Underwater Line Monitoring Using Optimally Placed Inclinometers

Abstract

:1. Introduction

2. Method

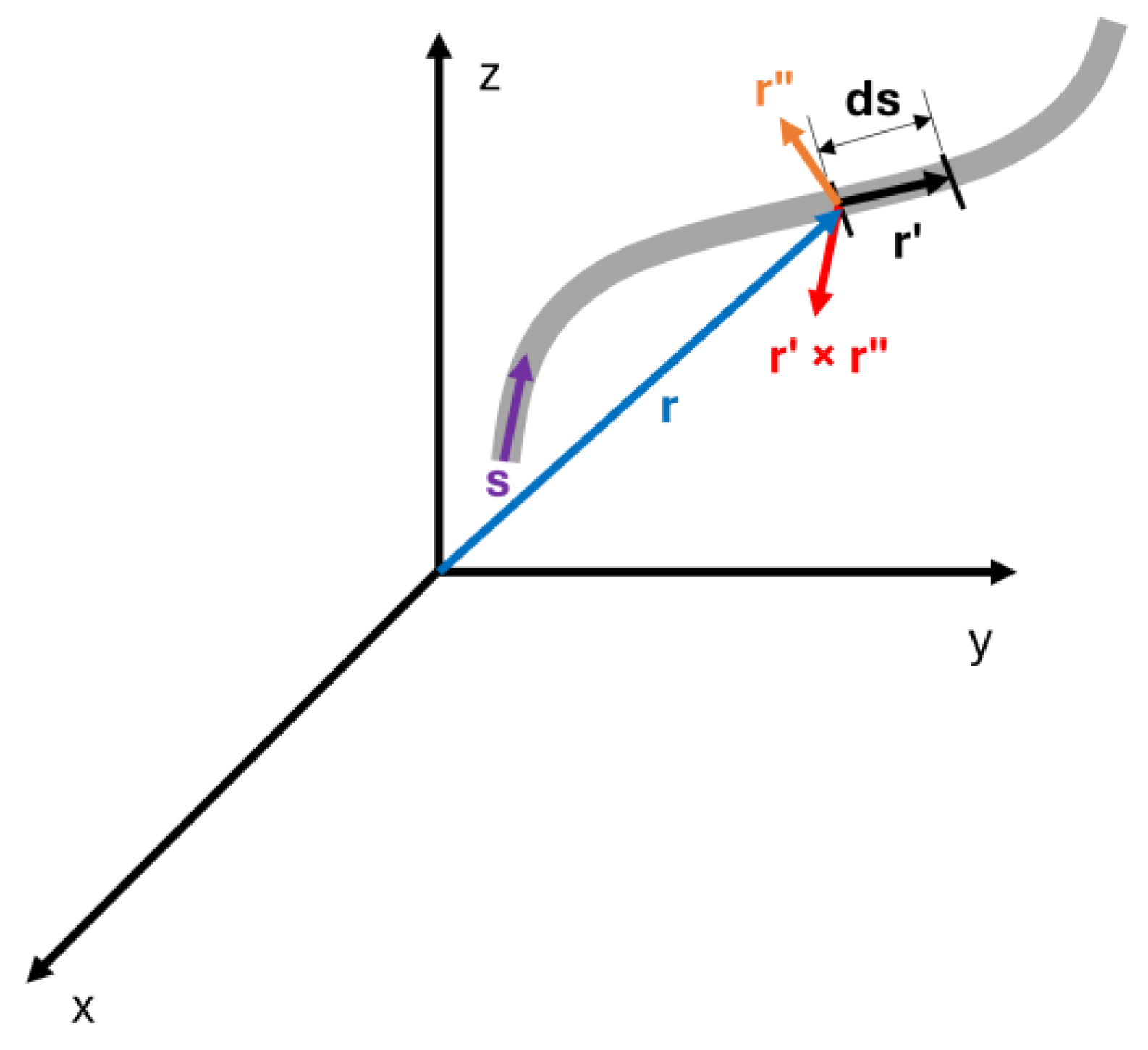

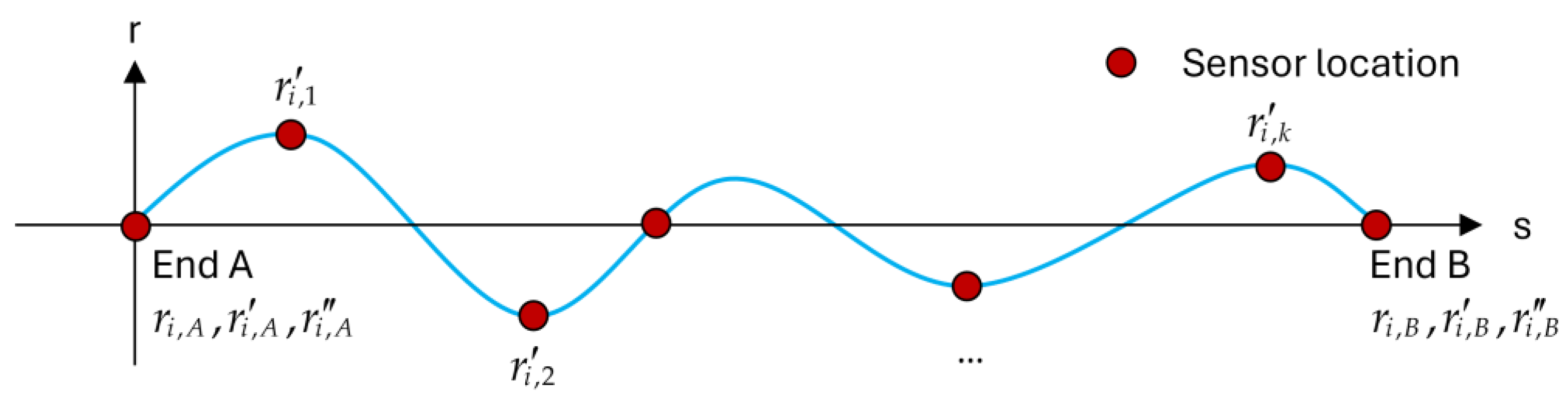

