Study on Bearing Capacity of Reinforced Composite Pipe Pile Group in Reclaimed Stratum under Vertical Load

Abstract

1. Introduction

2. Design of Field Test

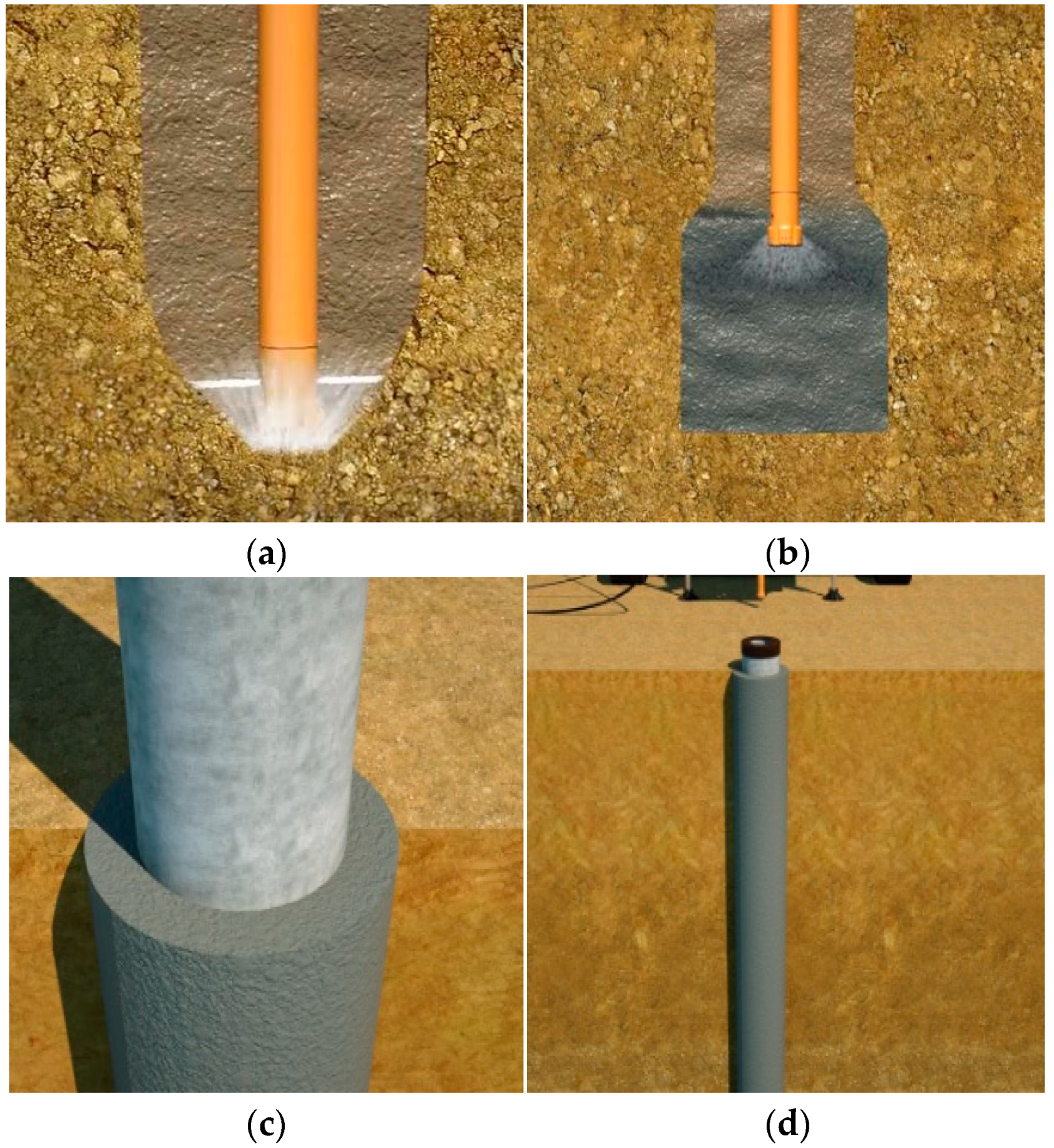

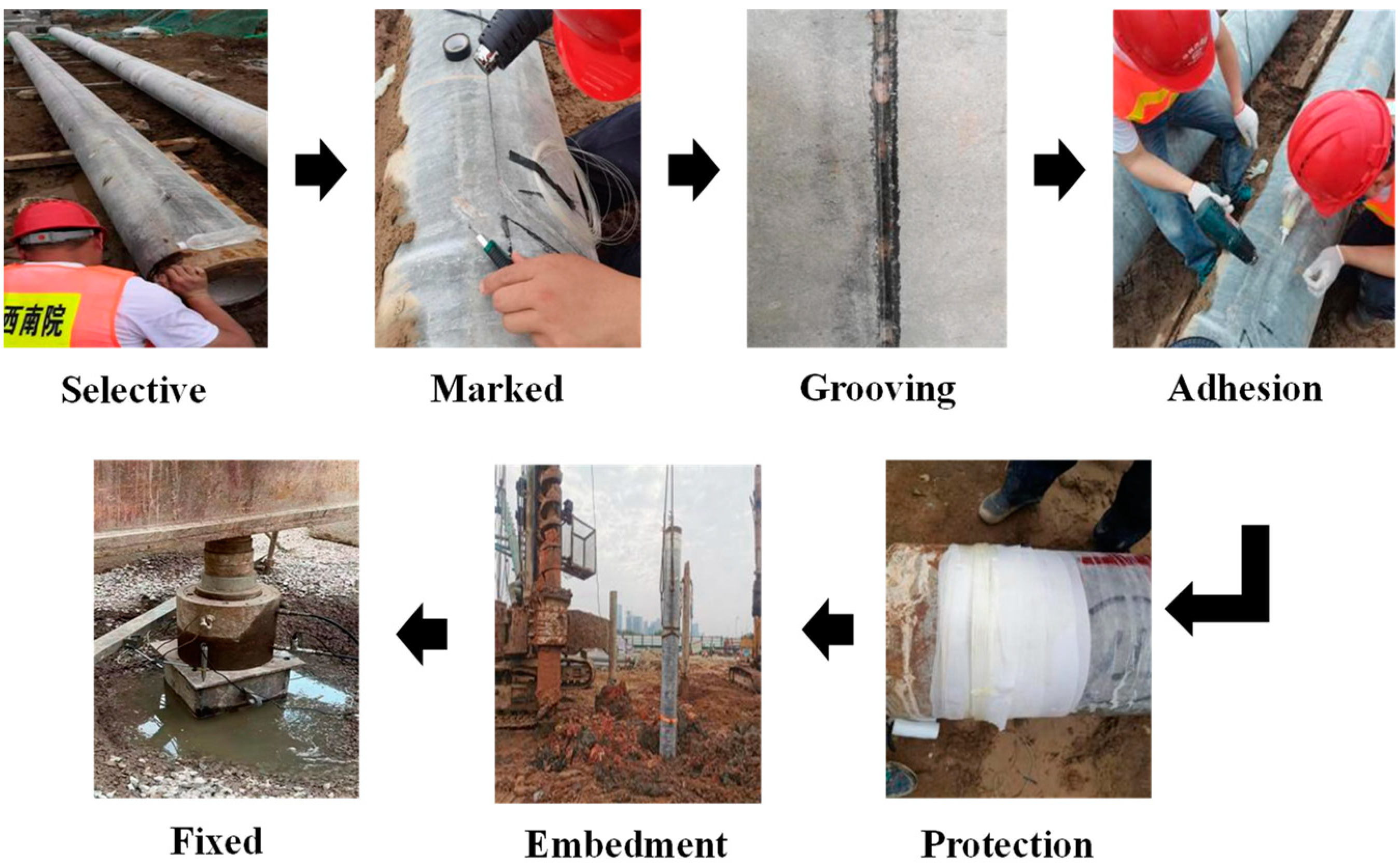

2.1. Technological Process of Stiffened Composite Pipe Pile

2.2. Test Preparation

- (1)

- The soil at the test site was cemented by the down-hole-impact jet grouting of the designed diameter and length.

- (2)

- According to the site requirements, the test pile would be placed at a designated position by the crane. To ensure that the setting-out lines were reasonable and straight, the core piles were marked symmetrically on both sides. A cutting machine was then used to cut the grooves along the marked lines. After the grooves were finished, the grooves were cleaned by a blower and checked for straightness and smoothness.

- (3)

- The optical fibre was implanted along the grooves, and an adequate length of optical fibre was reserved at the top of the pile. The optical fibre was fixed with strong glue.

- (4)

- After the optical fibre was fixed, ethyl polyurethane was used as a backfill to protect the optical fibre.

- (5)

- After the completion of the above steps, the pile was transferred to the designed position and then planted into cemented soil to a specified depth using a machine.

