Experimental Study on the Spring-like Effect on the Hydrodynamic Performance of an Oscillating Water Column Wave Energy Converter

Abstract

:1. Introduction

2. Model Design and Experimental Setup

2.1. Similarity Criterion of the Air Chamber Volume

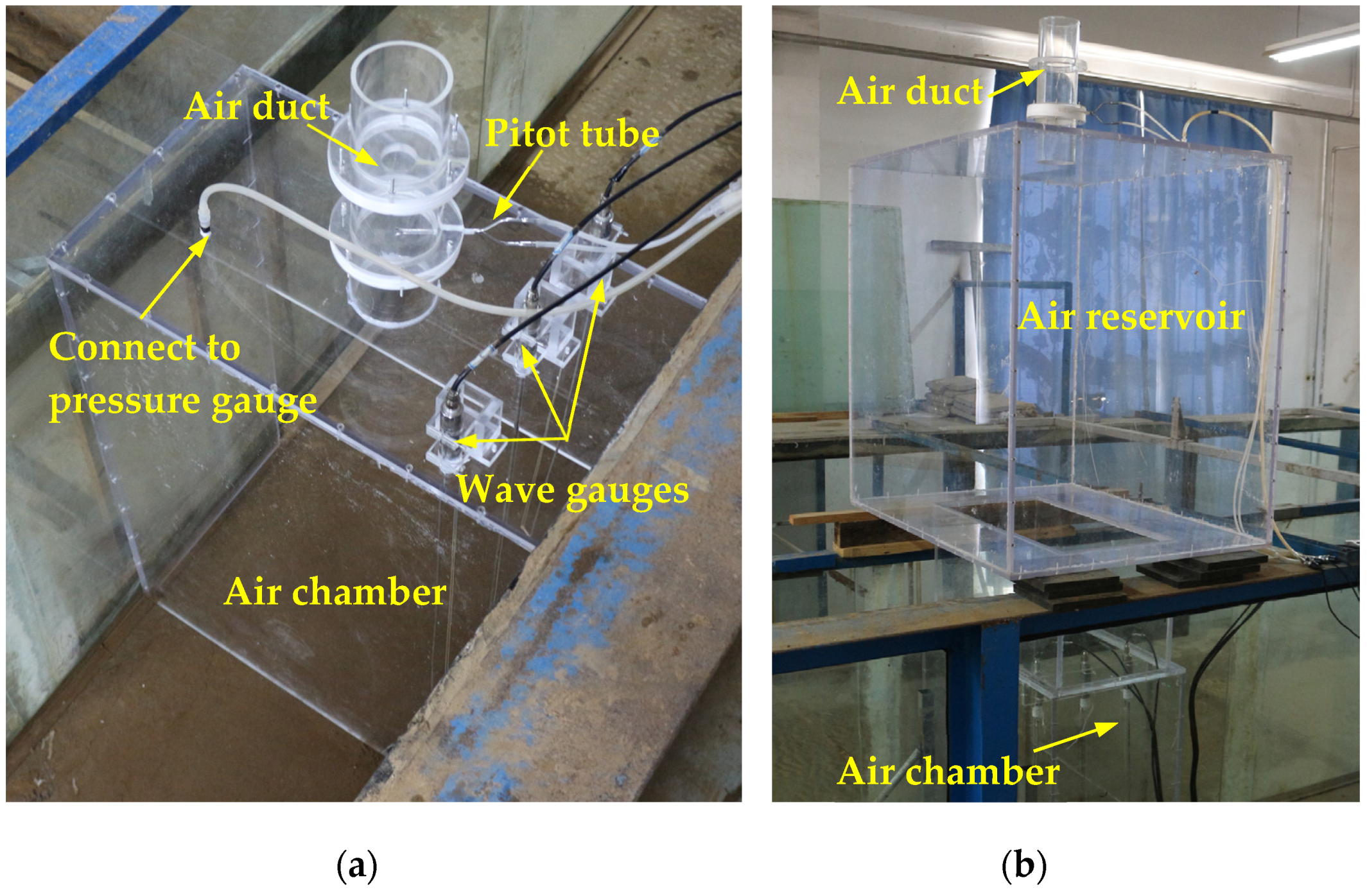

2.2. Model Design of the Air Chamber

2.3. Experimental Setup

3. Experimental Results and Discussion

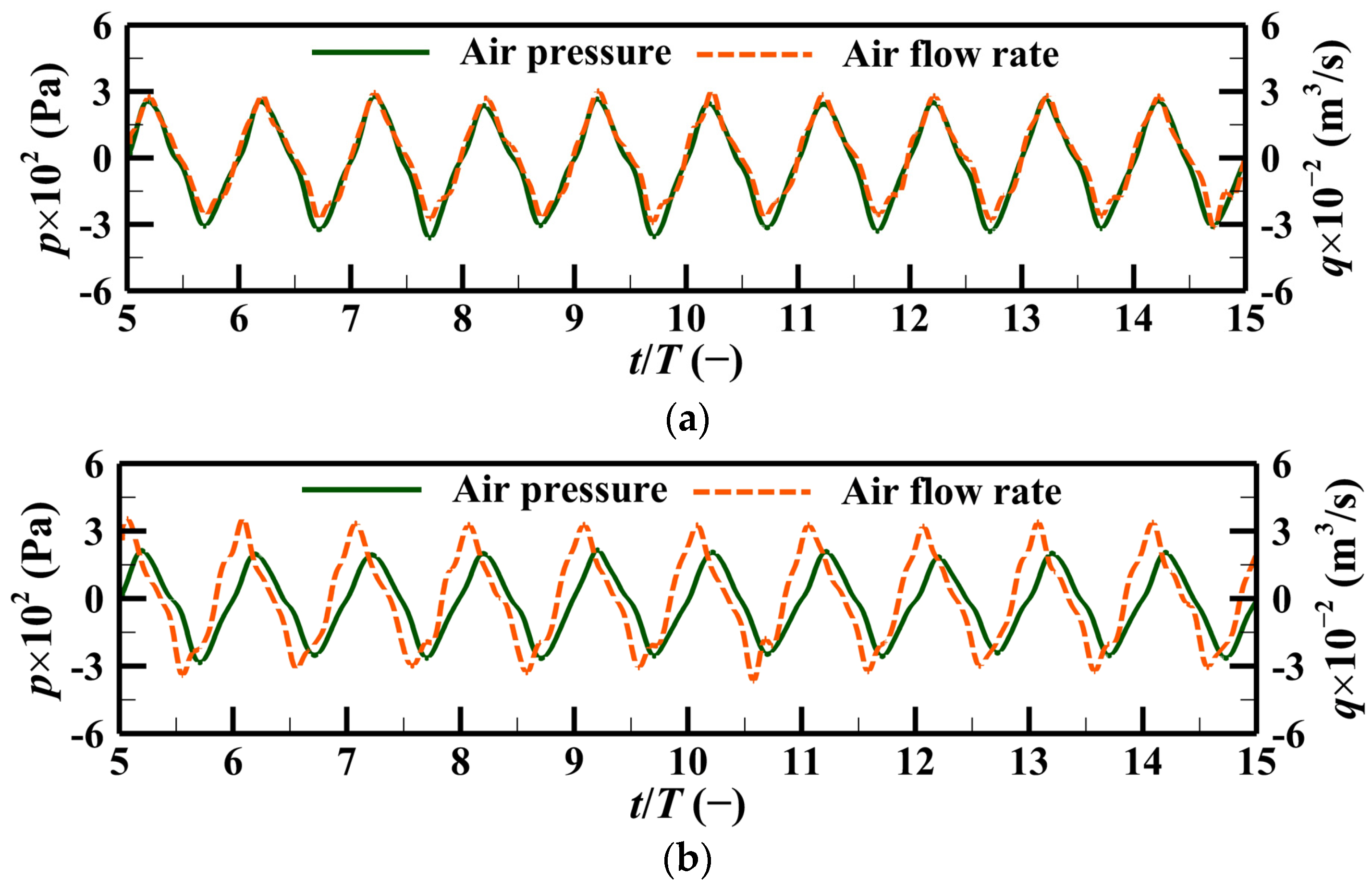

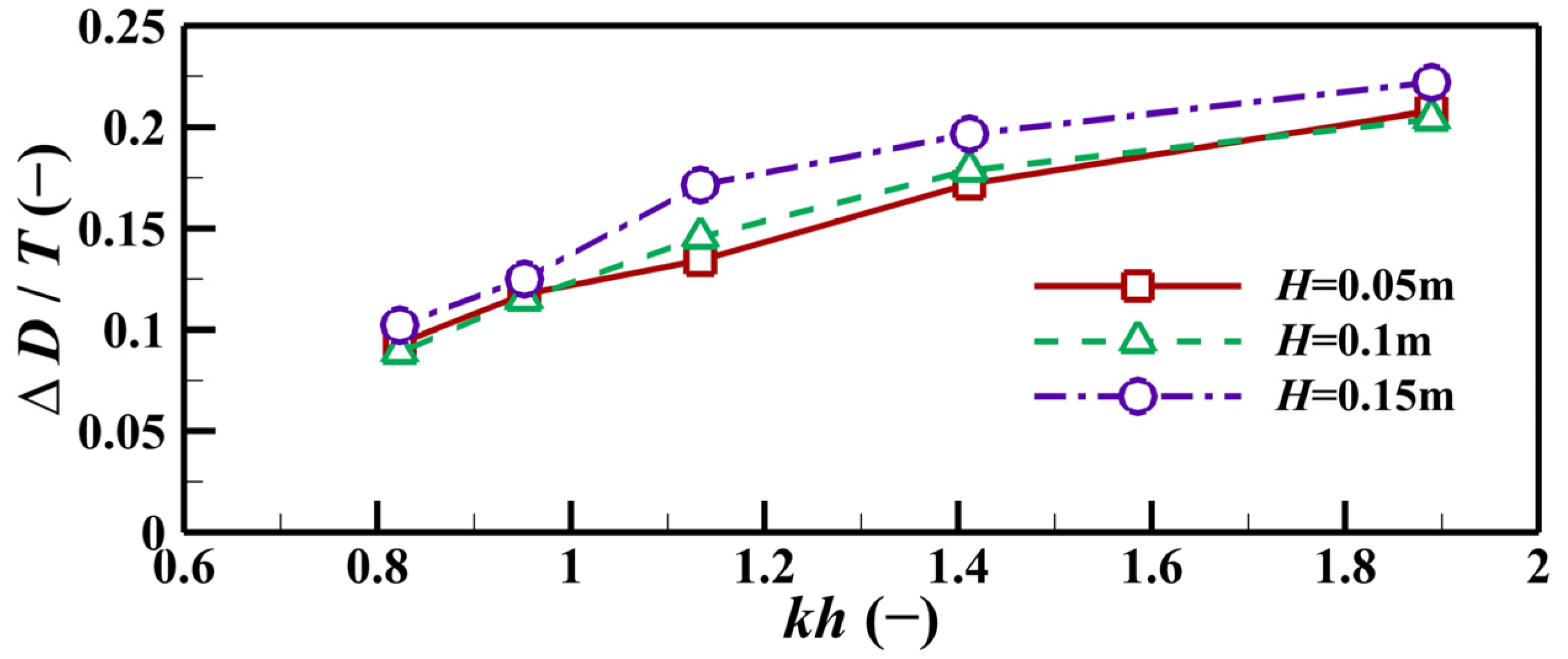

3.1. Phase Difference between Airflow Rate and Air Pressure Oscillation

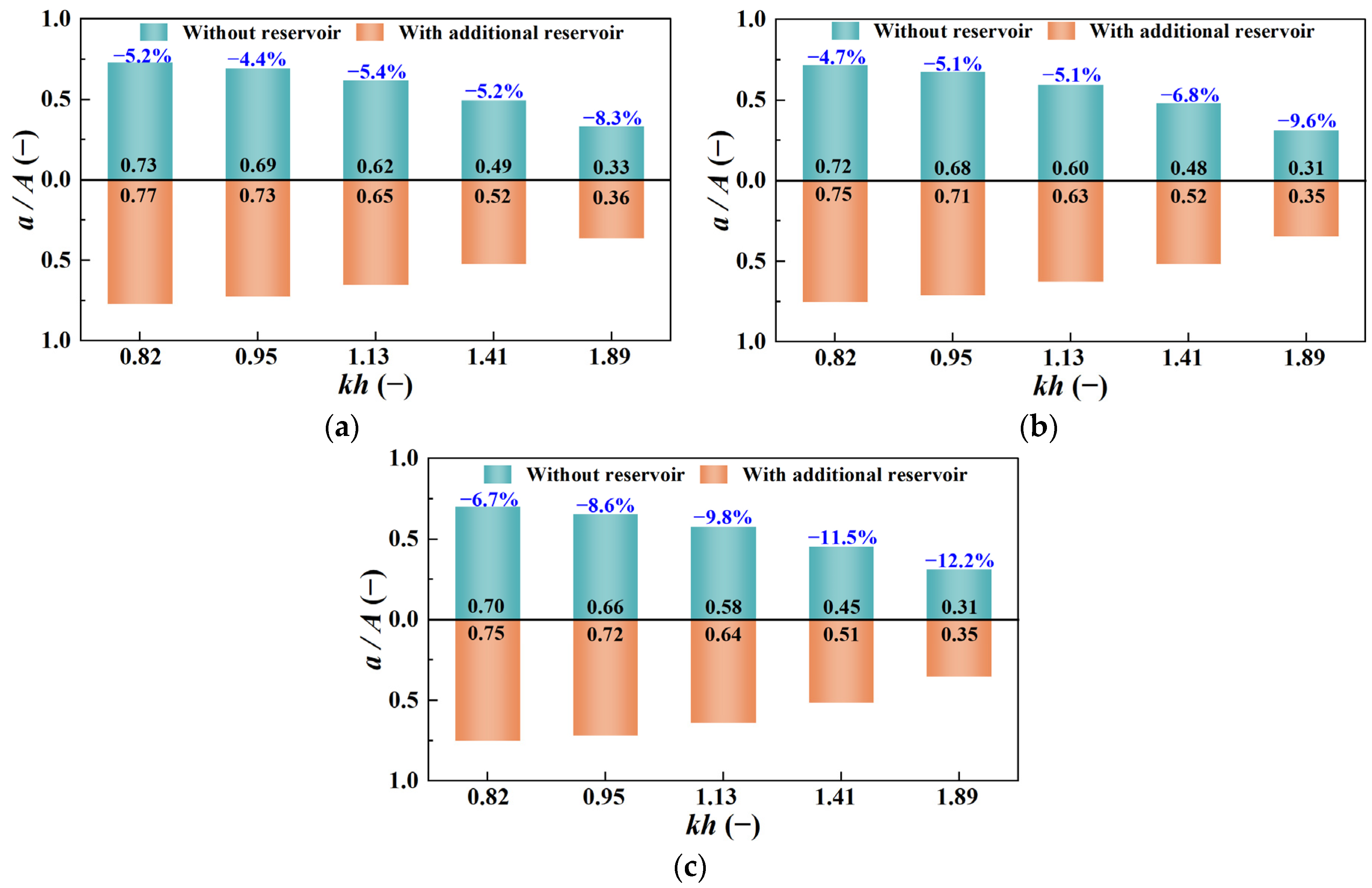

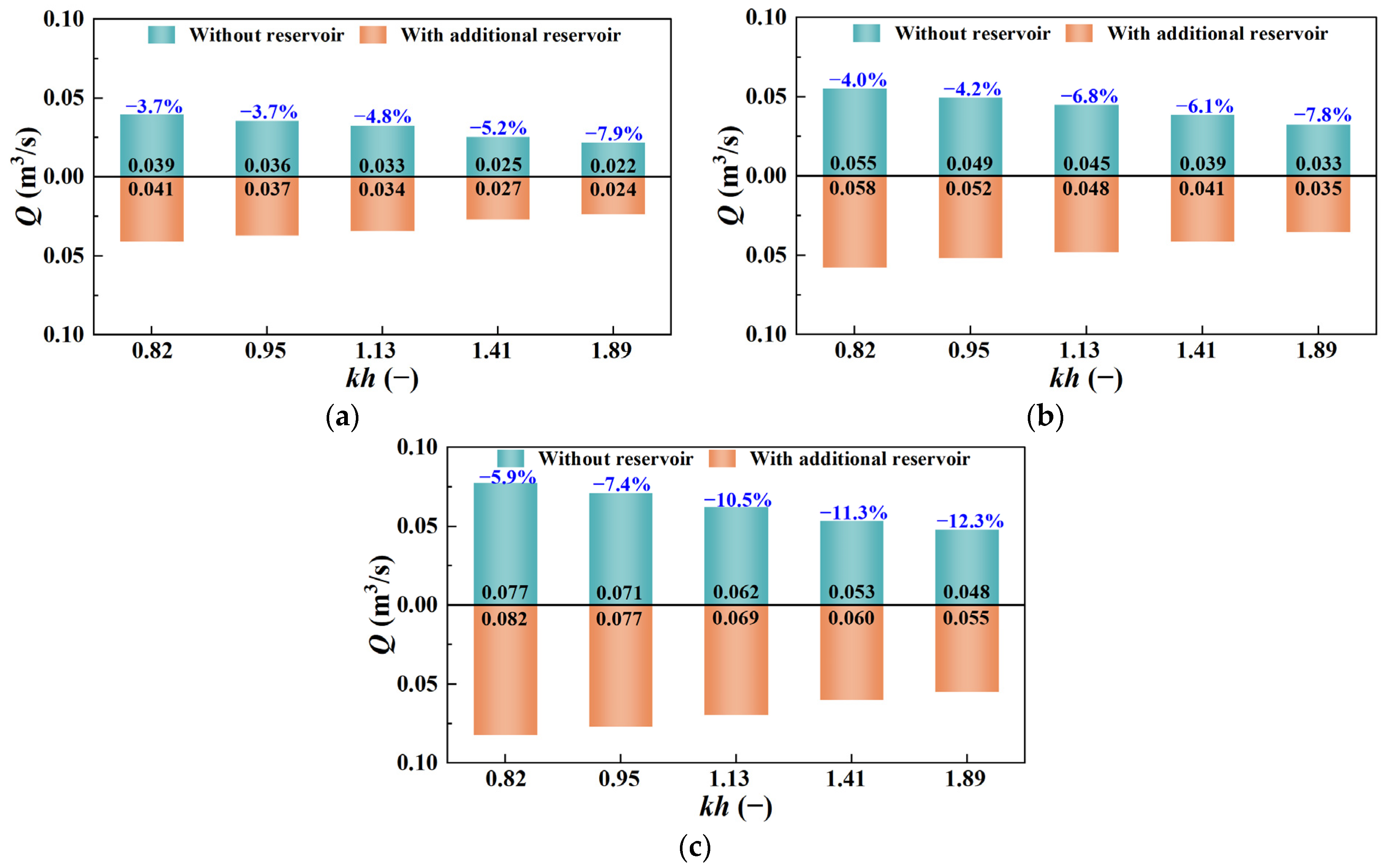

