Estimation of Effective Internal Friction Angle by Ball Penetration Test: Large-Deformation Analyses

Abstract

1. Introduction

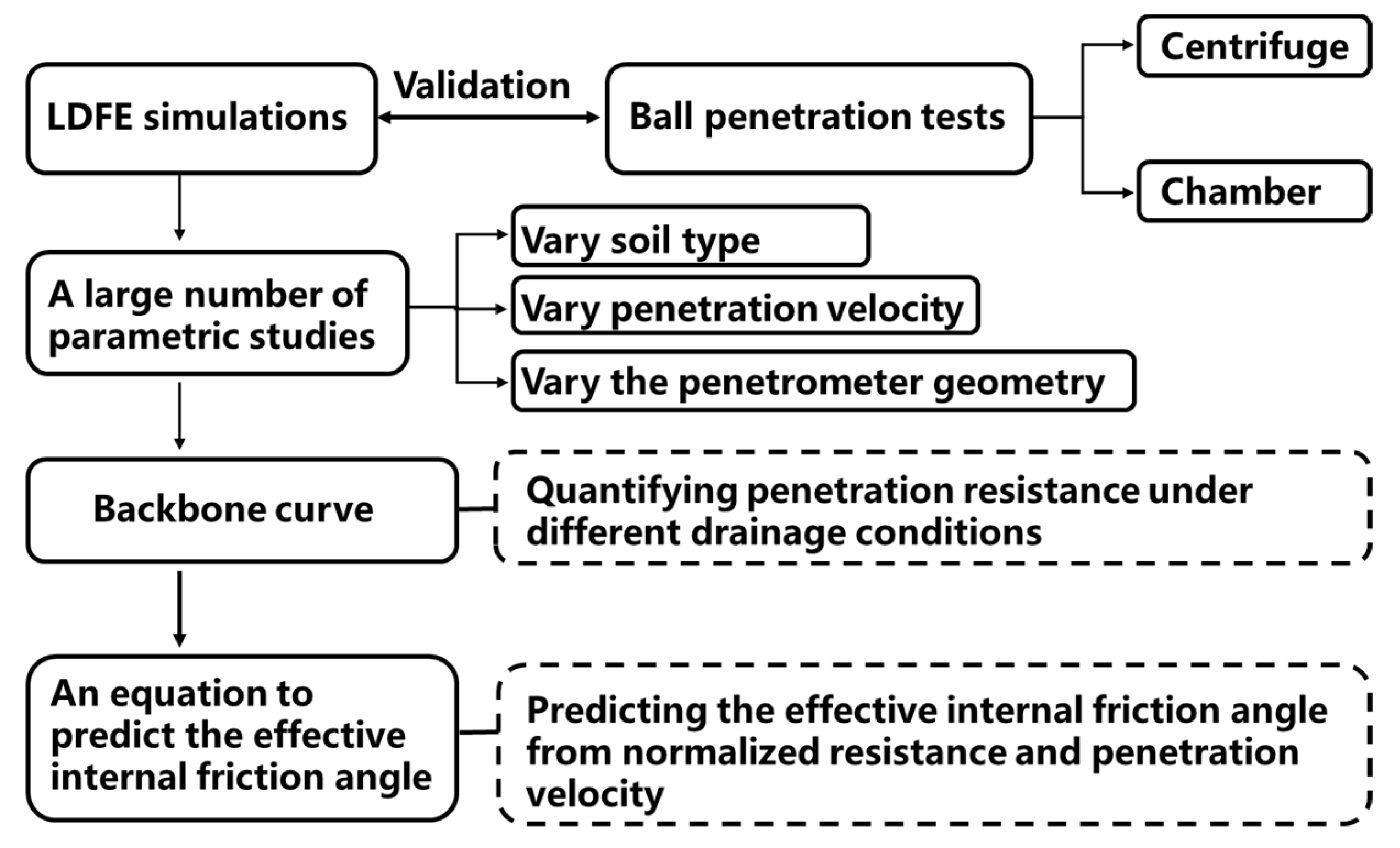

2. Materials and Methods

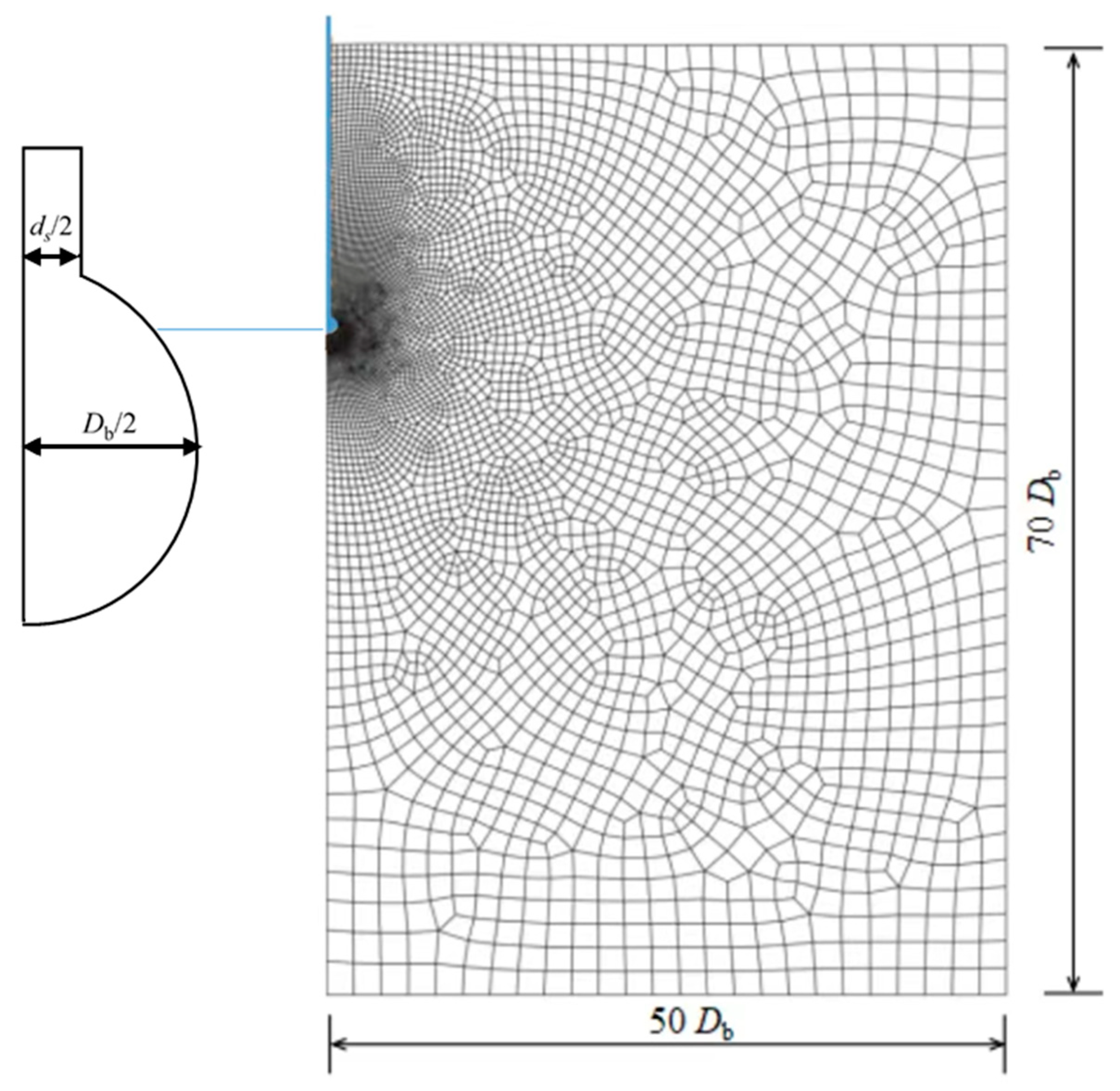

