Numerical and Experimental Investigations of Deicing Performance for the Pneumatic Impulse Deicing Method

Abstract

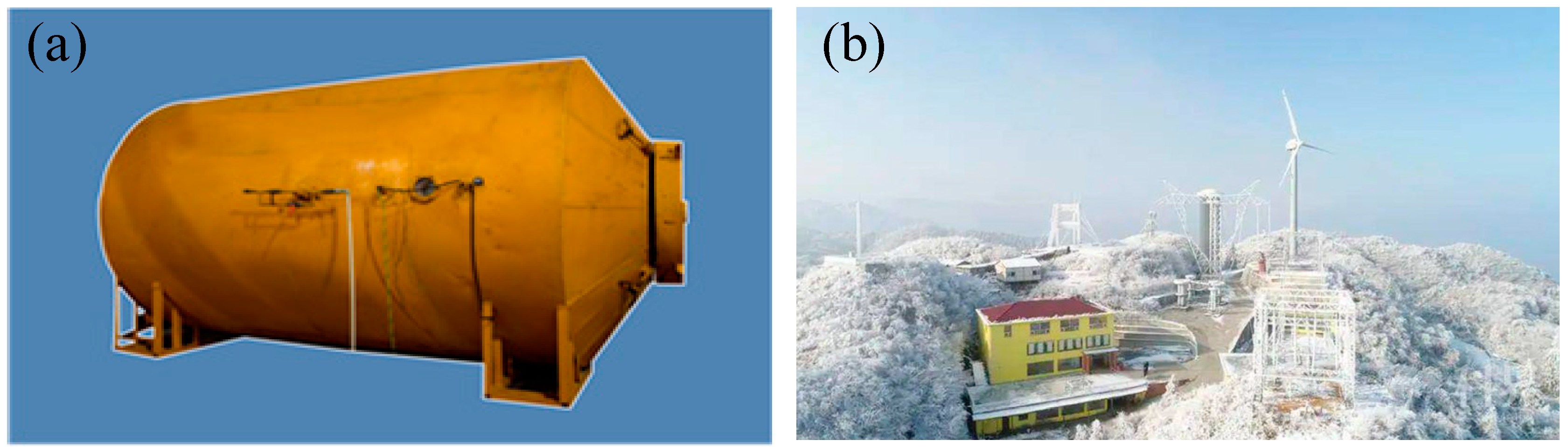

1. Introduction

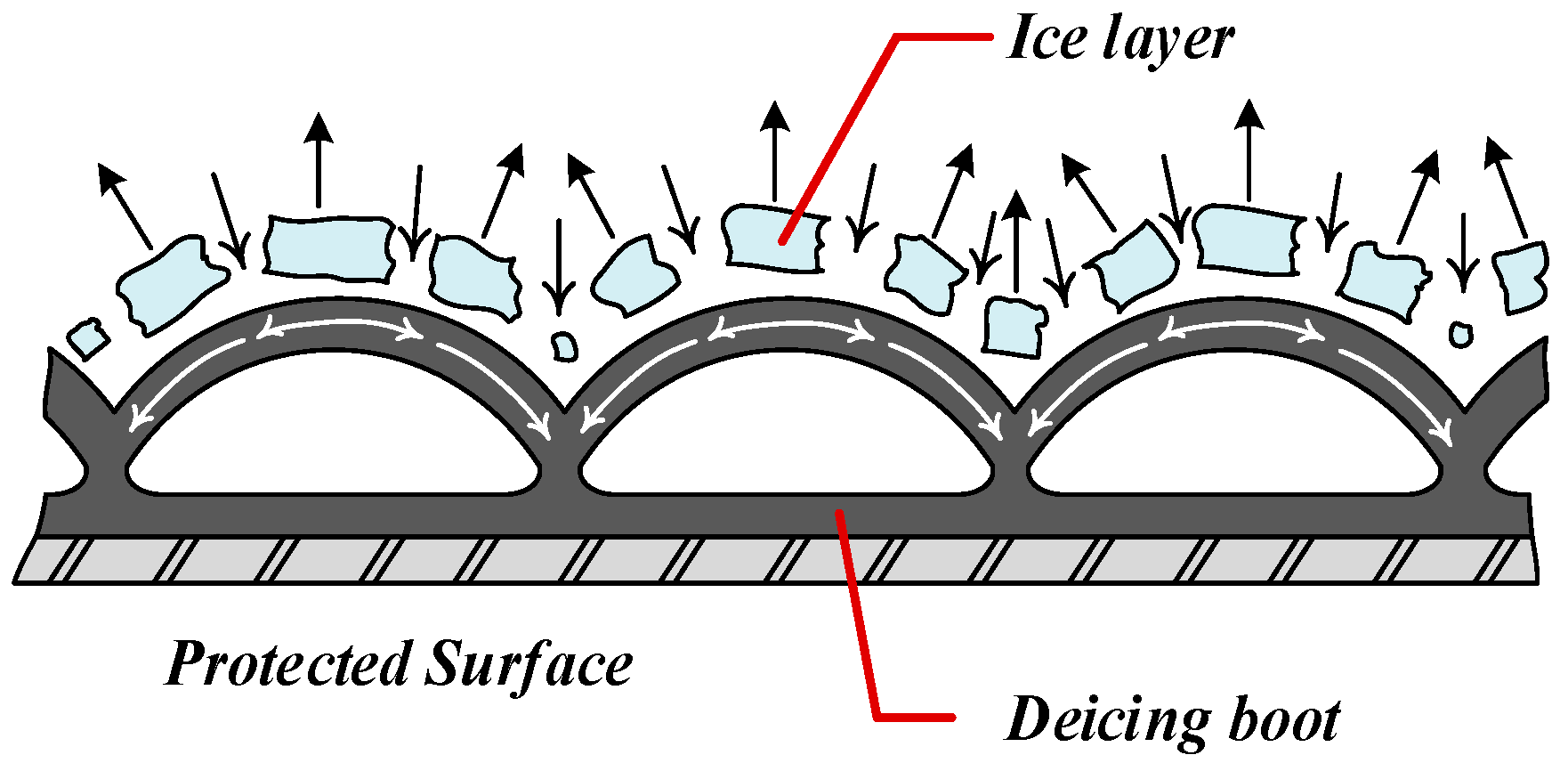

2. Structure of the Pneumatic Impulse Deicing Method

