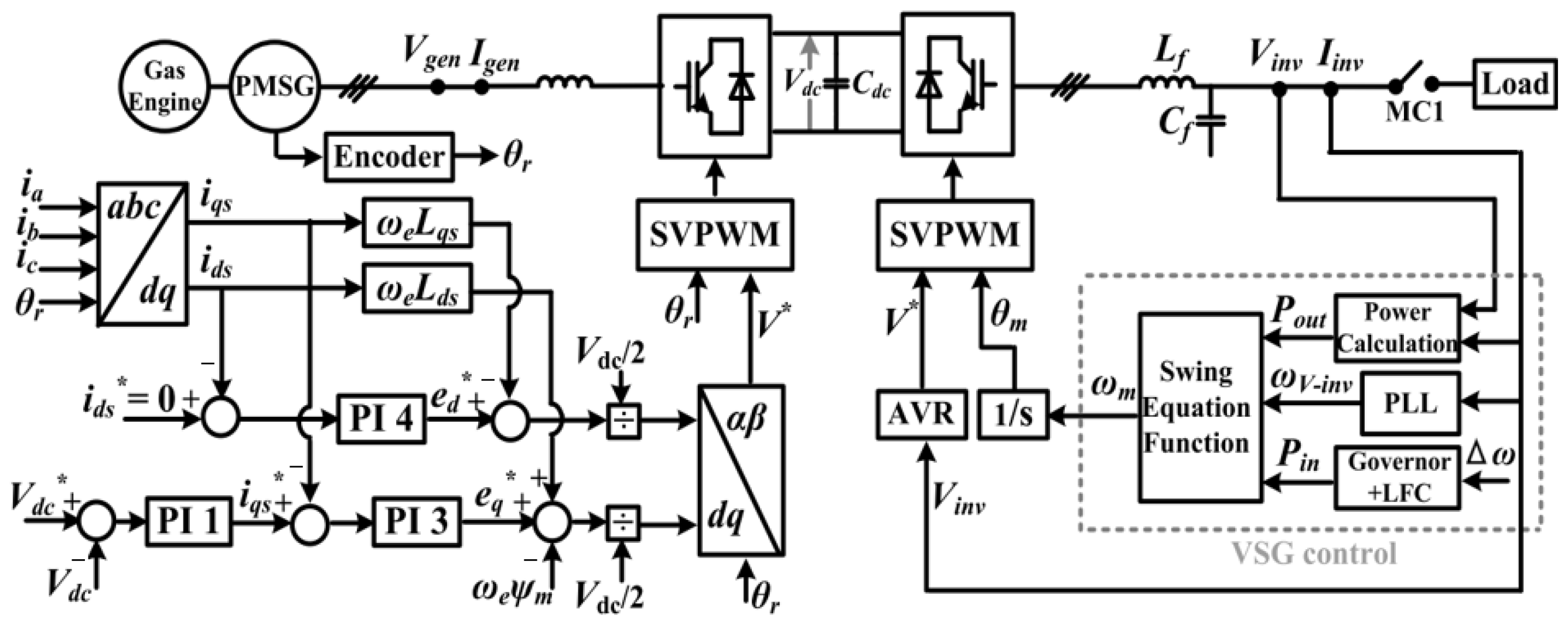

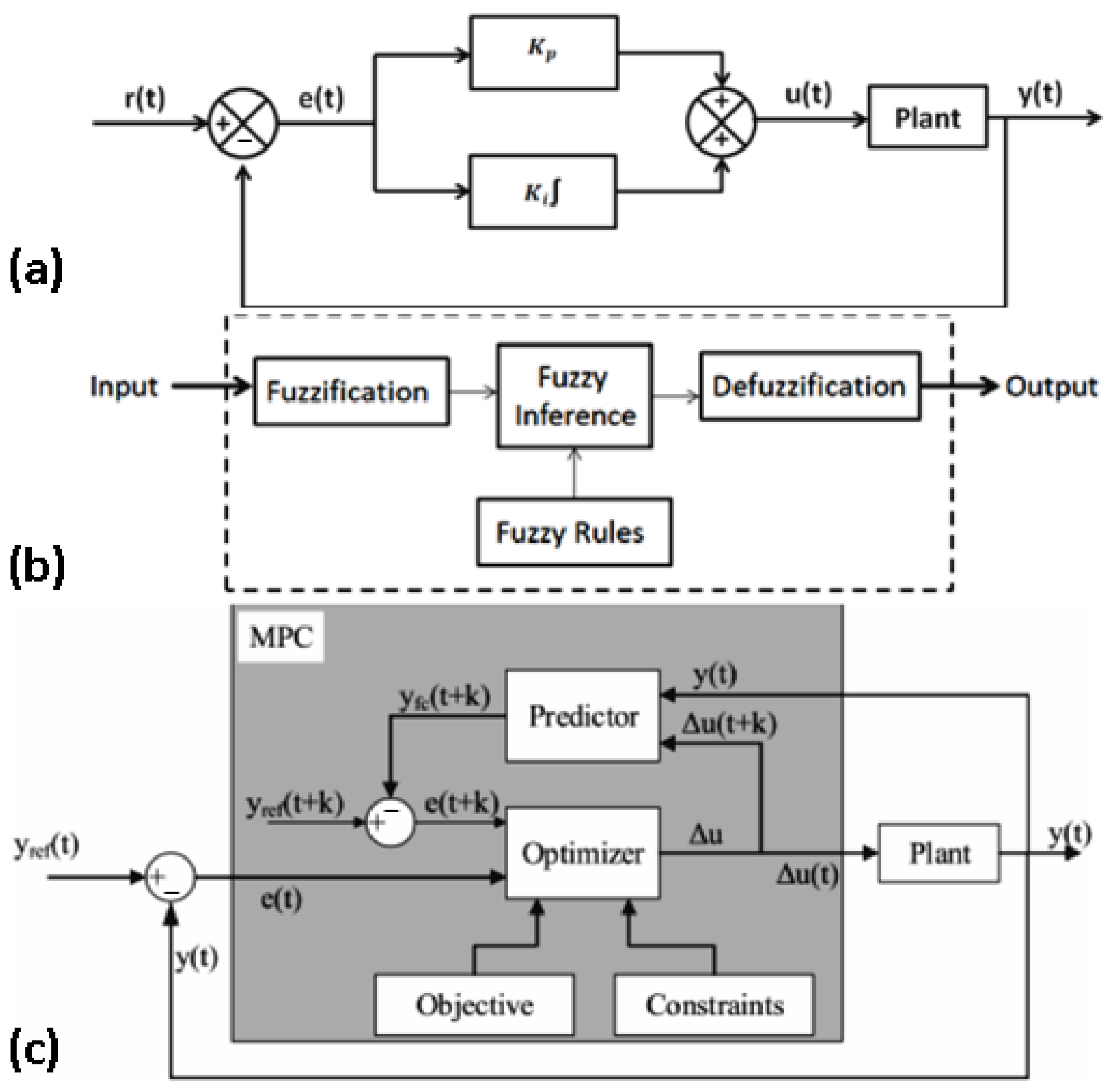

3.2. Power Management and Grid Control Development

3.3. Study Gaps

4. Transient Modeling for Marine Power System

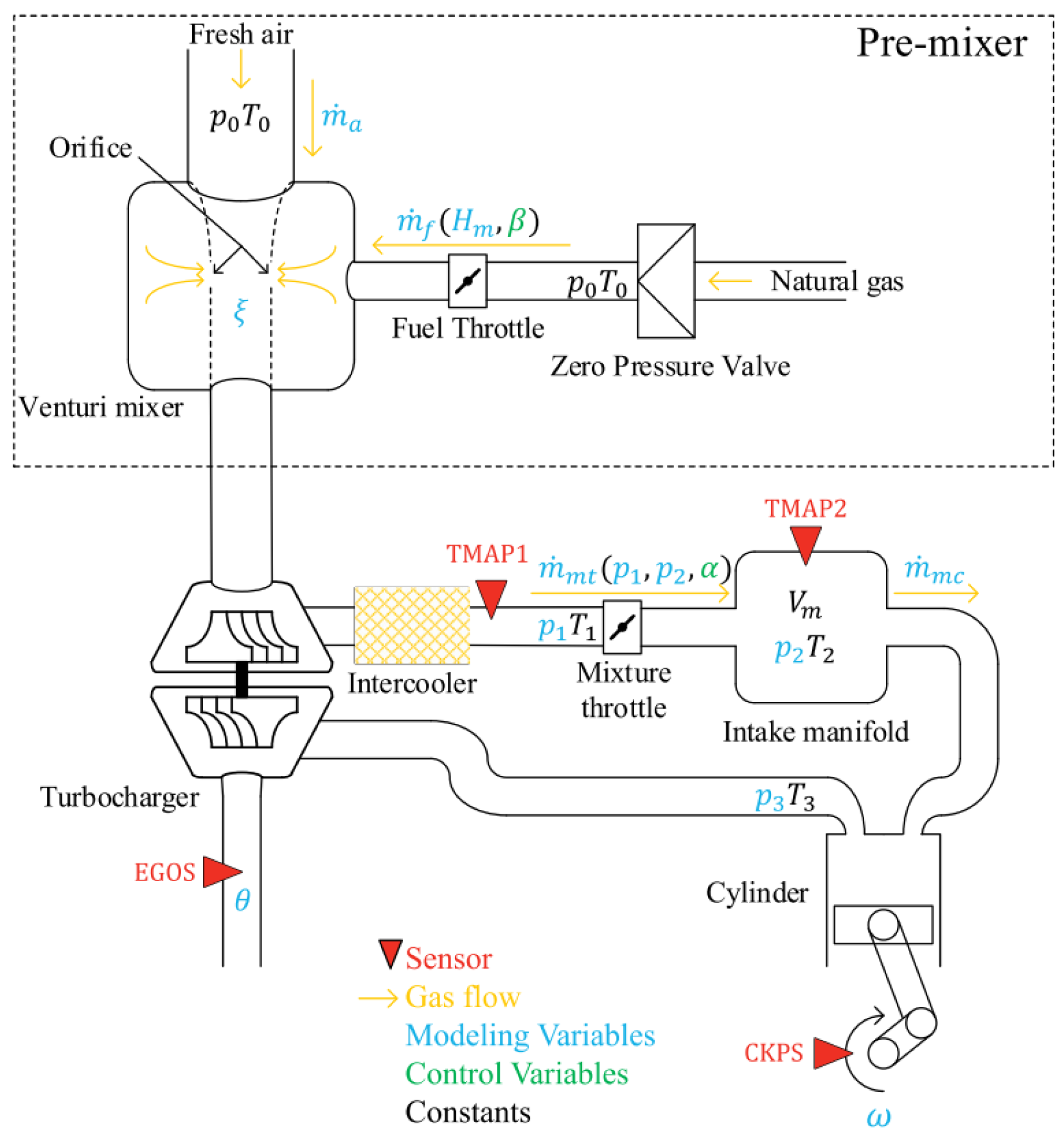

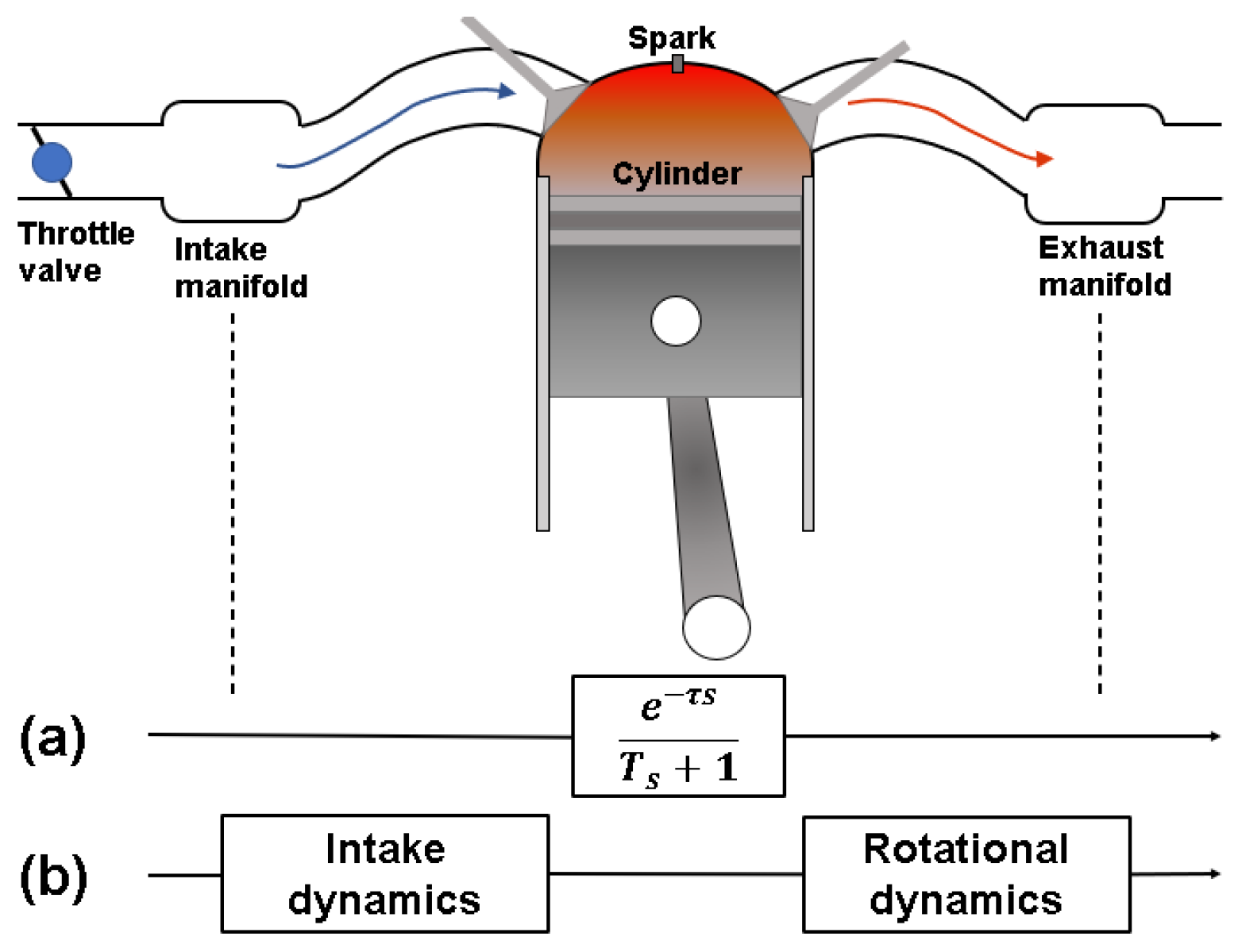

4.1. Gas Engine System

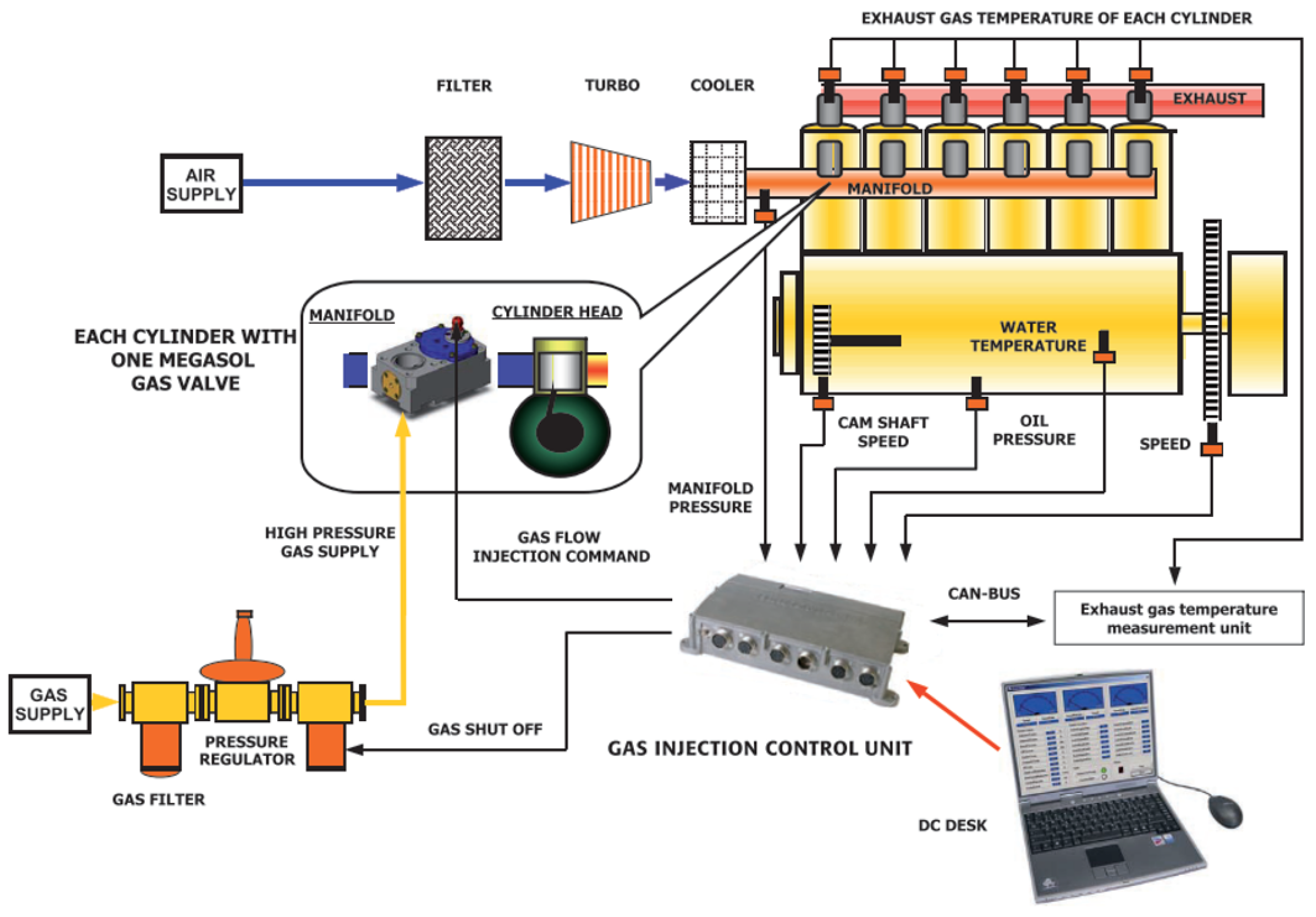

4.1.1. Inlet and Exhaust Modeling

4.1.2. Valve Flow Modeling

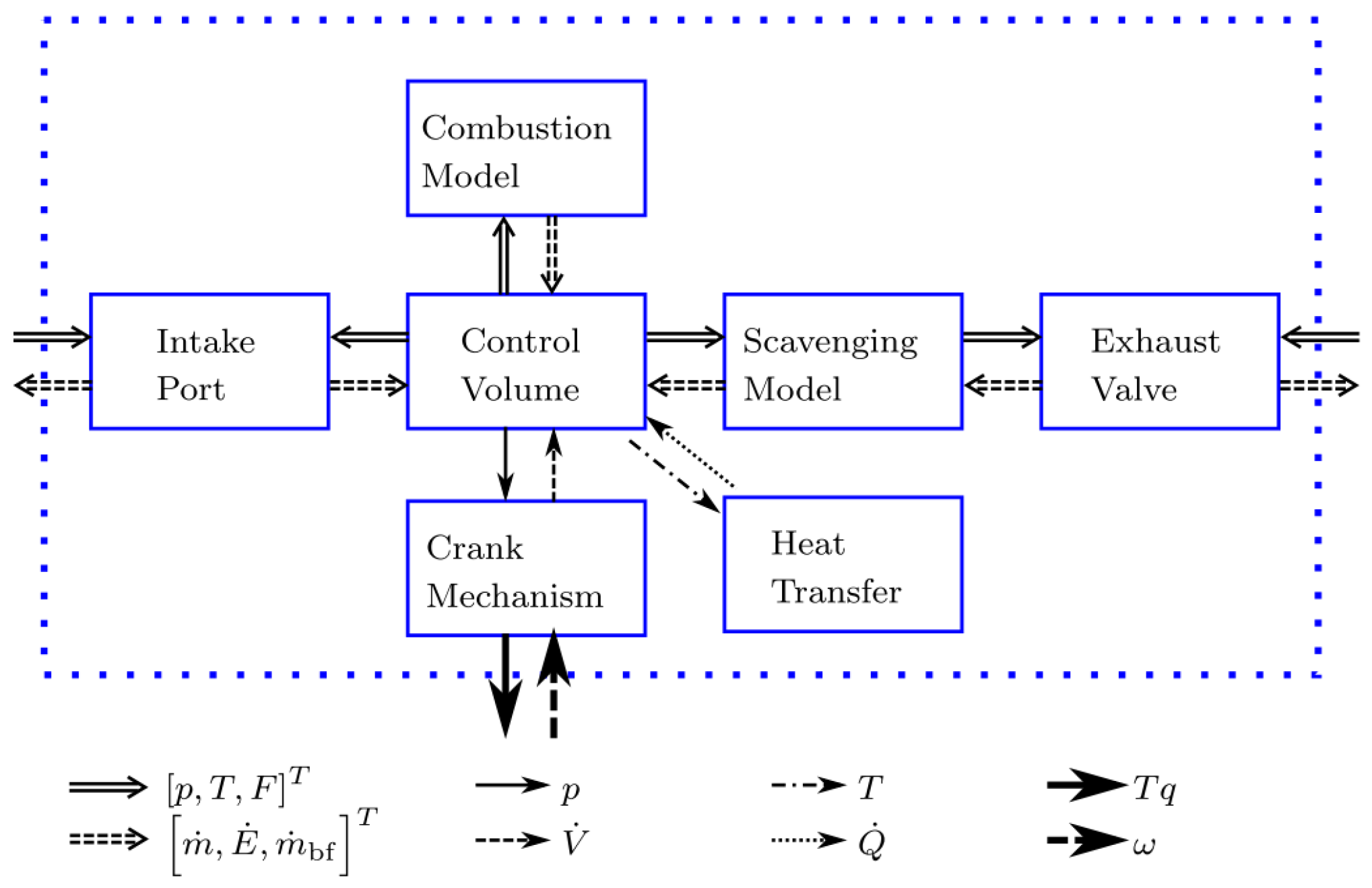

4.1.3. Engine Cylinder Modeling

4.1.4. Crankshaft Dynamic

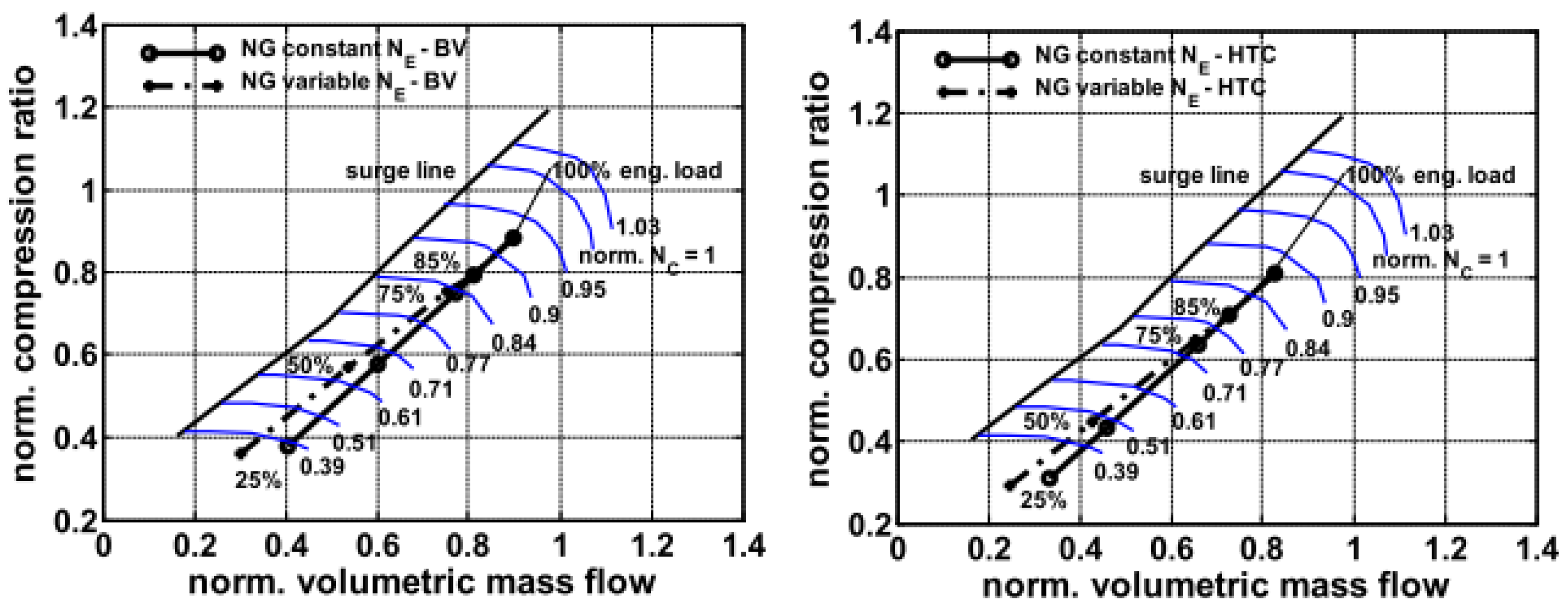

4.1.5. Turbocharger

| Components | Sub-Components | Process | Sub-Model |

|---|---|---|---|

| Cylinder | Control volume | Thermodynamic states | 0D single zone |

| Heat transfer | Convection and diffusion (Woschni) | ||

| Scavenge port | Mass flow | Isentropic compressible fluid flow with discharge coefficient | |

| Exhaust valve | Valve lift | Look-up table | |

| Mass flow | Isentropic compressible fluid flow with discharge coefficient | ||

| Combustion | Heat release rate | Wiebe or predictive model | |

| Scavenging | Scavenging | Empirical model for exhaust gas composition | |

| Crankshaft | Energy transformation | Kinematics | |

| Turbocharger | Compressor | Mass flow, efficiency | Look-up table |

| Compression | Isentropic compression with efficiency | ||

| Turbine | Mass flow, efficiency | Look-up table | |

| Compression | Isentropic compression with efficiency | ||

| Shaft | Speed | Shaft rotates kinematics | |

| Scavenge air cooler | Mass flow | Isentropic compressible fluid with discharge coefficient flow | |

| Heat transfer | Effectiveness-NTU method | ||

| Scavenge air & exhaust gas receiver | Control volume | Thermodynamic state | 0D single zone |

| Heat transfer | No heat transfer | ||

| Wastegate | Mass flow | Isentropic compressible fluid with discharge coefficient flow |

