Research on Train Loading and Unloading Mode and Scheduling Optimization in Automated Container Terminals

Abstract

:1. Introduction

- In this study, the “full unloading and full loading” and “synchronous loading and unloading” operation modes in RYACT train loading and unloading were researched. To fill a key research gap in the existing literature, an MILP model was established with the objective of minimizing the maximum completion time of ARMG tasks, and the scheduling effects of the two modes were compared.

- An MILP model was established with the objective of minimizing the maximum completion time for ARMG tasks in the case of “non-pre-assign” task arrangement under the “synchronous loading and unloading” mode. It was then compared with “pre-assign” task arrangement in terms of the calculation and completion times.

- The models, solution method, and experimental results presented in this paper have good reference value for managers of the RYACT, helping them to make decisions on equipment scheduling in the RYACT.

2. Literature Review

3. Problem Definition and Formulations

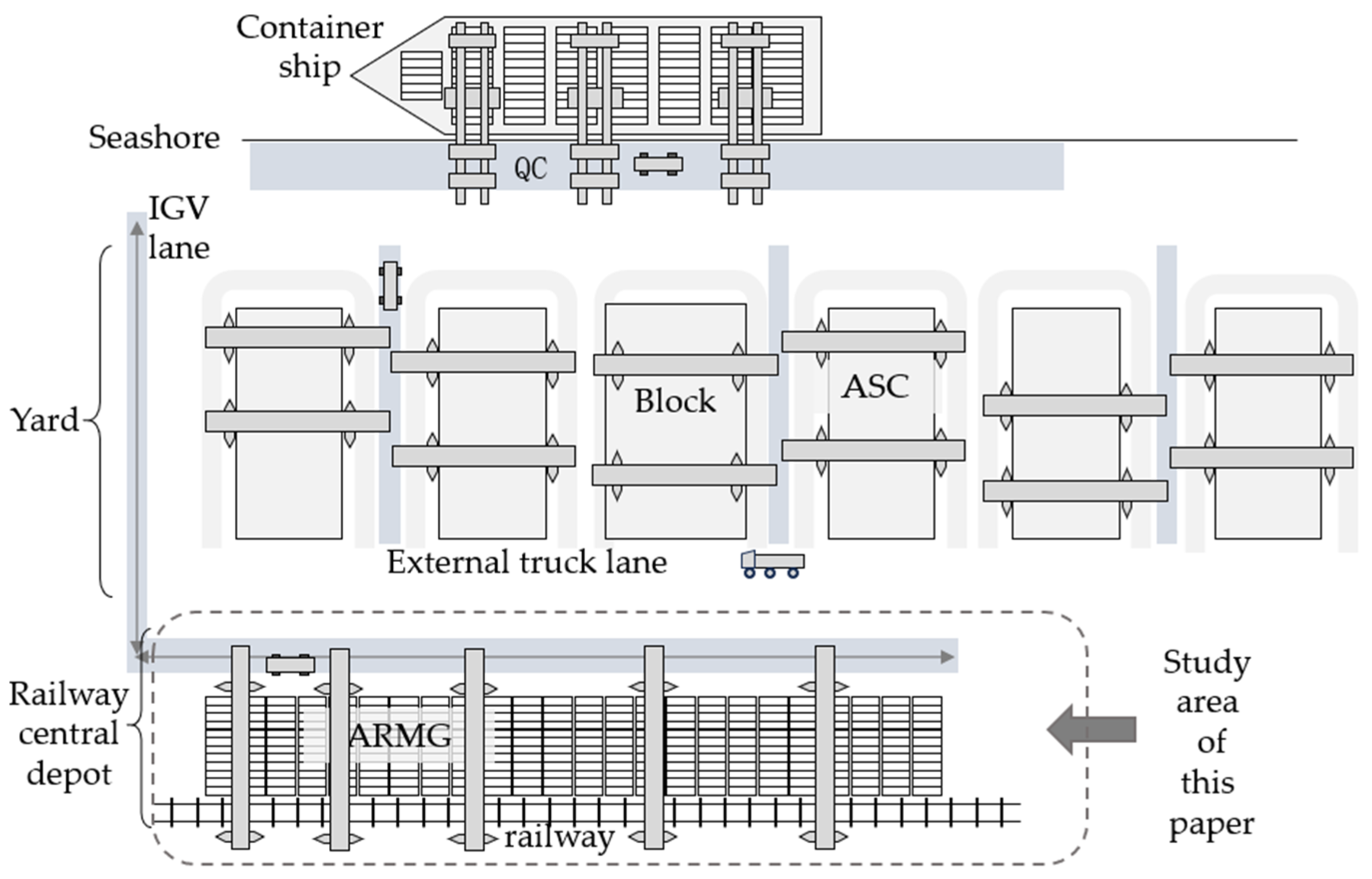

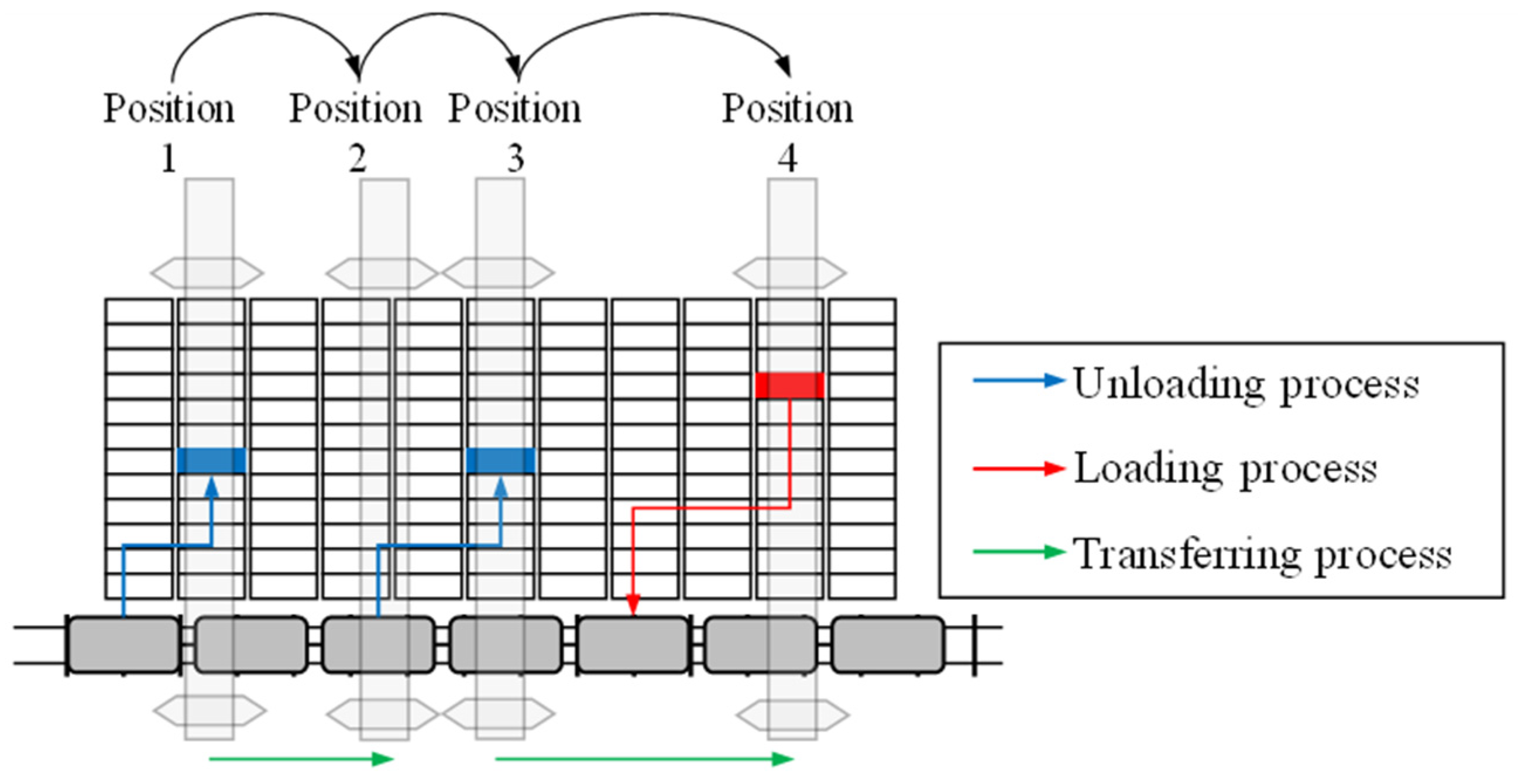

3.1. Problem Description

3.2. Assumptions

- The loading and unloading of containers by the ARMG system does not include shifting activities.

