An All-Electric Gate Valve Actuator for Subsea Production Control Systems, Part A: Prototype and Test

Abstract

:1. Introduction

2. Design of the All-Electric Subsea Gate Valve Actuator

2.1. Design Requirements

- (1)

- General requirements:

- (2)

- Basic requirements:

- (3)

- Additional requirements:

2.2. Functions

2.2.1. Failsafe Closing

2.2.2. Buffering

2.2.3. Redundant Drive

2.2.4. Low-Power Position Holding

2.2.5. Pressure Compensation and Corrosion Protection

2.3. Additional Functions

2.4. Working Principle

2.5. Design Process

3. Prototype

3.1. Parameters

3.2. Operation Modes

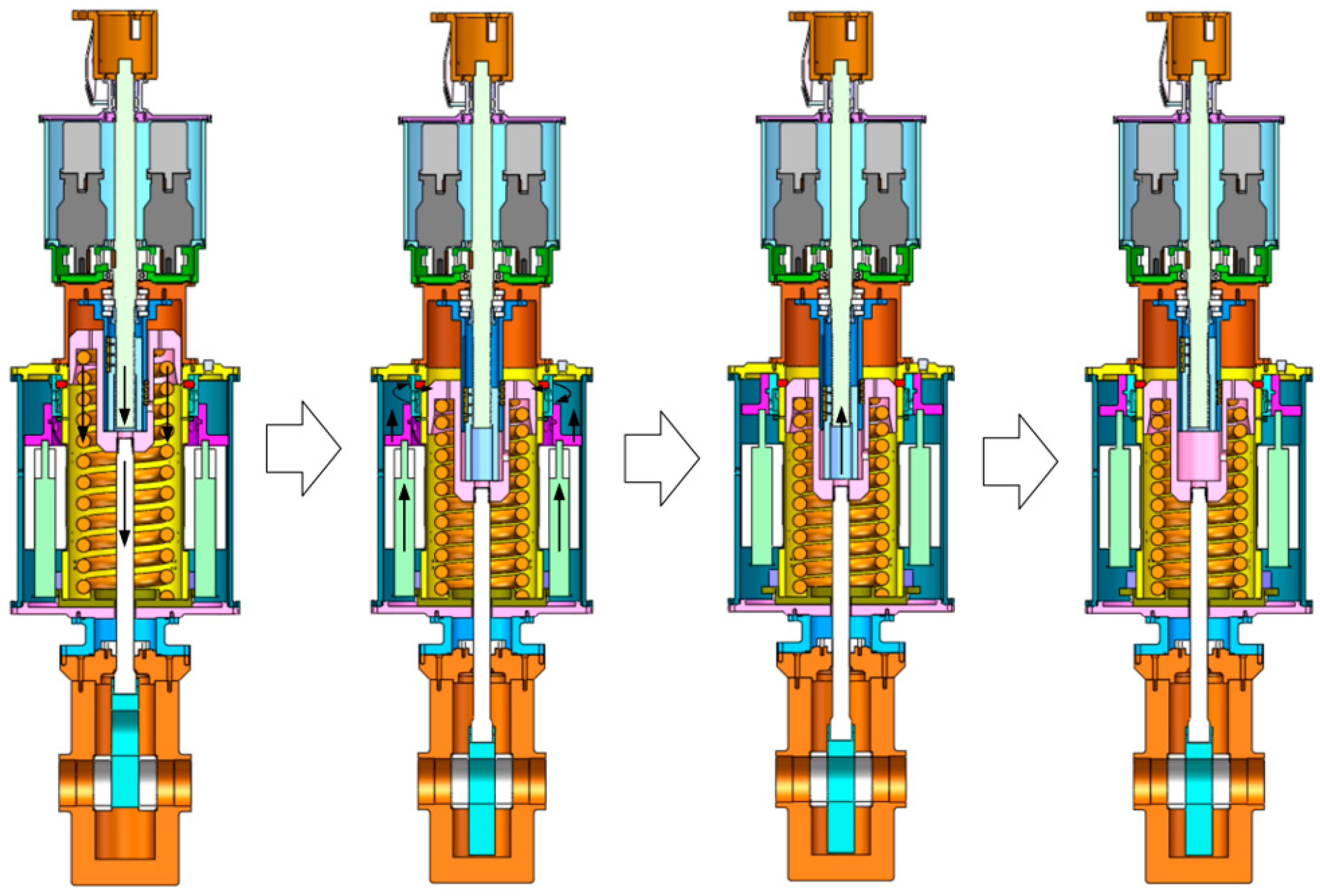

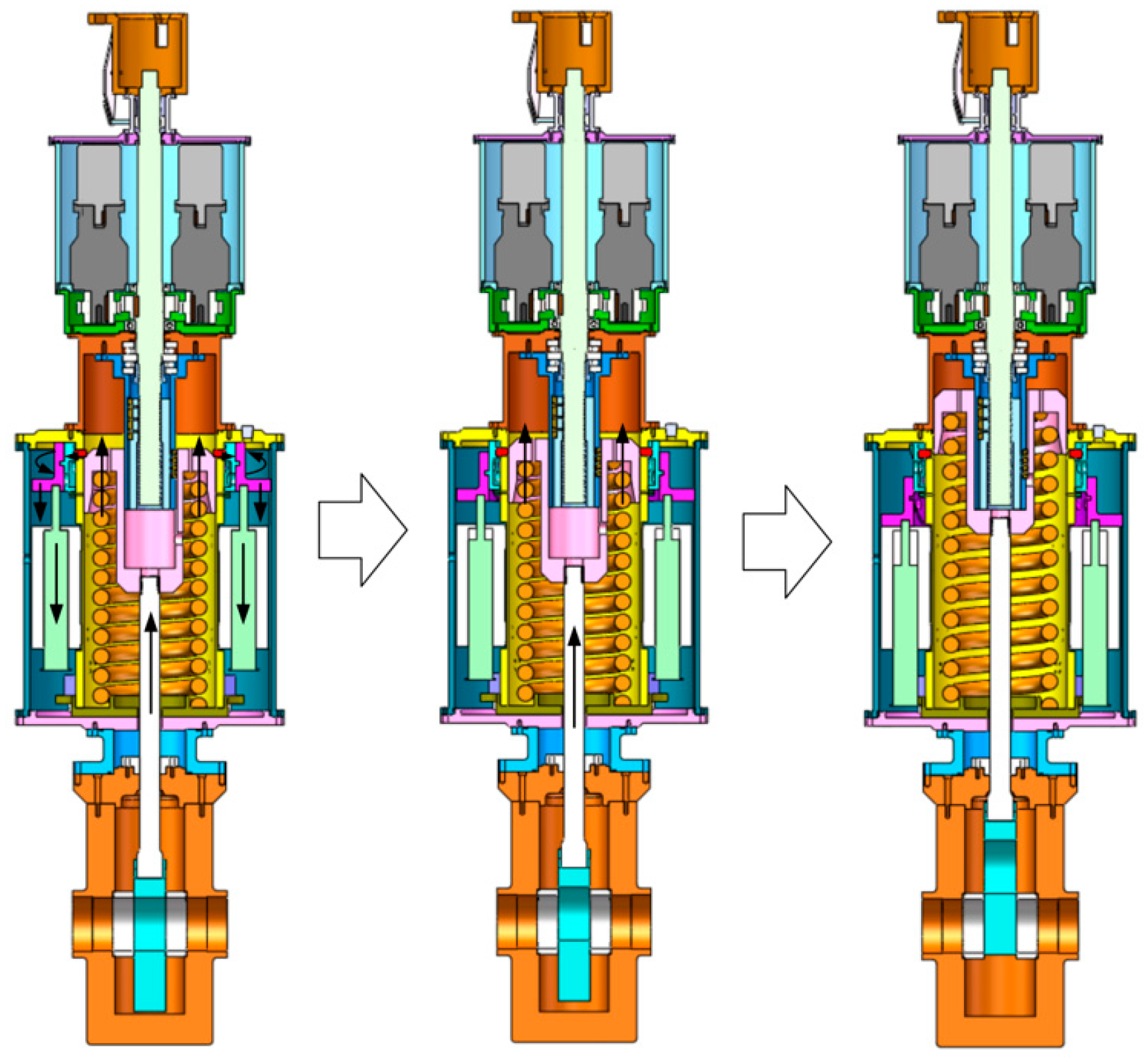

3.2.1. Normal Mode

3.2.2. Failsafe Closing Mode

3.2.3. Emergency Mode

4. Tests

4.1. Subsea Gate Valve Actuator Test System

4.2. Test Results

4.2.1. Redundant Motor Driving Test

- (1)