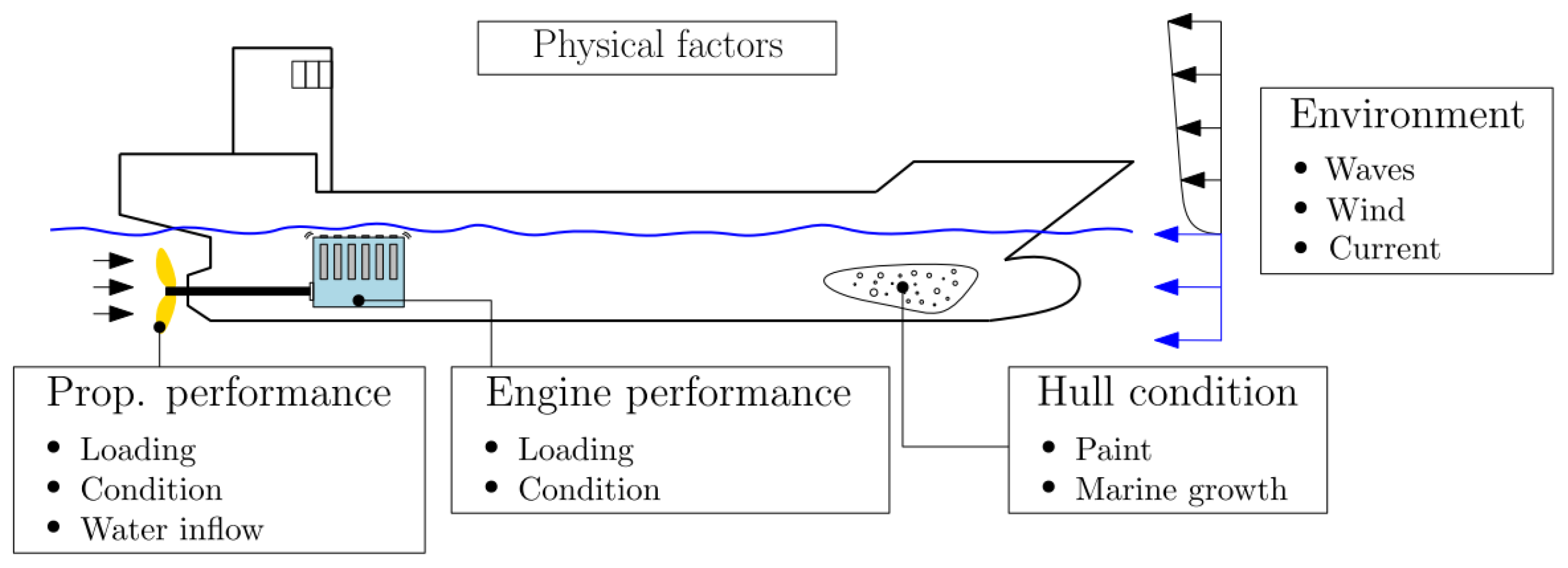

4.2. Propulsion Power and Hull Resistance

4.3. Power Grid Control and System Energy Management

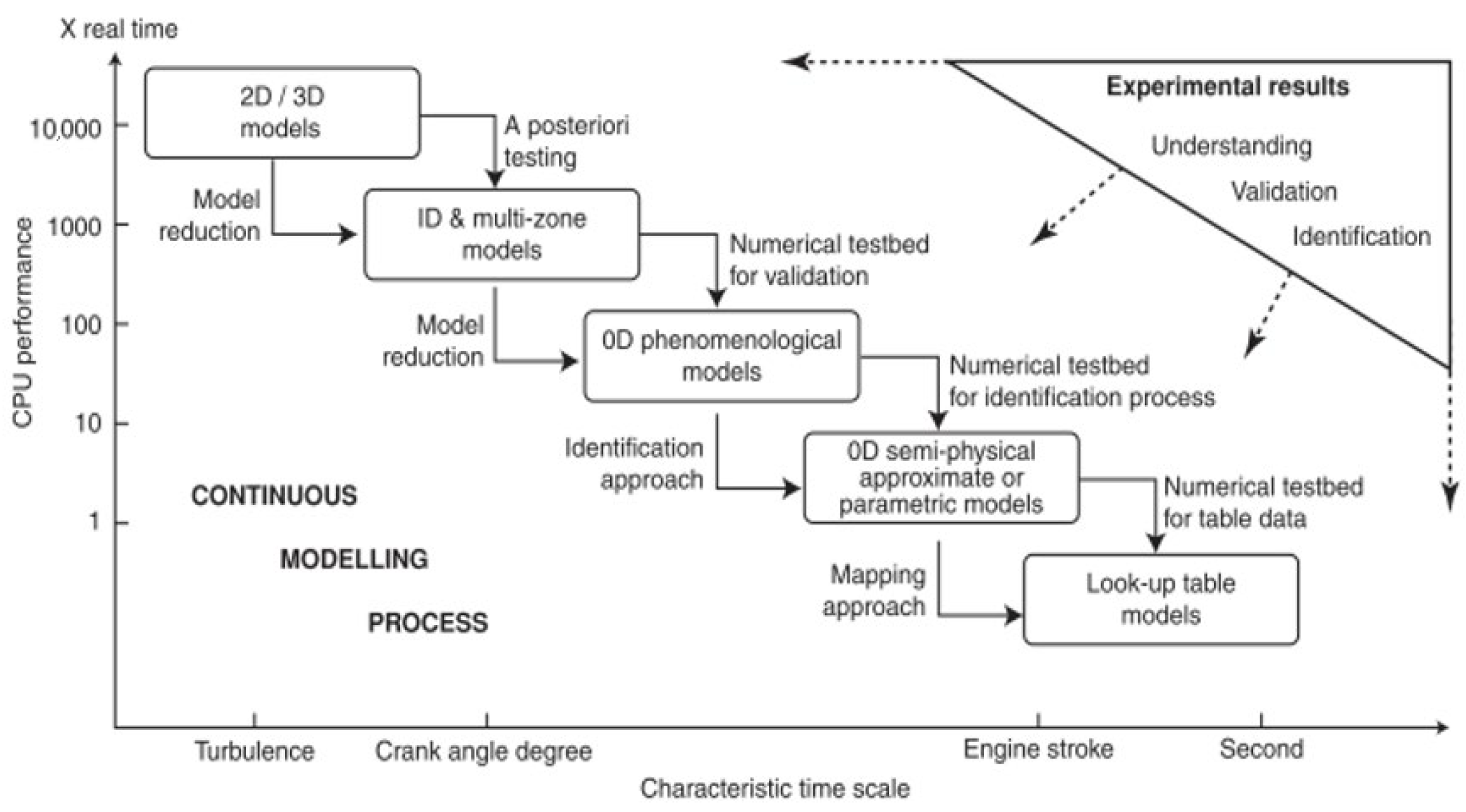

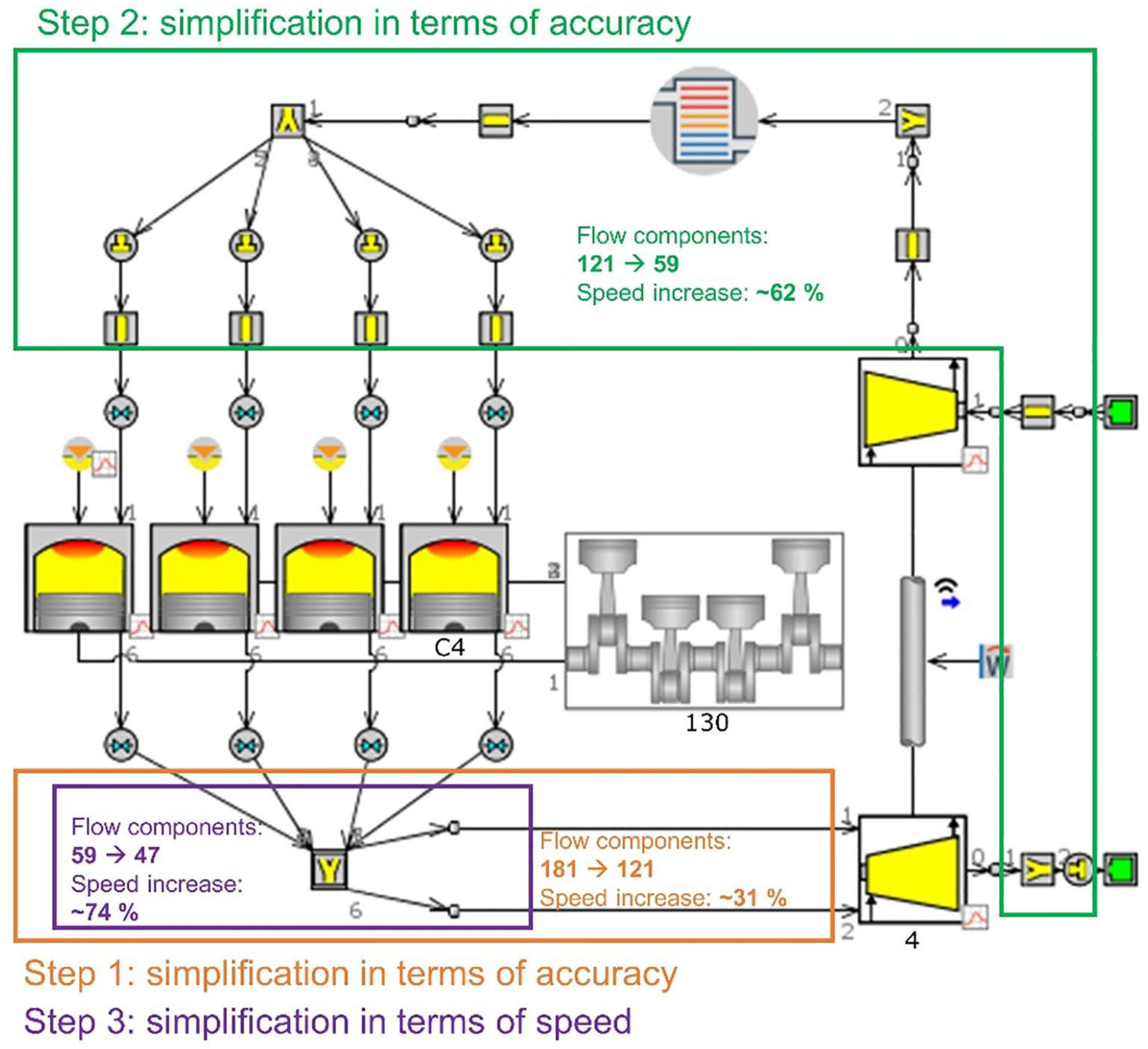

4.4. Model Fidelity and Transient Study-Oriented Reduction

5. Perspectives for Marine Gas Engine Dynamics Performance

5.1. Improving the Transient Control Accuracy for Future Alternative Fuels

5.2. Overcoming the Low System Inertia When Employing Renewable Energies

6. Summary and Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Abbreviations

| CII | Carbon Intensity Indicator |

| DT | Digital Twin |

| ECA | Emission Control Areas |

| EEDI | Energy Efficiency Design Index |

| EGR | Exhaust Gas Recirculation |

| EMS | Energy Management Strategy |

| ESS | Energy Storage System |

| ETC | Electric Turbocharger |

| FRM | Fast Running Model |

| HIL | Hardware In the Loop |

| HPDF | High-Pressure Dual-Fuel engine |

| IGBT | Insulated Gate Bipolar Transistors |

| IMO | International Maritime Organization |

| LBSI | Lean-Burn Spark Ignition |

| LNG | Liquefied Natural Gas |

| LPDF | Low-Pressure Dual-Fuel engine |

| MPC | Model-Based Predictive Control |

| MVM | Mean Value Model |

| PID | Proportional Integral Derivative controller |

| PV | Photovoltaic |

| RT | Real Time |

| SAI | Secondary Air Injection |

| SOC | State Of Charge |

| TF | Transfer Function |

| VCM | Valve Control Management |

| VGT | Variable Geometry Turbocharger |

| VSG | Virtual Synchronous Generator |

References

- Chu Van, T.; Ramirez, J.; Rainey, T.; Ristovski, Z.; Brown, R.J. Global impacts of recent IMO regulations on marine fuel oil refining processes and ship emissions. Transp. Res. Part D Transp. Environ. 2019, 70, 123–134. [Google Scholar] [CrossRef]

- Aakko-Saksa, P.T.; Lehtoranta, K.; Kuittinen, N.; Järvinen, A.; Jalkanen, J.-P.; Johnson, K.; Jung, H.; Ntziachristos, L.; Gagné, S.; Takahashi, C.; et al. Reduction in greenhouse gas and other emissions from ship engines: Current trends and future options. Prog. Energy Combust. Sci. 2023, 94, 101055. [Google Scholar] [CrossRef]

- Tan, Z.; Liu, H.; Shao, S.; Liu, J.; Chen, J. Efficiency of Chinese ECA policy on the coastal emission with evasion behavior of ships. Ocean. Coast. Manag. 2021, 208, 105635. [Google Scholar] [CrossRef]

- Nikopoulou, Z.; Cullinane, K.; Jensen, A. The role of a cap-and-trade market in reducing NOx and SOx emissions: Prospects and benefits for ships within the Northern European ECA. Proc. Inst. Mech. Eng. Part M J. Eng. Marit. Environ. 2012, 227, 136–154. [Google Scholar] [CrossRef]

- Wang, Y.; Guo, C.; Du, C.; Chen, X.; Jia, L.; Guo, X.; Chen, R.; Zhang, M.; Chen, Z.; Wang, H. Carbon peak and carbon neutrality in China: Goals, implementation path, and prospects. China Geol. 2021, 4, 720–746. [Google Scholar] [CrossRef]

- SZEP. Roadmap to Zero Emission from International Shipping; Ministry of Land, Infrastructure, Transport and Tourism: Tokyo, Japan, 2020. [Google Scholar]

- Holtbecker, R.; Luo, Y.; Nilsson, J.; Tzanos, S.; Kyrtatos, P. WiDE—An example on how digitalization creates value for ship operators. In Proceedings of the 30th CIMAC World Congress 2023, Busan, Republic of Korea, 12–16 June 2023. [Google Scholar]

- MORSFERA. IMO Action to Reduce Greenhouse Gas Emissions from International Shipping; International Maritime Organization (IMO): London, UK, 2021. [Google Scholar]

- DNV. Achieving the IMO Decarbonization Goals. Available online: https://www.dnv.com/expert-story/maritime-impact/How-newbuilds-can-comply-with-IMOs-2030-CO2-reduction-targets.html (accessed on 9 November 2023).

