Influence of Guide Vane Opening on the Runaway Stability of a Pump-Turbine Used for Hydropower and Ocean Power

Abstract

:1. Introduction

2. Parameters of Pump-Turbine

3. Model Test Method

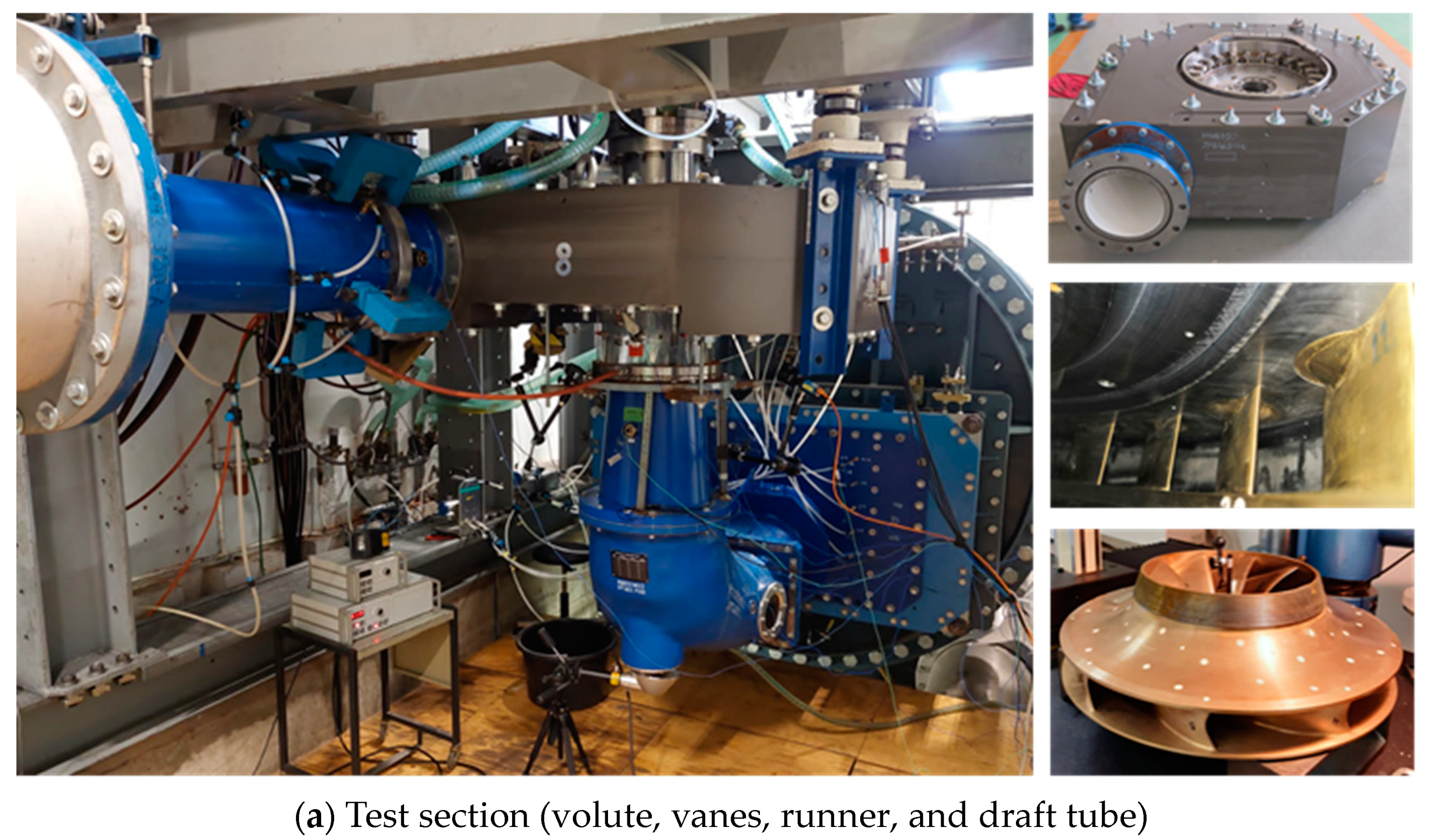

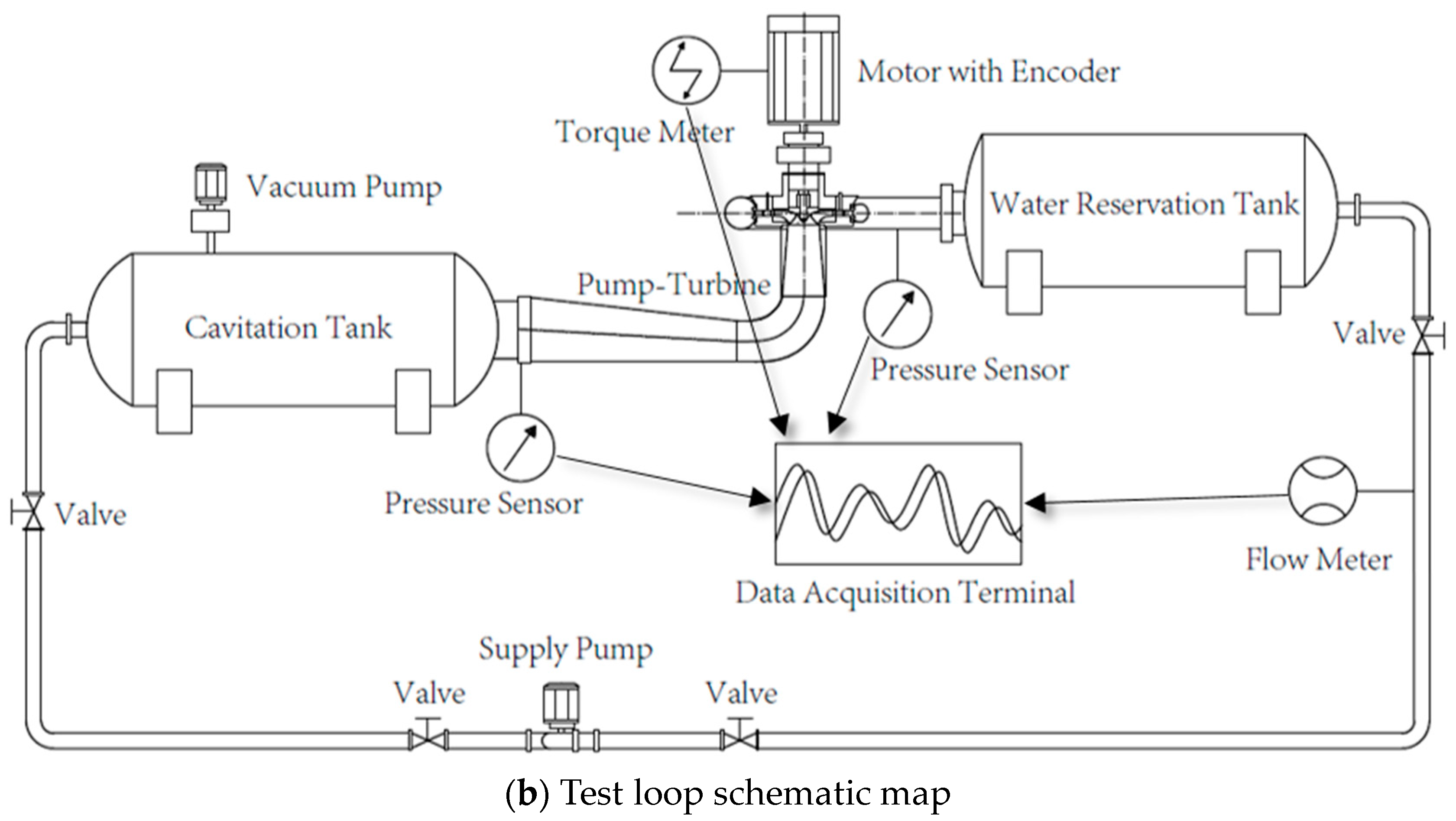

3.1. Hydraulic Test Rig and Apparatus

3.2. Test Strategy of Runaway Point

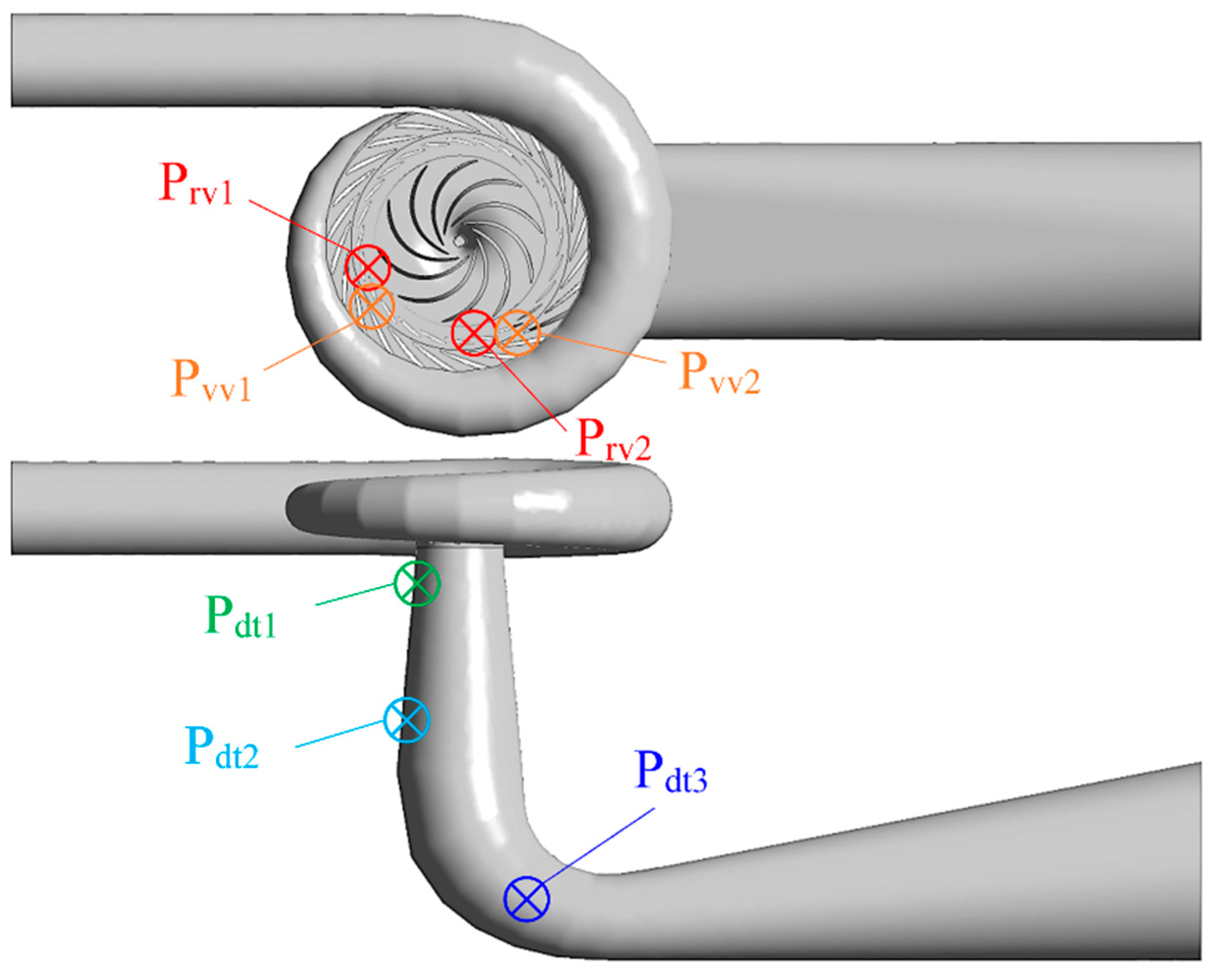

3.3. Positions of Pressure Pulsation Measurement

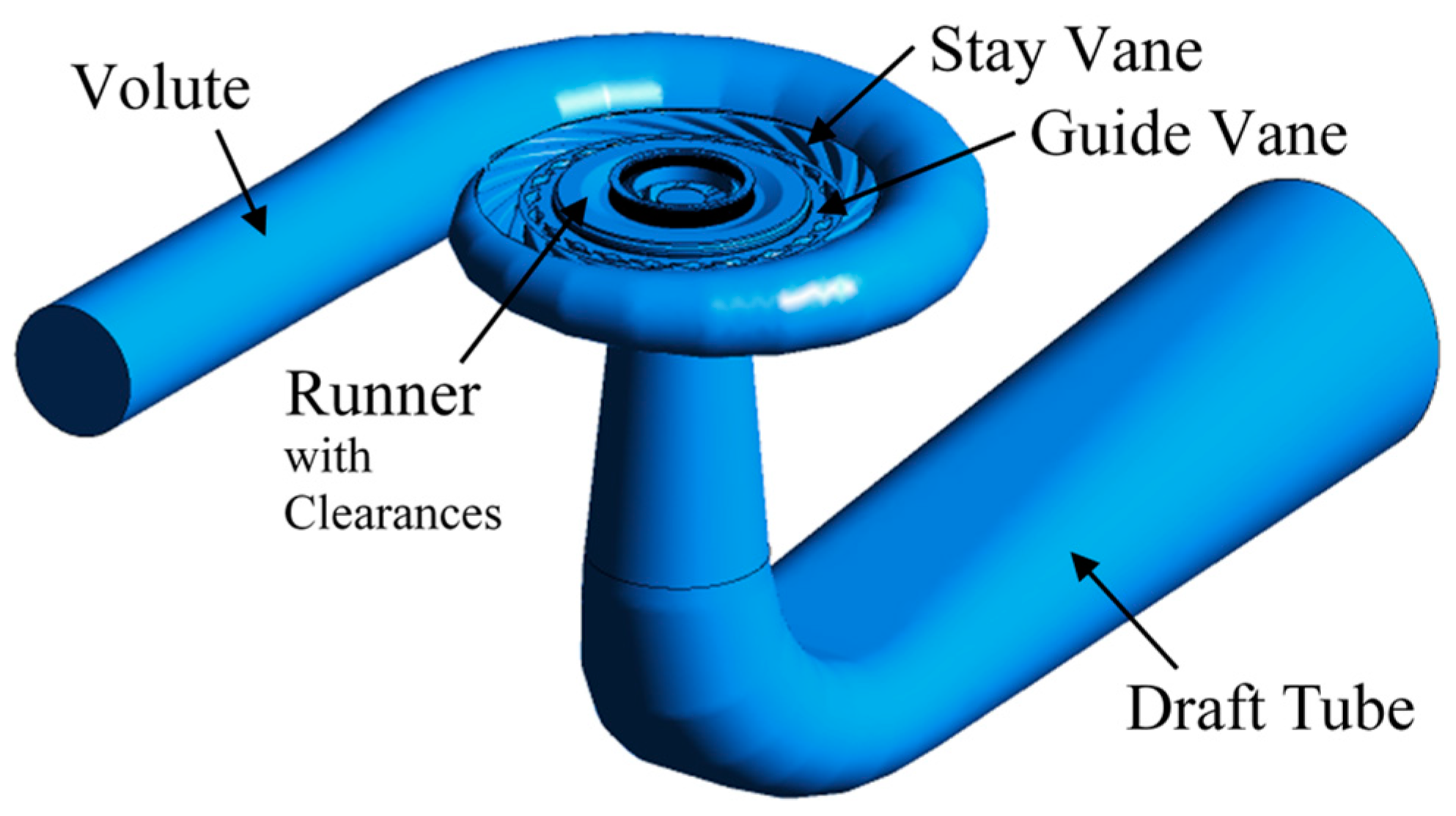

4. CFD Method

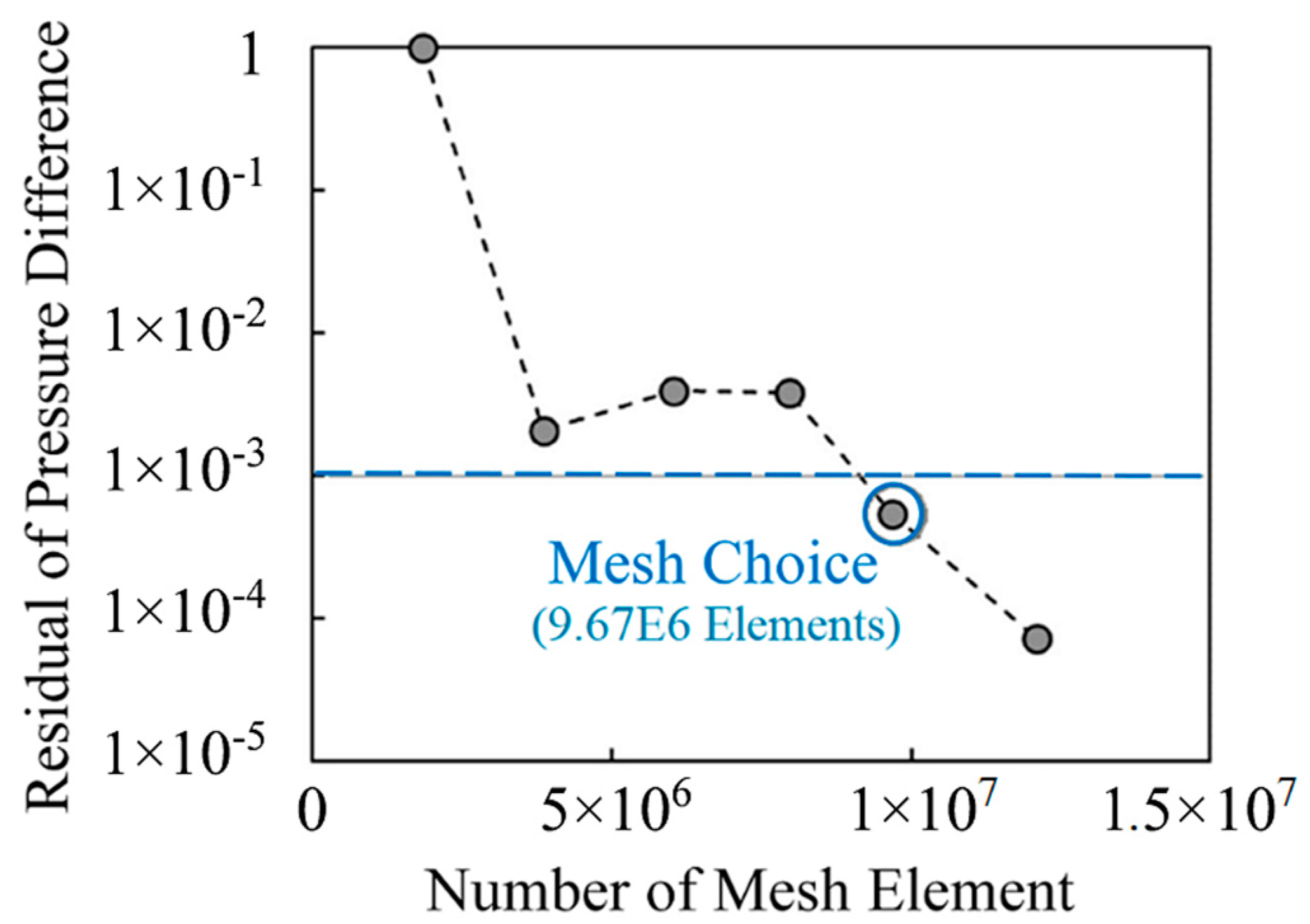

4.1. Fluid Domain and Mesh

4.2. Setup of CFD Simulation

5. Results and Analysis

5.1. Pressure Pulsation Intensity by Guide Vane Opening

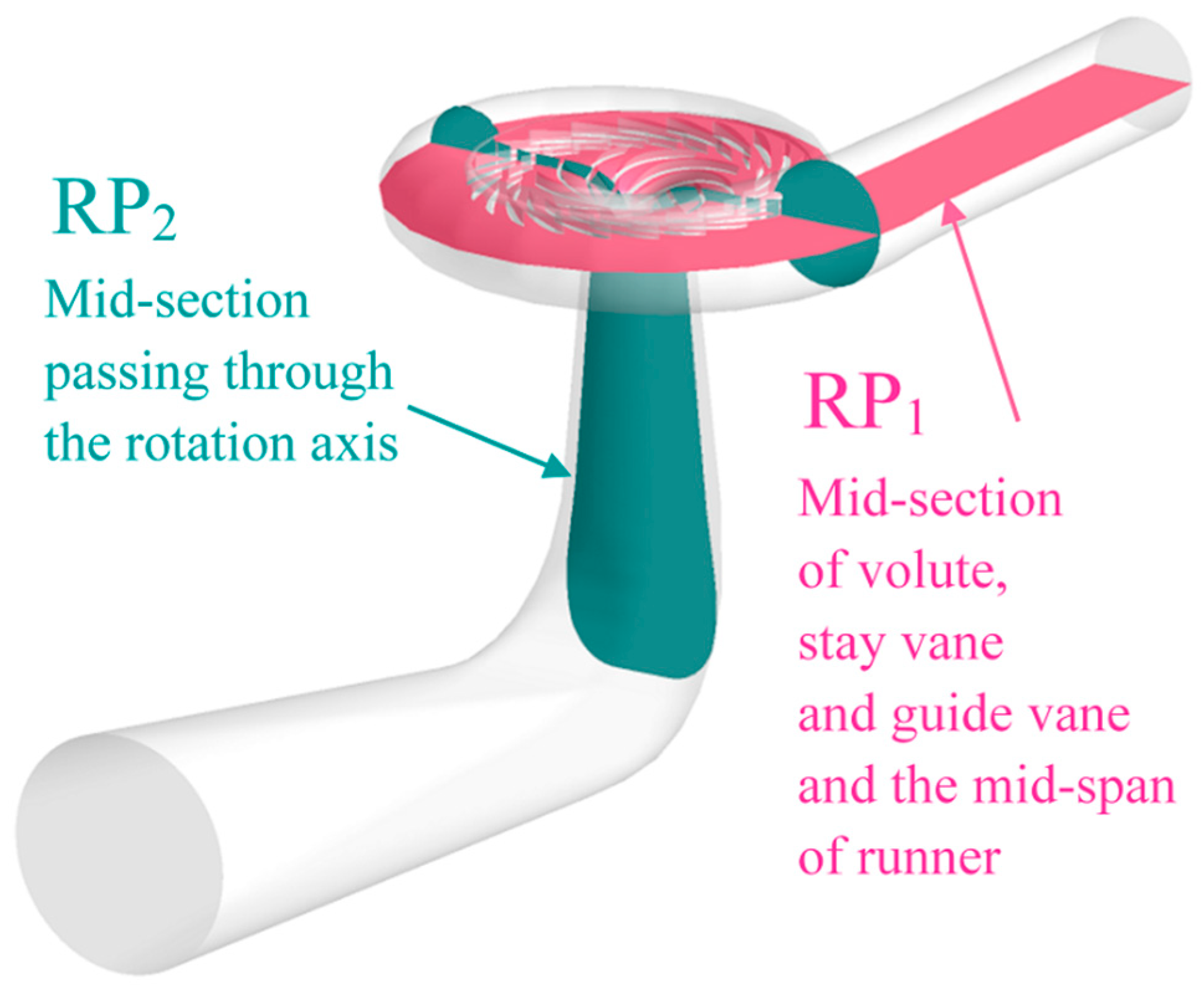

