1. Introduction

The flow around single cylinder or group of cylinders is a fundamental fluid dynamics problem that has attracted considerable research due to its wide engineering significance. The flow past a cylinder typically involves boundary layer separation/reattachments, free shear layers, and vortex shedding, which induces cylinder vibrations and noise generation. These flow dynamics become more complicated when there are interferences or interactions with neighboring cylinders. The understanding behind such flow past multiple cylinders provide important insight as they are found in many branches of engineering applications, for example, cooling cores in nuclear reactors, heat exchanger tube bundles, offshore structures, marine risers, and pipelines. Among flow past multiple cylinders, the case involving two cylinders has been investigated both numerically and experimentally under several configurations, in-tandem, side-by-side, or staggered arrangements, and provides some fundamental understanding of flow or wake interactions [

1,

2].

The flow characteristics past two side-by-side cylinders are strongly influenced by the gap between cylinders and their diameter-based Reynolds number,

. Denoting

T as the transverse center-to-center distance between cylinders and

D as the cylinder diameter, the flow behavior around side-by-side cylinders may be classified into three main regimes [

3,

4]: (i) When

1.1–1.2, the gap between cylinders is small and the flow behaves similar to passing a single bluff body where vortices are shed alternately from the outer surfaces of the top and bottom cylinders, forming an asymmetric single vortex street. In this single-bluff body regime, the Strouhal number (

) is approximately 0.2—similar to a single-bluff body case, but with characteristic length of

[

5]. (ii) When

2.0–2.2, this intermediate spacing between cylinders is within a critical range where the flow between the gap is bistable and switches direction (flip-flopping) towards either cylinders at irregular intervals (with periods several orders of magnitude larger than the vortex shedding period). As a result, in this biased flow regime, a narrower and wider wake region forms behind either cylinders, corresponding to higher (

0.2–0.4) and lower (

0.1–0.2) vortex shedding frequencies, respectively [

6]. Within this regime, the Reynolds number

may also influence the transition between single and twin vortex streets [

7,

8]. In their 3D numerical study, Liu et al. [

9] also showed the influence of cylinder inclination (or conversely, flow angle) on formation of these vortex streets. (iii) When

, the gap is sufficiently large that both cylinders behaves more as isolated bluff bodies resulting in predominantly symmetric (or anti-phase) parallel wake patterns that are coupled with a single Strouhal number

of approximately 0.21 [

6]. Intermittent in-phase wake patterns may also take place in this symmetric flow regime, but would then synchronize back to the more stable anti-phase or symmetric pattern. At much higher gaps (

), any interference associated with proximity of cylinders are negligible and each cylinder behaves as independent bluff bodies with uncoupled flow patterns [

3].

Previous studies on flow around bluff bodies with adjacent plates may also provide useful context for the present work. The flow past a single cylinder with plates has received much attention in the past decades, especially for passive flow/vortex control (and, subsequently, flow-induced vibration control) of a cylinder (see, for example, [

10,

11,

12,

13]), understanding of plate dynamics (for instance, [

14,

15]), and potential for energy harvesting (see, for example, [

16,

17]). Less well explored is the flow with plates behind two or multiple cylinders. Furquan et al. [

18] computationally investigated vibration response of two flexible splitter plates, each placed behind two side-by-side square cylinders (that are separated by center-to-center distance equal to twice the square edge length

L) at

under varying reduced velocities (

, where

is plate natural frequency). Their results indicate initial anti-phase plate vibration as the plates are attracted towards each other with the accelerating gap flow, before finally synchronizing into an in-phase plate vibration pattern that also exhibits the “lock-in” phenomenon at certain range of

, as either plate undergoes large vibration amplitudes when its response frequency approaches the plate’s first mode natural frequency. The effect of short splitter plates behind two side-by-side square cylinders (with center-to-center distance equal 3.6 times the square edge length) on their vortex shedding and subsequent sound generation were examined experimentally for

of 10,000–33,000 by Octavianty and Asai [

19]. In this symmetric flow regime and high

, generated vortices past the side-by-side square cylinders were highly synchronized and coherent spanwise, allowing effective sound reduction even with shorter splitter plates—in contrast to a single square cylinder where vortices were more three-dimensional and the effect of splitter plate was limited. Oruc et al. [

20] experimented with splitter plates centrally placed between two side-by-side circular cylinders and examined their effect on the flip-flopping gap flow in the biased flow regime. It was found that, at sufficient plate lengths, the asymmetric and bistable wake flow were suppressed, resulting in two symmetric and stable wake patterns.