- Perčić, M.; Vladimir, N.; Fan, A. Life-cycle cost assessment of alternative marine fuels to reduce the carbon footprint in short-sea shipping: A case study of Croatia. Appl. Energy 2020, 279, 115848. [Google Scholar] [CrossRef]

- DNV-GL. Energy Transition Outlook 2021; DNV: Bærum, Norway, 2021. [Google Scholar]

- Stolz, B.; Held, M.; Georges, G.; Boulouchos, K. Techno-economic analysis of renewable fuels for ships carrying bulk cargo in Europe. Nat. Energy 2022, 7, 203–212. [Google Scholar] [CrossRef]

- CIMAC. Future Marine eFuels; CIMAC: Frankfurt, Germany, 2021. [Google Scholar]

- O’Malley, S.; Walsh, K.; Hasen, A.; Bratvold, D.; Ratafia-Brown, J. Marine Fuel Choice for Ocean Going Vessels within Emissions Control Areas; US Energy Information Administration: Washington, DC, USA, 2015. [Google Scholar]

- Manouchehrinia, B.; Dong, Z.; Gulliver, T.A. Well-to-Propeller environmental assessment of natural gas as a marine transportation fuel in British Columbia, Canada. Energy Rep. 2020, 6, 802–812. [Google Scholar] [CrossRef]

- DNV-GL. Bridging Fuels. Available online: https://www.dnv.com/maritime/hub/decarbonize-shipping/fuels/bridging-fuels.html2021 (accessed on 9 November 2023).

- Khan, M.I.; Yasmin, T.; Shakoor, A. Technical overview of compressed natural gas (CNG) as a transportation fuel. Renew. Sustain. Energy Rev. 2015, 51, 785–797. [Google Scholar] [CrossRef]

- Fan, A.; Wang, J.; He, Y.; Perčić, M.; Vladimir, N.; Yang, L. Decarbonising inland ship power system: Alternative solution and assessment method. Energy 2021, 226, 120266. [Google Scholar] [CrossRef]

- Clarkson. Alternative Fuels Installations by Vessel; Clarkson Research: London, UK, 2020. [Google Scholar]

- Formosa, W.; Sant, T.; De Marco Muscat-Fenech, C.; Figari, M. Wind-Assisted Ship Propulsion of a Series 60 Ship Using a Static Kite Sail. J. Mar. Sci. Eng. 2023, 11, 117. [Google Scholar] [CrossRef]

- Abdullah-Al-Mahbub, M.; Towfiqul Islam, A.R.M.; Alam, E.; Asha, M.R. Sustainable solar energy potential on marine passenger ships of Bay of Bengal: A way of reducing carbon dioxide emissions and disaster risk reduction. Energy Explor. Exploit. 2023, 41, 1697–1723. [Google Scholar] [CrossRef]

- Johnson, J.; Ellis, A.; Denda, A.; Morino, K.; Shinji, T.; Ogata, T.; Tadokoro, M. PV output smoothing sing a battery and natural gas engine-generator. In Proceedings of the 2013 IEEE 39th Photovoltaic Specialists Conference (PVSC), Tampa, FL, USA, 16–21 June 2013. [Google Scholar]

- Li, B.; Lv, J.; Deng, F.; Cui, Y.; Zhang, B. The Energy Recovery Effect of Wave Energy Utilization System under the Rolling Motion of Ships. J. Waterw. Port Coast. Ocean. Eng. 2023, 149, 04022030. [Google Scholar] [CrossRef]

- Leong, P. Berge Bulk Unveils the World’s Most Powerful Sailing Cargo Ship. Available online: https://www.bergebulk.com/berge-bulk-unveils-the-worlds-most-powerful-sailing-cargo-ship/2023 (accessed on 9 November 2023).

- Brouwer, E.; Brands, D.; Content, J.; Lenders, E. The Position of the Dutch Solar PV Sector in the European Value Chain; SEO Amsterdam: Amsterdam, The Netherlands, 2023. [Google Scholar]

- Naderipour, A.; Abdul-Malek, Z.; Nowdeh, S.A.; Kamyab, H.; Ramtin, A.R.; Shahrokhi, S.; Klemeš, J.J. Comparative evaluation of hybrid photovoltaic, wind, tidal and fuel cell clean system design for different regions with remote application considering cost. J. Clean. Prod. 2021, 283, 124207. [Google Scholar] [CrossRef]

- Tavakoli, S.; Bagherabadi, K.M.; Schramm, J.; Pedersen, E. Fuel consumption and emission reduction of marine lean-burn gas engine employing a hybrid propulsion concept. Int. J. Engine Res. 2021, 23, 1406–1416. [Google Scholar] [CrossRef]

- Kelling, U.S. Electric drive system for marime propulsion what can we learn from the vehicles business. In Proceedings of the 29th CIMAC World Congress 2019, Vancouver, BC, Canada, 10–14 June 2019. [Google Scholar]

- Nuchturee, C.; Li, T.; Xia, H. Design of Cost-Effective and Emission-Aware Power Plant System for Integrated Electric Propulsion Ships. J. Mar. Sci. Eng. 2021, 9, 684. [Google Scholar] [CrossRef]

- Mongird, K.; Viswanathan, V.; Balducci, P.; Alam, J. Energy Storage Technology and Cost Characterization Report; U.S. Department of Energy: Washington, DC, USA, 2019. [Google Scholar]

- Kim, S.; Jeon, H.; Kim, J. Trend analysis of domestic and international regulations for electric propulsion system. J. Int. Marit. Saf. Environ. Aff. Shipp. 2020, 4, 113–121. [Google Scholar] [CrossRef]

- ADB. Handbook on Battery Energy Storage System; Asian Development Bank: Mandaluyong, Philippines, 2018. [Google Scholar]

- Hou, J.; Sun, J.; Hofmann, H. Control development and performance evaluation for battery/flywheel hybrid energy storage solutions to mitigate load fluctuations in all-electric ship propulsion systems. Appl. Energy 2018, 212, 919–930. [Google Scholar] [CrossRef]

- Nuchturee, C.; Li, T. A review of energy efficiency improvement strategies for all electric ships. In Proceedings of the 2018 International Conference on New Energy and Future Energy System (NEFES 2018), Shanghai, China, 21–24 August 2018. [Google Scholar]

- Sirimanne, S.N.; Hoffmann, J.; Asariotis, R. Review of Maritime Transport 2022; UN: New York, NY, USA, 2022. [Google Scholar]

- Xie, Y. World’s First 700TEU Pure Battery-Powered Container Ship Sets Sail in Yangzhou. Available online: http://en.sasac.gov.cn/2023/08/02/c_15693.htm2023 (accessed on 9 November 2023).

- Chehrmonavari, H.; Kakaee, A.; Hosseini, S.E.; Desideri, U.; Tsatsaronis, G.; Floerchinger, G.; Braun, R.; Paykani, A. Hybridizing solid oxide fuel cells with internal combustion engines for power and propulsion systems: A review. Renew. Sustain. Energy Rev. 2023, 171, 112982. [Google Scholar] [CrossRef]

- Giap, V.-T.; Lee, Y.D.; Kim, Y.S.; Ahn, K.Y.; Kim, D.H.; Lee, J.I. System simulation and exergetic evaluation of hybrid propulsion system for crude oil tanker: A hybrid of solid-oxide fuel cell and gas engine. Energy Convers. Manag. 2020, 223, 113265. [Google Scholar] [CrossRef]

- Nuchturee, C.; Li, T.; Xia, H. Energy efficiency of integrated electric propulsion for ships—A review. Renew. Sustain. Energy Rev. 2020, 134, 110145. [Google Scholar] [CrossRef]

- Xing, H.; Spence, S.; Chen, H. A comprehensive review on countermeasures for CO2 emissions from ships. Renew. Sustain. Energy Rev. 2020, 134, 110222. [Google Scholar] [CrossRef]

- García-Olivares, A.; Solé, J.; Osychenko, O. Transportation in a 100% renewable energy system. Energy Convers. Manag. 2018, 158, 266–285. [Google Scholar] [CrossRef]

- Yuan, Y.; Wang, J.; Yan, X.; Shen, B.; Long, T. A review of multi-energy hybrid power system for ships. Renew. Sustain. Energy Rev. 2020, 132, 110081. [Google Scholar] [CrossRef]

- Theotokatos, G.; Stoumpos, S.; Bolbot, B.; Boulougouris, E.; Vassalos, D. Marine Dual Fuel Engine Control System Modelling and Safety Implications Analysis. In Proceedings of the International Naval Engineering Conference and Exhibition (INEC), Glasgow, UK, 2–4 October 2018. [Google Scholar]

- Mizythras, P.; Boulougouris, E.; Theotokatos, G. Numerical study of propulsion system performance during ship acceleration. Ocean. Eng. 2018, 149, 383–396. [Google Scholar] [CrossRef]

- Engines ICOC. Position Paper Transient Response Behaviour of Gas Engines; CIMAC: Frankfurt, Germany, 2011. [Google Scholar]

- Wu, S.; Li, T.; Chen, R.; Zhou, X.; Huang, S.; Wang, B. Research on dynamic performance of gas engine power systems for marine applications under the background of energy diversification—A review. In Proceedings of the 10th International Conference on Modeling and Diagnostics for Advanced Engine Systems (COMODIA 2022), Sapporo, Japan, 5–8 July 2022. [Google Scholar]

- Wartsila. Wartsila 31DF Product Guide; Wartsila: Helsinki, Finland, 2020; Available online: https://cdn.wartsila.com/docs/default-source/product-files/engines/df-engine/product-guide-w31df.pdf?sfvrsn=96a9145_21 (accessed on 9 November 2023).

- Ratnam, K.S.; Palanisamy, K.; Yang, G. Future low-inertia power systems: Requirements, issues, and solutions—A review. Renew. Sustain. Energy Rev. 2020, 124, 109773. [Google Scholar] [CrossRef]

- Xia, Y.; Wei, W.; Long, T.; Blaabjerg, F.; Wang, P. New Analysis Framework for Transient Stability Evaluation of DC Microgrids. IEEE Trans. Smart Grid 2020, 11, 2794–2804. [Google Scholar] [CrossRef]

- Daido, T.; Miura, Y.; Ise, T.; Sato, Y. Transient characteristics for load changes of a doubly fed induction generator applied to gas engine congeneration system in stand alone operation. In Proceedings of the 2012 IEEE Energy Conversion Congress and Exposition (ECCE), Raleigh, NC, USA, 15–20 September 2012. [Google Scholar]

- Daido, T.; Miura, Y.; Ise, T.; Sato, Y. Characteristics on Stand-alone Operation of a Doubly-fed Induction Generator Applied to Adjustable Speed Gas Engine Cogeneration System. J. Power Electron. 2013, 13, 841–853. [Google Scholar] [CrossRef]

- Zeng, Q.; Fang, J.; Li, J.; Chen, Z. Steady-state analysis of the integrated natural gas and electric power system with bi-directional energy conversion. Appl. Energy 2016, 184, 1483–1492. [Google Scholar] [CrossRef]

- Dag, S.; Ole, T. GHG and NOx Emissions from Gas Fuelled Engines; SINTEF Ocean AS: Trondheim, Norway, 2017. [Google Scholar]

- Heywood, J.B. Internal Combustion Engine Fundamentals, 2nd ed.; McGraw-Hill Education: New York, NY, USA, 2018. [Google Scholar]

- GBT 13030-2009; Specification for Electric Propulsion Plant of Ship. CSIC: Madrid, Spain, 2009.

- Tian, Y.; Crous, R. Reciprocating Engine Step Load Response in Islanded Power Generation. Energy Power Eng. 2013, 05, 337–343. [Google Scholar] [CrossRef]

- Wartsila. Wartsila 31SG Product Guide; Wartsila: Helsinki, Finland, 2020; Available online: https://cdn.wartsila.com/docs/default-source/product-files/engines/wartsila-31sg-product-guide.pdf?sfvrsn=5dada044_2 (accessed on 9 November 2023).