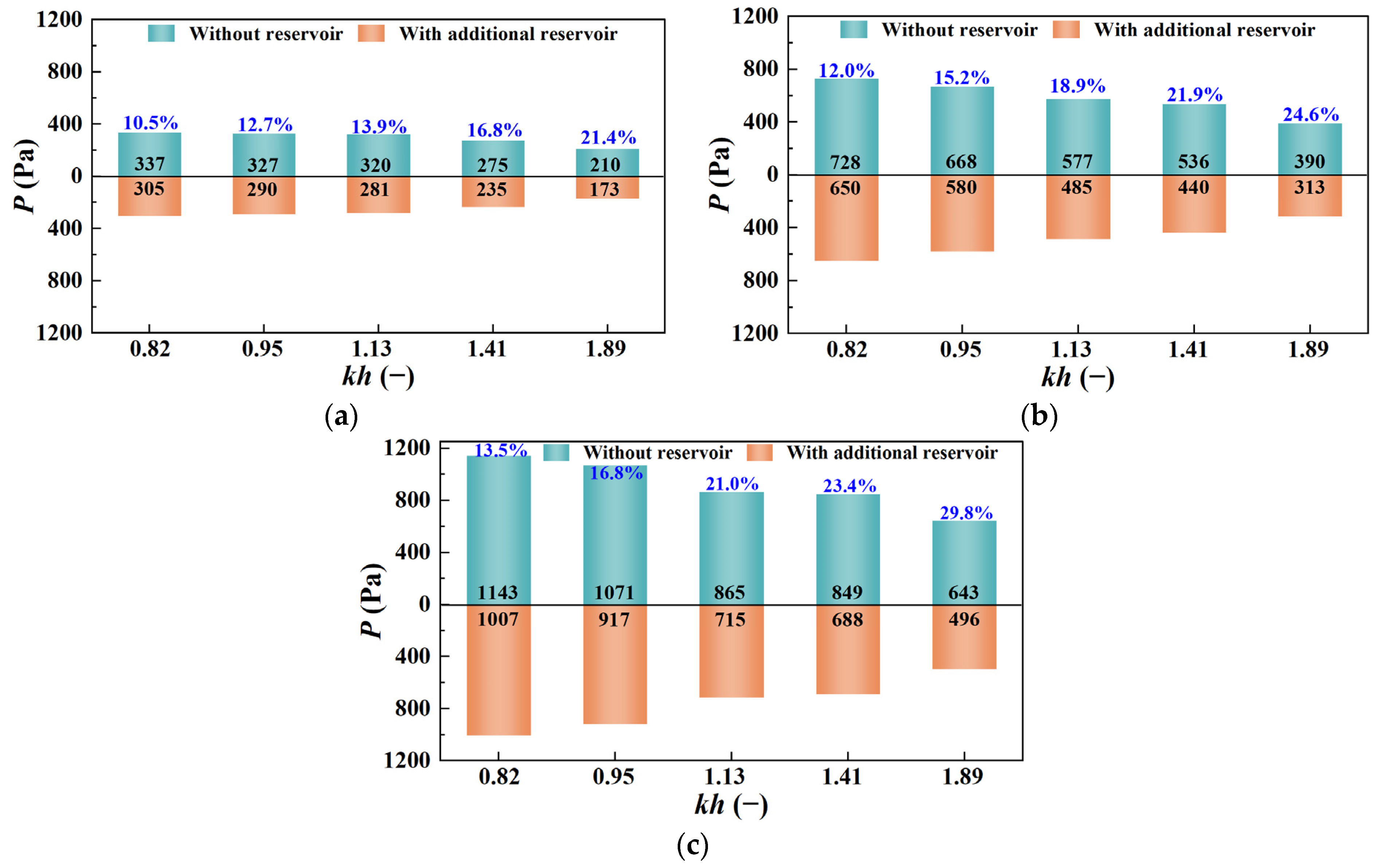

3.2. Spring-like Effect on the Hydrodynamic Performance in Regular Waves

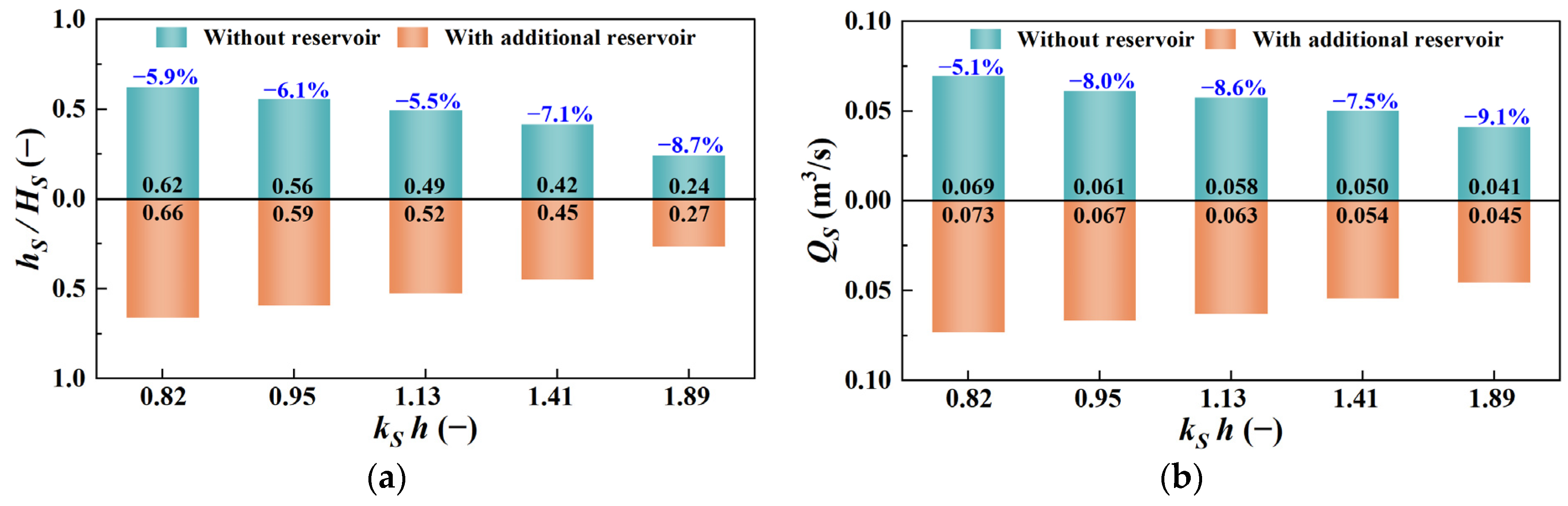

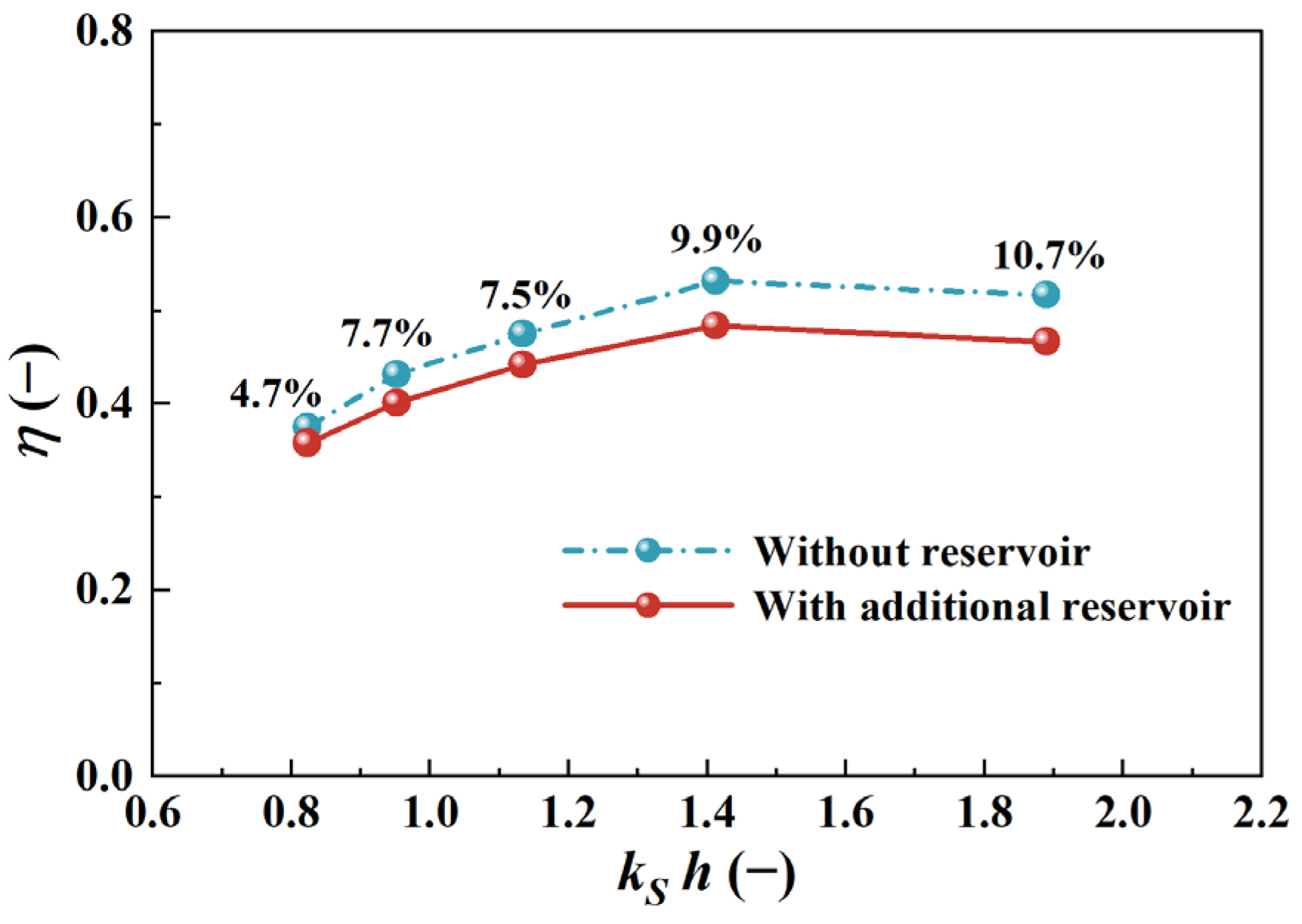

3.3. Spring-like Effect on the Hydrodynamic Performance in Irregular Waves

4. Conclusions

- The spring-like effect induces a phase difference between the air pressure oscillation and the airflow rate displaced by the motion of the free surface elevation. The phase difference increases as the wave frequency increases due to the faster air exchange process.