5.2. Reference Plotting Positions

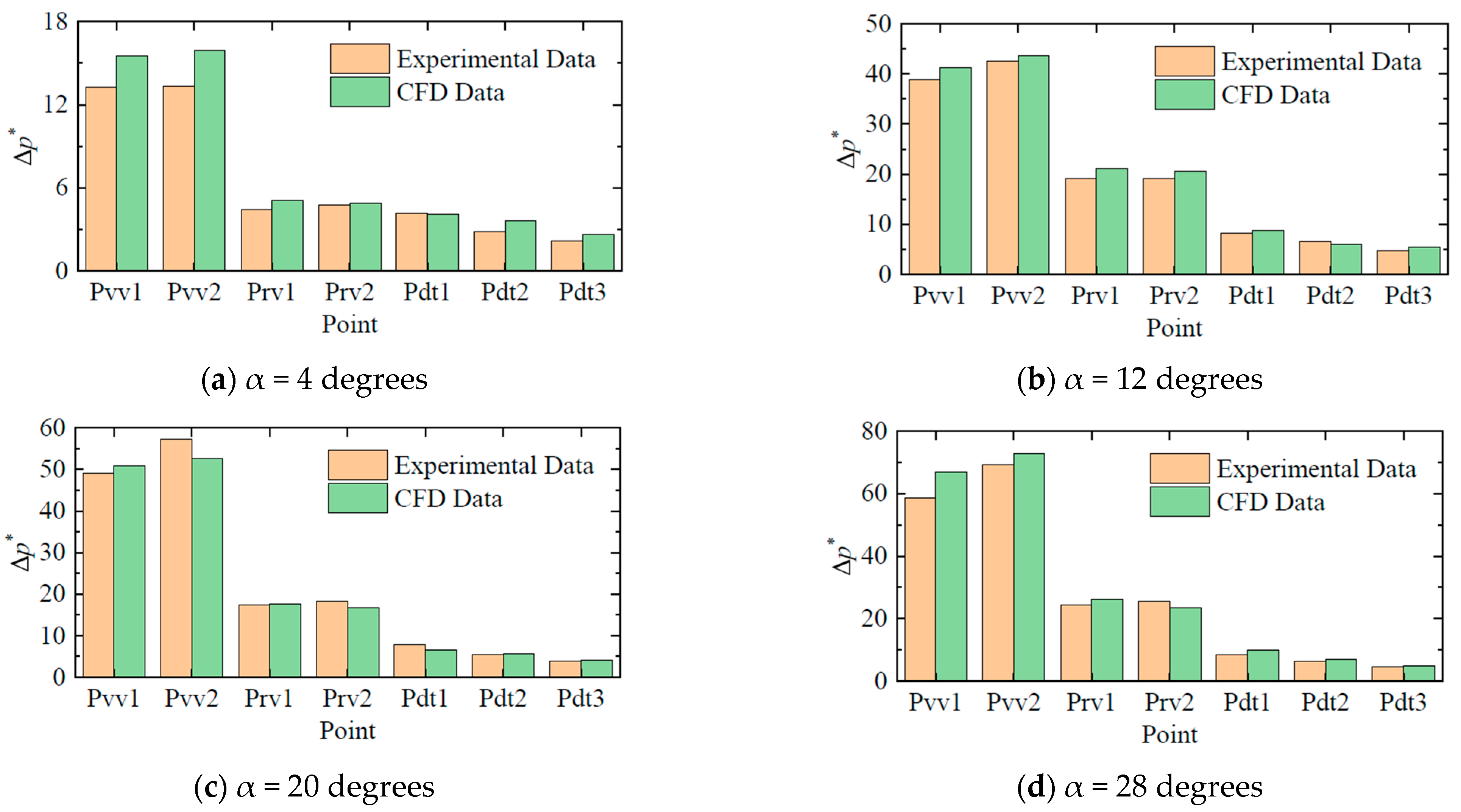

5.3. Experimental-Numerical Comparison of Pressure Pulsation Intensity

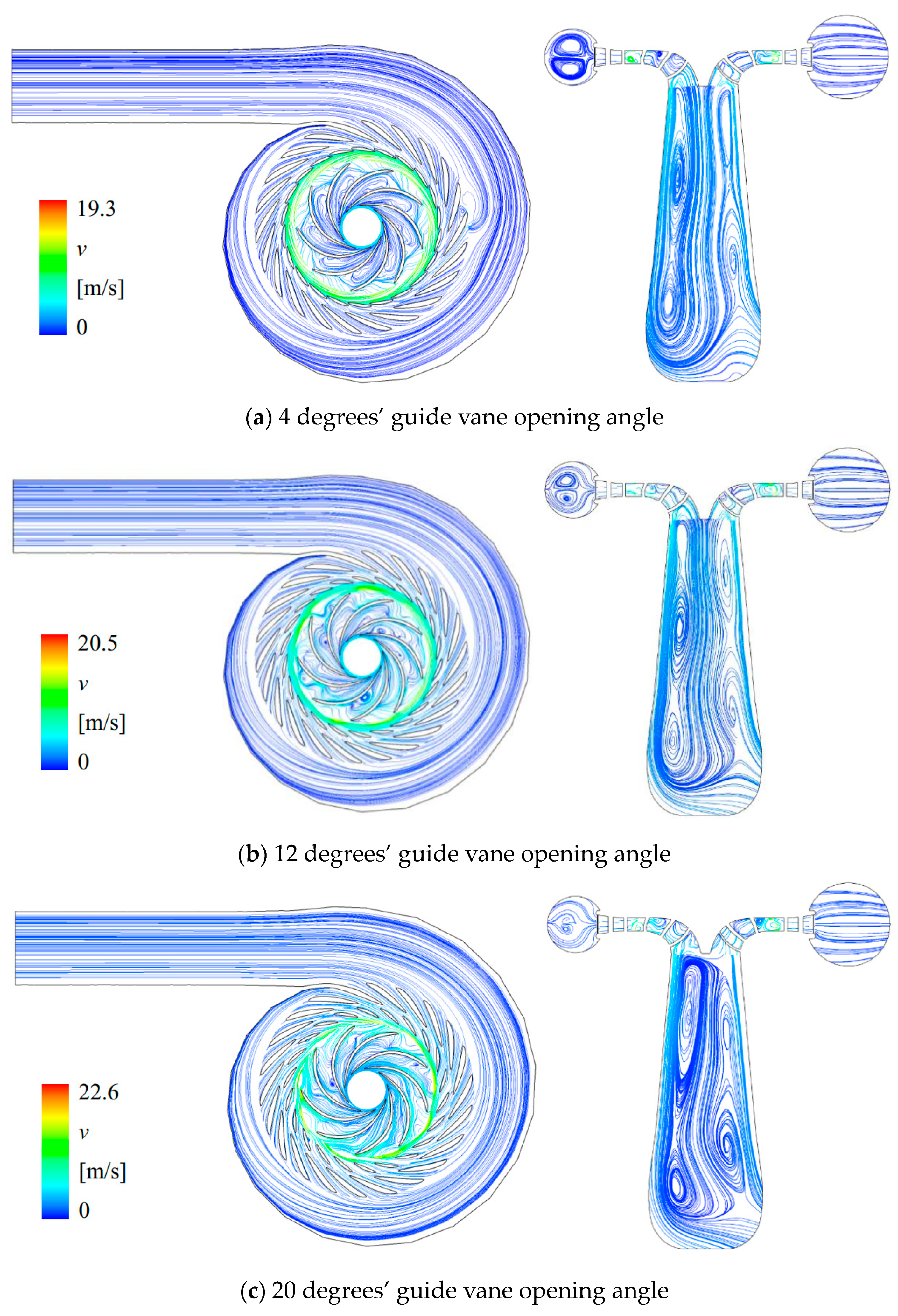

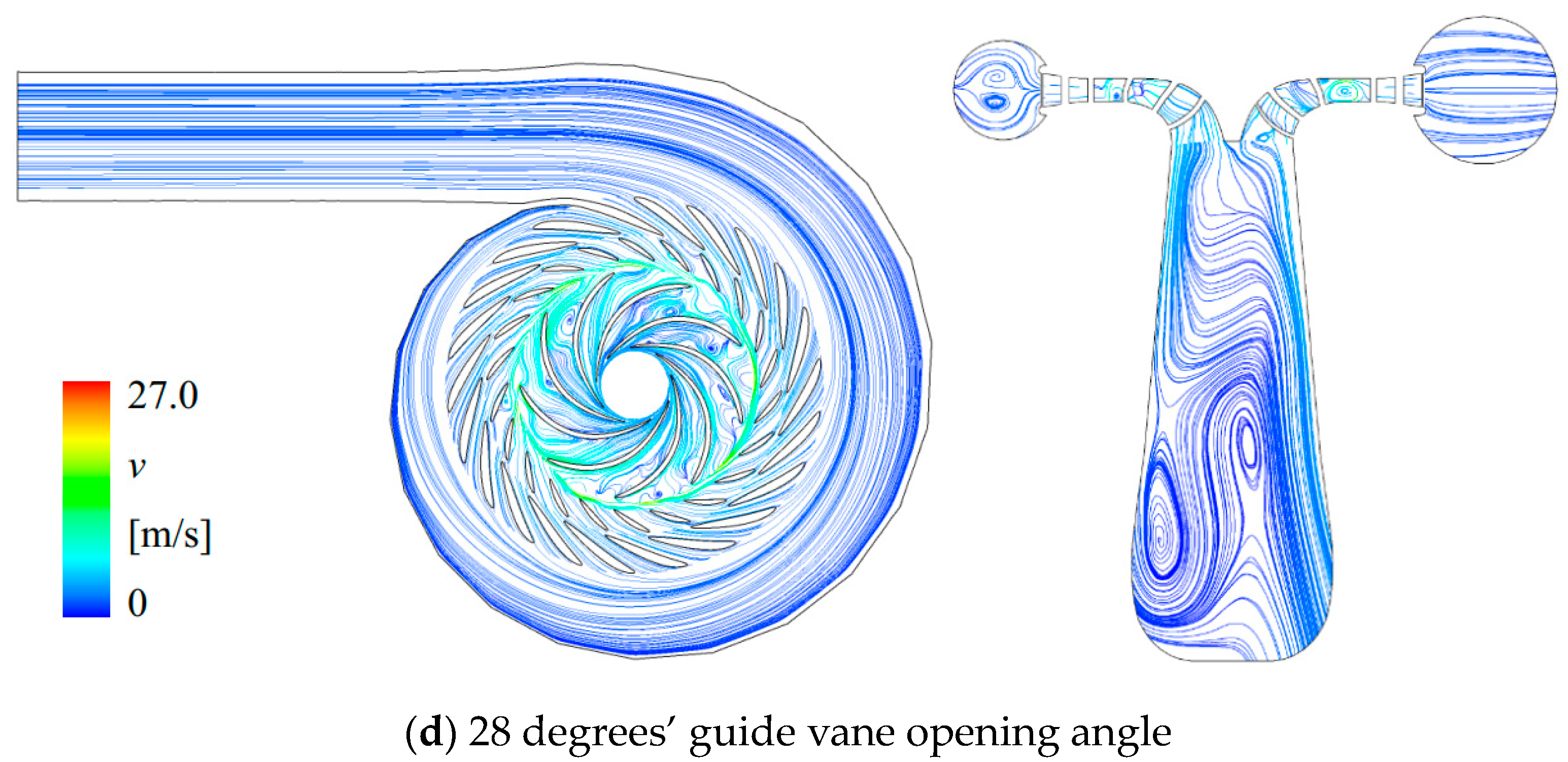

5.4. Internal Flow Pattern in Pump-Turbine

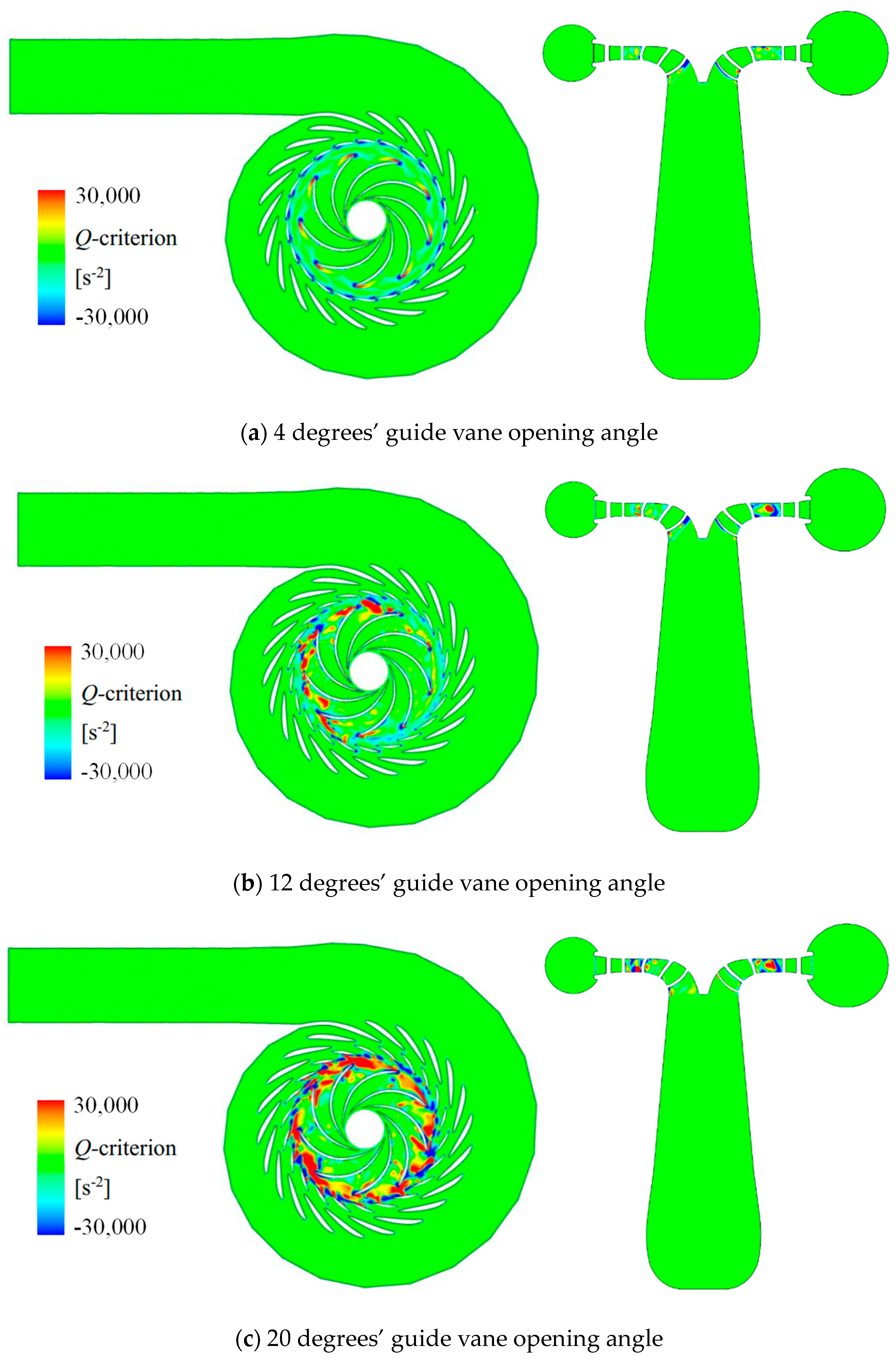

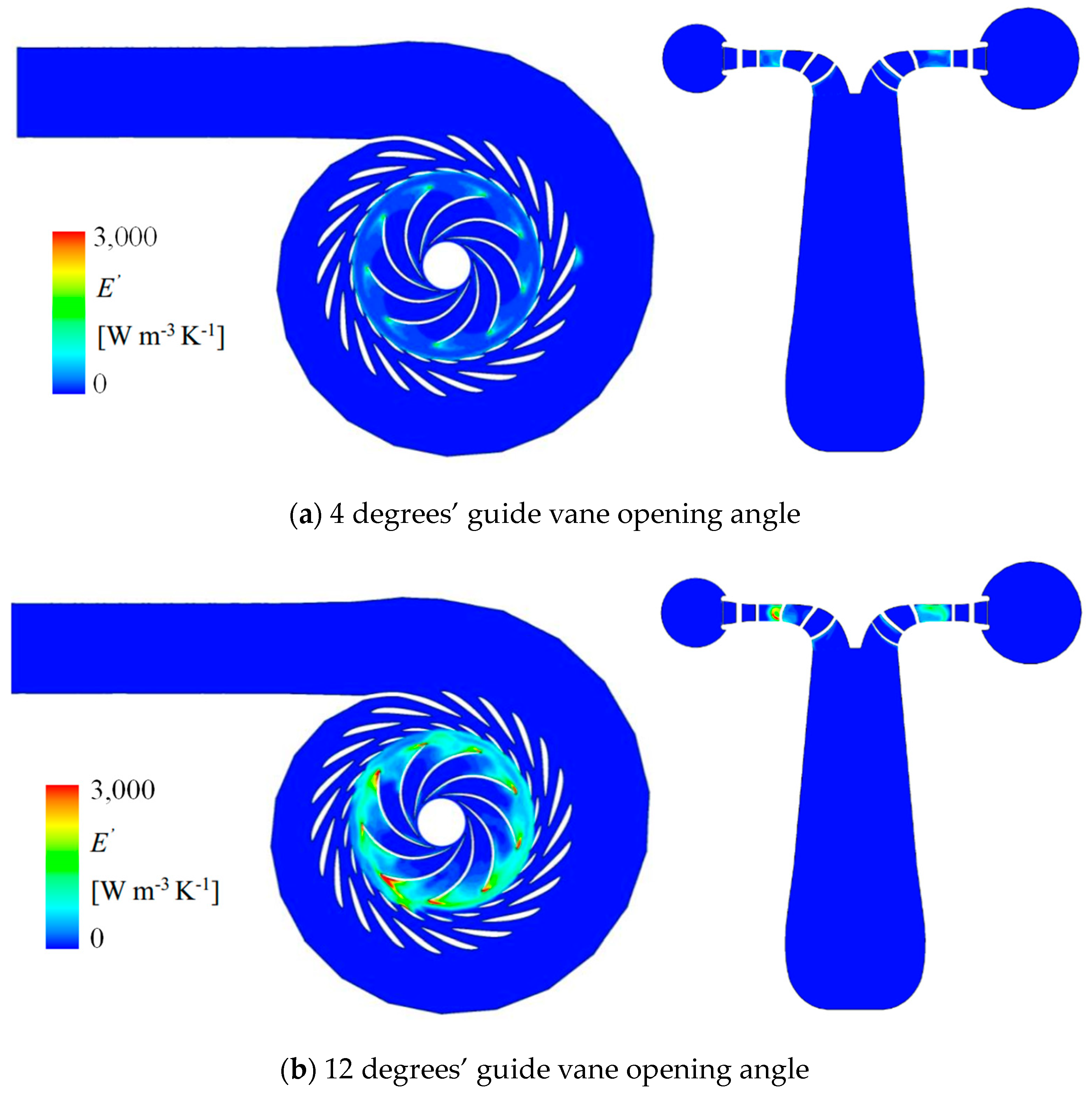

5.5. Vortex Intensity in Pump-Turbine

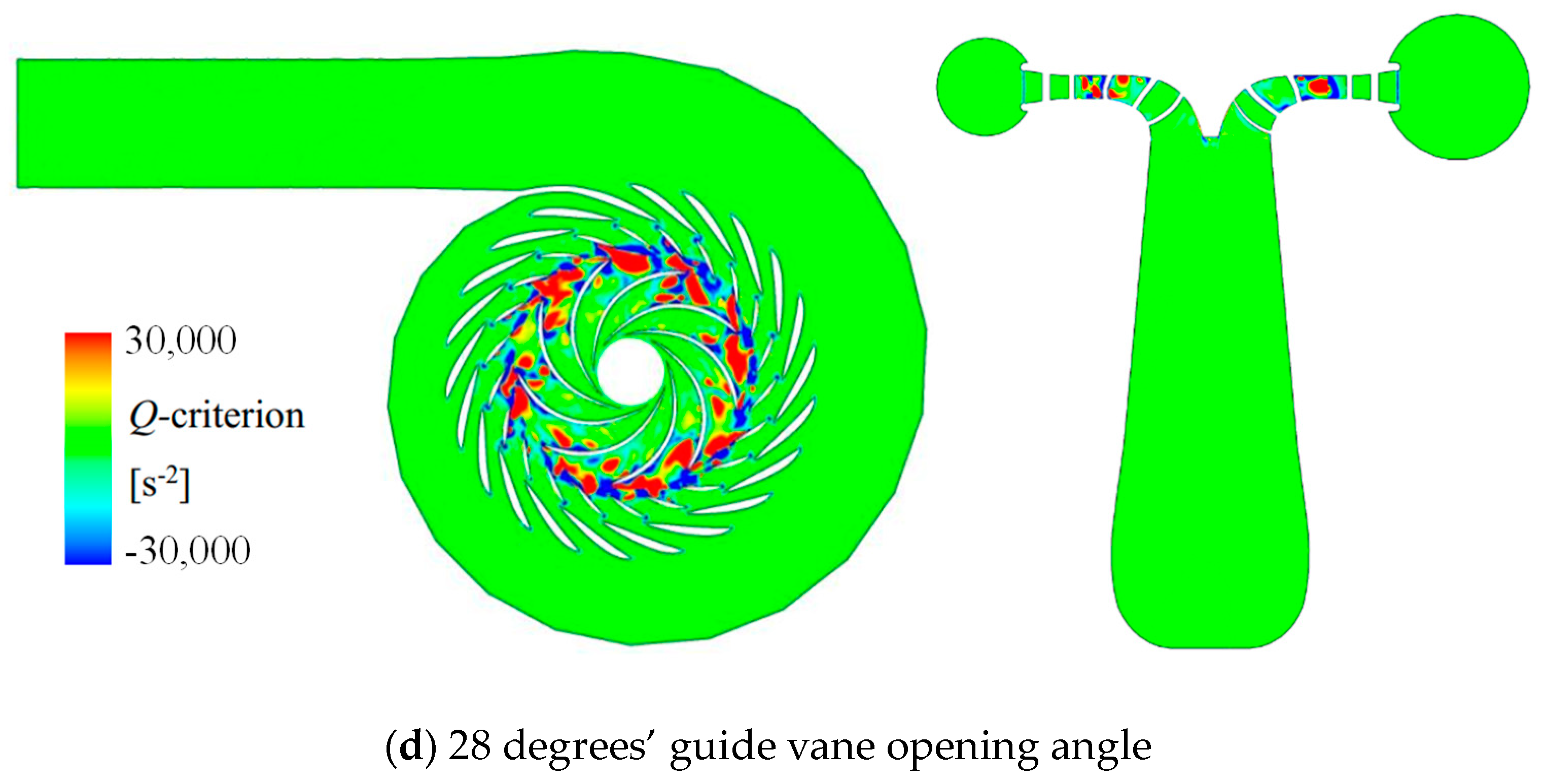

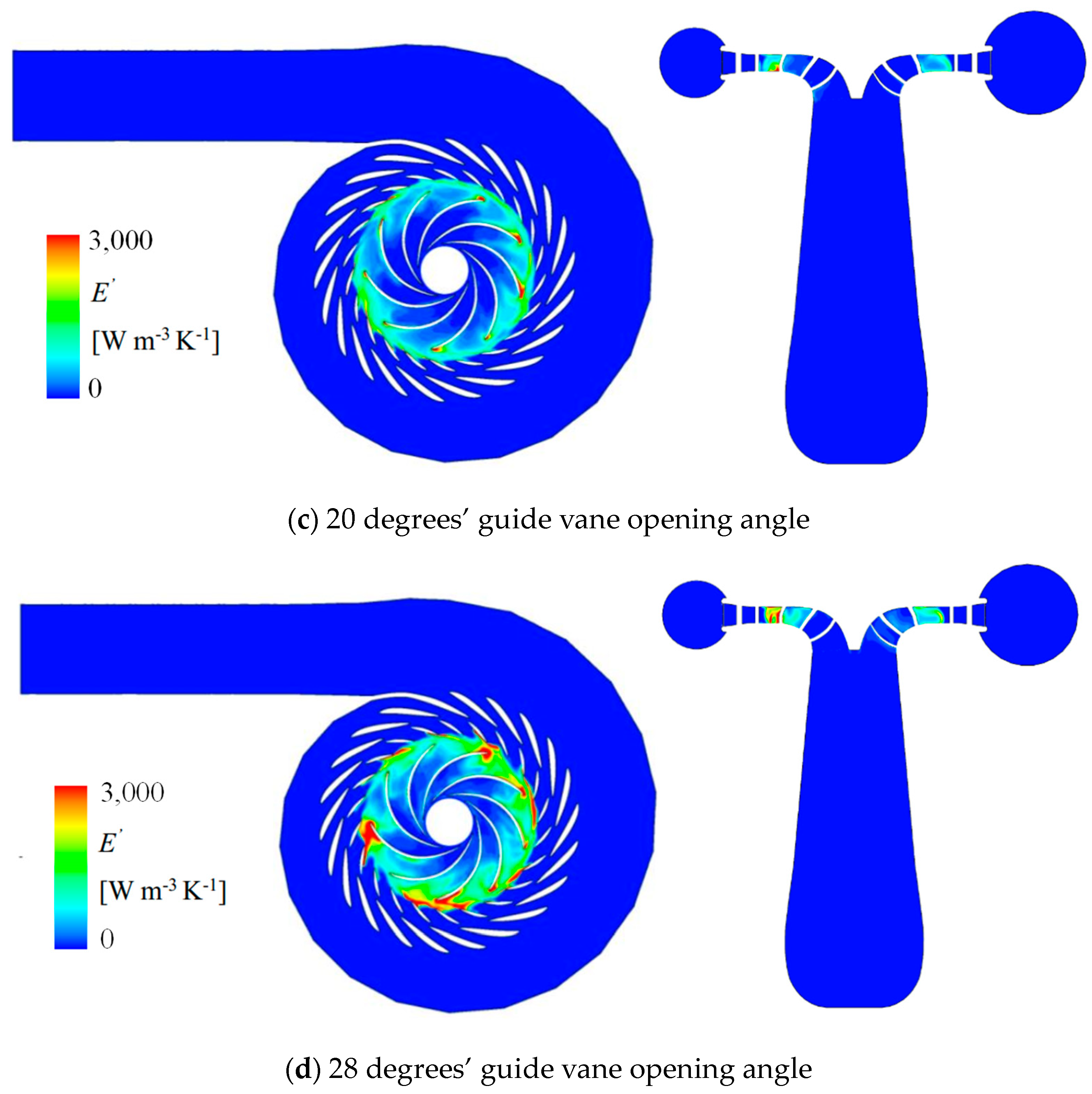

5.6. Entropy Production in Pump-Turbine

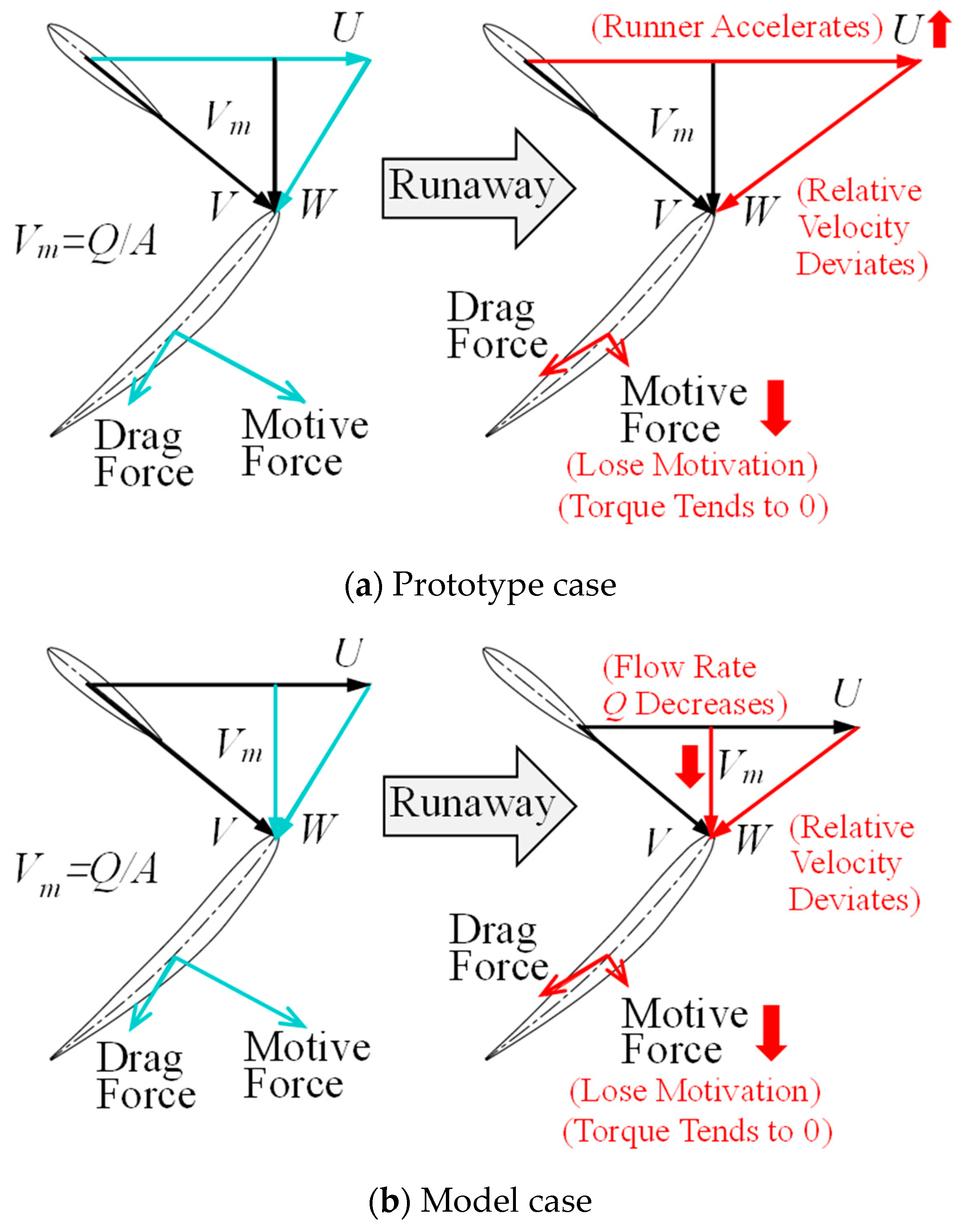

6. Discussion

7. Conclusions

- (1)