2.3. Test Loading Condition

3. Analysis of Single Pile

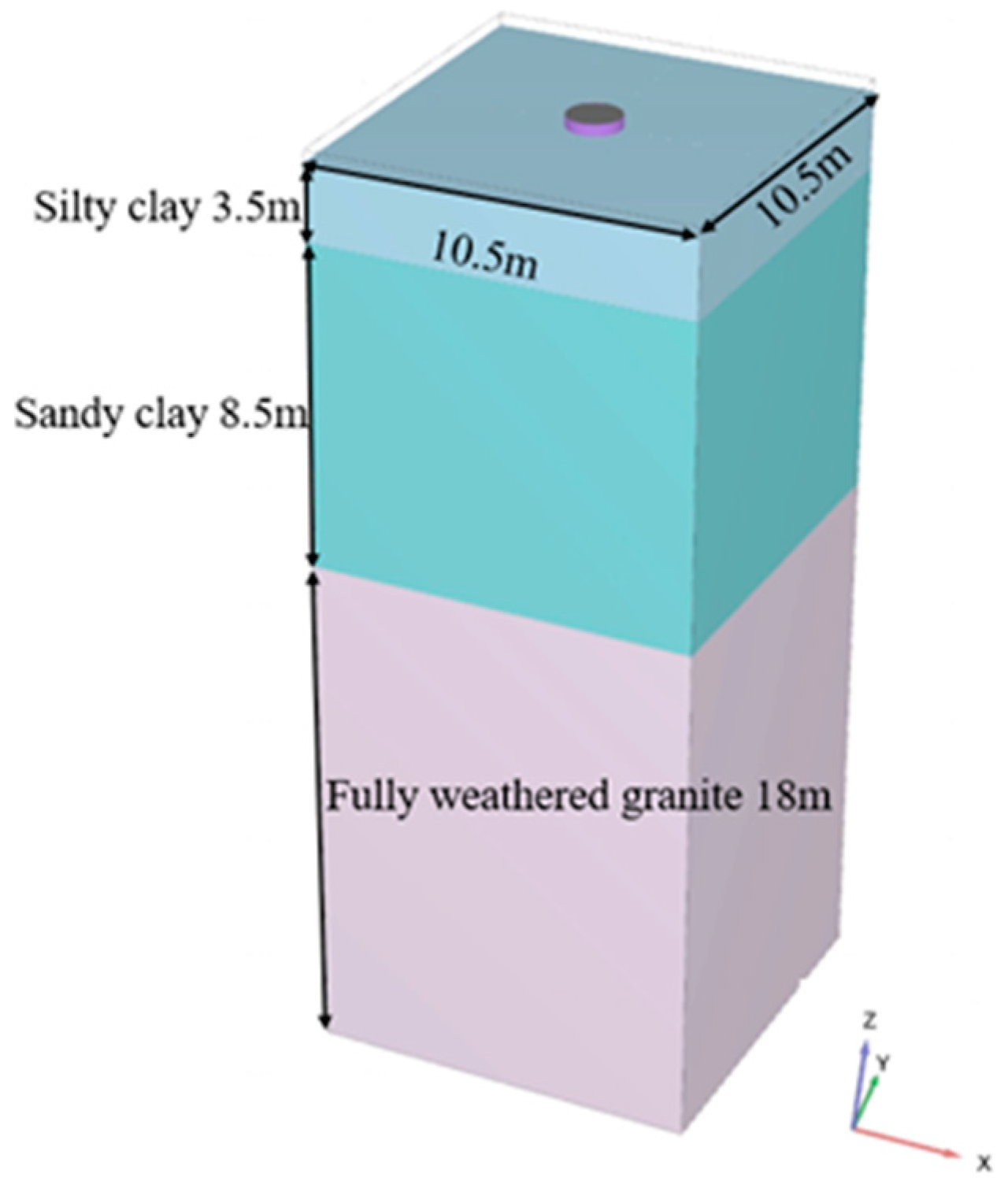

3.1. Numerical Model

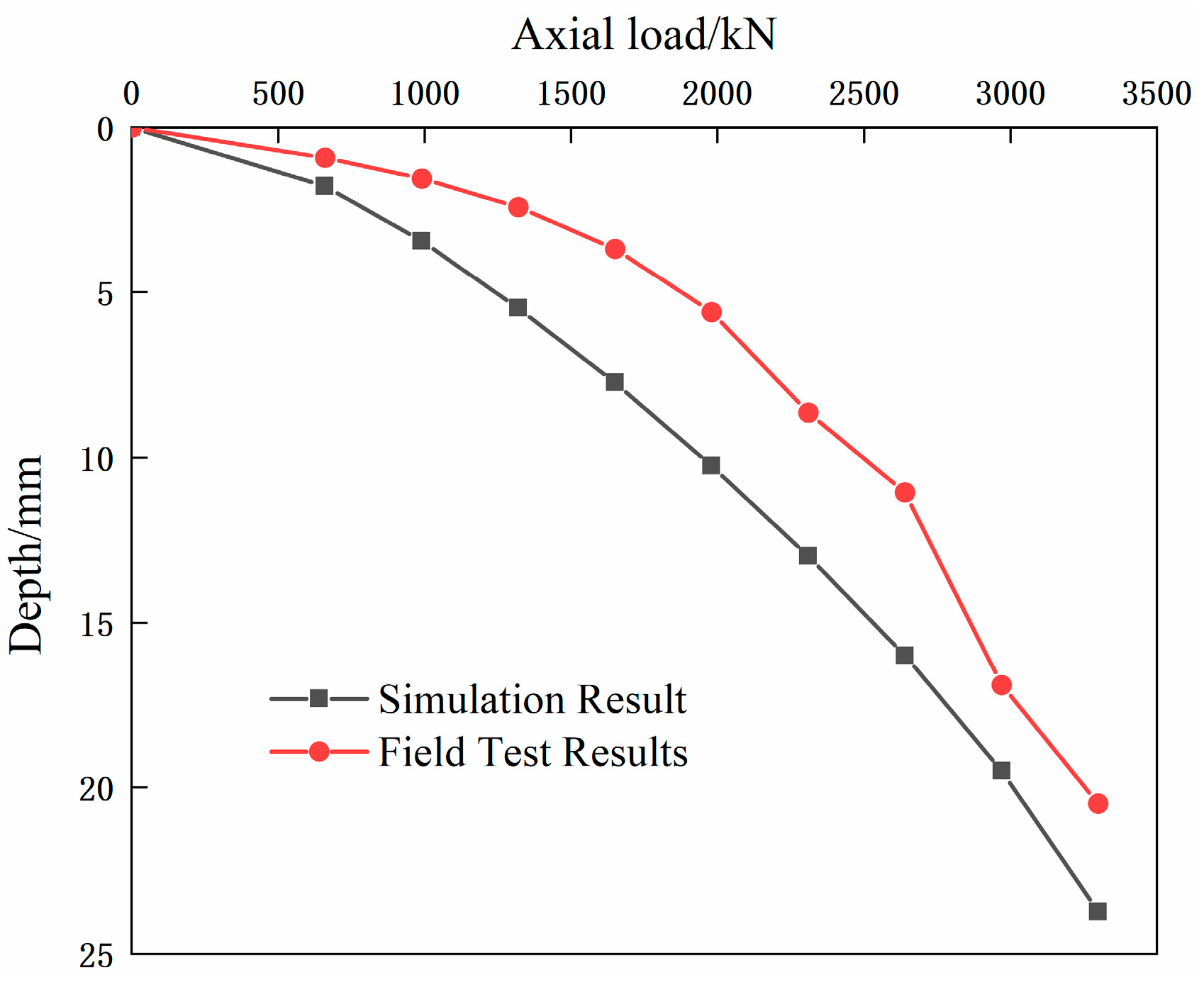

3.2. Pile Displacement

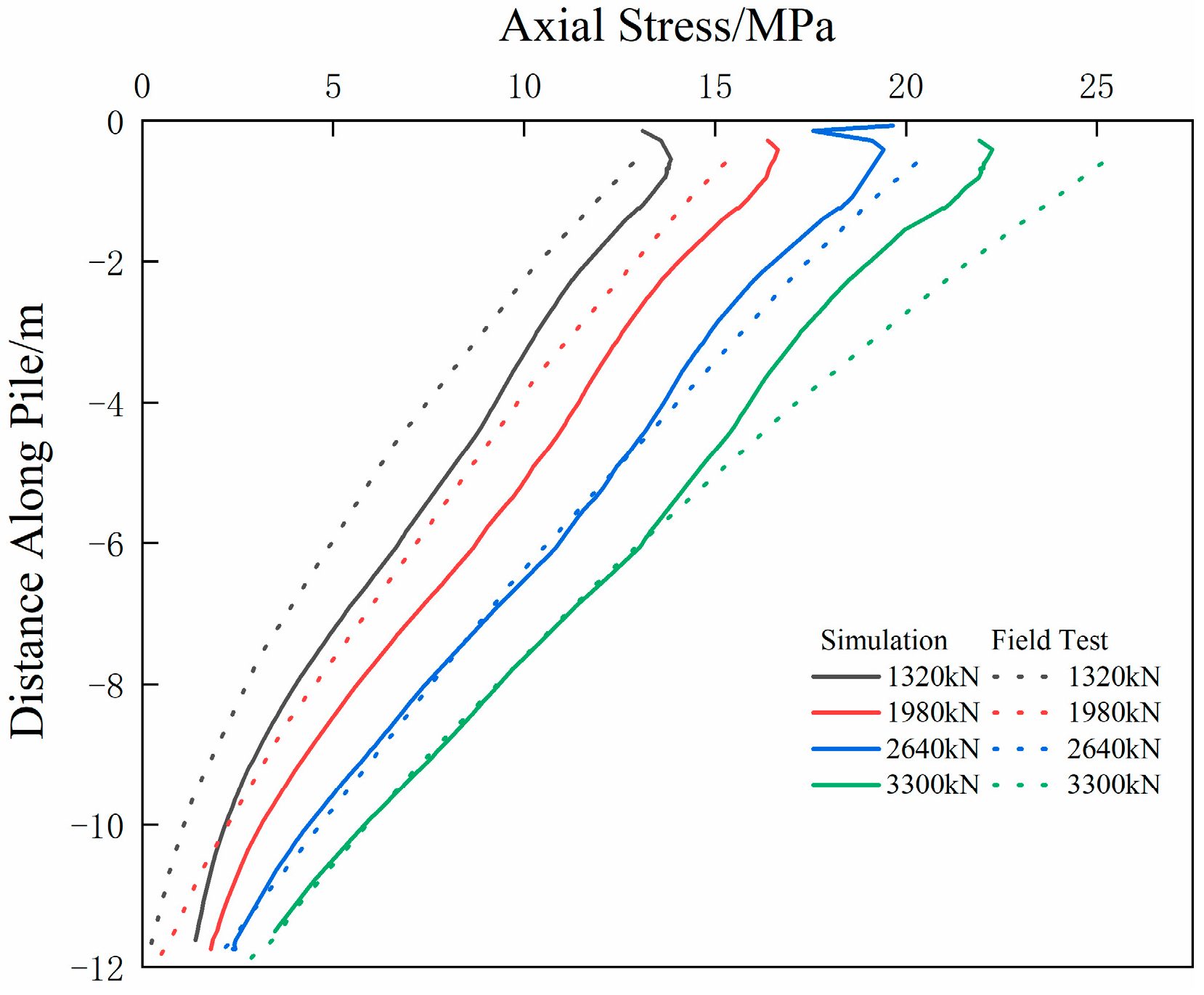

3.3. Axial Stress of Stiffened Core

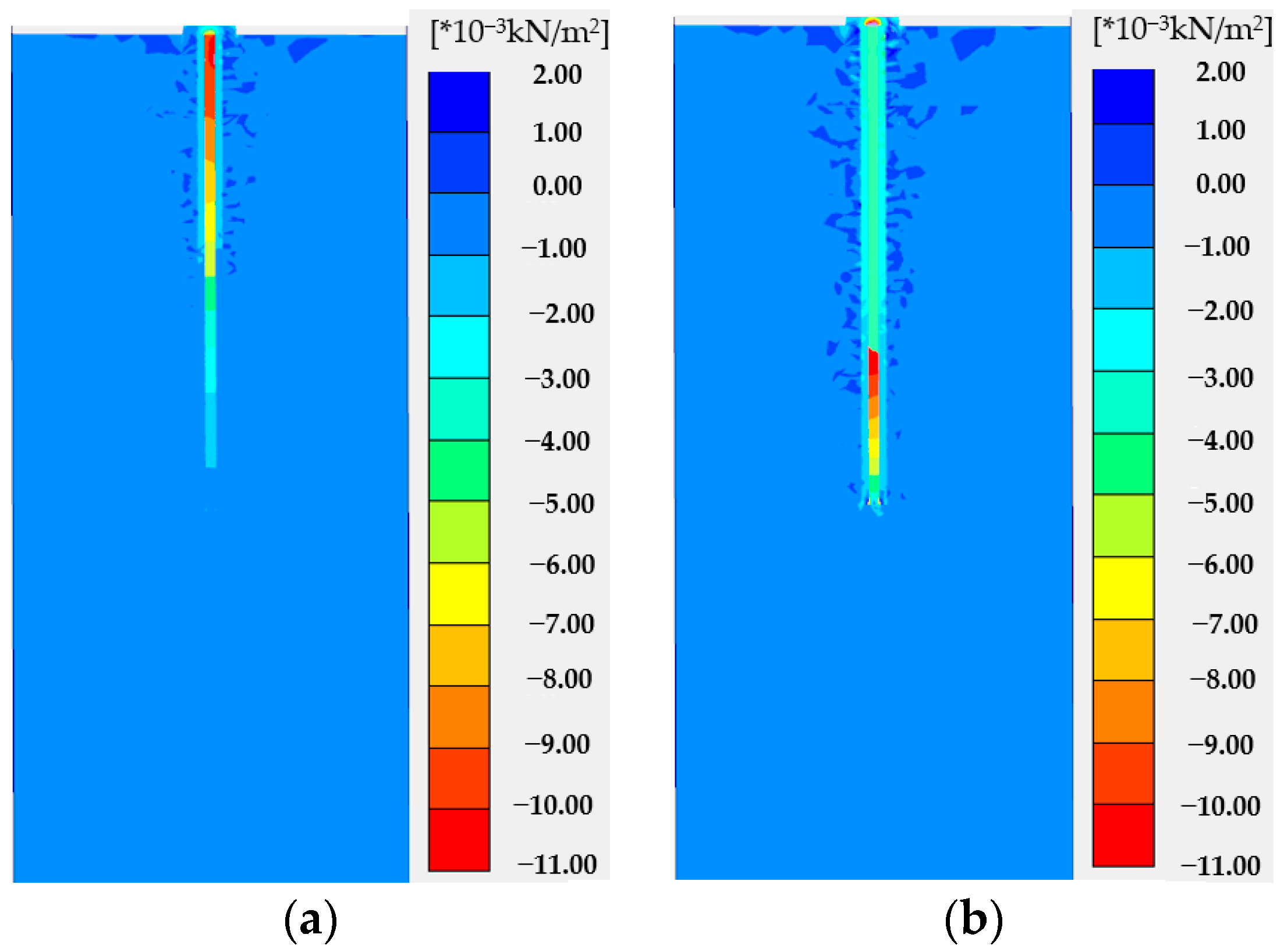

