Numerical Study on the Anti-Sloshing Effect of Horizontal Baffles in a Cargo Hold Loaded with Liquefied Cargo

Abstract

1. Introduction

2. Theoretical Background of DEM

2.1. Particle Motion Equation

2.2. Rolling Resistance Linear Model

3. DEM Model Setup and Numerical Verification

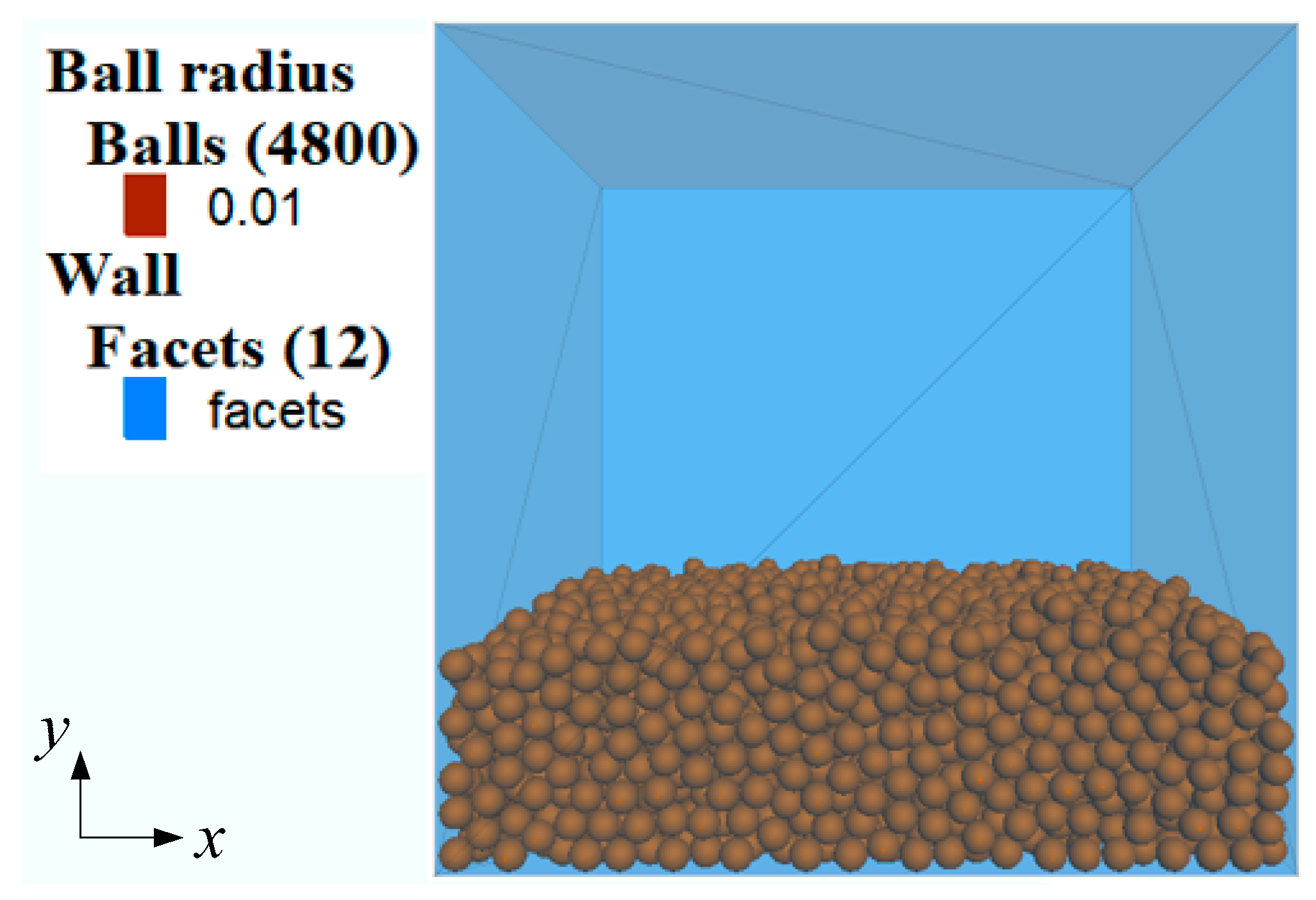

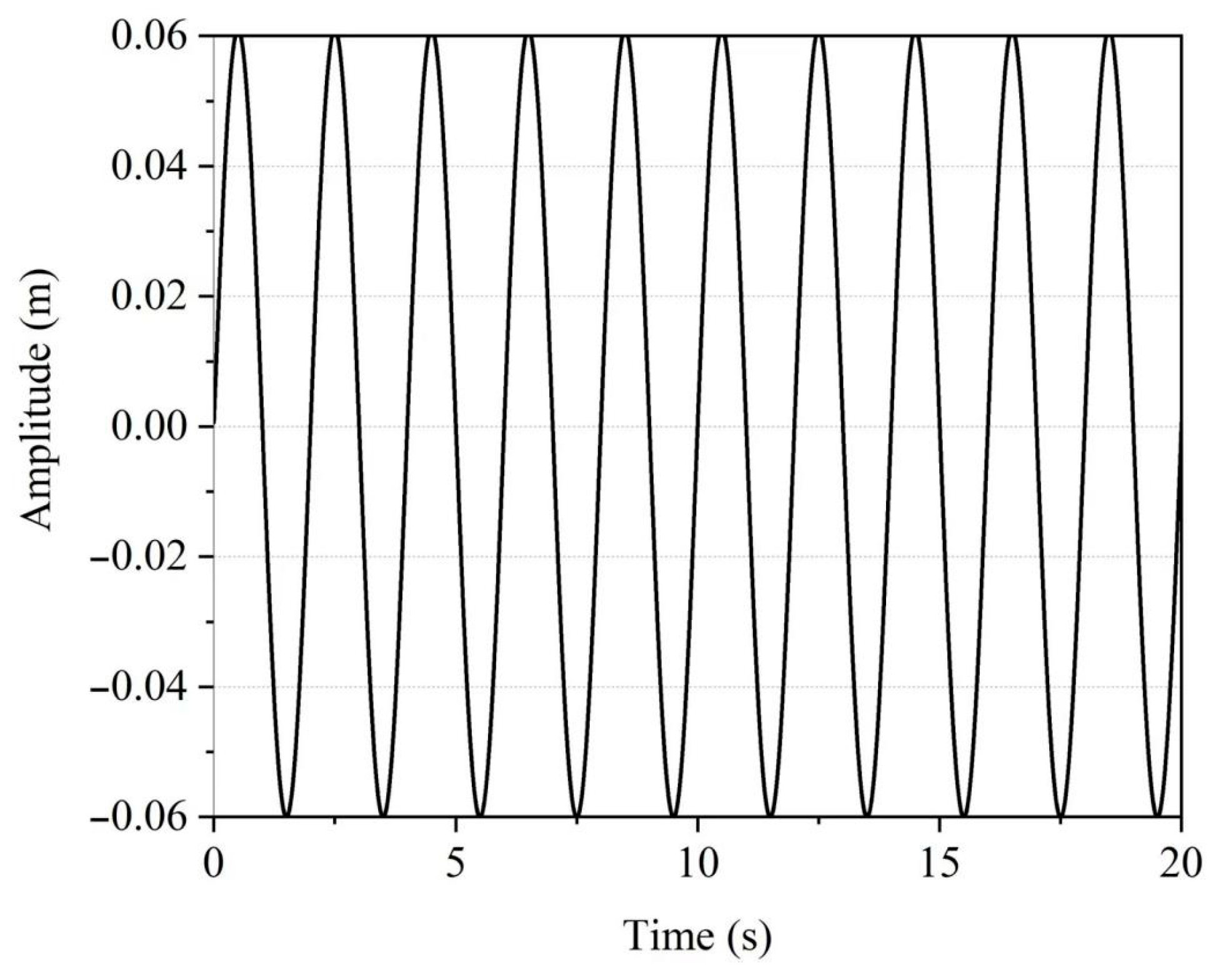

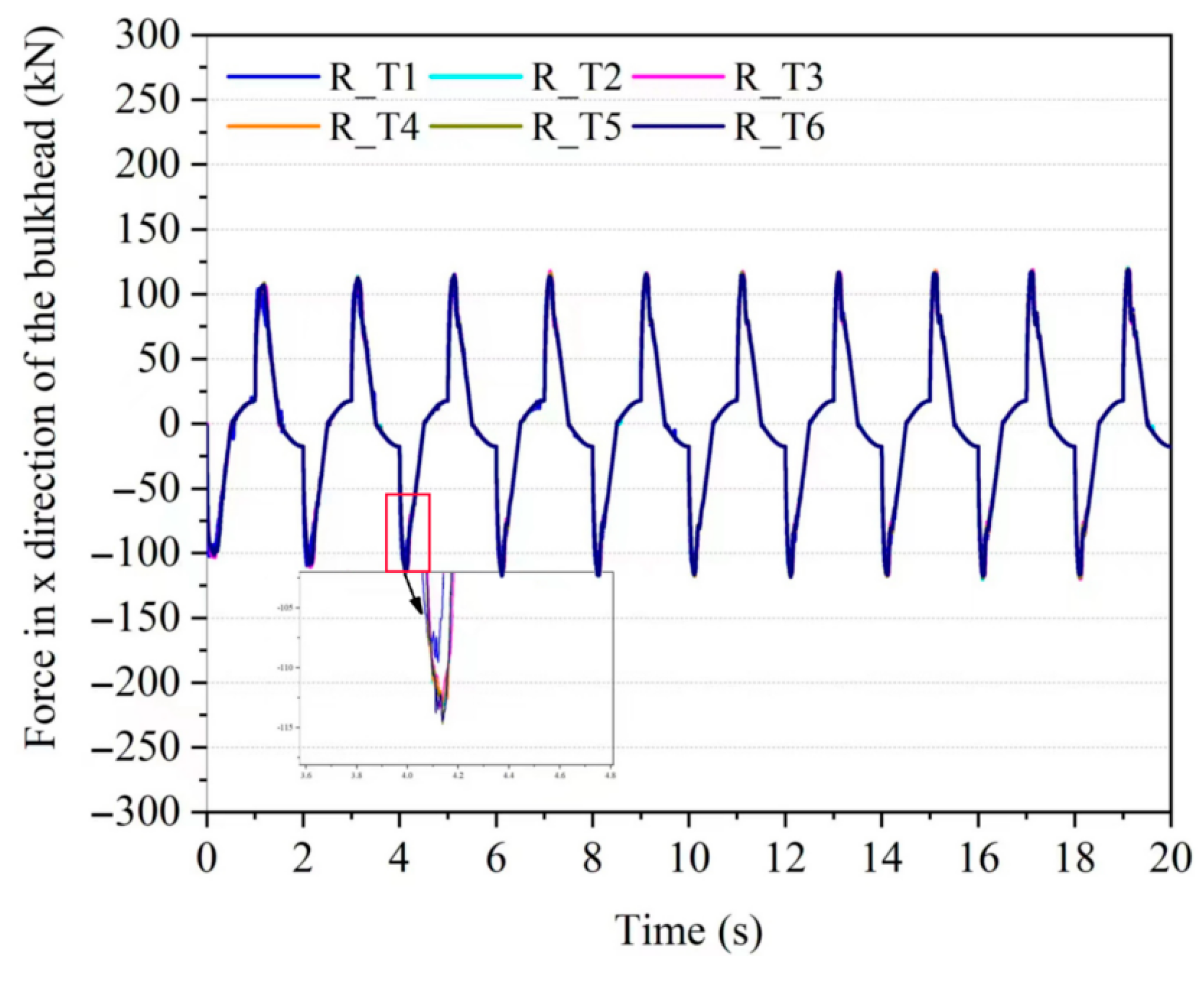

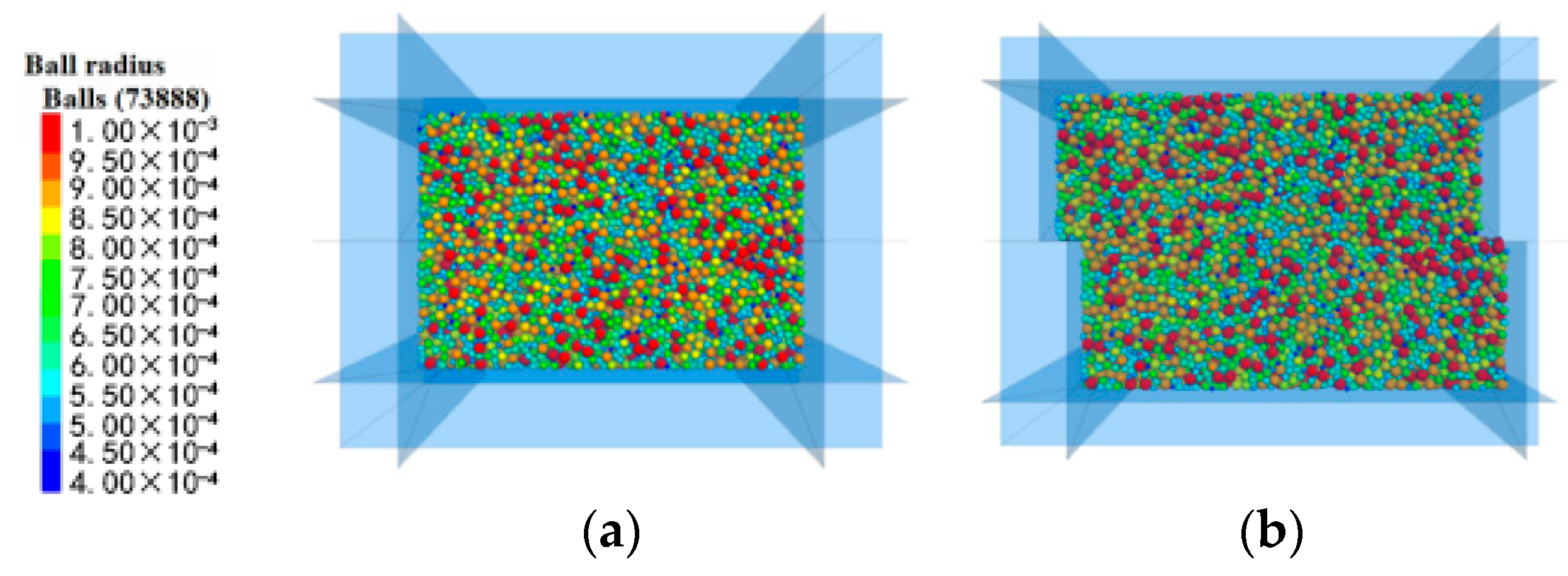

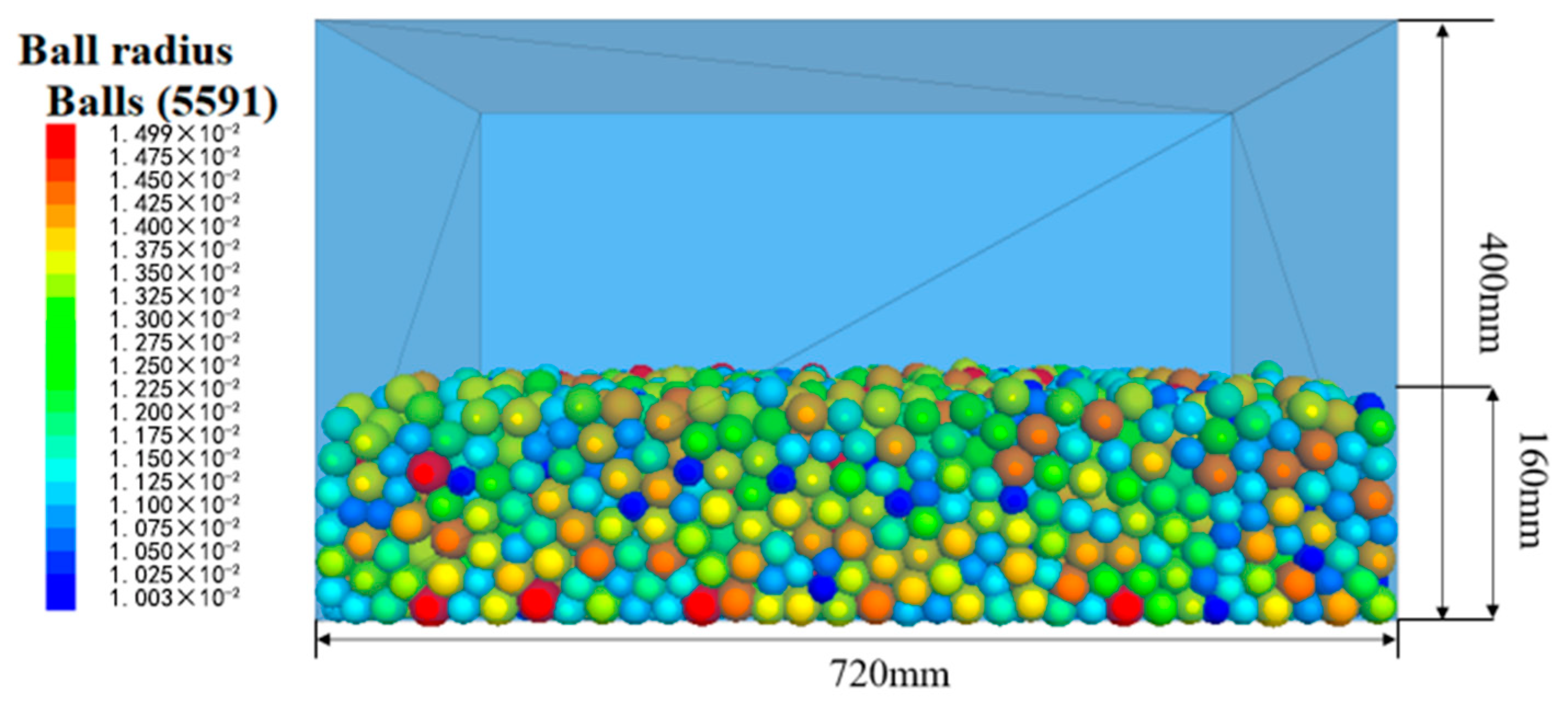

3.1. Sensitivity Analysis of Particle Radius and Time Steps

3.2. Verification of Direct Shear Test

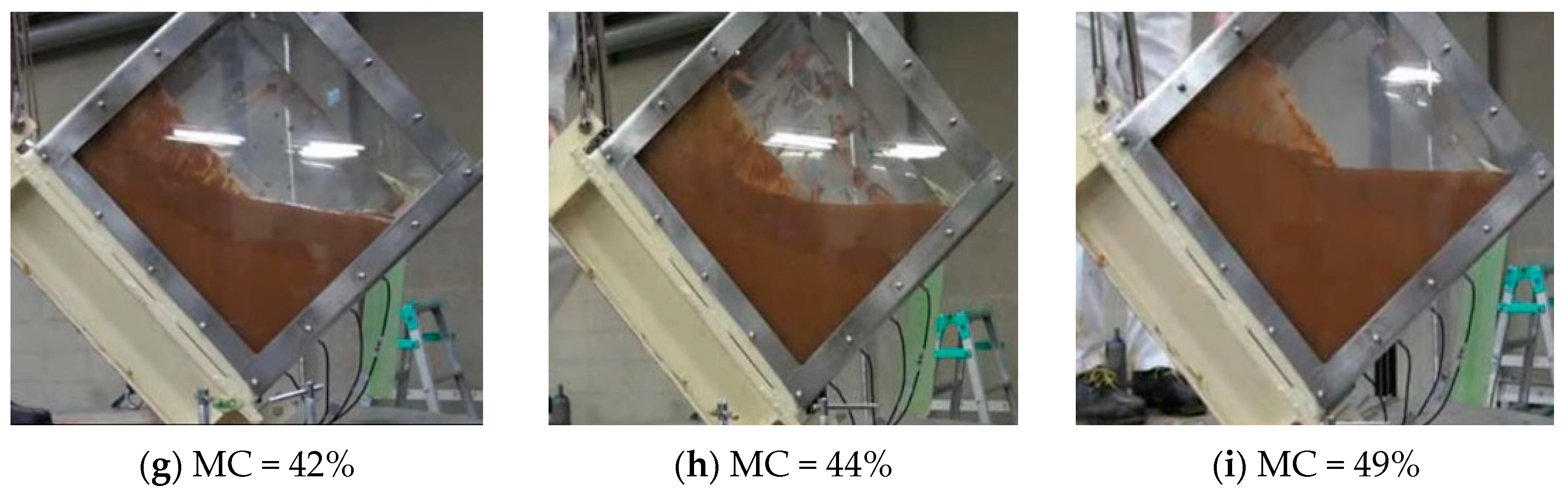

3.3. Numerical Static Tilt Test

4. Simulation Results and Discussion

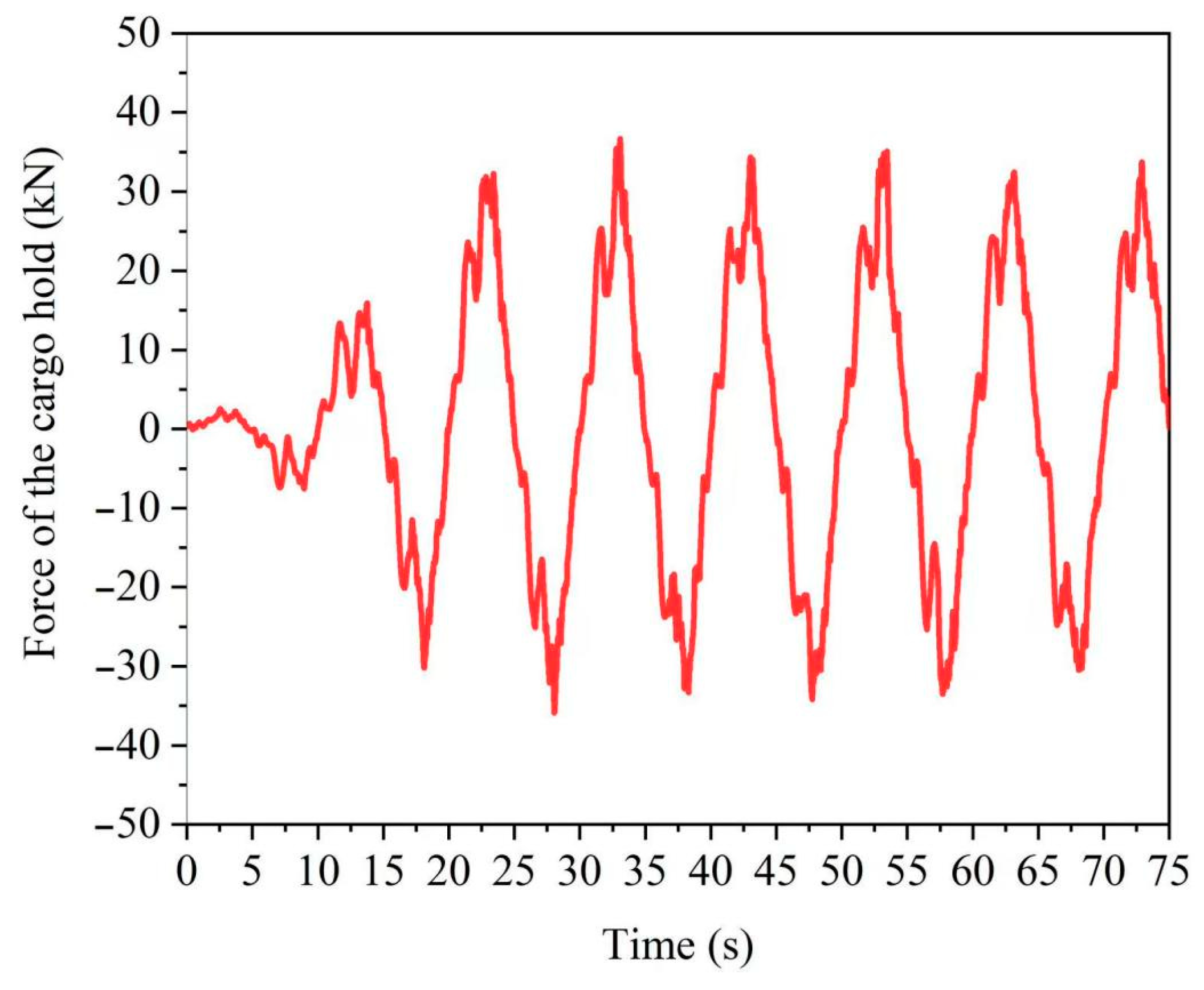

4.1. Without Baffles

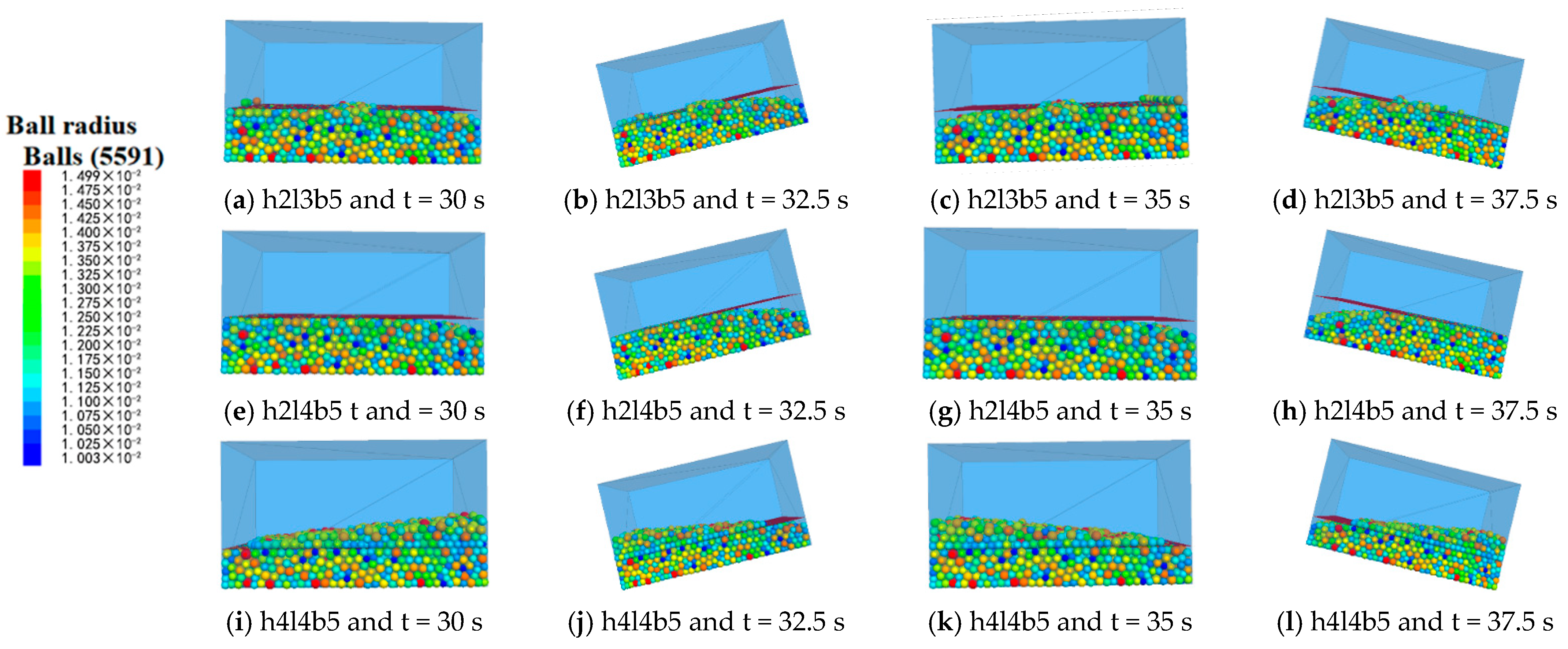

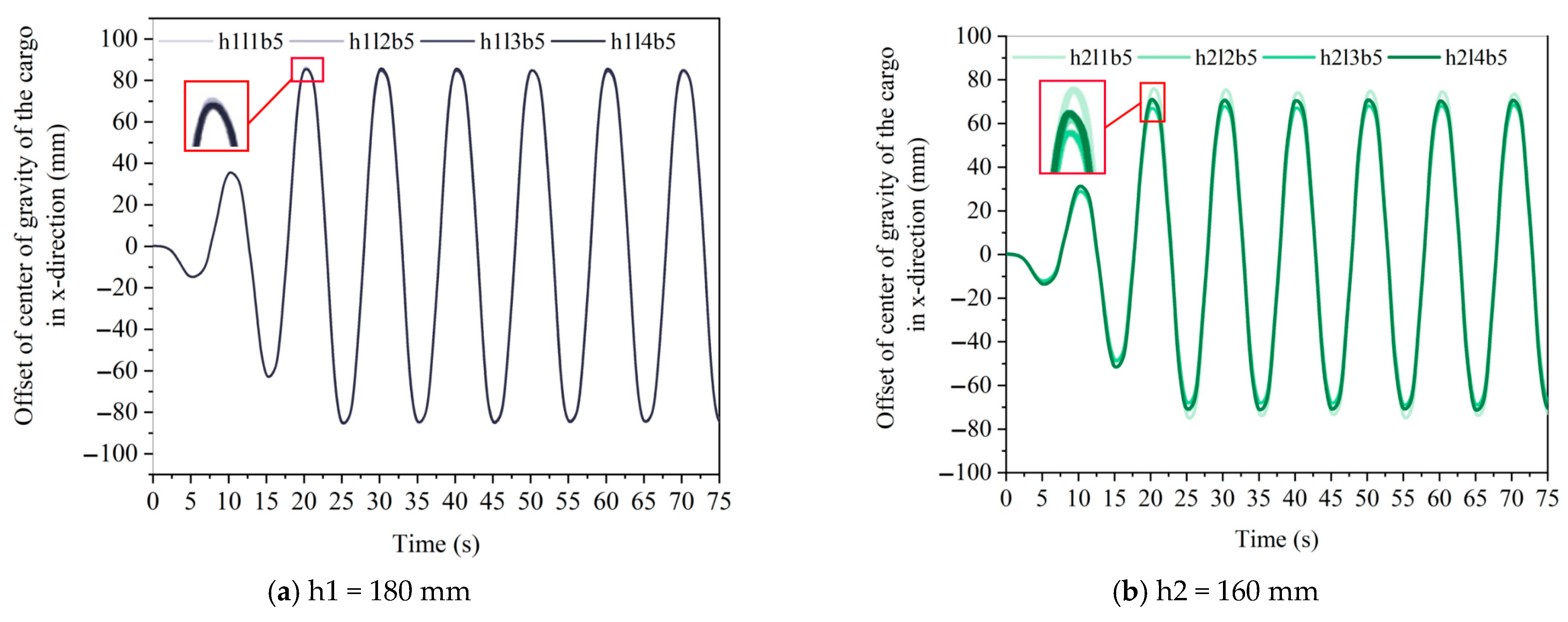

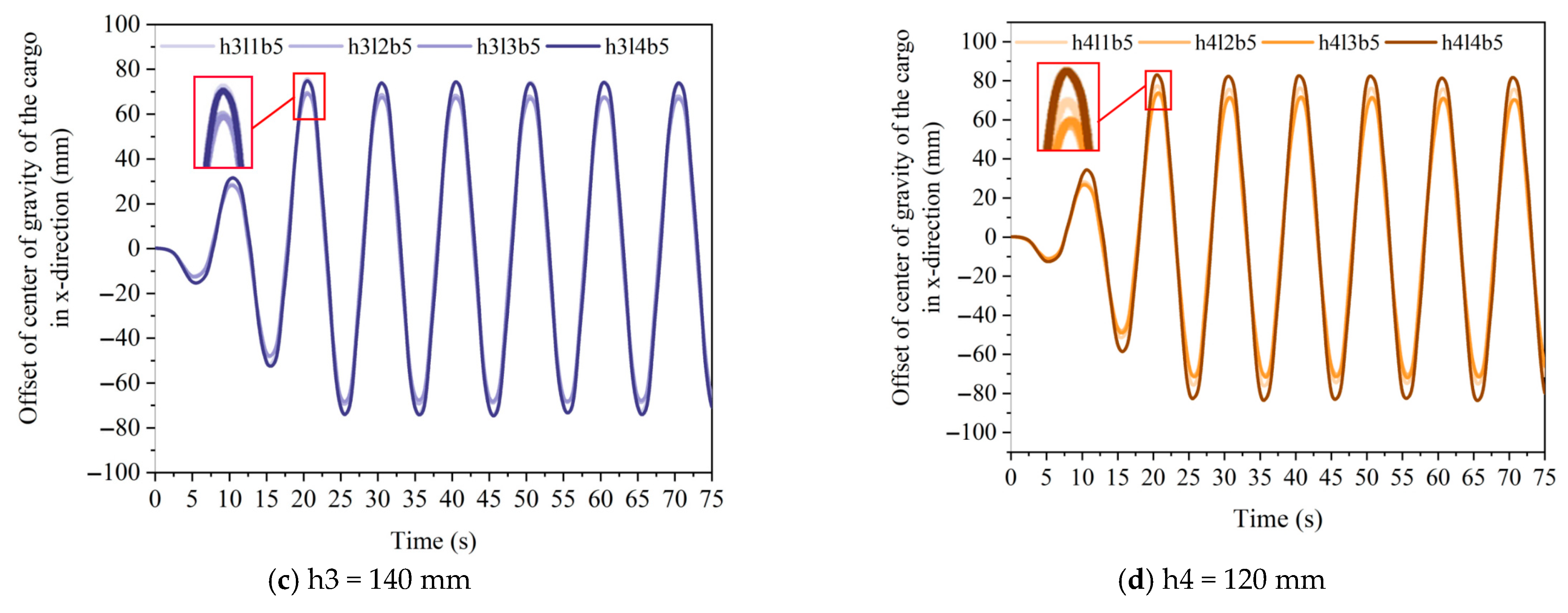

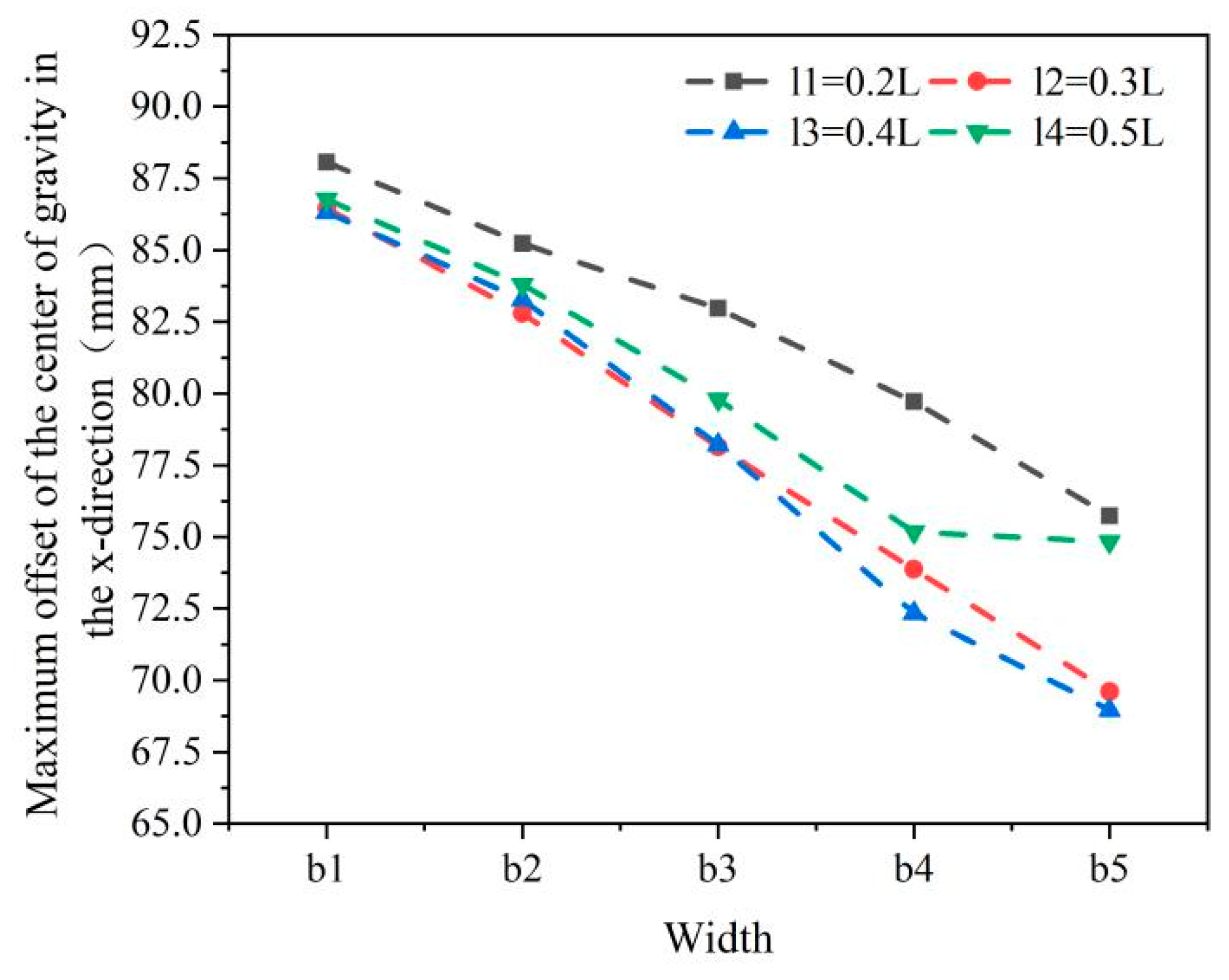

4.2. With One Pair of Horizontal Baffles

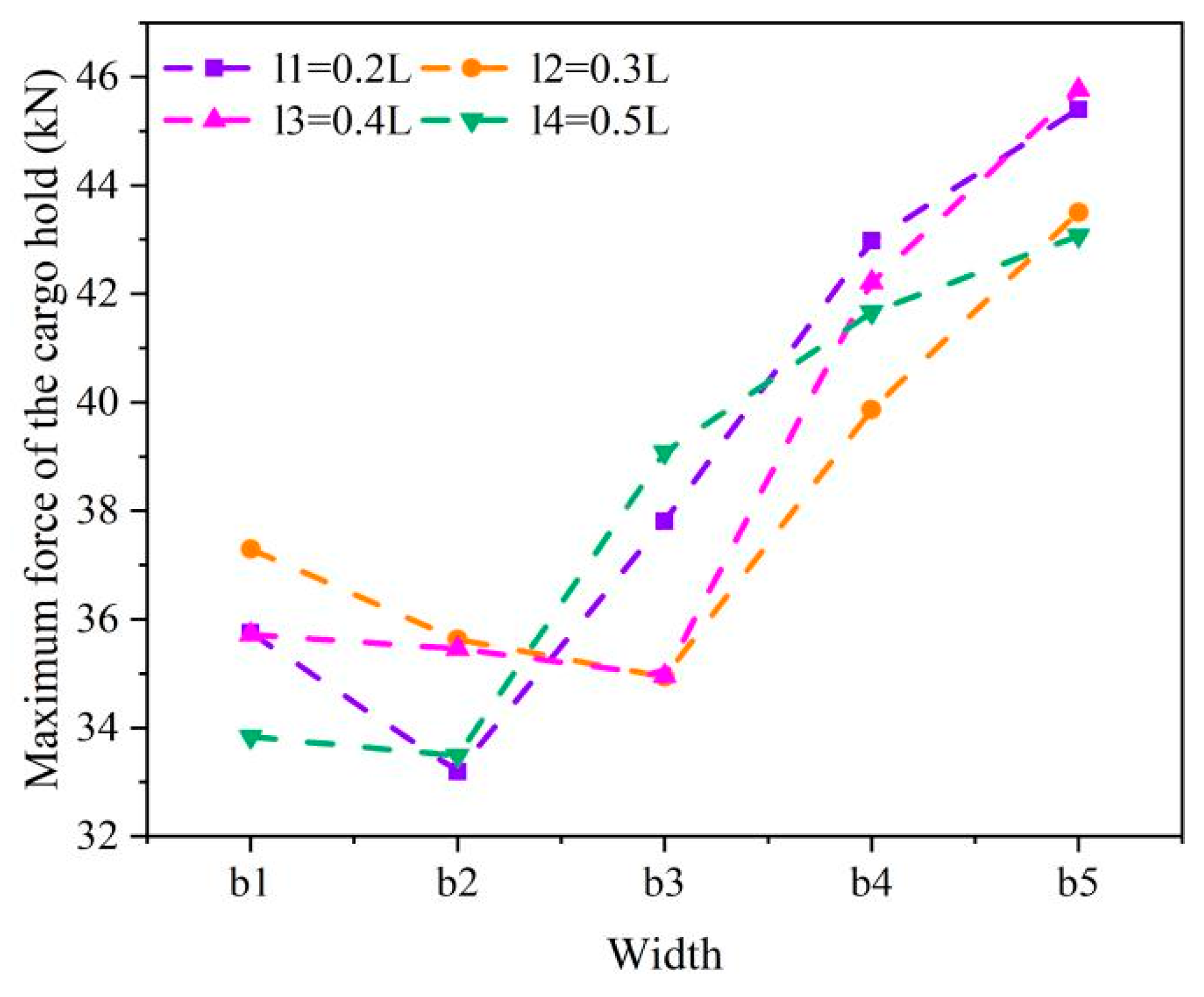

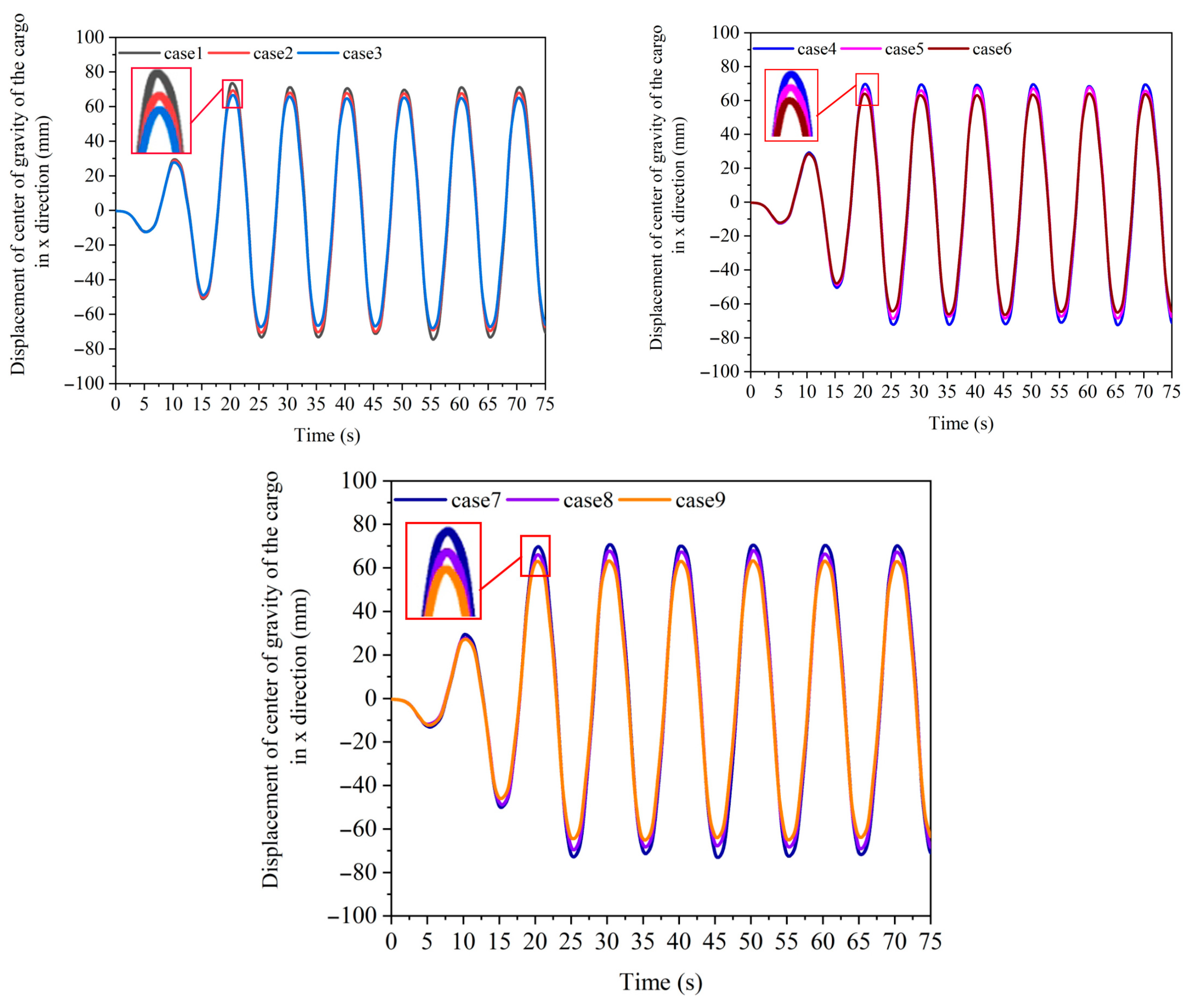