- Containers that have been unloaded from the train will not impact subsequent loading operations.

- The operational speed of the ARMG system remains consistent throughout the modeling process.

- The precise starting and ending positions of container tasks, along with their corresponding coordinate values, are known and accounted for.

- The time required for the ARMG system to both grab and release containers is assumed to be equal, with the initial position of the ARMG system being predetermined.

- To ensure the safety of container handling operations, the trolley will remain stationary during the movement of the ARMG system’s gantry.

3.3. Parameter Description

3.4. Model Formulation

3.4.1. “Full Unloading and Full Loading” Mode

3.4.2. “Synchronous Loading and Unloading” Mode

3.4.3. Considering “Non-Pre-Assignment” of Tasks

- -

- indicates the set of tasks that may conflict among ARMG tasks, where indicates that if the start and end positions of tasks i and j overlap, they may interfere with each other when assigned to two ARMGs.

- -

- indicates the position coordinates of task i in the direction of the railway yard.

- -

- indicates that container task is assigned to ARMG for operation; otherwise, .

- -

- indicates that ARMG starts task immediately after completing task ; otherwise, .

4. Solution Approach

| Algorithm 1 Adaptive large neighborhood algorithm | |

| 1: | Input data: ; |

| 2: | Set algorithm parameters: |

| 3: | The number of solutions generated per iteration: ; |

| 4: | Maximum number of iterations: ; |

| 5: | The maximum number of iterations with the same optimal value: ; |

| 6: | The initial solution is generated by RSA and its score is calculated; |

| 7: | Initialize the data: |

| 8: | Set iteration number ; |

| 9: | The score and sequence of the m code of the n iteration; |

| 10: | Optimal score and corresponding sequence . |

| 11: | While : |

| 12: | Determine the list of domain search operators; |

| 13: | Search the neighborhood of to generate new encodings; . |

| 14: | For : |

| 15: | Use Algorithm 1 to calculate the score of ; |

| 16: | End for; |

| 17: | Determine the optimal score and corresponding sequence ; |

| 18: | End while. |

| 19: | Calculate according to the optimal sequence ; . |

| 20: | Return . |

5. Numerical Experiments and Results

5.1. Comparison of “Full Unloading and Full Loading” and “Synchronous Loading and Unloading”

- Set the number of tasks to values ranging between 20 and 120, and generate corresponding examples.

- Keep the parameter settings of the ALNS algorithm the same as those in [34].

- For each numerical example of the number of tasks, solve the scenario 10 times and return the minimum value obtained.