- When the spring-like effect is not involved, the free surface elevation and the airflow rate are underestimated, and the average errors in regular waves are 7.2% and 6.8%, respectively. On the contrary, the air pressure in the chamber is overestimated by an average of 18.2%.

- The air compressibility does not change the resonant period of the air chamber, but failure to reproduce it will result in an overestimation in the hydrodynamic efficiency. The average error introduced by the spring-like effect on the efficiency is 11.4% for regular waves and 8.1% for irregular waves.

- The results suggest that if the conventional Froude similarity law is used when evaluating the OWC device, the pneumatic outputs should be corrected, and a reduction in conversion performance should be considered.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Khojasteh, D.; Shamsipour, A.; Huang, L.; Tavakoli, S.; Haghani, M.; Flocard, F.; Farzadkhoo, M.; Iglesias, G.; Hemer, M.; Lewis, M.; et al. A Large-Scale Review of Wave and Tidal Energy Research over the Last 20 Years. Ocean Eng. 2023, 282, 114995. [Google Scholar] [CrossRef]

- Zhang, Y.; Zhao, Y.; Sun, W.; Li, J. Ocean Wave Energy Converters: Technical Principle, Device Realization, and Performance Evaluation. Renew. Sustain. Energy Rev. 2021, 141, 110764. [Google Scholar] [CrossRef]

