Decarbonization and Improvement of Energy Efficiency of FSRU by Cryogenic CO2 Capture

Abstract

:1. Introduction

2. Methodology

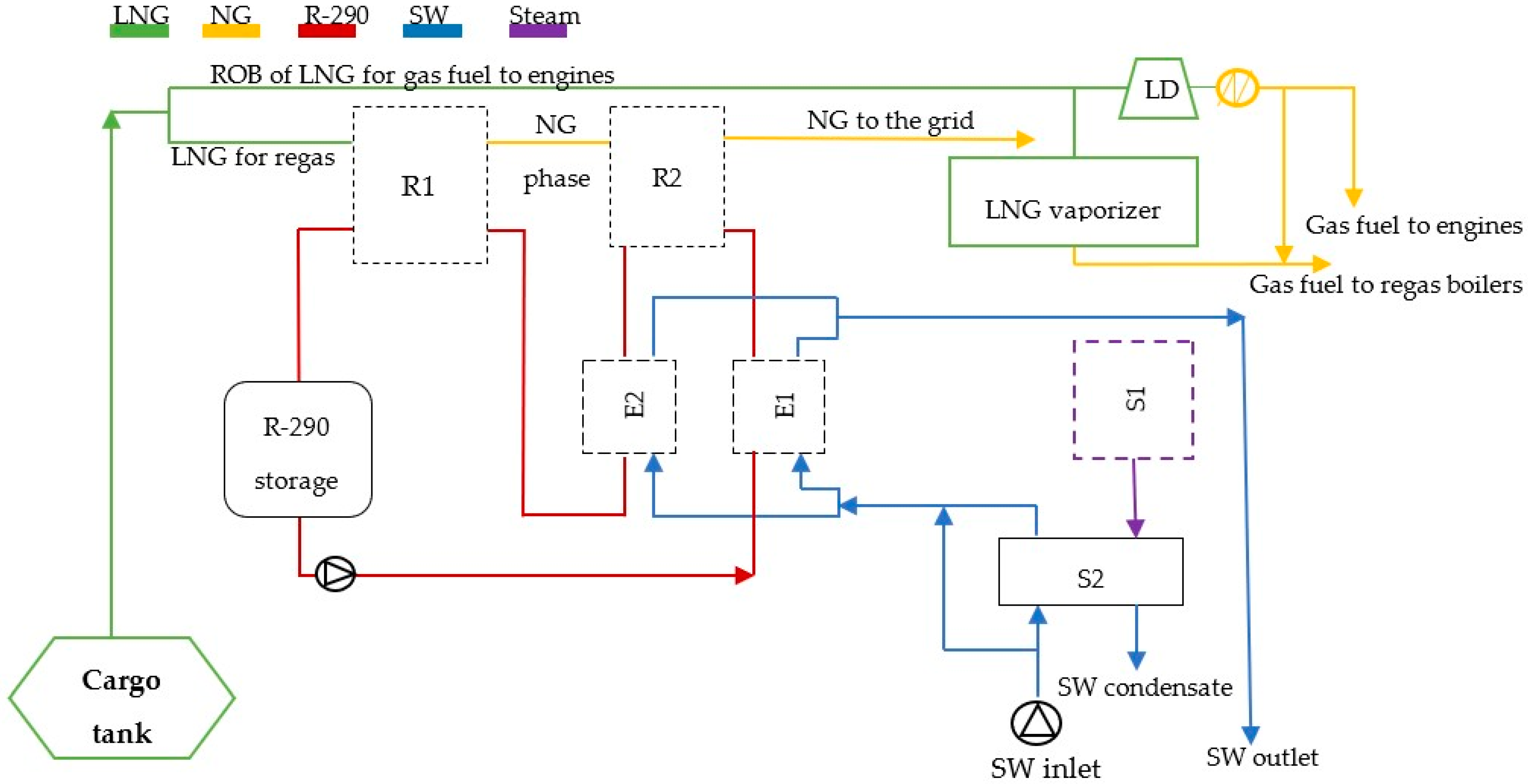

2.1. Structure of the Research Object

2.2. Structure of the Energy Balance