- ISO. Reciprocating Internal Combustion Engine Driven Alternating Current Generating Sets—Part 5: Generating Sets; ISO: Geneva, Switzerland, 2022. [Google Scholar]

- Ponte, P. Transient Performance of Generating Sets; Bulletin 5544421|Technical Information from Cummins; Cummins: Columbus, IN, USA, 2020. [Google Scholar]

- Latarche, M. Dual-fuel and gas engines. In Pounder’s Marine Diesel Engines and Gas Turbines; Elsevier: Amsterdam, The Netherlands, 2021; pp. 59–86. [Google Scholar]

- Krivopolianskii, V.; Valberg, I.; Stenersen, D.; Ushakov, S. Control of the combustion process and emission formation in marine gas engines. J. Mar. Sci. Technol. 2018, 24, 593–611. [Google Scholar] [CrossRef]

- Delneri, D.; Sirch, G.; Germani, M.; Zubin, L. Enhanced Flexibility in Gas Engine Operation for Marine and Power Generation Demanding Applications. In Proceedings of the 29th CIMAC World Congress 2019, Vancouver, BC, Canada, 10–14 June 2019. [Google Scholar]

- Benajes, J.; Luján, J.M.; Bermúdez, V.; Serrano, J.R. Modelling of turbocharged diesel engines in transient operation. Part 1: Insight into the relevant physical phenomena. Proc. Inst. Mech. Eng. Part D J. Automob. Eng. 2016, 216, 431–441. [Google Scholar] [CrossRef]

- CIMAC. Information Concerning the Application of Gas Engines in the Marine Industry; CIMAC: Frankfurt, Germany, 2013. [Google Scholar]

- Stoumpos, S.; Theotokatos, G.; Mavrelos, C.; Boulougouris, E. Towards Marine Dual Fuel Engines Digital Twins—Integrated Modelling of Thermodynamic Processes and Control System Functions. J. Mar. Sci. Eng. 2020, 8, 200. [Google Scholar] [CrossRef]

- Engines’, C.W.G. CIMAC Position Paper—Impact of Gas Quality on Gas Engine Performance; CIMAC: Frankfurt, Germany, 2015. [Google Scholar]

- Rönn, K.; Pehlivanla, B.; Göbel, C.; Pischinger, S.; Karvo, A.; Lehto, K.; Fryjan, J. Pre-ignition Behavior of Gasoline Blends in a Single–Cylinder Engine with Varying Boost Pressure and Compression Ratio. In Proceedings of the 2023 JSAE/SAE Powertrains, Energy and Lubricants International Meeting, Tokyo, Japan, 29 August 29–1 September 2023. [Google Scholar]

- Schneßl, E.; Wimmer, A. Trends in the Development of Large Gas Engines for Power Generation. In Proceedings of the International Conference and Workshop REMOO, Budva, Montenegro, 18 May–20 June 2016. [Google Scholar]

- Ushakov, S.; Stenersen, D.; Einang, P.M. Methane slip from gas fuelled ships: A comprehensive summary based on measurement data. J. Mar. Sci. Technol. 2019, 24, 1308–1325. [Google Scholar] [CrossRef]

- Mikko Heikkilä, J.-P.J.; Päivi Aakko-Saksa, K.L. Methane slip emissions from LNG vessels—Review. In Proceedings of the 30th CIMAC World Congress 2023, Busan, Republic of Korea, 12–16 June 2023. [Google Scholar]

- Wideskog, M. Introducing the World’s Largest Gas Engine; Energy/In Detail; Wärtsilä Power Plants: Chiyoda, Tokyo, 2011. [Google Scholar]

- WinGD. WinGD X92DF-2.0. Available online: https://www.wingd.com/en/engines/engine-types/x-df-dual-fuel/x92df-2-0/2023 (accessed on 9 November 2023).

- MAN. MAN Engine Products; MAN: Munich, Germany, 2020. [Google Scholar]

- Wartsila. Wartsila Product Guide; Wartsila Energy: Chiyoda, Tokyo, 2022. [Google Scholar]

- Caterpillar. Caterpillar Product Guide; Caterpillar: Irving, TX, USA, 2019. [Google Scholar]

- MTU. MTU Series 4000 Gas Generator Sets; MTU-Solutions: Friedrichshafen, Germany, 2021. [Google Scholar]

- Jenbacher. Jenbacher J Type Gas Engine; Jenbacher: Jenbach, Austria, 2022. [Google Scholar]

- CSSC. “Green Pearl River” Another Milestone. Available online: http://www.csic.com.cn/n135/n171/n179/c21847/content.html2022 (accessed on 9 November 2023).

- WEICHAI. Weichai Natural Gas Engines. Available online: https://www.weichai.com/cpyfw/wmdyw/dlzc/xnyfdj/2023 (accessed on 9 November 2023).

- Higashikawa, S.; Tsujioka, K.; Tanaka, T.; Tokuoka, T. Development of a low-speed four- stroke gas engine. In Proceedings of the 30th CIMAC World Congress 2023, Busan, Republic of Korea, 12–16 June 2023. [Google Scholar]

- Moriyoshi, Y. Current Status and Future Trend of Research on Gas Engine Combustion. J. Combust. Soc. Jpn. 2020, 62, 285–292. [Google Scholar]

- Zakrzewski, T.; Stephens, B. Updated generalized natural gas reciprocating engine part-load performance curves for cogeneration applications. Sci. Technol. Built Environ. 2017, 23, 1151–1158. [Google Scholar] [CrossRef]

- Tavakoli, S.; Jensen, M.V.; Pedersen, E.; Schramm, J. Unburned hydrocarbon formation in a natural gas engine under sea wave load conditions. J. Mar. Sci. Technol. 2020, 26, 128–140. [Google Scholar] [CrossRef]

- Gronholm, T.; Makela, T.; Hatakka, J.; Jalkanen, J.P.; Kuula, J.; Laurila, T.; Laakso, L.; Kukkonen, J. Evaluation of Methane Emissions Originating from LNG Ships Based on the Measurements at a Remote Marine Station. Environ. Sci. Technol. 2021, 55, 13677–13686. [Google Scholar] [CrossRef] [PubMed]

- Higa, N.; Hirose, K.; Nishioka, K.; Doui, M. Development of Marine Dual Fuel Engine (EY26DF). In Proceedings of the 30th CIMAC World Congress 2023, Busan, Republic of Korea, 12–16 June 2023. [Google Scholar]

- Delneri, D.; Axelsson, M.; Varjosaari, M.; Sirch, G. Wartsila ultra-low emission gas engine technology. In Proceedings of the 30th CIMAC World Congress 2023, Busan, Republic of Korea, 12–16 June 2023. [Google Scholar]

- Chen, Z.; Tang, X.; Li, X.; Hu, J.; Shi, L.; Deng, K. Collaborative optimization of EGR and Miller cycle of two-stage turbocharged marine diesel engine. In Proceedings of the 30th CIMAC World Congress 2023, Busan, Republic of Korea, 12–16 June 2023. [Google Scholar]

- Park, H.; Lee, Y.-S.; Jung, C.; Jung, K.; Lim, C.; Lee, H. Methane emission reduction technologies for medium-speed dual-fuel engines. In Proceedings of the 30th CIMAC World Congress 2023, Busan, Republic of Korea, 12–16 June 2023. [Google Scholar]

- Gutierrez, F.L.; Schneider, M.; Akira, H.; Niedziela, S.; Thalhauser, J.; Leroux, C.; Farre, G.; Sakotnig, A. Development of the next Generation Gas Engine with Increased Efficiency and Reduced Emissions. In Proceedings of the 30th CIMAC World Congress 2023, Busan, Republic of Korea, 12–16 June 2023. [Google Scholar]

- Moser, M.; Walther, H.-P.; Koschany, F.; Jacobsen, D. MAN Energy Solutions-Technologies to reduce methane slip of dual fuel engines. In Proceedings of the 30th CIMAC World Congress 2023, Busan, Republic of Korea, 12–16 June 2023. [Google Scholar]

- Zelenka, J.; Kirsten, M.; Kammel, G.; Wimmer, A. Overcoming Misfire in Large Bore Gas Engines Fueled with High Inert Content Flare Gases. In Proceedings of the 11th Dessau Gas Engine Conference, Dessau, Germany, 11–12 April 2019; pp. 140–150. [Google Scholar]

- Vera-Tudela, W.; Schneider, B.; Wüthrich, S.; Herrmann, K. Study on the ignitability of a high-pressure direct-injected methane jet using a scavenged pre-chamber under a wide range of conditions. Int. J. Engine Res. 2023, 24, 1603–1616. [Google Scholar] [CrossRef]

- Lopez Gutierrez, F.; Graus, M.; Spyra, N.; Schaumberger, H. Improved transient performance of GE’s Jenbacher type 6 gas engines. In Heavy-Duty-, On- und Off-Highway-Motoren 2015; Siebenpfeiffer, W., Ed.; Springer Fachmedien Wiesbaden: Wiesbaden, Germany, 2018; pp. 77–97. [Google Scholar]

- Pirker, G.; Wimmer, A. Sustainable power generation with large gas engines. Energy Convers. Manag. 2017, 149, 1048–1065. [Google Scholar] [CrossRef]

- Tavakoli, S.; Schramm, J.; Pedersen, E. The Effect of Air Throttle on Combustion Process and Emission Formation in Marine Lean-Burn Gas Engines. In Proceedings of the 5th World Congress on Momentum, Heat and Mass Transfer, Lisbon, Portugal, 14–16 October 2020. [Google Scholar]

- Tavakoli, S.; Schramm, J.; Pedersen, E. Influence of Turbocharger Inertia and Air Throttle on marine gas engine response. J. Fluid Flow Heat Mass Transf. (JFFHMT21) 2021, 8, 112–132. [Google Scholar]

- Park, C.; Ebisu, M.; Bae, C. Effects of turbocharger rotational inertia on engine and turbine performance in a turbocharged gasoline direct injection engine under transient and steady conditions. Int. J. Engine Res. 2021, 23, 90–103. [Google Scholar] [CrossRef]

- ABB. Variable Turbine Geometry VTG—The Blades of Flexibility; ABB Turbo Systems Ltd.: Baden, Switzerland, 2012. [Google Scholar]

- Stork, M.; Grießhaber, F.; Aurahs, L.; Münch, S.; Weihard, S.; Michael, S.M. Development of a high flow (TCF) and a high pressure (TCP) radial turbocharger series. In Proceedings of the 30th CIMAC World Congress 2023, Busan, Republic of Korea, 12–16 June 2023. [Google Scholar]

- Behr, T.; Kahi, M.; Reichl, A.; Hubacher, M. Seceond Generation of Two Satge Turbochaarging Power 2 Systems for Medium Speed Gas and Diesel Engines; International Council on Combustion Engines: Frankfurt, Germany, 2013. [Google Scholar]

- Kang, J.; Lee, B.; Jung, D. Evaluating the Effect of Two-Stage Turbocharger Configurations on the Perceived Vehicle Acceleration Using Numerical Simulation; SAE Technical Paper Series; SAE: Warrendale, PA, USA, 2016. [Google Scholar]

- Leng, L.; Wang, P.; Shi, L.; Deng, K. Switching process control of two-stage sequential turbocharging system for marine diesel engines. In Proceedings of the 30th CIMAC World Congress 2023, Busan, Republic of Korea, 12–16 June 2023. [Google Scholar]

- Marelli, S.; Usai, V. Experimental analysis and 1D simulation of an advanced hybrid boosting system for automotive applications in transient operation. Int. J. Engine Res. 2021, 24, 639–651. [Google Scholar] [CrossRef]

- Salehi, R.; Martz, J.; Stefanopoulou, A.; Hansen, T.; Haughton, A. Comparison of High- and Low-Pressure Electric Supercharging of a HDD Engine: Steady State and Dynamic Air-Path Considerations; SAE Technical Paper Series; SAE: Warrendale, PA, USA, 2016. [Google Scholar]

- Liu, R.; Ma, Y.; Yi, R.; Li, H.; Wang, X.; Wang, C.; Zheng, L. The Influence of Dual Electric Turbo Compound System on the Performance of Marine Diesel Engine. In Proceedings of the 30th CIMAC World Congress 2023, Busan, Republic of Korea, 12–16 June 2023. [Google Scholar]

- Baoyin, D.; Chuanlei, Y.; Yinyan, W.; Hechun, W.; Binbin, W.; Deng, H.; Baohua, W. Model-based Performance Study of Electrically Assisted Turbocharging Diesel Engine. In Proceedings of the 3rd International Conference on Mechanical Engineering and Materials (ICMEM 2022), Nanchang, China, 18–19 November 2022. [Google Scholar]

- Lefebvre, A.; Guilain, S. Transient Response of a Turbocharged SI Engine with an Electrical Boost Pressure Supply. In Proceedings of the 2003 JSAE/SAE International Spring Fuels and Lubricants Meeting, Yokohama, Japan, 19–22 May 2003. [Google Scholar]

- Zhao, D.; Stobart, R.; Mason, B. Optimising the Energy Efficiency and Transient Response of Diesel Engines through an Electric Turbocharger. In Proceedings of the 2019 American Control Conference, Philadelphia, PA, USA, 10–12 July 2019. [Google Scholar]

- Yadla, S.K.; Terber, D.; Keuler, J.; Davies, P. Secondary Air Injection with e-Boosting Device; Garrett Motion: Rolle, Switzerland, 2023. [Google Scholar]

- Zsiga, N.; Skopil, M.A.; Wang, M.; Klein, D.; Soltic, P. Comparison of Turbocharging and Pressure Wave Supercharging of a Natural Gas Engine for Light Commercial Trucks and Vans. Energies 2021, 14, 5306. [Google Scholar] [CrossRef]

- Galindo, J.; Climent, H.; de la Morena, J.; González-Domínguez, D.; Guilain, S. Assessment of air management strategies to improve the transient response of advanced gasoline engines operating under high EGR conditions. Energy 2023, 262, 125586. [Google Scholar] [CrossRef]

- Galindo, J.; Climent, H.; de la Morena, J.; González-Domínguez, D.; Guilain, S.; Besançon, T. Assessment of air-management strategies to improve the transient performance of a gasoline engine under high EGR conditions during load-decrease operation. Int. J. Engine Res. 2021, 24, 506–520. [Google Scholar] [CrossRef]

- Behr, T.; Hubacher, M.; Seiler, M. Second Generation Two-stage Turbocharging for Large Four-strokes. MTZ Ind. 2014, 4, 26–33. [Google Scholar] [CrossRef]

- Jung, M.; Ford, R.G.; Glover, K.; Collings, N.; Christen, U.; Watts, M.J. Parameterization and Transient Validation of a Variable Geometry Turbocharger for Mean-Value Modeling at Low and Medium Speed-Load Points; SAE Technical Paper 2002-01-2729; SAE International: Warrendale, PA, USA, 2002; Available online: https://saemobilus.sae.org/content/2002-01-2729/ (accessed on 9 November 2023).