2.1. Strategies of Numerical Analysis

2.2. Soil Properties

3. Results

3.1. Validation

3.1.1. Chamber Test by Low and Randolph (2010)

3.1.2. Centrifuge Tests by Mahmoodzadeh and Randolph (2014) [23]

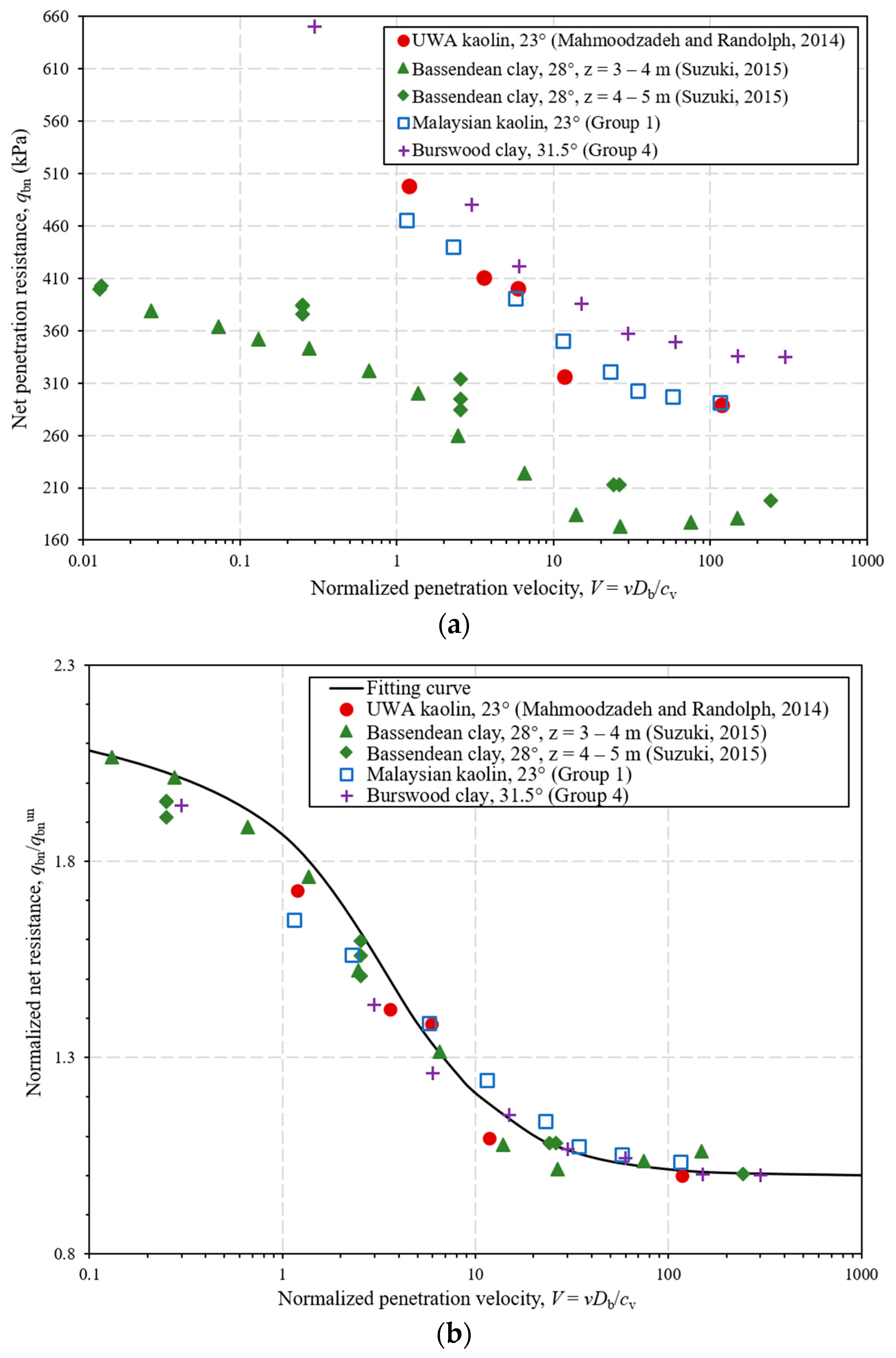