Demand for clean and sustainable energy that requires minimal human intervention or maintenance (for example, to power wireless sensors in remote areas, electronic devices for structural health monitoring of airborne vehicles or deep ocean structures) have prompted increasing development of various energy harvesting systems. One of a number of prototypes include exploiting wakes behind a single bluff body (for example, [

16,

17,

21,

22]) and wake-induced vibration of cylinders (for example, [

23]) to induce oscillations of flexible membranes or plates consisting of piezoelectric materials—converting the fluctuating mechanical strains or energy into electrical energy and have been shown to reach outputs up to 30 V [

24,

25]. Although multiple bluff bodies are ubiquitous in many engineering applications, limited investigation on their potential to excite piezoelectric energy harvesters may be found.

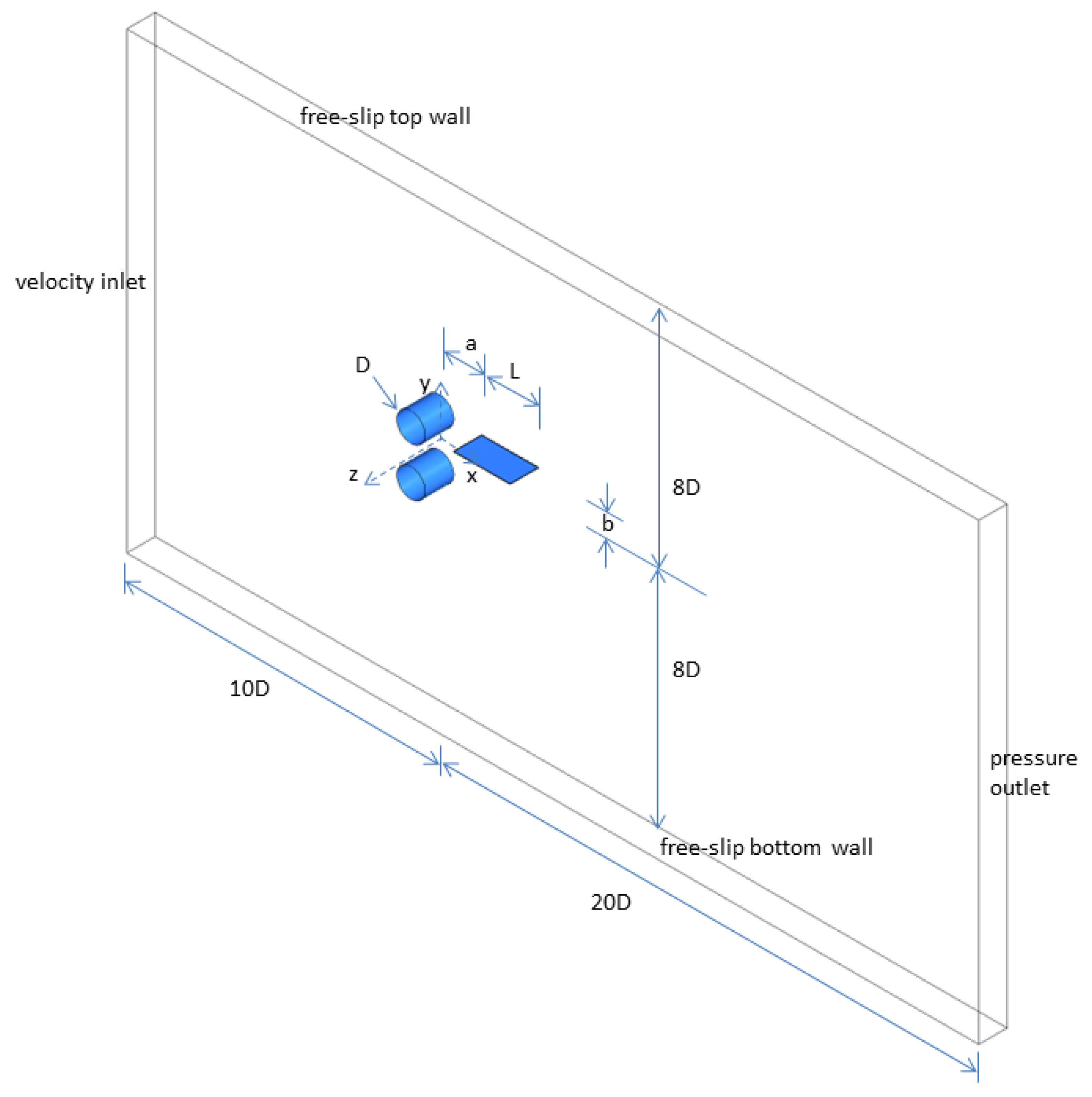

Therefore, in the present study, we aimed to extend the current results in the literature by exploring wake-excited piezoelectric energy harvesters placed behind two side-by-side cylinders and also analyze their vibrations at various placements in the wake region with the view of maximizing energy harvesting performance. To that end, we performed a computational investigation on the unsteady flow past two side-by-side circular cylinders interacting with a thin flexible plate placed at a number of streamwise and crossflow positions behind both cylinders. As the side-by-side cylinders behave as a single bluff body, either in unison or separated when the gap is small or large enough, respectively, we considered a center-to-center cylinder spacing of (in the bias flow regime) for the present study, to include effects of multiple bluff body flow interaction or interference. In addition, a moderately high sub-critical flow past cylinders of 10,000 was considered in the present work.