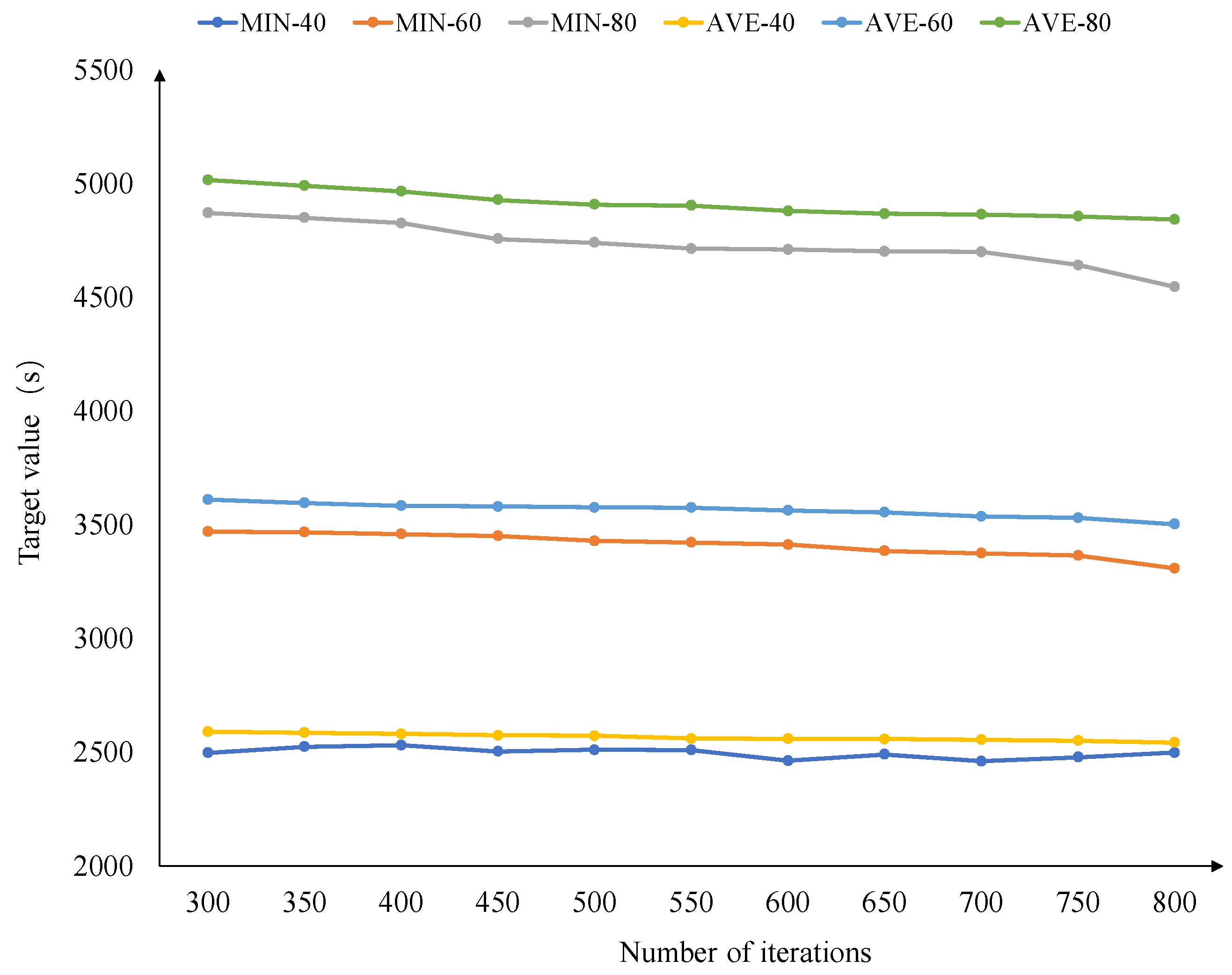

5.2. Comparison of the Task Distribution Methods

- -

- Set the number of tasks from 10 to 20 and generate corresponding examples.

- -

- Limit the model solution time to 1200 s.

- -

- Solve the models M2 and M3 using the solver CPLEX and return the experimental results.

- -

- Set the number of tasks to 40, 60, 80, …, 160, and generate corresponding examples.

- -

- Solve the models M2 and M3 using an ALNS algorithm with the same number of iterations (600) and return the experimental results.

- -

- Compare the experimental results between the two models. The experimental results are shown in Table 6.

6. Discussion

7. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Li, J.; Yan, L.; Xu, B. Research on Multi-Equipment Cluster Scheduling of U-Shaped Automated Terminal Yard and Railway Yard. J. Mar. Sci. Eng. 2023, 11, 417. [Google Scholar] [CrossRef]

- Vacca, I.; Salani, M.; Bierlaire, M. An Exact Algorithm for the Integrated Planning of Berth Allocation and Quay Crane Assignment. Transp. Sci. 2013, 47, 148–161. [Google Scholar] [CrossRef]

- Zhen, L.; Hu, H.; Wang, W.; Shi, X.; Ma, C. Cranes scheduling in frame bridges based automated container terminals. Transp. Res. Part C Emerg. Technol. 2018, 97, 369–384. [Google Scholar] [CrossRef]

- Iris, Ç.; Lam, J.S.L. Recoverable robustness in weekly berth and quay crane planning. Transp. Res. Part B Methodol. 2019, 122, 365–389. [Google Scholar] [CrossRef]