2.3. Composition of Combustion Flue Gas

2.4. The Mathematical Expression of the Regasification Energy Balance

3. Results

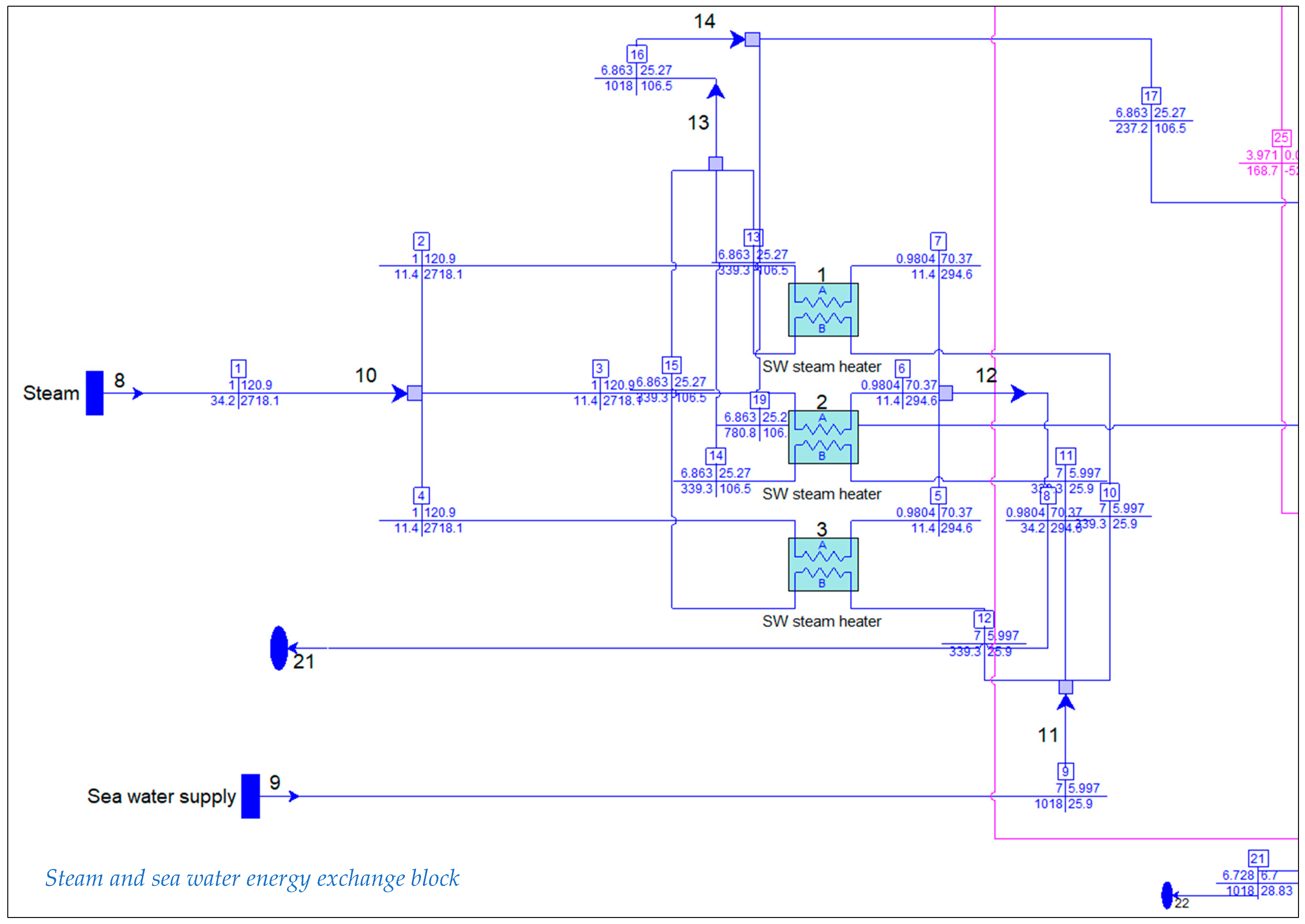

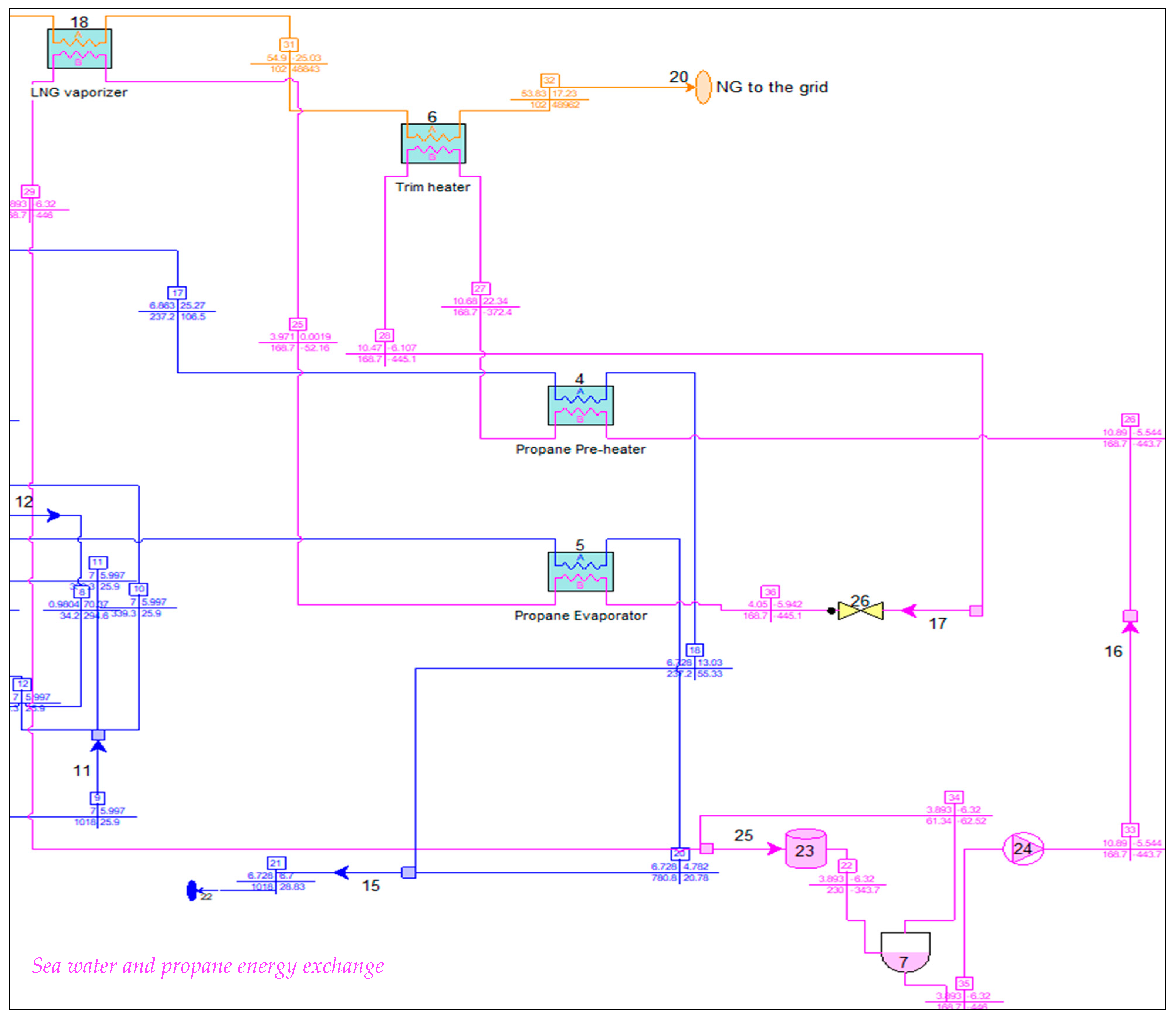