- Dual-motor driving test

- (2)

- Single-Motor Driving Test

4.2.2. Low-Power Position Holding Test

4.2.3. Failsafe Closing Test

4.2.4. Subsea Gate Valve Position Indication Test

5. Conclusions

- (1)

- The proposed redundant drive mechanism with the parallel arrangement of dual motors, combining gear transmission and the nut–screw transmission, was not only able to open and close the subsea gate valve with dual motors, but also independently with a single motor. The output characteristics of both methods satisfy the requirements of the subsea production control system.

- (2)

- The proposed design of the closing spring and the self-circulating damping mechanism were able to achieve fast and safe closing of the subsea gate valve with minimized impact when the system failed.

- (3)

- The previously proposed low-power holding mechanism design was applied to the concept prototype. The mechanism was refined to satisfy the requirements of both the holding and unlocking performances. The closing spring could be reliably locked by the mechanism during the long-term opening of the subsea gate valve with minimal power consumption and a cable number for control, and the unlocking process of the mechanism could be automatically completed only by the release of the closing spring, without other auxiliary mechanical structures.

- (4)

- The proposed override and position-indicating mechanism with the nut–screw transmission and crank slider was found to be suitable for the ROV or diver emergency operation, with a visual indication function of the valve status.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Zhang, X.; Duan, M.; Mao, D.; Yu, Y. A mathematical model of virtual simulation for deepwater installation of subsea production facilities. Ships Offshore Struct. 2017, 12, 182–195. [Google Scholar] [CrossRef]

- Johansen, C.; Rokne, Ø.; Moe, S.; Magnus, H. Real Application of Electric Controls Technology to Subsea System: Success, Learnings and Recommendations. In Proceedings of the Offshore Technology Conference, Houston, TX, USA, 1–4 May 2017. [Google Scholar] [CrossRef]

- Bhattacharyya, S.K.; Cheliyan, A.S. Optimization of a subsea production system for cost and reliability using its fault tree model. Reliab. Eng. Syst. Saf. 2019, 185, 213–219. [Google Scholar] [CrossRef]

- Shen, W.; Zhang, J.; Sun, Y.; Zhang, D. Effect of cavitation bubble collapse on hydraulic oil temperature. J. Cent. South Univ. 2016, 23, 1657–1668. [Google Scholar] [CrossRef]

- Huang, H.; Zhang, S.; Yang, Z.; Tian, Y. Modified Smith fuzzy PID temperature control in an oil-replenishing device for deep-sea hydraulic system. Ocean Eng. 2018, 149, 14–22. [Google Scholar] [CrossRef]

- Wilson, A. All-electric subsea well brings benefits vs. traditional hydraulic technology. J. Petrol. Technol. 2018, 70, 65–66. [Google Scholar] [CrossRef]

- Monteverde, C.; Novello, M.; Kristiansen, K. A New All Electric Subsea Control System Development. In Proceedings of the Offshore Technology Conference, Houston, TX, USA, 6–9 May 2019. [Google Scholar] [CrossRef]

- Orth, A.; Hendrix, G. An Electro-Mechanical Actuator with Hydrostatic Drive for Subsea Trees to Reduce CAPEX and OPEX with Higher Reliability and Safety Levels. In Proceedings of the Offshore Technology Conference, Houston, TX, USA, 30 April–3 May 2018. [Google Scholar] [CrossRef]

- Elgsaas, K.M.; Hjertvikrem, T.; Hua, W.; Tryti, S.; Glomsaker, T. All-Electric Subsea Systems—Intelligence on Demand. In Proceedings of the Offshore Technology Conference, Houston, TX, USA, 30 April–3 May 2018. [Google Scholar] [CrossRef]

- Li, Z.; Jia, P.; Wang, H.; Zhang, N.; Wang, L. Development trend and active research areas of subsea production system. J. Harbin Eng. Univ. 2019, 40, 944–952. [Google Scholar]