- Tan, C.; Yan, W.; Yue, J. Quay crane scheduling in automated container terminal for the trade-off between operation efficiency and energy consumption. Adv. Eng. Inform. 2021, 48, 101285–101295. [Google Scholar] [CrossRef]

- Cai, B.; Huang, S.; Liu, D.; Dissanayake, G. Rescheduling policies for large-scale task allocation of autonomous straddle carriers under uncertainty at automated container terminals. Robot. Auton. Syst. 2014, 62, 506–514. [Google Scholar] [CrossRef]

- Choe, R.; Kim, J.; Ryu, K.R. Online preference learning for adaptive dispatching of AGVs in an automated container terminal. Appl. Soft Comput. 2016, 38, 647–660. [Google Scholar] [CrossRef]

- Luo, J.; Wu, Y.; Mendes, A.B. Modelling of integrated vehicle scheduling and container storage problems in unloading process at an automated container terminal. Comput. Ind. Ind. Eng. 2016, 94, 32–44. [Google Scholar] [CrossRef]

- Wu, M.; Gao, J.; Li, L.; Wang, Y. Control optimisation of automated guided vehicles in container terminal based on Petri network and dynamic path planning. Comput. Electr. Eng. 2022, 104, 108471–108485. [Google Scholar] [CrossRef]

- Xiang, X.; Liu, C. Modeling and analysis for an automated container terminal considering battery management. Comput. Ind. Ind. Eng. 2021, 156, 107258–107284. [Google Scholar] [CrossRef]

- Li, L.; Li, Y.; Liu, R.; Zhou, Y.; Pan, E. A Two-stage Stochastic Programming for AGV scheduling with random tasks and battery swapping in automated container terminals. Transp. Res. Part E Logist. Transp. Rev. 2023, 174, 103110–103138. [Google Scholar] [CrossRef]

- Drungilas, D.; Kurmis, M.; Senulis, A.; Lukosius, Z.; Andziulis, A.; Januteniene, J.; Bogdevicius, M.; Jankunas, V.; Voznak, M. Deep reinforcement learning based optimization of automated guided vehicle time and energy consumption in a container terminal. Alex. Eng. J. 2023, 67, 397–407. [Google Scholar] [CrossRef]

- Gharehgozli, A.H.; Yu, Y.; de Koster, R.; Udding, J.T. An exact method for scheduling a yard crane. Eur. J. Oper. Res. 2014, 235, 431–447. [Google Scholar] [CrossRef]

- Yang, X.; Hu, H.; Jin, J.; Luo, N. Joint optimization of space allocation and yard crane deployment in container terminal under uncertain demand. Comput. Ind. Ind. Eng. 2022, 172, 108425–108439. [Google Scholar] [CrossRef]

- Vallada, E.; Belenguer, J.M.; Villa, F.; Alvarez-Valdes, R. Models and algorithms for a yard crane scheduling problem in container ports. Eur. J. Oper. Res. 2023, 309, 910–924. [Google Scholar] [CrossRef]

- Hu, Z.-H.; Sheu, J.-B.; Luo, J.X. Sequencing twin automated stacking cranes in a block at automated container terminal. Transp. Res. Part C Emerg. Technol. 2016, 69, 208–227. [Google Scholar] [CrossRef]

- Lu, H.; Wang, S. A study on multi-ASC scheduling method of automated container terminals based on graph theory. Comput. Ind. Ind. Eng. 2019, 129, 404–416. [Google Scholar] [CrossRef]

- Oladugba, A.O.; Gheith, M.; Eltawil, A. A new solution approach for the twin yard crane scheduling problem in automated container terminals. Adv. Eng. Inform. 2023, 57, 102015–102537. [Google Scholar] [CrossRef]

- Chu, F.; He, J.; Zheng, F.; Liu, M. Scheduling multiple yard cranes in two adjacent container blocks with position-dependent processing times. Comput. Ind. Ind. Eng. 2019, 136, 355–365. [Google Scholar] [CrossRef]

- Han, X.; Wang, Q.; Huang, J. Scheduling cooperative twin automated stacking cranes in automated container terminals. Comput. Ind. Ind. Eng. 2019, 128, 553–558. [Google Scholar] [CrossRef]

