Study on Sensitivity Mechanism of Low-Permeability Sandstone Reservoir in Huilu Area of Pearl River Mouth Basin

Abstract

:1. Introduction

2. Geological Setting

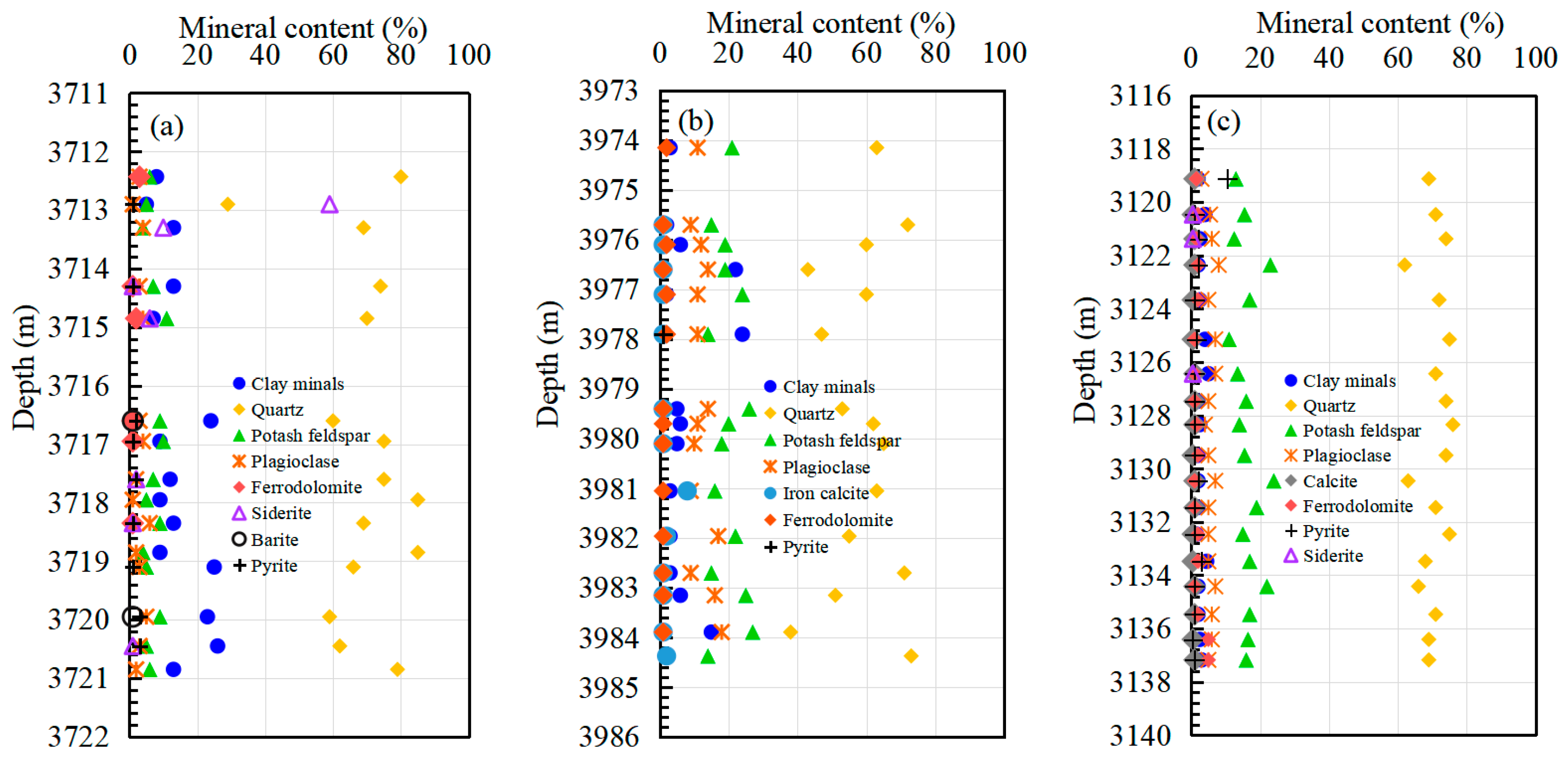

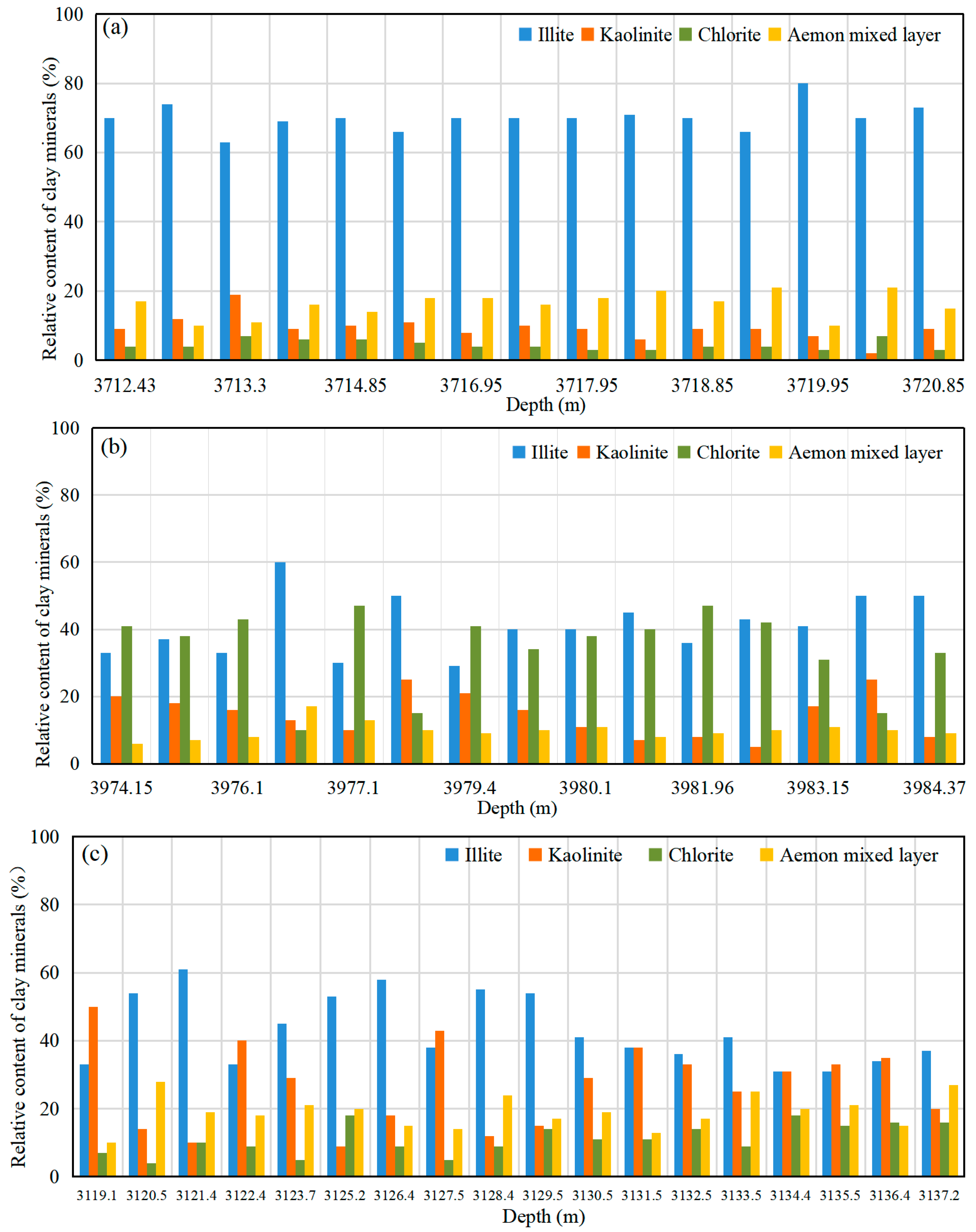

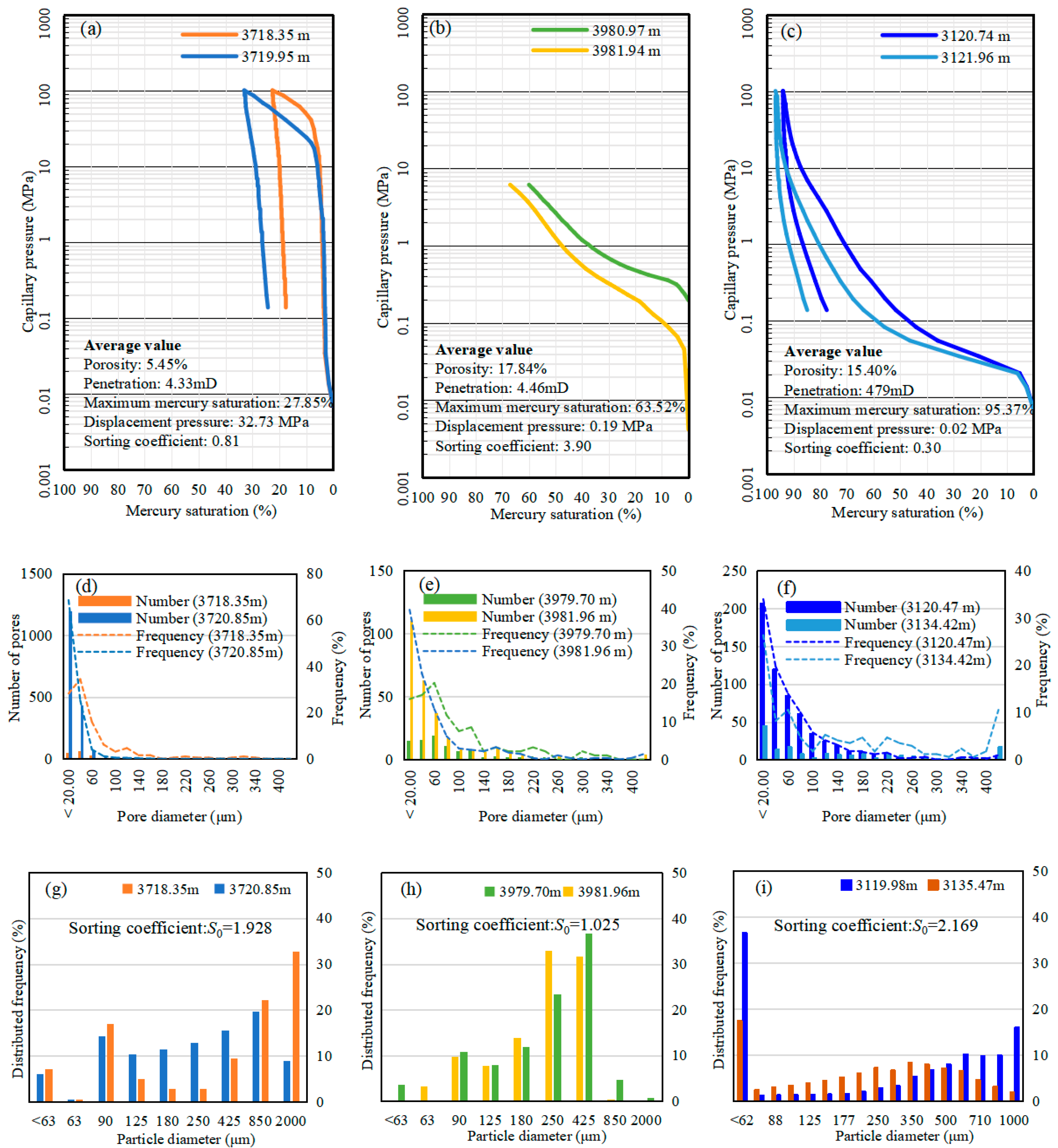

3. Experiments and Results

3.1. Samples

3.2. Experimental Principle and Process

3.3. Experimental Results

4. Results

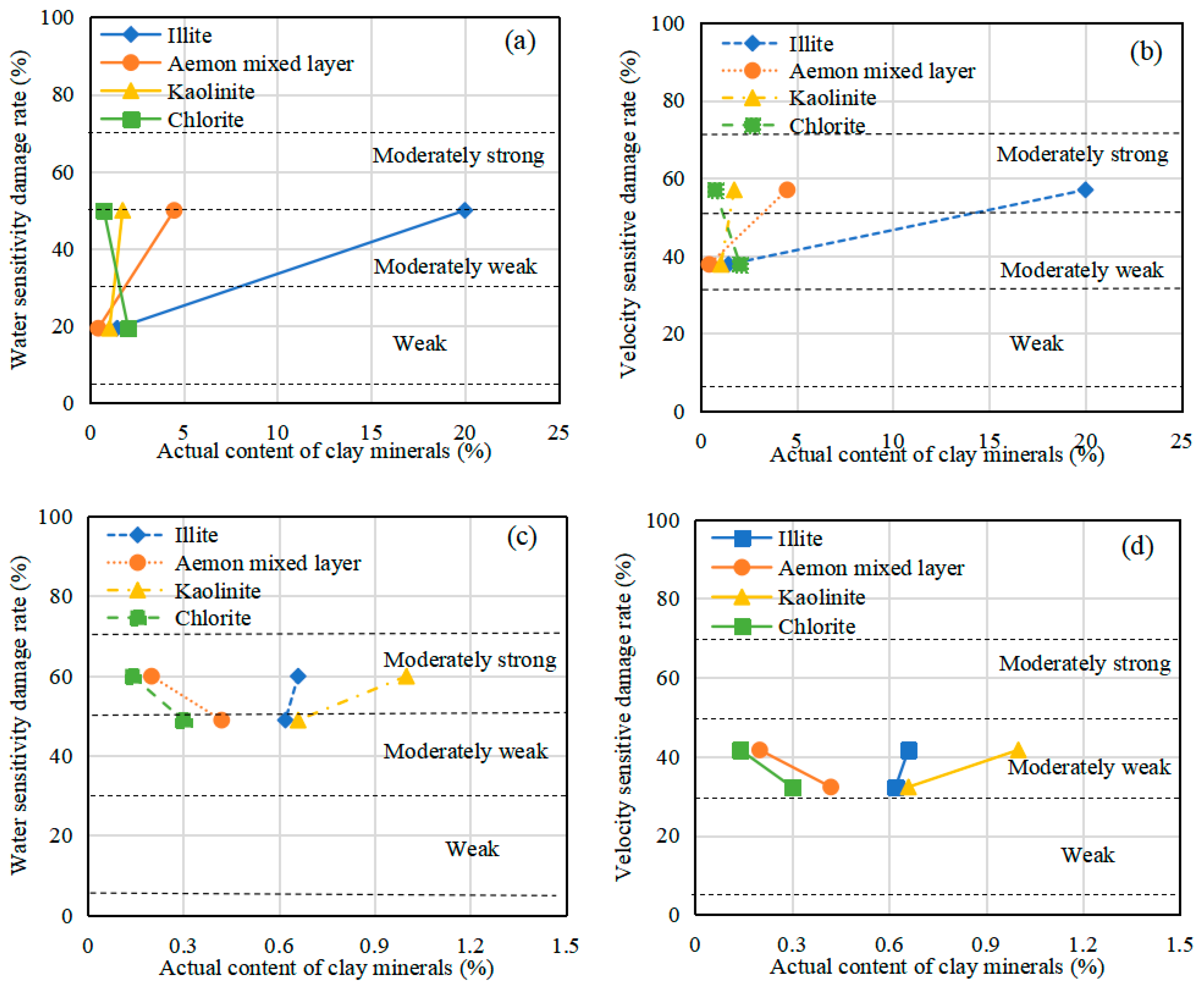

4.1. Mineral Sensitivity