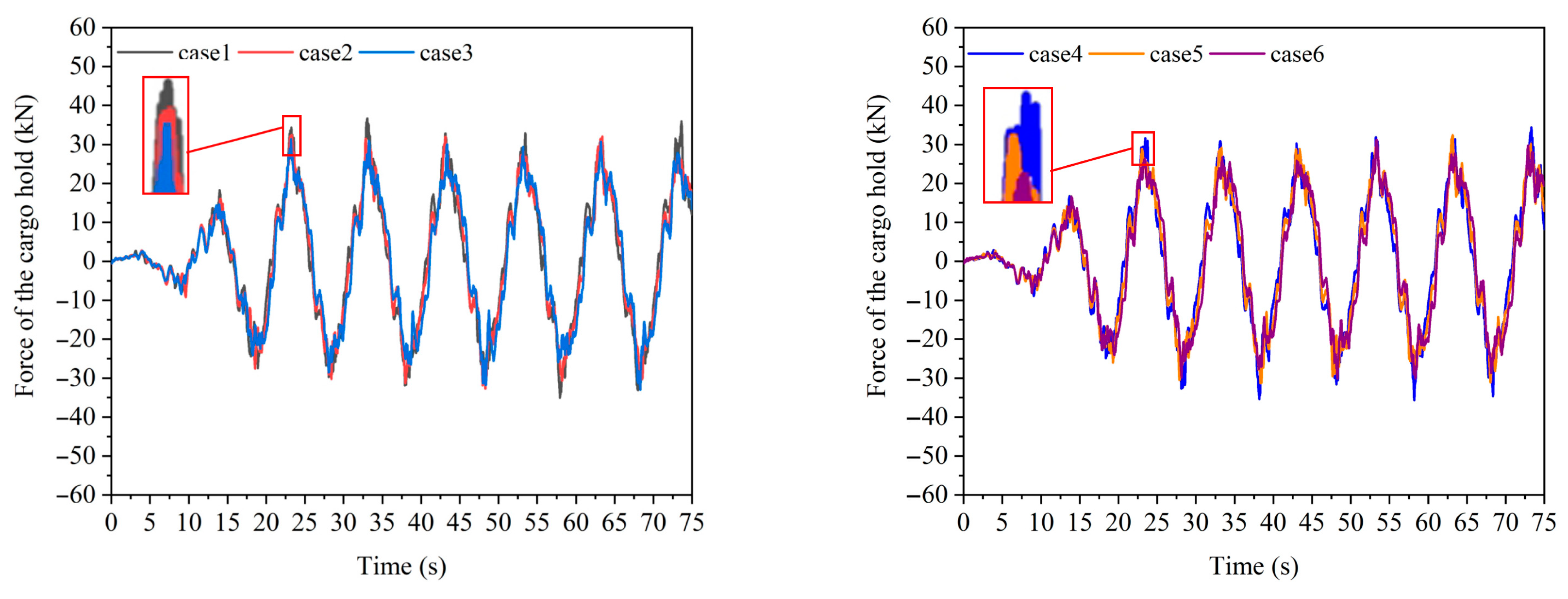

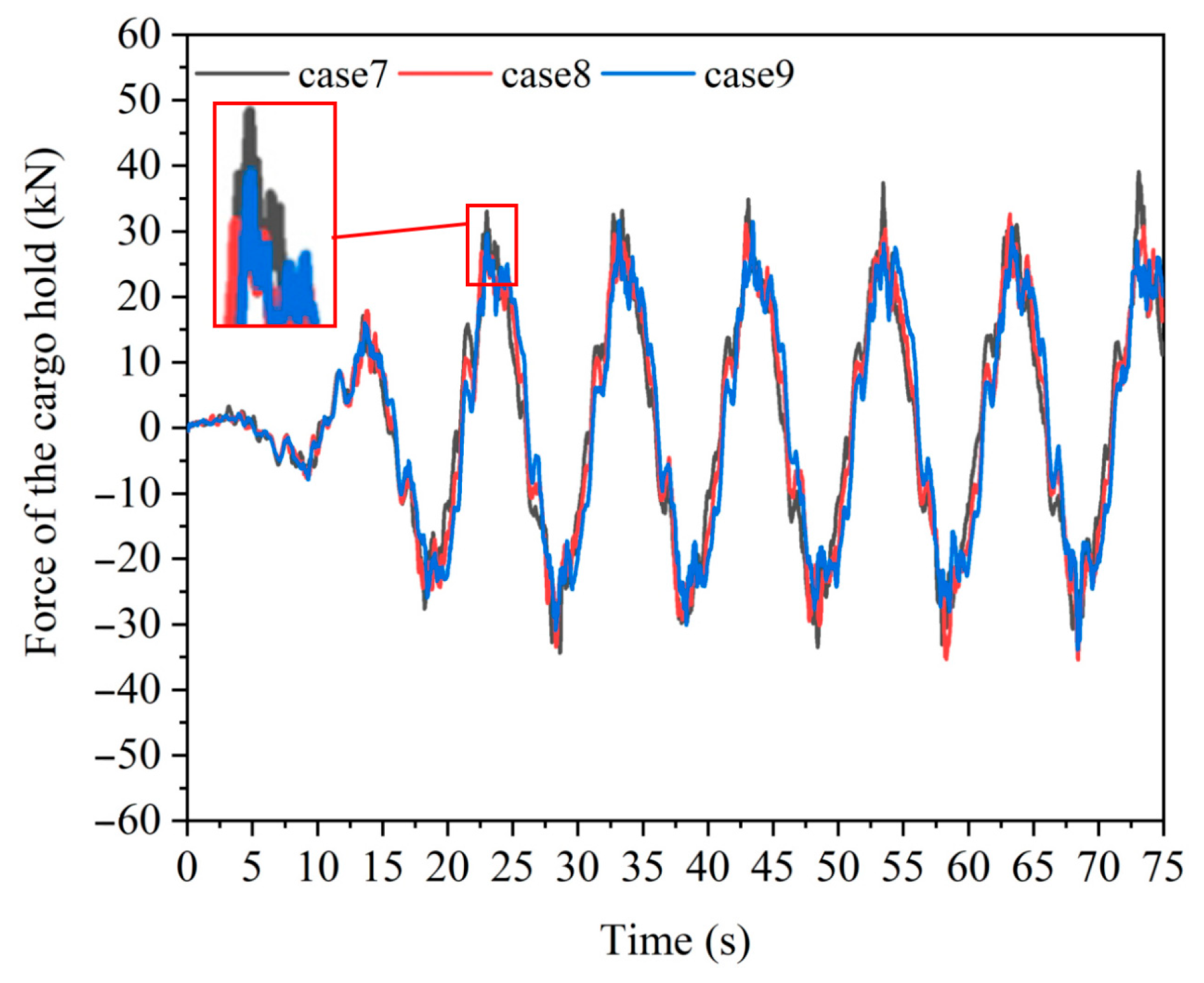

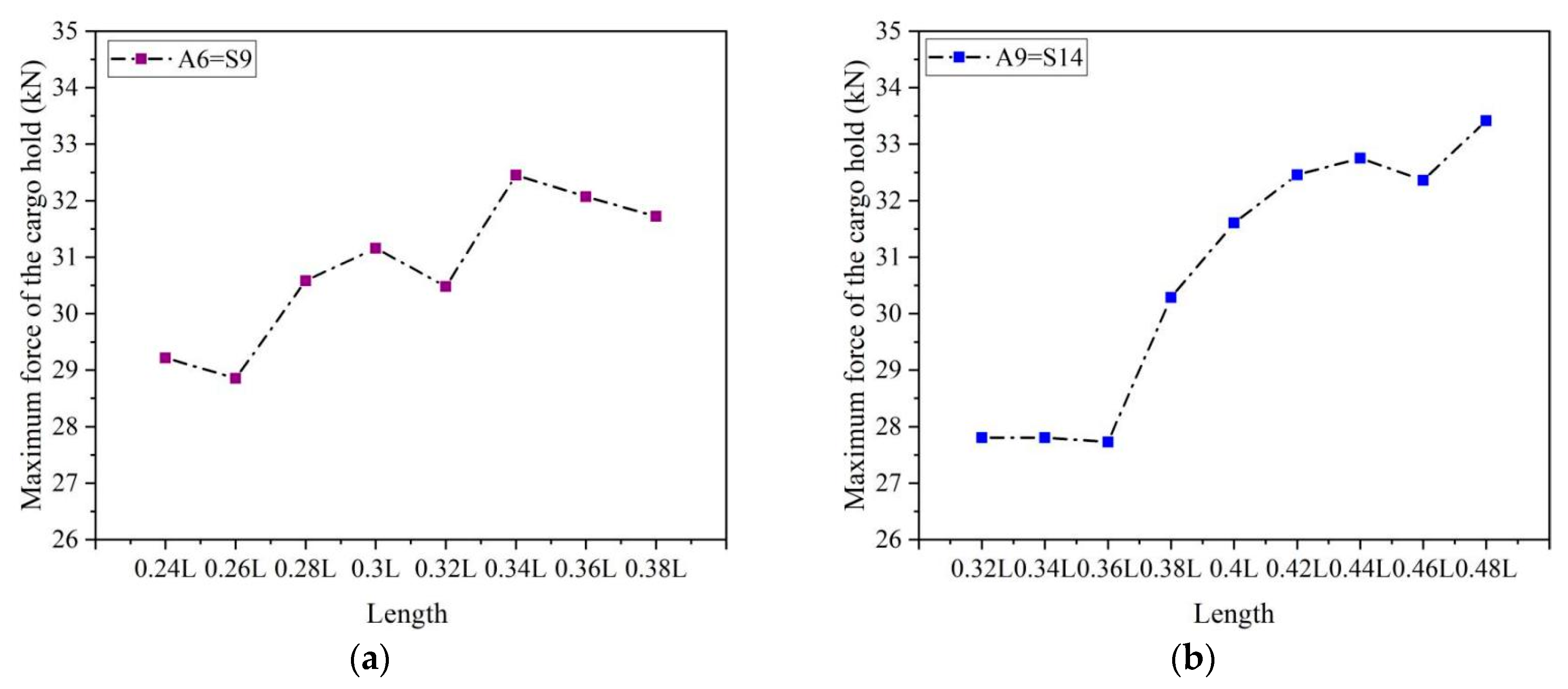

4.3. With Two Pairs of Horizontal Baffles

5. Conclusions

- (1)

- Based on the verification of the direct shear test, the effect of moisture content on particle motion could be estimated by the particle friction coefficients. Characteristics of liquefied cargo sloshing could be captured, and the anti-sloshing effect of different baffles could be interpreted well by the present method.

- (2)

- For liquefied cargo motion in the cargo hold without baffles, cargo accumulation on one side of the cargo hold also occurred. For the roll motion with a frequency of 0.1 Hz and amplitude of 15°, the maximum offset of the cargo gravity center reached about 90.8 mm, accounting for 12.61% of the length of the cargo hold. The maximum force on the cargo hold was about 36.71 kN. These are the two main reasons for the capsizing of these kinds of ships.

- (3)

