Experimental Study on the Hydraulic Characteristics and Shape Optimization of Ship Lock Water Conveyance Systems

Abstract

:1. Introduction

2. Materials and Methods

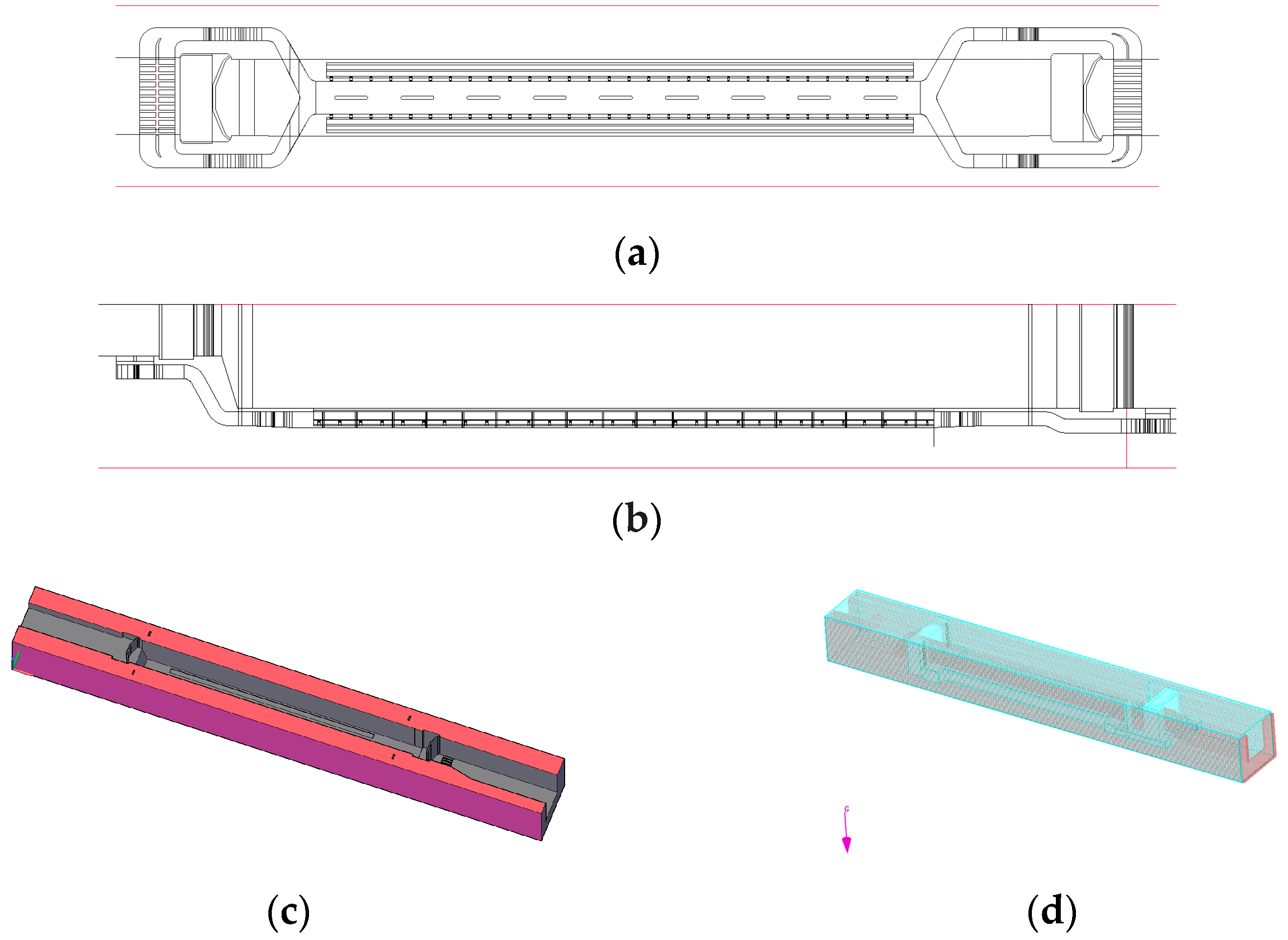

2.1. Construction of the Three-Dimensional Mathematical Model

2.1.1. Basic Theory

2.1.2. Model Scope

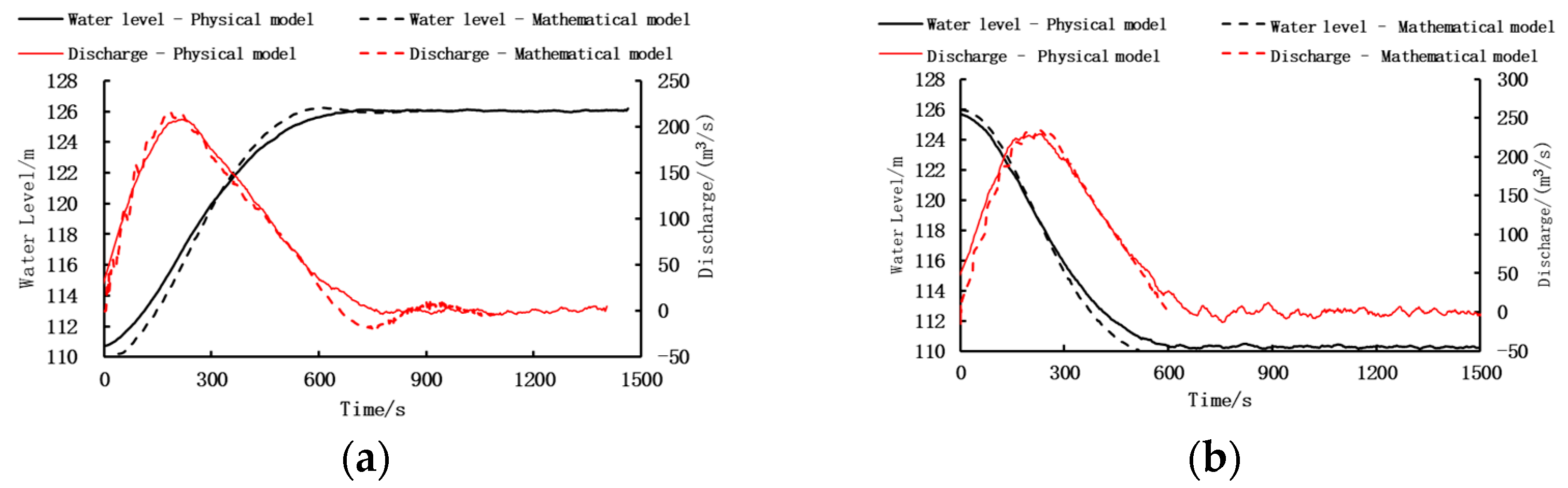

2.1.3. Model Verification

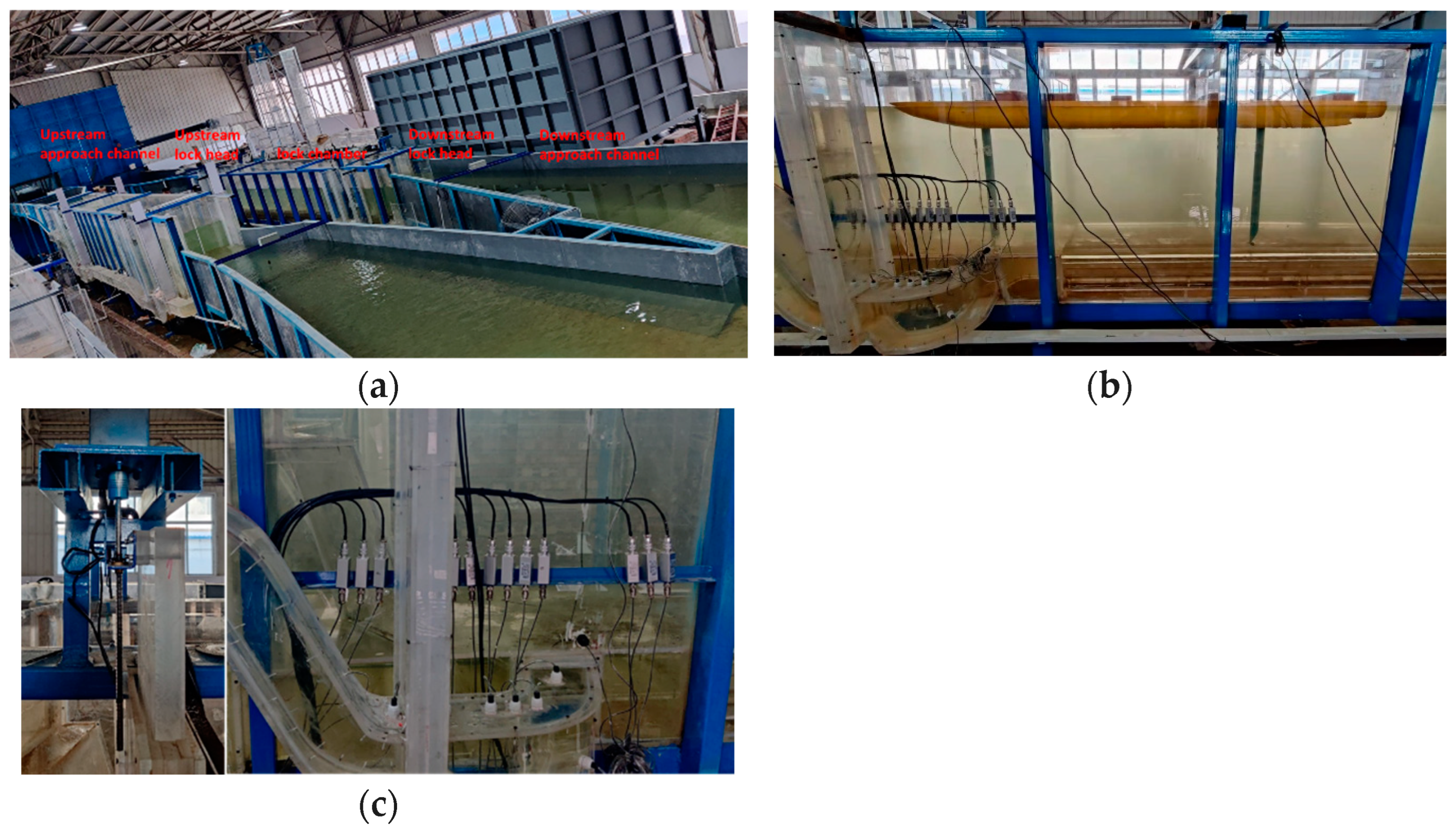

