1.1. Background

In the face of mounting environmental challenges, one critical issue that has emerged as a defining concern for the maritime industry is decarbonization. The global shipping sector, which is responsible for transporting approximately 90% of the world’s goods, plays a pivotal role in international trade and economic prosperity. However, this essential industry has also been a significant contributor to greenhouse gas emissions and climate change. As the consequences of climate change become increasingly evident, the urgency to address maritime decarbonization is reaching a tipping point. Transitioning toward cleaner, more sustainable practices within the maritime sector has become an imperative shared by governments, industry stakeholders, and environmental advocates alike.

Decarbonization within the maritime industry hinges on the seamless coordination of stakeholders in the shipping supply chain. To achieve this, a system capable of monitoring, sharing, and scheduling the operations of each actor becomes essential. One such system is the digital twin, a concept that holds promise as a suitable system for this purpose.

A digital twin represents a virtual counterpart of a physical object, system, or process. It is continually updated with real-time data from its physical counterpart. The term ‘digital twin’ was first introduced at the SME (Society of Manufacturing Engineering) conference in Troy, Michigan in October 2002 [

1]. Initially conceived within the context of product lifecycle management (PLM), the concept evolved over time, transitioning from PLM to the Mirrored Spaces Model, then to the Information Mirroring Model, and finally, in 2010, it assumed the name ‘Digital Twin’ [

2]. The strength of digital twins lies in their ability to replicate tasks performed in the physical world, commencing from the support and operational stages of the product life cycle. Unlike physical spaces with a single instance, their power resides in their capacity to manifest an infinite number of instances in the digital realm. Digital twin applications become pertinent when an object system is too complex and vast to construct in a real-scale test facility, thereby mitigating high costs. Examples range from simulating entire cities to ports, airports, and industrial plants. Real-time remote monitoring and effective decision-making are facilitated with the development of digital twin cities (DTCs), underpinned by core technologies such as surveying and mapping, building information modeling, 5G-enabled Internet of Things (IoT), blockchain, and collaborative computing [

3]. The concept of DTCs holds the potential to enhance not only urban planning, disaster management, construction, and transportation but also the efficiency and sustainability of logistics, energy consumption, and communication.

Given the colossal scale of maritime shipping chain components, conducting tests for informed decision-making is exceedingly challenging. For instance, when managers at a container terminal seek to experiment with a trial scheme to reduce carbon emissions from vessels berthing at the terminal by developing a berth allocation policy, they face formidable financial barriers to conducting validation tests with real ships and berths, as real-scale operational trials incur substantial costs. In contrast, a digital twin model that can be used for simulation testing is a more cost-effective alternative, requiring only the initial investment to construct the model.

Maritime shipping plays an indispensable role in global trade. However, it also exerts a significant influence on greenhouse gas emissions, which are a primary driver of climate change. In 2018, the International Maritime Organization (IMO) reported that shipping accounted for approximately 2.89% of the global greenhouse gas emissions [

4]. As the demand for maritime shipping continues to surge, emissions follow suit, presenting a considerable predicament for the shipping industry. The industry must now seek solutions to curtail emissions while upholding its essential role in global trade. Recent regulations on CO

2 emissions have been reinforced on a global scale. To counterbalance the cumulative greenhouse gases released into the atmosphere by numerous vessels, the IMO introduced new CO

2 regulations aimed at steering the maritime shipping chain toward “net-zero” emissions during the 80th MEPC (Marine Environment Protection Committee) meeting. Concurrently, the European Union (EU) imposed additional taxes on vessels emitting CO

2 while sailing in EU waters.

The significance of digital twins extends beyond shipping and encompasses port infrastructures as well. A port digital twin serves as a digital replica of a physical port in the real world, encompassing vessels, quay cranes, yard tractors, and hinterland transportation. These digital models allow port stakeholders to monitor and forecast operational efficiency in real time, thereby reducing energy consumption and promoting greener port operations. Moreover, digital twins enable the identification of optimal energy efficiency measures using simulation and data analysis, contributing to emissions reduction and the realization of sustainable port operations. Consequently, a port digital twin is recognized as an indispensable element in attaining carbon neutrality at the port level.

