The Application and Research of New Digital Technology in Marine Aquaculture

Abstract

:1. Introduction

2. New Digital Technologies

3. The Application of New Digital Technologies in Marine Aquaculture

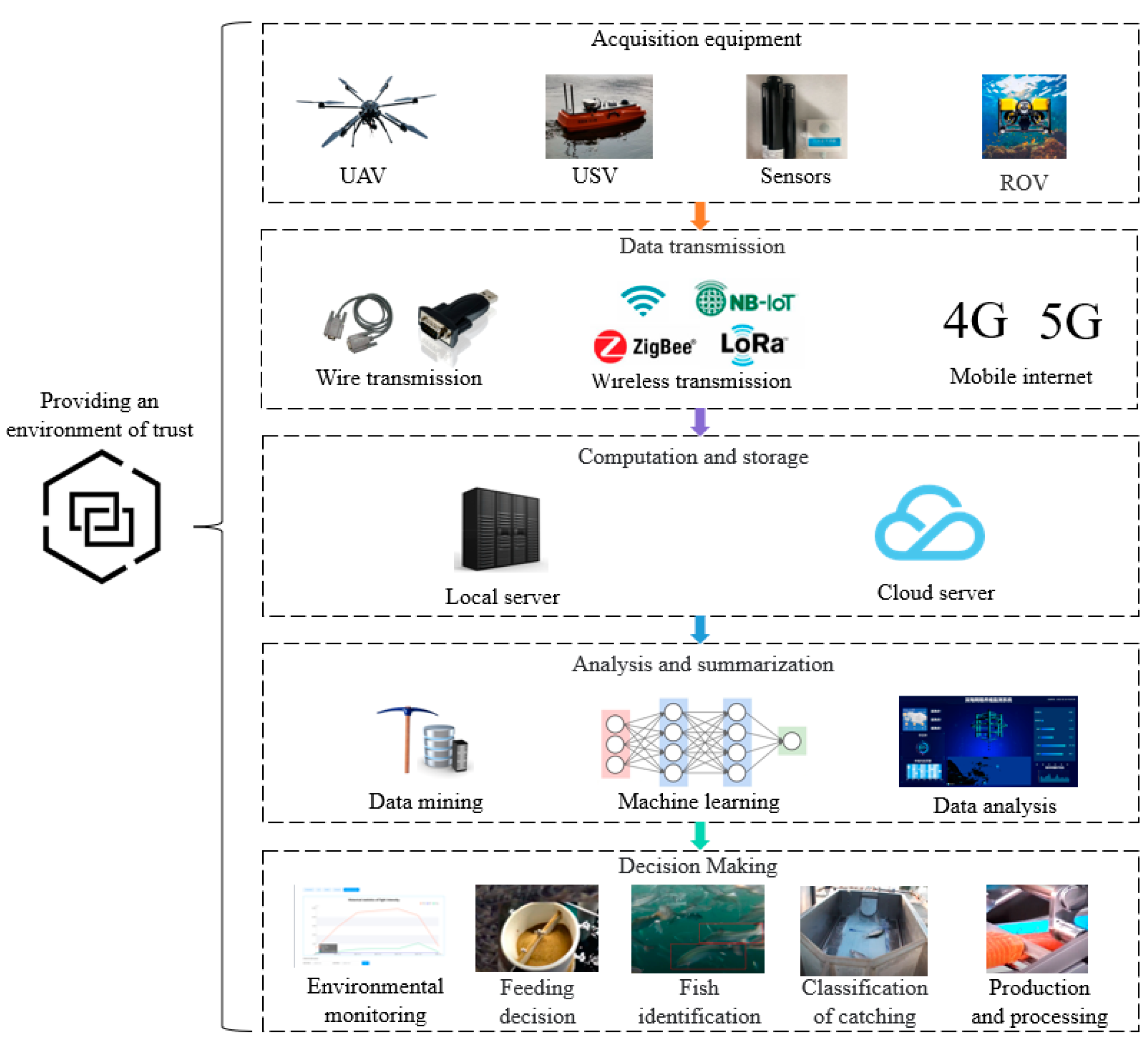

3.1. IoT Applications

3.2. Big Data Applications

3.3. AI Applications

3.4. Blockchain Applications

4. The Application of New Digital Technologies in Deep-Sea Aquaculture Facilities

5. Conclusions and Outlook

- In marine aquaculture, the wireless communication technology of IoT enables the real-time monitoring of water quality, and the data can be processed in real time and fed back to the terminal equipment. With the rapid development of online platforms, fishery managers can obtain a large amount of data related to marine aquaculture at a low cost. Owing to the special factors of marine aquaculture environment, such as climatic conditions, geographical location, and biological diversity, not only are marine sensors susceptible to corrosion, but they also cause obstacles to underwater communication functions. This results in the continuous collection of aquaculture data that are often missing or inaccurate. Therefore, data mining and machine learning models must overcome the complexity of incomplete datasets.

- Machine vision technology can reliably estimate marine biomass in real-time, in a contact-free manner, non-destructively, and safely. This feeds the visual estimation of marine biomass back to the big data platform for analysis and decision and then combines the feeder and catching equipment to enable intelligent feeding and accurate fishing. Machine learning technology can provide relatively efficient technical methods for marine aquaculture in data processing, information extraction, real-time monitoring, decision management, and other aspects. This describes the developmental trend of enabling intelligent marine aquaculture. However, underwater image processing and the collection of other types of information are still difficult owing to the multiple interference of the marine environment light changes and the complex and diverse organisms.