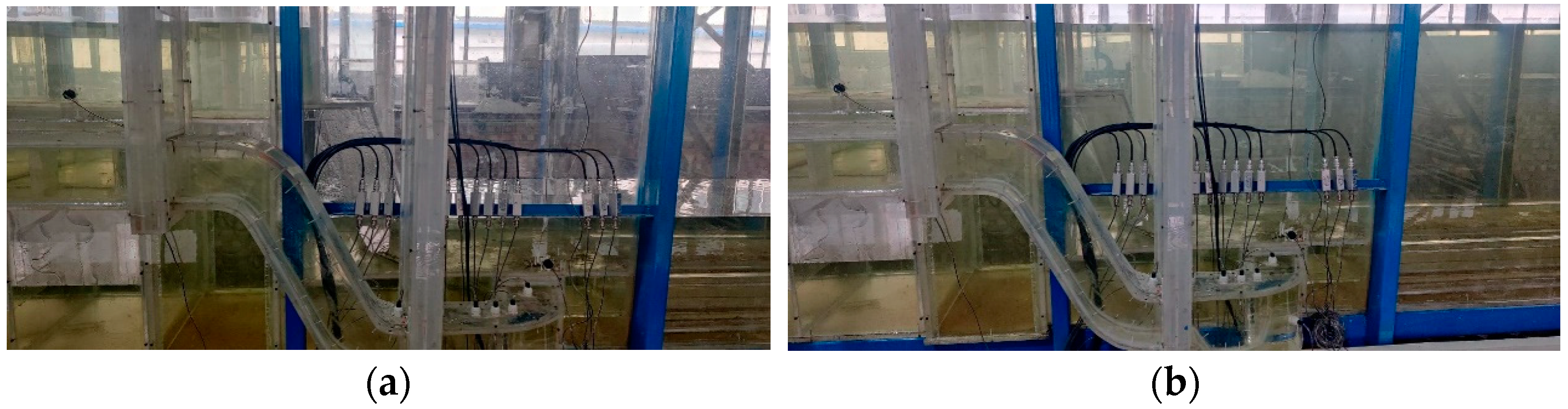

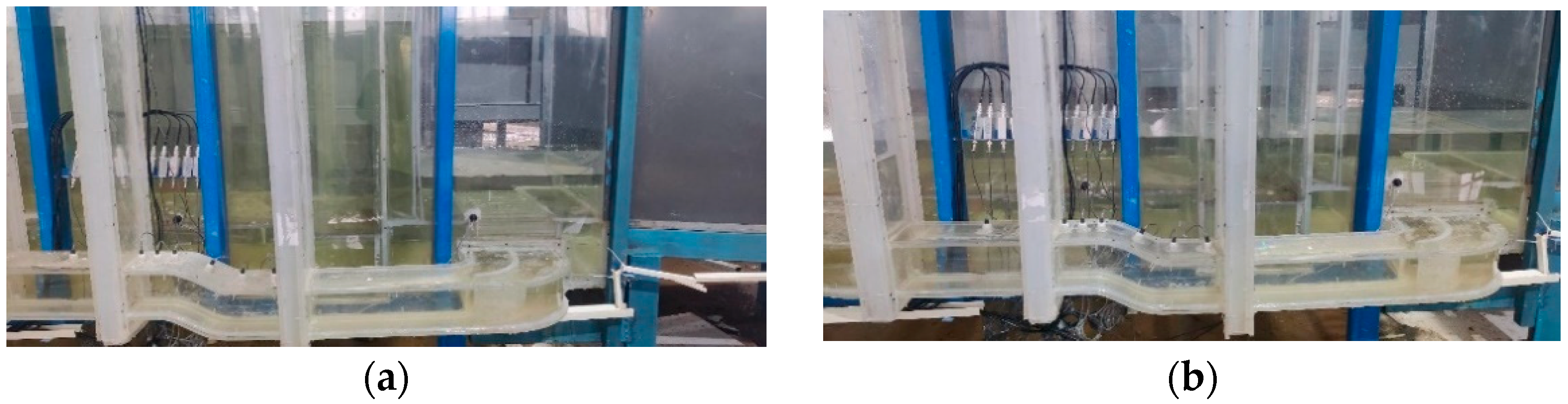

2.2. Construction of the Physical Model

2.2.1. Physical Model

2.2.2. Sensor Arrangement

2.3. Experimental Content

3. Results and Discussion

3.1. Numerical Analysis Results of the Mathematical Model

3.1.1. Shape Optimization

3.1.2. Hydraulic Characteristics of Chamber Filling

3.1.3. Pressure Characteristics of Mathematical Model Valve Section Corridor