- Feng, X.; He, Y.; Kim, K.-H. Space planning considering congestion in container terminal yards. Transp. Res. Part B Methodol. 2022, 158, 52–77. [Google Scholar] [CrossRef]

- Gao, Y.; Chang, D.; Chen, C.-H. A digital twin-based approach for optimizing operation energy consumption at automated container terminals. J. Clean. Prod. 2023, 385, 135782–135794. [Google Scholar] [CrossRef]

- Skaf, A.; Lamrous, S.; Hammoudan, Z.; Manier, M.-A. Integrated quay crane and yard truck scheduling problem at port of Tripoli-Lebanon. Comput. Ind. Ind. Eng. 2021, 159, 107448–107458. [Google Scholar] [CrossRef]

- Kong, L.; Ji, M.; Yu, A.; Gao, Z. Scheduling of automated guided vehicles for tandem quay cranes in automated container terminals. Comput. Oper. Oper. Res. 2024, 163, 106505–106524. [Google Scholar] [CrossRef]

- Luo, J.; Wu, Y. Modelling of dual-cycle strategy for container storage and vehicle scheduling problems at automated container terminals. Transp. Res. Part E Logist. Transp. Rev. 2015, 79, 49–64. [Google Scholar] [CrossRef]

- Chen, X.; He, S.; Zhang, Y.; Tong, L.; Shang, P.; Zhou, X. Yard crane and AGV scheduling in automated container terminal: A multi-robot task allocation framework. Transp. Res. Part C Emerg. Technol. 2020, 114, 241–271. [Google Scholar] [CrossRef]

- Liu, W.; Zhu, X.; Wang, L.; Wang, S. Multiple equipment scheduling and AGV trajectory generation in U-shaped sea-rail intermodal automated container terminal. Measurement 2023, 206, 112262–112273. [Google Scholar] [CrossRef]

- Lau, H.Y.K.; Zhao, Y. Integrated scheduling of handling equipment at automated container terminals. Int. J. Prod. Econ. 2008, 112, 665–682. [Google Scholar] [CrossRef]

- Shouwen, J.; Di, L.; Zhengrong, C.; Dong, G. Integrated scheduling in automated container terminals considering AGV conflict-free routing. Transp. Lett. 2020, 13, 501–513. [Google Scholar] [CrossRef]

- Zhong, M.; Yang, Y.; Dessouky, Y.; Postolache, O. Multi-AGV scheduling for conflict-free path planning in automated container terminals. Comput. Ind. Ind. Eng. 2020, 142, 106371–106381. [Google Scholar] [CrossRef]

- Anghinolfi, D.; Caballini, C.; Sacone, S. Optimizing train loading operations in innovative and automated container terminals. In Proceedings of the 19th World Congress, Cape Town, South Africa, 24–29 August 2014. [Google Scholar]

- Chang, Y.; Zhu, X.; Yan, B.; Wang, L. Integrated scheduling of handling operations in railway container terminals. Transp. Lett. 2017, 11, 402–412. [Google Scholar] [CrossRef]

- Yang, Y.; Sun, S.; He, S.; Jiang, Y.; Wang, X.; Yin, H.; Zhu, J. Research on the Multi-Equipment Cooperative Scheduling Method of Sea-Rail Automated Container Terminals under the Loading and Unloading Mode. J. Mar. Sci. Eng. 2023, 11, 1975. [Google Scholar] [CrossRef]

- Chen, H.; Liu, W. An Adaptive Large Neighborhood Search Algorithm for Equipment Scheduling in the Railway Yard of an Automated Container Terminal. J. Mar. Sci. Eng. 2024, 12, 710. [Google Scholar] [CrossRef]

- Ropke, S.; Pisinger, D. An Adaptive Large Neighborhood Search Heuristic for the Pickup and Delivery Problem with Time Windows. Transp. Sci. 2006, 40, 455–472. [Google Scholar] [CrossRef]

- Ghilas, V.; Demir, E.; Van Woensel, T. An adaptive large neighborhood search heuristic for the Pickup and Delivery Problem with Time Windows and Scheduled Lines. Comput. Oper. Oper. Res. 2016, 72, 12–30. [Google Scholar] [CrossRef]