- The combination of blockchain and IoT technology can trace any violation or security problem to the relevant links in the supply chain of marine aquaculture products, which ensures the authenticity and reliability of product information and enhances the trust of consumers in products. Simultaneously, data related to the choice of seafood by consumers can also be analyzed by big data and AI to select high-quality seafood and feed back to the aquacultural source to adjust the strategy for aquaculture. However, the separation of the IoT from human intervention and methods to ensure the authenticity and reliability of the data before the IoT is an important problem that merits additional study.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Nayar, S.; Bott, K. Current status of global cultivated seaweed production and markets. World Aquac. 2014, 45, 32–37. [Google Scholar]

- Moffitt, C.M.; Cajas-Cano, L. Blue growth: The 2014 FAO state of world fisheries and aquaculture. Fisheries 2014, 39, 552–553. [Google Scholar] [CrossRef]

- Pauly, D.; Zeller, D. Comments on FAOs state of world fisheries and aquaculture (SOFIA 2016). Mar. Policy 2017, 77, 176–181. [Google Scholar] [CrossRef]

- Mathiesen, Á.M. The State of World Fisheries and Aquaculture 2012. Available online: https://epub.sub.uni-hamburg.de/epub/volltexte/2012/16991/pdf/2012.pdf (accessed on 11 January 2023).

- Merrifield, M.; Gleason, M.; Bellquist, L.; Kauer, K.; Oberhoff, D.; Burt, C.; Reinecke, S.; Bell, M. eCatch: Enabling collaborative fisheries management with technology. Ecol. Inform. 2019, 52, 82–93. [Google Scholar] [CrossRef]

- Fisheries and Fisheries Administration Bureau of the Ministry of Agriculture and Rural Areas, National Aquatic Technology Promotion Center, Compiled by the Chinese Fishery Society. China Fishery Statistics Yearbook; China Agriculture Press: Beijing, China, 2021. (In Chinese) [Google Scholar]

- Ji, J.; Li, Y. The development of China’s fishery informatization and its impact on fishery economic efficiency. Mar. Policy 2021, 133, 104711. [Google Scholar] [CrossRef]

- Hu, J.; Yang, N.S.; Ou Yang, H.Y.; Sun, Y.Z.; Chen, B.S. Application progress on data mining in field of fishery production. J. Agric. Sci. Technol. 2013, 15, 176–182. (In Chinese) [Google Scholar]

- Hu, L.Y.; Wei, Y.Y.; Zheng, D.; Chen, J.H. Research on intelligent bait casting method based on machine vision technology. J. Trop. Oceanogr. 2015, 34, 90–95. (In Chinese) [Google Scholar]

- Tang, T.L.; Tang, R.; Liu, S.J.; Chen, J.; Miao, L.; Zhou, R. Acoustic control of feeding in Tilapia culture. Prog. Fish. Sci. 2014, 35, 40–43. (In Chinese) [Google Scholar]

- Liu, Y.Q.; Chen, Z.H.; Cao, S.Q. Design of water quality sensor monitoring and self-cleaning device based on Internet of Things. Fish. Mod. 2019, 46, 42–48. (In Chinese) [Google Scholar]

- Chu, S.P.; Xu, Z.Q.; Tang, T.L.; Wang, Z.Y.; Chen, Z.X. Vacuum Fish Pump for Deep Sea Aquaculture Platform. Ship Eng. 2020, 42, 68–71. (In Chinese) [Google Scholar]

- Jiang, Q.J.; Liu, C.X.; Qiu, K.C. Factor inputs, returns to scale and technical efficiency analysis of Chinese fisheries. J. Shanghai Ocean Univ. 2021, 45, 785–797. (In Chinese) [Google Scholar]

- Lin, X.; Zheng, L.; Li, W. Measurement of the contributions of science and technology to the marine fisheries industry in the coastal regions of China. Mar. Policy 2019, 108, 103647. [Google Scholar] [CrossRef]

- Yang, H.S. Development ideas and implementation approaches of blue granary scientific and technological innovation in China. J. Shanghai Ocean Univ. 2019, 43, 97–104. (In Chinese) [Google Scholar]

- Zhao, K.; Ge, L. A survey on the internet of things security. In Proceedings of the 2013 Ninth International Conference on Computational Intelligence and Security, Emeishan, China, 14–15 December 2013. [Google Scholar]

- Rao, B.B.P.; Saluia, P.; Sharma, N.; Mittal, A.; Sharma, S.V. Cloud computing for Internet of Things & sensing based applications. In Proceedings of the 2012 Sixth International Conference on Sensing Technology (ICST), Kolkata, India, 18–21 December 2012. [Google Scholar]

- Qi, Q.; Tao, F. Digital twin and big data towards smart manufacturing and industry 4.0: 360 degree comparison. IEEE Access 2018, 6, 3585–3593. [Google Scholar] [CrossRef]

- Shabbir, J.; Anwer, T. Artificial intelligence and its role in near future. arXiv 2018, arXiv:1804.01396. [Google Scholar]

- Dhar Dwivedi, A.; Singh, R.; Kaushik, K.; Mukkamala, R.R.; Alnumay, W.S. Blockchain and artificial intelligence for 5G-enabled Internet of Things: Challenges, opportunities, and solutions. Trans. Emerg. Telecommun. Technol. 2021, e4329. [Google Scholar] [CrossRef]