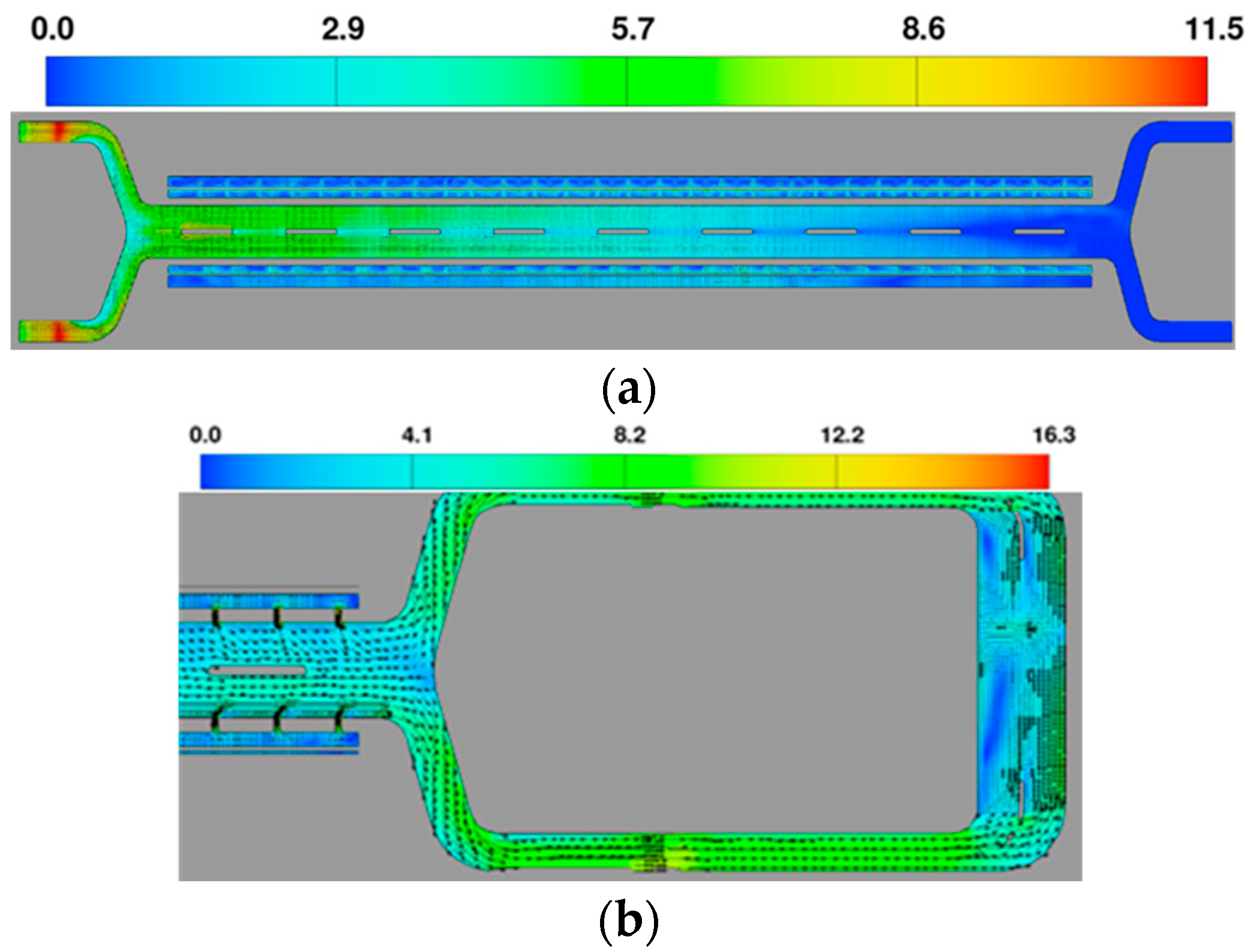

3.1.4. Water Flow Patterns in Typical Sections

- (1)

- Water Flow Pattern in the Filling Valve Section

- (2)

- Water Flow Pattern in the Emptying Valve Corridor Section

3.2. Experimental Analysis Results of the Physical Model

3.2.1. Hydraulic Characteristics of Chamber Water Conveyance

- (1)

- Filling and Emptying Processes

- (2)

- Flow Coefficient of the Water Conveyance System

- (3)