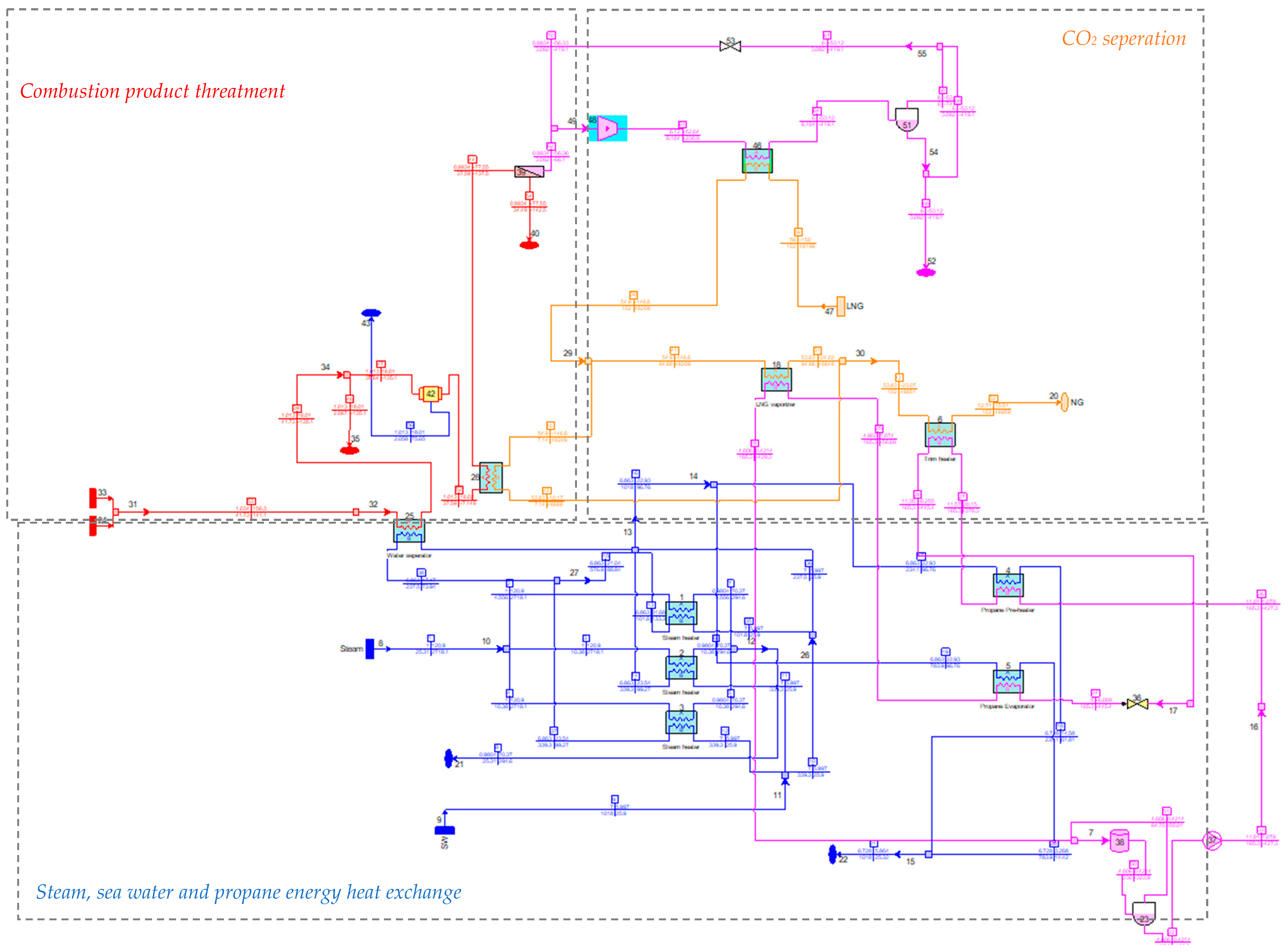

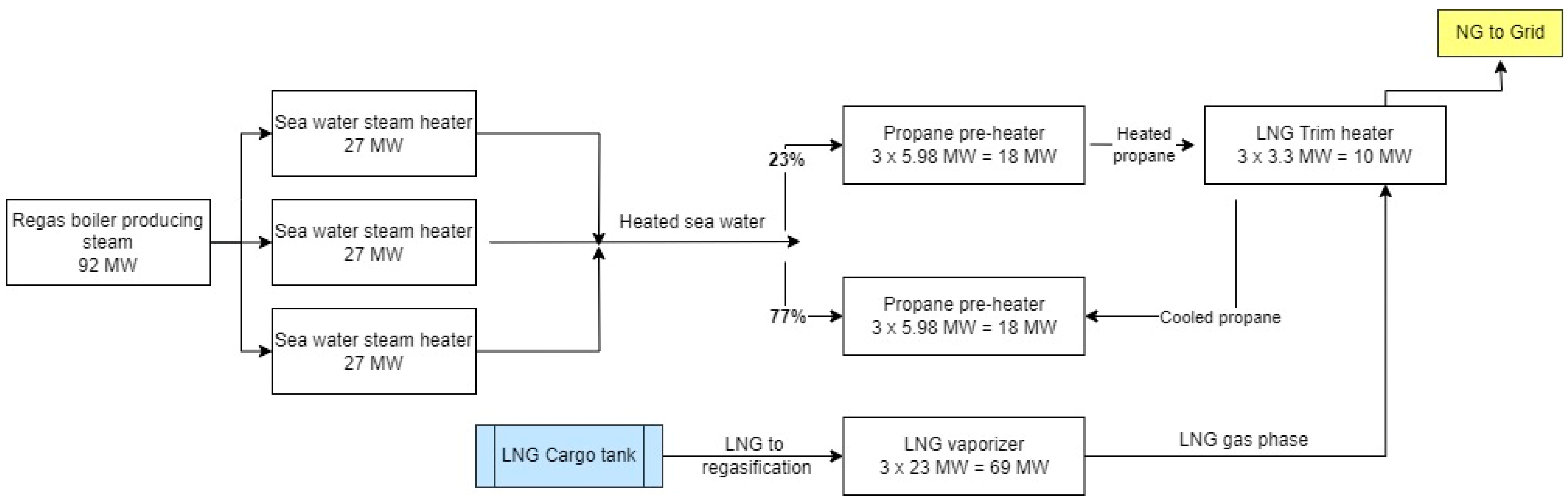

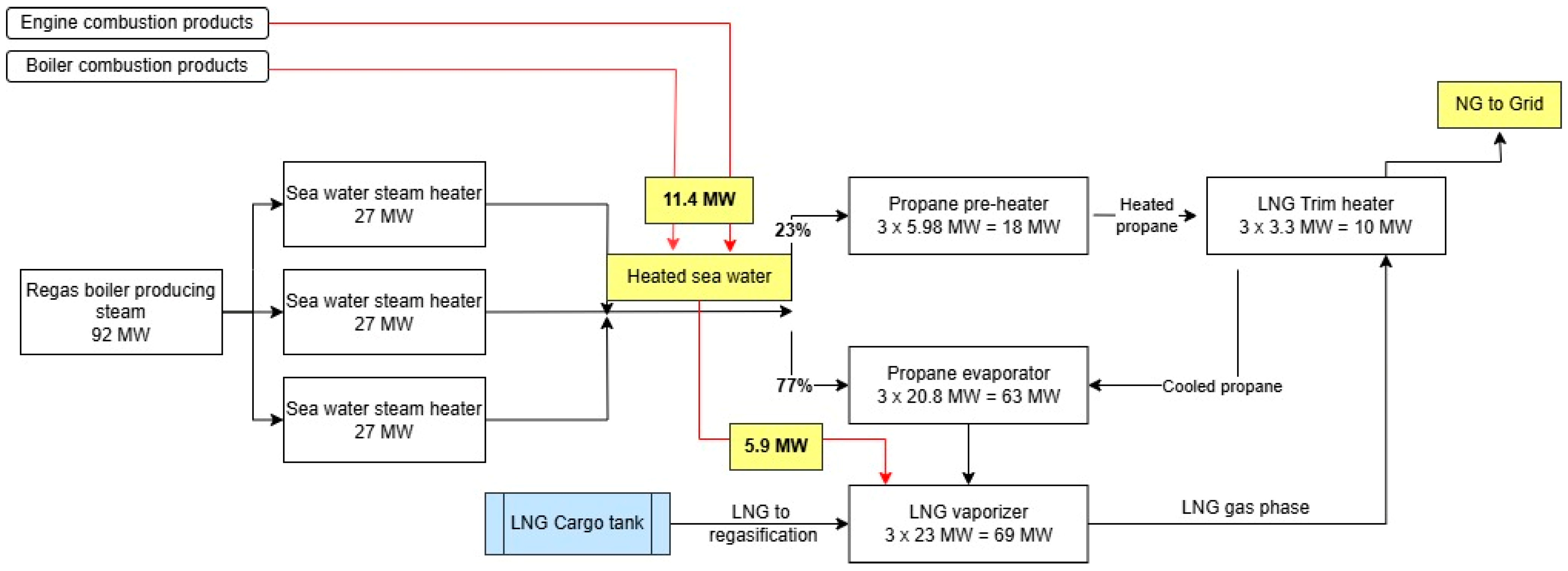

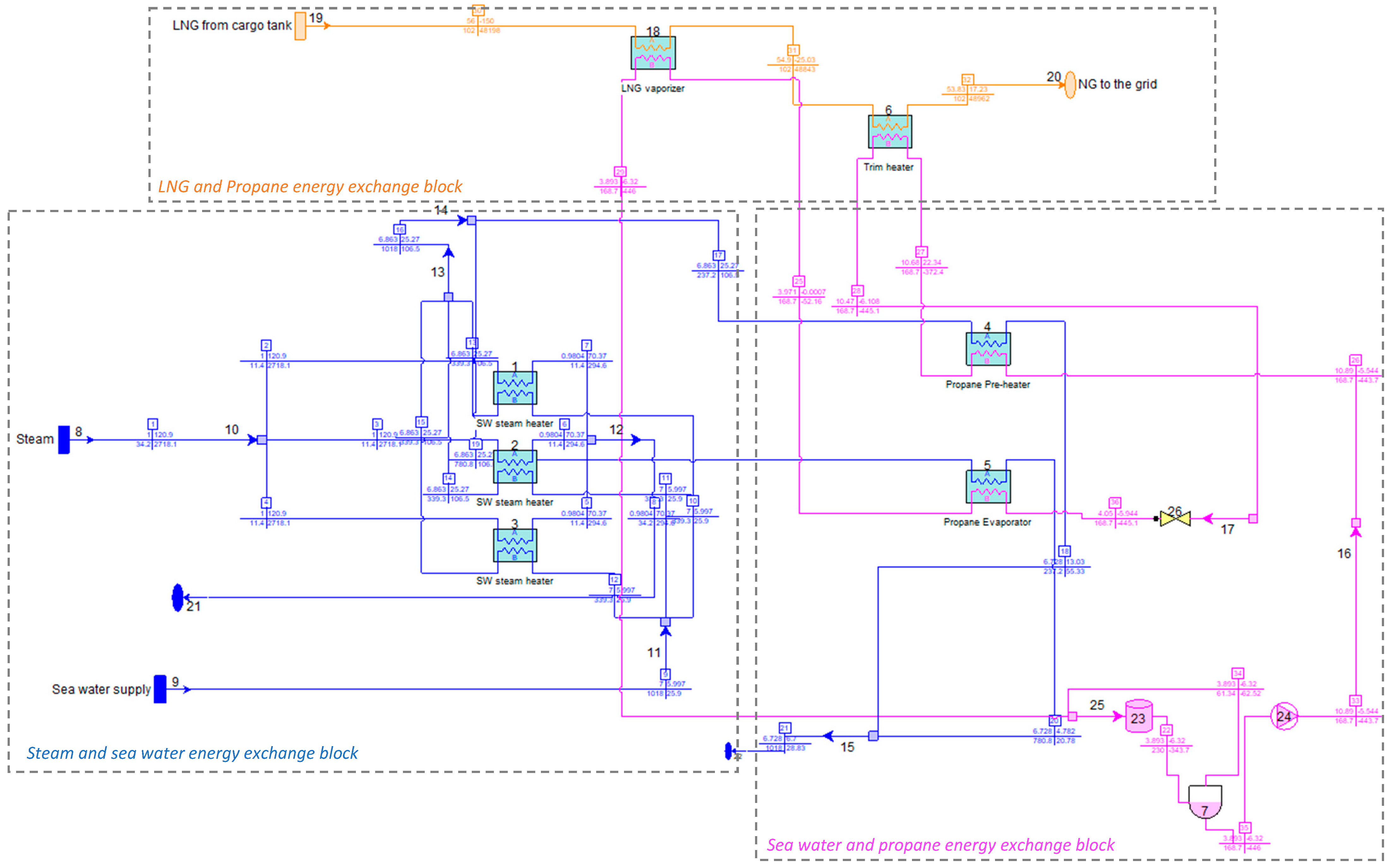

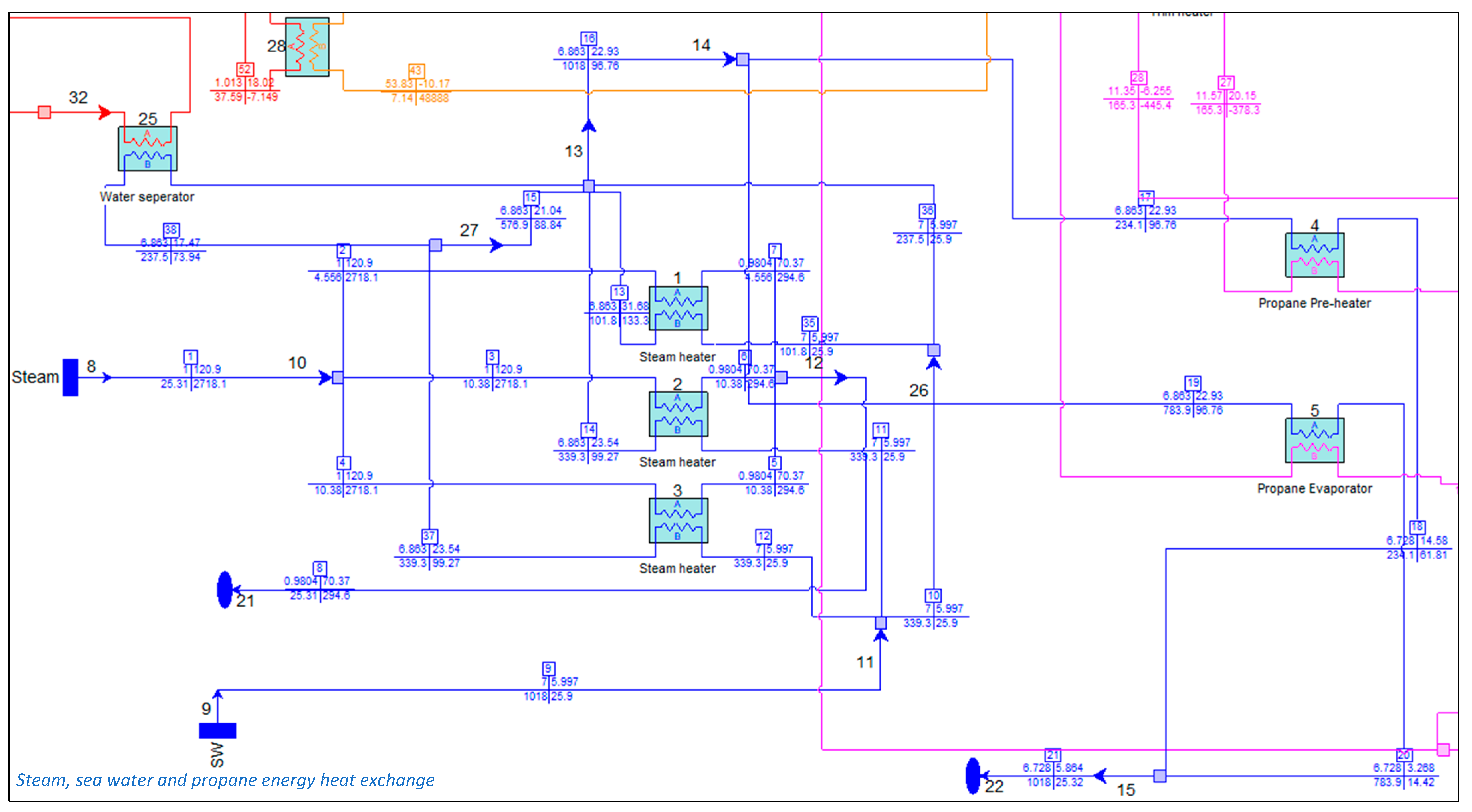

3.1. Structural Analysis of the Regasification Energy System

3.2. FSRU Regasification System Energy Balance Structural Review

- LNG vaporizer: heat transfer of 65,763 kW;

- Trim heater: heat transfer of 12,131 kW;

- Propane pre-heater: heat transfer of 12,018 kW;

- Propane evaporator: heat transfer of 66,272 kW;

- Total: 156,184 kW.

- -

- Regasification is running at peak load capacity;

- -

- Fuel consumption is 90 m3 LNG for the engines and 218.3 m3 LNG for regasification boilers;