- Under the runaway condition, there is a certain regularity in the strength of pressure pulsation inside the unit, which is clearly reflected through the pressure pulsation amplitude at a 97% confidence level. Firstly, the area between the runner and guide vane is the strongest. Secondly, the area between the guide vane and the stay vane is the second strongest, only lower than in the area between the runner and the guide vane. The amplitude of pressure pulsation in the draft tube increases with the distance away from the runner. It can be seen that the runner is the cause of strong pressure pulsation.

- (2)

- Within the guide vane opening angle range of 1 to 28 degrees, as the guide vane opening increases, the pressure pulsation mainly shows an upward trend, but there are also local pulsations and peaks. When the opening of the guide vane is small, the pressure pulsation caused by runaway is less than 5% even in the area between the runner and the guide vanes. When the opening of the guide vane increases to 12 degrees, a local peak appears, and the amplitude of pressure pulsation can reach 40~50%. When the opening of the guide vane is at 28 degrees, the pressure pulsation is very intense, with an amplitude of nearly 70%, making operation very dangerous.

- (3)

- From the streamlined distribution, it can be seen that the cause of pressure pulsation may be related to the uneven distribution of vortexes. Especially the uneven distribution of vortexes inside the runner can lead to local peaks in pressure pulsation. From the vortex identification method based on the Q-criterion, it can be seen that pressure pulsation is related to the uniformity of vortex distribution at the inlet circumference of the runner. The pulsating flow field leads to the dissipation of flow energy, causing changes between mechanical energy and internal energy.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Vagnoni, E.; Andolfatto, L.; Guillaume, R. Interaction of a rotating two-phase flow with the pressure and torque stability of a reversible pump-turbine operating in condenser mode. Int. J. Multiph. Flow 2018, 111, 112–121. [Google Scholar] [CrossRef]