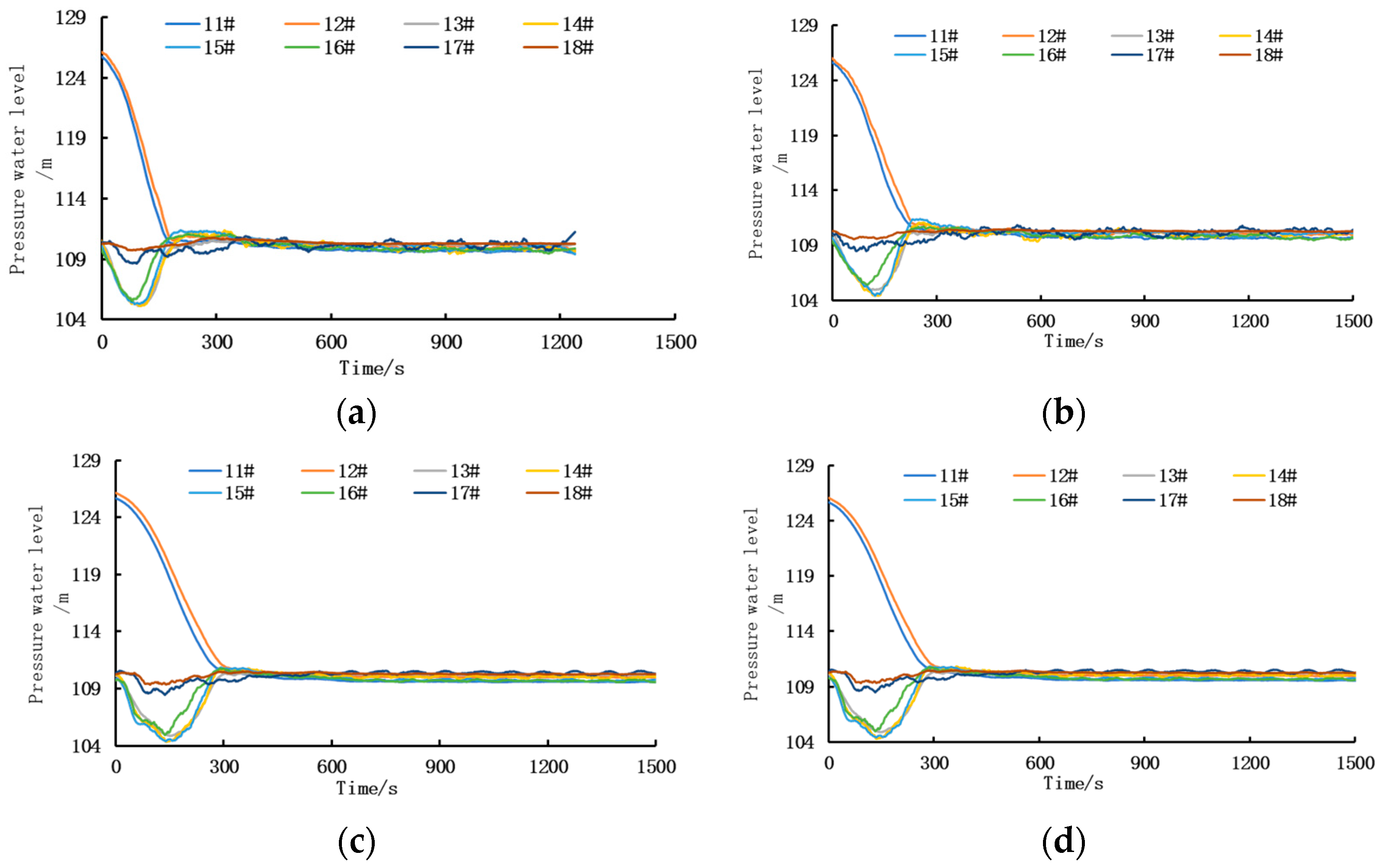

- Hydraulic Characteristics

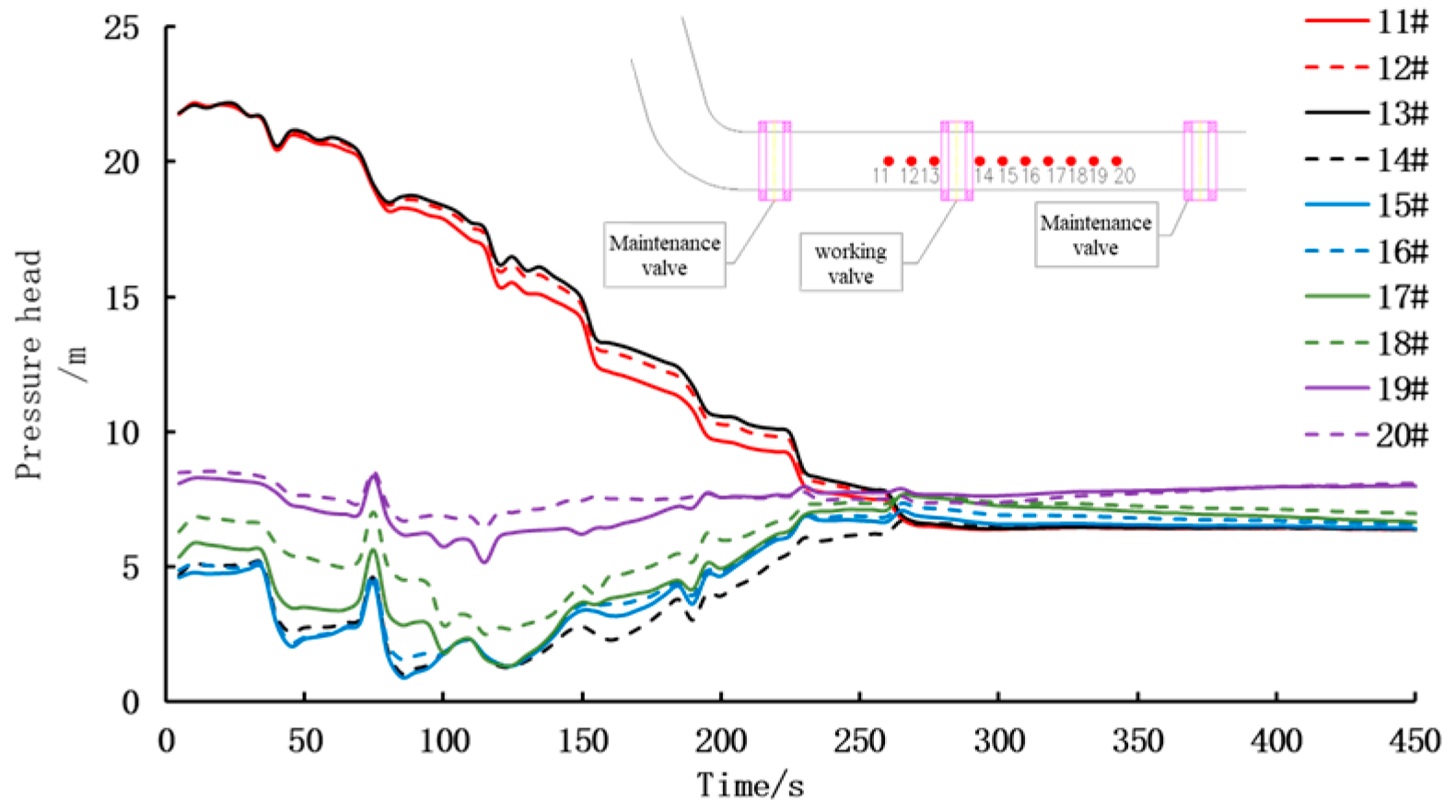

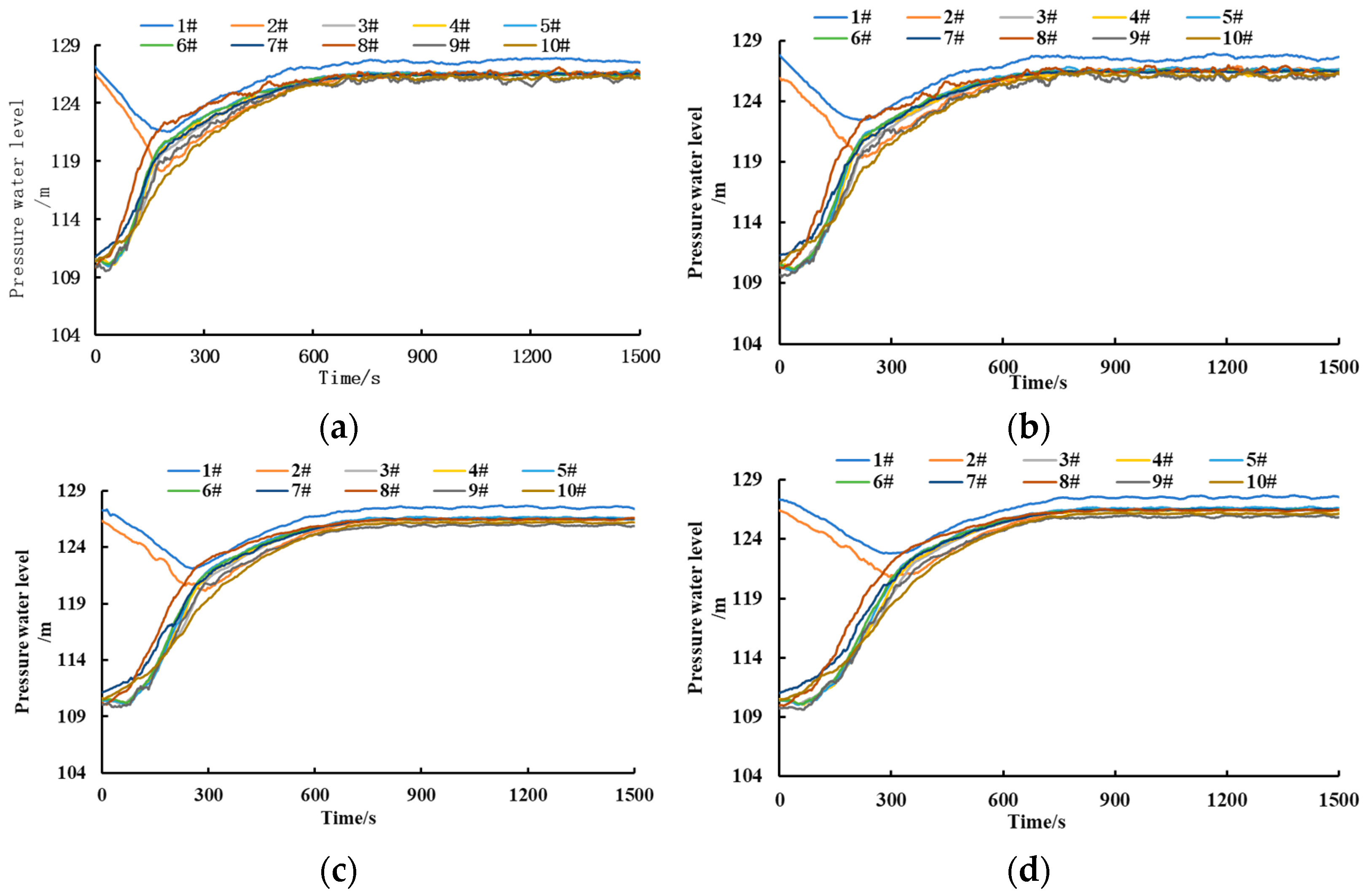

3.2.2. Pressure Characteristics of Physical Model Valve Section Corridor

- (1)

- Pressure Characteristics of the Upstream Corridor of the Lock Chamber

- (2)

- Pressure Characteristics of the Downstream Corridor of the Lock Chamber

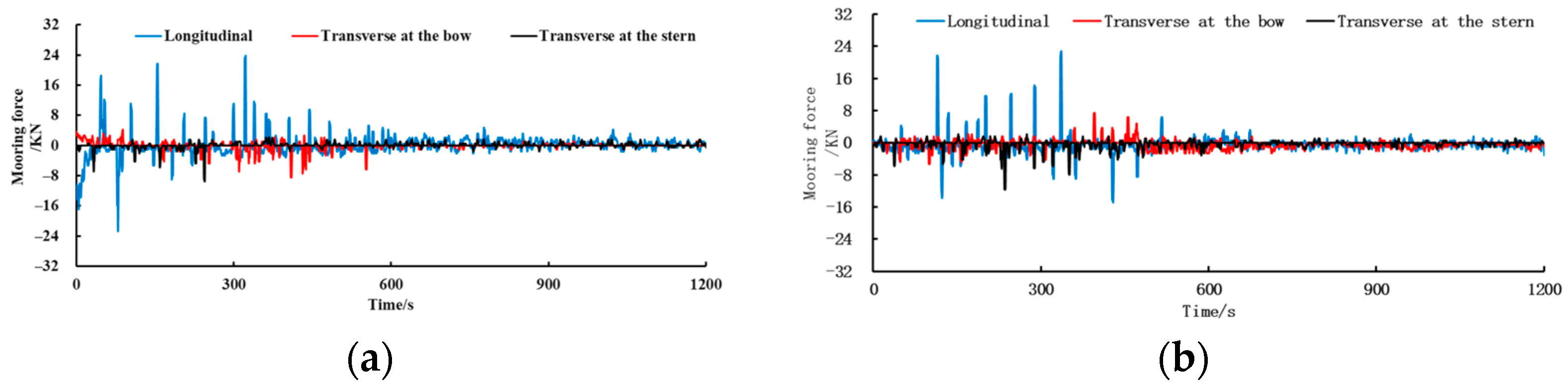

3.2.3. Ship Stability

4. Conclusions

- (1)

- By performing a sudden-expansion treatment on the bottom of the corridor behind the valve and reducing the angle of the turning section, the contracted water flow behind the valve can be forced to diffuse, effectively reducing the range of the high-velocity zone behind the valve and the hydrodynamic pressure on the outer side wall of the bend-confluence section. In the optimized shape scheme, the range of the high-velocity zone is shortened from 3.0 m to 1.5 m, and the velocity in the horizontal section is less than 15 m/s. The pressure difference between the inner and outer sides of the horizontal turning section corridor is reduced from 5.35 m to 4.32 m of pressure head at the moment of maximum flow rate, effectively ensuring the safe operation of the corridor.

- (2)