- Rosati, M.; Henriques, J.C.C.; Ringwood, J.V. Oscillating-Water-Column Wave Energy Converters: A Critical Review of Numerical Modelling and Control. Energy Convers. Manag. X 2022, 16, 100322. [Google Scholar] [CrossRef]

- Falcão, A.F.O.; Henriques, J.C.C.; Gato, L.M.C. Self-Rectifying Air Turbines for Wave Energy Conversion: A Comparative Analysis. Renew. Sustain. Energy Rev. 2018, 91, 1231–1241. [Google Scholar] [CrossRef]

- Falcão, A.F.O.; Henriques, J.C.C. Oscillating-Water-Column Wave Energy Converters and Air Turbines: A Review. Renew. Energy 2016, 85, 1391–1424. [Google Scholar] [CrossRef]

- Falcão, A.F.d.O. Wave Energy Utilization: A Review of the Technologies. Renew. Sustain. Energy Rev. 2010, 14, 899–918. [Google Scholar] [CrossRef]

- Prasad, K.A.; Chand, A.A.; Kumar, N.M.; Narayan, S.; Mamun, K.A. A Critical Review of Power Take-Off Wave Energy Technology Leading to the Conceptual Design of a Novel Wave-Plus-Photon Energy Harvester for Island/Coastal Communities’ Energy Needs. Sustainability 2022, 14, 2354. [Google Scholar] [CrossRef]

- Folley, M.; Curran, R.; Whittaker, T. Comparison of LIMPET Contra-Rotating Wells Turbine with Theoretical and Model Test Predictions. Ocean Eng. 2006, 33, 1056–1069. [Google Scholar] [CrossRef]