2.1. Line Monitoring Method

2.2. Optimization

3. Case Studies

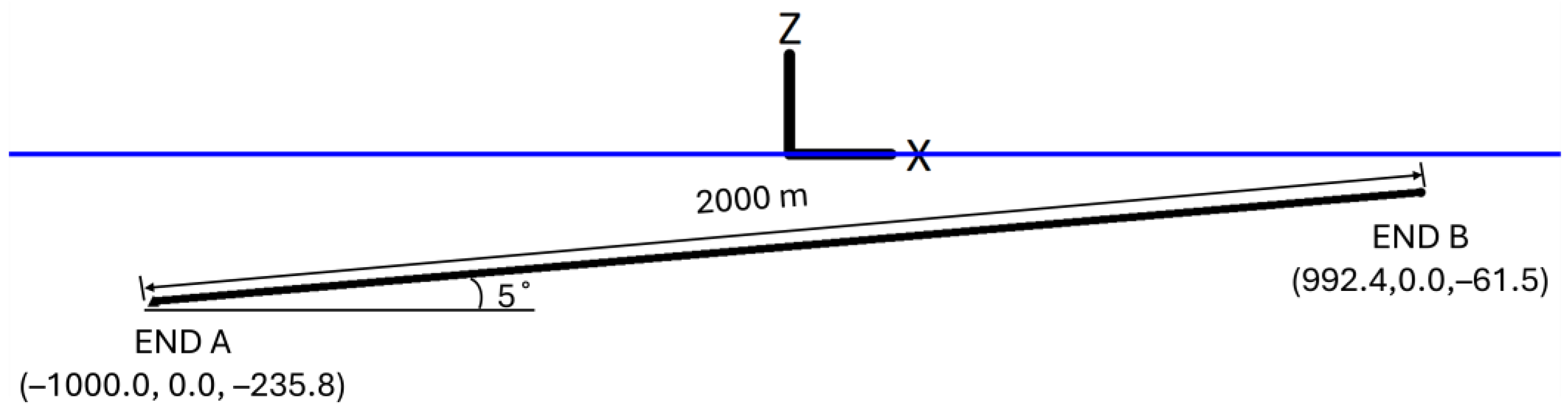

3.1. Case Study I: Underwater Inclined Tunnel

3.1.1. Case Description