- Han, H.; Liu, Z.; Wang, X.; Li, S. Research of the relations among cloud computing, internet of things, big data, artificial intelligence, block chain and their application in maritime field. J. Phys. Conf. Ser. 2021, 1927, 12026. [Google Scholar] [CrossRef]

- Xu, G.; Shen, W.; Wang, X. Applications of wireless sensor networks in marine environment monitoring: A survey. Sensors 2014, 14, 16932–16954. [Google Scholar] [CrossRef]

- Lu, C.W.; Li, S.C.; Wu, Q. Interconnecting ZigBee and 6LoWPAN wireless sensor networks for smart grid applications. In Proceedings of the 2011 Fifth International Conference on Sensing Technology, Palmerston North, New Zealand, 28 November–1 December 2011. [Google Scholar]

- Domingo, M.C. An overview of the internet of underwater things. J. Netw. Comput. Appl. 2012, 35, 1879–1890. [Google Scholar] [CrossRef]

- Akyildiz, I.F.; Pompili, D.; Melodia, T. Underwater acoustic sensor networks: Research challenges. Ad. Hoc. Netw. 2005, 3, 257–279. [Google Scholar] [CrossRef]

- Schmidt, W.; Raymond, D.; Parish, D.; Ashton, I.G.; Miller, P.I.; Campos, C.J.; Shutler, J.D. Design and operation of a low-cost and compact autono-mous buoy system for use in coastal aquaculture and water quality monitoring. Aquac. Eng. 2018, 80, 28–36. [Google Scholar] [CrossRef]

- Wada, M.; Hatanaka, K.; Natsir, M. Development of Automated Sea-condition Monitoring System for Aquaculture in Indonesia. Sens. Mater. 2019, 31, 773–784. [Google Scholar] [CrossRef]

- Aguzzi, J.; López-Romero, D.; Marini, S.; Costa, C.; Berry, A.; Chumbinho, R.; Ciuffardi, T.; Fanelli, E.; Pieretti, N.; Del Rio, J.; et al. Multiparametric monitoring of fish activity rhythms in an Atlantic coastal cabled observatory. J. Mar. Syst. 2020, 212, 103424. [Google Scholar] [CrossRef]

- Sheehan, E.V.; Bridger, D.; Nancollas, S.J.; Pittman, S.J. PelagiCam: A novel underwater imaging system with computer vision for semi-automated monitoring of mobile marine fauna at offshore structures. Environ. Monit. Assess. 2020, 192, 1–13. [Google Scholar] [CrossRef] [PubMed]

- Hassan, W.; Føre, M.; Ulvund, J.B.; Alfredsen, J.A. Internet of Fish: Integration of acoustic telemetry with LPWAN for efficient real-time monitoring of fish in marine farms. Comput. Electron. Agric. 2019, 163, 104850. [Google Scholar] [CrossRef]

- Piramuthu, S.; Zhou, W. RFID and Sensor Network Automation in the Food Industry: Ensuring Quality and Safety Through Supply Chain Visibility; John Wiley & Sons: Hoboken, NJ, USA, 2016. [Google Scholar]

- Kokkinos, K.; Exadactylos, A.; Vafidis, D.; Hatziioannou, M. Efficient traceability of aquatic products on the cold supply chain management via IoT and artificial neural networks. In Proceedings of the 3rd International Congress on Applied Ichthyology & Aquatic Environment, Volos, Greece, 8–11 November 2018. [Google Scholar]

- Trebar, M.; Grah, A.; Melcon, A.A.; Parreno, A. Towards RFID traceability systems of farmed fish supply chain. In Proceedings of the SoftCOM 2011, 19th IEEE International Conference on Software; Telecommunications and Computer Networks, Split, Croatia, 15–17 September 2011. [Google Scholar]

- Yan, B.; Hu, D.; Shi, P. A traceable platform of aquatic foods supply chain based on RFID and EPC internet of things. Int. J. RF Technol. 2012, 4, 55–70. [Google Scholar] [CrossRef]

- Tian, Z.; Liu, F.; Li, Z.; Malekian, R.; Xie, Y. The development of key technologies in applications of vessels connected to the internet. Symmetry 2017, 9, 211. [Google Scholar] [CrossRef]

- Hao, Q.; Wang, Z.; Qin, L. Design of beidou satellite system in ocean logistics real-time tracking system. J. Coast. Res. 2019, 94, 204–207. [Google Scholar] [CrossRef]

- Liu, S.; Chen, G.; Liu, Y.J.; Tian, F.L. Research and analysis on marine big data applied technology. Period. Ocean Univ. China 2020, 50, 154–164. (In Chinese) [Google Scholar]

- Penry-Williams, I.L.; Kalantzi, I.; Tzempelikou, E.; Tsapakis, M. Intensive marine finfish aquaculture impacts community structure and metal bioaccumulation in meso-zooplankton. Mar. Pollut. Bull. 2022, 182, 114015. [Google Scholar] [CrossRef]

- Shi, P.; Li, G.; Yuan, Y.; Huang, G.; Kuang, L. Prediction of dissolved oxygen content in aquaculture using Clustering-based Softplus Extreme Learning Machine. Comput. Electron. Agric. 2019, 157, 329–338. [Google Scholar] [CrossRef]