- Tao, R.; Song, X.; Ye, C. Pumped storage technology, reversible pump turbines and their importance in power grids. Water 2022, 14, 3569. [Google Scholar] [CrossRef]

- Hu, W.; Wang, Z.; Fan, H. Grid synchronization of variable speed pump-turbine units in turbine mode. Renew. Energy 2021, 173, 625–638. [Google Scholar]

- Bidgoli, M.A.; Yang, W.; Ahmadian, A. DFIM versus synchronous machine for variable speed pumped storage hydropower plants: A comparative evaluation of technical performance. Renew. Energy 2020, 159, 72–86. [Google Scholar] [CrossRef]

- Wang, C.; Wang, D.; Zhang, J. Experimental study on isolated operation of hydro-turbine governing system of Lunzua hydropower station in Zambia. Renew. Energy 2021, 180, 1237–1247. [Google Scholar] [CrossRef]

- Trivedi, C.; Cervantes, M.J.; Gandhi, B.K. Transient pressure measurements on a high head model Francis turbine during emergency shutdown, total load rejection, and runaway. J. Fluids Eng. 2014, 136, 121107. [Google Scholar] [CrossRef]

- Sun, L.; Guo, P.; Yan, J. Transient analysis of load rejection for a high-head Francis turbine based on structured overset mesh. Renew. Energy 2021, 171, 658–671. [Google Scholar] [CrossRef]

- Betz, A. Introduction to the Theory of Flow Machines; Pergamon Press: Oxford, UK, 1966. [Google Scholar]

- Peng, J.; Zhang, J.; Cui, X. On-the-spot Research on load-rejection transient of the Francis turbine installation in the Shiban hydropower plant. J. China Agric. Univ. 2002, 4, 48–53. [Google Scholar]