4.2. Pore Structure Sensitivity

5. Discussion

5.1. Water Sensitivity and Velocity Sensitivity

5.2. Acid Sensitivity and Alkali Sensitivity

5.3. Salinity Sensitivity

6. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Xie, Y.H.; Yuan, Q.H. Practice and prospects of deep-water and deep-formation geophysica exploration. Geophys. Prospect. Pet. 2023, 62, 183–193. (In Chinese) [Google Scholar]

- Kokkinos, N.C.; Nkagbu, D.C.; Marmanis, D.I.; Dermentzis, K.I.; Maliaris, G. Evolution of Unconventional Hydrocarbons: Past, Present, Future and Environmental FootPrint. J. Eng. Sci. Technol. Rev. 2022, 15, 15–24. [Google Scholar] [CrossRef]

- Quan, Y.B.; Liu, J.Z.; Zhao, D.J.; Hao, F.; Wang, Z.F.; Tian, J.Q. The origin and distribution of crude oil in Zhu III sub-basin, Pearl River Mouth Basin, China. Mar. Pet. Geol. 2015, 66, 732–747. [Google Scholar] [CrossRef]

- Peng, J.W.; Pang, X.Q.; Shi, H.S.; Peng, H.J.; Xiao, S.; Yu, Q.H.; Wu, L.Y. Hydrocarbon generation and expulsion characteristics of Eocene source rocks in the Huilu area, northern Pearl River Mouth basin, South China Sea: Implications for tight oil potential. Mar. Pet. Geol. 2016, 72, 463–487. [Google Scholar] [CrossRef]

- Randolph, M.F.; Gaudin, C.; Gourvenec, S.M.; White, D.J.; Boylan, N.; Cassidy, M.J. Recent advances in offshore geotechnics for deep water oil and gas developments. Ocean Eng. 2011, 28, 818–834. [Google Scholar] [CrossRef]