- During the filling process, as the filling valve gradually opens, the pressure head in front of the valve shows a trend of first decreasing significantly and then increasing significantly, while the pressure head behind the valve shows a trend of first decreasing slightly and then increasing significantly. During the emptying process, as the emptying valve gradually opens, the pressure head in front of the valve shows a significant decreasing trend, and the pressure head behind the valve shows a trend of first decreasing and then increasing. During the research process, special attention should be paid to the pressure head situation in the corridor behind the valve to avoid the occurrence of negative pressure.

- (3)

- As the opening time of the corridor valve increases, the water conveyance completion time gradually increases, and the maximum flow rate and the average sectional velocity of each part decrease. In the research of the filling process, as the valve opening time is prolonged, the minimum pressure at the top of the corridor gradually increases; in the research of the emptying process, as the valve opening time is prolonged, the minimum pressure at the top of the corridor gradually decreases.

- (4)

- The three-dimensional numerical model constructed in this paper can clearly display the water flow pattern characteristics of each part. The independently developed system can effectively monitor the hydraulic characteristics of the physical test model and the stability of the ship. The combination of the research results of the numerical model and the physical model can effectively ensure the scientific nature of the research. The research method proposed in this paper can effectively optimize the design shape scheme and further improve the scientific nature of the optimized scheme, providing effective technical guidance for engineering construction.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Natale, L.; Savi, F. Minimization of filling and emptying time for navigation locks. J. Waterw. Port Coast. Ocean. Eng. 2000, 126, 274–280. [Google Scholar] [CrossRef]

- Wang, S.M.; Jiang, Y.Z.; Wu, Y.Z.; Li, J. Research on the water conveyance system of large-scale ship locks with ultra-high water head. Yangtze River 2017, 48, 75–79. [Google Scholar]

- Chen, M.; Xuan, G.X.; Chen, M.D. A review of hydrodynamic research on ship lock water conveyance systems. J. Chongqing Jiaotong Univ. (Nat. Sci.) 2013, 32, 157–160+168. [Google Scholar]

- Richard, L.S.; Frank, M.N.; Victor, L.Z. Hydraulic calculations for flow in lock manifolds. J. Hydraul. Eng. 1991, 117, 1026–1041. [Google Scholar]