- -

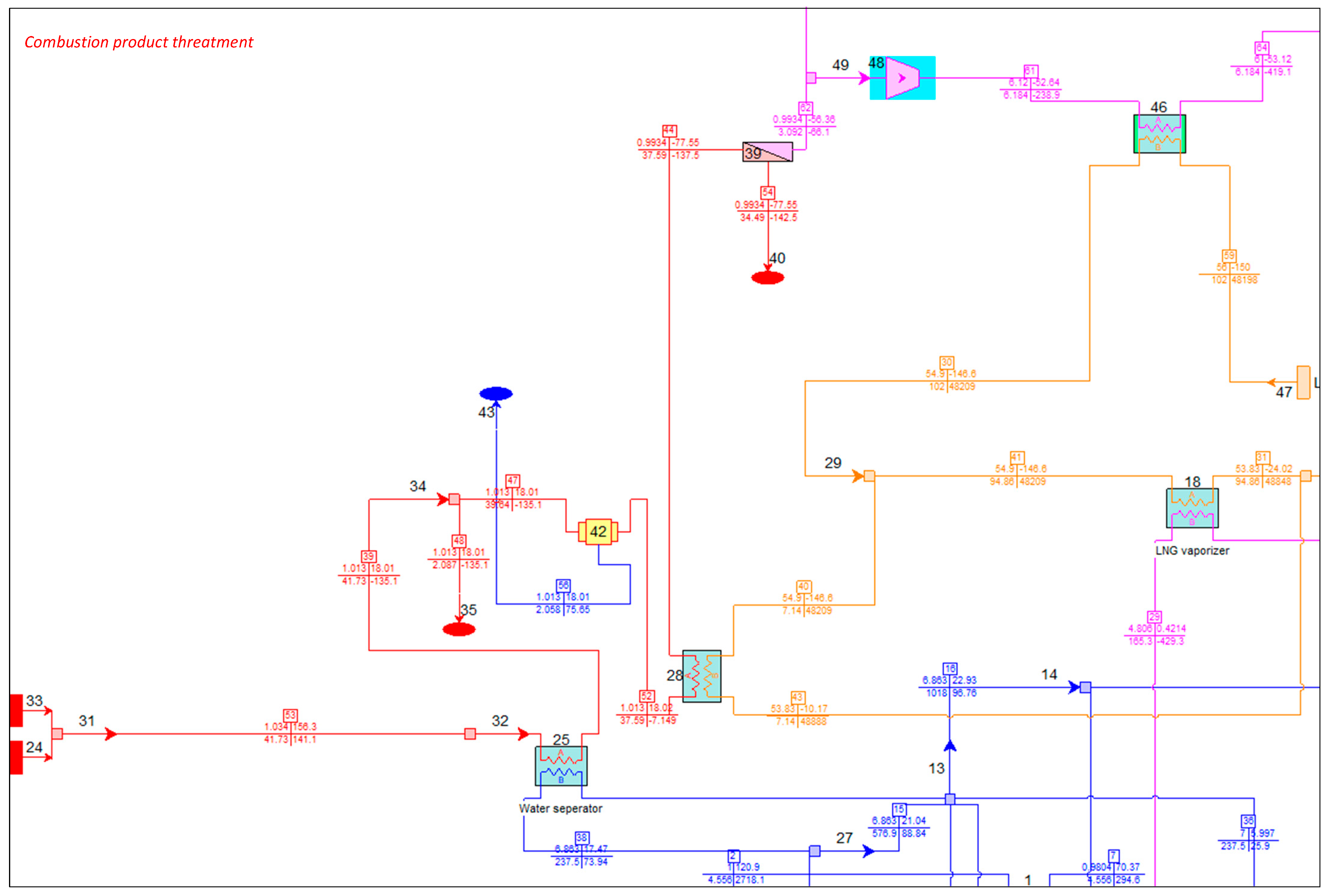

- Result of simulated multifaceted system is presented in Figure A3.

- Exhaust gas cooler (28) = 4851 kW;

- Water separator (25) = 11,411 kW;

- Exhaust gas cooler (46) = 1103 kW;

- Total thermal energy required for CO2 capture = 17,365 kW.

- LNG vaporizer: heat transfer of 60,632 kW;

- Trim heater: heat transfer of 10,982 kW;

- Propane pre-heater: heat transfer of 8101 kW;

- Propane evaporator: heat transfer of 63,903 kW;

- Total: 143,618 kW.

4. Discussion

5. Conclusions

- The decarbonisation of FSRUs is inherent in the IMO’s strategy objectives, which are reflected in international regulations covering the reduction in emissions from ships. Apart from the CII, EEXI, and EEDI indexes, the financial impact on emissions generation is seen through the guidelines of the EU ETS. Under the EU ETS framework until 2030, CO2 emission taxes are subsidized with a gradual annual reduction. This financial mechanism compels shipowners to seek effective solutions to lower CO2 emissions. Currently, LNG as a fuel complies with maritime industry regulations; however, it is recognized as a transitional fuel source until truly carbon-neutral or zero-emission alternative fuel infrastructure is widely developed and available. Today, significant attention is given to LNG fuel’s compliance with the Carbon Intensity Indicator, with projections suggesting that by approximately 2030, LNG-fuelled ships will need to adopt additional technologies—such as carbon capture systems or blending with bio-LNG or synthetic LNG—to meet increasingly stringent carbon intensity standards. Therefore, LNG-fuelled vessels and the growing FSRU market require a thorough assessment of alternative technologies to ensure compliance with environmental performance regulations;

- To achieve long-term decarbonisation results, this research investigates a solution for the modification of the FSRU energy system was proposed and functional decarbonisation indicators were investigated. The efficiency of these indicators is characterised by the 100% CO2 liquefaction of exhaust gas generated by boilers of 2 × 65,000 kg/h capacity and the four units of Wärtsilä electric-diesel generators Wärtsilä 8L50DF 7800 kW and 1 × 6L50DF 5850 kW. The implementation principle is predicated on modifying the energy balance of the existing system by integrating exhaust gas heat recovery to preheat water. This approach reduces the boiler load, thereby lowering direct fuel consumption. The system facilitates the cooling of flue gases through water injection, enabling the subsequent liquefaction of CO2 to utilize the cryogenic potential of LNG. The object of the research is characterised by the typical structure of regasification systems, meaning that the solutions implemented in the study share common features that enable practical application which is essential considering the limited availability of studies evaluating FSRU regasification systems with a focus on assessing CCC integration;

- This study employed Thermoflow Thermoflex 32 software to simulate the regasification performance of an LNG vessel operating at 100% load, enabling a comprehensive evaluation of system modifications for integrating CCC technology. The simulations facilitated the conceptual design of a retrofit solution aimed at enhancing energy efficiency and reducing emissions. Results indicate that the regasification boiler load can be reduced by approximately 22%, allowing for the utilization of 11.4 MW of energy to separate water (H2O) from the engine exhaust gas. Additionally, an extra 5.9 MW of recovered energy can be used for LNG regasification and the liquefaction-based CO2 capture process. Simulation results showed that LNG regasification with the CCC system requires 78 MW of energy, to achieve a 15.5 °C send-out temperature. It is important to highlight that the simulation results achieved with Thermoflex 32 software indicate solid accuracy compared to the actual FSRU system performance where the deviation between simulated and actual system equipment in the sea water steam heater case is below 1%. The generated simulation foundation will allow us to further modify the system and assess equipment performance changes;