3.2. Interpretation of Ball Resistance under Partial Drainage Condition Penetrations

3.2.1. Backbone Curve

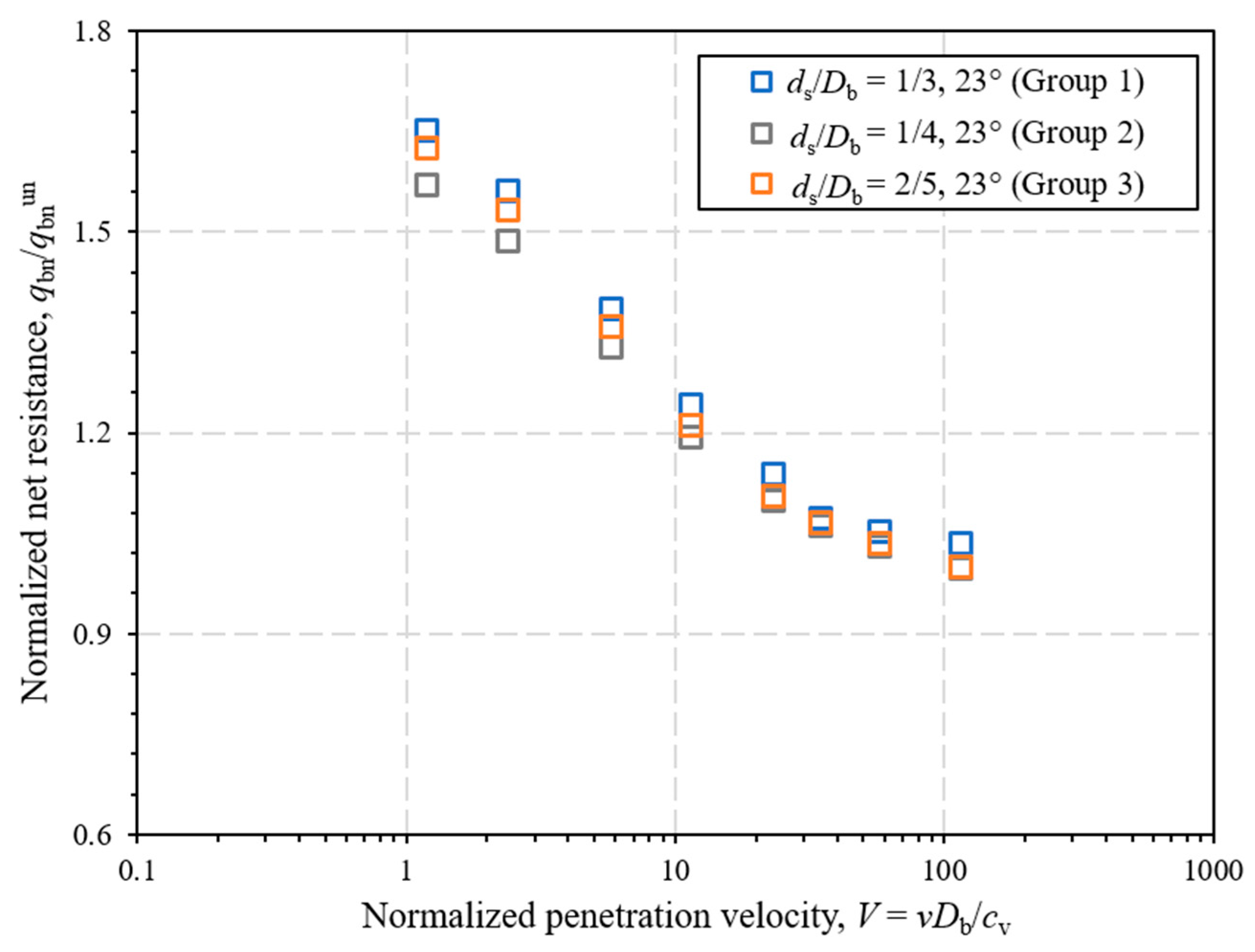

3.2.2. Effect of the Penetrometer Geometry

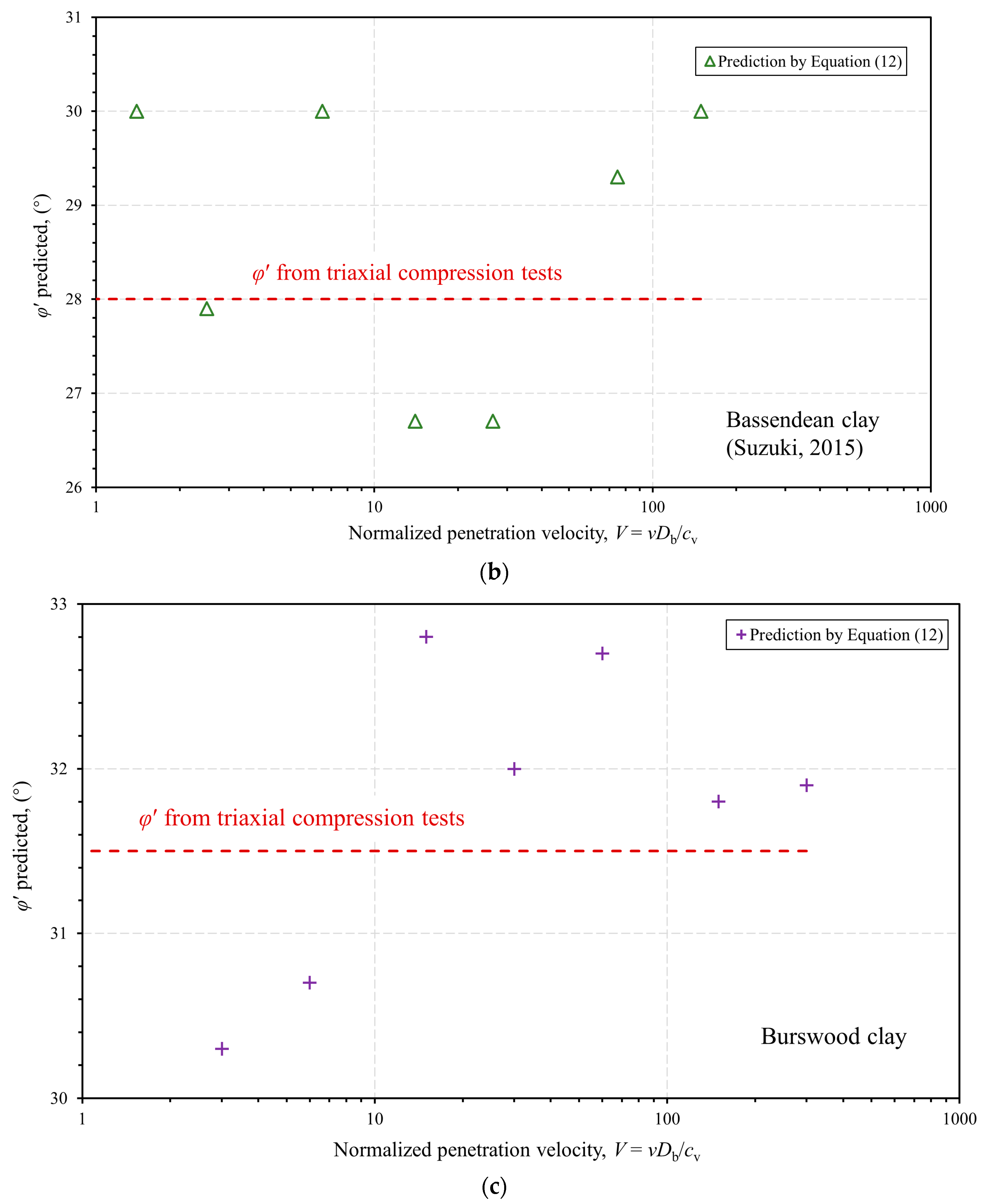

3.3. A New Method to Predict φ′ by Q and V

4. Discussions

- (a)

- Given that the ball diameter, the coefficient of consolidation of soil, and the penetration velocity are known, the normalized penetration rate is calculated through Equation (7).

- (b)

- As the net resistance (Equation (5)) and the effective vertical stress are recorded, the normalized ball resistance Q is determined through Equation (6).

- (c)

- Equation (12) is employed to estimate the slope of the critical state line M and then the value of φ′.

