Experimental Study on Cyclic Simple Shear Test of Coastal Tidal Soft Soil

Abstract

:1. Research Status and Significance

2. Test Introduction

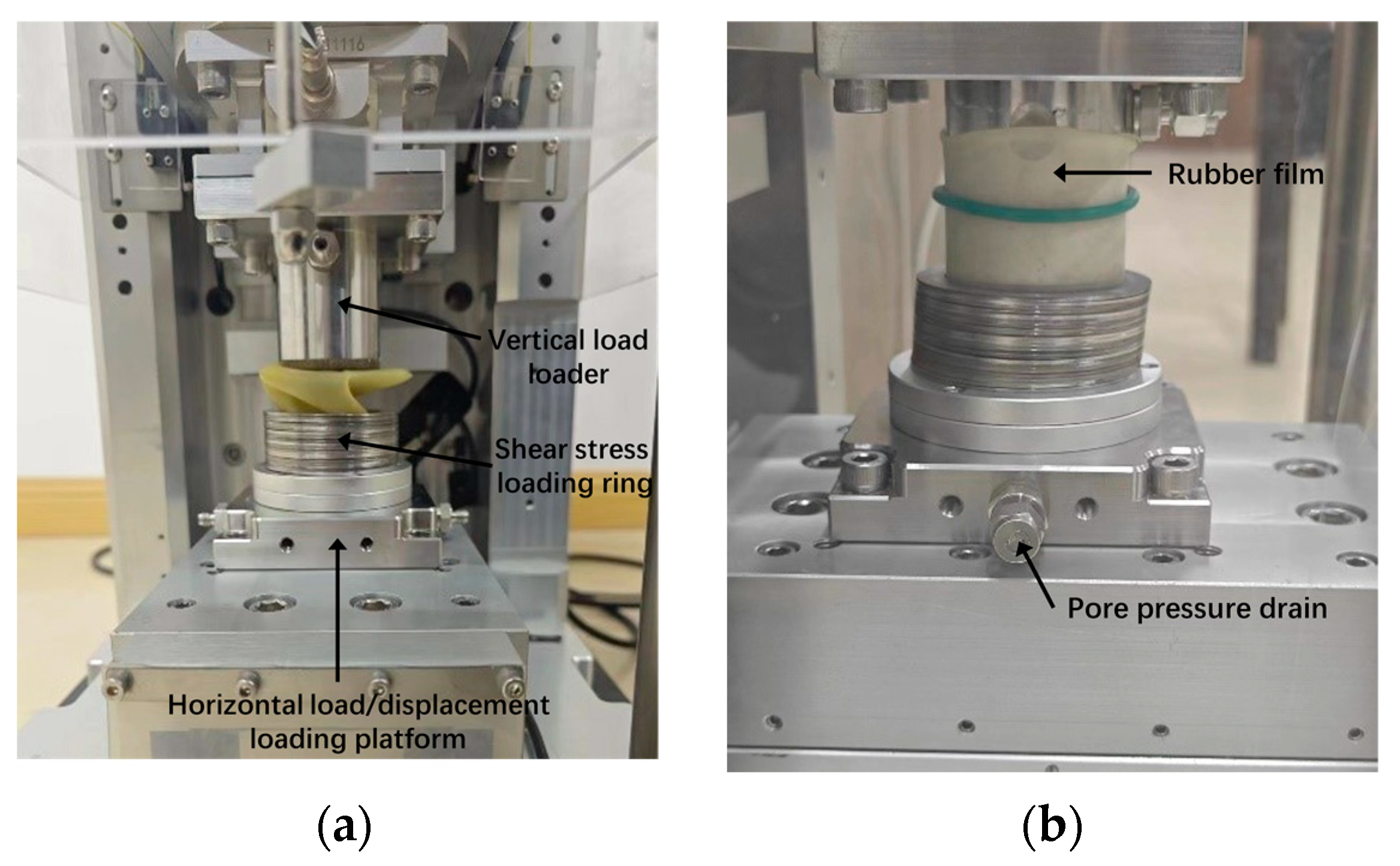

2.1. Test Equipment

2.2. Test Soil Samples and Preparation