- Zhang, J.Z.; Chen, S.J.; Xiao, Y.; Lu, J.G.; Yang, G.P.; Tang, H.P.; Liu, C.W. Characteristics of the Chang 8 tight sandstone reservoirs and their genesis in Huaqing area, Ordos Basin. Oil Gas Geol. 2013, 34, 679–684. (In Chinese) [Google Scholar]

- Moghanloo, R.G.; Dadmohammadi, Y.; Bin, Y.; Salahshoor, S. Applying fractional flow theory to evaluate CO2, storage capacity of an aquifer. J. Pet. Sci. Eng. 2015, 125, 154–161. [Google Scholar] [CrossRef]

- Cheng, Q.Y.; Zhou, S.D.; Li, B.B.; Pan, Z.J.; Liu, D.M.; Yan, D.T. Integrating embedment and creep behavior for multisize proppant in shale: Conceptual model and validation. SPE J. 2023, 28, 3389–3408. [Google Scholar] [CrossRef]

- Lv, W.F.; Leng, Z.P.; Liu, Q.J.; Jia, N.H.; Luo, M.L.; Li, T.; Jin, X.; Qin, J.H.; Jiang, Z.B. Reservoir Sensitivity Evaluation by Monitoring Displacement Experiment with X-ray CT Imaging. In Proceedings of the SPE/IATMI Asia Pacific Oil & Gas Conference and Exhibition, Nusa Dua, Indonesia, 20–22 October 2015. [Google Scholar]

- Cui, G.L.; Feng, X.T.; Pan, Z.J.; Chen, T.Y.; Liu, J.S.; Elsworth, D.; Tan, Y.L.; Wang, C.G. Impact of shale matrix mechanical interactions on gas transport during production. J. Pet. Sci. Eng. 2020, 184, 106524. [Google Scholar] [CrossRef]

- Lyu, Z.; Song, X.; Geng, L.; Li, G. Optimization of multilateral well configuration in fractured reservoirs. J. Pet. Sci. Eng. 2019, 172, 1153–1164. [Google Scholar] [CrossRef]

- Sun, L.; Zou, X.B.; Li, X.G.; Yang, M.; Du, K.; Cao, P.F. Feasibility study on acidification of volcanic rocks in Huizhou Sag, Pearl River Mouth Basin. Pet. Geol. Recovery Effic. 2022, 29, 145–154. (In Chinese) [Google Scholar]

- Ma, K.; Jiang, H.Q.; Li, J.J.; Zhao, L. Experimental study on the micro alkali sensitivity damage mechanism in low-permeability reservoirs using QEMSCAN. J. Nat. Gas Sci. Eng. 2016, 36, 1004–1017. [Google Scholar] [CrossRef]

- Chai, G.S.; Shi, Y.M.; Du, S.H.; Wei, Y.; Zhang, Z.Q.; Guo, C.A.; Sun, T. Sensitivity Evaluation and Influencing Factors Analysis of Tight Sandstone Reservoirs: A Case Study of the Chang-8 Reservoir in Yanchi Area of Ordos Basin. Acta Sci. Nat. Univ. Pekin. 2020, 56, 253–261. (In Chinese) [Google Scholar]

- Tao, S.; Tang, D.Z.; Xu, H.; Li, S.; Geng, Y.G.; Zhao, J.L.; Wu, S.; Meng, Q.; Kou, X.; Yang, S.Y.; et al. Fluid velocity sensitivity of coal reservoir and its effect on coalbed methane well productivity: A case of Baode Block, northeastern Ordos Basin, China. J. Pet. Sci. Eng. 2017, 152, 229–237. [Google Scholar] [CrossRef]

- Davarpanah, A.; Mirshekari, B. Sensitivity analysis of reservoir and rock properties during low salinity water injection. Energy Rep. 2020, 5, 1001–1009. [Google Scholar] [CrossRef]

- Khilar, K.C.; Fogler, H.S. The existence of a critical salt concentration for particle release. J. Colloid Interface Sci. 1984, 101, 214–224. [Google Scholar] [CrossRef]

- Fang, W.; Jiang, H.; Li, J.; Li, W.; Li, J.J.; Zhao, L.; Feng, X.N. A new experimental methodology to investigate formation damage in clay-bearing reservoirs. J. Pet. Sci. Eng. 2016, 143, 226–234. [Google Scholar] [CrossRef]