3. Numerical Simulation Methods

3.1. Dynamical Equation

3.2. The Constitutive Equations

3.3. The Brittle Cracking Model of the Ice Layer

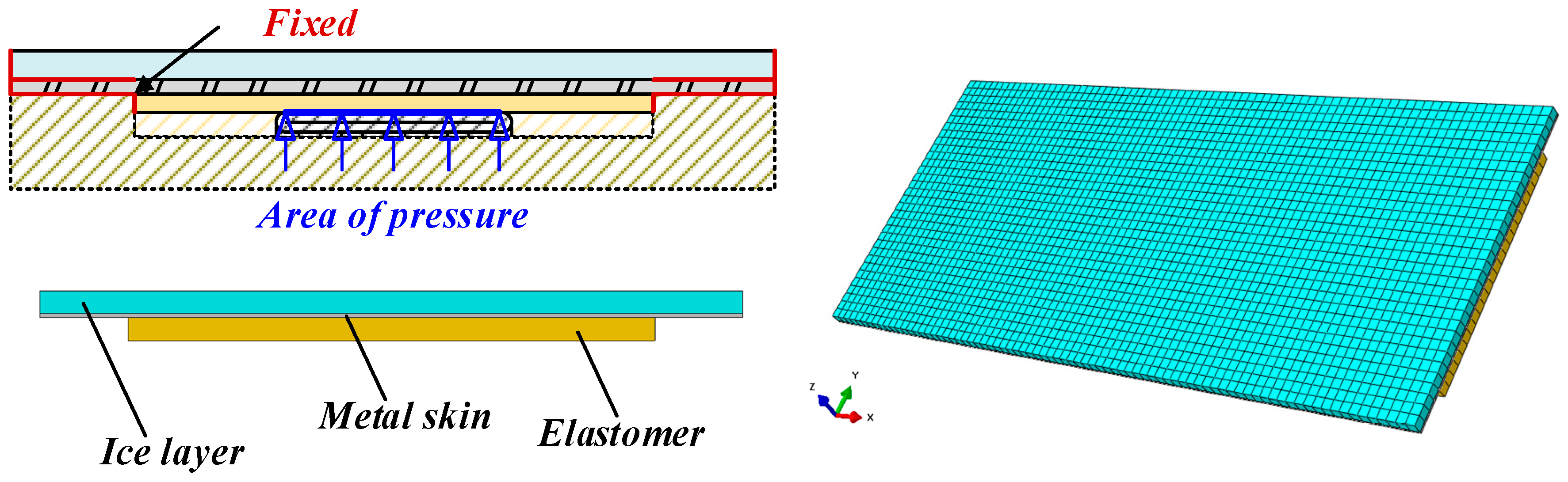

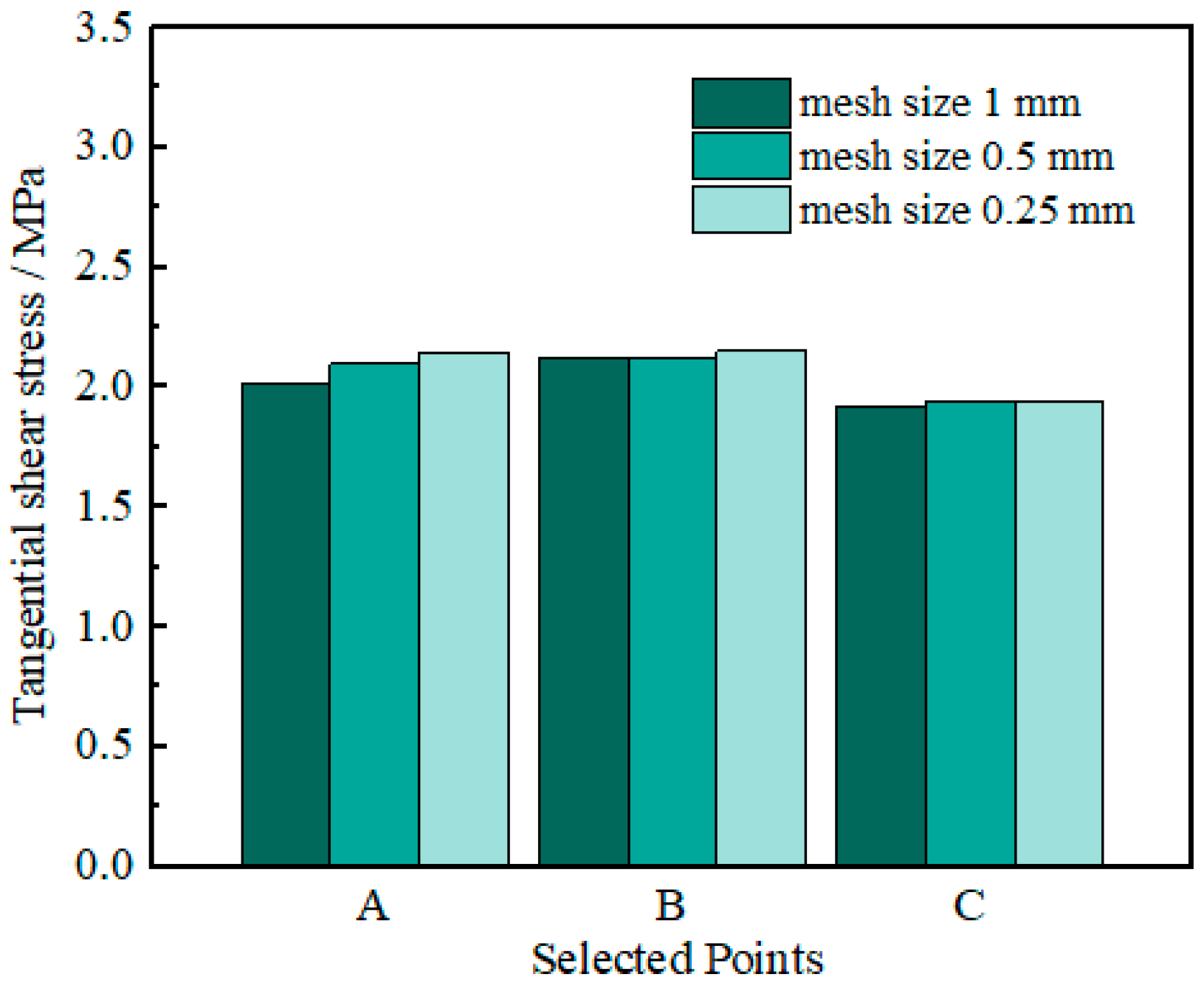