3.4. Axial Stress of Cemented Soil

3.5. Friction Resistance between the Stiffened Core and Cemented Soil

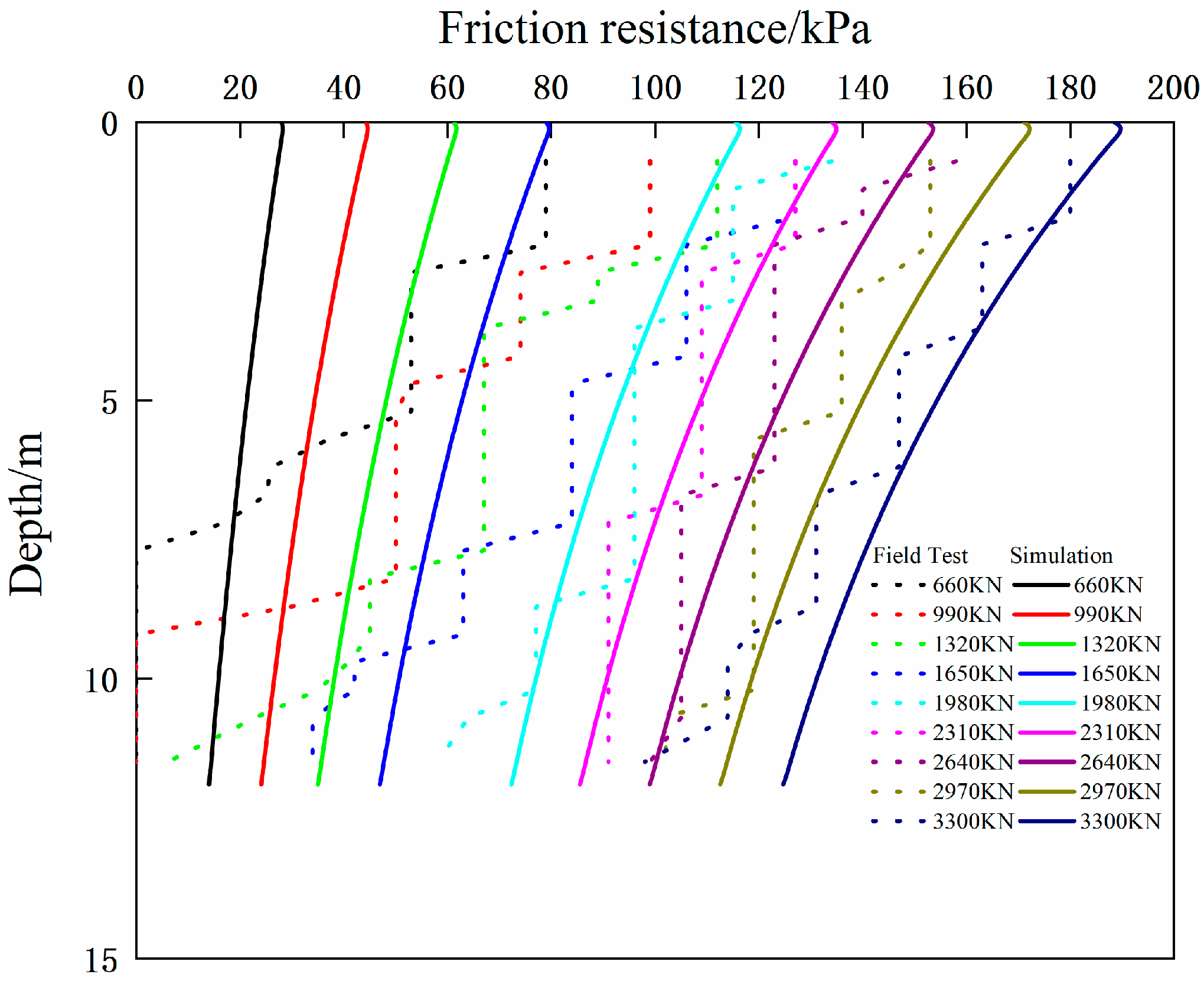

3.6. Friction Resistance between the Cemented Soil and Soil

4. Analysis of the Group Piles

4.1. Finite Element Model of Pile Group

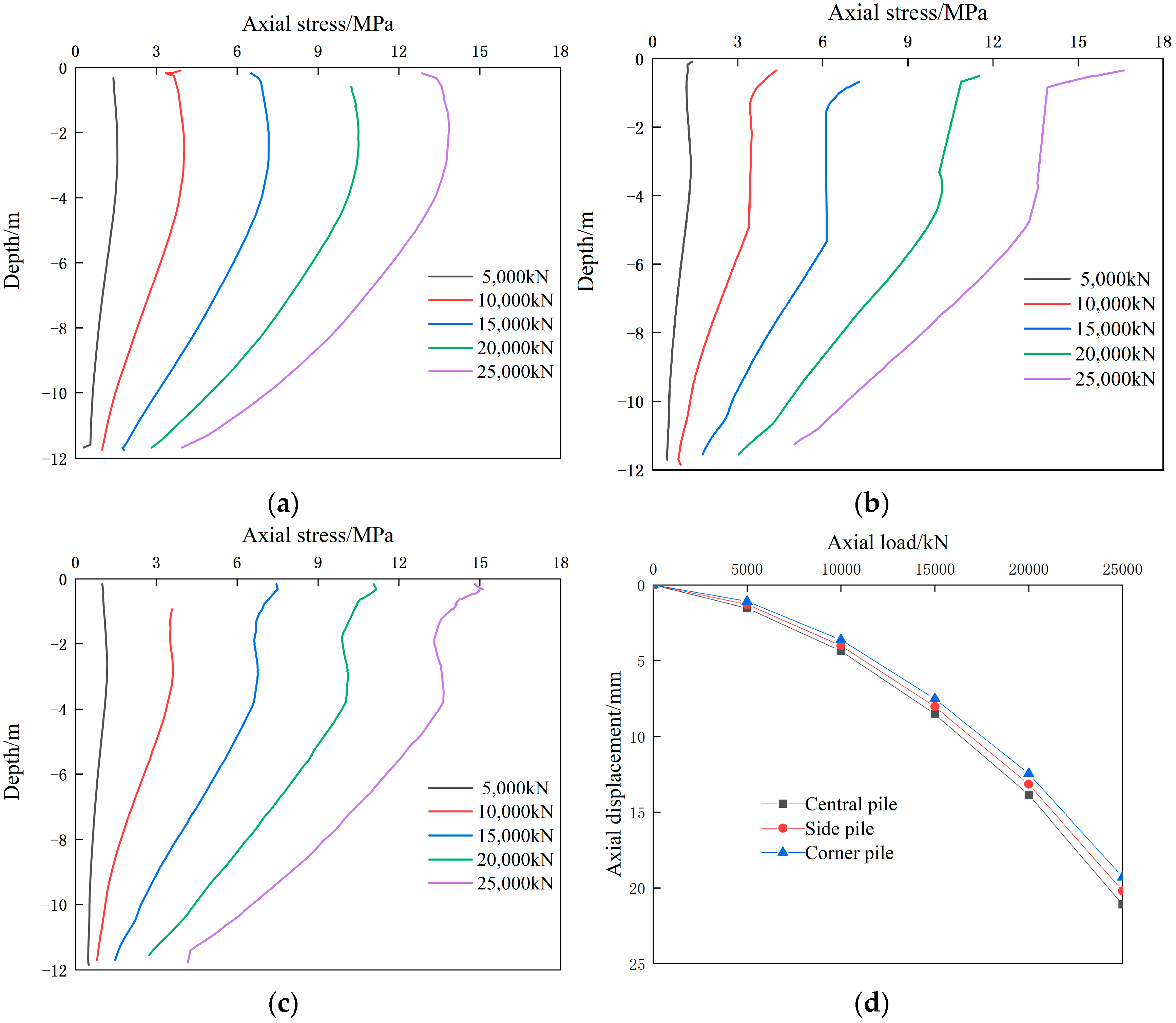