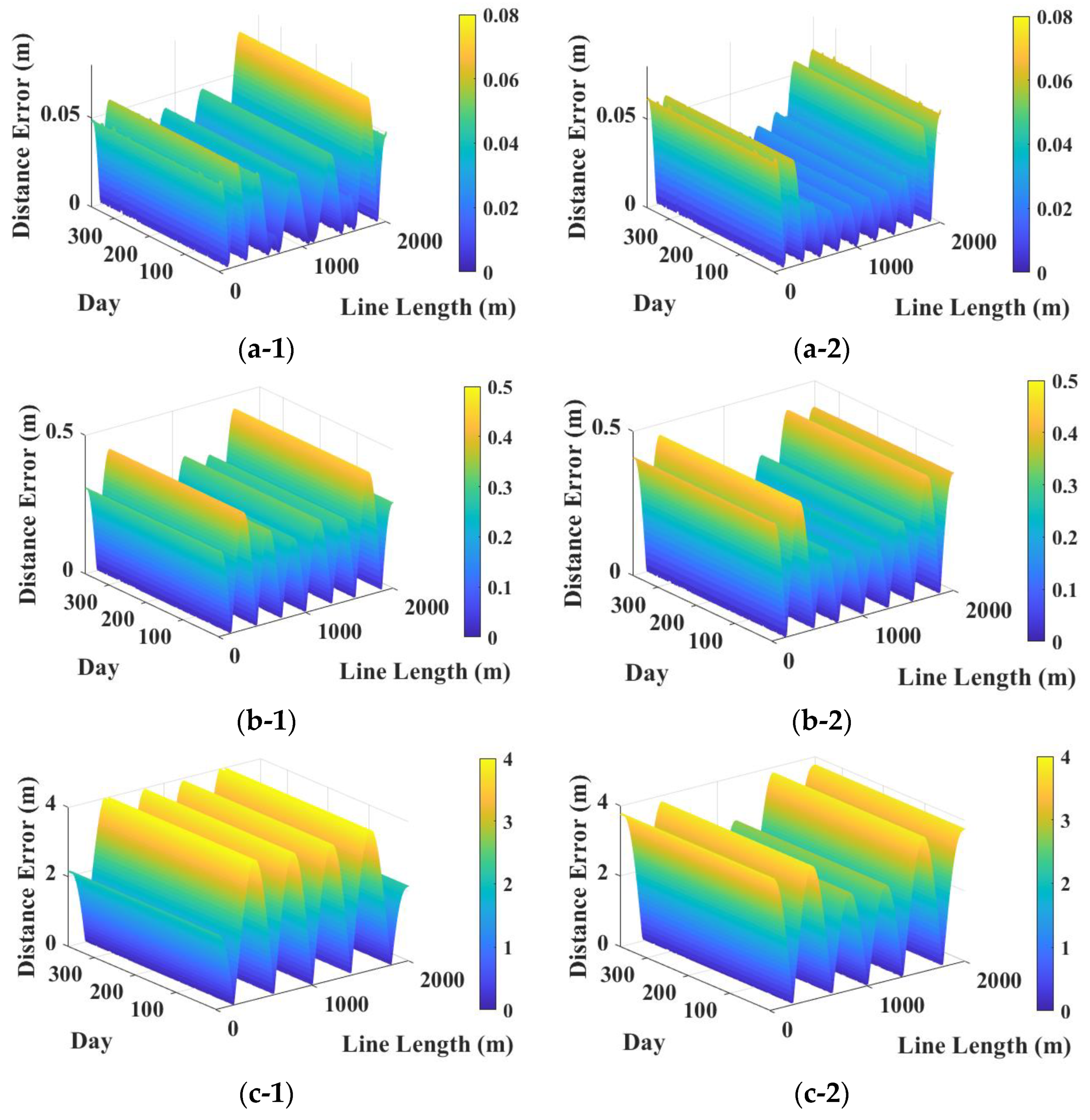

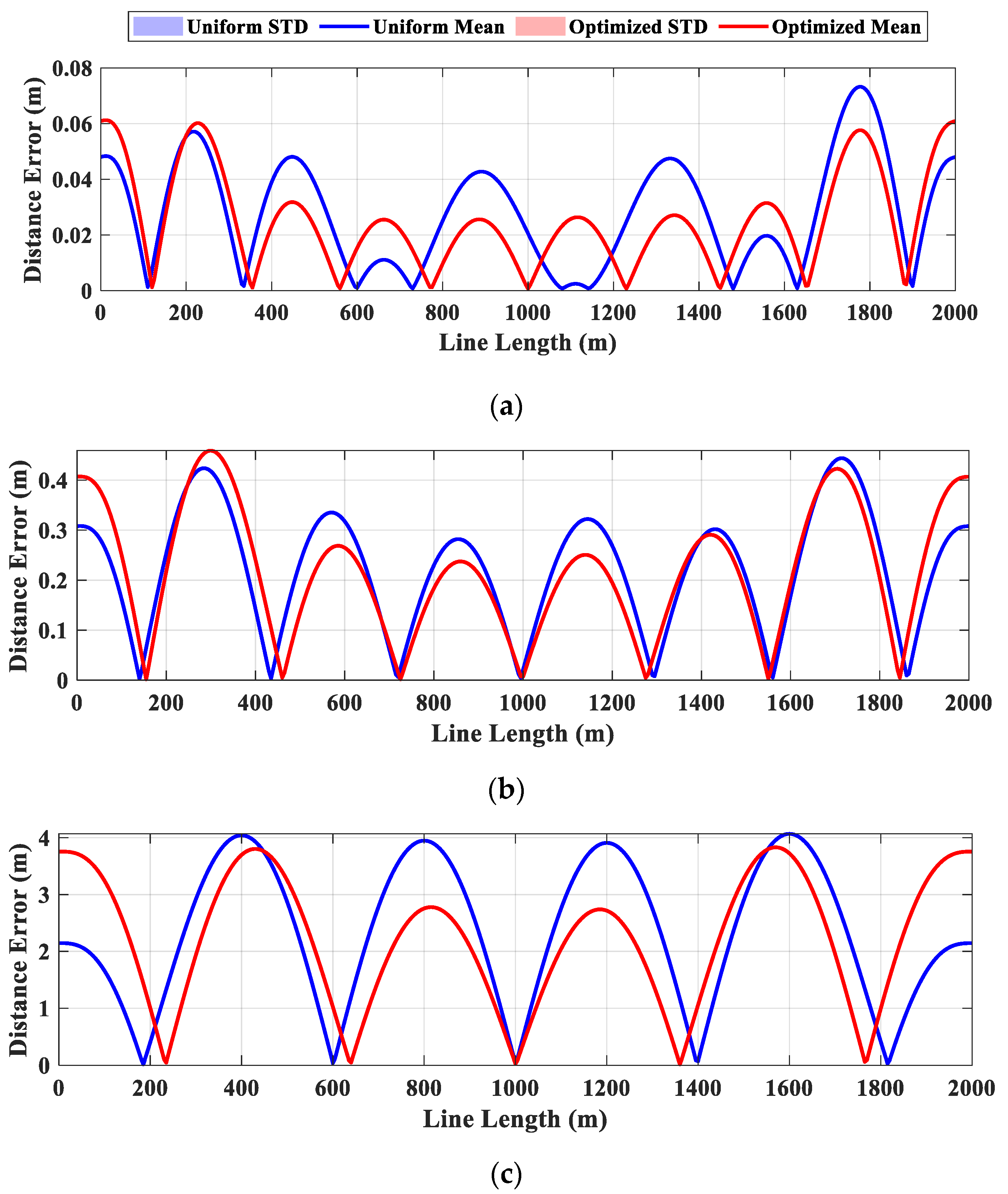

3.1.2. Results and Discussion

3.2. Case Study II: Steel Catenary Riser Attached to