3.4. Geometric Model and Parameters Settings

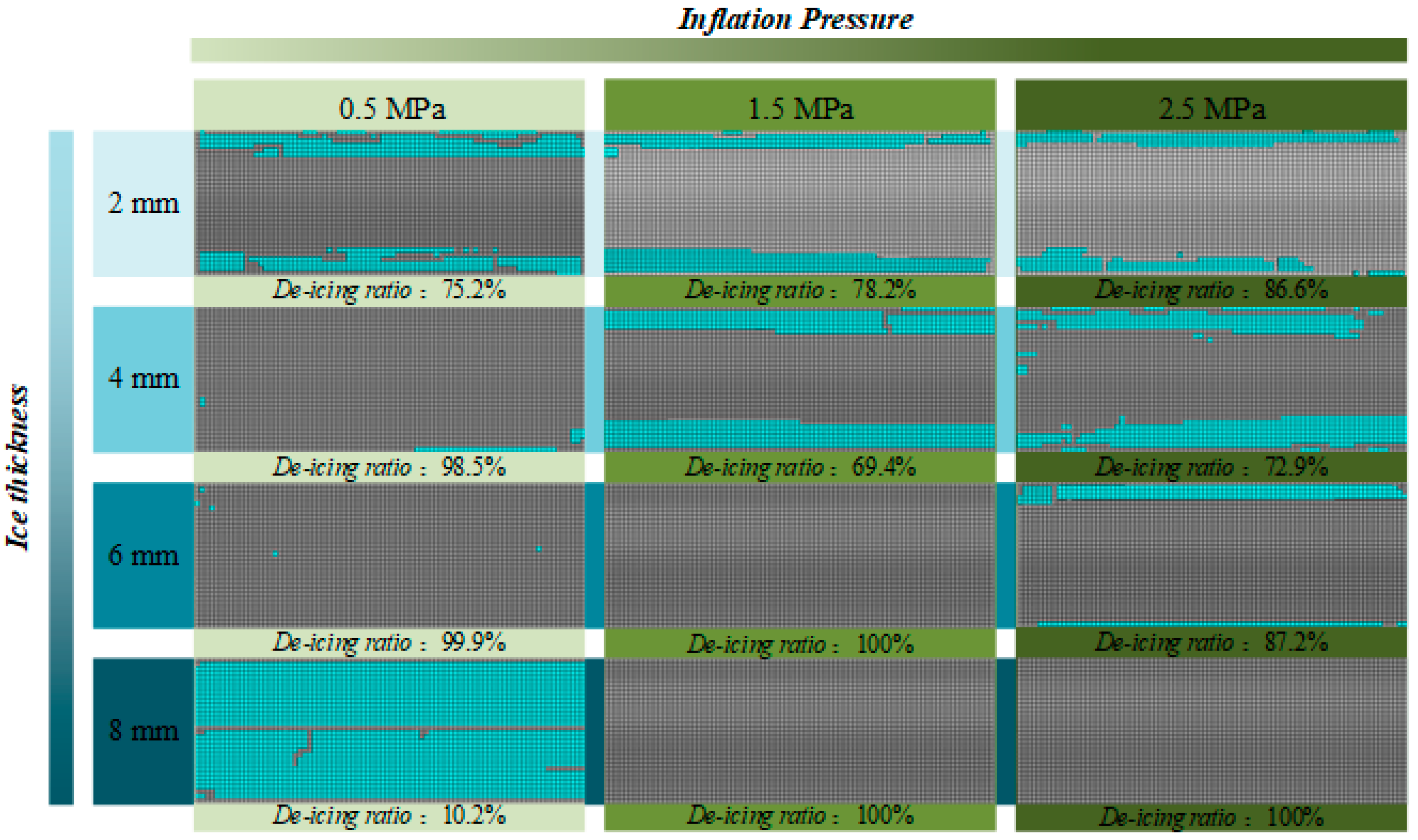

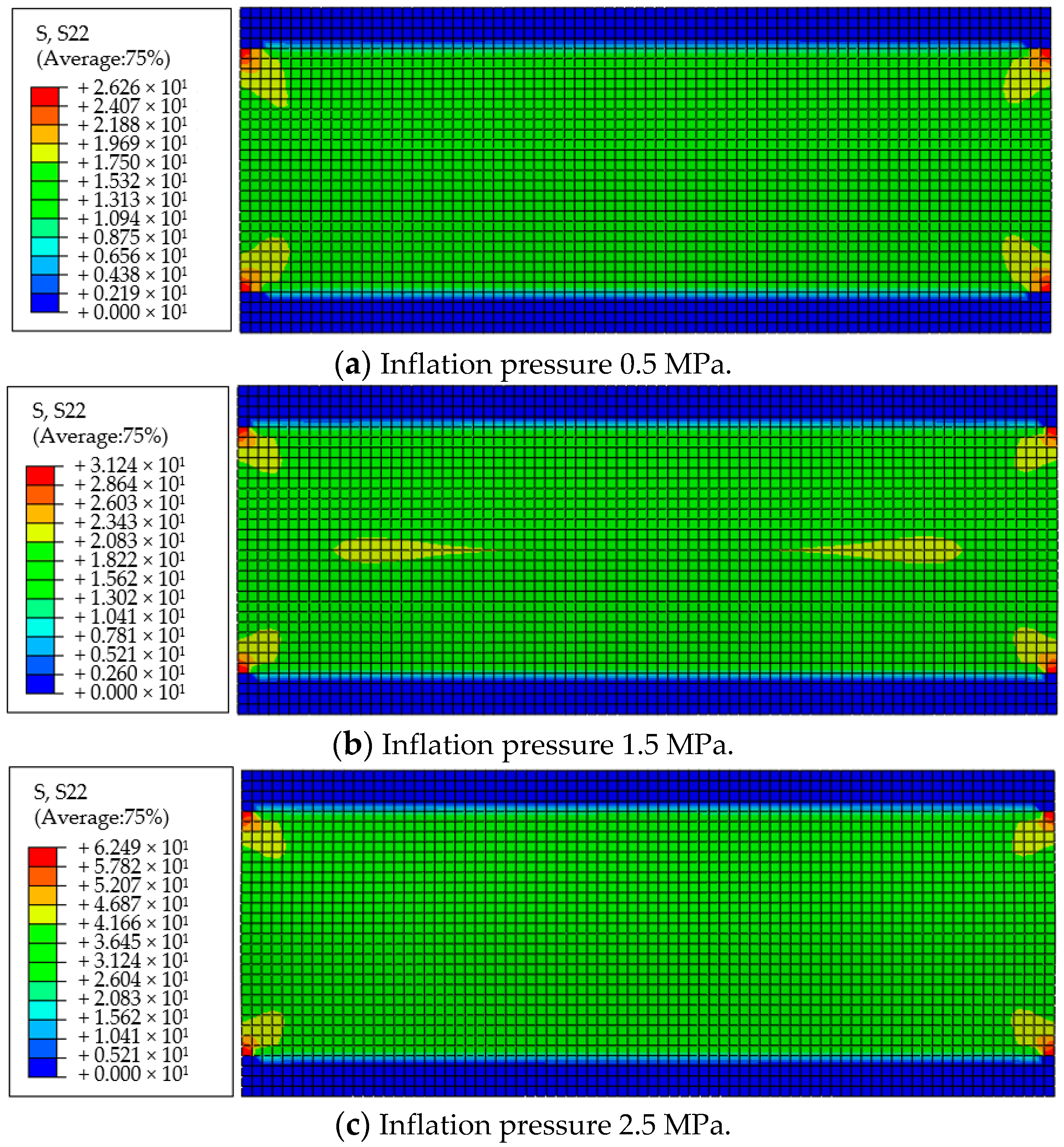

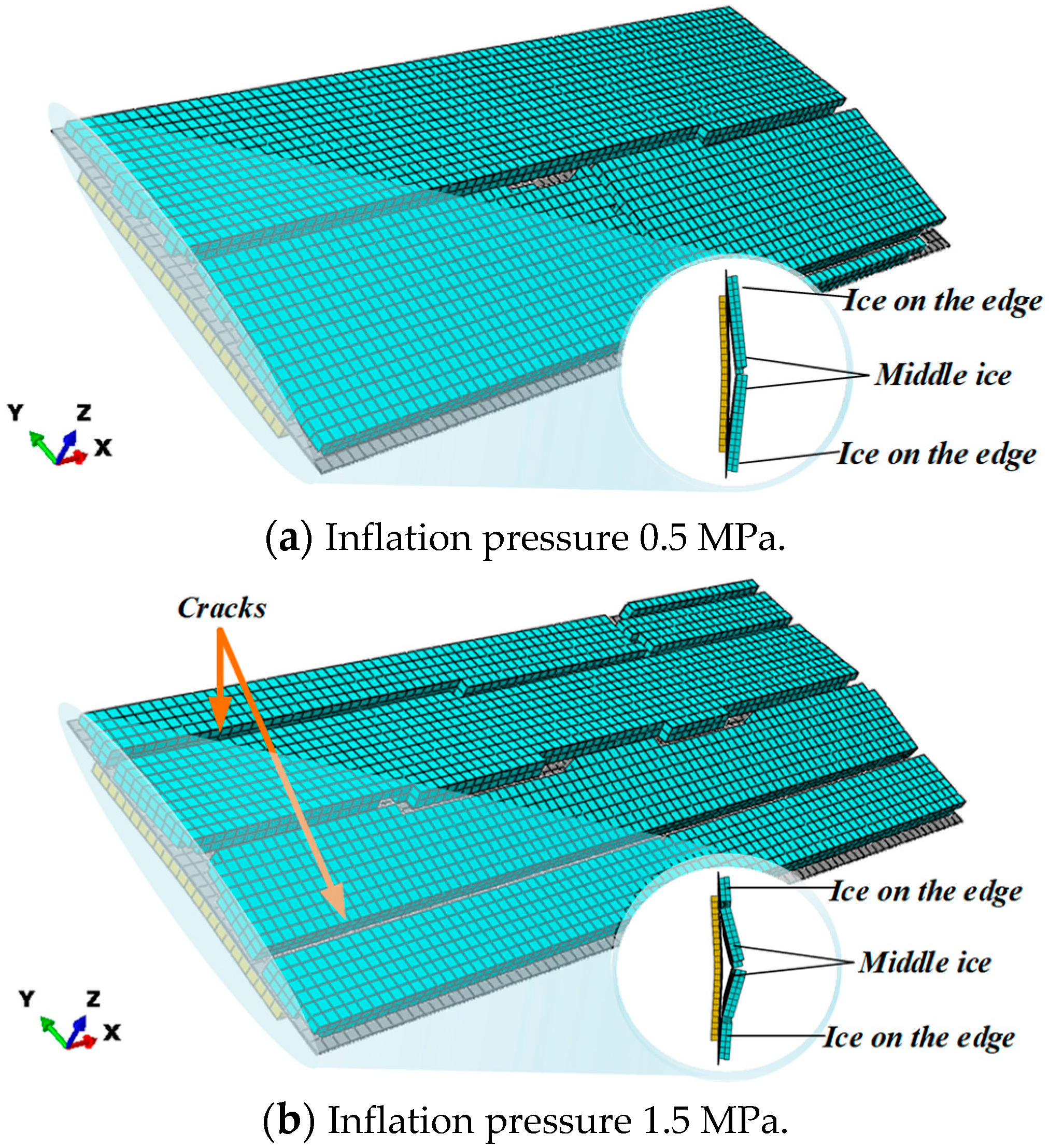

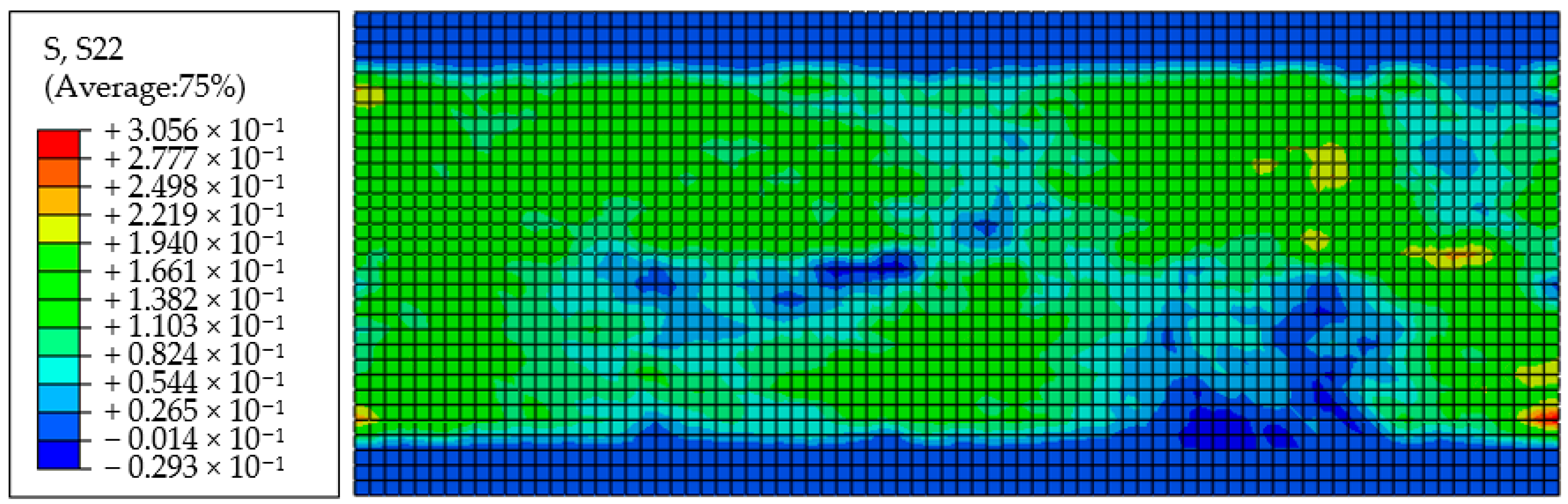

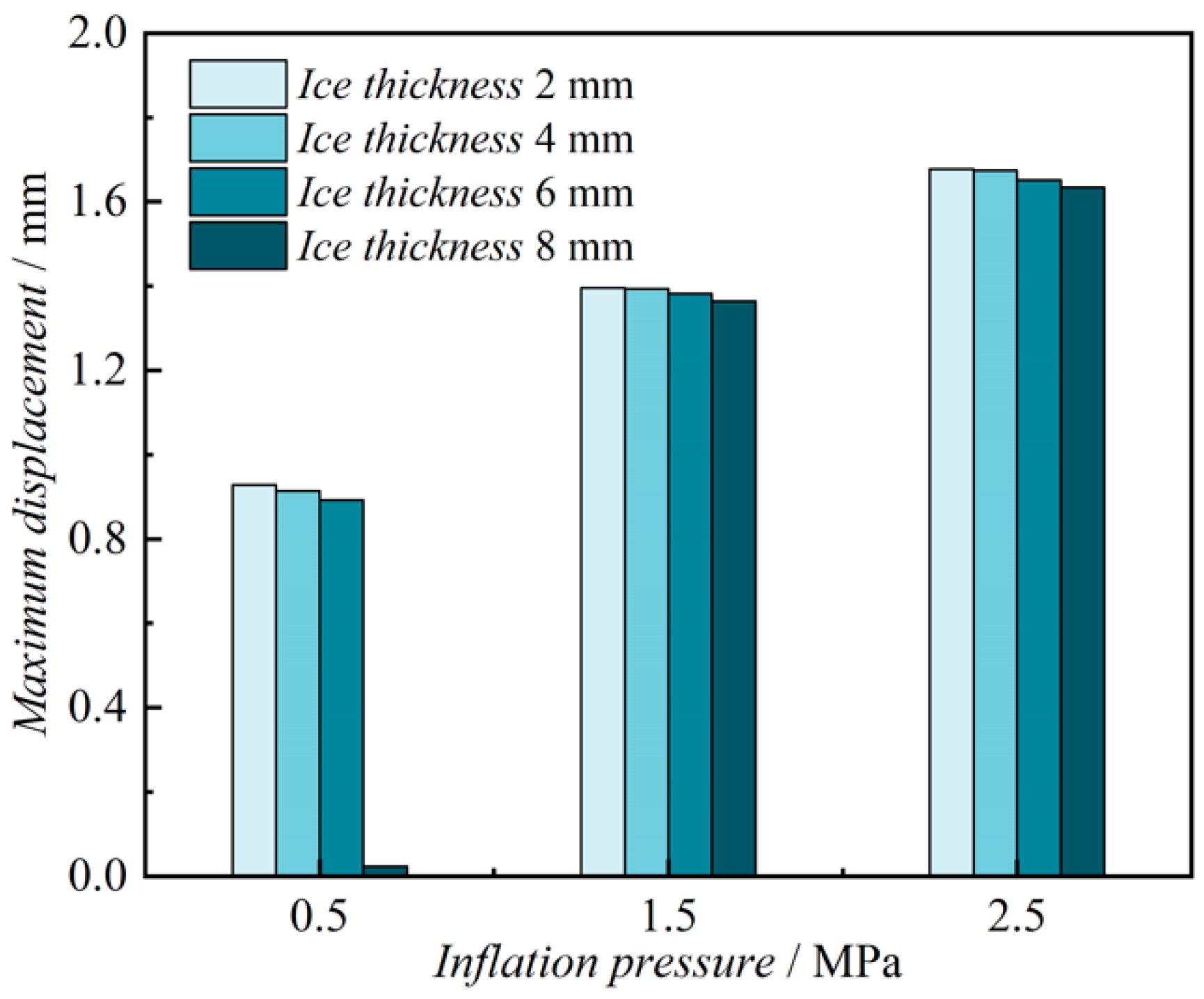