In contrast with the conventional berth planning method used in commercial digital port solutions, which does not incorporate real-time data from moving objects such as ships, terminal equipment, and hinterland transportation, the digital twin model proposed in this study leverages current data for real-time-based simulation and decision-making, thus eliminating time delays. This approach enables efficient operation planning using real-time-based simulation and forecasting.

This study implements a port digital twin to reduce CO2 emissions from vessels and terminals. It showcases the simulation model, the data structure, and case studies that compare CO2 reduction performance with and without the developed digital twin. Furthermore, it presents real terminal case results demonstrating carbon emission reductions achieved with the application of the digital twin at the Pusan Newport International Terminal (PNIT).

1.2. Literature Review

A digital twin is a research field wherein a twin of a real-world physical entity is made in digital space. As complexity and integration become defining characteristics of various subsystems, the demand for digital twins continues to grow. Particularly, digital twins are essential for testing and simulating intricate and interconnected operations. Augustine [

5] underscored the application of digital twins in diverse projects, including space initiatives and aircraft development. Taylor et al. [

6] delineated domains where digital twins are useful, with a focus on the manufacturing sector.

Given the intricate dynamics and large-scale operations involving multiple stakeholders such as shipping companies, terminals, tugboats, pilot boats, hinterland trucks, and port authorities, ports represent ideal environments for implementing digital twins. Recent research efforts have aimed to develop specialized digital twins tailored to the unique requirements of port areas. Hofmann and Branding [

7] advocated for the implementation of the Internet of Things (IoT) and cloud-based digital twins to support real-time decision-making in port operations. The International Maritime Organization (IMO) has suggested the adoption of port community systems to enhance communication between ships and ports during recent facilitation committee meetings [

8]. The Digital Container Shipping Association (DCSA) and the Maritime & Port Authority of Singapore (MPA) have also bolstered communication infrastructures between ships and ports to reduce CO

2 emissions and improve ship arrival and departure efficiency [

9]. The digital twin emerges as a pivotal infrastructure for facilitating data exchange between ships and ports, thus enhancing their interaction.

The maritime industry has embraced digital twins as a valuable tool for validation and integrated simulation. For instance, Liu, Zhou et al. [

10] applied digital twin tools to analyze variations in ship voyage performance. Stoumpos et al. [

11] performed research to develop high-fidelity digital twins as integrated models for modeling dual-fuel engines and ship control systems. Gao et al. [

12] harnessed digital twins for automated storage scheduling in container terminals. Wang et al. [

13] integrated digital twins into management infrastructure within smart port contexts. Wang, Hu, and Liu [

14] asserted that digital twins are apt tools for managing shipping industry processes and outlined their potential application in the smart port concept.

Digital twin technology has also made inroads into the shipbuilding industry, primarily for performance analysis. Fonseca and Gaspar [

15] proposed data modeling for digital twin ships. Coraddu et al. [

16] estimated ship fouling using a data-driven digital twin model. Danielsen-Haces [

17] introduced a comprehensive digital twin model for simulating electricity-driven model vessels. Vasstein [

18] proposed a high-fidelity digital twin framework for testing autonomous vessels, while Raza et al. [

19] applied digital twins to an application framework for autonomous ship development.

The existing digital twin research has predominantly focused on either ships [

10,

11,

15,

16,

17,

19] or terminal yards [

7,

12]. Even when digital twins have been proposed for an entire port infrastructure [

13,

14], they often omit critical interfaces between ships, ports, terminals, and dynamic objects. This study strives to establish a coupled operational digital twin platform that facilitates interaction among vessels, terminal assets, and port authorities. Real-world equipment and situational data from actual ports are harnessed to create a functional port digital twin and its associated simulation algorithm.