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- DeJong, J.T.; Yafrate, N.J.; Degroot, D.J. Evaluation of Undrained Shear Strength Using Full-Flow Penetrometers. J. Geotech. Geoenviron. Eng. 2011, 137, 14–26. [Google Scholar] [CrossRef]

- Lunne, T.; Andersen, K.H.; Low, H.E.; Randolph, M.F.; Sjursen, M. Guidelines for offshore in situ testing and interpretation in deepwater soft clays. Can. Geotech. J. 2011, 48, 543–556. [Google Scholar] [CrossRef]

- Zhang, W.; Liu, K.; Wang, D.; Zheng, J. Coefficient of consolidation measured by cone penetration tests in overconsolidated cohesive soils. Ocean Eng. 2023, 276, 114301. [Google Scholar] [CrossRef]

- Peuchen, J.; Adrichem, J.; Hefer, P.A. Practice notes on push-in penetrometers for offshore geotechnical investigation. In Proceedings of the 1st International Symposium on Frontiers in Offshore Geotechnics, London, UK, 19–21 September 2005. [Google Scholar]

- Nguyen, T.D.; Chung, S.G. Ball penetration test for characterisation of soft clays. Proc. Inst. Civil Eng.-Geotech. Eng. 2018, 171, 133–146. [Google Scholar] [CrossRef]

- Mayne, P.W.; Campanella, R.G. Versatile site characterization by seismic cone. In Proceedings of the 16th International Conference on Soil Mechanics and Geotechnical Engineering, Osaka, Japan, 12–16 September 2005. [Google Scholar]

- Ouyang, Z.; Mayne, P.W. Variable rate piezocone data evaluated using NTH limit plasticity solution. Geotech. Test. J. 2021, 44, 174–190. [Google Scholar] [CrossRef]

- Lim, Y.X.; Tan, S.A.; Phoon, K. Friction angle and overconsolidation ratio of soft clays from cone penetration test. Eng. Geol. 2020, 274, 105730. [Google Scholar] [CrossRef]

- Zhang, W.; Wang, D.; Zheng, J.; Fu, D. A new method to predict the effective internal friction angle of cohesive soil through cone penetration test. Eng. Geol. 2024; under review. [Google Scholar]

- Lehane, B.M.; O’Loughlin, C.D.; Gaudin, C.; Randolph, M.F. Rate effects on penetrometer resistance in kaolin. Géotechnique 2009, 59, 41–52. [Google Scholar] [CrossRef]

- Chow, S.H.; O’Loughlin, C.D.; Zhou, Z.; White, D.J.; Randolph, M.F. Penetrometer testing in a calcareous silt to explore changes in soil strength. Géotechnique 2020, 70, 1160–1173. [Google Scholar] [CrossRef]

- Mo, P.; Gao, X.; Yang, W.; Yu, H. A cavity expansion-based solution for interpretation of CPTu data in soils under partially drained conditions. Int. J. Numer. Anal. Methods Geomech. 2020, 44, 1053–1076. [Google Scholar] [CrossRef]

- DeJong, J.T.; Randolph, M. Influence of Partial Consolidation during cone penetration on estimated soil behavior type and pore pressure dissipation measurements. J. Geotech. Geoenviron. Eng. 2012, 138, 777–788. [Google Scholar] [CrossRef]

- Dientmann, G.; Schnaid, F.; Maghous, S.; Dejong, J. Piezocone penetration rate effects in transient gold tailings. J. Geotech. Geoenviron. Eng. 2018, 144, 04017116. [Google Scholar] [CrossRef]

- Peuchen, J.; Terwindt, J. Critical appraisal of T-bar penetration tests. In Proceedings of the 5th International Conference on Geotechnical and Geophysical Site Characterization, Gold Coast, Queensland, Australia, 5–9 September 2016; pp. 351–356. [Google Scholar]

- Low, H.E.; Landon Maynard, M.; Randolph, M.F.; DeGroot, D.J. Geotechnical characterization and engineering properties of Burswood clay. Géotechnique. 2011, 61, 575–591. [Google Scholar] [CrossRef]

- Zhou, M.; Hossain, M.S.; Hu, Y.; Liu, H. Scale issues and interpretation of ball penetration in stratified deposits in centrifuge testing. J. Geotech. Geoenviron. Eng. 2016, 142, 04015103. [Google Scholar] [CrossRef]

- Chow, S.H.; O’Loughlin, C.D.; Goh, C.L.V.; Mcllduff, R.; White, D.J.; Chow, F.C. A comparative field study of free-fall cone and sphere penetrometers in soft sediment. Ocean Eng. 2023, 280, 114094. [Google Scholar] [CrossRef]

- Liyanapathirana, D. Evaluation of penetration resistance of a Ball penetrometer in strain softening clay. In Futures in Mechanics of Structures and Materials, 2nd ed.; Aravinthan, T., Karunasena, W., Wang, H., Eds.; Taylor and Francis Group: London, UK, 2009; pp. 255–260. [Google Scholar]