- Altosole, M.; Balsamo, F.; Campora, U.; Mocerino, L. Marine Dual-Fuel Engines Power Smart Management by Hybrid Turbocharging Systems. J. Mar. Sci. Eng. 2021, 9, 663. [Google Scholar] [CrossRef]

- Leng, L.; Chen, T.; Shi, L.; Deng, K. Air-path System Transient Control of Dual-Combustion- Mode Diesel Engine Based on Universal Sliding Mode Method. In Proceedings of the 2023 JSAE/SAE Powertrains, Energy and Lubricants International Meeting, Tokyo, Japan, 29 August 29–1 September 2023. [Google Scholar]

- Maur, T.O.A.d. VCM’s Bright Future on the Sea; ABB: Baden, Switzerland, 2018. [Google Scholar]

- Claudio, C.; Ennio, C. Engine Control and Performance Enhancement with Variable Valve Train for Gas Engines. Available online: https://dokumen.tips/documents/engine-control-and-performance-enhancement-with-control-and-performance-enhancement.html?page=1 (accessed on 9 November 2023).

- Zelenka, J.; Christen, C.; Thalhauser, J.; Wimmer, A. Fully Variable Intake Valve Train—Advanced Air Management for Improved Dynamic Performance of Large Bore Gas Engines. In Proceedings of the 29th CIMAC World Congress 2019, Vancouver, BC, Canada, 10–14 June 2019. [Google Scholar]

- Yang, M.; Hu, C.; Bai, Y.; Deng, K.; Gu, Y.; Qian, Y.; Liu, B. Matching method of electric turbo compound for two-stroke low-speed marine diesel engine. Appl. Therm. Eng. 2019, 158, 113752. [Google Scholar] [CrossRef]

- Xia, C.; Zhang, W.; Feng, Y.; Wang, T.; Zhu, Y.; Shreka, M.; Wu, X.; Zhou, W. Investigation on control strategy optimisation of harsh transient condition for a marine natural gas engine. Ships Offshore Struct. 2022, 18, 1286–1299. [Google Scholar] [CrossRef]

- Harsha Rayasam, S.; Qiu, W.; Rimstidt, T.; Shaver, G.M.; Van Alstine, D.G.; Graziano, M. Control-oriented modeling, validation, and interaction analysis of turbocharged lean-burn natural gas variable speed engine. Int. J. Engine Res. 2021, 24, 738–754. [Google Scholar] [CrossRef]

- Ando, T.; Yamada, Y.; Suzuki, K.; Yanaka, T. Development of model-based control system for a low pressure loop EGR with a negative pressure control valve. In Proceedings of the 2023 JSAE/SAE Powertrains, Energy and Lubricants International Meeting, Tokyo, Japan, 29 August 29–1 September 2023. [Google Scholar]

- Wang, H.; Kolmanovsky, I.; Sun, J.; Ozaki, Y. Feedback control during mode transition for a marine dual fuel engine. In Proceedings of the International Federation of Automatic Control, Linz, Austria, 15–17 July 2015. [Google Scholar]

- Anand Nageswaran, B.; Rolf, D.R.; Christopher, J.R. Impact of Active Control Turbocharging on the Fuel Economy and Emissions of a Light-Duty Reactivity Controlled Compression Ignition Engine: A Simulation Study. Front. Mech. Eng. 2021, 7, 610891. [Google Scholar]

- HELLR. Secondary Air Injection System. Available online: https://www.hella.com/techworld/sg/Technical/Car-electronics-and-electrics/Secondary-air-injection-system-3296/2023 (accessed on 9 November 2023).

- Borgwarner. Electric Boosting Technologies. Available online: https://www.borgwarner.com/technologies/electric-boosting-technologies2023 (accessed on 9 November 2023).

- Avtotachki. Twin Turbo System. Available online: https://en.avtotachki.com/sistema-dvojnogo-turbonadduva-twin-turbo/2022 (accessed on 9 November 2023).

- Geertsma, R.D.; Negenborn, R.R.; Visser, K.; Hopman, J.J. Design and control of hybrid power and propulsion systems for smart ships: A review of developments. Appl. Energy 2017, 194, 30–54. [Google Scholar] [CrossRef]

- Li, Y.; Ding, Z.; Yu, Y.; Liu, Y. Mitigation effect of flywheel energy storage on the performance of marine gas turbine DC microgrid under high-power load mutation. Energy Rep. 2023, 9, 1380–1396. [Google Scholar] [CrossRef]

- Tsitsilonis, K.-M.; Theotokatos, G. A novel systematic methodology for ship propulsion engines energy management. J. Clean. Prod. 2018, 204, 212–236. [Google Scholar] [CrossRef]

- Dotto, A.; Sacchi, R.; Satta, F.; Campora, U. Dynamic performance simulation of combined gas electric and steam power plants for cruise-ferry ships. Next Energy 2023, 1, 100020. [Google Scholar] [CrossRef]

- Du, Z.; Chen, Q.; Guan, C.; Chen, H. Improvement and Optimization Configuration of Inland Ship Power and Propulsion System. J. Mar. Sci. Eng. 2023, 11, 135. [Google Scholar] [CrossRef]

- Sun, X.; Yao, C.; Song, E.; Liu, Z.; Yang, X.; Yang, Q. Analysis of Operating Characteristics for Marine Gas-Electric Hybrid Power System. J. Inst. Eng. (India) Ser. C 2022, 104, 1–13. [Google Scholar] [CrossRef]

- Xu, L.; Meng, S.; Zhou, X.; Liu, L.; Liu, Z. Research on dynamic performance optimization of marine LNG engine propulsion power system. In Proceedings of the 29th CIMAC World Congress 2019, Vancouver, BC, Canada, 10–14 June 2019. [Google Scholar]

- Hlaing, H.S.; Liu, J.; Miura, Y.; Bevrani, H.; Ise, T. Enhanced Performance of a Stand-Alone Gas-Engine Generator Using Virtual Synchronous Generator and Energy Storage System. IEEE Access 2019, 7, 176960–176970. [Google Scholar] [CrossRef]

- Bosch, R.; Casals-Torrens, P.; Alvarez-Florez, J.; Serrano-Fontova, A. Hybrid Gas-Electrical Power & Heavy Duty Propulsion: Test Platform. In Proceedings of the 19th Annual General Assembly—AGA 2018, Barcelona, Spain, 17–19 October 2018. [Google Scholar]

- Ito, T.; Tsukada, T.; Sato, S.; Nii, S.; Yokoyama, R. Improvement of island operating stability for lean burn gas engine by effective use of power storage device. In Proceedings of the 2011 IEEE International Conference on Smart Grid Communications (SmartGridComm), Brussels, Belgium, 17–20 October 2011; pp. 493–498. [Google Scholar]

- Ito, T.; Sato, S.; Arai, J.; Yokoyama, R.; Tsukada, T.; Nii, S. Effective control method of power storage system for the operating stability improvement of lean burn gas engine. In Proceedings of the 2012 Asia-Pacific Power and Energy Engineering Conference, Shanghai, China, 27–29 March 2012. [Google Scholar]

- Luo, Y.; Fang, S.; Kong, L.; Niu, T.; Liao, R. Dynamic power management of Shipboard Hybrid Energy Storage System under Uncertain Navigation Conditions. IEEE Trans. Transp. Electrif. 2023, 1. [Google Scholar] [CrossRef]

- Liu, Z.; Liu, Y.; Yu, Y.; Yang, R. Coordinated control and optimal flow of shipboard MVDC system for adapting to large pulsed power load. Electr. Power Syst. Res. 2023, 221, 109354. [Google Scholar] [CrossRef]

- Payvand, B.; Hosseini, S.M.H. A new method for mitigating frequency fluctuations in ships with electrical propulsion. ISA Trans. 2022, 125, 707–713. [Google Scholar] [CrossRef]

- Hlaing, H.S.; Miura, Y.; Ise, T. A permanent magnet synchronous generator control approach for stand alone gas engine generation system. In Proceedings of the 2016 IEEE 8th International Power Electronics and Motion Control Conference (IPEMC-ECCE Asia), Hefei, China, 22–26 May 2016. [Google Scholar]

- Hlaing, H.S.; Liu, J.; Bevrani, H.; Ise, T. PMSG Control for a Stand-Alone Gas Engine Generator Using Active Rectifier and VSG-Controlled Inverter. Energies 2020, 13, 233. [Google Scholar] [CrossRef]

- Dickinson, P.; Glover, K.; Collings, N.; Yamashita, Y.; Yashiro, Y.; Hoshi, T. Transient Evaluation of Two-Stage Turbocharger Configurations Using Model Predictive Control; SAE Technical Paper 2015-01-1980; SAE: Warrendale, PA, USA, 2015. [Google Scholar] [CrossRef]

- Figari, M.; Theotokatos, G.; Coraddu, A.; Stoumpos, S.; Mondella, T. Parametric investigation and optimal selection of the hybrid turbocharger system for a large marine four-stroke dual-fuel engine. Appl. Therm. Eng. 2022, 208, 117991. [Google Scholar] [CrossRef]

- ABB. Valve Control Management–VCM® The Flexibility to Meet Future Challenges; ABB Turbo Systems Ltd.: Baden, Switzerland, 2016. [Google Scholar]

- Zelenka, J.; Christen, C.; Hoff, C.; Wimmer, A. Optimum operations strategies fro gas engines using variable intake valve tarin. In Proceedings of the ASME 2018 Internal Combustion Engine Division Fall Technical Conference ICEF2018, San Diego, CA, USA, 4–7 November 2018. [Google Scholar]

- Ammann, M.; Fekete, N.; Guzzella, L.; Glattfelder, A. Model-Based Control of the VGT and EGR in a Turbocharged Common-Rail Diesel Engine Theory and Passenger Car Implementation; SAE Technical: Warrendale, PA, USA, 2003. [Google Scholar]

- Chen, R.; Kuboyama, T.; Moriyoshi, Y.; Yasueda, S.; Doyen, V.; Martin, J.-B. Effects of Engine Operating Condition and Fuel Property on Pre-Ignition Phenomenon in a Highly Boosted Premixed Natural Gas Engine; SAE International: Warrendale, PA, USA, 2019. [Google Scholar]

- Tilz, A.; Kiesling, C.; Meyer, G.; Nickl, A.; Pirker, G.; Wimmer, A. Experimental investigation of the influence of ignition system parameters on combustion behavior in large lean burn spark ignited gas engines. Exp. Therm. Fluid Sci. 2020, 119, 110176. [Google Scholar] [CrossRef]

- Cao, E.; Liu, B.; Dong, J.; Zhou, X. Design of a Low Cost and Flexible Supercharging System for a Low- Speed Single Cylinder Engine. In Proceedings of the 30th CIMAC World Congress 2023, Busan, Republic of Korea, 12–16 June 2023. [Google Scholar]

- Li, G.H.; Zhang, B.H.; Hao, Z.G.; Wang, J.; Bo, Z.Q.; Writer, D.; Yip, T. Modeling of DFIG based wind generator and transient characteristics analysis. In Proceedings of the 2011 10th International Conference on Environment and Electrical Engineering, Rome, Italy, 8–11 May 2011. [Google Scholar]

- Gong, Q.; Ye, J.; Xu, J.; Xiong, W.; Feng, H.; Wang, D.; Shen, A. Hybrid model predictive control for premixed natural gas engine as distributed generator. Energy 2023, 278, 127728. [Google Scholar] [CrossRef]

- Belmonte, M.A.R. Contribution to the Experimental Characterization and 1-D Modelling of Turbochargers for IC Engines; Universidad Polit’ecnica de Valencia: Valencia, Spain, 2013. [Google Scholar]

- Millet, J.-B.; Maroteaux, F.; Aubertin, F. Air System and Diesel Combustion Modeling for Hardware in the Loop Applications. J. Eng. Gas Turbines Power 2012, 134, 042802. [Google Scholar] [CrossRef]

- Yum, K.K.; Taskar, B.; Pedersen, E.; Steen, S. Simulation of a two-stroke diesel engine for propulsion in waves. Int. J. Nav. Archit. Ocean. Eng. 2017, 9, 351–372. [Google Scholar] [CrossRef]

- IDAJ. GT-Suite Guide; GT-Power: Malvern, PA, USA, 2020. [Google Scholar]

- Xu, S.; Anderson, D.; Singh, A.; Hoffman, M.; Prucka, R.; Filipi, Z. Development of a Phenomenological Dual-Fuel Natural Gas Diesel Engine Simulation and Its Use for Analysis of Transient Operations. SAE Int. J. Engines 2014, 7, 1665–1673. [Google Scholar] [CrossRef]

- Stoumpos, S.; Theotokatos, G.; Boulougouris, E.; Vassalos, D.; Lazakis, I.; Livanos, G. Marine dual fuel engine modelling and parametric investigation of engine settings effect on performance-emissions trade-offs. Ocean. Eng. 2018, 157, 376–386. [Google Scholar] [CrossRef]

- Shen, T.; Zhang, J.; Jiao, X.; Kang, M.; Kako, J.-i.; Ohata, A. Transient Control of Gasoline Engines; Routledge: Oxfordshire, UK, 2015. [Google Scholar]

- Misono, Y.; Kuboyama, T.; Moriyoshi, Y.; Yamada, T. Improvement in accuracy of engine cycle simulations by using a turbocharger prediction model instead of measured efficiency map. J. Phys. Conf. Ser. 2021, 1909, 012027. [Google Scholar] [CrossRef]

- Yum, K.K.; Pedersen, E. Architecture of model libraries for modelling turbocharged diesel engines. Math. Comput. Model. Dyn. Syst. 2016, 22, 584–612. [Google Scholar] [CrossRef]

- Katiraei, F. Computer Simulation Modeling and Analysis of the Danamic Behavior of a Reciprocating Engine Based Distributed Generation Unit during Island Transition; CANMET Energy Technology Centre—Varennes Natural Resources Canada: Varennes, QC, Canada, 2007. [Google Scholar]

- Martelli, M.; Figari, M. Real-Time model-based design for CODLAG propulsion control strategies. Ocean Eng. 2017, 141, 265–276. [Google Scholar] [CrossRef]