2.3. Test Scheme

3. Analysis of Test Results

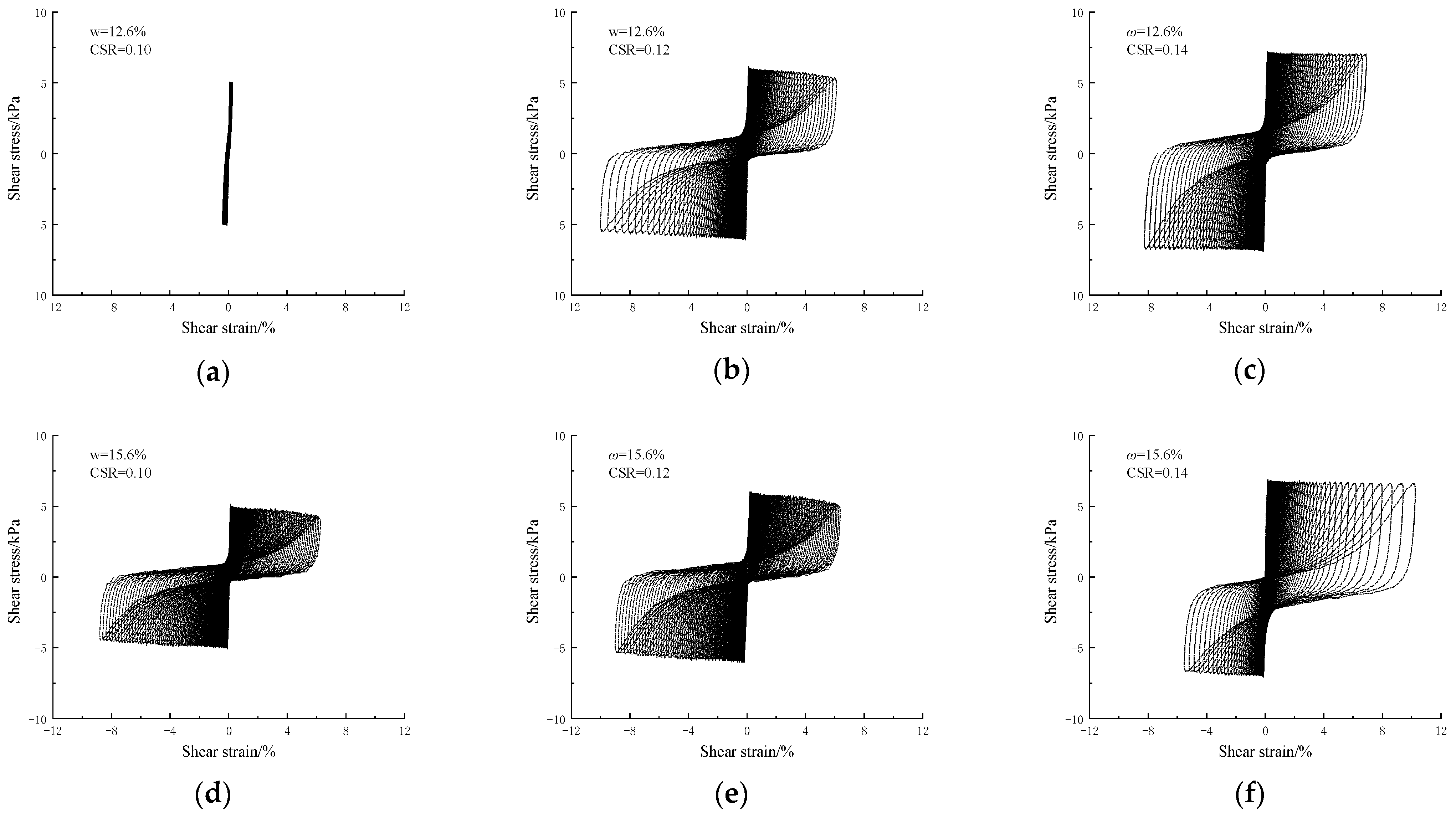

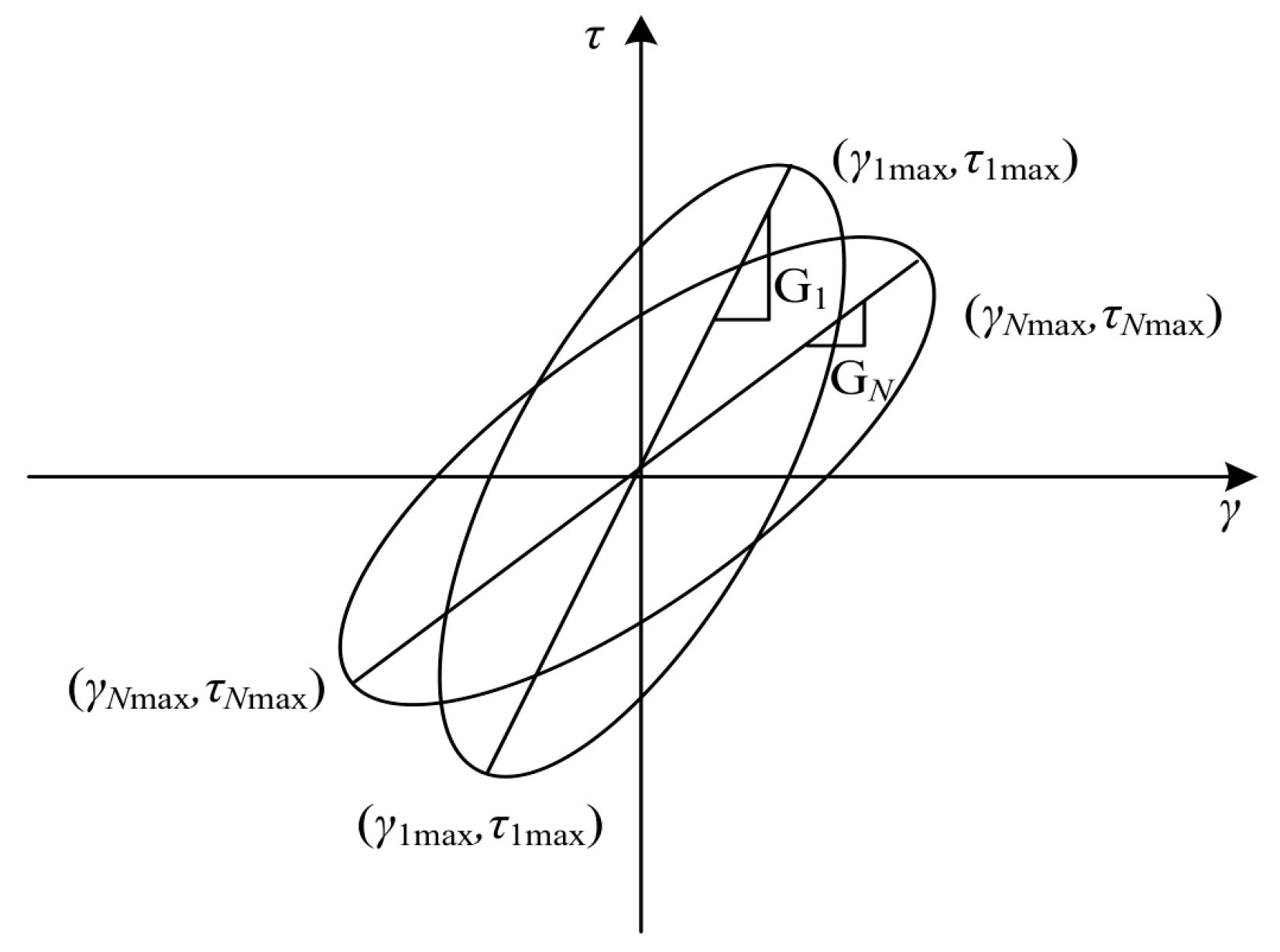

3.1. Stress–Strain Hysteresis Curve

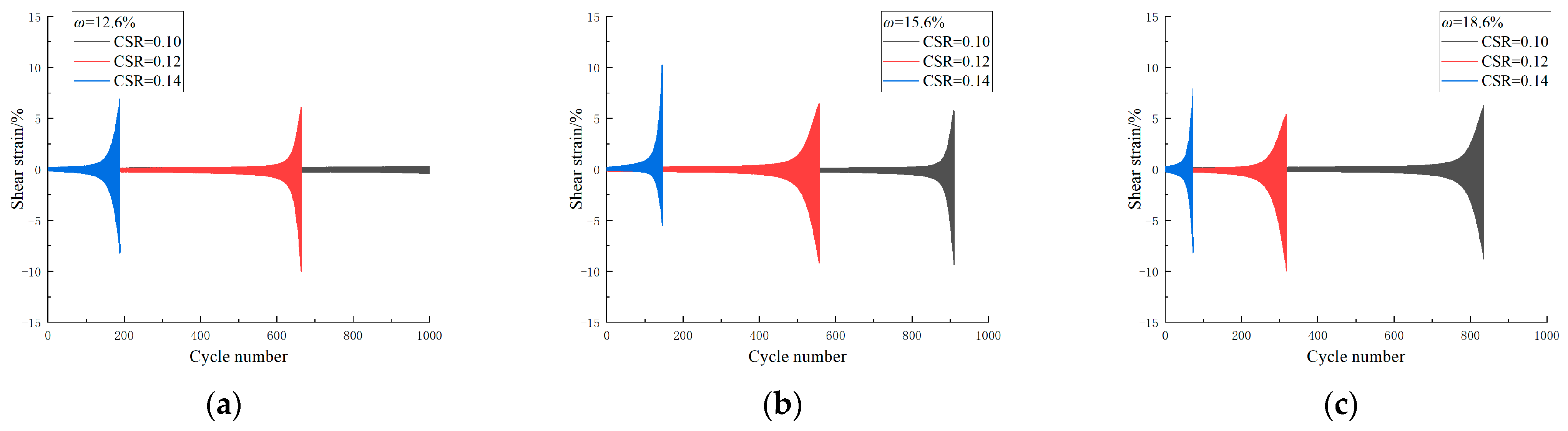