- Hu, Y.; Randolph, M.F. A practical numerical approach for large deformation problems in soil. Int. J. Numer. Anal. Methods Geomech. 1998, 22, 327–350. [Google Scholar] [CrossRef]

- Wang, D.; White, D.J.; Randolph, M.F. Large-deformation finite element analysis of pipe penetration and large-amplitude lateral displacement. Can. Geotech. J. 2010, 47, 842–856. [Google Scholar] [CrossRef]

- Wang, D.; Bienen, B. Numerical investigation of penetration of a large-diameter footing into normally consolidated kaolin clay with a consolidation phase. Géotechnique 2016, 66, 947–952. [Google Scholar] [CrossRef]

- Mahmoodzadeh, H.; Randolph, M.F. Penetrometer testing: Effect of partial consolidation on subsequent dissipation response. J. Geotech. Geoenviron. Eng. 2014, 140, 04014022. [Google Scholar] [CrossRef]

- Purwana, O.A. Centrifuge Model Study on Spudcan Extraction in Soft Clay. Ph.D. Thesis, National University of Singapore, Singapore, 2006. [Google Scholar]

- Stewart, D.P. Lateral Loading of Pile Bridge Abutments Due to Embankment Construction. Ph.D. Thesis, University of Western Australia, Perth, Australia, 1992. [Google Scholar]

- Low, H.E.; Randolph, M.F. Strength measurement for near-seabed surface soft soil using manually operated miniature full-flow penetrometer. J. Geotech. Geoenviron. Eng. 2010, 136, 1565–1573. [Google Scholar] [CrossRef]

- Purwana, O.A.; Leung, C.F.; Chow, Y.K.; Foo, K.S. Influence of base suction on extraction of jack-up spudcans. Géotechnique 2005, 55, 741–753. [Google Scholar] [CrossRef]

- Hossain, M.S.; Hu, Y.; Randolph, M.F.; White, D.J. Limiting cavity depth for spudcan foundations penetrating clay. Géotechnique 2005, 55, 679–690. [Google Scholar] [CrossRef]

- Zhang, Y.; Wang, D.; Cassidy, M.J.; Bienen, B. Effect of installation on the bearing capacity of a spudcan under combined loading in soft clay. J. Geotech. Geoenviron. Eng. 2014, 140, 04014029. [Google Scholar] [CrossRef]

- Satchithananthan, U.; Ullah, S.N.; Lee, F.H.; Gu, H. Axial sliding resistance of partially embedded offshore pipelines. Géotechnique 2021, 71, 893–910. [Google Scholar] [CrossRef]

- Gaudin, C.; O’loughlin, C.D.; Randolph, M.F.; Lowmass, A.C. Influence of the installation process on the performance of suction embedded plate anchors. Géotechnique. 2006, 56, 381–391. [Google Scholar] [CrossRef]

- Hossain, M.S.; Kim, Y.; Gaudin, C. Experimental investigation of installation and pullout of dynamically penetrating anchors in clay and silt. J. Geotech. Geoenviron. 2014, 140, 04014026. [Google Scholar] [CrossRef]

- Wroth, C.P. The interpretation of in situ soil tests. Geotechnique 1984, 34, 449–489. [Google Scholar] [CrossRef]

- Bryant, W.R.; Hottman, W.; Trabant, P. Permeability of unconsolidated and consolidated marine sediments, Gulf of Mexico. Mar. Georesources Geotechnol. 1975, 1, 1–14. [Google Scholar] [CrossRef]

- Lekha, K.R.; Krishnaswamy, N.R.; Basak, P. Consolidation of clays for variable permeability and compressibility. J. Geotech. Geoenviron. Eng. 2003, 129, 1001–1009. [Google Scholar] [CrossRef]

- Zhou, H.; Randolph, M.F. Numerical investigations into cycling of full-flow penetrometers in soft clay. Géotechnique 2009, 59, 801–812. [Google Scholar] [CrossRef]

- Suzuki, Y. Investigation and interpretation of cone penetration rate effects. Ph.D. Thesis, University of Western Australia, Crawley, Australia, 2015. [Google Scholar]