Floating Production Storage and Offloading Vessel

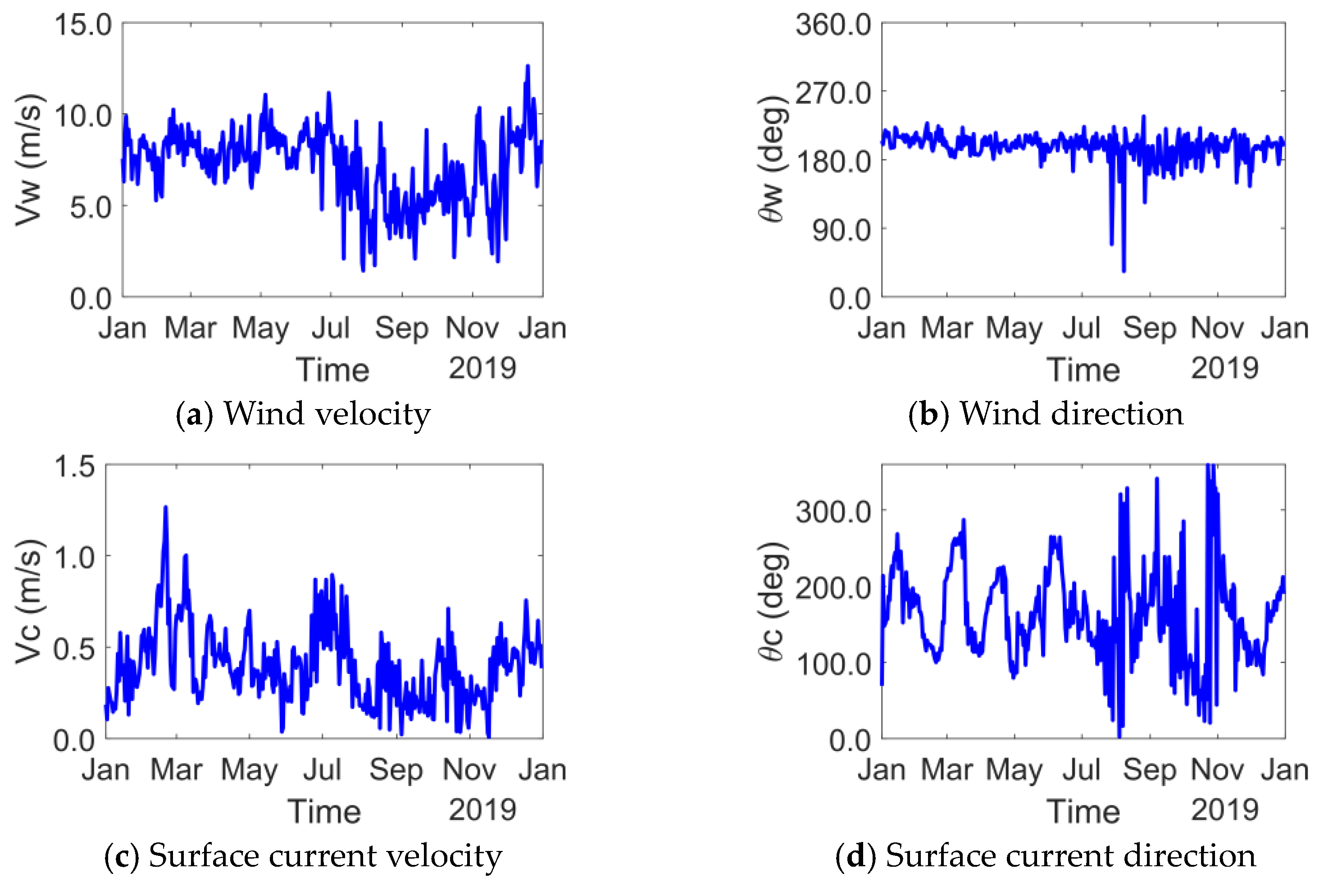

3.2.1. Case Description

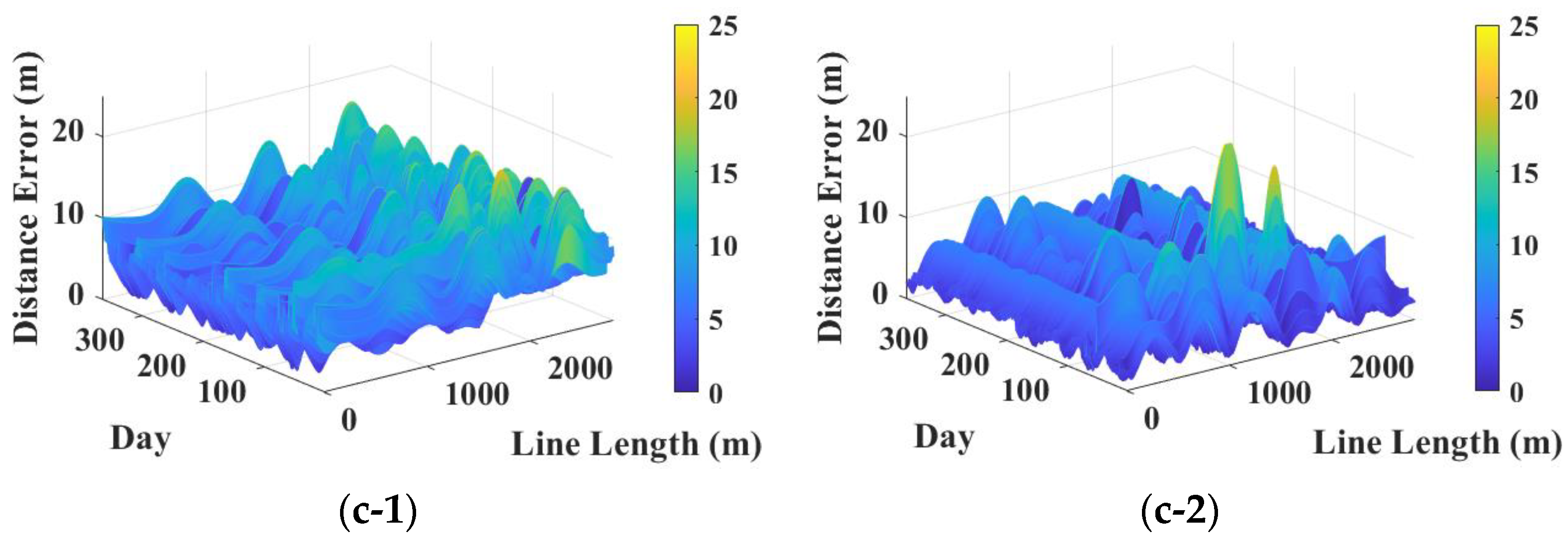