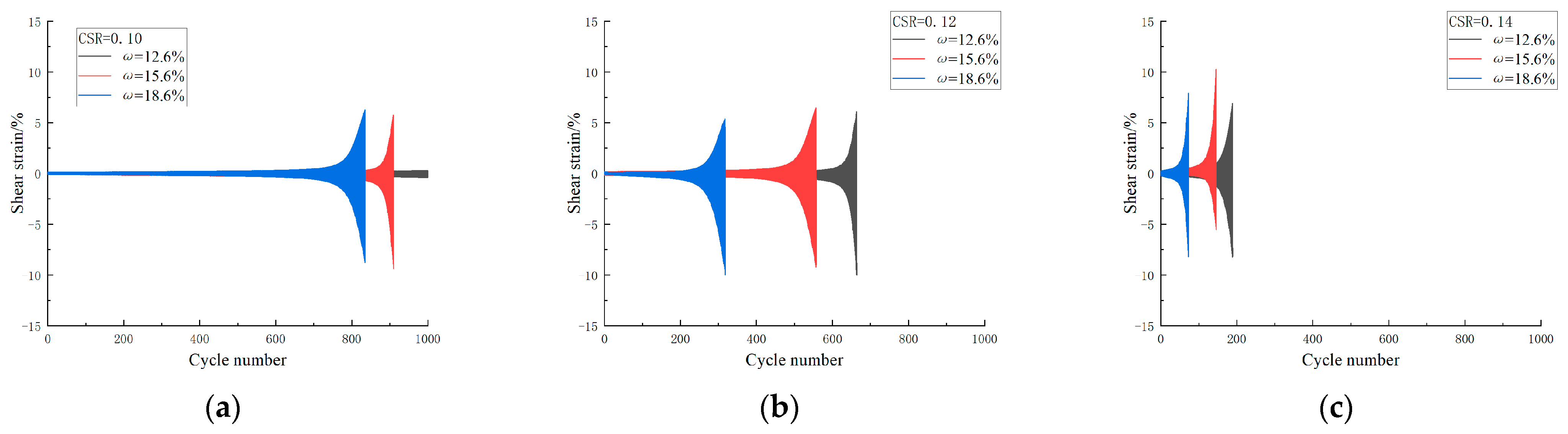

3.2. Cyclic Cumulative Strain

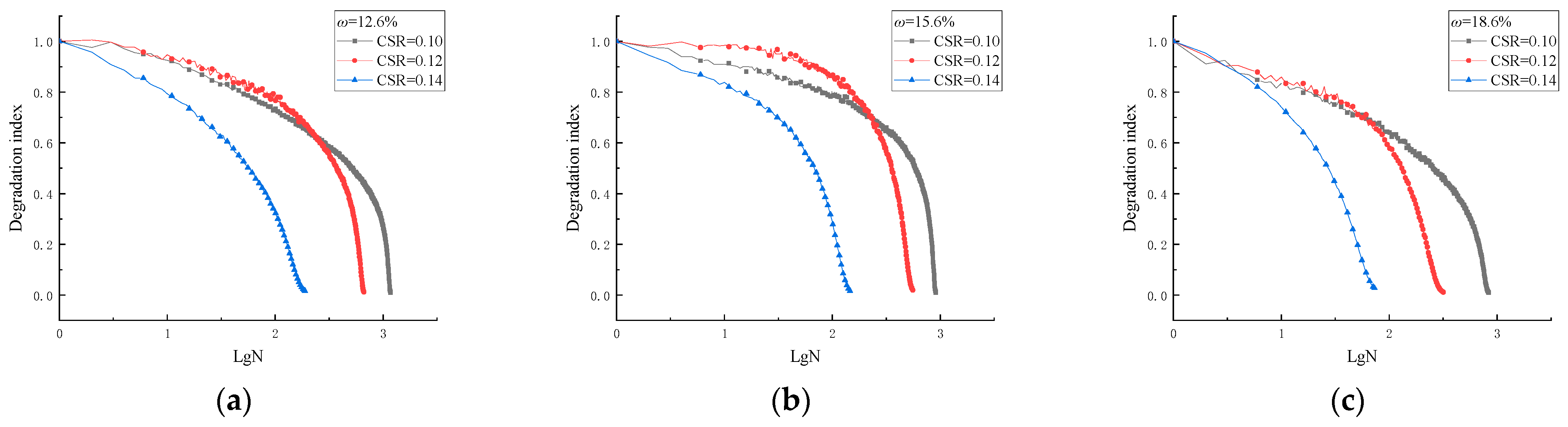

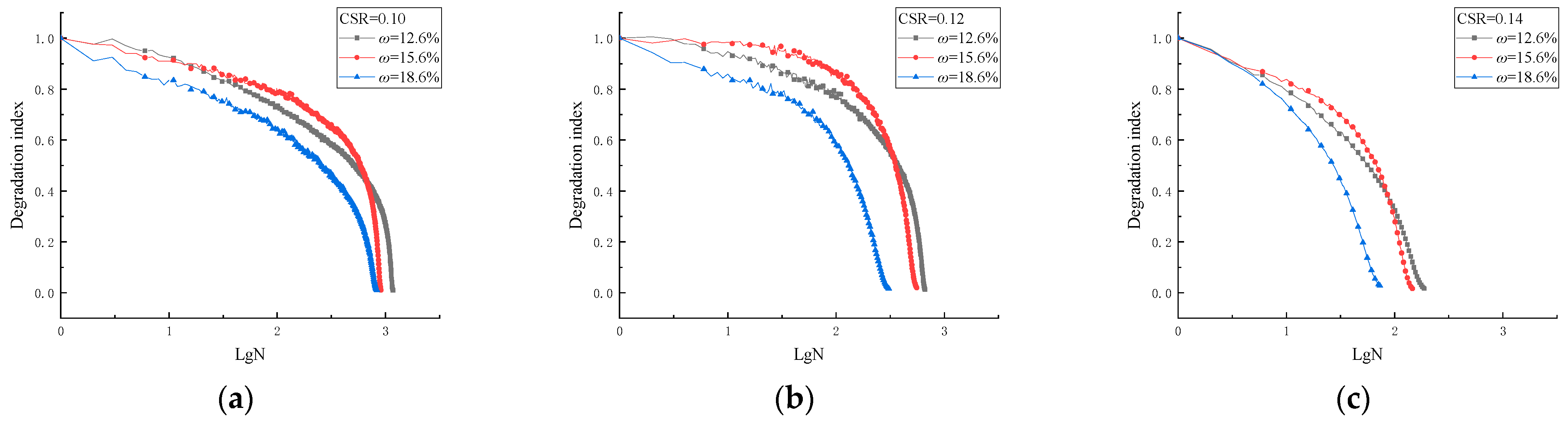

3.3. Softening Index

4. Conclusions

- As the water content and stress cycle ratio increase, the stress–strain hysteresis loop widens, the strain differential grows, the curve transitions from dense to sparse, the symmetry of the hysteresis curve is lost in the later stages of shearing, and soil damage intensifies.