- Sotoodeh, K. Actuator selection and sizing for valves. SN Appl. Sci. 2019, 1, 1207. [Google Scholar] [CrossRef]

- Abicht, D.; Akker, J.V.D. The 2nd Generation DC All-Electric Subsea Production Control System. In Proceedings of the Offshore Technology Conference, Houston, TX, USA, 2–5 May 2011. [Google Scholar] [CrossRef]

- Jia, Y.; Zhao, H. All-electric subsea production control system. Appl. Mech. Mater. 2013, 251, 196–200. [Google Scholar] [CrossRef]

- Micali, S. Subsea All-Electric Technology Now Available for the Future Field Developments [EB/OL]. 20 October 2016. Available online: https://www.sut.org/wp-content/uploads/2015/09/Salvatore-Micali-v3-Aker-Solutions-Subsea-All-Electric-Technology-without-notes.pdf (accessed on 17 April 2023).

- Oh, J.S.; Kang, S.R. Merits of all-electric subsea production control system. J. Korean Soc. Mar. Eng. 2014, 38, 162–168. [Google Scholar] [CrossRef]

- Rokne, Ø. Deepwater developments can benefit from all-electric controls. Offshore 2013, 7, 108–109. [Google Scholar]

- Rexroth Bosch Group. SVA R2—The World’s First Subsea Electric Actuator with Safety Spring, as Compact as Hydraulic Cylinders [EB/OL]. 3 May 2021. Available online: https://www.boschrexroth.com/en/xc/sustainable-subsea-operations/ (accessed on 17 April 2023).

- Offshore Network. Bosch Rexroth to Present World’s Smallest Electric Subsea Valve Actuator at Hannover Messe [EB/OL]. 16 April 2021. Available online: https://offsnet.com/content/north-sea/bosch-rexroth-to-present-world-s-smallest-electric-subsea-valve-actuator-at-hannover-messe (accessed on 17 April 2023).

- OneSubsea. Electric High-Power Rotary Actuator [EB/OL]. 24 June 2018. Available online: https://www.onesubsea.slb.com/-/media/onesubsea/files/product-sheet/oss-high-power-rotary-actuator-ps.ashx (accessed on 17 April 2023).

- OneSubsea. Electric Low-Power Rotary Actuator [EB/OL]. 24 June 2018. Available online: https://www.onesubsea.slb.com/-/media/onesubsea/files/product-sheet/oss-low-power-rotary-actuator-ps.ashx (accessed on 17 April 2023).

- Winther-Larssen, E. Design of an Electric X-Mas Tree Gate Valve Actuator. Master’s Thesis, Norwegian University of Science and Technology, Trondheim, Norway, 2007. [Google Scholar]

- Berven, J. Subsea Production Control Systems for All-Electric Xmas Trees. Master’s Thesis, University of Stavanger, Stavanger, Norway, 2013. [Google Scholar]

- Wang, X.; Liu, P.; Jia, P.; Zhang, L.; Wang, H.; Wang, S. Design of an all-electric subsea valve actuator and the strategy for multi-motor synchronous control. China Offshore Oil Gas 2017, 29, 149–156. [Google Scholar]

- Xiao, Y.; Wu, D.; Xiang, C.; Li, S. Design of production gate valve and actuator for subsea all-electric Christmas tree. China Petrol. Mach. 2018, 46, 60–64. [Google Scholar] [CrossRef]

- Liu, P.; Liu, Y.; Wei, X.; Xin, C.; Sun, Q.; Wu, X. Performance analysis and optimal design based on dynamic characteristics for pressure compensated subsea all-electric valve actuator. Ocean Eng. 2019, 191, 106568. [Google Scholar] [CrossRef]

- Liu, P.; Wang, K.; Chen, Q.; Wei, X. Optimization Design and Analysis of Valve Actuator for All-Electric Christmas Tree. In Proceedings of the 20th China Ocean (Offshore) Engineering Symposium, Zhanjiang, China, 15–17 December 2022. [Google Scholar]

- Tian, B.; Molinas, M.; Moen, S.; An, Q. High Dynamic Speed Control of the Subsea Smart Electrical Actuator for A Gas Production System. In Proceedings of the 2020 IEEE International Conference on Industrial Technology, Buenos Aires, Argentina, 26–28 February 2020. [Google Scholar] [CrossRef]