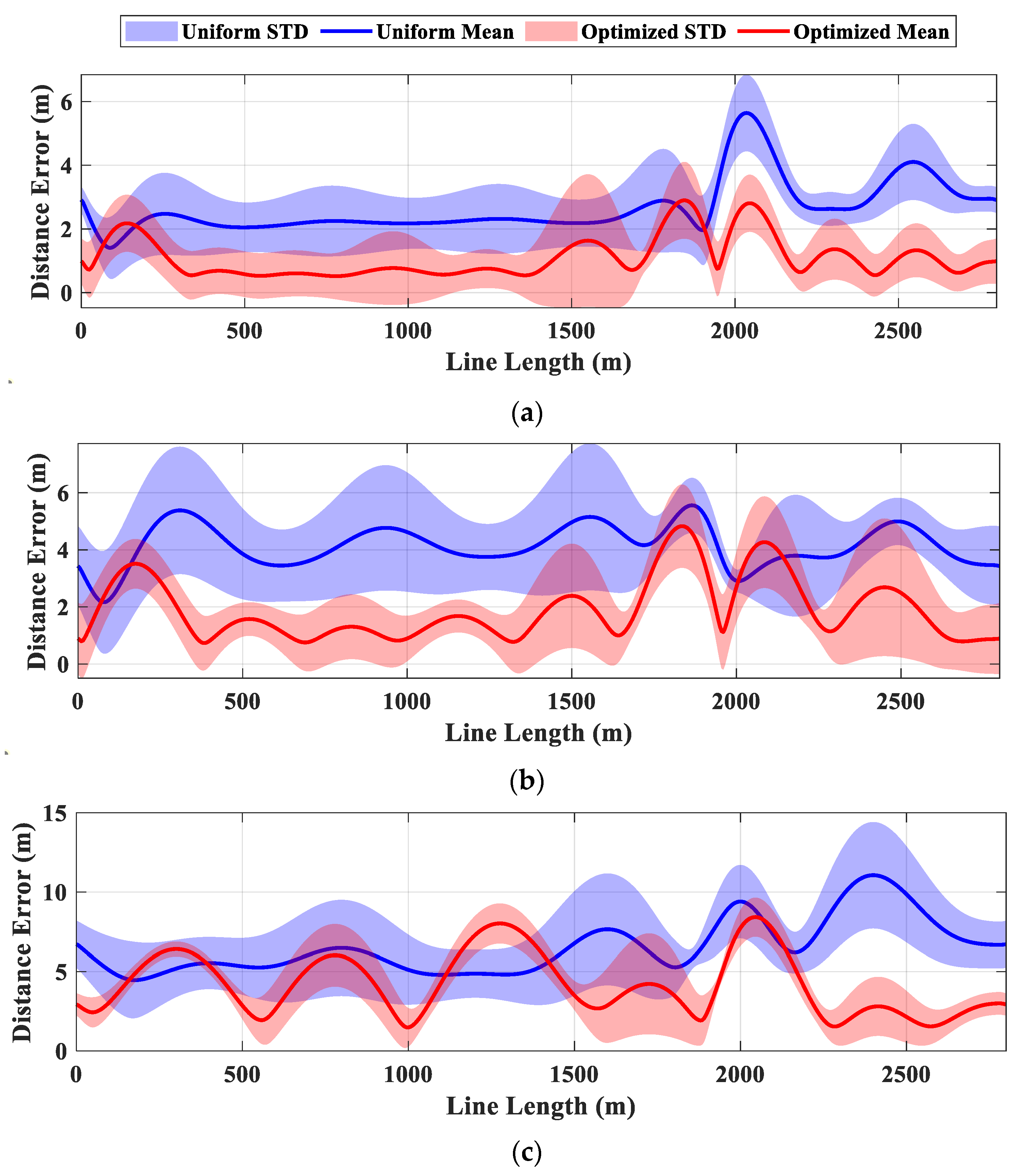

3.2.2. Results and Discussion

4. Conclusions

- Increasing the number of sensors improved accuracy by capturing critical line excitations more effectively.