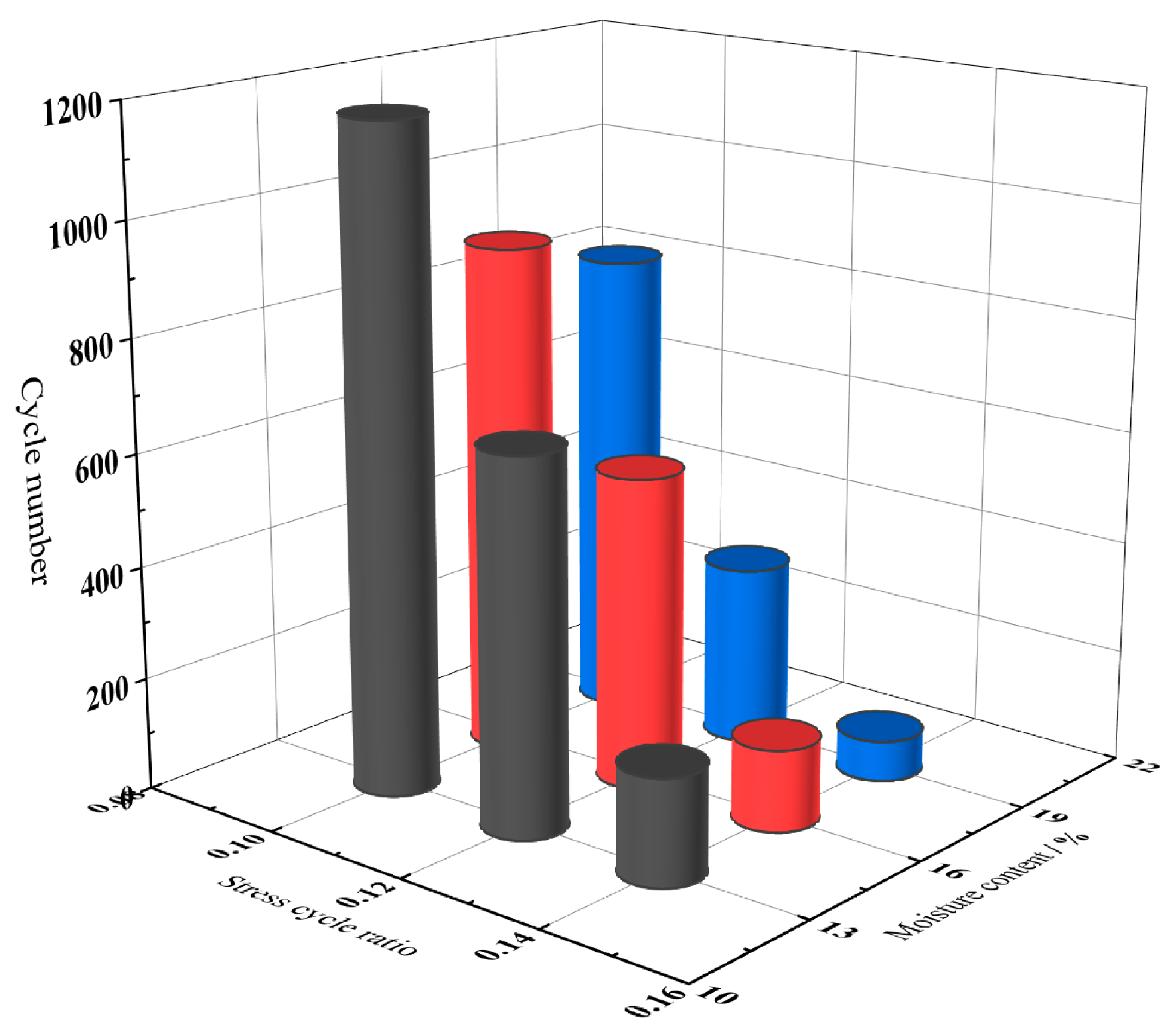

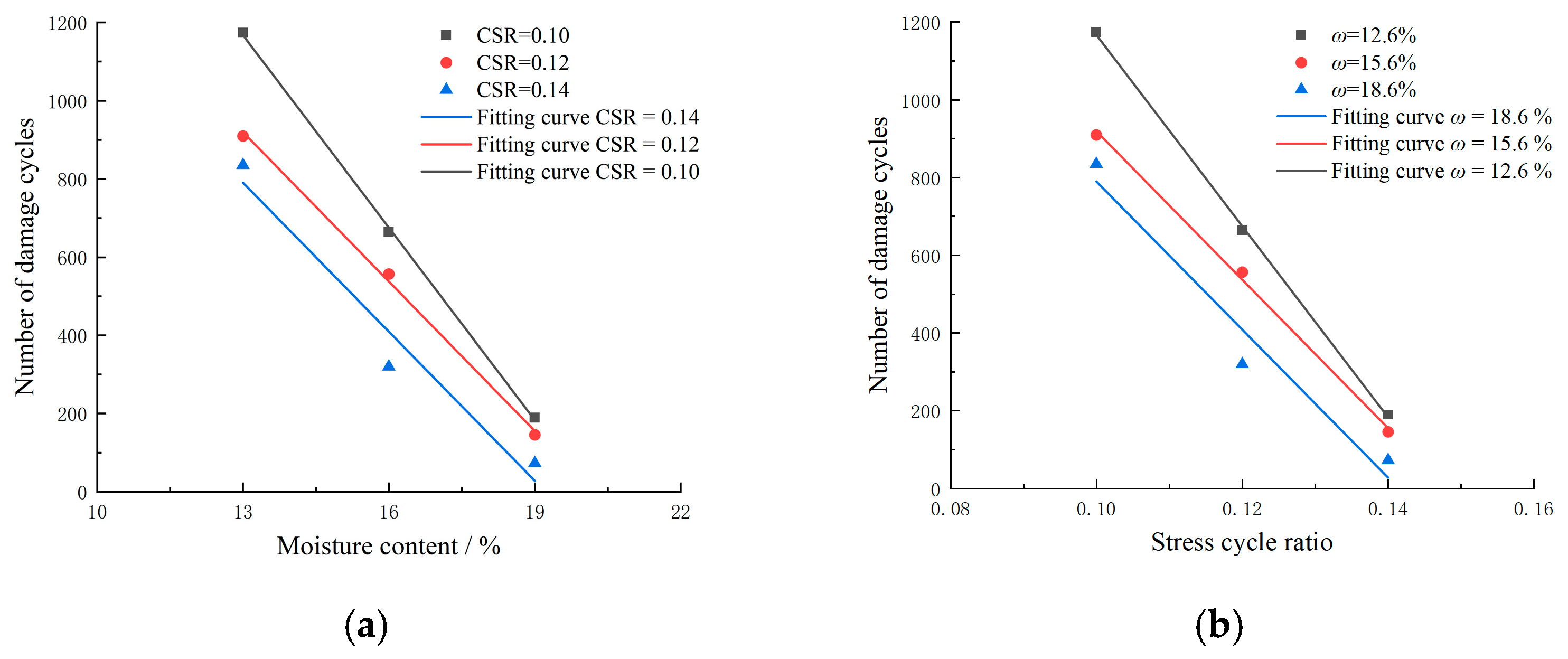

- This study discusses the impact of different water content conditions and stress cycle ratios on the shear strain and soil failure behavior. The results indicate that the strain increases with cycle number, while higher water contents and stress cycle ratios lead to reduced shear strain and accelerated soil failure. Moreover, soil’s strength deteriorates more rapidly above its optimal water content. A predictive formula for the number of failure cycles, considering varying cyclic stress ratios and water content conditions, was developed based on our test results.