- Şatir Akpunar, Ö.; Akpinar, Ş. A hybrid adaptive large neighbourhood search algorithm for the capacitated location routing problem. Expert Syst. Appl. 2021, 168, 114304–114319. [Google Scholar] [CrossRef]

- SteadieSeifi, M.; Dellaert, N.; Van Woensel, T. Multi-modal transport of perishable products with demand uncertainty and empty repositioning: A scenario-based rolling horizon framework. EURO J. Transp. Logist. 2021, 10, 100044–100057. [Google Scholar] [CrossRef]

- Zhang, Y.; Atasoy, B.; Negenborn, R.R. Preference-Based Multi-Objective Optimization for Synchromodal Transport Using Adaptive Large Neighborhood Search. Transp. Res. Rec. J. Transp. Res. Board 2021, 2676, 71–87. [Google Scholar] [CrossRef]

- Zhang, Y.; Li, X.; van Hassel, E.; Negenborn, R.R.; Atasoy, B. Synchromodal transport planning considering heterogeneous and vague preferences of shippers. Transp. Res. Part E Logist. Transp. Rev. 2022, 164, 102827–102849. [Google Scholar] [CrossRef]

- Wang, X.; Liang, Y.; Wei, X.; Chew, E.P. An adaptive large neighborhood search algorithm for the tugboat scheduling problem. Comput. Ind. Ind. Eng. 2023, 177, 109039–109052. [Google Scholar] [CrossRef]

| Literature | Solved Problem | Berth | Horizontal Transport | Container Yard | Railway Yard |

|---|---|---|---|---|---|

| Vacca et al. [2] | QC scheduling problem | √ | |||

| Iris and Lam [4] | QC assignment problem | √ | |||

| Luo et al. [8] | Container storage and AGV scheduling | √ | |||

| Xiang and Liu [10] | Battery replacement strategy of AGVs | √ | |||

| Drungilas et al. [12] | Energy-saving problem of AGVs | √ | |||

| Gharehgozli et al. [13] | YCs and yard resource scheduling | √ | |||

| Oladugba et al. [18] | Twin ASC sequencing and scheduling | √ | |||

| Skaf et al. [23] | Joint scheduling | √ | √ | ||

| D. Anghinolfi et al. [31] | Optimization of the operation of loading containers to wagon | √ | |||

| Chang et al. [32] | Joint scheduling of equipment | √ | √ | √ | |

| Yang et al. [33] | Cooperative scheduling | √ | √ | √ |

| Set | Definition |

|---|---|

| Set of ARMGs indexed by . | |

| Set of ARMG tasks for loading containers indexed by and . | |

| Set of ARMG tasks for unloading containers indexed by and . | |

| Set of ARMG tasks for loading and unloading containers that verify . | |

| Set of tasks for loading and unloading containers , where represents a virtual start task; similarly, we can define sets and . | |

| Set of tasks for loading and unloading containers verifying , where represents a virtual start task; similarly, we can define and . | |

| Set of tasks that may interfere with one another when adjacent ARMGs operate tasks, where . |

| Parameter | Definition |

|---|---|

| The ARMG assigned to task . | |

| A 0–1 integer parameter that represents the conflict between the nodes selected in the middle of the moment of tasks and . When its value is 0, it is the middle time of ARMG operation in the RYACT, and when it is 1, it is the middle time of ARMG operation in the train carriage. | |

| A 0–1 integer parameter that represents the middle of the moment to avoid conflict between tasks and . When its value is 0, it refers to the middle moment of the starting position, and when it is 1, it refers to the middle moment of the ending position. | |

| The operation time of the ARMG for grabbing/releasing containers in the RYACT. | |

| The operation time of the ARMG for grabbing/releasing containers on the train. | |

| Operation task time of the ARMG for loading/unloading containers. | |

| The minimum time interval between ARMG container tasks and . | |

| The time the ARMG moves from the end position of container task to the start position of container task . | |

| The moving time of the trolley during ARMG operation to complete task . | |

| A positive number that is large enough, where . |

| Variable | Definition |

|---|---|

| A binary decision variable that takes the value of if the ARMG starts container task immediately after completing container task ; otherwise, it takes the value of 0. | |

| A binary decision variable that takes the value of if task is completed before task ; otherwise, it takes the value of 0, . | |