4.2. Bearing Capacity of Pile Group

4.3. Influence of Pile Cap

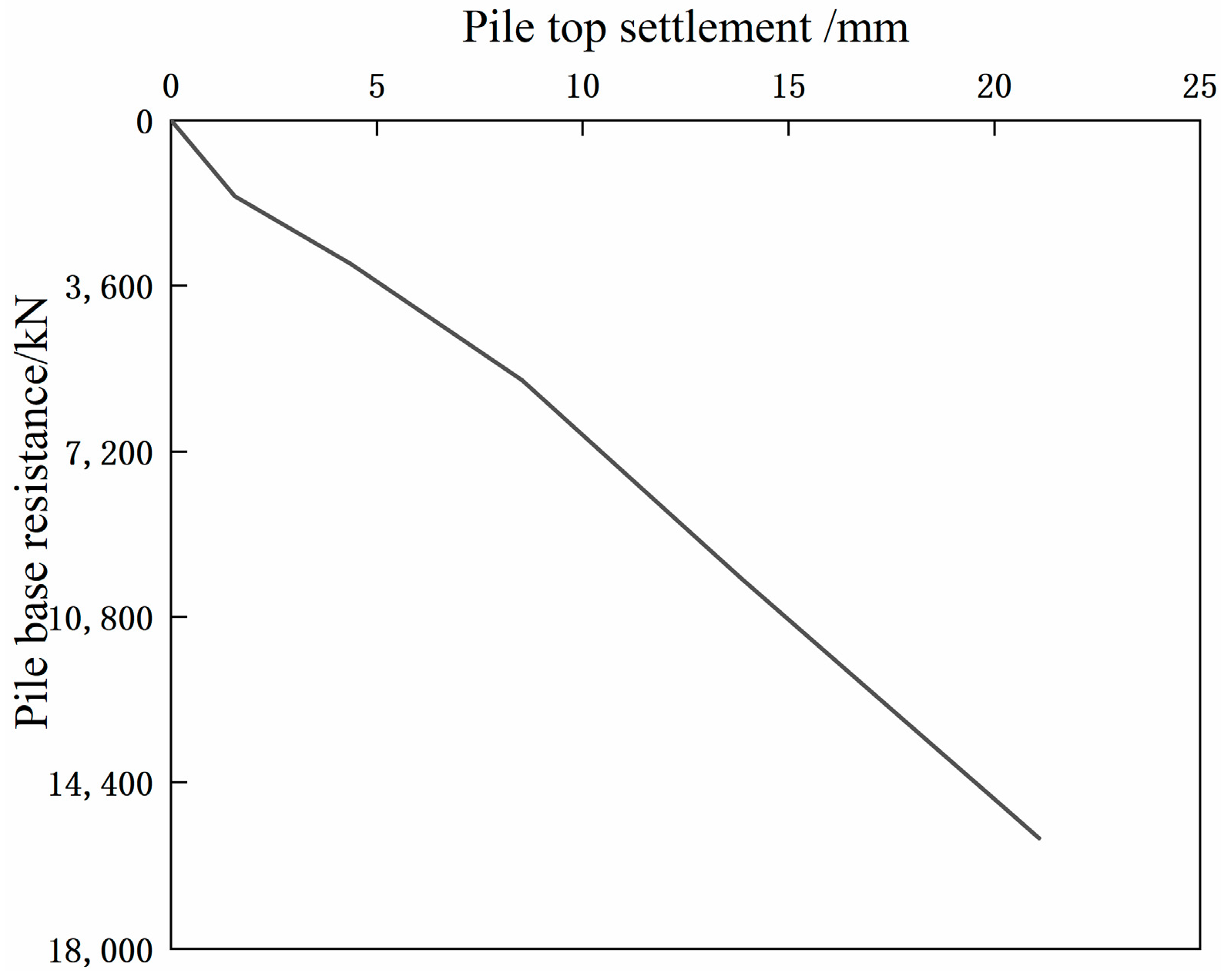

4.4. Influence of Pile Base Resistance

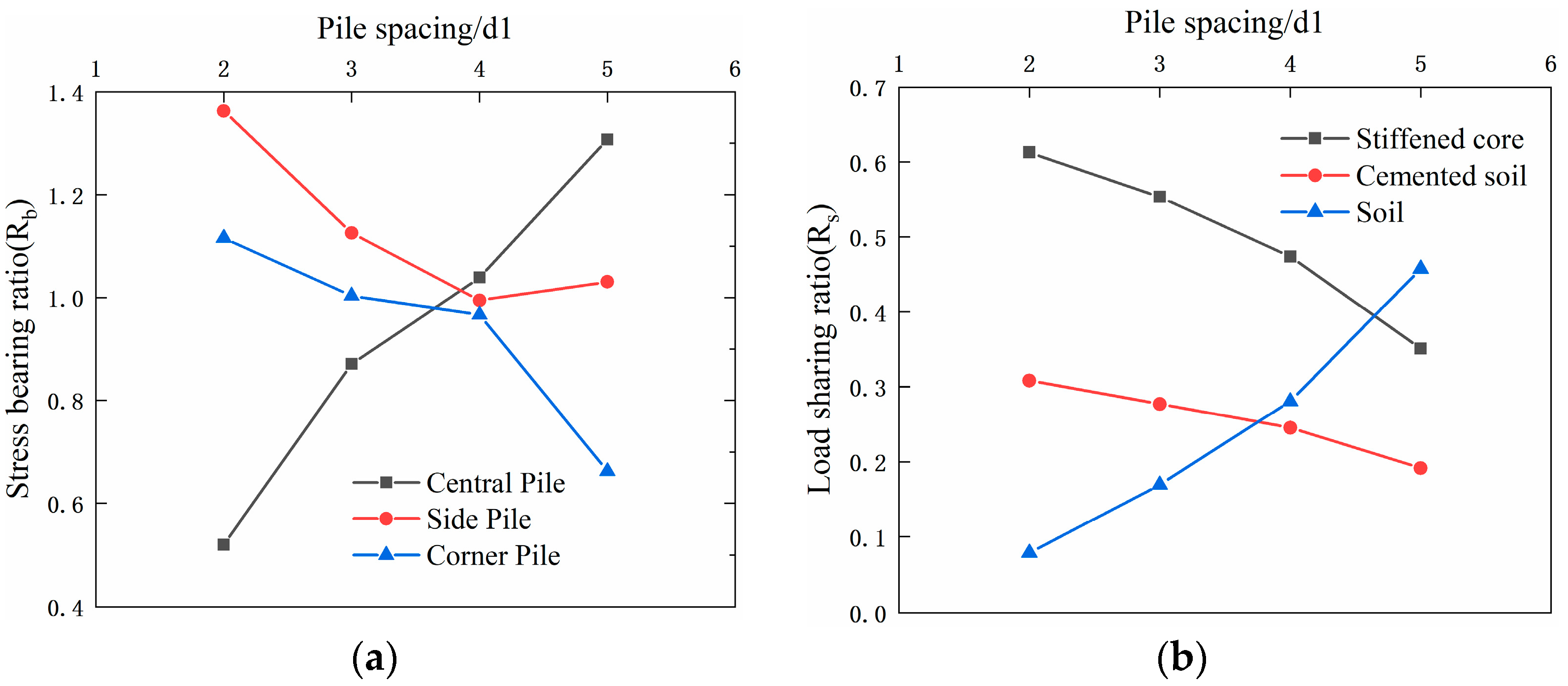

4.5. Influence of Pile Spacing

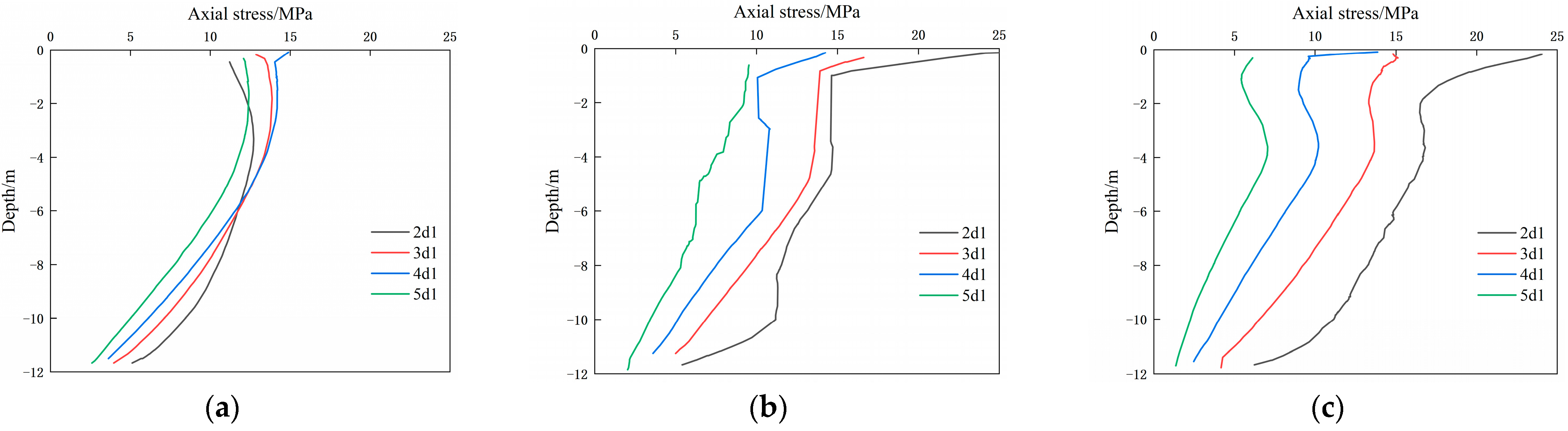

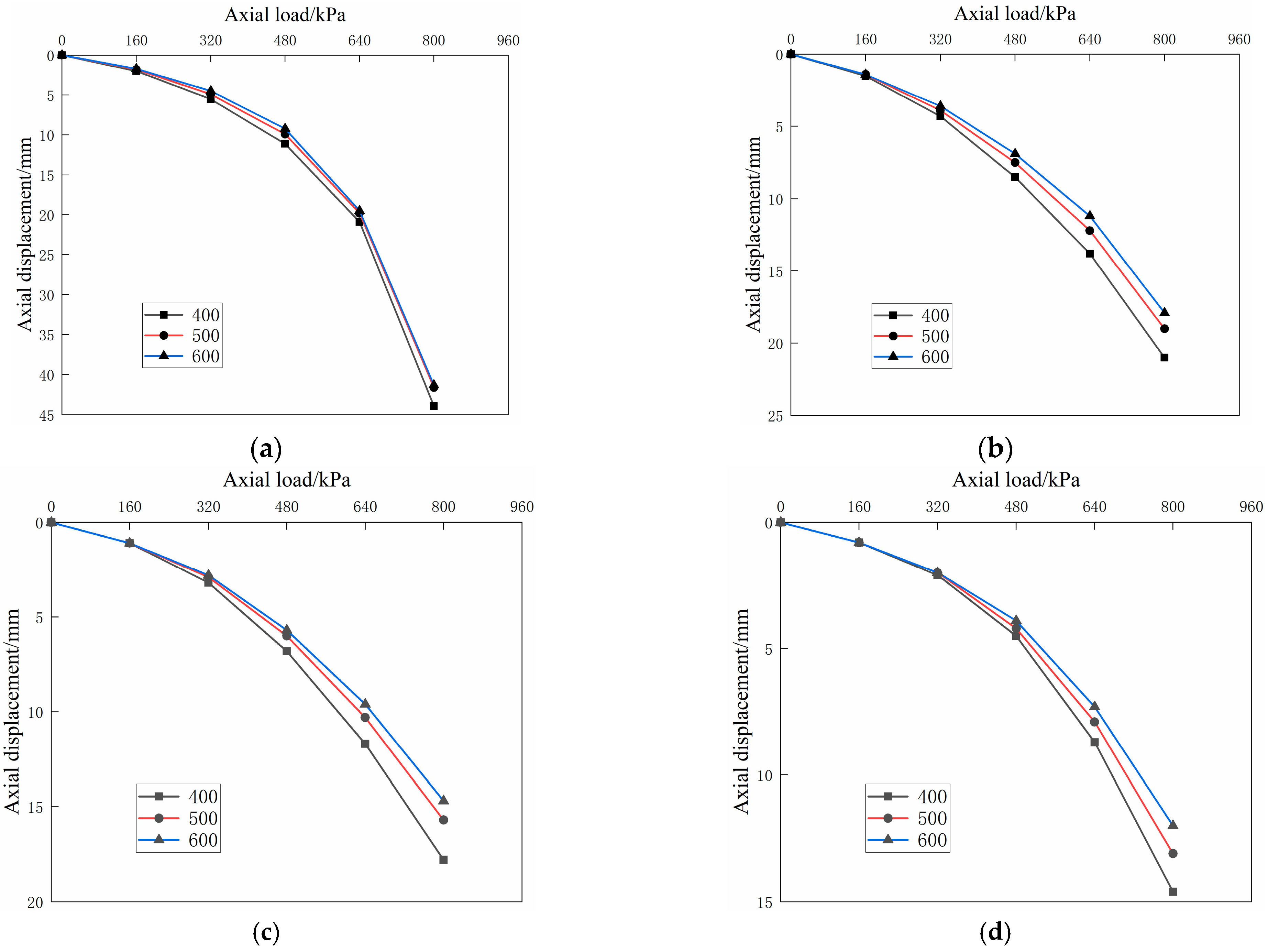