- Hu, W.C.; Wu, H.T.; Zhan, J.W.; Zhang, J.M. Big Data Analysis on Water Quality Condition in a White Shrimp Farming Environment. J. Internet Technol. 2021, 22, 1563–1573. [Google Scholar]

- Zhou, Y. Real-time probabilistic forecasting of river water quality under data missing situation: Deep learning plus post-processing techniques. J. Hydrol. 2020, 589, 125164. [Google Scholar] [CrossRef]

- Weitzman, J.; Filgueira, R. The evolution and application of carrying capacity in aquaculture: Towards a research agenda. Rev. Aquac. 2020, 12, 1297–1322. [Google Scholar] [CrossRef]

- Hai, A.T.N.; Speelman, S. Economic-environmental trade-offs in marine aquaculture: The case of lobster farming in Vietnam. Aquaculture 2020, 516, 734593. [Google Scholar]

- Santa Marta, A.; Ferreira, J.G.; Pitcher, G.C.; Lencart e Silva, J. Sustainable shellfish aquaculture in Saldanha Bay, South Africa. Afr. J. Mar. Sci. 2020, 42, 151–166. [Google Scholar] [CrossRef]

- Gu, Y. Application of Big Data Analysis in Cost Control of Marine Fishery Breeding. Discret. Dyn. Nat. Soc. 2022, 2022, 6827469. [Google Scholar]

- He, Y.; Su, F.; Du, Y.; Xiao, R. Web-based spatiotemporal visualization of marine environment data. Chin. J. Ocean. Limnol. 2010, 28, 1086–1094. [Google Scholar] [CrossRef]

- Peng, Z.; Chen, Y.; Zhang, Z.; Qiu, Q.; Han, X. Implementation of water quality management platform for aquaculture based on big data. In Proceedings of the 2020 International Conference on Computer Information and Big Data Applications (CIBDA), Guiyang, China, 17–19 April 2020. [Google Scholar]

- Su, T.; Cao, Z.; Lv, Z.; Liu, C.; Li, X. Multi-dimensional visualization of large-scale marine hydrological environmental data. Adv. Eng. Softw. 2016, 95, 7–15. [Google Scholar]

- Clawson, G.; Kuempel, C.D.; Frazier, M.; Blasco, G.; Cottrell, R.S.; Froehlich, H.E.; Metian, M.; Nash, K.L.; Többen, J.; Verstaen, J.; et al. Mapping the spatial distribution of global mariculture production. Aquaculture 2022, 553, 738066. [Google Scholar] [CrossRef]

- Dogan, A.; Birant, D. Machine learning and data mining in manufacturing. Expert Syst. Appl. 2021, 166, 114060. [Google Scholar]

- Li, D.; Sun, Y.; Sun, J.; Wang, X.; Zhang, X. An advanced approach for the precise prediction of water quality using a discrete hidden markov model. J. Hydrol. 2022, 609, 127659. [Google Scholar] [CrossRef]

- Rijayanti, R.; Hwang, M. Prediction of Sea Water Condition Changes using LSTM Algorithm for the Fish Farm. J. Korea Inst. Inf. Commun. Eng. 2022, 26, 374–380. [Google Scholar]

- Chen, Z.; Hu, Z.; Xu, L.; Zhao, Y.; Zhou, X. DA-Bi-SRU for water quality prediction in smart mariculture. Comput. Electron. Agric. 2022, 200, 107219. [Google Scholar] [CrossRef]

- Hu, Z.; Zhang, Y.; Zhao, Y.; Xie, M.; Zhong, J.; Tu, Z.; Liu, J. A water quality prediction method based on the deep LSTM network considering correlation in smart mariculture. Sensors 2019, 19, 1420. [Google Scholar] [CrossRef]

- Yñiguez, A.T.; Ottong, Z.J. Predicting fish kills and toxic blooms in an intensive mariculture site in the Philippines using a machine learning model. Sci. Total Environ. 2020, 707, 136173. [Google Scholar] [CrossRef]

- Yina, B.; Wanga, R.; Qia, S.; Yub, J.; Jiangb, W. Prediction model of dissolved oxygen in marine pasture based on hybrid gray wolf algorithm optimized support vector regression. Desalination Water Treat. 2021, 222, 156–167. [Google Scholar] [CrossRef]

- Ma, Z.; Song, X.; Wan, R.; Gao, L.; Jiang, D. Artificial neural network modeling of the water quality in intensive Litopenaeus vannamei shrimp tanks. Aquaculture 2014, 433, 307–312. [Google Scholar] [CrossRef]

- Liu, J.; Yu, C.; Hu, Z.; Zhao, Y.; Bai, Y.; Xie, M.; Luo, J. Accurate prediction scheme of water quality in smart mariculture with deep Bi-S-SRU learning network. IEEE Access 2020, 8, 24784–24798. [Google Scholar] [CrossRef]

- Yang, L.; Liu, Y.; Yu, H.; Fang, X.; Song, L.; Li, D.; Chen, Y. Computer vision models in intelligent aquaculture with emphasis on fish detection and behavior analysis: A review. Arch. Computat. Methods Eng. 2021, 28, 2785–2816. [Google Scholar] [CrossRef]

- Hu, W.C.; Wu, H.T.; Zhang, Y.F.; Zhang, S.H.; Lo, C.H. Shrimp recognition using ShrimpNet based on convolutional neural network. J. Ambient Intell. Human. Comput. 2020, 1–8. [Google Scholar] [CrossRef]