- Wang, B.Y.; Qin, Y.; Shen, J.; Wang, G.; Zhang, Q.S.; Liu, M. Experimental study on water sensitivity and salt sensitivity of lignite reservoir under different PH. J. Pet. Sci. Eng. 2019, 172, 1202–1214. [Google Scholar] [CrossRef]

- Fang, W.C.; Jiang, H.Q.; Li, J.; Li, W.; Li, P.; Gu, H.; Feng, X.N.; Zhao, L. Investigation of salt and alkali sensitivity damage mechanisms in clay-containing reservoirs using nuclear magnetic resonance. Part. Sci. Technol. 2017, 35, 533–540. [Google Scholar] [CrossRef]

- Wilson, M.J.; Wilson, L.; Patey, I. The influence of individual clay minerals on formation damage of reservoir sandstones: A critical review with some new insights. Clay Miner. 2014, 49, 147–164. [Google Scholar] [CrossRef]

- Wei, J.G.; Zhang, A.; Li, J.T.; Shang, D.M.; Zhou, X.F. Study on microscale pore structure and bedding fracture characteristics of shale oil reservoir. Energy 2023, 278, 127829. [Google Scholar] [CrossRef]

- Cui, C.; Zheng, R.C.; Jiang, Y.Q.; Jin, J.; Wen, H. Characteristics and sensitivity of the Middle Jurassic Toutunhe Formation inFudong slope, Junggar Basin. Oil Gas Geol. 2018, 39, 398–408. (In Chinese) [Google Scholar]

- Xue, D.; Zhang, S.A.; Wu, X.M.; Li, X.H.; Du, J.J.; Lu, C.G. Sensitivity experiment of shale gas reservoir of Chang 7 reservoir in Xiasiwan oilfield. Lithol. Reserv. 2019, 31, 135–144. (In Chinese) [Google Scholar]

- Jin, Z.H.; Yuan, G.H.; Zhang, X.T.; Cao, Y.C.; Ding, L.; Li, X.Y.; Fu, X.H. Differences of tuffaceous components dissolution and their impact on physical properties in sandstone reservoirs: A case study on Paleogene Wenchang Formation in Huizhou-Lufeng area, Zhu I Depression, Pearl River Mouth Basin, China. Pet. Explor. Dev. 2023, 50, 111–124. [Google Scholar] [CrossRef]

- Ge, J.W.; Zhu, X.M.; Zhang, X.T.; Lei, Y.C.; Niu, Z.C.; Li, M. Tectono-sedimentation model of the Eocene Wenchang formation in the Lufeng depression, Pearl River Mouth basin. J. China Univ. Min. Technol. 2018, 47, 308–322. (In Chinese) [Google Scholar]

- Peng, G.R.; Liu, P.; Song, P.L.; Gao, X.; Xiong, W.L.; Xiang, Q.W.; Han, B. Characteristics of the “fan-braid” complex and main controlling factors offavorable reservoir in the Enping Formation, Huizhou 26 Sag, Pearl RiverMouth Basin. Earth Sci. 2023, 1–18. (In Chinese). Available online: http://kns.cnki.net/kcms/detail/42.1874.P.20231127.1128.004.html (accessed on 29 April 2024).

- SY/T 6285-2011, Evaluating Methods of Oil and Gas Reservoirs. Available online: http://www.petrostd.com/km/front/standard/stdQuery/std.jsp?keyword=6285-2011 (accessed on 29 April 2024).

- Sanaei, A.; Shakiba, M.; Varavei, A.; Sepehrnoori, K. Mechanistic modeling of clay swelling in hydraulic-fractures network. SPE Res Eval. Eng. 2017, 21, 96–108. [Google Scholar] [CrossRef]

- Xi, K.; Cao, Y.; Jahren, J.; Zhu, R.K.; Bjorlykke, K.; Haile, B.G.; Zheng, L.J.; Hellevang, H. Diagenesis and reservoir quality of the Lower Cretaceous Quantou Formation tight sandstones in the southern Songliao Basin, China. Sediment. Geol. 2015, 330, 90–107. [Google Scholar] [CrossRef]

- Wang, Y.X.; Zhou, L.F.; Jiao, Z.S.; Shang, Q.; Huang, S. Sensitivity Evaluation of Tight Sandstone Reservoir in Yanchang Formation in shanbei Area. Ordos Basin. J. Jilin Univ. Earth Sci. Ed. 2018, 48, 981–990. (In Chinese) [Google Scholar]