- This study also explores the effects of water content and cyclic stress ratios on soil softening behavior. The findings reveal a gradual decrease in the softening index with an increasing cycle number, while higher water contents and cyclic stress ratios accelerate the soil softening process. At high cyclic stress ratios, more severe damage evolution may occur within the soil, leading to a rapid decline in its cyclic shear strength. Conversely, under optimal water content conditions, the soil may exhibit strong resistance to deformation due to the relative stability of the particle arrangement and structure, resulting in a slow softening rate during initial shear stages.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Xu, Y.; Guo, J. Analysis on the causes of special engineering properties of marine soil. Rock Soil Mech. 1989, 67–74. [Google Scholar] [CrossRef]

- Veletsos, A.S.; Meek, J.W. Dynamic Behavior of Building-foundation Systems. Earthq. Eng. Struct. D. 1974, 3, 121–138. [Google Scholar] [CrossRef]

- Ahmad, M.; Ray, R. Modeling the Stiffening Behavior of Sand Subjected to Dynamic Loading. Geosciences 2024, 14, 26. [Google Scholar] [CrossRef]

- Wang, J.; Yao, S.; Guo, L.; Sun, Y.; Fu, H.; Gao, Z. Cyclic Softening Characteristics of Soft Clay Considering Initial Shear Stress in Same or Perpendicular Direction. Ocean Eng. 2024, 293, 116515. [Google Scholar] [CrossRef]

- Nikitas, G.; Arany, L.; Aingaran, S.; Vimalan, J.; Bhattacharya, S. Predicting Long Term Performance of Offshore Wind Turbines Using Cyclic Simple Shear Apparatus. Soil Dyn. Earthq. Eng. 2017, 92, 678–683. [Google Scholar] [CrossRef]

- Cui, L.; Aleem, M.; Shivashankar; Bhattacharya, S. Soil–Structure Interactions for the Stability of Offshore Wind Foundations under Varying Weather Conditions. J. Mar. Sci. Eng. 2023, 11, 1222. [Google Scholar] [CrossRef]

- Andersen, K.H.; Lauritzsen, R. Bearing Capacity for Foundations with Cyclic Loads. J. Geotech. Eng. 1988, 114, 540–555. [Google Scholar] [CrossRef]

- Andersen, K.H.; Kleven, A.; Heien, D. Cyclic Soil Data for Design of Gravity Structures. J. Geotech. Eng. 1988, 114, 517–539. [Google Scholar] [CrossRef]

- Wang, J.; Cai, Y.; Xu, C. Experimental study on the stiffness softening characteristics of soft clay under cyclic loading. Rock Soil Mech. 2007, 2138–2144. [Google Scholar] [CrossRef]

- Liu, F.; Cai, Y.; Xu, C.; Wang, J. Research on the attenuation law of dynamic elastic modulus of soft soil under cyclic loading. J. Zhejiang Univ. 2008, 1479–1483. [Google Scholar]

- Guo, L.; Jin, H.; Wang, J.; Shi, L. Undrained Monotonic Shear Behavior of Marine Soft Clay after Long-Term Cyclic Loading. Mar. Georesour. Geotechnol. 2020, 38, 854–866. [Google Scholar] [CrossRef]

- Chen, Z.; Zheng, S.; Qian, C.; Wu, H.; Xu, H.; Tu, D.; Chen, C. Experimental study on the deformation characteristics of soft clay foundation under multi-directional cyclic shear stress path. Archit. Sci. 2023, 39, 114–120. [Google Scholar] [CrossRef]

- Wang, J.; Yuan, W.; Yin, X.; Li, W.; Li, X. One-Dimensional Consolidation Properties of Soft Clay under Multi-Stage Loading. Appl. Sci. 2023, 13, 10340. [Google Scholar] [CrossRef]

- Zhang, Y.; Jia, M.; Xie, Z. Effect of Stress Rotation Angles on Dynamic Responses of Soft Clay under Multi-Directional Loading. Soil Dyn. Earthq. Eng. 2023, 165, 107711. [Google Scholar] [CrossRef]

- Ansal, A.M.; Erken, A. Undrained Behavior of Clay Under Cyclic Shear Stresses. J. Geotech. Eng. 1989, 115, 968–983. [Google Scholar] [CrossRef]

- Zhou, J.; Gong, X. Strain Degradation of Saturated Clay under Cyclic Loading. Can. Geotech. J. 2001, 38, 208–212. [Google Scholar] [CrossRef]