- Ordoñez, A.; Eikvil, L.; Salberg, A.B.; Harbitz, A.; Murray, S.M.; Kampffmeyer, M.C. Explaining decisions of deep neural networks used for fish age prediction. PLoS ONE 2020, 15, e0235013. [Google Scholar] [CrossRef]

- Cui, Y.; Pan, T.; Chen, S.; Zou, X. A gender classification method for Chinese mitten crab using deep convolutional neural network. Multimed. Tools Appl. 2020, 79, 7669–7684. [Google Scholar] [CrossRef]

- Salman, A.; Jalal, A.; Shafait, F.; Mian, A.; Shortis, M.; Seager, J.; Harvey, E. Fish species classification in unconstrained underwater environments based on deep learning. Limnol. Oceanogr. Methods 2016, 14, 570–585. [Google Scholar] [CrossRef]

- Mia, M.J.; Mahmud, R.B.; Sadad, M.S.; Al Asad, H.; Hossain, R. An in-depth automated approach for fish disease recognition. J. King Saud Univ. Comput. Inf. Sci. 2022, 34, 7174–7183. [Google Scholar] [CrossRef]

- Zhao, S.; Zhang, S.; Lu, J.; Wang, H.; Feng, Y.; Shi, C.; Li, D.; Zhao, R. A lightweight dead fish detection method based on deformable convolution and YOLOV4. Comput. Electron. Agric. 2022, 198, 107098. [Google Scholar] [CrossRef]

- Meng, J.; Du, H.; Zhao, Y.P.; Ye, Z.Y.; Liu, S.C. An extraction method of fish vector field for marine cage culture based on UAV vision. Aquac. Eng. 2022, 98, 102276. [Google Scholar] [CrossRef]

- Føre, M.; Frank, K.; Norton, T.; Svendsen, E.; Alfredsen, J.A.; Dempster, T.; Eguiraun, H.; Watson, W.; Stahl, A.; Sunde, L.M.; et al. Precision fish farming: A new framework to improve production in aquaculture. Biosyst. Eng. 2018, 173, 176–193. [Google Scholar] [CrossRef]

- Yang, L.; Yu, H.; Cheng, Y.; Mei, S.; Duan, Y.; Li, D.; Chen, Y. A dual attention network based on efficientNet-B2 for short-term fish school feeding behavior analysis in aquaculture. Comput. Electron. Agric. 2021, 187, 106316. [Google Scholar] [CrossRef]

- Måløy, H.; Aamodt, A.; Misimi, E. A spatio-temporal recurrent network for salmon feeding action recognition from underwater videos in aquaculture. Comput. Electron. Agric. 2019, 167, 105087. [Google Scholar] [CrossRef]

- Hu, X.; Liu, Y.; Zhao, Z.; Liu, J.; Yang, X.; Sun, C.; Chen, S.; Li, B.; Zhou, C. Real-time detection of uneaten feed pellets in underwater images for aquaculture using an improved YOLO-V4 network. Comput. Electron. Agric. 2021, 185, 106135. [Google Scholar] [CrossRef]

- Cubitt, K.F.; Williams, H.T.; Rowsell, D.; McFarlane, W.J.; Gosine, R.G.; Butterworth, K.G.; McKinley, R.S. Development of an intelligent reasoning system to distinguish hunger states in Rainbow trout (Oncorhynchus mykiss). Comput. Electron. Agric. 2008, 62, 29–34. [Google Scholar] [CrossRef]

- Zhao, S.; Ding, W.; Zhao, S.; Gu, J. Adaptive neural fuzzy inference system for feeding decision-making of grass carp (Ctenopharyngodon idellus) in outdoor intensive culturing ponds. Aquaculture 2019, 498, 28–36. [Google Scholar] [CrossRef]

- Chen, F.; Sun, M.; Du, Y.; Xu, J.; Zhou, L.; Qiu, T.; Sun, J. Intelligent feeding technique based on predicting shrimp growth in recirculating aquaculture system. Aquac. Res. 2022, 53, 4401–4413. [Google Scholar] [CrossRef]

- Muñoz-Benavent, P.; Andreu-García, G.; Valiente-González, J.M.; Atienza-Vanacloig, V.; Puig-Pons, V.; Espinosa, V. Enhanced fish bending model for automatic tuna sizing using computer vision. Comput. Electron. Agric. 2018, 150, 52–61. [Google Scholar] [CrossRef]

- Saberioon, M.; Císař, P. Automated within tank fish mass estimation using infrared reflection system. Comput. Electron. Agric. 2018, 150, 484–492. [Google Scholar] [CrossRef]

- Zhang, S.; Yang, X.; Wang, Y.; Zhao, Z.; Liu, J.; Liu, Y.; Sun, C.; Zhou, C. Automatic fish population counting by machine vision and a hybrid deep neural network model. Animals 2020, 10, 364. [Google Scholar] [CrossRef]

- Gamage, L.B.; De Silva, C.W.; Gosine, R.G. Statistical pattern recognition for cutter positioning in automated fish processing. In Proceedings of the IEEE Pacific Rim Conference on Communications Computers and Signal Processing, Victoria, BC, Canada, 19–21 May 1993. [Google Scholar]

- Odone, F.; Trucco, E.; Verri, A. A trainable system for grading fish from images. Appl. Artif. Intell. 2001, 15, 735–745. [Google Scholar] [CrossRef]