| A real variable representing the start time of task . | |

| A real variable representing the end time of task . | |

| A real variable representing the midpoint of the moment to grab or release the container for the ARMG operating conflict task . |

| Mode | Full Unloading and Full Loading (M1) | Synchronous Loading and Unloading (M2) | |||||

|---|---|---|---|---|---|---|---|

| Number of Tasks | |||||||

| 20 | 2830.07 | 2867.49 | 2.68 | 2654.36 | 2753.84 | 2.31 | |

| 40 | 2615.44 | 2661.64 | 4.57 | 2518.30 | 2566.37 | 4.70 | |

| 60 | 3557.49 | 3690.65 | 4.89 | 3417.90 | 3535.45 | 4.57 | |

| 80 | 4750.69 | 4993.32 | 6.27 | 4661.40 | 4910.53 | 5.48 | |

| 100 | 6009.37 | 6291.13 | 5.68 | 5949.71 | 6190.91 | 5.18 | |

| 120 | 7581.89 | 7724.49 | 8.25 | 7374.37 | 7593.14 | 7.08 | |

| 140 | 8620.06 | 8999.28 | 7.61 | 8473.79 | 8946.89 | 7.33 | |

| 160 | 9906.03 | 10,384.06 | 7.96 | 9736.71 | 9943.30 | 7.58 | |

| Number of Tasks | “Pre-Assign” Method (M2) | “Non-Pre-Assign” Method (M3) | ||||

|---|---|---|---|---|---|---|

| 10 | 1623.18 | 0.11 | 1512.67 | −6.80 | 3.00 | 2627.27 |

| 11 | 1607.07 | 0.20 | 1510.14 | −6.03 | 35.89 | 17,845 |

| 12 | 1683.74 | 0.29 | 1683.74 | 0 | 157.65 | 54,262.06 |

| 13 | 1766.60 | 0.06 | 1766.60 | 0 | 1201.23 | 2,001,950 |

| 14 | 1850.19 | 0.72 | 1850.19 | 0 | 1201.40 | 166,761.11 |

| 15 | 1960.76 | 7.79 | 1960.76 | 0 | 1233.00 | 15,727.98 |

| 16 | 2094.00 | 1.74 | 2094.00 | 0 | 1202.82 | 69,027.59 |

| 17 | 2125.84 | 27.44 | — | — | >1200 | — |

| 18 | 2253.09 | 59.28 | — | — | >1200 | — |

| 19 | 2334.37 | 84.63 | — | — | >1200 | — |

| 20 | 2446.46 | 115.10 | — | — | >1200 | — |

| 40 | 2508.77 | 4.79 | 2508.77 | 0 | 10.58 | 120.88 |

| 60 | 3514.99 | 4.27 | 3506.47 | −0.24 | 9.66 | 126.23 |

| 80 | 4655.61 | 5.75 | 4601.04 | −1.17 | 12.50 | 117.39 |

| 100 | 5949.71 | 5.40 | 5946.44 | −0.05 | 11.80 | 118.52 |

| 120 | 7371.59 | 7.25 | 7286.47 | −1.15 | 15.50 | 113.79 |

| 140 | 8477 | 7.37 | 8448.33 | −0.34 | 15.74 | 113.57 |

| 160 | 9730.31 | 7.81 | 9380.31 | −3.60 | 17.62 | 125.61 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chen, H.; Liu, W.; Oldache, M.; Pervez, A. Research on Train Loading and Unloading Mode and Scheduling Optimization in Automated Container Terminals. J. Mar. Sci. Eng. 2024, 12, 1415. https://doi.org/10.3390/jmse12081415

Chen H, Liu W, Oldache M, Pervez A. Research on Train Loading and Unloading Mode and Scheduling Optimization in Automated Container Terminals. Journal of Marine Science and Engineering. 2024; 12(8):1415. https://doi.org/10.3390/jmse12081415

Chicago/Turabian StyleChen, Hongbin, Wei Liu, Mehdi Oldache, and Amjad Pervez. 2024. "Research on Train Loading and Unloading Mode and Scheduling Optimization in Automated Container Terminals" Journal of Marine Science and Engineering 12, no. 8: 1415. https://doi.org/10.3390/jmse12081415