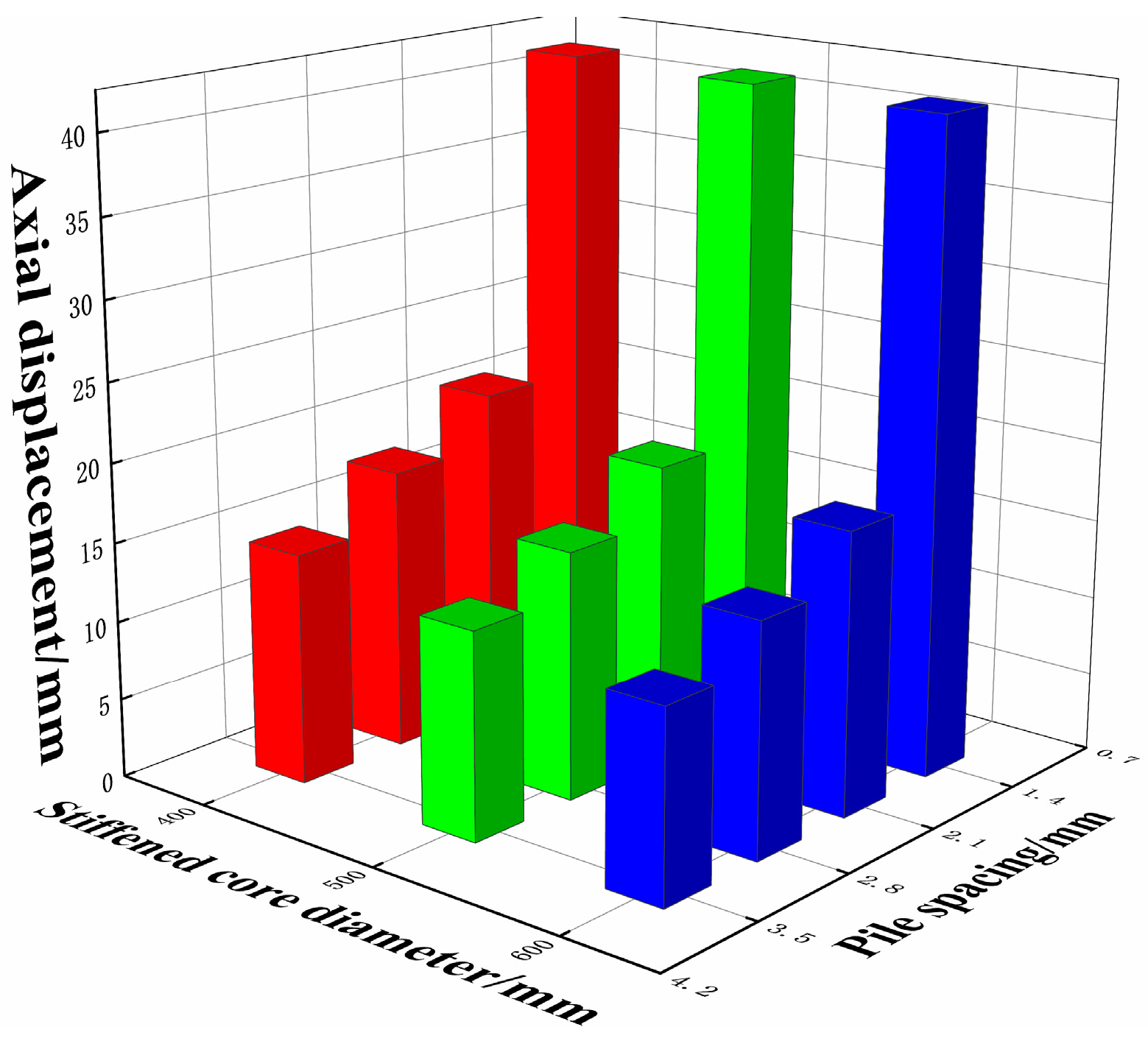

4.6. Influence of Stiffened Core Diameter

5. Conclusions

- (1)

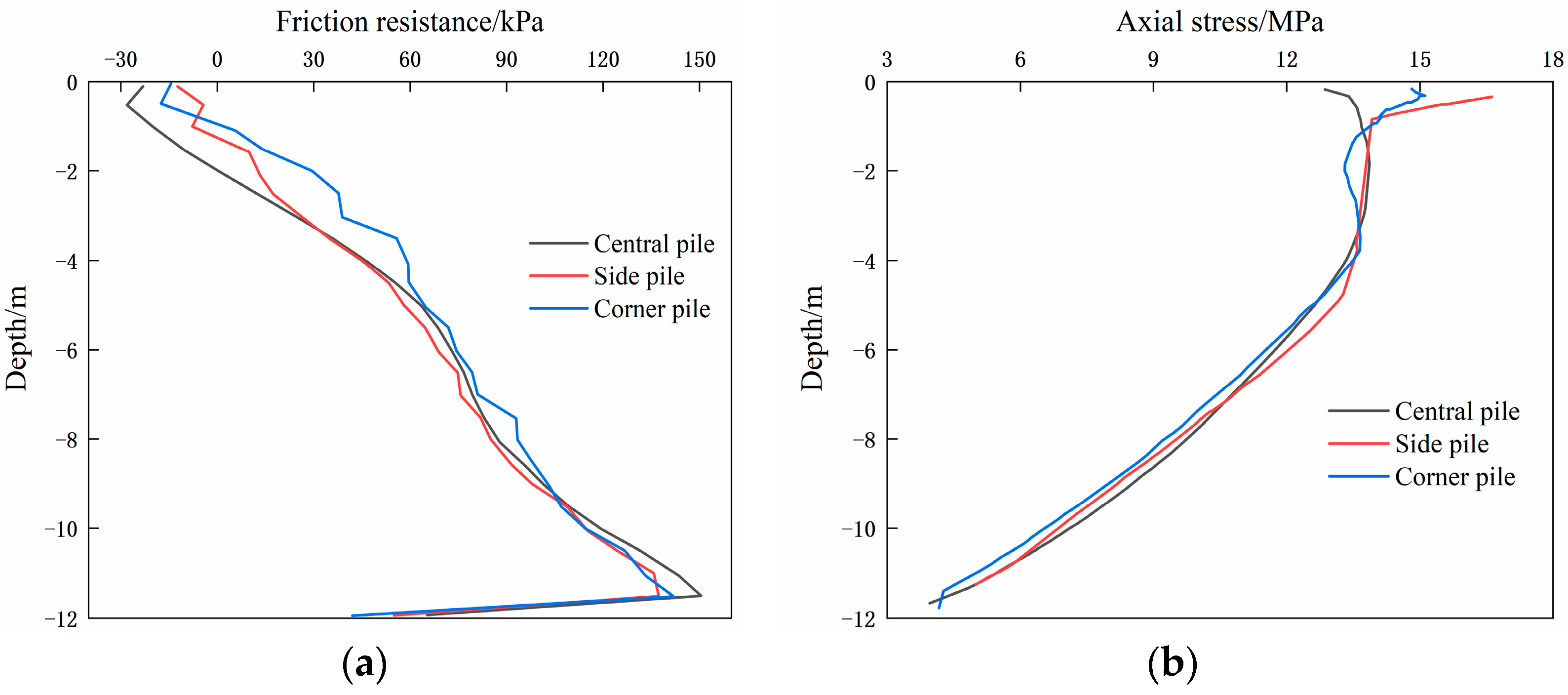

- The axial stress of the stiffened core decreased with the increasing depth along the pile. The axial stress of the cemented soil increased with an increase in the depth along the pile and reached a peak value at 4.5–7.5 m. The friction resistance between the stiffened core and cemented soil decreased gradually with an increase in the depth along the pile. The lateral friction between the cemented soil and the soil around the pile increased along the depth of the pile.