- Martinez, M.G.; Tonni, L.; Gottardi, G.; Rocchi, I. Analysis of CPTU data for the geotechnical characterization of intermediate sediments. In Cone Penetration Testing: Proceedings of the 4th International Symposium on Cone Penetration Testing; CRC Press: Boca Raton, FL, USA, 2018; pp. 281–287. [Google Scholar]

- Chung, S.F.; Randolph, M.F.; Schneider, J.A. Effect of penetration rate on penetrometer resistance in clay. J. Geotech. Geoenviron. Eng. 2006, 132, 1188–1196. [Google Scholar] [CrossRef]

- Colreavy, C.; O’Loughlin, C.D.; Randolph, M.F. Estimating consolidation parameters from field piezoball tests. Géotechnique 2016, 66, 333–343. [Google Scholar] [CrossRef]

| Property | UWA Kaolin | Malaysian Kaolin | Burswood Clay |

|---|---|---|---|

| Angle of internal friction, : degree | 23 | 23 | 31.5 |

| Void ratio at p′ = 1 kPa on virgin consolidated line, | 2.25 | 2.35 | 2.25 |

| Slope of normal consolidation line, | 0.205 | 0.244 | 0.330 |

| Slope of swelling line, | 0.044 | 0.053 | 0.036 |

| Poisson’s ratio, | 0.3 | 0.3 | 0.3 |

| Submerged unit weight, : kN/m3 | 6 | 6 | 5.2 |

| Group | Soil | z/Db | ds/Db | v: mm/s | V = vDb/cv |

|---|---|---|---|---|---|

| 1 | Malaysian kaolin | 10.67 | 1/3 | 10 | 115.3 |

| 5 | 57.6 | ||||

| 3 | 34.6 | ||||

| 2 | 23.1 | ||||

| 1 | 11.5 | ||||

| 0.5 | 5.8 | ||||

| 0.2 | 2.4 | ||||

| 0.1 | 1.2 | ||||

| 2 | Malaysian kaolin | 10.67 | 1/4 | 10 | 115.3 |

| 5 | 57.6 | ||||

| 3 | 34.6 | ||||

| 2 | 23.1 | ||||

| 1 | 11.5 | ||||

| 0.5 | 5.8 | ||||

| 0.2 | 2.4 | ||||

| 0.1 | 1.2 | ||||

| 3 | Malaysian kaolin | 10.67 | 2/5 | 10 | 115.3 |

| 5 | 57.6 | ||||

| 3 | 34.6 | ||||

| 2 | 23.1 | ||||

| 1 | 11.5 | ||||

| 0.5 | 5.8 | ||||

| 0.2 | 2.4 | ||||

| 0.1 | 1.2 | ||||

| 4 | Burswood clay | 10.67 | 1/3 | 1 | 300 |

| 0.5 | 150 | ||||

| 0.2 | 60 | ||||

| 0.1 | 30 | ||||

| 0.05 | 15 | ||||

| 0.02 | 6 | ||||

| 0.01 | 3 | ||||

| 0.001 | 0.3 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhou, B.; Zhang, W.; Wang, D.; Fu, D. Estimation of Effective Internal Friction Angle by Ball Penetration Test: Large-Deformation Analyses. J. Mar. Sci. Eng. 2024, 12, 230. https://doi.org/10.3390/jmse12020230

Zhou B, Zhang W, Wang D, Fu D. Estimation of Effective Internal Friction Angle by Ball Penetration Test: Large-Deformation Analyses. Journal of Marine Science and Engineering. 2024; 12(2):230. https://doi.org/10.3390/jmse12020230

Chicago/Turabian StyleZhou, Bohan, Wenli Zhang, Dong Wang, and Dengfeng Fu. 2024. "Estimation of Effective Internal Friction Angle by Ball Penetration Test: Large-Deformation Analyses" Journal of Marine Science and Engineering 12, no. 2: 230. https://doi.org/10.3390/jmse12020230

APA StyleZhou, B., Zhang, W., Wang, D., & Fu, D. (2024). Estimation of Effective Internal Friction Angle by Ball Penetration Test: Large-Deformation Analyses. Journal of Marine Science and Engineering, 12(2), 230. https://doi.org/10.3390/jmse12020230