- Wen, F.; You, J.; Chen, H. Influence of ball valve closing on runaway process of pump-turbine based on CFD. Water Resour. Power 2018, 36, 170–174. [Google Scholar]

- Nicolet, C.; Alligne, S.; Kawkabani, B. Stability study of Francis pump-turbine at runaway. In Proceedings of the 3rd IAHR International Meeting of the Workshop on Cavitation and Dynamic Problems in Hydraulic Machinery and Systems, Brno, Czech Republic, 14–16 October 2009. [Google Scholar]

- Chen, Z.; Jiang, Z.; Chen, S.; Zhang, W.; Zhu, B. Experimental and numerical study on flow instability of pump-turbine under runaway conditions. Renew. Energy 2023, 210, 335–345. [Google Scholar] [CrossRef]

- Fu, X.; Li, D.; Wang, H. Influence of the clearance flow on the load rejection process in a pump-turbine. Renew. Energy 2018, 127, 310–321. [Google Scholar] [CrossRef]

- Bi, H.; Chen, F.; Wang, C. Analysis of dynamic performance in a pump-turbine during the successive load rejection. IOP Conf. Ser. Earth Environ. Sci. 2021, 774, 012152. [Google Scholar] [CrossRef]

- Wang, H.; Qin, D.; Wei, X. Hydraulic research and development of splitter runner of Francis pump turbine in HEC. Hydropower Pumped Storage 2016, 2, 38–43. [Google Scholar]

- Tao, R.; Zhou, X.; Xu, B. Numerical investigation of the flow regime and cavitation in the vanes of reversible pump-turbine during pump mode’s starting up. Renew. Energy 2019, 141, 9–19. [Google Scholar] [CrossRef]

- Fu, X.; Li, D.; Wang, H. Hydraulic fluctuations during the pump power-off runaway transient process of a pump turbine with consideration of cavitation effects. J. Hydrodyn. 2021, 33, 1162–1175. [Google Scholar] [CrossRef]

- Rezghi, A.; Riasi, A. Sensitivity analysis of transient flow of two parallel pump-turbines operating at runaway. Renew. Energy 2016, 86, 611–622. [Google Scholar] [CrossRef]

- Zhang, F.; Fang, M.; Pan, J. Guide vane profile optimization of pump-turbine for grid connection performance improvement. Energy 2023, 274, 127369. [Google Scholar] [CrossRef]

- Nicolet, C.; Alligne, S.; Kawkabani, B. Unstable operation of Francis pump-turbine at runaway: Rigid and elastic water column oscillation modes. In Proceedings of the IAHR 24th Symposium on Hydraulic Machinery and Systems, Foz do Iguassu, Brazil, 27–31 October 2008. [Google Scholar]

- Zeng, W.; Yang, J.; Guo, W. Runaway instability of pump-turbines in S-shaped regions considering water compressibility. J. Fluids Eng. 2015, 137, 051401. [Google Scholar] [CrossRef]

- Cavazzini, G.; Covi, A.; Pavesi, G. Analysis of the unstable behavior of a pump-turbine in turbine mode: Fluid-dynamical and spectral characterization of the S-shape characteristic. J. Fluids Eng. 2016, 138, 021105. [Google Scholar] [CrossRef]

- Zhang, F.; Xiao, R.; Zhu, D. Pressure pulsation reduction in the draft tube of pump turbine in turbine mode based on optimization design of runner blade trailing edge profile. J. Energy Storage 2023, 59, 106541. [Google Scholar] [CrossRef]

- Menter, F.; Kuntz, M.; Langtry, R. Ten years of industrial experience with the SST turbulence model. Turbul. Heat Mass Transf. 2003, 4, 625–632. [Google Scholar]

- Mos, D.C.; Muntean, S.; Bosoic, A.I.; Tanasa, C.; Susan-Resiga, R. Experimental investigation of the unsteady pressure field in decelerated swirling flow with 74° sharp heel elbow. J. Phys. Conf. Ser. 2017, 813, 012046. [Google Scholar] [CrossRef]

- Spence, R.; Amaral-Teixeira, J. Investigation into pressure pulsations in a centrifugal pump using numerical methods supported by industrial tests. Comput. Fluids 2008, 37, 690–704. [Google Scholar] [CrossRef]

- Bosoic, A.I.; Tanasa, C. Experimental study of swirling flow from conical diffusers using the water jet control method. Renew. Energy 2020, 152, 385–398. [Google Scholar] [CrossRef]

- Zhan, J.; Li, Y.; Wai, W.O. Comparison between the Q criterion and Rortex in the application of an in-stream structure. Phys. Fluids 2019, 31, 121701. [Google Scholar]

- Herwig, H.; Kock, F. Direct and indirect methods of calculating entropy generation rates in turbulent convective heat transfer problems. Heat Mass Transf. 2007, 43, 207–215. [Google Scholar] [CrossRef]

- Tao, R.; Wang, Z. Comparative numerical studies for the flow energy dissipation features in a pump-turbine in pump mode and turbine mode. J. Energy Storage 2021, 41, 102835. [Google Scholar] [CrossRef]

- Zhu, D.; Tao, R.; Xiao, R. Large eddy simulation of the flow energy dissipation in the blade channels of a stalled pump impeller. J. Power Energy 2022, 236, 1227–1235. [Google Scholar] [CrossRef]

- Yan, W.; Zhu, D.; Tao, R.; Wang, Z. Analysis of the flow energy loss and Q-H stability in reversible pump turbine as pump with different guide vane opening angles. Water 2022, 14, 2526. [Google Scholar] [CrossRef]

| Condition No. | α [Degrees] | n11 | Q11 | Shaft Torque [N·m] |

|---|---|---|---|---|

| C01 | 1 | 35.598 | 0.052 | −0.85 |

| C02 | 2 | 40.526 | 0.074 | −0.37 |

| C03 | 3 | 42.849 | 0.091 | −0.52 |

| C04 | 4 | 44.724 | 0.107 | 0.20 |

| C05 | 5 | 46.144 | 0.120 | −0.77 |

| C06 | 6 | 47.063 | 0.134 | −0.55 |

| C07 | 7 | 47.819 | 0.146 | −0.54 |

| C08 | 8 | 48.447 | 0.157 | −0.79 |

| C09 | 9 | 48.971 | 0.170 | −0.15 |

| C10 | 10 | 49.483 | 0.181 | −0.65 |

| C11 | 12 | 50.409 | 0.206 | −0.32 |

| C12 | 14 | 51.208 | 0.231 | −0.40 |

| C13 | 16 | 52.072 | 0.256 | −0.83 |

| C14 | 18 | 52.822 | 0.283 | −0.00 |

| C15 | 20 | 53.561 | 0.310 | 0.00 |

| C16 | 22 | 54.267 | 0.337 | −0.37 |

| C17 | 24 | 54.911 | 0.368 | 0.00 |

| C18 | 26 | 55.481 | 0.395 | −0.32 |

| C19 | 28 | 55.94 | 0.421 | −0.32 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhu, D.; Yan, W.; Guang, W.; Wang, Z.; Tao, R. Influence of Guide Vane Opening on the Runaway Stability of a Pump-Turbine Used for Hydropower and Ocean Power. J. Mar. Sci. Eng. 2023, 11, 1218. https://doi.org/10.3390/jmse11061218

Zhu D, Yan W, Guang W, Wang Z, Tao R. Influence of Guide Vane Opening on the Runaway Stability of a Pump-Turbine Used for Hydropower and Ocean Power. Journal of Marine Science and Engineering. 2023; 11(6):1218. https://doi.org/10.3390/jmse11061218

Chicago/Turabian StyleZhu, Di, Wei Yan, Weilong Guang, Zhengwei Wang, and Ran Tao. 2023. "Influence of Guide Vane Opening on the Runaway Stability of a Pump-Turbine Used for Hydropower and Ocean Power" Journal of Marine Science and Engineering 11, no. 6: 1218. https://doi.org/10.3390/jmse11061218

APA StyleZhu, D., Yan, W., Guang, W., Wang, Z., & Tao, R. (2023). Influence of Guide Vane Opening on the Runaway Stability of a Pump-Turbine Used for Hydropower and Ocean Power. Journal of Marine Science and Engineering, 11(6), 1218. https://doi.org/10.3390/jmse11061218