3. Results and Discussion

Overall, 10–20 internal coupling iterations were necessary for fluid–structure coupling convergence at each time step. Computations for the initial stationary plate could take up to 24 h, while the following fluid–structure computations could run up to 45 h, depending on the case simulated. We begin by presenting the oscillation history of the flexible plate when they are placed at each of the 15 locations highlighted in

Figure 3. Plate tip displacements (in the y-direction) over time, when the plate is positioned along various streamwise locations at each

, are shown in

Figure 4a–e. Tip oscillations show lowest amplitudes when flexible plate is placed along the centerline (

) between the two side-by-side cylinders, compared to other

locations. Furthermore, their oscillating amplitude appears to be lowest when the plate is closest to the cylinders (

) before maximizing at

and decreases as the plate is placed further downstream, as shown in

Figure 4c. To better quantify plate vibration behavior behind the cylinders, the mean y-displacements (

) of the tip was calculated for each case. In addition, as piezoelectric effect is affected by their mechanical strains, which occur irrespective of positive or negative direction in plate deflection, we considered taking their vibration amplitude (

A) over time and calculated their root-mean-square (

) as an indication of the overall level in mechanical strains experienced by the piezoelectric beam (and, hence, energy harvesting potential), for all 15 cases.

Table 6 summarizes these

and

values for all the cases simulated in the present study. Inspecting the table, a number of observations may be hypothesized in regards to variation in

and

with respect to plate placement in the wake region:

The mean y-displacements show opposing deflections between plate positioned above and below the centerline . At locations immediately behind both cylinders (i.e., ), the plate placed above the centerline () tended to oscillate about a mean position that is deflected downwards (), while the plate placed below the centerline () tended to oscillate about a mean position that deflects upwards ( > 0). However, away from the cylinders (i.e., ), the opposite occurs, where the plate positioned above the centerline appears to oscillate about a mean position that is deflected upwards (i.e., > 0) and the plate positioned below the centerline appears to deflect more downwards (i.e., < 0).

In the vicinity immediately behind the cylinders (i.e., ), putting the flexible plate on the rear center point of either cylinder (i.e., ) was found to promote highest overall plate oscillations (as indicated by maximum ). However, further downstream from both cylinders (i.e., ), placing the flexible plate at intermediate region above or below the centerline (i.e., at and ) was shown to generate highest overall amplitudes in plate oscillations along their respective streamwise positions.

The flexible plate placed along the centerline

showed the lowest root-mean-square in their oscillation amplitude. Furthermore, root-mean-square in amplitude of plate oscillation with respect to their placement behind two side-by-side cylinders appears to be mirrored about the centerline

(i.e.,

at

are closer in values to

at

, and

at

are closer in values to

at

) along a streamwise location. This is further evident from the contour plot showing distribution of

behind both cylinders, as depicted in

Figure 5.

Figure 5 shows the variation in root-mean-square of the oscillation amplitude (

) with respect to plate placement behind two side-by-side cylinders. The contours were generated from the results at the 15 locations in

Table 6 using a cubic spline interpolation, giving predicted

for the flexible plate if they are located along various (

,

) locations behind the two cylinders. Thus,

Figure 5 indicates potential locations where the flexible plate may be placed to undergo high overall vibration amplitudes. This include rear center points on either cylinders or in the intermediate region off-center from the centerline between the cylinders (for placements further downstream). Overall, maximum mean amplitude of oscillation was recorded when the flexible plate is placed at

(i.e., Case c4), where their mean amplitude is almost twice the mean amplitude on the centerline at similar streamwise (x) position.

Figure 6a–c highlights spanwise vorticity contour plot corresponding to cases with maximum mean amplitude for each streamwise locations

. While biased flow regime (with narrow and wide asymmetric wake patterns behind either cylinder) is expected to take place for side-by-side cylinders in the present

, it was found that this wake pattern still persists in the presence of a flexible plate. Comparing at instances when their respective plate amplitude is maximum, the narrow–wide wake pattern is more pronounced for Cases b2 and c2 (see

Figure 6b,c), where the plate is placed at

, compared to Case a5 where plate is placed centrally behind a cylinder at

. In contrast, the wake pattern for Case a3 (corresponding to lowest mean amplitude case located along centerline

) in

Figure 6d shows minimal difference in wake size between cylinders, highlighting: (i) the potential suppression of biased gap flow when the flexible plate is centrally positioned and close to both cylinders (similar to previous study by Oruc et al. [

20] but with plate length not extending upstream in the present study); and (ii) the important role of biased gap flow on plate vibrations behind two side-by-side cylinders. Consequently, the wake-excited energy harvesting plate may be positioned away from the centerline

to maximize their energy output for this type of bluff body configuration.