- (2)

- The load was transmitted downward along the stiffened core of the pile in the form of axial force. With an increase in depth along the pile, the axial stress of the core was gradually transferred to the outer cemented soil in the form of friction resistance. Part of the load was transferred to the end of the pile along the cemented soil in the form of axial stress, and the other part was transferred to the soil around the pile in the form of friction resistance.

- (3)

- In the square distribution pile group, the axial stress of the side pile was the largest, followed by that of the corner pile, and the axial stress of the central pile was the smallest. The q–s curves for each pile in the group were similar. The central pile was significantly affected by the group pile effect, and the bearing capacity was relatively low compared with that of the other piles.

- (4)

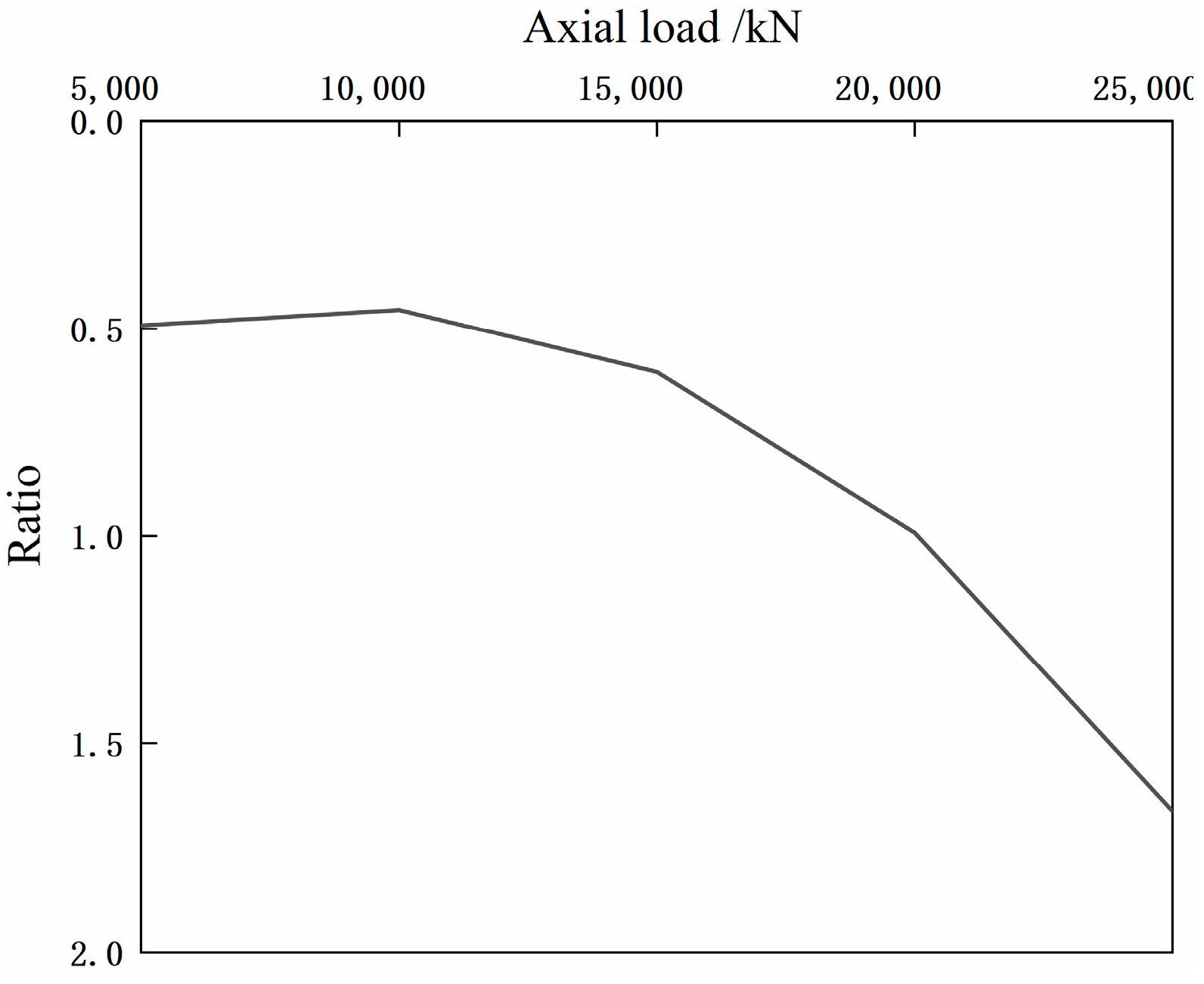

- The axial stress of the side and corner piles decreased rapidly with an increase in pile spacing, and the stress-bearing ratio decreased. The stress-bearing ratio of the central pile increased with an increase in pile spacing. The side and corner piles played the main roles in bearing the load when the pile spacing was small.

- (5)

- The smaller the pile spacing, the greater the proportion of the load shared by the piles and the smaller the bearing capacity of the foundation. When the pile spacing was two times the pile diameter, the q-s curve dropped sharply.

- (6)

- The coupling effects of different stiffened core diameters and pile spacings were compared, and the optimal parameters in this ground improvement project were se-lected as the pile group with a pile spacing of 2.8 m (four times the pile diameter), stiffened core diameter of 500 mm, and cemented soil diameter of 700 mm.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Chen, Y.; Zhao, W.; Han, J.; Jia, P. A CEL study of bearing capacity and failure mechanism of strip footing resting on c-φ soils. Comput. Geotech. 2019, 111, 126–136. [Google Scholar] [CrossRef]

- Ding, X.; Qu, L.; Yang, J.; Wang, C. Experimental study on the pile group-soil vibration induced by railway traffic under the inclined bedrock condition. Acta Geotech. 2020, 15, 3613–3620. [Google Scholar] [CrossRef]

- Jia, P.; Zhao, W.; Khoshghalb, A.; Ni, P.; Jiang, B.; Chen, Y.; Li, S. A new model to predict ground surface settlement induced by jacked pipes with flanges. Tunn. Undergr. Space Tech. 2020, 98, 103330. [Google Scholar] [CrossRef]

- Tong, L.; Li, H.; Ha, S.; Liu, S. Lateral bearing performance and mechanism of piles in the transition zone due to pit-in-pit excavation. Acta Geotech. 2022, 17, 1935–1948. [Google Scholar] [CrossRef]

- Wu, L.; Xiang, Z.; Jiang, H.; Liu, M.; Ju, X.; Zhang, W. A Review of Durability Issues of Reinforced Concrete Structures Due to Coastal Soda Residue Soil in China. J. Mar. Sci. Eng. 2022, 10, 1740. [Google Scholar] [CrossRef]

- Li, X.; Bai, M.; Li, T.; Qiu, S.; Shi, H. Application of Carbon-Fiber Composite Material in Micropile Structure. J. Perform. Constr. Fac. 2020, 34, 4020017. [Google Scholar] [CrossRef]

- Wu, P.; Yin, J.; Feng, W.; Chen, W. Experimental study on geosynthetic-reinforced sand fill over marine clay with or without deep cement mixed soil columns under different loadings. Undergr. Space 2019, 4, 340–347. [Google Scholar] [CrossRef]

- Zhang, J.; Liu, X.; Ren, T.; Shi, Y.; Yuan, Y. Numerical analysis of tunnel segments strengthened by steel–concrete composites. Undergr. Space 2022, 7, 1115–1124. [Google Scholar] [CrossRef]

- Zyka, K.; Mohajerani, A. Composite piles: A review. Constr. Build. Mater. 2016, 107, 394–410. [Google Scholar] [CrossRef]

- Ling, G.; Xie, D.; Wang, E. Experimental Study on Concrete Core Mixing Pile. J. Build. Struct. 2001, 22, 92–96. [Google Scholar]

- Li, Y.H.; Sun, L.Q.; Li, X.; Huang, M.S. Experimental study on the shear mechanical properties of the cemented soil-concrete interface. Eur. J. Environ. Civ. Eng. 2022, 26, 4725–4739. [Google Scholar] [CrossRef]