- Huo, T.; Yao, C.; Li, W. Model-Based Simulation Research for Speed Control of Marine Low-Speed Dual Fuel Engine. In Proceedings of the 30th CIMAC World Congress 2023, Busan, Republic of Korea, 12–16 June 2023. [Google Scholar]

- Han, Y.; Richards, D. Significant aftertreatment cost reduction with high precise AFR control for gaseous-fueled engines. In Proceedings of the 30th CIMAC World Congress 2023, Busan, Republic of Korea, 12–16 June 2023. [Google Scholar]

- Kronos. Kronos Gas Engine Control Systems; Kronos: Lowell, MA, USA, 2023. [Google Scholar]

- Holt, P.; Nielsen, U.D. Preliminary assessment of increased main engine load as a consequence of added wave resistance in the light of minimum propulsion power. Appl. Ocean. Res. 2021, 108, 102543. [Google Scholar] [CrossRef]

- Saettone, S.; Tavakoli, S.; Taskar, B.; Jensen, M.V.; Pedersen, E.; Schramm, J.; Steen, S.; Andersen, P. The importance of the engine-propeller model accuracy on the performance prediction of a marine propulsion system in the presence of waves. Appl. Ocean. Res. 2020, 103, 102320. [Google Scholar] [CrossRef]

- Nielsen, J.B.; Sandvik, E.; Pedersen, E.; Asbjørnslett, B.E.; Fagerholt, K. Impact of simulation model fidelity and simulation method on ship operational performance evaluation in sea passage scenarios. Ocean. Eng. 2019, 188, 106268. [Google Scholar] [CrossRef]

- Blendermann, W. Wind Loading of Ships: Collected Data from Wind Tunnel Tests in Uniform Flow; Inst. für Schiffbau: Hamburg, Germany, 1996. [Google Scholar]

- Fujiwara, T.; Ueno, M.; Ikeda, Y. A New Estimation Method of Wind Forces and Moments acting on Ships on the basis of Physical Component Models. Jpn. Soc. Shipbuild. Mar. Eng. 1994, 2, 243–255. [Google Scholar]

- Kramel, D.; Muri, H.; Kim, Y.; Lonka, R.; Nielsen, J.B.; Ringvold, A.L.; Bouman, E.A.; Steen, S.; Strømman, A.H. Global Shipping Emissions from a Well-to-Wake Perspective: The MariTEAM Model. Environ. Sci. Technol. 2021, 55, 15040–15050. [Google Scholar] [CrossRef]

- Tillig, F.; Ringsberg, J.W.; Psaraftis, H.N.; Zis, T. Reduced environmental impact of marine transport through speed reduction and wind assisted propulsion. Transp. Res. Part D Transp. Environ. 2020, 83, 102380. [Google Scholar] [CrossRef]

- Martinsen, M.A. A Design Tool for Estimating the Added Wave Resistance of Container Ships. Master’s Thesis, Technical University of Denmark, Kongens Lyngby, Denmark, 2016. [Google Scholar]

- ITTC. Recommended procedures and guidelines: 1978 ITTC performance prediction method. In Proceedings of the International Towing Tank Conference 2017, Wuxi, China, 17–22 September 2017. [Google Scholar]

- van den Boom, H.; Huisman, H.; Mennen, F. New Guidelines for Speed/Power Trials. Level Playing Field Established for IMO EEDI; SWZ Maritime: Rotterdam, The Netherlands, 2013; pp. 1–11. [Google Scholar]

- Liu, S.; Shang, B.; Papanikolaou, A.; Bolbot, V. Improved formula for estimating added resistance of ships in engineering applications. J. Mar. Sci. Appl. 2016, 15, 442–451. [Google Scholar] [CrossRef]

- Liu, S.; Papanikolaou, A. Regression analysis of experimental data for added resistance in waves of arbitrary heading and development of a semi-empirical formula. Ocean Eng. 2020, 206, 107357. [Google Scholar] [CrossRef]

- Kim, Y.-R.; Steen, S.; Kramel, D.; Muri, H.; Strømman, A.H. Modelling of ship resistance and power consumption for the global fleet: The MariTEAM model. Ocean Eng. 2023, 281, 114758. [Google Scholar] [CrossRef]

- ECMWF ERA5. Available online: https://www.ecmwf.int/en/forecasts/datasets/archive-datasets/reanalysis-datasets/era5.2018 (accessed on 9 November 2023).

- Hasselmann, K.; Barnett, T.P.; Bouws, E.; Carlson, H.; Cartwright, D.E.; Enke, K.; Ewing, J.; Gienapp, A.; Hasselmann, D.; Kruseman, P. Measurements of wind-wave growth and swell decay during the Joint North Sea Wave Project (JONSWAP); Technical Report; Deutches Hydrographisches Institut: Hamburg, Germany, 1973. [Google Scholar]

- Tavakoli, S.; Saettone, S.; Steen, S.; Andersen, P.; Schramm, J.; Pedersen, E. Modeling and analysis of performance and emissions of marine lean-burn natural gas engine propulsion in waves. Appl. Energy 2020, 279, 115904. [Google Scholar] [CrossRef]

- Saettone, S.; Taskar, B.; Regener, P.B.; Andersen, P. Unsteady propeller forces and hull pressure pulses in waves. In Proceedings of the NuTTS’18, Cortona, Italy, 30 September–2 October 2018. [Google Scholar]

- Marques, C.H.; Belchior, C.R.P.; Caprace, J.D. Optimising the engine-propeller matching for a liquefied natural gas carrier under rough weather. Appl. Energy 2018, 232, 187–196. [Google Scholar] [CrossRef]

- Taskar, B.; Yum, K.K.; Steen, S.; Pedersen, E. The effect of waves on engine-propeller dynamics and propulsion performance of ships. Ocean Eng. 2016, 122, 262–277. [Google Scholar] [CrossRef]

- Acanfora, M.; Altosole, M.; Balsamo, F.; Micoli, L.; Campora, U. Simulation Modeling of a Ship Propulsion System in Waves for Control Purposes. J. Mar. Sci. Eng. 2021, 10, 36. [Google Scholar] [CrossRef]

- Oleksiy, B.; Yasushi, K. Application of the Kalman filtering technique for nonlinear state estimation in propulsion system. J. Mar. Sci. Technol. 2020, 26, 618–631. [Google Scholar]

- Geertsma, R.D.; Negenborn, R.R.; Visser, K.; Loonstijn, M.A.; Hopman, J.J. Pitch control for ships with diesel mechanical and hybrid propulsion: Modelling, validation and performance quantification. Appl. Energy 2017, 206, 1609–1631. [Google Scholar] [CrossRef]

- IMO. Fourth IMO GHG Study 2020; IMO: London, UK, 2021. [Google Scholar]

- Shi, J.; Amgai, R.; Abdelwahed, S. Modelling of shipboard medium-voltage direct current system for system level dynamic analysis. IET Electr. Syst. Transp. 2015, 5, 156–165. [Google Scholar] [CrossRef]

- Hlaing, H.S. Studies on Enhanced Performance of a Stand-Alone Gas Engine Generator with a Permanent Magnet Synchronous Generator by Applying Active Rectifier and Virtual Synchronous Generator Control. Ph.D. Thesis, Graduate School of Engineering, Osaka University, Osaka, Japan, 2020. [Google Scholar]

- Alafnan, H.; Zhang, M.; Yuan, W.; Zhu, J.; Li, J.; Elshiekh, M.; Li, X. Stability Improvement of DC Power Systems in an All-Electric Ship Using Hybrid SMES/Battery. IEEE Trans. Appl. Supercond. 2018, 28, 1–6. [Google Scholar] [CrossRef]

- Xu, Y.; Yang, Z.; Jiao, K.; Hao, D.; Du, Q. Development of a comprehensive transient fuel cell-battery hybrid system model and rule-based energy management strategy. Int. J. Green Energy 2022, 20, 844–858. [Google Scholar] [CrossRef]

- Pan, H.; Feng, X.; Li, F.; Yang, J. Energy coordinated control of DC microgrid integrated incorporating PV, energy storage and EV charging. Appl. Energy 2023, 342, 121155. [Google Scholar] [CrossRef]

- He, H.; Xiong, R.; Guo, H.; Li, S. Comparison study on the battery models used for the energy management of batteries in electric vehicles. Energy Convers. Manag. 2012, 64, 113–121. [Google Scholar] [CrossRef]

- Mylonopoulos, F.; Polinder, H.; Coraddu, A. A Comprehensive Review of Modeling and Optimization Methods for Ship Energy Systems. IEEE Access 2023, 11, 32697–32707. [Google Scholar] [CrossRef]

- de Siqueira, L.M.S.; Peng, W. Control strategy to smooth wind power output using battery energy storage system: A review. J. Energy Storage 2021, 35, 102252. [Google Scholar] [CrossRef]

- Hou, J.; Song, Z.; Park, H.; Hofmann, H.; Sun, J. Implementation and evaluation of real-time model predictive control for load fluctuations mitigation in all-electric ship propulsion systems. Appl. Energy 2018, 230, 62–77. [Google Scholar] [CrossRef]

- Fang, C.; Chai, W.; Gu, H.; Wang, L.; Cai, X. A fuzzy control scheme of the wind-storage combined system for power complementary. In Proceedings of the 2016 IEEE 8th International Power Electronics and Motion Control Conference (IPEMC-ECCE Asia), Hefei, China, 22–26 May 2016; pp. 1474–1479. [Google Scholar]

- Albrecht, A.; Grondin, O.; Le Berr, F.; Le Solliec, G. Towards a stronger simulation support for engine control design: A methodological point of view. Oil Gas Sci. Technol. 2007, 62, 437–456. [Google Scholar] [CrossRef]

- Amin, A.A.; Mahmood-ul-Hasan, K. Robust Passive Fault Tolerant Control for Air Fuel Ratio Control of Internal Combustion Gasoline Engine for Sensor and Actuator Faults. IETE J. Res. 2023, 69, 2846–2861. [Google Scholar] [CrossRef]

- Ju, F.; Murgovski, N.; Zhuang, W.; Hu, X.; Song, Z.; Wang, L. Predictive energy management with engine switching control for hybrid electric vehicle via ADMM. Energy 2023, 263, 125971. [Google Scholar] [CrossRef]

- Renjit, A.A.; Illindala, M.S.; Klapp, D.A. Modeling and analysis of the CERTS microgrid with natural gas-powered distributed energy resouurces. In Proceedings of the 2015 IEEE/IAS 51st Industrial & Commercial Power Systems Technical Conference (I&CPS), Calgary, AB, Canada, 5–8 May 2015. [Google Scholar]

- Westman, J.; Hadidi, R.; Fox, C.; Leonard, J. Modeling of a Reciprocating Engine-Generator Set for Controller Hardware in the Loop Testing of Island Microgrid Control Systems. In Proceedings of the 2020 IEEE Industry Applications Society Annual Meeting, Detroit, MI, USA, 10–16 October 2020; pp. 1–7. [Google Scholar]

- Rayasam, S.H.; Qiu, W.; Rimstidt, T.; Shaver, G.M.; Van Alstine, D.G. Robust model-based switching MIMO air handling control of turbocharged lean-burn SI natural gas variable speed engines. Int. J. Engine Res. 2022, 24, 2783–2804. [Google Scholar] [CrossRef]

- Robertson, D.; Conway, G.; Chadwell, C.; McDonald, J.; Barba, D.; Stuhldreher, M.; Birckett, A. Predictive GT-Power Simulation for VNT Matching on a 1.6 L Turbocharged GDI Engine; SAE Technical Paper Series; SAE: Warrendale, PA, USA, 2018. [Google Scholar]

- Tahtouh, T.; Andre, M.; Millo, F.; Rolando, L.; Castellano, G.; Bocchieri, F.; Cambriglia, L.; Raimondo, D. Development of a Digital Twin to Support the Calibration of a Highly Efficient Spark Ignition Engine; SAE Technical Paper Series; SAE: Warrendale, PA, USA, 2023. [Google Scholar]

- Theotokatos, G.; Stoumpos, S.; Bolbot, V.; Boulougouris, E. Simulation-based investigation of a marine dual-fuel engine. J. Mar. Eng. Technol. 2020, 19, 5–16. [Google Scholar] [CrossRef]

- Wang, Z.; Ma, C.; Wang, H. An evaluation method for transient response performance of a turbocharger in gasoline engine: Simulation and experiment. Proc. Inst. Mech. Eng. Part A J. Power Energy 2022, 237, 67–78. [Google Scholar] [CrossRef]

- Xia, C.; Zhu, Y.; Zhou, S.; Peng, H.; Feng, Y.; Zhou, W.; Shi, J.; Zhang, J. Simulation study on transient performance of a marine engine matched with high-pressure SCR system. Int. J. Engine Res. 2022, 24, 1327–1345. [Google Scholar] [CrossRef]

- Bastidaa, H.; Ugalde-Looa, C.E.; Abeysekeraa, M. Dynamic modeling and control of a reciprocating engine. In Proceedings of the 9th International Conference on Applied Energy ICAE2017, Cardiff, UK, 21–24 August 2017. [Google Scholar]

- Figari, M.; Altosole, M. Effective simple methods for numerical modelling of marine engines in ship propulsion control systems design. J. Nav. Archit. Mar. Eng. 2011, 8, 129–147. [Google Scholar]

- Nahim, H.M.; Younes, R.; Nohra, C.; Ouladsine, M. Complete modeling for systems of a marine diesel engine. J. Mar. Sci. Appl. 2015, 14, 93–104. [Google Scholar] [CrossRef]

- Sui, C.; de Vos, P.; Stapersma, D.; Visser, K.; Hopman, H.; Ding, Y. Mean value first principle engine model for predicting dynamic behaviour of two-stroke marine diesel engine in various ship propulsion operations. Int. J. Nav. Archit. Ocean. Eng. 2022, 14, 100432. [Google Scholar] [CrossRef]