- For one pair of horizontal baffles, when it is located close to the cargo top surface, the motion amplitude of the cargo and the force on the cargo hold could be reduced to the largest extent. The anti-sloshing effect is proportional to the baffle width, and there is a critical baffle length at which the baffle effect is better.

- (4)

- For two pairs of horizontal baffles, the anti-sloshing effect is better than for one pair of horizontal baffles at the same area rate. But the anti-sloshing effect does not have a linear correlation with the baffle area rate. There is an optimal combination of baffle length and width for a better cargo motion suppression effect. For the present research, the baffle located on the cargo top surface with a baffle length of 0.26 L and a width of 0.46 B had a better anti-sloshing effect and had the smallest baffle area rate.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Xu, Y.; Zhang, J.; Liu, J. Review and prospects on research methods of strength failure for shipped bulk granular cargoes. Marine Georesour. Geotechnol. 2024, 1–19. [Google Scholar] [CrossRef]

- Zhang, J.; Wu, W.; Hu, J. A numerical study of the effects of the longitudinal baffle on nickel ore slurry sloshing in a prismatic cargo hold. Mar. Struct. 2016, 46, 149–166. [Google Scholar] [CrossRef]

- Zhang, J.; Wu, W.; Zhao, Z.; Chen, Y. Numerical study on coupled effect of a vessel loaded with liquefied nickel ore. J. Mar. Sci. Technol. 2020, 25, 520–535. [Google Scholar] [CrossRef]

- Seed, H.B.; Idriss, I.M. Simplified procedure for evaluating soil liquefaction potential. J. Soil Mech. Found. Div. 1971, 97, 1249–1273. [Google Scholar] [CrossRef]

- Munro, M.C.; Mohajerani, A. Bulk cargo liquefaction incidents during marine transportation and possible causes. Ocean Eng. 2017, 141, 125–142. [Google Scholar] [CrossRef]

- Intercargo. Bulk Carrier Casualty Report 2014–2023—Intercargo. 2023. Available online: https://www.intercargo.org/bulk-carrier-casualty-report-2014-2023/ (accessed on 10 July 2024).

- Mohajerani, A.; Dean, J.; Munro, M.C. An overview of the behaviour of iron ore fines cargoes, and some recommended solutions for the reduction of shifting incidents during marine transportation. Ocean Eng. 2019, 182, 451–474. [Google Scholar] [CrossRef]