- Falcão, A.F.O.; Sarmento, A.J.N.A.; Gato, L.M.C.; Brito-Melo, A. The Pico OWC Wave Power Plant: Its Lifetime from Conception to Closure 1986–2018. Appl. Ocean Res. 2020, 98, 102104. [Google Scholar] [CrossRef]

- Sheng, W. Wave Energy Conversion and Hydrodynamics Modelling Technologies: A Review. Renew. Sustain. Energy Rev. 2019, 109, 482–498. [Google Scholar] [CrossRef]

- Gallutia, D.; Tahmasbi Fard, M.; Gutierrez Soto, M.; He, J.B. Recent Advances in Wave Energy Conversion Systems: From Wave Theory to Devices and Control Strategies. Ocean Eng. 2022, 252, 111105. [Google Scholar] [CrossRef]

- Simonetti, I.; Cappietti, L. Hydraulic Performance of Oscillating Water Column Structures as Anti-Reflection Devices to Reduce Harbour Agitation. Coast. Eng. 2021, 165, 103837. [Google Scholar] [CrossRef]

- Cheng, Y.; Du, W.; Dai, S.; Yuan, Z.; Incecik, A. Wave Energy Conversion by an Array of Oscillating Water Columns Deployed along a Long-Flexible Floating Breakwater. Renew. Sustain. Energy Rev. 2024, 192, 114206. [Google Scholar] [CrossRef]

- Gubesch, E.; Abdussamie, N.; Penesis, I.; Chin, C. Maximising the Hydrodynamic Performance of Offshore Oscillating Water Column Wave Energy Converters. Appl. Energy 2022, 308, 118304. [Google Scholar] [CrossRef]

- Giorgi, G.; Gomes, R.P.F.; Henriques, J.C.C.; Gato, L.M.C.; Bracco, G.; Mattiazzo, G. Detecting Parametric Resonance in a Floating Oscillating Water Column Device for Wave Energy Conversion: Numerical Simulations and Validation with Physical Model Tests. Appl. Energy 2020, 276, 115421. [Google Scholar] [CrossRef]

- Kim, J.S.; Nam, B.W.; Kim, S.; Park, J.; Park, S.; Kim, K.H. Experimental Study on Hydrodynamic Behavior and Energy Conversion of Multiple Oscillating-Water-Column Chamber in Regular Waves. Ocean Eng. 2023, 280, 114495. [Google Scholar] [CrossRef]

- Liu, Z.; Xu, C.; Kim, K.; Choi, J.; Hyun, B. An Integrated Numerical Model for the Chamber-Turbine System of an Oscillating Water Column Wave Energy Converter. Renew. Sustain. Energy Rev. 2021, 149, 111350. [Google Scholar] [CrossRef]

- Ciappi, L.; Simonetti, I.; Bianchini, A.; Cappietti, L.; Manfrida, G. Application of Integrated Wave-to-Wire Modelling for the Preliminary Design of Oscillating Water Column Systems for Installations in Moderate Wave Climates. Renew. Energy 2022, 194, 232–248. [Google Scholar] [CrossRef]

- Henriques, J.C.C.; Portillo, J.C.C.; Sheng, W.; Gato, L.M.C.; Falcão, A.F.O. Dynamics and Control of Air Turbines in Oscillating-Water-Column Wave Energy Converters: Analyses and Case Study. Renew. Sustain. Energy Rev. 2019, 112, 571–589. [Google Scholar] [CrossRef]

- Falcão, A.F.D.O.; Justino, P.A.P. OWC Wave Energy Devices with Air Flow Control. Ocean Eng. 1999, 26, 1275–1295. [Google Scholar] [CrossRef]

- Falcão, A.F.O.; Henriques, J.C.C. The Spring-like Air Compressibility Effect in Oscillating-Water-Column Wave Energy Converters: Review and Analyses. Renew. Sustain. Energy Rev. 2019, 112, 483–498. [Google Scholar] [CrossRef]

- Dimakopoulos, A.S.; Cooker, M.J.; Bruce, T. The Influence of Scale on the Air Flow and Pressure in the Modelling of Oscillating Water Column Wave Energy Converters. Int. J. Mar. Energy 2017, 19, 272–291. [Google Scholar] [CrossRef]

- Sheng, W.; Alcorn, R.; Lewis, A. On Thermodynamics in the Primary Power Conversion of Oscillating Water Column Wave Energy Converters. J. Renew. Sustain. Energy 2013, 5, 023105. [Google Scholar] [CrossRef]

- Şentürk, U.; Özdamar, A. Modelling the Interaction between Water Waves and the Oscillating Water Column Wave Energy Device. Math. Comput. Appl. 2011, 16, 630–640. [Google Scholar] [CrossRef]

- Thakker, A.; Takao, M.; Setoguchi, T.; Dhanasekaran, T.S. Effects of Compressibility on the Performance of a Wave-Energy Conversion Device with an Impulse Turbine Using a Numerical Simulation Technique. Int. J. Rotating Mach. 2003, 9, 443–450. [Google Scholar] [CrossRef]

- Gonçalves, R.A.A.C.; Teixeira, P.R.F.; Didier, E.; Torres, F.R. Numerical Analysis of the Influence of Air Compressibility Effects on an Oscillating Water Column Wave Energy Converter Chamber. Renew. Energy 2020, 153, 1183–1193. [Google Scholar] [CrossRef]

- Elhanafi, A.; Macfarlane, G.; Fleming, A.; Leong, Z. Scaling and Air Compressibility Effects on a Three-Dimensional Offshore Stationary OWC Wave Energy Converter. Appl. Energy 2017, 189, 1–20. [Google Scholar] [CrossRef]