- For Case Study I, optimization yields only marginal improvements. This is due to the narrow frequency range of input loads, which involves only wave-induced forces without second-order wave loads, the absence of initial curvature or discontinuities in the tunnel shape, and the sinusoidal-like dominant mode shapes under the given configuration and boundary conditions. These factors lead to large displacements around uniformly distributed sensor locations, diminishing the benefit of optimization.

- For Case Study II, optimization significantly improves accuracy. The large standard deviation fluctuations observed in Case Study II are attributed to the riser’s highly curved initial shape, minor discontinuities near the touch-down zone, and low- and high-frequency riser excitations from both environmental loads and FPSO motions. These factors make uniform sensor placement less effective, and optimization highlights the importance of identifying the best sensor locations.

- Optimization can reduce the required number of sensors. In Case Study II, the performance of 8 optimally placed intermediate sensors is comparable to that of 10 uniformly distributed intermediate sensors. While previous studies on riser monitoring focused primarily on minimizing the number of sensors, optimizing sensor placement provides a viable alternative for solving this challenge.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Bogue, R. Underwater robots: A review of technologies and applications. Ind. Robot Int. J. 2015, 42, 186–191. [Google Scholar] [CrossRef]

- Huvenne, V.A.; Robert, K.; Marsh, L.; Lo Iacono, C.; Le Bas, T.; Wynn, R.B. ROVs and AUVs. In Submarine Geomorphology; Springer: Cham, Switzerland, 2018; pp. 93–108. [Google Scholar]

- Cruz, N.A.; Matos, A.C.; Almeida, R.M.; Ferreira, B.M.; Abreu, N. TriMARES-a hybrid AUV/ROV for dam inspection. In Proceedings of the OCEANS’11 MTS/IEEE KONA, Waikoloa, HI, USA, 19–22 September 2011; pp. 1–7. [Google Scholar]

- Shilling, R.; Campbell, M.; Howells, H. Drilling riser vortex induced vibration analysis calibration using full scale field data. In Proceedings of the Deep Offshore Tech Conference, Vitoria, Espirito Santo, Brazil, 2–5 May 2005. [Google Scholar]

- Tognarelli, M.A.; Taggart, S.; Campbell, M. Actual VIV fatigue response of full scale drilling risers: With and without suppression devices. In Proceedings of the International Conference on Offshore Mechanics and Arctic Engineering, Estoril, Portugal, 15–20 June 2008; pp. 513–525. [Google Scholar]

- McNeill, S.; Agarwal, P. Efficient modal decomposition and reconstruction of riser response due to VIV. In Proceedings of the International Conference on Offshore Mechanics and Arctic Engineering, Rotterdam, The Netherlands, 19–24 June 2011; pp. 345–354. [Google Scholar]

- Saruhashi, T.; Kluk, D.J.; Kyo, M.; Bhalla, K.; Sawada, I.; Miyazaki, E.; McNeill, S.; Yamazaki, Y. Development of a real-time riser fatigue monitoring system. In Proceedings of the Offshore Technology Conference, Houston, TX, USA, 6–9 May 2013; p. OTC–24216–MS. [Google Scholar]

- Mukundan, H.; Hover, F.; Triantafyllou, M. A systematic approach to riser VIV response reconstruction. J. Fluids Struct. 2010, 26, 722–746. [Google Scholar] [CrossRef]

- Mercan, B.; Campbell, M.; Thompson, C. Fatigue Monitoring and Life Extension for Top Tensioned Production Riser Systems. In Proceedings of the Offshore Technology Conference, Virtual, Houston, TX, USA, 16–19 August 2021; p. D021S017R006. [Google Scholar]

- Bakker, M. An Alternative Methodology for Riser Lifetime Prediction. Master’s Thesis, Department of Offshore Engineering, Delft University of Technology, Delft, The Netherlands, 2011. [Google Scholar]

- Wang, J.; Sheng, L.; Geng, Y.; Wang, M.; Wang, Y.; Li, Y.; Liu, X. Fatigue damage assessment methodology for a deepwater subsea wellhead based on monitoring data. Ships Offshore Struct. 2023, 1–13. [Google Scholar] [CrossRef]

- Ge, M.L.; Kannala, J.; Li, S.; Maheshwari, H.; Campbell, M. A new riser fatigue monitoring methodology based on measured accelerations. In Proceedings of the International Conference on Offshore Mechanics and Arctic Engineering, San Francisco, CA, USA, 8–13 June 2014; p. V06AT04A063. [Google Scholar]

- Mercan, B.; Chandra, Y.; Maheshwari, H.; Campbell, M. Comparison of Riser Fatigue Methodologies Based on Measured Motion Data. In Proceedings of the Offshore Technology Conference, Houston, TX, USA, 2–5 May 2016. [Google Scholar]

- Kim, H.; Jin, C.; Kim, M. Real-time estimation of riser’s deformed shape using inclinometers and Extended Kalman Filter. Mar. Struct. 2021, 77, 102933. [Google Scholar] [CrossRef]

- Choi, J.; Kim, J.M.-H. Development of a new methodology for riser deformed shape prediction/monitoring. In Proceedings of the International Conference on Offshore Mechanics and Arctic Engineering, Madrid, Spain, 17–22 June 2018; p. V005T004A041. [Google Scholar]