- Moreira, D.D.; dos Santos, C.A.; Mesquita, A.L.; Moreira, D.C. Influence of particle size distribution of iron ore fines on liquefaction during marine transportation. Powder Technol. 2020, 373, 301–309. [Google Scholar] [CrossRef]

- Ferreira, R.F.; Lima RM, F. Relationship between particle size distribution and the PFD80 transportable moisture limit of iron ore fines. Powder Technol. 2023, 414, 118072. [Google Scholar] [CrossRef]

- Airey, D.W.; Ghorbani, J. Analysis of unsaturated soil columns with application to bulk cargo liquefaction in ships. Comput. Geotech. 2021, 140, 104402. [Google Scholar] [CrossRef]

- Guideline for the Safe Carriage of Nickel Ore, 2nd ed.; Nippon Kaiji Kyokai (ClassNK) Research Institute: Chiyoda-ku, Japan, 2012.

- Ju, L.; Vassalos, D.; Wang, Q.; Wang, Y.; Liu, Y. Numerical investigation of solid bulk cargo liquefaction. Ocean Eng. 2018, 159, 333–347. [Google Scholar] [CrossRef]

- Zhou, J.; Du, Q.; Jian, Q.W.; Li, C.; Zhang, Z.Q. Discrete element numerical simulation of model experiments of iron concentrate ore fluidization during shipping. J. Hohai Univ. (Nat. Sci.) 2016, 44, 219–225. [Google Scholar]

- Zou, Y.; Deng, J. Horizontal impact loads and torsional moment induced by partial cargo shifts. Ocean Eng. 2022, 252, 111260. [Google Scholar] [CrossRef]

- Wu, W.; Li, Y.; Zhao, Z.; Zheng, Q.; Zhang, C.; Ji, H.; Yu, X.; Yu, S. Quantitative analysis of liquefaction risk of liquefiable solid bulk cargoes during sea transport. Ocean Eng. 2022, 258, 111751. [Google Scholar] [CrossRef]

- Qin, H.; Mu, L.; Tang, W.; Hu, Z. Numerical study on structural response of anti-sloshing baffles of different configurations in a sloshing tank considering hydroelasticity. Ocean Eng. 2019, 188, 106290. [Google Scholar] [CrossRef]

- George, A.; Cho, I.H. Anti-sloshing effects of a vertical porous baffle in a rolling rectangular tank. Ocean Eng. 2020, 214, 107871. [Google Scholar] [CrossRef]

- Bellezi, C.A.; Cheng, L.Y.; Nishimoto, K. A numerical study on sloshing mitigation by vertical floating rigid baffle. J. Fluids Struct. 2022, 109, 103456. [Google Scholar] [CrossRef]