- Mahdi, H.; Alireza, S.; Kamy, S. Hydraulic fracturing fluid effect on clay swelling in stimulated naturally fractured reservoirs. In Proceedings of the SPE/AAPG/SEG Unconventional Resources Technology Conference, Austin, TX, USA, 24–26 July 2017. [Google Scholar]

- Boyer, C.; Kieschnick, J.; Suarez-Rivera, R.; Lewis, R.E.; Waters, G. Producing gas from its source. Oilfield Rev. 2006, 18, 36–49. [Google Scholar]

- Puntervold, T.; Mamonov, A.; Aghaeifar, Z.; Frafjord, G.O.; Moldestad, G.M.; Strand, S.; Austad, T. Role of kaolinite clay minerals in enhanced oil recovery by low salinity water injection. Energy Fuels 2018, 32, 7374–7382. [Google Scholar] [CrossRef]

- Aksulu, H.; Hamso, D.; Strand, S.; Puntervold, T.; Austad, T. Evaluation of low-salinity enhanced oil recovery effects in sandstone: Effects of the temperature and pH gradient. Energy Fuels 2012, 26, 3497–3503. [Google Scholar] [CrossRef]

- Li, F.F.; Gao, W.L.; Yang, S.L.; Hua, X.W. Study on reservoir sensitivity for low permeability reservoirs in the Gao 52 block of Ansai oilfield. Spec. Oil Gas Reserv. 2012, 19, 126–129. (In Chinese) [Google Scholar]

- Wang, X.W. Study on Reservoir Sensitivity Evaluation and Key Control Factors of Tight Oil Reservoirs. Spec. Oil Gas Reserv. 2021, 28, 103–110. (In Chinese) [Google Scholar]

- Yadav, V.P.; Sharma, T.; Saxena, V.K. Dissolution kinetics of potassium from glauconitic sandstone in acid lixiviant. Int. J. Miner. Process. 2000, 60, 15–36. [Google Scholar] [CrossRef]

| Region | Formation | Well | Sample | Length (cm) | Diameter (cm) | Porosity (%) | Permeability (mD) | Depth (m) | |

|---|---|---|---|---|---|---|---|---|---|

| Lufeng Sag | Wenchang | LF15-5-A | 1-29B | 3.732 | 2.524 | 2.7 | 0.05 | 3719.90 | |

| 1-29D | 3.171 | 2.526 | 2.4 | 0.40 | 3719.88 | ||||

| LF13-9-A | 2-15A | 3.006 | 2.536 | 12.1 | 0.68 | 3979.40 | |||

| 2-25A | 3.665 | 2.513 | 16.5 | 2.88 | 3981.96 | ||||

| Huizhou Sag | Enping | HZ26-6-A | 1-03F | 1 | 5.523 | 2.527 | 12.6 | 200 | 3119.62 |

| 2 | 5.624 | 2.531 | 10.6 | 54.70 | 3119.62 | ||||

| 3 | 5.200 | 2.500 | 13.0 | 256 | 3120.00 | ||||

| 4 | 5.336 | 2.527 | 13.2 | 257 | 3119.68 | ||||

| 5 | 5.111 | 2.527 | 11.7 | 80.60 | 3119.68 | ||||

| 1-64F | 1 | 5.481 | 2.533 | 12.0 | 48 | 3135.00 | |||

| 2 | 5.394 | 2.531 | 11.4 | 33.60 | 3134.80 | ||||

| 3 | 5.853 | 2.534 | 13.0 | 101 | 3134.90 | ||||

| 4 | 5.308 | 2.534 | 15.0 | 254 | 3135.00 | ||||

| 5 | 5.375 | 2.534 | 12.5 | 171 | 3134.97 | ||||

| Well | Samples | Water-Sensitive Damage Rate (%) | Speed-Sensitive Damage Rate (%) | Acid-Sensitive Damage Rate (%) | Alkali-Sensitive Damage Rate (%) | Salt Sensitivity Damage Rate (%) |

|---|---|---|---|---|---|---|

| LF15-5-A | 1-29B | 49.90 | — | — | — | — |

| 1-29D | — | 56.93 | — | — | — | |

| LF13-9-A | 2-15A | 19.36 | — | — | — | — |

| 2-25A | — | 37.73 | — | — | — | |

| HZ26-6-A | 1-03F | 59.89 | 41.65 | 33.88 | 25.30 | 56.32 |

| 1-64F | 48.87 | 32.27 | 43.57 | 23.10 | 47.27 |

| Mineral | SEM Map of the Distribution Pattern | Description | Sensitive Type | Potential Damage |

|---|---|---|---|---|

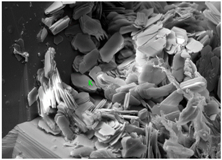

| K |  | Laminated kaolinite, filled with intergranular pores | Velocity sensitivity, alkali sensitivity, water sensitivity (weak) | The migration of particles clogs the pore throat, and the particles are more likely to fall off in an alkaline environment |