- Wu, Y.; Zhuang, R.; Cui, Z. Automatic sorting system of large yellow croaker based on machine vision. In Proceedings of the 2019 International Conference on High Performance Big Data and Intelligent Systems (HPBD&IS), Shenzhen, China, 9–11 May 2019. [Google Scholar]

- Singh, S.K.; Rathore, S.; Park, J.H. Blockio Tintelligence: A blockchain-enabled intelligent IoT architecture with artificial intelligence. Future Gener. Comput. Syst. 2020, 110, 721–743. [Google Scholar] [CrossRef]

- Howson, P. Building trust and equity in marine conservation and fisheries supply chain management with blockchain. Mar. Policy 2020, 115, 103873. [Google Scholar] [CrossRef]

- Visser, C.; Hanich, Q.A. How Blockchain Is Strengthening Tuna Traceability to Combat Illegal Fishing. Available online: https://ro.uow.edu.au/lhapapers/3359/ (accessed on 22 January 2018).

- Hang, L.; Ullah, I.; Kim, D.H. A secure fish farm platform based on blockchain for agriculture data integrity. Comput. Electron. Agric. 2020, 170, 105251. [Google Scholar] [CrossRef]

- Zhang, Y.; Liu, Y.; Jiong, Z.; Zhang, X.; Li, B.; Chen, E. Development and assessment of blockchain-IoT-based traceability system for frozen aquatic product. J. Food Process Eng. 2021, 44, e13669. [Google Scholar] [CrossRef]

- Stephane, I.; Saputra, H.; Alhaj, N.; Maltaf Putra, L. Utilization of blockchain for marine products tracking. Indones. J. Comput. Sci. 2022, 11. [Google Scholar]

- Khan, M.A.; Hossain, M.E.; Shahaab, A.; Khan, I. ShrimpChain: A blockchain-based transparent and traceable framework to enhance the export potentiality of Bangladeshi shrimp. Smart Agric. Technol. 2022, 2, 100041. [Google Scholar] [CrossRef]

- Patro, P.K.; Jayaraman, R.; Salah, K.; Yaqoob, I. Blockchain-based traceability for the fishery supply chain. IEEE Access 2022, 10, 81134–81154. [Google Scholar] [CrossRef]

- Garrard, R.; Fielke, S. Blockchain for trustworthy provenances: A case study in the Australian aquaculture industry. Technol. Soc. 2020, 62, 101298. [Google Scholar] [CrossRef]

- Li, Z.Y.; Tong, B.; Shao, W.H. Discussion on General Design of Large Aquaculture Ship Using Recirculating Water Technology. Ship Boat. 2022, 33, 20–29. (In Chinese) [Google Scholar]

- Chu, Y.I.; Wang, C.M.; Park, J.C.; Lader, P.F. Review of cage and containment tank designs for offshore fish farming. Aquaculture 2020, 519, 734928. [Google Scholar] [CrossRef]

- Sun, Y.W.; Dai, H.J.; Luo, R.; Ren, N. Research Situation Analysis of the Sensor Technology of Facility Aquaculture Based on Patentometrics. J. Anhui Agric. Sci. 2021, 49, 228–234. (In Chinese) [Google Scholar]

- Dong, X.N.; Wang, Z.Y.; Xu, Z.Q.; Tang, T.L. Design of feeding control system for 100000 ton aquaculture vessel. Fish. Mod. 2022, 49, 61–67. (In Chinese) [Google Scholar]

- Huang, W.Y.; Yu, D.S.; Dong, X.N.; Jiang, Y.; Wang, P.C.; Guo, H.T. Research on the centralized control system of aquaculture platform. Fish. Mod. 2022, 49, 89–96. (In Chinese) [Google Scholar]

- Li, J.X.; Wang, J. Scheme design of power system for a deep sea aquaculture platform. Fish. Mod. 2020, 47, 74–81. (In Chinese) [Google Scholar]

- Offshore Fish Farming: A New Era in Fish Farming Is on Its Way. Available online: https://www.salmar.no/en/offshore-fish-farming-a-new-era/?tdsourcetag=s_pcqq_aiomsg (accessed on 11 January 2022).

- Havfarm: A New Salmon Fishing Revolution in Norway. Available online: https://ship.nridigital.com/ship_jan19/a_new_salmon_fishing_revolution_norway (accessed on 11 January 2022).

- The Ocean Farm “Jostein Albert”. Available online: https://www.nordlaks.com/ocean-farm-jostein-albert/ (accessed on 11 January 2022).

- Feed Systems: The Central Feed System Concept Was Invented by AKVA Group in 1980 and is Today the World’s Best-Selling Feeding System. Available online: https://www.akvagroup.com/sea-based/precision-feeding/feed-systems/ (accessed on 11 January 2022).

- Environmental Technologies Inc.: FEEDMASTER. Available online: https://www.transvac.com/project-2 (accessed on 11 January 2022).

- Aurora: Rov Services Vessel. Available online: https://www.oceanfarmservices.com/vessels/aurora (accessed on 11 January 2022).

- Remote Net Cleaner Sub-Mergible Cleaner for Fish Farming Nets. Available online: https://vakiiceland.is/pumps/ (accessed on 11 January 2022).

- Fish Pumps: High Capacity, Efficient and Easy to Move. Available online: https://vakiiceland.is/pumps/ (accessed on 11 January 2022).