- Tang, H.; Copeland, C.; Akehurst, S.; Brace, C.; Davies, P.; Pohorelsky, L.; Smith, L.; Capon, G. A novel predictive semi-physical feed-forward turbocharging system transient control strategy based on mean-value turbocharger model. Int. J. Engine Res. 2016, 18, 765–775. [Google Scholar] [CrossRef]

- Altosole, M.; Campora, U.; Figari, M.; Laviola, M.; Martelli, M. A Diesel Engine Modelling Approach for Ship Propulsion Real-Time Simulators. J. Mar. Sci. Eng. 2019, 7, 138. [Google Scholar] [CrossRef]

- Albrecht, A.; Knop, V.; Corde, G.; Simonet, L.; Castagné, M. Observer Design for Downsized Gasoline Engine Control Using 1D Engine Simulation. Oil Gas Sci. Technol. 2007, 61, 165–179. [Google Scholar] [CrossRef]

- Mayr, P.; Pirker, G.; Wimmer, A.; Krenn, M. Simulation-Based Control of Transient SCE Operation; SAE Technical Paper 2017-01-0544; SAE International: Warrendale, PA, USA, 2017. [Google Scholar] [CrossRef]

- Gambarotta, A.; Lucchetti, G.; Vaja, I. Real-time modelling of transient operation of turbocharged diesel engines. Proc. Inst. Mech. Eng. Part D J. Automob. Eng. 2011, 225, 1186–1203. [Google Scholar] [CrossRef]

- Alsuwian, T.; Amin, A.A.; Iqbal, M.S.; Qadir, M.B.; Almasabi, S.; Jalalah, M. Design of Active Fault-Tolerant Control System for Air-Fuel Ratio control of Internal Combustion engine using nonlinear regression-based observer model. PLoS ONE 2022, 17, e0279101. [Google Scholar] [CrossRef] [PubMed]

- Al Jarrah, M.A.; Jarrah, A.; Alawaisah, A. Automotive engine idle speed controller: Nonlinear model predictive control utilizing the firefly algorithm. Comput. Electr. Eng. 2023, 108, 108688. [Google Scholar] [CrossRef]

- Wan, P.; Liu, B.; Li, B.; Liu, F.; Zhang, J.; Fan, W.; Tang, J. Engine modelling architecture study for hybrid electric vehicle diagnosis application. Energy 2023, 282, 128408. [Google Scholar] [CrossRef]

- Wu, H.; Li, M.-F. A Hardware-in-the-Loop (HIL) Bench Test of a GT-Power Fast Running Model for Rapid Control Prototyping (RCP) Verification; SAE Technical Paper Series; SAE: Warrendale, PA, USA, 2016. [Google Scholar]

- Millo, F.; Di Lorenzo, G.; Servetto, E.; Capra, A.; Pettiti, M. Analysis of the Performance of a Turbocharged S.I. Engine under Transient Operating Conditions by Means of Fast Running Models. SAE Int. J. Engines 2013, 6, 968–978. [Google Scholar] [CrossRef]

- Ogata, K.; Matsuda, H.; Kawai, H.; Shiota, K. Highly efficient development of powertrain systems using 1D Real-Time Engine Model. In Proceedings of the 2023 JSAE/SAE Powertrains, Energy and Lubricants International Meeting, Tokyo, Japan, 29 August–1 September 2023. [Google Scholar]

- Sharma, R.; Nesic, D.; Manzie, C. Model Reduction of Turbocharged (TC) Spark Ignition (SI) Engines. IEEE Trans. Control. Syst. Technol. 2011, 19, 297–310. [Google Scholar] [CrossRef]

- Söderäng, E.; Hautala, S.; Mikulski, M.; Storm, X.; Niemi, S. Development of a digital twin for real-time simulation of a combustion engine-based power plant with battery storage and grid coupling. Energy Convers. Manag. 2022, 266, 115793. [Google Scholar] [CrossRef]

- Tang, J.; Zhu, G.G.; Men, Y. Review of engine control-oriented combustion models. Int. J. Engine Res. 2021, 23, 347–368. [Google Scholar] [CrossRef]

- Stapersma, D.; Vrijdag, A. Linearisation of a ship propulsion system model. Ocean Eng. 2017, 142, 441–457. [Google Scholar] [CrossRef]

- Huijgens, L.; Vrijdag, A.; Hopman, H. Hardware in the loop experiments with ship propulsion systems in the towing tank: Scale effects, corrections and demonstration. Ocean Eng. 2021, 226, 108789. [Google Scholar] [CrossRef]

- Theotokatos, G.P. Ship propulsion plant transient response investment using a mean value model. Int. J. Energy 2008, 4, 66–74. [Google Scholar]

- Foteinos, M.; Christofilis, G.; Kyrtatos, N. Transient Operation of a Large Two Stroke Marine Diesel Engine Equipped with a High-Pressure SCR Aftertreatment System in Heavy Weather Conditions. In Proceedings of the 29th CIMAC World Congress 2019, Vancouver, BC, Canada, 10–14 June 2019. [Google Scholar]

- Foteinos, M.I.; Christofilis, G.I.; Kyrtatos, N.P. Response of a direct-drive large marine two-stroke engine coupled to a selective catalytic reduction exhaust aftertreatment system when operating in waves. Proc. Inst. Mech. Eng. Part M J. Eng. Marit. Environ. 2020, 234, 651–667. [Google Scholar] [CrossRef]

- Mestemaker, B.T.W.; Goncalves Castro, M.B.; van den Heuvel, H.N.; Visser, K. Dynamic simulation of a vessel drive system with dual fuel engines and energy storage. Energy 2020, 194, 116792. [Google Scholar] [CrossRef]

- Kranawetter, K.; Seeber, R.; Mayr, P.; Pirker, G.; Bauer, R.; Horn, M. Charge Air and Fuel Gas Pressure Control on a HiL Development of Transient Large Bore Gas. In Proceedings of the 2018 IEEE Conference on Control Technology and Applications (CCTA), Copenhagen, Denmark, 21–24 August 2018. [Google Scholar]

- Käseberg, S.; Risse, S.; Schröder, B.G.H.; Schulz, O. Alternative fuels and their consequences for exhaust gas turbocharging. In Proceedings of the CIMAC2023, Busan, Republic of Korea, 12–16 June 2023. [Google Scholar]

- Ryser, R.; Bessonnard, C.; Wimmer, A. Influence of blend ratio on turbocharging & combustion in HS gas eng. applications with CH4H2 blend. In Proceedings of the 30th CIMAC World Congress 2023, Busan, Republic of Korea, 12–16 June 2023. [Google Scholar]

- Muljadi, E.; Butterfield, C.P.; Parsons, B.; Ellis, A. Effect of Variable Speed Wind Turbine Generator on Stability of a Weak Grid. IEEE Trans. Energy Convers. 2007, 22, 29–36. [Google Scholar] [CrossRef]

- Carpanese, M.P.; D’Agostino, F.; Gabriele, B.; Silvestro, F.; Trasverso, A.; Sala, S.; Tucker, D.; Bellotti, D.; Pais, T.; Vaccaro, L.; et al. Contribution to Electrical System Inertia of Dual Fuel two-stroke Engines in Isolated Grid: A Case Study. E3S Web Conf. 2023, 414, 02001. [Google Scholar]

- Ranjan, M.; Shankar, R. A literature survey on load frequency control considering renewable energy integration in power system: Recent trends and future prospects. J. Energy Storage 2022, 45, 103717. [Google Scholar] [CrossRef]

- Basit, M.A.; Dilshad, S.; Badar, R.; Sami ur Rehman, S.M. Limitations, challenges, and solution approaches in grid-connected renewable energy systems. Int. J. Energy Res. 2020, 44, 4132–4162. [Google Scholar] [CrossRef]

- Srivastava, V.; Schaub, J.; Pischinger, S. Model-based closed-loop control strategies for flex-fuel capability. Appl. Energy 2023, 350, 121795. [Google Scholar] [CrossRef]

| Performance | Diesel Engine | Pure Gas Engine | Dual-Fuel Engine | |

|---|---|---|---|---|

| Gas Mode | Diesel Mode | |||

| Efficiency | ○ | + | ○ | -- |

| Power density | ++ | + | + | + |

| Load response | ++ | - | ○ | ++ |

| Maintenance | ++ | - | + | + |

| Long-term stability | + | - | - | ○ |

| Fuel flexibility | + | - | - | + |

| Pathway | Advanced Technology | Advanced Control | Fuel | Engine Power kW | Method | Reference |

|---|---|---|---|---|---|---|

| Air path system & control | Two-stage TC | / | Diesel | 162 | Experiment | [101] |

| Valve control | Diesel | 170 | Experiment | [102] | ||

| MPC 1 | Diesel | 78 | Simulation | [145] | ||

| ETC | Predictive control | Diesel | 150 | Experiment | [108] | |

| MBC 2 | Diesel | 1920 | Simulation | [106] | ||

| / | Diesel | 1760 | Simulation | [105] | ||

| / | Gas | 8775 | Simulation | [146] | ||

| / | Diesel | 300 | Simulation | [104] | ||

| / | Diesel | 5000 | Simulation | [120] | ||

| SAI | / | Diesel & Gas | 100 | / | [109] | |

| / | Gasoline | 20 | Simulation | [111,112] | ||

| VCM | / | Diesel & Gas | 400 | / | [117,147] | |

| / | Gas | 4400 | Simulation | [119,148] | ||

| VGT | Coordinate control 3 | Diesel | / | Experiment | [116] | |

| MBC | Diesel | 1600 | Experiment | [149] | ||

| / | Diesel & Gas | / | / | [98] | ||

| / | Diesel | 61 | Experiment | [114] | ||

| / | Gas | 12,000 | Simulation | [115] | ||

| / | Coordinate control | Gas | 1600 | Simulation | [121] | |

| Load splitting & grids control | ESS | / | Gas | 218 | Simulation | [134] |

| Gas | 1000 | Simulation | [138,139] | |||

| ESS | VSG control | Gas | 10 | Simulation | [136] | |

| / | VSG control | Gas | 10 | Simulation | [143,144] | |

| ESS | Dynamic energy control | Diesel | 2420 | Simulation | [140] | |

| / | Direct frequency control | / | / | Simulation | [142] |

| Study Purpose | System Structure | Engine | Power Grid | Propeller–Hull | Reference |

|---|---|---|---|---|---|

| System transient response | Mechanical drive | MVM | / | Propeller coefficients | [233] |

| Mechanical drive | 1D GT | / | / | [214] | |

| Mechanical drive | 1D | / | Propeller coefficients | [234] | |

| Mechanical drive | 1D GT | / | Engine load model | [121] | |

| Mechanical drive | MVM | / | Engine propeller curve | [216] | |

| All-electric power | TF | Detailed | Regular load step | [192] | |

| Island grid | TF | Detailed | Regular load step | [164] | |

| Mechanical drive | 1D | / | Propeller coefficients | [235] | |

| Mechanical drive | MVM | / | Propeller coefficients | [187] | |

| Mechanical drive | 1D GT | / | Detailed boundary-element method | [184] | |

| Mechanical drive | MVM | / | Propeller coefficients | [188] | |

| Island grid | TF | Detailed | / | [205] | |

| Hybrid power | MVM | Efficiency | Given curve | [236] | |

| Mechanical drive | / | / | Linear Propeller coefficients | [231] | |

| Hybrid power | MVM | / | Propeller coefficients | [135] | |

| HIL System | Island grid | TF | Detailed | / | [206] |

| System control | Island grid | TF | Detailed | Regular load step | [136,144] |

| Island grid | TF | Detailed | Regular load step | [143] | |

| Engine transient control | / | 1D GT | / | / | [159] |

| Engine only | MVM | / | / | [124] | |

| Engine only | MVM | / | / | [154] | |

| Engine only | 1D GT | / | / | [166] | |

| Engine fast control | HIL Engine only | MVM | / | / | [218] |

| HIL Engine only | MVM | / | / | [237] | |

| HIL Engine only | FRM | / | / | [225] | |

| RT Engine only | MVM | / | / | [221] | |

| DT Engine only | 1D GT | / | / | [65] | |

| Engine only | 1D GT | / | / | [95] | |

| Engine only | 1D GT | / | / | [210] | |

| Engine only | 1D GT | / | / | [217] | |

| Engine only | MVM | / | / | [207] | |

| Engine only | 1D | / | / | [115] | |

| HIL Engine only | MVM | / | / | [156] | |

| Engine only | Linear MVM | / | / | [122] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wu, S.; Li, T.; Chen, R.; Huang, S.; Xu, F.; Wang, B. Transient Performance of Gas-Engine-Based Power System on Ships: An Overview of Modeling, Optimization, and Applications. J. Mar. Sci. Eng. 2023, 11, 2321. https://doi.org/10.3390/jmse11122321

Wu S, Li T, Chen R, Huang S, Xu F, Wang B. Transient Performance of Gas-Engine-Based Power System on Ships: An Overview of Modeling, Optimization, and Applications. Journal of Marine Science and Engineering. 2023; 11(12):2321. https://doi.org/10.3390/jmse11122321

Chicago/Turabian StyleWu, Shen, Tie Li, Run Chen, Shuai Huang, Fuguo Xu, and Bin Wang. 2023. "Transient Performance of Gas-Engine-Based Power System on Ships: An Overview of Modeling, Optimization, and Applications" Journal of Marine Science and Engineering 11, no. 12: 2321. https://doi.org/10.3390/jmse11122321

APA StyleWu, S., Li, T., Chen, R., Huang, S., Xu, F., & Wang, B. (2023). Transient Performance of Gas-Engine-Based Power System on Ships: An Overview of Modeling, Optimization, and Applications. Journal of Marine Science and Engineering, 11(12), 2321. https://doi.org/10.3390/jmse11122321