- Sarmento, A.J.N.A.; De Falcao, A.F.O. Wave Generation by an Oscillating Surface-Pressure and Its Application in Wave-Energy Extraction. J. Fluid Mech. 1985, 150, 467–485. [Google Scholar] [CrossRef]

- Weber, J. Representation of Non-Linear Aero-Thermodynamic Effects during Small Scale Physical Modeling of OWC Wave Energy Converters. In Proceedings of the 7th European Wave and Tidal Energy Conference, Porto, Portugal, 11–13 September 2007. [Google Scholar]

- Sheng, W.; Lewis, A. Wave Energy Conversion of Oscillating Water Column Devices Including Air Compressibility. J. Renew. Sustain. Energy 2016, 8, 054501. [Google Scholar] [CrossRef]

- Falcão, A.F.O.; Henriques, J.C.C. Model-Prototype Similarity of Oscillating-Water-Column Wave Energy Converters. Int. J. Mar. Energy 2014, 6, 18–34. [Google Scholar] [CrossRef]

- Viviano, A.; Naty, S.; Foti, E. Scale Effects in Physical Modelling of a Generalized OWC. Ocean Eng. 2018, 162, 248–258. [Google Scholar] [CrossRef]

- Fairhurst, J.; Van Niekerk, J.L. Modelling, Simulation and Testing of a Submerged Oscillating Water Column. Int. J. Mar. Energy 2016, 16, 181–195. [Google Scholar] [CrossRef]

- Perez-Collazo, C.; Greaves, D.; Iglesias, G. A Novel Hybrid Wind-Wave Energy Converter for Jacket-Frame Substructures. Energies 2018, 11, 637. [Google Scholar] [CrossRef]

- Howe, D.; Nader, J.-R.; Macfarlane, G. Experimental Analysis into the Effects of Air Compressibility in OWC Model Testing. In Proceedings of the 4th Asian Wave and Tidal Energy Conference, Taipei, Taiwan, 9–13 September 2018. [Google Scholar]

- Benreguig, P.; Murphy, J. Modelling Air Compressibility in OWC Devices with Deformable Air Chambers. J. Mar. Sci. Eng. 2019, 7, 268. [Google Scholar] [CrossRef]

- Rosa-Santos, P.; Taveira-Pinto, F.; Clemente, D.; Cabral, T.; Fiorentin, F.; Belga, F.; Morais, T. Experimental Study of a Hybrid Wave Energy Converter Integrated in a Harbor Breakwater. J. Mar. Sci. Eng. 2019, 7, 33. [Google Scholar] [CrossRef]

- López, I.; Carballo, R.; Taveira-Pinto, F.; Iglesias, G. Sensitivity of OWC Performance to Air Compressibility. Renew. Energy 2020, 145, 1334–1347. [Google Scholar] [CrossRef]

- Portillo, J.C.C.; Henriques, J.C.C.; Gato, L.M.C.; Falcão, A.F.O. Model Tests on a Floating Coaxial-Duct OWC Wave Energy Converter with Focus on the Spring-like Air Compressibility Effect. Energy 2023, 263, 125549. [Google Scholar] [CrossRef]

- Portillo, J.C.C.; Gato, L.M.C.; Henriques, J.C.C.; Falcão, A.F.O. Implications of Spring-like Air Compressibility Effects in Floating Coaxial-Duct OWCs: Experimental and Numerical Investigation. Renew. Energy 2023, 212, 478–491. [Google Scholar] [CrossRef]

- Ciappi, L.; Cheli, L.; Simonetti, I.; Bianchini, A.; Manfrida, G.; Cappietti, L. Wave-to-Wire Model of an Oscillating-Water-Column Wave Energy Converter and Its Application to Mediterranean Energy Hot-Spots. Energies 2020, 13, 5582. [Google Scholar] [CrossRef]

- Kharkeshi, B.A.; Shafaghat, R.; Jahanian, O.; Alamian, R.; Rezanejad, K. Experimental Study of an Oscillating Water Column Converter to Optimize Nonlinear PTO Using Genetic Algorithm. Energy 2022, 260, 124925. [Google Scholar] [CrossRef]

| Definition | Symbol | Value | Definition | Symbol | Value |

|---|---|---|---|---|---|

| Chamber height | HC | 1.0 m | Skirt height | HCS | 0.5 m |

| Chamber length | LC | 0.4 m | Chamber width | WC | 0.8 m |

| Diameter of duct | ϕD | 0.1 m | Diameter of orifice | ϕO | 0.064 m |

| Air chamber thickness | TC | 0.01 m | Reservoir thickness | TR | 0.015 m |

| Air chamber volume | VC | 0.096 m3 | Reservoir volume | VR | 0.0864 m3 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yuan, N.; Xu, C.; Liu, Z. Experimental Study on the Spring-like Effect on the Hydrodynamic Performance of an Oscillating Water Column Wave Energy Converter. J. Mar. Sci. Eng. 2024, 12, 1327. https://doi.org/10.3390/jmse12081327

Yuan N, Xu C, Liu Z. Experimental Study on the Spring-like Effect on the Hydrodynamic Performance of an Oscillating Water Column Wave Energy Converter. Journal of Marine Science and Engineering. 2024; 12(8):1327. https://doi.org/10.3390/jmse12081327

Chicago/Turabian StyleYuan, Ning, Chuanli Xu, and Zhen Liu. 2024. "Experimental Study on the Spring-like Effect on the Hydrodynamic Performance of an Oscillating Water Column Wave Energy Converter" Journal of Marine Science and Engineering 12, no. 8: 1327. https://doi.org/10.3390/jmse12081327