- Blondeau, S.; Andre, M.; Garnier, P.; Benmedakhene, S.; Quesnel, J. Riser integrity monitoring system for offshore fields. In Proceedings of the Offshore Technology Conference Asia, Kuala Lumpur, Malaysia, 25–28 March 2014; pp. OTC–24791–MS. [Google Scholar]

- Inaudi, D.; Glisic, B.; Gasparoni, F.; Cenedese, S.; Zecchin, M. Strain sensors for deepwater applications. In Proceedings of the Proceedings of the 3rd International Conference on Structural Health Monitoring of Intelligent Infrastructure, Vancouver, BC, Canada, 13–16 November 2007. [Google Scholar]

- Brower, D.; Hedengren, J.D.; Shishivan, R.A.; Brower, A. Advanced deepwater monitoring system. In Proceedings of the International Conference on Offshore Mechanics and Arctic Engineering, Nantes, France, 9–14 June 2013; p. V001T001A048. [Google Scholar]

- Sundararaman, S.; Thethi, R.; Hill, M. Data driven virtual sensors for riser prognostic integrity management. In Proceedings of the Offshore Technology Conference, Houston, TX, USA, 30 April–3 May 2018; p. D011S014R006. [Google Scholar]

- Repalle, N.; Thethi, R.; Viana, P.; Tellier, E. Application of Machine Learning for Fatigue Prediction of Flexible Risers-Digital Twin Approach. In Proceedings of the SPE Asia Pacific Oil and Gas Conference and Exhibition, Virtual, 17–19 November 2020; p. D013S104R005. [Google Scholar]

- Sivaprasad, H.; Lekkala, M.R.; Latheef, M.; Seo, J.; Yoo, K.; Jin, C. Fatigue damage prediction of top tensioned riser subjected to vortex-induced vibrations using artificial neural networks. Ocean Eng. 2023, 268, 113393. [Google Scholar] [CrossRef]

- Lekkala, M.R.; Latheef, M.; Jung, J.H.; Kim, Y.T. Fatigue damage assessment of offshore riser subjected to vortex-induced vibrations by SHEAR7. Int. J. Nav. Archit. Ocean Eng. 2022, 14, 100464. [Google Scholar] [CrossRef]

- Rombado, G.; Wadhwa, H.; Cooke, N.; Pasala, D.; Paulin, M.; Rao, P.; Majed, A. A Flexible Riser Digital Twin for Real-Time Monitoring and Asset Management. In Proceedings of the SNAME Offshore Symposium, Virtual, 6–7 April 2021; p. D011S002R007. [Google Scholar]

- Chen, M.; Li, C.B.; Han, Z.; Lee, J.-b. A simulation technique for monitoring the real-time stress responses of various mooring configurations for offshore floating wind turbines. Ocean Eng. 2023, 278, 114366. [Google Scholar] [CrossRef]

- Albani, Y.; Cavallini, F.; Girello, E.; Lazzarin, D.; Massari, G.; Novello, M. RIMS: A Fully Integrated Technology for Long-Term Riser Monitoring. In Proceedings of the Offshore Technology Conference Brasil, Rio de Janeiro, Brazil, 24–26 October 2023; p. D011S010R005. [Google Scholar]

- Jin, C.; Kim, M.-H. Tunnel-mooring-train coupled dynamic analysis for submerged floating tunnel under wave excitations. Appl. Ocean Res. 2020, 94, 102008. [Google Scholar] [CrossRef]

- Hong, S.H.; Cornelius, J.; Wang, Y.; Pant, K. Fault compensation by online updating of genetic algorithm-selected neural network model for model predictive control. SN Appl. Sci. 2019, 1, 1–16. [Google Scholar] [CrossRef]

- Lambora, A.; Gupta, K.; Chopra, K. Genetic algorithm-A literature review. In Proceedings of the 2019 International Conference on Machine Learning, Big Data, Cloud and Parallel Computing (COMITCon), Faridabad, India, 14–16 February 2019; pp. 380–384. [Google Scholar]

- Mirjalili, S.; Mirjalili, S. Genetic algorithm. In Evolutionary Algorithms and Neural Networks: Theory and Applications; Springer: Cham, Switzerland, 2019; pp. 43–55. [Google Scholar]

- Katoch, S.; Chauhan, S.S.; Kumar, V. A review on genetic algorithm: Past, present, and future. Multimed. Tools Appl. 2021, 80, 8091–8126. [Google Scholar] [CrossRef] [PubMed]

- Lee, S.-L.; Shin, S.J. Structural design optimization of a wind turbine blade using the genetic algorithm. Eng. Optim. 2022, 54, 2053–2070. [Google Scholar] [CrossRef]

- Owoyele, O.; Pal, P.; Vidal Torreira, A. An automated machine learning-genetic algorithm framework with active learning for design optimization. J. Energy Resour. Technol. 2021, 143, 082305. [Google Scholar] [CrossRef]

- Hamdia, K.M.; Zhuang, X.; Rabczuk, T. An efficient optimization approach for designing machine learning models based on genetic algorithm. Neural Comput. Appl. 2021, 33, 1923–1933. [Google Scholar] [CrossRef]

- Han, S.; Sun, X. Optimizing Product Design using Genetic Algorithms and Artificial Intelligence Techniques. IEEE Access 2024, 12, 151460–151475. [Google Scholar] [CrossRef]