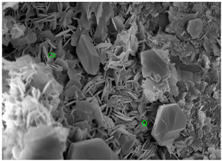

| I |  | Filamentous illite is distributed on the surface of quartz grains | Water sensitivity (weak) and velocity sensitivity | After absorbing water, the particles expand and block the pore throat |

| Ch |  | Coniferous chlorite is associated with authigenic quartz | Water sensitivity (weak), acid sensitivity | Dissolve in acid fracturing fluid and form a gel |

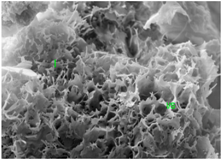

| I/S |  | Montmorillonite and illite symbiotic development, forming a honeycomb-like mixed layer | Water sensitivity | After absorbing water, the particles expand and block the pore throat |

| Well | Formation | Sample | Relative Content (%)/Actual Content (%) | Water Sensitivity Damage Rate (%) | Velocity Sensitivity Damage Rate (%) | |||

|---|---|---|---|---|---|---|---|---|

| I/S | I | K | Ch | |||||

| LF15-5-A | Wenchang | 1-29B | 18/4.5 | 80/20 | 7/1.8 | 3/0.8 | 49.9 | 56.9 |

| LF13-9-A | 2-25A | 9/0.5 | 29/1.5 | 21/1.1 | 41/2.1 | 19.4 | 37.7 | |

| HZ26-6-A | Enping | 1-03F | 10/0.2 | 33/0.7 | 50/1 | 7/0.1 | 59.9 | 41.7 |

| 1-64F | 21/0.4 | 31/0.6 | 33/0.7 | 15/0.3 | 48.9 | 32.3 | ||

| Formation | Sample | Alkali Sensitivity Mineral Content (%) | Acid Sensitivity Mineral Content (%) | Damage Rate (%) | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Q | F | P | K | Ca | A | Py | S | Ch | Alkali | Acid | ||

| Wenchang | 1-03F | 71 | 17.5 | 5.5 | 1 | 0.5 | 2 | 1 | 0.5 | 0.1 | 25.3 | 33.9 |

| 1-64F | 71 | 17 | 6 | 0.7 | 1 | 2 | 1 | 0 | 0.3 | 23.1 | 43.6 | |

| Well | Formation | Sample | Total Clay (%) | Water Sensitivity Damage Rate (%) | Salinity Sensitivity Damage Rate (%) |

|---|---|---|---|---|---|

| HZ26-6-A | Enping | 1-03F | 2 | 59.9 | 56.3 |

| 1-64F | 2 | 48.9 | 47.3 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, H.; Ding, L.; Zang, Q.; Wu, Q.; Ma, Y.; Wang, Y.; Zhou, S.; Cheng, Q.; Tian, X.; Niu, J.; et al. Study on Sensitivity Mechanism of Low-Permeability Sandstone Reservoir in Huilu Area of Pearl River Mouth Basin. J. Mar. Sci. Eng. 2024, 12, 888. https://doi.org/10.3390/jmse12060888

Li H, Ding L, Zang Q, Wu Q, Ma Y, Wang Y, Zhou S, Cheng Q, Tian X, Niu J, et al. Study on Sensitivity Mechanism of Low-Permeability Sandstone Reservoir in Huilu Area of Pearl River Mouth Basin. Journal of Marine Science and Engineering. 2024; 12(6):888. https://doi.org/10.3390/jmse12060888

Chicago/Turabian StyleLi, Hongbo, Lin Ding, Qibiao Zang, Qiongling Wu, Yongkun Ma, Yuchen Wang, Sandong Zhou, Qiaoyun Cheng, Xin Tian, Jiancheng Niu, and et al. 2024. "Study on Sensitivity Mechanism of Low-Permeability Sandstone Reservoir in Huilu Area of Pearl River Mouth Basin" Journal of Marine Science and Engineering 12, no. 6: 888. https://doi.org/10.3390/jmse12060888