- These achieved results underscore the potential of an optimized CCC integration onboard LNG vessels to contribute to decarbonization efforts by leveraging waste heat for CO2 capture. Further studies are necessary to validate the feasibility of these modifications under real operating conditions, considering dynamic load variations and economic factors. Future research should also explore the scalability of the proposed CCC system across different LNG carrier designs and operational profiles to support industry-wide adoption. Further research is essential to comprehensively evaluate the practical implementation of the proposed system modification;

- The integration of cryogenic carbon capture in FSRUs has significant social and theoretical implications. Socially, it enhances environmental sustainability by reducing emissions, aligns with regulatory frameworks, and strengthens the LNG industry’s commitment to decarbonization, improving public perception and economic viability. Theoretically, this study advances research on CCC in maritime applications, providing insights into system optimization, scalability, and integration with onboard energy systems. These findings could pave the way for broader adoption across floating energy platforms, contributing to a more sustainable and efficient LNG supply chain.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Appendix A

Appendix B

References

- Wang, Z.; Lu, M.; Dong, S.; Tang, M.; Yan, X.; Li, K.; Yang, H. Study of ship-based carbon capture optimization considering multiple evaluation factors and main engine loads. J. Clean. Prod. 2024, 478, 143996. [Google Scholar] [CrossRef]

- Cret, L.; Baudry, M.; Lantz, F. How to implement the 2023 IMO GHG strategy? Insights on the importance of combining policy instruments and on the role of uncertainty. Mar. Policy 2024, 169, 106332. [Google Scholar] [CrossRef]

- Caiafa, C.; Hattori, T.; Nam, H.; Coninck, H. International technology innovation to accelerate energy transitions: The case of the international energy agency technology collaboration programmes. Environ. Innov. Soc. Transit. 2023, 48, 100766. [Google Scholar] [CrossRef]

- Park, S.; Lee, H.; Kim, D. Regulatory compliance and operational efficiency in maritime transport: Strategies and insights. Transp. Policy 2024, 155, 161–177. [Google Scholar] [CrossRef]

- Chen, Y.; Zhou, X.; Chen, S.; Mi, J. LNG freight rate and LNG price, carbon price, geopolitical risk: A dynamic connectedness analysis. Energy 2024, 302, 131517. [Google Scholar] [CrossRef]

- European Commission. Regulation of the European Parliament and of the Council on the Use of Renewable and Low-Carbon Fuels in Maritime Transport and Amending Directive 2009/16/EC; European Commission: Brussels, Belgium, 2021.

- Bayramoğlu, K. The effects of alternative fuels, cruising duration and variable generators combination on exhaust emissions, energy efficiency existing ship index (EEXI) and carbon intensity rating (CII). Ocean Eng. 2024, 302, 117723. [Google Scholar] [CrossRef]

- Balcombe, P.; Staffell, I.; Kerdan, I.G.; Speirs, J.; Brandon, N.; Hawke, A.D. How can LNG-fuelled ships meet decarbonisation targets? An environmental and economic analysis. Energy 2021, 227, 120462. [Google Scholar] [CrossRef]

- GIIGNL Annual Report 2024. Available online: https://www.scribd.com/document/804232933/GIIGNL-2024-Annual-Report-1 (accessed on 14 November 2024).

- SEA-LNG Ltd. LNG-Fuelled Vessels Accelerate to 6% of the Global Fleet. Available online: https://sea-lng.org/2024/10/lng-fuelled-vessels-accelerate-to-6-of-the-global-fleet/?utm_source=chatgpt.com (accessed on 4 December 2024).

- Tianbiao, H.; Jibao, Z.; Ning, M.; Praveen, L. Organic Rankine cycle integrated with hydrate-based desalination for a sustainable energy–water nexus system. Appl. Energy 2021, 291, 116839. [Google Scholar]

- Mazyan, W.; Ahmadi, A.; Ahmed, H.; Hoorfar, M. Market and technology assessment of natural gas processing: A review. J. Nat. Gas Sci. Eng. 2016, 30, 487–514. [Google Scholar] [CrossRef]

- Feenstra, M.; Monteiro, J.; Akker, J.; Abu-Zahra, M.; Gilling, E.; Goetheer, E. Ship-based carbon capture onboard of diesel or LNG-fuelled ships. Int. J. Greenh. Gas Control 2019, 85, 1–10. [Google Scholar] [CrossRef]

- DNV. Energy Transition Outlook 2024: Maritime Forecast to 2050. Available online: https://www.dnv.com/maritime/publications/maritime-forecast/ (accessed on 10 November 2024).

- DNV. Standards and Guidelines. Available online: https://www.dnv.com/focus-areas/ccs/standards-and-guidelines/ (accessed on 21 September 2024).

- Kanbur, B.; Xiang, L.; Dubey, S.; Choo, F.H.; Duan, F. Cold utilization systems of LNG: A review. Renew. Sustain. Energy Rev. 2017, 79, 1171–1188. [Google Scholar] [CrossRef]

- Shen, M.; Tong, L.; Yin, S.; Liu, C.; Wang, L.; Feng, W.; Ding, Y. Cryogenic technology progress for CO2 capture under carbon neutrality goals: A review. Sep. Purif. Technol. 2022, 299, 121734. [Google Scholar] [CrossRef]

- Enobong, H.; Chukwuebuka, N.; Victor, O. Carbon capture, utilization, and storage (CCUS) technologies: Evaluating the effectiveness of advanced CCUS solutions for reducing CO2 emissions. Results Surf. Interfaces 2024, 18, 100381. [Google Scholar]

- The Global CCS Institute. Global Status of CCS Report 2024; The Global CCS Institute: Melbourne, Australia, 2024. [Google Scholar]

- Park, J.; Kim, Y.; Lim, D.; Kim, J.; Lee, J.; Cho, H. Advancing greener LNG-fueled vessels: Compact simultaneous reduction system for CH4, NOX and CO2 emissions. J. Clean. Prod. 2024, 478, 143902. [Google Scholar] [CrossRef]

- Sultan, H.; Muhammad, H.; Bhatti, U.; Hong Min, G.; Il Hyun Baek Baik, Y.; Nam, S. Reducing the efficiency penalty of carbon dioxide capture and compression process in a natural gas combined cycle power plant by process modification and liquefied natural gas cold energy integration. Energy Convers. Manag. 2021, 244, 114495. [Google Scholar] [CrossRef]