- Orcina, L. OrcaFlex User Manual, Version 11.4; Orcina: Cumbria, UK, 2023. [Google Scholar]

- Jin, C.; Kim, M. The effect of key design parameters on the global performance of submerged floating tunnel under target wave and earthquake excitations. Comput. Model. Eng. Sci. 2021, 128, 315–337. [Google Scholar] [CrossRef]

- Kwon, D.-S.; Kim, S.-J.; Jin, C.; Kim, M.; Guha, A.; Esenkov, O.E.; Ryu, S. Inverse estimation of a vertical current velocity profile using motions of an FPSO and artificial neural network. Ocean Eng. 2023, 285, 115343. [Google Scholar] [CrossRef]

- Cummins, W. The Impulse Response Function and Ship Motions; David Taylor Model Basin: Washington, DC, USA, 1962. [Google Scholar]

- Jin, C.; Kim, S.-J.; Kim, M.; Lee, Y.; Guha, A.; Ryu, S.; Xu, W. Real-time dynamic and structural behavior estimation of a steel lazy wave riser through finite-element-based digital twin and hull-motion sensor. Appl. Ocean Res. 2024, 150, 104137. [Google Scholar] [CrossRef]

| Parameter | Value | Unit |

|---|---|---|

| Length | 2000 | m |

| Outer diameter | 10 | m |

| Shell thickness | 1.22 | m |

| End boundary condition | Hinged boundary condition | - |

| Mass/unit length | 80.5 | t/m |

| BWR | 1.0 | - |

| Axial stiffness | 1.01 × 109 | kN |

| Bending stiffness | 9.89 × 109 | kNm2 |

| Torsional stiffness | 8.24 × 109 | kNm2 |

| Added mass coefficient | 1.0 | - |

| Drag coefficient | 0.55 | - |

| Number of Intermediate Sensors | ||||

|---|---|---|---|---|

| 8 | 6 | 4 | ||

| Average mean distance error | Uniform | 0.0281 m | 0.2230 m | 2.3367 m |

| Optimized | 0.0252 m | 0.2182 m | 2.2234 m | |

| Maximum mean distance error | Uniform | 0.0734 m | 0.4441 m | 4.0695 m |

| Optimized | 0.0641 m | 0.4591 m | 3.8330 m | |

| Parameter | Value | Unit |

|---|---|---|

| Length between perpendicular (Lpp) | 310 | m |

| Breadth (B) | 47.17 | m |

| Depth (H) | 28.04 | m |

| Draft (d) | 18.90 | m |

| Displacement | 240,869 | MT |

| Center of gravity above base (KG) | 13.30 | m |

| Roll radius of gyration at CoG (Rxx) | 14.77 | m |

| Pitch radius of gyration at CoG (Ryy) | 77.47 | m |

| Yaw radius of gyration at CoG (Rzz) | 79.30 | m |

| Heave natural period | 14.62 | s |

| Roll natural period | 12.88 | s |

| Pitch natural period | 11.79 | s |

| Parameter | Value | Unit | |||

|---|---|---|---|---|---|

| Mooring Lines | Steel Catenary Riser | ||||

| Segment 1 (Chain) | Segment 2 (Polyester) | Segment 3 (Chain) | |||

| Length | 120 | 2290 | 90 | 2800 | m |

| Diameter * | 9.52 | 16.0 | 9.52 | 25.4 | cm |

| Mass/unit length | 189.2 | 20.4 | 189.2 | 131.0 | kg/m |

| Axial stiffness | 9.12 × 105 | 2.79 × 104 | 9.12 × 105 | 3.34 × 106 | kN |

| Bending stiffness | - | - | - | 2.25 × 104 | kNm2 |

| Torsional stiffness | - | - | - | 1.84 × 104 | kNm2 |

| Added mass coefficient ** | 1.0 | 1.0 | 1.0 | 1.0 | - |

| Drag coefficient | 2.4 | 1.2 | 2.4 | 1.0 | - |

| Number of Intermediate Sensors | ||||

|---|---|---|---|---|

| 10 | 8 | 6 | ||

| Average mean distance error | Uniform | 2.6512 m | 4.1470 m | 6.5259 m |

| Optimized | 1.0960 m | 1.9135 m | 4.2016 m | |

| Maximum mean distance error | Uniform | 17.7508 m | 15.7451 m | 19.4728 m |

| Optimized | 11.7648 m | 14.6098 m | 25.4105 m | |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Jin, C.; Hong, S.H. Underwater Line Monitoring Using Optimally Placed Inclinometers. J. Mar. Sci. Eng. 2024, 12, 1939. https://doi.org/10.3390/jmse12111939

Jin C, Hong SH. Underwater Line Monitoring Using Optimally Placed Inclinometers. Journal of Marine Science and Engineering. 2024; 12(11):1939. https://doi.org/10.3390/jmse12111939

Chicago/Turabian StyleJin, Chungkuk, and Seong Hyeon Hong. 2024. "Underwater Line Monitoring Using Optimally Placed Inclinometers" Journal of Marine Science and Engineering 12, no. 11: 1939. https://doi.org/10.3390/jmse12111939

APA StyleJin, C., & Hong, S. H. (2024). Underwater Line Monitoring Using Optimally Placed Inclinometers. Journal of Marine Science and Engineering, 12(11), 1939. https://doi.org/10.3390/jmse12111939