- Saito, Y.; Sawada, T. Dynamic pressure change in a rotating, laterally oscillating cylindrical container. J. Ocean Eng. Sci. 2018, 3, 91–95. [Google Scholar] [CrossRef]

- Molin, B. Hydrodynamic modeling of perforated structures. Appl. Ocean Res. 2011, 33, 1–11. [Google Scholar] [CrossRef]

- Molin, B.; Remy, F. Experimental and numerical study of the sloshing motion in a rectangular tank with a perforated screen. J. Fluids Struct. 2013, 43, 463–480. [Google Scholar] [CrossRef]

- Chu, C.R.; Wu, Y.R.; Wu, T.R.; Wang, C.Y. Slosh-induced hydrodynamic force in a water tank with multiple baffles. Ocean Eng. 2018, 167, 282–292. [Google Scholar] [CrossRef]

- Miles, J.W. Ring damping of free surface oscillations in a circular tank. J. Appl. Mech. 1958, 25, 274–276. [Google Scholar] [CrossRef]

- Liang, B.; Zhou, K. Experimental study on rigid and flexible anti-slosh plates in storage tank. J. Astronaut. 1993, 3, 83–89. Available online: https://www.cnki.com.cn/Article/CJFDTotal-YHXB199303011.htm (accessed on 10 July 2024).