4. Numerical Simulation Results

5. Icing and Deicing Experiments

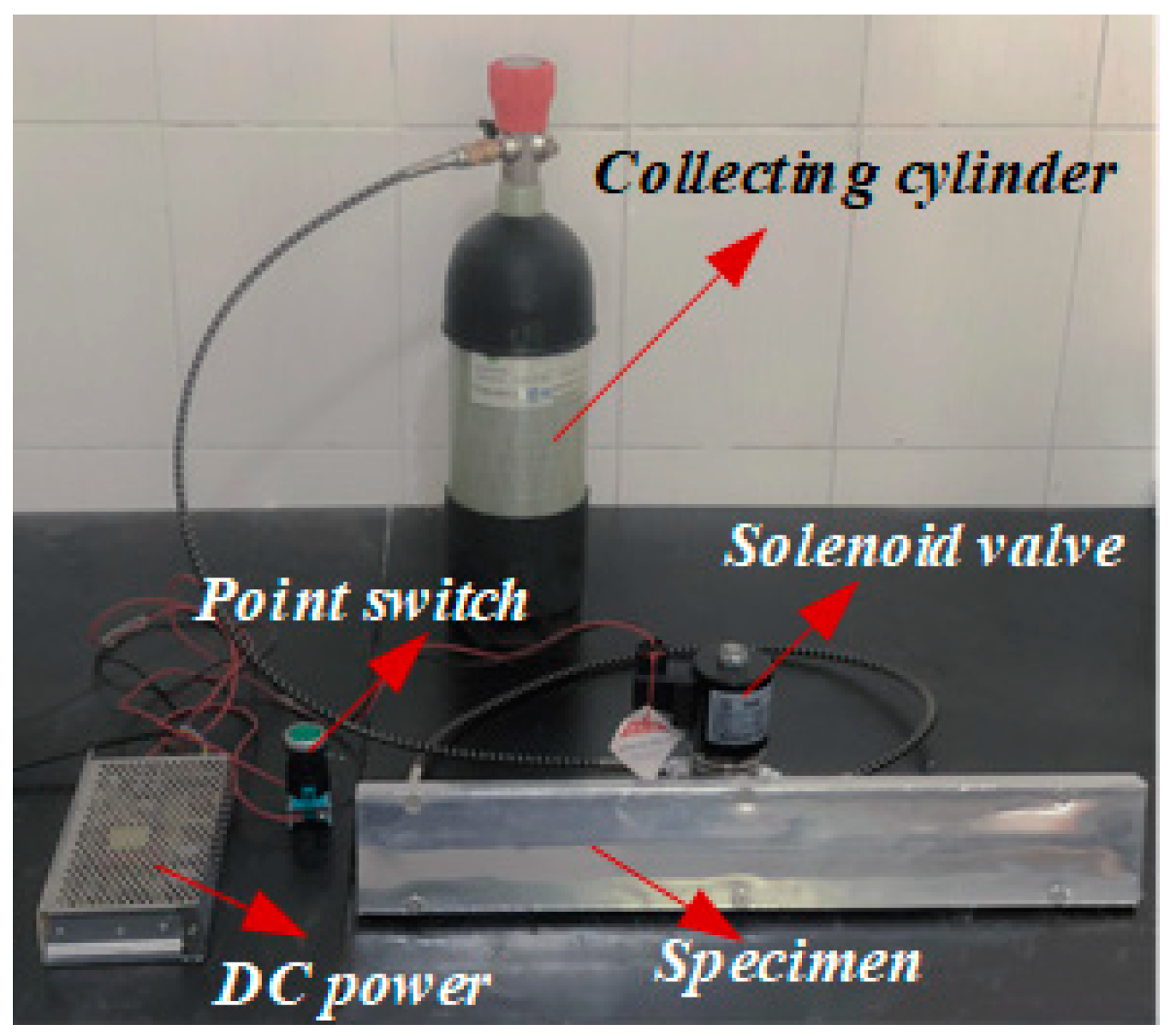

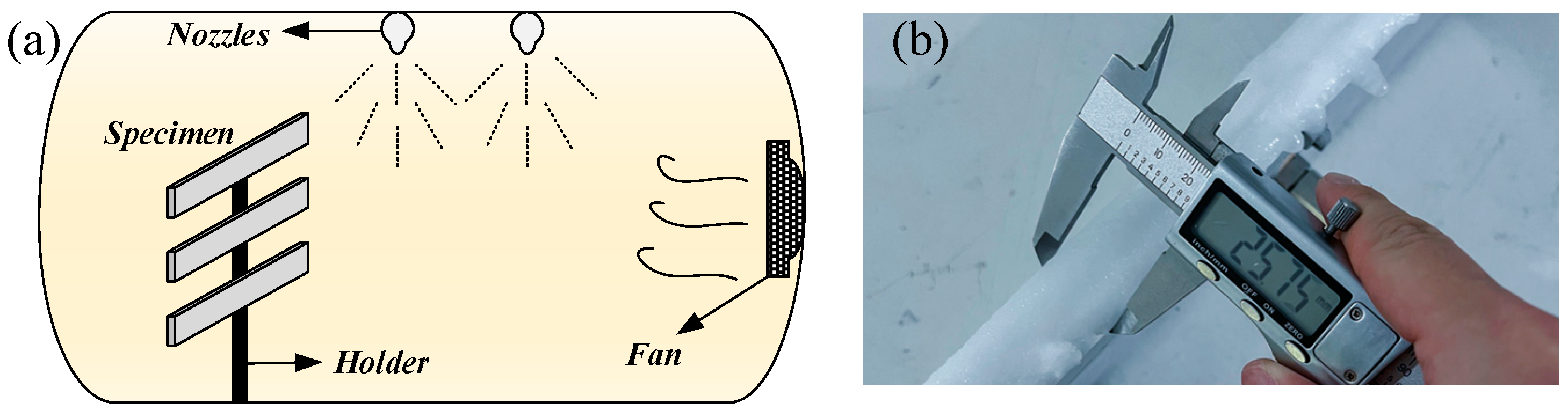

5.1. Experiment Facility and Specimen

5.2. Experiment Procedure

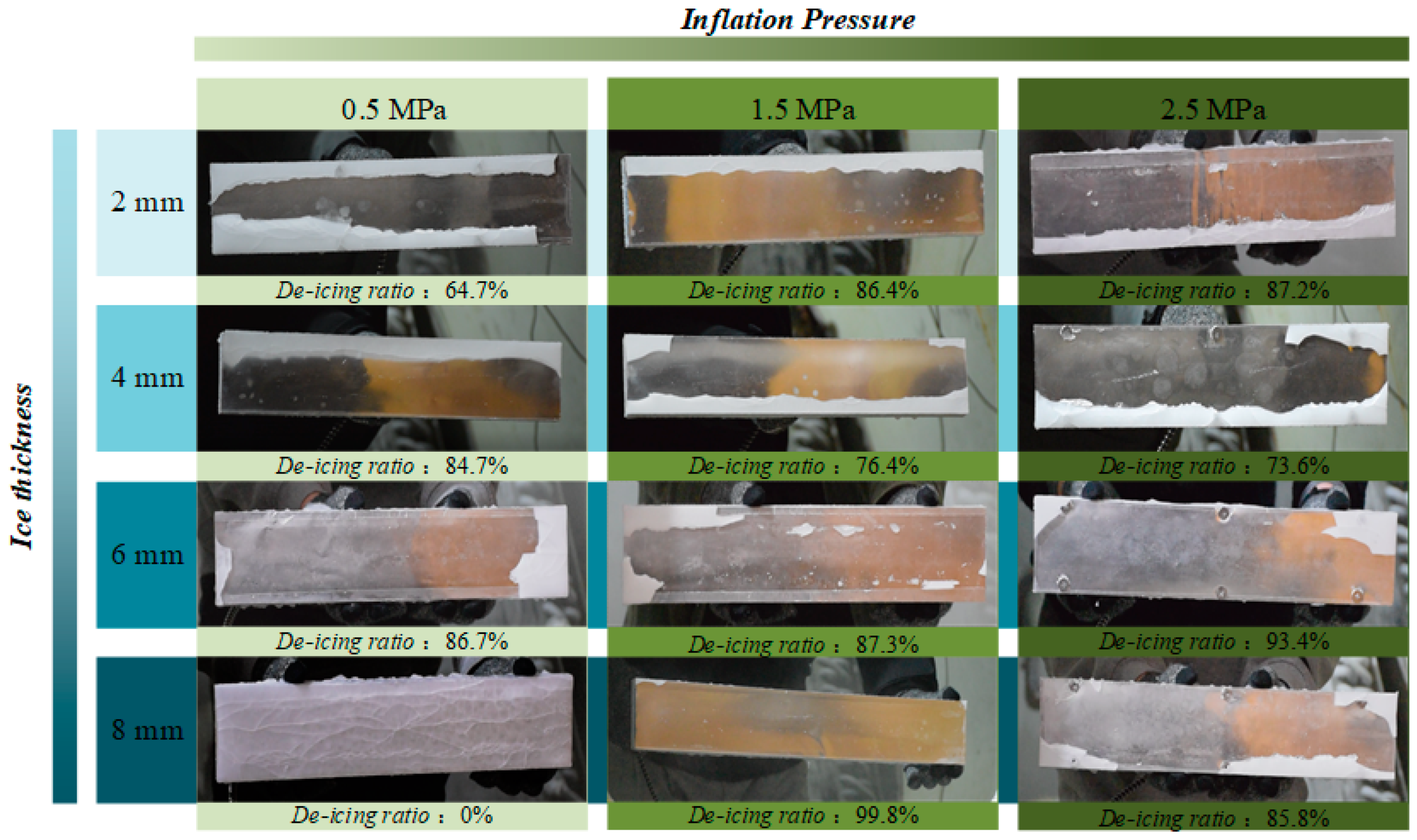