- Jamsawang, P.; Bergado, D.T.; Bhandari, A.; Voottipruex, P. Behavior of stiffened Deep Cement Mixing pile in laboratory. Lowland Technol. Int. 2009, 11, 20–28. [Google Scholar]

- Voottipruex, P.; Jamsawang, P.; Sukontasukkul, P.; Jongpradist, P.; Horpibulsuk, S.; Chindaprasirt, P. Performances of SDCM and DCM walls under deep excavation in soft clay: Field tests and 3D simulations. Soils Found. 2019, 59, 1728–1739. [Google Scholar] [CrossRef]

- Zhu, S.; Chen, C.; Cai, H.; Mao, F. Analytical modeling for the load-transfer behavior of stiffened deep cement mixing (SDCM) pile with rigid cap in layer soils. Comput. Geotech. 2022, 144, 104618. [Google Scholar] [CrossRef]

- Shafaghat, A.; Khabbaz, H.; Fatahi, B. Axial and Lateral Efficiency of Tapered Pile Groups in Sand Using Mathematical and Three-Dimensional Numerical Analyses. Perform. Constr. Fac. 2022, 36, 4021108. [Google Scholar] [CrossRef]

- Pang, L.; Jiang, C.; Chen, L. Nonlinear Predictive Framework of the Undrained Clay Slope Effect on the Initial Stiffness of p-y Curves of Laterally Loaded Piles by FEM. J. Mar. Sci. Eng. 2022, 10, 1684. [Google Scholar] [CrossRef]

- Wang, A.; Zhang, D.; Liu, S.; Deng, Y. Bearing capacity behavior of strength composite pipe pile subjected to lateral loading. Zhongguo Kuangye Daxue Xuebao/J. China Univ. Min. Technol. 2018, 47, 853–861. [Google Scholar]

- Dong, P.; Qin, R.; Chen, Z.Z. FEM study of concrete-cored DCM pile. Rock Soil Mech. 2003, 24, 344–348. [Google Scholar]

- Lu, X.H.; Song, M.G.; Wang, P.F. Numerical simulation of the composite foundation of cement soil mixing piles using FLAC3D. Clust. Comput. 2019, 22, S7965–S7974. [Google Scholar] [CrossRef]

- Zhou, M.; Li, Z.T.; Han, Y.S.; Ni, P.P.; Wang, Y.L. Experimental Study on the Vertical Bearing Capacity of Stiffened Deep Cement Mixing Piles. Int. J. Geomech. 2022, 22, 04022043. [Google Scholar] [CrossRef]

- Ning, P.L.; Zhang, J.T.; Tian, Q.Y. Numerical simulation analysis of the application of cement-mixed pile curtain in an expressway extension project. Int. J. Pavement Eng. 2020, 21, 170–176. [Google Scholar] [CrossRef]

- Wonglert, A.; Jongpradist, P. Impact of reinforced core on performance and failure behavior of stiffened deep cement mixing piles. Comput. Geotech. 2015, 69, 93–104. [Google Scholar] [CrossRef]

- Nguyen, N.V.; Vinh, L.B.; Vo, T. Load-sharing mechanism of piled-raft foundation: A numerical study. Eur. J. Environ. Civ. Eng. 2022, 26, 7916–7931. [Google Scholar] [CrossRef]

- Mali, S.; Singh, B. Behavior of large piled-raft foundation on clay soil. Ocean Eng. 2018, 149, 205–216. [Google Scholar] [CrossRef]

- Zhang, J. Finite Element Analysis of Ultra-deep Foundation Pit Covered Top-Down Excavation Based on PLAXIS. IOP Conf. Ser. Earth Environ. Sci. 2019, 300, 22158. [Google Scholar] [CrossRef]

- Consoli, N.C.; Foppa, D.; Festugato, L.; Heineck, K.S. Key parameters for strength control of artificially cemented soils. J. Geotech. Geoenviron. 2007, 133, 197–205. [Google Scholar] [CrossRef]

- Consoli, N.C.; Viana Da Fonseca, A.; Cruz, R.C.; Heineck, K.S. Fundamental parameters for the stiffness and strength control of artificially cemented sand. J. Geotech. Geoenviron. 2009, 135, 1347–1353. [Google Scholar] [CrossRef]

- Zhou, J.; Gong, X.; Wang, K.; Zhang, R.; Yan, T. A Model Test on the Behavior of a Static Drill Rooted Nodular Pile Under Compression. Mar. Georesour. Geotec. 2016, 34, 293–301. [Google Scholar] [CrossRef]

- Jamsawang, P.; Bergado, D.; Bandari, A.; Voottipruex, P. Investigation and simulation of behavior of stiffened deep cement mixing (SDCM) piles. Int. J. Geotech. Eng. 2008, 2, 229–246. [Google Scholar] [CrossRef]

- Voottipruex, P.; Bergado, D.T.; Suksawat, T.; Jamsawang, P.; Cheang, W. Behavior and Simulation of Deep Cement Mixing (DCM) and Stiffened Deep Cement Mixing (SDCM) Piles Under Full Scale Loading. Soils Found. 2011, 51, 307–320. [Google Scholar] [CrossRef]

- Ying, L. Model test study on bearing capacity of different pile spacing super-long pile group. In Proceedings of the IEEE 2011 International Conference on Remote Sensing, Nanjing, China, 24–26 June 2011. [Google Scholar]

| Stratigraphic Division | Stratigraphic Division | Depth (Elevation) (Thickness) (m) |

|---|---|---|

| Qm1①1 | plain fill | 2.00 (2.59) (2.00) |

| Qm1①6 | alluvium | 7.80 (−3.21) (5.80) |

| Q4m③1 | silt | 13.10 (−8.51) (7.30) |

| Q4a1 + p1⑤1 | ball clay | 18.50 (−13.91) (5.40) |

| Q2c1⑧1 | sand viscosity soil | 27.61 (−23.02) (9.11) |

| JX-Qby⑩1 | fully weathered granite | 35.00 (−30.41) (7.39) |

| Step | Load (kN) | Load Time (min) |

|---|---|---|

| 1 | 660 | 120 |

| 2 | 990 | 120 |

| 3 | 1320 | 120 |

| 4 | 1650 | 150 |

| 5 | 1980 | 270 |

| 6 | 2310 | 900 |

| 7 | 2640 | 420 |

| 8 | 2970 | 990 |

| 9 | 3300 | 600 |

| Material Name | Thickness | γ/ kN· m−3 | E50/ MPa | Eoed/ MPa | Eur/ MPa | C/ kPa | φ/ ° | Ν | m | γ0.7 | G0/ MPa | Rinter |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| silty clay | 3.5 | 18.3 | 8.0 | 8.0 | 32.0 | 25.0 | 28.0 | 0.2 | 0.8 | 0.0002 | 160 | 1.0 |

| sandy clay | 8.5 | 21.0 | 12.0 | 12.0 | 48.0 | 30.0 | 35.0 | 0.2 | 0.8 | 0.0002 | 180 | 1.0 |

| fully weathered granite | 18 | 22.0 | 30.0 | 25.0 | 100.0 | 35.0 | 40.0 | 0.2 | 0.5 | 0.0002 | 360 | 1.0 |

| Material Name | E/GPa | ν | Rinter |

|---|---|---|---|

| Stiffened core (pipe pile) | 8.0 | 0.15 | 0.3 |

| Cemented soil | 1.2 | 0.25 | 0.3 |

| Steel plates on pile head | 30 | 0.2 | 1.0 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Bao, X.; Cheng, Z.; Shen, J.; Zhang, X.; Chen, X.; Cui, H. Study on Bearing Capacity of Reinforced Composite Pipe Pile Group in Reclaimed Stratum under Vertical Load. J. Mar. Sci. Eng. 2023, 11, 597. https://doi.org/10.3390/jmse11030597

Bao X, Cheng Z, Shen J, Zhang X, Chen X, Cui H. Study on Bearing Capacity of Reinforced Composite Pipe Pile Group in Reclaimed Stratum under Vertical Load. Journal of Marine Science and Engineering. 2023; 11(3):597. https://doi.org/10.3390/jmse11030597

Chicago/Turabian StyleBao, Xiaohua, Zilong Cheng, Jun Shen, Xiaodong Zhang, Xiangsheng Chen, and Hongzhi Cui. 2023. "Study on Bearing Capacity of Reinforced Composite Pipe Pile Group in Reclaimed Stratum under Vertical Load" Journal of Marine Science and Engineering 11, no. 3: 597. https://doi.org/10.3390/jmse11030597

APA StyleBao, X., Cheng, Z., Shen, J., Zhang, X., Chen, X., & Cui, H. (2023). Study on Bearing Capacity of Reinforced Composite Pipe Pile Group in Reclaimed Stratum under Vertical Load. Journal of Marine Science and Engineering, 11(3), 597. https://doi.org/10.3390/jmse11030597