Research into port call optimization delves into resolving scheduling challenges between ships and ports. Initiatives such as port collaborative decision-making (PortCDM) and just-in-time arrival (JITA) have aimed to reduce ship, tug, and terminal waiting times. Unfortunately, these concepts have not been widely adopted within the industry due to technical limitations of the digital infrastructure among port members and data standardization issues. Jahn and Scheidweiler [

20] sought to optimize port calls by exchanging estimated time of arrivals (ETAs), while Cho et al. [

21] proposed the development of a digital infrastructure to facilitate communication and data sharing among port stakeholders.

Ports represent significant hubs for addressing carbon dioxide emissions, given the substantial emissions from various moving objects such as ships, yard tractors, container trailers, and quay cranes. Congestion among these moving objects exacerbates carbon emissions in ports. To mitigate congestion and reduce excessive carbon emissions, seamless communication between these objects becomes paramount. Sarantakos, Bowkett et al. [

22] introduced digital infrastructure aimed at improving a port’s carbon emissions profile. Alamoush, Ölçer, and Ballini [

23] conducted a review of the existing regulations and incentives for potentially reducing CO

2 emissions in port areas. Both the European Union (EU) and the United States have established emission control areas (ECAs) to regulate gas emissions in nearshore and port areas. Additionally, the IMO’s data collection system (DCS) and the EU’s monitoring, reporting, and verification (MRV) framework have been instrumental in monitoring and controlling CO

2 emissions.

This study’s prime contribution lies in the application of digital twins within the maritime industry, specifically addressing challenges involving terminals, ships, and tugboats. Most previous berth scheduling models primarily focus on one or two elements, often overlooking complex considerations. For instance, Lu and Le [

24] focused on equipment planning in the yard to reduce costs, while Ismail et al. [

25] considered the berth’s surroundings in their berth planning. In order to solve an unexpected delay in a ship’s arrival, which affects berth operation plans in addition to terminal conditions, Du, Xu, and Chen [

26] solved a berth assignment problem by considering the ship’s delay probabilistically. Their study adjusted the time buffer for each ship and supported planner decision-making with a diagram showing the frequency distribution of the time buffer. Xiang, Liu, and Miao [

27] addressed uncertainty in berthing schedules using discrete scenarios and accounting for ship arrival and sailing times. Park, Cho, and Lee [

28] introduced time buffers to accommodate uncertain ship arrival times in berth scheduling.

In contrast to previous studies that often treated ship arrival times as probabilistic or inserted time buffers into plans to account for ship and terminal scheduling uncertainties, this study leverages real-time ship location data for accurate ship arrival time prediction and terminal operation data to plan schedules, considering a terminal’s operational status. By collecting real-time data from ships and terminals and incorporating it into schedule planning, this study enhances operational efficiency using dynamic data integration. Compared with previous port call optimization research, this study distinguishes itself by focusing on schedule optimization among ships, terminals, and tugboats, thus encompassing more than just terminal yard scheduling problems.