5.3. Deicing Test Results

6. Conclusions

- (1)

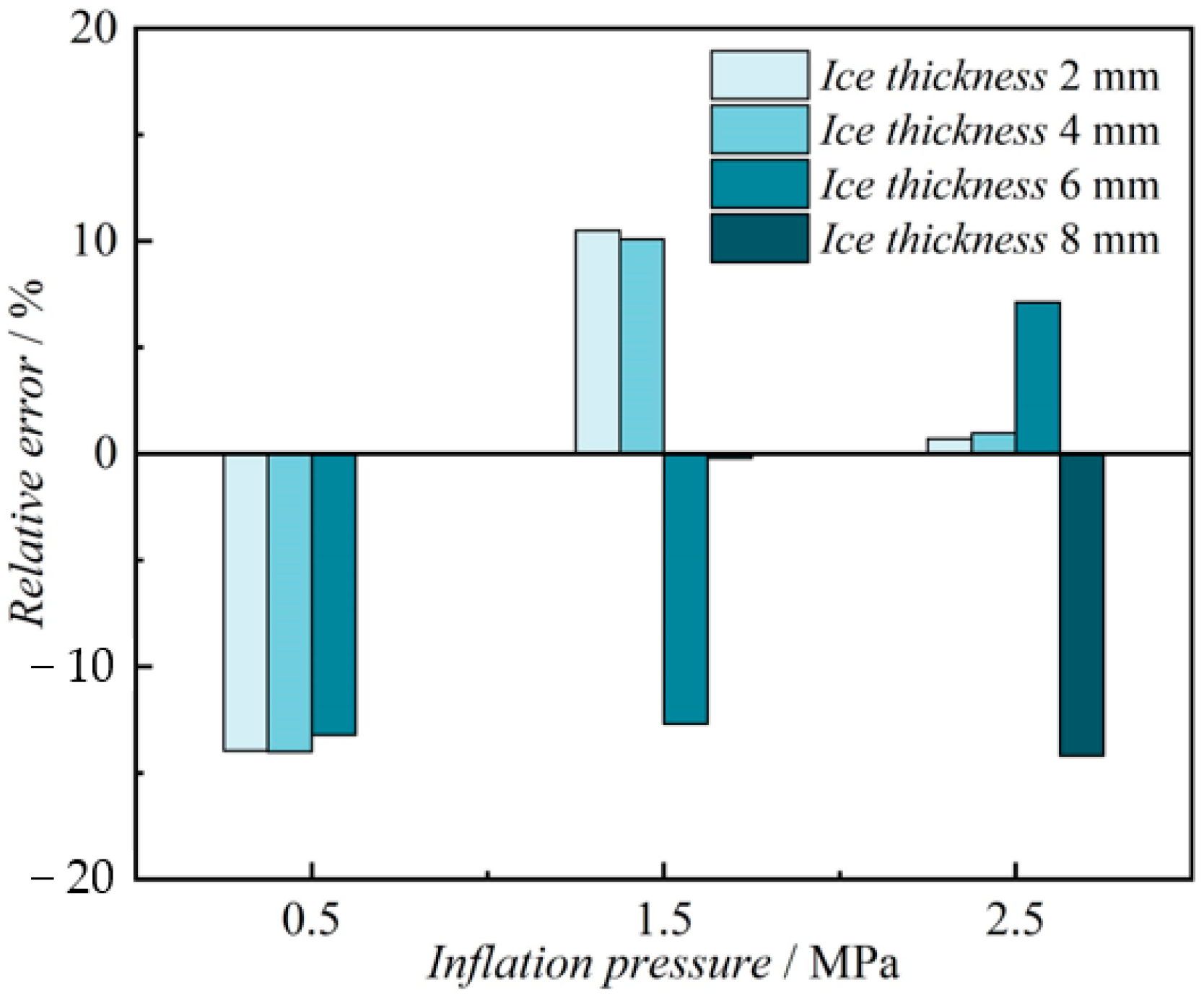

- The experimental results are consistent with the numerical simulation results, and the maximum absolute relative error of the deicing ratio is 14.1%. Comparative analyses of the numerical and experimental results verify that the pneumatic impulse deicing structure can eliminate the ice layer with smaller displacement and shorter time than the conventional pneumatic deicing boot.