- Faltinsen, O.M.; Timokha, A.N. Sloshing; Cambridge University Press: New York, NY, USA, 2009. [Google Scholar]

- Wang, J.H.; Sun, S.L. Study on liquid sloshing characteristics of a swaying rectangular tank with a rolling baffle. J. Eng. Math. 2019, 119, 23–41. [Google Scholar] [CrossRef]

- Celebi, M.S.; Akyildiz, H. Nonlinear modeling of liquid sloshing in a moving rectangular tank. Ocean Eng. 2002, 29, 1527–1553. [Google Scholar] [CrossRef]

- Tsao, W.H.; Chen, Y.C.; Kees, C.E.; Manuel, L. The effect of porous media on wave-induced sloshing in a floating tank. Appl. Sci. 2022, 12, 5587. [Google Scholar] [CrossRef]

- Cho, J.R.; Lee, H.W. Numerical study on liquid sloshing in baffled tank by nonlinear finite element method. Comput. Methods Appl. Mech. Eng. 2004, 193, 2581–2598. [Google Scholar] [CrossRef]

- Cho, J.R.; Lee, H.W.; Ha, S.Y. Finite element analysis of resonant sloshing response in 2-D baffled tank. J. Sound Vib. 2005, 288, 829–845. [Google Scholar] [CrossRef]

- Smaradhana, D.F.; Prabowo, A.R.; Ganda, A.N. Exploring the potential of graphene materials in marine and shipping industries—A technical review for prospective application on ship operation and material structure aspects. J. Ocean Eng. Sci. 2021, 6, 299–316. [Google Scholar] [CrossRef]

- Shi, C.; Zhang, Q.; Wang, S.N. Numerical simulation technology and application with particle flow code (PFC5.0). Rock Soil Mech. 2018, 39, 43. [Google Scholar]

- PFC Help Manual; ITASCA Consulting Group, Inc.: Minneapolis, MN, USA, 2016.

- Verlet, L. Computer “experiments” on classical fluids. I. Thermodynamical properties of Lennard-Jones molecules. Phys. Rev. 1967, 159, 98. [Google Scholar] [CrossRef]

- Zhou, J.; Jian, Q.W.; Wu, X.H.; Li, N.; Zhu, Y.M. Model experimental study of fluidization of iron concentrate ore in bulk. Chin. J. Rock Mech. Eng. 2013, 32, 2536–2543. [Google Scholar]

- Qian, J.G.; Yuan, J.Y.; Zhao, C.F. Soil Properties and Soil Mechanics; China Communications Press Co., Ltd.: Beijing, China, 2015. [Google Scholar]

- Zhang, J.; Wang, Z.; Lu, J.; Ju, L.; Chen, G. DEM modeling of the effects external loads and material properties on the stability of nickel ore in a cargo hold. Appl. Ocean Res. 2021, 117, 102949–102965. [Google Scholar] [CrossRef]

- Zhou, J.; Zhu, Y.M.; Jian, Q.W.; Jia, M.C.; Jin, Y.L. Modeling experiments on the fluidization of laterite nickel ore in bulk. Chin. J. Geotech. Eng. 2014, 8, 1515–1520. [Google Scholar]

| Parameters | Value | Parameters | Value |

|---|---|---|---|

| Particle density | 2500 | Acceleration of gravity | 9.8 |

| Normal stiffness | 1 × 105 | Shear stiffness | 5 × 104 |

| Equivalent elastic modulus | 1 × 106 | Stiffness ratio | 2 |

| Friction coefficient | 0.5 | Rolling friction coefficient | 0.5 |

| Groups | Radius/m | Particle Number | Simulation Time/s | Time Steps/s | Computation Time/s |

|---|---|---|---|---|---|

| R_T1 | 0.02 | 600 | 20 | 1 × 10−4 | 1241 |

| R_T2 | 0.01 | 4800 | 20 | 1 × 10−4 | 9405 |

| R_T3 | 0.008 | 9375 | 20 | 1 × 10−4 | 18,074 |

| R_T4 | 0.01 | 4800 | 20 | 2 × 10−4 | 4693 |

| R_T5 | 0.01 | 4800 | 20 | 8 × 10−5 | 11,666 |

| R_T6 | 0.01 | 4800 | 20 | 6 × 10−5 | 14,175 |

| Parameters | Value | Parameters | Value |

|---|---|---|---|

| Normal stiffness | 1 × 108 | Particle density | 2700 |

| Shear stiffness | 1 × 108 | Particle friction coefficient | 0.5 |

| Stiffness ratio | 1 | Wall friction coefficient | 0.2 |

| Confining Pressure (Normal Strength)/kPa | Shear Strength/kPa |

|---|---|

| 100 | 86 |

| 200 | 159 |

| 300 | 237 |

| 400 | 291 |

| Moisture Content | Friction Coefficient (μ) | Rolling Friction Coefficient () | Moisture Content | Friction Coefficient (μ) | Rolling Friction Coefficient () | Moisture Content | Friction Coefficient (μ) | Rolling Friction Coefficient () |

|---|---|---|---|---|---|---|---|---|

| 35% | 0.7 | 0.5 | 38% | 0.35 | 0.22 | 42% | 0.08 | 0.02 |

| 36% | 0.6 | 0.4 | 39% | 0.2 | 0.05 | 44% | 0.02 | 0.02 |

| 37% | 0.4 | 0.35 | 40% | 0.1 | 0.02 | 49% | 0.005 | 0.005 |

| Cases | Baffle Length/mm | Baffle Width/mm | Installation Height/mm | |

|---|---|---|---|---|

| l1b1 | l1 = 0.2 L = 144 | b1 = 0.2 B = 96 b2 = 0.4 B = 192 b3 = 0.6 B = 288 b4 = 0.8 B= 384 b5 = B = 480 | h1 = 180 h2 = 160 h3 = 140 h4 = 120 | |

| l1b2 | ||||

| l1b3 | ||||

| l1b4 | ||||

| l1b5 | ||||

| l2b1 | l2 = 0.3 L = 216 | |||

| l2b2 | ||||

| l2b3 | ||||

| l2b4 | ||||

| l2b5 | ||||

| l3b1 | l3 = 0.4 L= 288 | |||

| l3b2 | ||||

| l3b3 | ||||

| l3b4 | ||||

| l3b5 | ||||

| l4b1 | l4 = 0.5 L= 360 | |||

| l4b2 | ||||

| l4b3 | ||||

| l4b4 | ||||

| l4b5 |

| Cases | Length of a Single Baffle/mm | Width of a Single Baffle/mm | Area Rate | |

|---|---|---|---|---|

| Case 1 | 0.2 L = 144 | 0.2 B = 96 | 16% | |

| Case 2 | 0.2 L = 144 | 0.3 B = 144 | 24% | |

| Case 3 | 0.2 L = 144 | 0.4 B = 192 | 32% | |

| Case 4 | 0.3 L = 216 | 0.2 B = 96 | 24% | |

| Case 5 | 0.3 L = 216 | 0.3 B = 144 | 36% | |

| Case 6 | 0.3 L = 216 | 0.4 B = 192 | 48% | |

| Case 7 | 0.4 L = 288 | 0.2 B = 96 | 32% | |

| Case 8 | 0.4 L = 288 | 0.3 B = 144 | 48% | |

| Case 9 | 0.4 L = 288 | 0.4 B = 192 | 64% |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, J.; Wang, A.; Chen, P.; Liu, J.; Yang, D. Numerical Study on the Anti-Sloshing Effect of Horizontal Baffles in a Cargo Hold Loaded with Liquefied Cargo. J. Mar. Sci. Eng. 2024, 12, 1234. https://doi.org/10.3390/jmse12071234

Zhang J, Wang A, Chen P, Liu J, Yang D. Numerical Study on the Anti-Sloshing Effect of Horizontal Baffles in a Cargo Hold Loaded with Liquefied Cargo. Journal of Marine Science and Engineering. 2024; 12(7):1234. https://doi.org/10.3390/jmse12071234

Chicago/Turabian StyleZhang, Jianwei, Anqi Wang, Peng Chen, Jian Liu, and Deqing Yang. 2024. "Numerical Study on the Anti-Sloshing Effect of Horizontal Baffles in a Cargo Hold Loaded with Liquefied Cargo" Journal of Marine Science and Engineering 12, no. 7: 1234. https://doi.org/10.3390/jmse12071234

APA StyleZhang, J., Wang, A., Chen, P., Liu, J., & Yang, D. (2024). Numerical Study on the Anti-Sloshing Effect of Horizontal Baffles in a Cargo Hold Loaded with Liquefied Cargo. Journal of Marine Science and Engineering, 12(7), 1234. https://doi.org/10.3390/jmse12071234