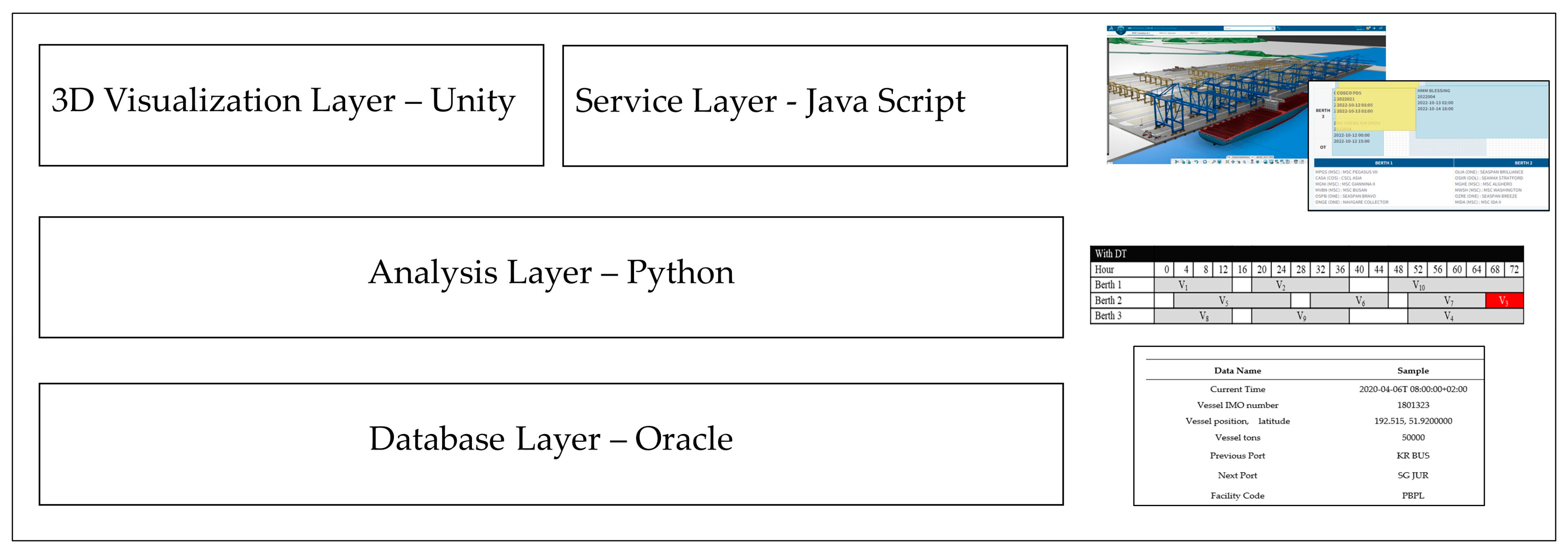

1.3. Physical Asset in the Real World—Pusan Newport International Container Terminal

The focus of this study was the Pusan Newport International Terminal (PNIT) located in the Busan New Port of South Korea, which is recognized as the seventh largest container port globally. In 2022, the volume of containers handled at the Busan port amounted to approximately 22 million. To construct a fully operational technical system for the digital twin, real-time operational data from PNIT was harnessed. The development of this system was underpinned by various technologies: Unity for 3D object visualization, the Oracle Database for database management, Java for web application development, and Python for simulation modeling, as illustrated in

Figure 1.

Geographic and climatic data, including geometric details, weather forecasts, bathymetry, and static and dynamic elements of PNIT, were transformed into digital representations. Dynamic elements included vessels, quay cranes, yard cranes, yard tractors, and containers, with PNIT typically accommodating 400 vessel arrivals and handling an average of 8,000,000 containers per year. PNIT boasts a 1.2 km quay wall and 27-yard blocks for container stacking.

Figure 2 provides an overhead view of the case study, highlighting the PNIT terminal within the broader context of the Busan New Port.

Figure 3 illustrates the outcome of this study, showcasing digitally replicated dynamic elements such as vessels, cranes, containers, buildings, roads, gateways, and trailers.

The initial step in this study involved digitally reproducing all real physical assets within the digital twin model. The selection of these digital assets was driven by their capacity to emulate real-world phenomena.

Table 1 lists the digital assets incorporated into the target digital twin.

Figure 4 showcases a representative digital twin model from

Table 1, including ships, yard cranes, and quay cranes. Each digital asset’s position, speed, and identification were meticulously recorded within the digital twin. Additionally, each object features a cost model that calculated the performance of the digital twin.

Traditional port system scheduling often operates independently in silos, where the actions of one object do not correspond with others. When delays occur, other related objects can become idle while waiting for congestion to subside, which can exacerbate CO

2 emissions. Recognizing this issue, the concept of chained scheduling has been proposed by multiple authors [

13,

14] to address downtime. For instance, when unexpected delays due to weather or prior port conditions occur, a ship may inform the terminal operator and shipping agent via email. However, if changing the original berth schedule to accommodate the delay is more efficient, but the terminal operator cannot make the change without confirmation from another shipper, it becomes challenging to resolve this issue within the current system. Nevertheless, digital twins (DTs) offer a potential solution. DTs can be accessible to all port members, including the port, terminal, and tug operators. This open platform allows everyone to monitor ship arrivals and departures and share their schedules with others using the DT schedule model. Such a system can serve as a valuable tool for collaborative scheduling among port stakeholders.