- (2)

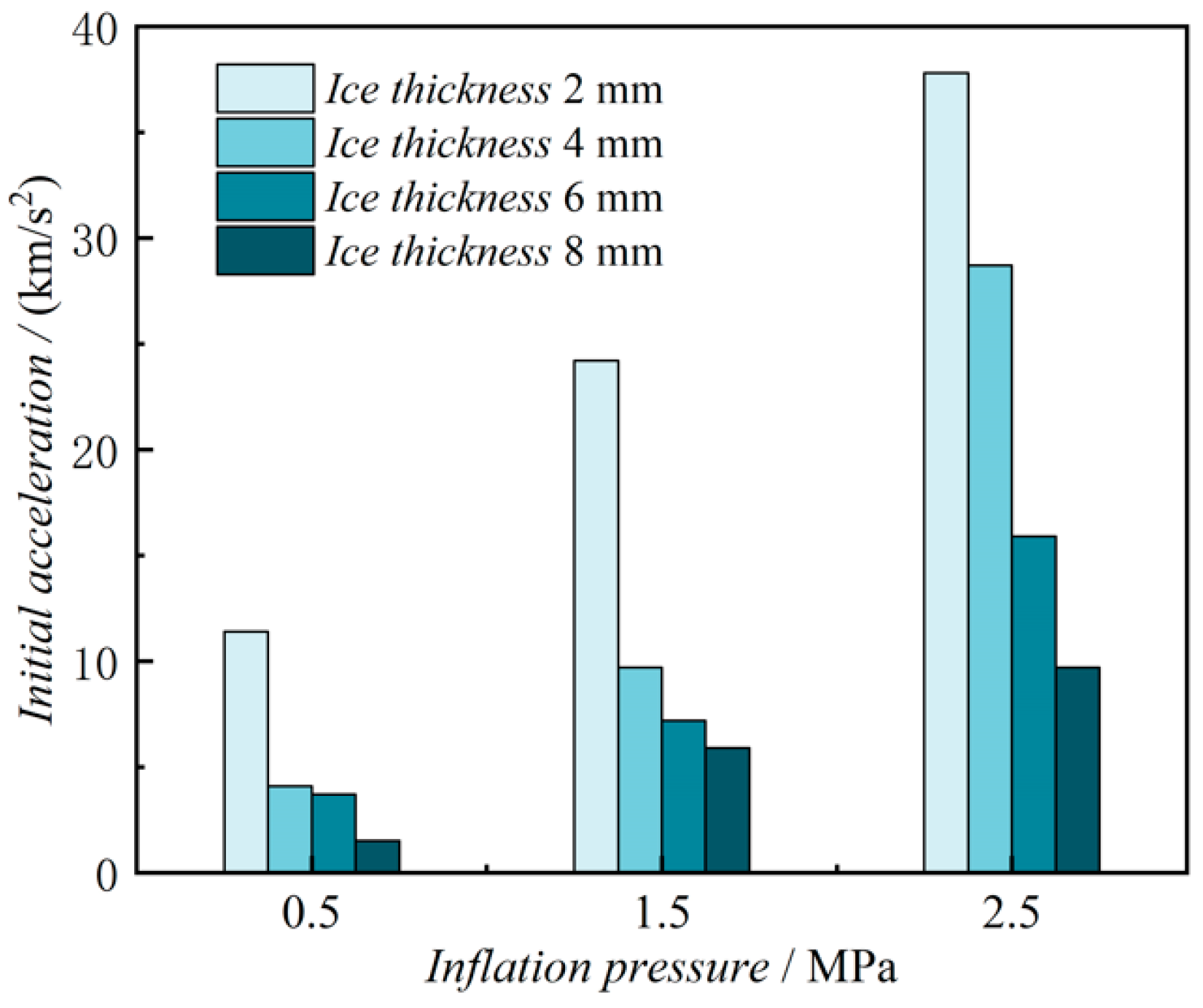

- Simulation and experimental results indicate that the pneumatic deicing structure performs better under an ice thickness of 6 mm or 8 mm and an inflation pressure of 1.5 MPa or 2.5 MPa. The main reason for this phenomenon is that the ice layer is difficult to break off near the edges, and the middle ice layer will drag the ice layer on the edges off as a whole. In practical application, the deicing operation could be launched when the ice thickness reached a certain value, usually 6 mm, and the pneumatic impulse deicing method would perform better.

- (3)

- Although using 0.5 MPa inflation pressure could reduce the pressure charge time and save energy, according to the experiment results, the deicing performances are worse than the simulation results due to the fast dissipation. Therefore, a higher inflation pressure, such as 1.5 MPa or 2.5 MPa, is recommended in practical application.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Shu, L.; Qiu, G.; Hu, Q.; Jiang, X.; McClure, G.; Yang, H. Numerical and field experimental investigation of wind turbine dynamic de-icing process. J. Wind Eng. Ind. Aerodyn. 2018, 175, 90–99. [Google Scholar] [CrossRef]

- Han, Y.; Palacios, J.; Schmitz, S. Scaled ice accretion experiments on a rotating wind turbine blade. J. Wind. Eng. Ind. Aerodyn. 2012, 109, 55–67. [Google Scholar] [CrossRef]

- Fakorede, O.; Feger, Z.; Ibrahim, H.; Ilinca, A.; Perron, J.; Masson, C. Ice protection systems for wind turbines in cold climate: Characteristics, comparisons and analysis. Renew. Sustain. Energy Rev. 2016, 65, 662–675. [Google Scholar] [CrossRef]

- Hu, L.; Zhu, X.; Hu, C.; Chen, J.; Du, Z. Wind turbines ice distribution and load response under icing conditions. Renew. Energy 2017, 113, 608–619. [Google Scholar] [CrossRef]

- Lamraoui, F.; Fortin, G.; Benoit, R.; Perron, J.; Masson, C. Atmospheric icing impact on wind turbine production. Cold Reg. Sci. Technol. 2014, 100, 36–49. [Google Scholar] [CrossRef]

- Wang, Y.; Xu, Y.; Su, F. Damage accumulation model of ice detach behavior in ultrasonic de-icing technology. Renew. Energy 2020, 153, 1396–1405. [Google Scholar] [CrossRef]

- Wei, K.; Yang, Y.; Zuo, H.; Zhong, D. A review on ice detection technology and ice elimination technology for wind turbine. Wind Energy 2020, 3, 433–457. [Google Scholar] [CrossRef]

- Qin, C.; Mulroney, A.T.; Gupta, M.C. Anti-icing epoxy resin surface modified by spray coating of PTFE Teflon particles for wind turbine blades. Mater. Today Commun. 2020, 22, 100770. [Google Scholar] [CrossRef]

- Bhushan, B.; Multanen, V. Designing liquid repellent, icephobic and self-cleaning surfaces with high mechanical and chemical durability. Philos. Trans. R. Soc. A-Math. Phys. Eng. Sci. 2019, 377, 20180270. [Google Scholar] [CrossRef]