- Wichtmann, T.; Andersen, K.H.; Sjursen, M.A.; Berre, T. Cyclic Tests on High-Quality Undisturbed Block Samples of Soft Marine Norwegian Clay. Can. Geotech. J. 2013, 50, 400–412. [Google Scholar] [CrossRef]

- Leng, J.; Ye, G.; Ye, B.; Jeng, D.-S. Laboratory Test and Empirical Model for Shear Modulus Degradation of Soft Marine Clays. Ocean Eng. 2017, 146, 101–114. [Google Scholar] [CrossRef]

- Huang, B.; Cai, S.; Li, J.; Wu, K.; Yang, W. Undrained Strength of Clay Determined from Simple Shear Test. Front. Earth Sci. 2023, 10, 1098846. [Google Scholar] [CrossRef]

- Jin, H.; Guo, L.; Sun, H.; Shi, L.; Cai, Y. Undrained Cyclic Shear Strength and Stiffness Degradation of Over consolidated Soft Marine Clay in Simple Shear Tests. Ocean Eng. 2022, 262, 112270. [Google Scholar] [CrossRef]

- Jin, H.; Guo, L.; Sun, H.; Wu, T.; Shi, L.; Cai, Y. Energy-Based Evaluation of Undrained Cyclic Behavior of Marine Soft Clay under Multidirectional Simple Shear Stress Paths. Acta Geotech. 2023, 18, 2883–2898. [Google Scholar] [CrossRef]

- Xiao, X.; Wang, Z.; Wu, Q.; Zhou, R.; Chen, G. Shear-Thinning Non-Newtonian Fluid-Based Method for Investigating Cyclic Stiffness Degradation of Marine Clay. Ocean Eng. 2024, 300, 117499. [Google Scholar] [CrossRef]

- GB/T 50123-2019; Standard for Soil Test Methods. Ministry of Housing and Urban-Rural Development of the People’s Republic of China: Beijing, China, 2019.

- Idriss, I.M.; Singh, R.D.; Dobry, R. Nonlinear behavior of soft clay during cyclic loading. J. Geotech. Eng. 1978, 104, 1427–1447. [Google Scholar] [CrossRef]

| Displacement (mm) | Measurement Accuracy (um) | Loading Range (kN) | Sample Size (mm) |

|---|---|---|---|

| ±25 (Axial) ±15 (Shear) | 0.3 | Axial = 5 Shear = 2 | 50 × 20 |

| Moisture Content ω/% | Specific Gravity ds | Void Ratio e | Liquid Limit wl/% | Plastic Limit wp/% | Maximum Dry Density ρ/(g/cm3) | Optimal Moisture Content % |

|---|---|---|---|---|---|---|

| 76.10 | 2.69 | 1.65 | 68 | 35 | 1.68 | 15.6 |

| No. | Axial Stress σ/(kPa) | Stress Cycle Ratio CSR | Moisture Content ω/(%) |

|---|---|---|---|

| T-1 | 50 | 0.10 | 12.6 |

| T-2 | 50 | 0.12 | 15.6 |

| T-3 | 50 | 0.14 | 18.6 |

| T-4 | 50 | 0.10 | 12.6 |

| T-5 | 50 | 0.12 | 15.6 |

| T-6 | 50 | 0.14 | 18.6 |

| T-7 | 50 | 0.10 | 12.6 |

| T-8 | 50 | 0.12 | 15.6 |

| T-9 | 50 | 0.14 | 18.6 |

| Moisture Content | A (104) | B (104) | R2 |

|---|---|---|---|

| 12.6% | 0.3627 | −2.46 | 0.99 |

| 15.6% | 0.2829 | −1.91 | 0.99 |

| 17.6% | 0.2695 | −1.905 | 0.92 |

| Stress Cycle Ratio | A (104) | B (102) | R2 |

|---|---|---|---|

| 0.10 | 0.3233 | −1.64 | 0.99 |

| 0.12 | 0.2524 | −1.273 | 0.99 |

| 0.14 | 0.2390 | −1.27 | 0.92 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yu, X.; Sun, H.; Liu, J.; Zhao, H.; Han, Y. Experimental Study on Cyclic Simple Shear Test of Coastal Tidal Soft Soil. J. Mar. Sci. Eng. 2024, 12, 1066. https://doi.org/10.3390/jmse12071066

Yu X, Sun H, Liu J, Zhao H, Han Y. Experimental Study on Cyclic Simple Shear Test of Coastal Tidal Soft Soil. Journal of Marine Science and Engineering. 2024; 12(7):1066. https://doi.org/10.3390/jmse12071066

Chicago/Turabian StyleYu, Xiuxia, Honglei Sun, Junwei Liu, Hongxuan Zhao, and Yu Han. 2024. "Experimental Study on Cyclic Simple Shear Test of Coastal Tidal Soft Soil" Journal of Marine Science and Engineering 12, no. 7: 1066. https://doi.org/10.3390/jmse12071066