- Lucas, E.; Calvo, G. Design of the filling and emptying system of the new Panama Canal locks. J. Appl. Water Eng. Res. 2013, 1, 28–38. [Google Scholar]

- Hite, J.E.; Stockstill, R.L. Hydraulic design of a longitudinal culvert for lock filling and emptying systems. J. Hydraul. Eng. 2004, 130, 381–388. [Google Scholar] [CrossRef]

- Liu, P.C.; Zhou, J.Y.; Wang, Z.B.; Ding, S.Q. Prototype observation research on the hydraulics of the water conveyance system of Jinpanzi Ship Lock on Qujiang River. J. Chongqing Jiaotong Univ. (Nat. Sci.) 2011, 30, 1396–1399+1419. [Google Scholar]

- Wang, L.J.; Liu, H.J.; Wu, Y.Z.; Jiang, Y.Z. Prototype observation research on the hydraulics of the water conveyance system of Xinglong Ship Lock on Hanjiang River. Yangtze River 2020, 51, 340–343. [Google Scholar]

- Ouyang, B.; Chen, L.; Ou, Z.Q.; Shu, Y.J.; Wang, Z.B. Prototype observation on hydraulic characteristics and full-scale ship test of the second-line ship lock of Qingyuan Hub on Beijiang River. Port Waterw. Eng. 2022, 6, 112–118. [Google Scholar]

- Hu, Y.A.; Zheng, C.P. Prototype monitoring of the cavitation characteristics of the water delivery valve of Gezhouba No.1 Ship Lock. Adv. Water Sci. 1994, 3, 235–241. [Google Scholar]

- Hu, Y.A.; Li, J.; Li, Z.H. Prototype debugging research on the hydraulic characteristics of the water conveyance system of Dahua Ship Lock on Hongshui River. Port Waterw. Eng. 2008, 3, 87–92+98. [Google Scholar]

- Ables, J.H.; Boyd, M.B. Filling and Emptying System Cannelton Main Lock, Ohio River, and Generalized Tests of Sidewall Port Systems for 110- by 1200- ft Locks. Hydraulic Model Investigation; U.S. Army Engineer Waterways Experiments Station: Vicksburg, MS, USA, 1966; pp. 2–713. [Google Scholar]

- Pickett, E.B.; Neilson, F.M. Lock Hydraulic System Model and Prototype Study Data; U.S. Army Engineer Waterways Experiment Station: Vicksburg, MS, USA, 1988. [Google Scholar]

- Hite, J.E. Model Study of Marmet Lock Filling and Emptying System, Kanawha River; U.S. Army Engineer Waterways Engineer Station: Vicksburg, MS, USA, 1999. [Google Scholar]

- Ning, W.; Li, J.; Xuan, G.X.; Guo, C.; Huang, Y. Layout and hydraulic model test research on the water conveyance system of the second-line ship lock of Honghua on Liujiang River. Port Waterw. Eng. 2017, 10, 154–159. [Google Scholar]

- Kan, Y.J.; Li, J.; Xuan, G.X.; Xu, X.M.; Zhao, Y.H. Hydraulic model test of the water conveyance system of Shushan Pumping Station Hub Ship Lock. Port Waterw. Eng. 2017, 9, 126–130+143. [Google Scholar]

- Tom, R.P.; Roux, S.; De Regge, J.; Wong, J.; De Mulder, T. Physical Model for the Filling and Emptying System of the Third Set of Panama Locks; CNR—Consorcio Pos Panamax: Paris, France, 2008. [Google Scholar]

- Hammack, E.A.; Stockstill, R.L. 3D numerical modeling of lock filling systems for hydraulic efficiency optimization. J. Hydraul. Eng. 2020, 146, 04020065. [Google Scholar]

- Yang, Z.C.; Yang, B.; Chen, M.D.; Hu, X.M. Simulation research on the hydraulic characteristics during the valve opening process of high-head ship locks. J. Chongqing Jiaotong Univ. (Nat. Sci.) 2009, 28, 758–762. [Google Scholar]

- Yang, Z.C.; Yang, B.; Chen, M.D.; Hu, X.M. Three-dimensional numerical simulation of the shape optimization of the valve section of high-head ship locks. Adv. Water Resour. Sci. Technol. 2010, 30, 10–13. [Google Scholar]

- Stockstill, R.L.; Berger, R.C. A three-dimensional numerical model for flow in a lock filling system. In Proceedings of the Great Rivers: World Environmental and Water Resources Congress, Kansas City, MS, USA, 17–21 May 2009; pp. 2737–2746. [Google Scholar]

- Badano, N.D.; Menéndez, Á.N. Numerical modeling of Reynolds scale effects for filling/emptying system of Panama Canal locks. Water Sci. Eng. 2021, 14, 237–245. [Google Scholar] [CrossRef]

- Tornstrom, T. Flow and Thermal Characteristics of Warm Plane Air Jets (Measurements and Predictions using Different k-ε models). In Proceedings of the Tenth International Conference on Computational Methods and Experimental Measurements, Alicante, Spain, 4–6 June 2001; pp. 33–44. [Google Scholar]

- Zhang, L.P. The 3D Flow Numerical Simulation Study on High-Lift Lock. Ph.D. Thesis, Chongqing Jiaotong University, Chongqing, China, 2008. [Google Scholar]

- Chen, M.; Liang, Y.C.; Xuan, G.X.; Chen, M.D. Dynamic simulation research on the three-dimensional hydraulic characteristics during the ship lock water conveyance process. J. Hydrodyn. Ser. A 2013, 28, 559–565. [Google Scholar]

- Chen, M.; Liang, Y.C.; Xuan, G.X.; Chen, M.D. Numerical simulation of the mooring force of ships in the lock chamber during the water conveyance process. J. Ship Mech. 2015, 1, 78–85. [Google Scholar]

- Dodaro, G.; Tafarojnoruz, A.; Stefanucci, F.; Adduce, C.; Calomino, F.; Gaudio, R.; Sciortino, G. An experimental and numerical study on the spatial and temporal evolution of a scour hole downstream of a rigid bed. In River Flow 2014; CRC Press: London, UK, 2014. [Google Scholar]