- Parent, O.; Ilinca, A. Anti-icing and de-icing techniques for wind turbines: Critical review. Cold Reg. Sci. Technol. 2011, 65, 88–96. [Google Scholar] [CrossRef]

- Roberge, P.; Lemay, J.; Ruel, J.; Bégin-Drolet, A. Field analysis, modeling and characterization of wind turbine hot air ice protection systems. Cold Reg. Sci. Technol. 2019, 163, 19–26. [Google Scholar] [CrossRef]

- Liu, X.; Zhao, Y.; Liu, W.; Yan, D. Microwave heating and deicing efficiency for asphalt concrete with SiC–Fe3O4 microwave enhanced functional layer. J. Clean. Prod. 2021, 332, 130111. [Google Scholar] [CrossRef]

- Ha, J.-H.; Hong, S.-K.; Ryu, J.-K.; Bae, J.; Park, S.-H. Development of Multi-Functional Graphene Polymer Composites Having Electromagnetic Interference Shielding and De-Icing Properties. Polymers 2020, 11, 2101. [Google Scholar] [CrossRef]

- Shu, L.; Qiu, G.; Hu, Q.; Jiang, X.; McClure, G.; Liu, Y. Numerical and experimental investigation of threshold de-icing heat flux of wind turbine. J. Wind. Eng. Ind. Aerodyn. 2018, 174, 296–302. [Google Scholar] [CrossRef]

- Zhao, Z.; Chen, H.; Liu, X.; Wang, Z.; Zhu, Y.; Zhou, Y. The development of electric heating coating with temperature controlling capability for anti-icing/deicing. Cold Reg. Sci. Technol. 2021, 184, 103234. [Google Scholar] [CrossRef]

- Wang, Y.; Jiang, X. Design Research and Experimental Verification of the Electro-Impulse De-Icing System for Wind Turbine Blades in the Xuefeng Mountain Natural Icing Station. IEEE Access 2020, 8, 28915–28924. [Google Scholar] [CrossRef]

- Wang, Y.; Xu, Y.; Lei, Y. An effect assessment and prediction method of ultrasonic de-icing for composite wind turbine blades. Renew. Energy 2018, 118, 1015–1023. [Google Scholar] [CrossRef]

- Daniliuk, V.; Xu, Y.; Liu, R.; He, T.; Wang, X. Ultrasonic de-icing of wind turbine blades: Performance comparison of perspective transducers. Renew. Energy 2020, 145, 2005–2018. [Google Scholar] [CrossRef]

- Shi, Z.; Zhao, Y.; Ma, C.; Zhang, J. Parametric Study of Ultrasonic De-Icing Method on a Plate with Coating. Coatings 2020, 10, 631. [Google Scholar] [CrossRef]

- Yamazaki, M.; Jemcov, A.; Sakaue, H. A Review on the Current Status of Icing Physics and Mitigation in Aviation. Aerospace 2021, 8, 188. [Google Scholar] [CrossRef]

- Thomas, S.K.; Cassoni, R.P.; MacArthur, C.D. Aircraft anti-icing and de-icing techniques and modeling. J. Aircr. 1996, 33, 841–854. [Google Scholar] [CrossRef]

- Weisend, N.A. Design of an advanced pneumatic deicer for the composite rotor blade. J. Aircr. 1989, 26, 947–950. [Google Scholar] [CrossRef]

- Palacios, J.; Wolfe, D.; Bailey, M.; Szefi, J. Ice Testing of a Centrifugally Power Pneumatic deicing system for helicopter rotor blades. J. Am. Helicopter Soc. 2016, 60, 1–12. [Google Scholar] [CrossRef]

- Laforte, C.; Laforte, J.-L. Deicing Strains and Stresses of Iced Substrates. J. Adhes. Sci. Technol. 2012, 26, 603–620. [Google Scholar] [CrossRef]

- Dong, W.; Ding, J.; Zhou, Z. Experimental Study on the Ice Freezing Adhesive Characteristics of Metal Surfaces. J. Aircr. 2014, 51, 719–726. [Google Scholar] [CrossRef]

- Schulson, E. The brittle compressive fracture of ice. Acta Metall. Mater. 1990, 38, 1963–1976. [Google Scholar] [CrossRef]

- Schulson, E.M.; Iliescu, D.; Renshaw, C.E. On the initiation of shear faults during brittle compressive failure: A new mechanism. J. Geophys. Res. Solid Earth 1999, 104, 695–705. [Google Scholar] [CrossRef]

- Petrovic, J.J. Review Mechanical properties of ice and snow. J. Mater. Sci. 2003, 38, 1–6. [Google Scholar] [CrossRef]

- Georges, D.; Saletti, D.; Montagnat, M.; Forquin, P.; Hagenmuller, P. Infuence of Porosity on Ice Dynamic Tensile Behavior as Assessed by Spalling Test. J. Dyn. Behav. Mater. 2021, 7, 575–590. [Google Scholar] [CrossRef]

- Shu, L.; Li, H.; Hu, Q.; Jiang, X.; Qiu, G.; McClure, G.; Yang, H. Study of ice accretion feature and power characteristics of wind turbines at natural icing environment. Cold Reg. Sci. Technol. 2018, 147, 45–54. [Google Scholar] [CrossRef]

| Brittle Cracking | Brittle Shear | Failure Displacement | ||

|---|---|---|---|---|

| Cracking Stress | Cracking Strain | Retention Factor | Opening Strain | |

| 0.27 | 5 × 10−5 | 5 × 10−5 | 1 | 1 × 10−4 |

| Parameters | Ice Layer | Metal Skin | Elastomer |

|---|---|---|---|

| Density/g/cm3 | 0.92 | 2.7 | 2.0 |

| Elastic modulus/MPa | 1500 | 70,000 | 400 |

| Poisson ration | 0.30 | 0.33 | 0.34 |

| Length × width × thickness/mm | 100 × 40 × 2 (4, 6, 8) | 100 × 40 × 0.05 | 100 × 30 × 2 |

| Icing Parameters | Temperature | Wind Velocity | Liquid Water Content |

|---|---|---|---|

| Value | −4~−8 °C | 5.0~8.0 m/s | 0.24~0.32 g/m3 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Shu, L.; Yu, Z.; Hu, Q.; Jiang, X. Numerical and Experimental Investigations of Deicing Performance for the Pneumatic Impulse Deicing Method. J. Mar. Sci. Eng. 2023, 11, 1371. https://doi.org/10.3390/jmse11071371

Shu L, Yu Z, Hu Q, Jiang X. Numerical and Experimental Investigations of Deicing Performance for the Pneumatic Impulse Deicing Method. Journal of Marine Science and Engineering. 2023; 11(7):1371. https://doi.org/10.3390/jmse11071371

Chicago/Turabian StyleShu, Lichun, Zhou Yu, Qin Hu, and Xingliang Jiang. 2023. "Numerical and Experimental Investigations of Deicing Performance for the Pneumatic Impulse Deicing Method" Journal of Marine Science and Engineering 11, no. 7: 1371. https://doi.org/10.3390/jmse11071371

APA StyleShu, L., Yu, Z., Hu, Q., & Jiang, X. (2023). Numerical and Experimental Investigations of Deicing Performance for the Pneumatic Impulse Deicing Method. Journal of Marine Science and Engineering, 11(7), 1371. https://doi.org/10.3390/jmse11071371