- Ou, Y.J.; Shen, J.; Zheng, X.W.; Huang, Y.X.; Xu, H. Research and application status and development tendency of aquatic products processing equipment. Fish. Mod. 2017, 44, 73–78. (In Chinese) [Google Scholar]

- Bjørlykhaug, E.; Egeland, O. Vision system for quality assessment of robotic cleaning of fish processing plants using CNN. IEEE Access 2019, 7, 71675–71685. [Google Scholar] [CrossRef]

- Bjørlykhaug, E.; Egeland, O. Mechanical design optimization of a 6DOF serial manipulator using genetic algorithm. IEEE Access 2018, 6, 59087–59095. [Google Scholar] [CrossRef]

- Chen, J. Research on Key Technologies of Aquatic Product Traceability System Based on Barcode Technology. Master’s Thesis, Wuhan University of Technology, Wuhan, China, 2015. [Google Scholar]

- Wei, L.F.; Zhu, J.Y.; Heng, X.R.; Zhu, Y.; Cen, T.W.; He, C.L. Design and realization of intelligent quality-and-safety traceability system for aquatic products based on blockchain combined with HACCP management. Fish. Mod. 2020, 47, 89–96. (In Chinese) [Google Scholar]

| Sources | Method | Speed | Difficulty Level | Reliability |

|---|---|---|---|---|

| IoT | Sensor | Quick | Easy | Moderate |

| Internet | Crawler | Quick | Easy | Moderate |

| Professional databases | Application programming interface (API) | Quick | Moderate | High |

| Marine fisheries management systems | Crawler/API | Moderate | Moderate | High |

| Traditional data sources | Inquiry/Consultation | Low | Difficulty | High |

| Scene | Prediction Method | Prediction Content | Evaluation Indicators/Effects | Reference |

|---|---|---|---|---|

| Marine ranches | Markov and K-means clustering | Dissolved oxygen saturation and turbidity | The model’s discrete HMM has a correlation coefficient of 0.9782, a standard deviation of 0.1619, and a root mean square error of 0.0357 | Li et al. [51] |

| Fish farms | LSTM | Dissolved oxygen, salinity, nitrogen ion concentration and water temperature | Accuracy rate of 87% | Rijayanti [52] |

| Fish cages | Double-attention-based bidirectional simple recurrent unit model (DA-Bi-SRU) | pH, water temperature and dissolved oxygen | Accuracy rate of 93.06% | Chen et al. [53] |

| Fish cages | LSTM | pH and water temperature | The prediction accuracy of pH and water temperature can reach 95.76% and 96.88%, respectively | Hu et al. [54] |

| Fish cages and fish pens | The random forest | Dissolved oxygen, water temperature, salinity and chlorophyll | Accuracy rate of 96.1% | Yñiguez [55] |

| Marine pasture | Wavelet analysis and hybrid gray wolf algorithm (HGWO) | Dissolved oxygen | The mean square error, mean absolute error and mean percentage error were 0.1658, 0.359 and 0.0305, respectively | Yina et al. [56] |

| Shrimp ponds | Backward propagation neural network (BP-NN) | Water temperature, pH, total ammonia nitrogen, nitrite nitrogen, nitrate nitrogen, dissolved inorganic phosphorus, chlorophyll-a, chemical oxygen demand, and five-day biochemical oxygen demand | The correlation coefficients of the training set, test set and training and test set with the experimental values were 0.990, 0.979 and 0.992, respectively | Ma et al. [57] |

| Marine aquaculture base | DA-Bi-SRU | pH, water temperature and dissolved oxygen | The prediction accuracy rate can reach 94.42% in the next 3~8 days | Liu et al. [58] |

| Key Technology | Function | Source of Decision | Reference |

|---|---|---|---|

| DANet-EfficientNet-B2 | To identify short-term feeding characteristics of shoals in specific feeding areas | Behavior of fish | Yang et al. [68] |

| Two-stream recursive Network (DSRN) | To identify the feeding and non-feeding behaviors of salmon in the absence of significant motor features | Behavior of fish | Måløy et al. [69] |

| The improved YOLO-V4 | To detect uneaten feed particles in underwater images | Residual feed amount | Hu et al. [70] |

| Quadratic vector machine | To determine if the fish are hungry based on data on the activity of electromyography | Electromyography | Cubitt et al. [71] |

| Adaptive fuzzy reasoning | To determine the feeding intensity by the dissolved oxygen saturation and temperature | Aquaculture environment | Zhao et al. [72] |

| MLR, artificial neural networks and SVM | Predictive model for shrimp biomass based on four main variables: water temperature, dissolved oxygen, pH and total feeding to develop feeding strategies | Growth model | Chen et al. [73] |

| Name | Introduction | Completion Time (Year and Month) | Characteristic | Farming Benefits |

|---|---|---|---|---|

| Shenlan 1 | Large-scale fully submersible deep-sea intelligent fishery farming equipment | 2018.5 | The equipment is equipped with approximately 20,000 sensors that enable fully automatic monitoring, feeding, and other work. | First harvest of 150,000 salmon, quality all meet EU export standards |

| Dehai 1 | 10,000-ton intelligent fish farm that consists of a mixture of plate structure floating body and truss structure farming area. | 2018.9 | This intelligent fishery is structurally safe, can evaluate aquaculture efficiently, and does not require manual control of the aquaculture. | After more than 8 months of growth, the average weight of each fish is 750 g |