- Alexandre, O.; Gottfried, H.; Markus, K.; Pedro, J.; Juliano, V. A Novel Subsea Actuator to Electrify Small-Bore Valve. In Proceedings of the Offshore Technology Conference, Virtual and Houston, TX, USA, 16–19 August 2021. [Google Scholar] [CrossRef]

- Liu, P.; Shen, D.; Ba, Y.; Cao, J. Development and control strategy of subsea all-electric actuators. J. Ocean Univ. China 2022, 21, 1133–1146. [Google Scholar] [CrossRef]

- Glenn-Roar, H.; Henrik, V.; Sigurd, M.; Guttorm, O. Electric Valve Operation Subsea—The 20 First Years. In Proceedings of the Offshore Technology Conference, Houston, TX, USA, 2–5 May 2022. [Google Scholar] [CrossRef]

- Carsten, M.; Harald, S.; Birthe, T.; Johannes, R. A Standardized Qualification Approach for Subsea All-Electric Drop-In-Place Actuators. In Proceedings of the Offshore Technology Conference, Houston, TX, USA, 2–5 May 2022. [Google Scholar] [CrossRef]

- Alexandre, O.; Amadeu, P.; Gottfried, H. Enabling All-Electric Subsea Control Systems without Compromising Safety—A Case Study Comparing Functional Safety Systems Using Springs or Batteries. In Proceedings of the Offshore Technology Conference, Houston, TX, USA, 2–5 May 2022. [Google Scholar] [CrossRef]

- Markus, H.; Sebastian, I.; Markus, G. Sensor design for saltwater ingress detection in high reliable all-electric deep sea actuators. J. Loss Prevent. Proc. 2023, 83, 105033. [Google Scholar] [CrossRef]

- Schwerdtfeger, T.; Scott, B.; Akker, J.V.D. World-First All-Electric Subsea Well. In Proceedings of the Offshore Technology Conference, Houston, TX, USA, 1–4 May 2017. [Google Scholar] [CrossRef]

- Xiao, X.; Zhao, H.; Wang, Y.; Peng, F.; Duan, M.; Yan, J.; Fan, X. Optimization design of coaxial parallel double spring of subsea valve actuator. Oil Field Equip. 2014, 43, 29–33. [Google Scholar]

- Yan, D.; Zhang, J.; Wang, P.; Feng, S. Design for a valve driver of subsea production system. Machinery 2017, 55, 13–15. [Google Scholar]

- Akker, J.V.D.; Burdick, J. All-electric actuated subsea system qualified, implemented. Oil Gas J. 2008, 106, 44–50. [Google Scholar]

- Stropnik, R.; Sekavčnik, M.; Ferriz, A.M.; Mori, M. Reducing environmental impacts of the ups system based on PEM fuel cell with circular economy. Energy 2018, 165, 824–835. [Google Scholar] [CrossRef]

- Dev, B.; Samudrala, O.; Wang, J. Characterization of leak rates in thermoplastic barrier valve seals under high static and cyclic pressure loads. J. Petrol. Sci. Eng. 2016, 145, 279–289. [Google Scholar] [CrossRef]

- Wang, H.; Jia, P.; Wang, L.; Yun, F. Design and performance analysis for the low-power holding mechanism of the all-electric subsea gate valve actuator. Appl. Sci. 2020, 10, 6119. [Google Scholar] [CrossRef]

- Sotoodeh, K. Conceptual design and selection of a bladder type pressure compensation system for subsea actuators to prevent failure due to seawater head. Int. J. Interact. Des. Manuf. 2021, 15, 673–680. [Google Scholar] [CrossRef]

- Paladugu, V.; Bikash, K. Electrohydraulic proportional valve-controlled vane type semi-rotary actuated wind turbine control by feedforward fractional-order feedback controller. Proc. Inst. Mech. Eng. Part I 2022, 236, 318–337. [Google Scholar] [CrossRef]

- Qi, M.; Yong, X.; Jie, C.; Tryphon, T. Implementation-oriented filtered PID control: Optimization of robustness margins. Automatica 2023, 152, 110974. [Google Scholar] [CrossRef]