- Alsanousie, A.; Attia, A.; Elhelw, M.; Elsamni, O. Towards nearly zero emissions natural gas-fired power plants using cryogenic carbon dioxide capture technology. Int. J. Greenh. Gas Control 2023, 127, 103928. [Google Scholar] [CrossRef]

- Ballout, J.; Al-Rawashdeh, M.; Al-Mohannadi, D.; Rousseau, J.; Burton, G.; Linke, P. Assessment of CO2 capture and storage onboard LNG vessels driven by energy recovery from engine exhaust. Clean. Eng. Technol. 2024, 22, 100802. [Google Scholar] [CrossRef]

- Wood, D.A.; Kulitsa, M. Chapter 7—LNG carriers and floating storage and regasification units: Opportunities to improve their operational efficiency. In The Fundamentals and Sustainable Advances in Natural Gas Science and Engineering, Sustainable Liquefied Natural Gas; Elsevier: Amsterdam, The Netherlands, 2024; Volume 3. [Google Scholar]

- Rifka, T.; Morosuk, T.; Tsatsaronis, G. Carbon capture and storage using low-temperature post-combustion technologies. Energy Sources Part A Recovery Util. Environ. Eff. 2019, 43, 3371–3380. [Google Scholar] [CrossRef]

- Naveiro, M.; Gómez, M.R.; Arias-Fernández, I.; Baaliña Insua, A. Thermodynamic and environmental analyses of a novel closed loop regasification system integrating ORC and CO2 capture in floating storage regasification units. Energy Convers. Manag. 2022, 257, 115410. [Google Scholar] [CrossRef]

- Lebedevas, S.; Malukas, A. The Application of Cryogenic Carbon Capture Technology on the Dual-Fuel Ship through the Utilisation of LNG Cold Potential. J. Mar. Sci. Eng. 2024, 12, 217. [Google Scholar] [CrossRef]

- Thermoflow. Available online: https://www.thermoflow.com/products_generalpurpose.html (accessed on 17 December 2024).

- Tianbiao, H.; Jie, M.; Huigang, M.; Tao, J. Exploiting cold energy associated with LNG regasification processes. In The Fundamentals and Sustainable Advances in Natural Gas Science and Engineering, Sustainable Liquefied Natural Gas; Elsevier: Amsterdam, The Netherlands, 2024; Volume 3. [Google Scholar]

- Enayatizadeh, H.; Arjomand, A.; Tynjälä, T.; Inkeri, E. Cryogenic carbon capture design through CO2 anti-sublimation for a gas turbine exhaust: Environmental, economic, energy, and exergy analysis. Energy 2024, 304, 132244. [Google Scholar] [CrossRef]

| Item | Description |

|---|---|

| Type of FSRU vessel | GTT Mark III membrane system of 170,000 m3 storage capacity; boil-off rate of 0.15% |

| Engine systems | Dual-fuel diesel-electric propulsion system (LNG boil-off gas with pilot fuel and Marine diesel oil. with pilot fuel): 3 × Wärtsilä -Hyundai 8L50DF 7800 kW 1 × Wärtsilä -Hyundai 6L50DF 5850 kW (Wärtsilä Itali SPA, Trieste, Italy) |

| Open-loop operational sea water temperature | SW > 13 °C |

| Closed-loop operational sea water temperature | SW < 13 °C |

| Regas boilers | 2 × 65,000 kg/h |

| Seawater/steam heaters for closed-loop, capacity | 3 × 36%; Heat exchange capacity: 3 × 27 MW |

| Operating fluid for the heat exchange | Propane R-290 type |

| Number of regasification trains | Four individual regasification trains with a send-out capacity of 3 × 142,799 Nm3/hour at 0 °C + one redundancy unit |

| CO2 | H2O | O2 | N2 | |

| 5% | 10% | 10% | 75% | |

| Engines | Mass flow | 12.17 kg/s | Temperature | 267 °C |

| Regas boilers | Mass flow | 29.56 kg/s | Temperature | 110 °C |

| Propane Pre-Heater, Propane Side | Propane Evaporator, Propane Side | Trim Heater, LNG Side | LNG Vaporizer, LNG Side | |

|---|---|---|---|---|

| Inlet pressure, bar | 10.9 | 4.05 | 54.9 | 54.3 |

| Outlet pressure, bar | 10.7 | 4.0 | 53.8 | 53.8 |

| Inlet temperature, °C | −5.5 | −5.9 | −25.0 | −25.0 |

| Outlet temperature, °C | 22.3 | −0.1 | 17.2 | 17.2 |

| Steam Heater 1 | Steam Heater 2 | Steam Heater 3 | Propane Pre-Heater | Propane Evaporator | Trim Heater | LNG Vaporizer | Total | |

|---|---|---|---|---|---|---|---|---|

| Before | 27,353 | 27,353 | 27,353 | 12,015 | 66,271 | 12,132 | 65,761 | 238,238 |

| After | 10,931 | 24,898 | 24,898 | 8101 | 63,903 | 10,982 | 60,632 | 221,710 |

| Compensating heaters | Water separator (25): 11,411 | Flue gas cooler (28): 4851 | CO2 cooler (18): 1103 | |||||

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Malūkas, A.; Lebedevas, S. Decarbonization and Improvement of Energy Efficiency of FSRU by Cryogenic CO2 Capture. J. Mar. Sci. Eng. 2025, 13, 770. https://doi.org/10.3390/jmse13040770

Malūkas A, Lebedevas S. Decarbonization and Improvement of Energy Efficiency of FSRU by Cryogenic CO2 Capture. Journal of Marine Science and Engineering. 2025; 13(4):770. https://doi.org/10.3390/jmse13040770

Chicago/Turabian StyleMalūkas, Audrius, and Sergejus Lebedevas. 2025. "Decarbonization and Improvement of Energy Efficiency of FSRU by Cryogenic CO2 Capture" Journal of Marine Science and Engineering 13, no. 4: 770. https://doi.org/10.3390/jmse13040770

APA StyleMalūkas, A., & Lebedevas, S. (2025). Decarbonization and Improvement of Energy Efficiency of FSRU by Cryogenic CO2 Capture. Journal of Marine Science and Engineering, 13(4), 770. https://doi.org/10.3390/jmse13040770