| Zhenbao 1 | Deep-sea abalone mechanized farming platform | 2018.10 | The platform can monitor various parameters of abalone production and the surrounding environment in real time and enable the intensification and standardization of abalone aquaculture. | The weight of each abalone is 10 to 15 g heavier than that in the bay |

| Changjing 1 | Deep-water seated-bottom aquaculture large-net cage | 2019.4 | The net cage is integrated to automatically lift net clothes, feed automatically, and monitor underwater and other automatic equipment, which can enable system timing and quantitative and efficient automatic control. | Annual production of over 1000 tons of black and yellow croaker |

| Fubao 1 | Deep-sea intelligent and environmentally friendly abalone farming platform | 2019.4 | The platform contains oxygenation, water quality monitoring, scenery complementary, and systems for the supply of daily power, sewage treatment, video monitoring and remote data transmission. | Over 40,000 kg production in 2022 |

| Penghu | Semi-submersible wave energy farming tourism platform | 2019.6 | The platform is equipped with desalination and sewage treatment equipment, and the aquaculture system is equipped with modern fishery production equipment, such as automatic feeding, the monitoring of fish and water quality, and the transmission of live fish. | The maximum capacity to raise common fish is about 300 tons |

| Changyu 1 | 5G technology-enabled marine ranching platform | 2020.6 | The platform is equipped with a big data monitoring system for marine pastures, which can enable real-time monitoring of marine data, such as meteorology, water temperature and quality, flow speed, and direction. It is also the first platform to carry a 5G communication base station. | 100,000 pounds of adult fish can be harvested in two years |

| Genghai 1 | Intelligent multi-functional ecological marine pasture complex platform | 2020.7 | The platform has automatic feeding, environmental monitoring, and ship anti-collision functions, and it is also loaded with unmanned ships, underwater inspection robots and other technical equipment, which can enable intelligent control of the entire production process. | Annual production capacity of 150,000 kg |

| Jinghai 1 | Steel structure seated-bottom deep- sea intelligent net cage platform | 2021.5 | The platform is equipped with a digital farming management system, an intelligent robot operating system, and a biological monitoring and operation system. | Annual production capacity of 700 tons |

| Guoxin 1 | 100,000-ton intelligent fishery large-scale farming work vessel | 2022.5 | This aquaculture vessel integrates the technologies of ship engineering, seawater aquaculture, and seed aquaculture and introduces six key technologies, such as shipboard cabin raising, water exchange, shake reduction, vibration and noise reduction, dirt cleaning and corrosion prevention, and intelligent set control. | First catch of 65 tons |

| Ningde 1 | Deep-sea semi-submersible farming platform | 2022.11 | Equipped with systems or facilities for automated control, feeding, water quality testing, fish harvesting, net-washing patrol marine robots, real-time marine monitoring and marine environmental weather monitoring. | Annual production capacity of 2000 tons |

| Name | Country | Completion and Delivery Time | Characteristic | Effectiveness |

|---|---|---|---|---|

| MarinaCCS (feeding system) [98] | Norway | A variety of sensors and cameras are used to monitor the underwater environment for accurate feeding, and self-developed software ensures the stability of the system. | The system can handle more than 40 feed lines running in parallel and more than 1000 tanks/units | |

| FEED-MASTER (feeding system) [99] | America | PLC-based control technology effectively solves the problem of feeding machine damage to the feed, with high reliability and high feeding accuracy. | Feeding over 100 kg/min at distances of up to 1000 m | |

| Aurora (ROV Net Washing vessel) [100] | Canada | 2012 | Provide semi-automatic net washing | Maximum speed 10.5 knots |

| YANMAR (Remote net cleaner) [101] | Japan | 2015 | Provide semi-automatic net washing | Maximum speed 50 m/min |

| VAKI Fish Pumps [102] | America | Provide safe, gentle and fast fish transfer | Maximum horizontal conveying: 2.000 m | |

| Ocean farm 1 [95] | Norway | 2017.6 | It has over 20,000 sensors and over 100 monitors and control units | Holds up to 1.5 million salmon |

| Havfarm 1 [96] | Norway | 2020.3 | The use of dynamic positioning systems allows the ship to automatically change its position and direction using propellers and propellers. | Holds up to 10,000 tons of salmon |

| JOSTEIN ALBERT | Norway | 2020.3 | It is equipped with functions to realize automatic fry transportation, automatic feed feeding, underwater light monitoring, underwater oxygenation, dead fish recovery, and automatic adult fish search and capture, and can adapt to the extremely cold climate and harsh sea conditions outside the Norwegian fjords. | Holds up to 10,000 tons of salmon. |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, H.; Gui, F. The Application and Research of New Digital Technology in Marine Aquaculture. J. Mar. Sci. Eng. 2023, 11, 401. https://doi.org/10.3390/jmse11020401

Zhang H, Gui F. The Application and Research of New Digital Technology in Marine Aquaculture. Journal of Marine Science and Engineering. 2023; 11(2):401. https://doi.org/10.3390/jmse11020401

Chicago/Turabian StyleZhang, Hanwen, and Fukun Gui. 2023. "The Application and Research of New Digital Technology in Marine Aquaculture" Journal of Marine Science and Engineering 11, no. 2: 401. https://doi.org/10.3390/jmse11020401

APA StyleZhang, H., & Gui, F. (2023). The Application and Research of New Digital Technology in Marine Aquaculture. Journal of Marine Science and Engineering, 11(2), 401. https://doi.org/10.3390/jmse11020401