- Francis, K.; Shemphang, M.; Teiborlin, M.; Bikash, K. Design and development of the pineapple harvesting robotic gripper. Commun. Control Robot. Syst. 2022, 229, 437–454. [Google Scholar] [CrossRef]

- Muhammad, N.; Usman, T.; Waseem, S. Fracture mechanics analysis of a closure head of a PWR reactor pressure vessel the effect of bolt pre-load and thermal stresses. Ann. Nucl. Energy. 2023, 189, 109843. [Google Scholar] [CrossRef]

- Cai, B.; Zhao, Y.; Liu, H.; Min, X. A data-driven fault diagnosis methodology in three-phase inverters for PMSM drive systems. IEEE Trans. Power Electr. 2017, 32, 5590–5600. [Google Scholar] [CrossRef]

| Parameters | Unit | Value |

|---|---|---|

| Line diameter | mm | 40 |

| Mean diameter | mm | 240 |

| Spring rate | N/mm | 150.5 |

| Number of active coils | coil | 12 |

| Preload (closed valve) | N | 40,033 |

| Ultimate load | N | 61,840 |

| Parameters | Unit | Value |

|---|---|---|

| Thickness of the spring support cylinder | mm | 53 |

| Internal diameter of the cavity | mm | 325 |

| Number of damping holes | / | 2 |

| Diameter of damping holes | mm | 2.4 |

| Kinematic viscosity of the insulating oil | mm2/s | 9.252 |

| Density of the insulating oil | g/mm3 | 8.95 × 10−4 |

| Motors | Reducers | ||

|---|---|---|---|

| Parameters | Value/Description | Parameters | Value/Description |

| Type | Brushless DC motor | Type | Planetary reducer |

| Input voltage | 340 V DC | Reduction ratio | 50 |

| Rated torque | 34 Nm | Efficiency | 94% |

| Rated speed | 1000 rpm | Output speed | 20 rpm |

| Rated power | 3.68 kW | Output torque | 1598 Nm |

| Parameters | Unit | Value |

|---|---|---|

| Number of electromagnets | / | 6 |

| Holding force | N | 2700 |

| Holding power | W | 180 |

| Lockable maximum load | kN | 70.48 |

| Unlocking torque | Nm | 468.53 |

| Parameters | Unit | Value |

|---|---|---|

| Working depth | m | 500 |

| Output opening force | kN | 240 |

| Output closing force | kN | 40 |

| Working stroke | mm | 144 |

| Power supply voltage | V DC | 340 |

| Opening power | kW | 3.68 |

| Holding power | W | 180 |

| Opening and closing valve time | s | 53 |

| Failsafe closing time | s | 6 |

| ROV interface | level | CLASS IV |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, H.; Wen, F.; Liu, G.; Jia, P.; Yun, F.; Wang, L.; Wang, Y.; Li, C. An All-Electric Gate Valve Actuator for Subsea Production Control Systems, Part A: Prototype and Test. J. Mar. Sci. Eng. 2023, 11, 1043. https://doi.org/10.3390/jmse11051043

Wang H, Wen F, Liu G, Jia P, Yun F, Wang L, Wang Y, Li C. An All-Electric Gate Valve Actuator for Subsea Production Control Systems, Part A: Prototype and Test. Journal of Marine Science and Engineering. 2023; 11(5):1043. https://doi.org/10.3390/jmse11051043

Chicago/Turabian StyleWang, Honghai, Fujun Wen, Guiqian Liu, Peng Jia, Feihong Yun, Liquan Wang, Yongchao Wang, and Chao Li. 2023. "An All-Electric Gate Valve Actuator for Subsea Production Control Systems, Part A: Prototype and Test" Journal of Marine Science and Engineering 11, no. 5: 1043. https://doi.org/10.3390/jmse11051043

APA StyleWang, H., Wen, F., Liu, G., Jia, P., Yun, F., Wang, L., Wang, Y., & Li, C. (2023). An All-Electric Gate Valve Actuator for Subsea Production Control Systems, Part A: Prototype and Test. Journal of Marine Science and Engineering, 11(5), 1043. https://doi.org/10.3390/jmse11051043