- Calomino, F.; Alfonsi, G.; Gaudio, R.; D’Ippolito, A.; Lauria, A.; Tafarojnoruz, A.; Artese, S. Experimental and Numerical Study of Free-Surface Flows in a Corrugated Pipe. Water 2018, 10, 638. [Google Scholar] [CrossRef]

- Lauria, A.; Alfonsi, G.; Tafarojnoruz, A. Flow Pressure Behavior Downstream of Ski Jumps. Fluids 2020, 5, 168. [Google Scholar] [CrossRef]

- Hirt, C.W.; Nichols, B.D. Volume of fluid (VOF) method for the dynamics of free boundary. J. Comput. Phys. 1981, 39, 201–225. [Google Scholar] [CrossRef]

- JTJ 306-2001; Code for Design of Ship Lock Water Conveyance Systems. China Communications Press: Beijing, China, 2001.

- DL/T 5244-2010; Code for Conventional Hydraulic Model Tests of Hydropower and Water Conservancy Projects. China Electric Power Press: Beijing, China, 2010.

| Items | Filling Process | Emptying Process | ||

|---|---|---|---|---|

| Filling Completion Time (s) | Maximum Discharge (m3/s) | Emptying Completion Time (s) | Maximum Discharge (m3/s) | |

| Numerical Simulation Results | 631 | 216.29 | 589 | 220.45 |

| Physical Model Results | 648 | 208.18 | 600 | 229.27 |

| Deviation | −2.59% | 3.90% | 1.80% | −3.85% |

| Upstream Navigable Water Level (m) | Downstream Navigable Water Level (m) | ||

|---|---|---|---|

| Upstream navigable water level | 126.00 | / | / |

| Highest upstream navigable water level | 131.73 | Highest downstream navigable water level | 127.48 |

| Lowest upstream navigable water level (m) | 125.00 | Lowest downstream navigable water level | 110.00 |

| Calculation Scheme | Filling Process | |

|---|---|---|

| Designed Scheme | Optimized Scheme | |

| Filling completion time T0 (s) | 625 | 631 |

| Time of maximum flow rate TQmax (s) | 296 | 277 |

| Maximum flow rate Qmax (m3/s) | 221.92 | 216.29 |

| Sectional velocity of valve corridor at maximum flow rate VQmax (m/s) | 6.94 | 6.76 |

| Maximum velocity of grid section Vmax (m/s) | 1.48 | 1.44 |

| Inertial super-elevation of water surface H0 (m) | 0.26 | 0.24 |

| Water Conveyance Method | Calculation Scheme | Typical Moment | Inner Side Wall Pressure Head/m | Outer Side Wall Pressure Head/m | Pressure Head Difference Between Inner and Outer Sides/m |

|---|---|---|---|---|---|

| Filling process | Designed scheme | TQMAX | 14.33 | 19.68 m | 5.35 |

| Optimized scheme | 14.49 | 18.81 | 4.32 | ||

| Designed scheme | TPMIN | 6.29 | 10.18 | 3.89 | |

| Optimized scheme | 7.75 | 9.27 | 1.52 |

| Valve Opening Time (min) | Filling/Emptying Time (s) | Maximum Flow Rate (m3/s) | Maximum Average Sectional Velocity of Inlet (m/s) | Maximum Sectional Velocity of Valve Corridor (m/s) | Inertia Ultra-High/Over-Low Value (m) | |

|---|---|---|---|---|---|---|

| Filling | 3 | 590 | 233.29 | 1.56 | 7.29 | 0.12 |

| 4 | 621 | 220.26 | 1.47 | 6.88 | 0.11 | |

| 5 | 648 | 208.18 | 1.39 | 6.51 | 0.08 | |

| 6 | 670 | 196.65 | 1.31 | 6.15 | 0.10 | |

| Emptying | 3 | 574 | 256.30 | - | 8.01 | −0.17 |

| 4 | 586 | 244.94 | - | 7.65 | −0.13 | |

| 5 | 600 | 229.27 | - | 7.16 | −0.16 | |

| 6 | 610 | 219.17 | - | 6.84 | −0.15 |

| Water Conveyance Type | Ship Berthing Position | Longitudinal Force/kN | Bow Lateral Force/kN | Stern Lateral Force/kN |

|---|---|---|---|---|

| Filling | Front | 17.46 | 5.29 | 8.47 |

| Middle | 29.81 | 10.47 | 9.53 | |

| Rear | 31.81 | 11.64 | 9.00 | |

| Emptying | Front | 13.76 | 9.00 | 9.35 |

| Middle | 22.76 | 7.41 | 11.64 | |

| Rear | 24.87 | 9.53 | 8.47 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Duan, Y.; Ma, D.; Gan, W.; Ji, C.; Zhou, J. Experimental Study on the Hydraulic Characteristics and Shape Optimization of Ship Lock Water Conveyance Systems. J. Mar. Sci. Eng. 2025, 13, 784. https://doi.org/10.3390/jmse13040784

Duan Y, Ma D, Gan W, Ji C, Zhou J. Experimental Study on the Hydraulic Characteristics and Shape Optimization of Ship Lock Water Conveyance Systems. Journal of Marine Science and Engineering. 2025; 13(4):784. https://doi.org/10.3390/jmse13040784

Chicago/Turabian StyleDuan, Yu, Dianguang Ma, Weidong Gan, Chao Ji, and Junwei Zhou. 2025. "Experimental Study on the Hydraulic Characteristics and Shape Optimization of Ship Lock Water Conveyance Systems" Journal of Marine Science and Engineering 13, no. 4: 784. https://doi.org/10.3390/jmse13040784

APA StyleDuan, Y., Ma, D., Gan, W., Ji, C., & Zhou, J. (2025). Experimental Study on the Hydraulic Characteristics and Shape Optimization of Ship Lock Water Conveyance Systems. Journal of Marine Science and Engineering, 13(4), 784. https://doi.org/10.3390/jmse13040784