Predicting the Deflection of Square Plates Subjected to Fully Confined Blast Loading

Abstract

:1. Introduction

2. New Dimensionless Number for Analysis of Plates under Confined Blast Loading

2.1. Confined Explosion in a Cubic Chamber

2.2. Confined Explosion in the Cuboid Chamber

3. Analysis of the Deformation of Plates under Confined Explosion in Cubic Chamber

3.1. Application of the New Dimensionless Number for Confined Explosion in Cubic Chamber

3.2. Comparison with Nurick’s Dimensionless Number

4. Analysis of the Deformation of Plates under Confined Explosion in Cuboid Chamber

4.1. Numerical Simulations

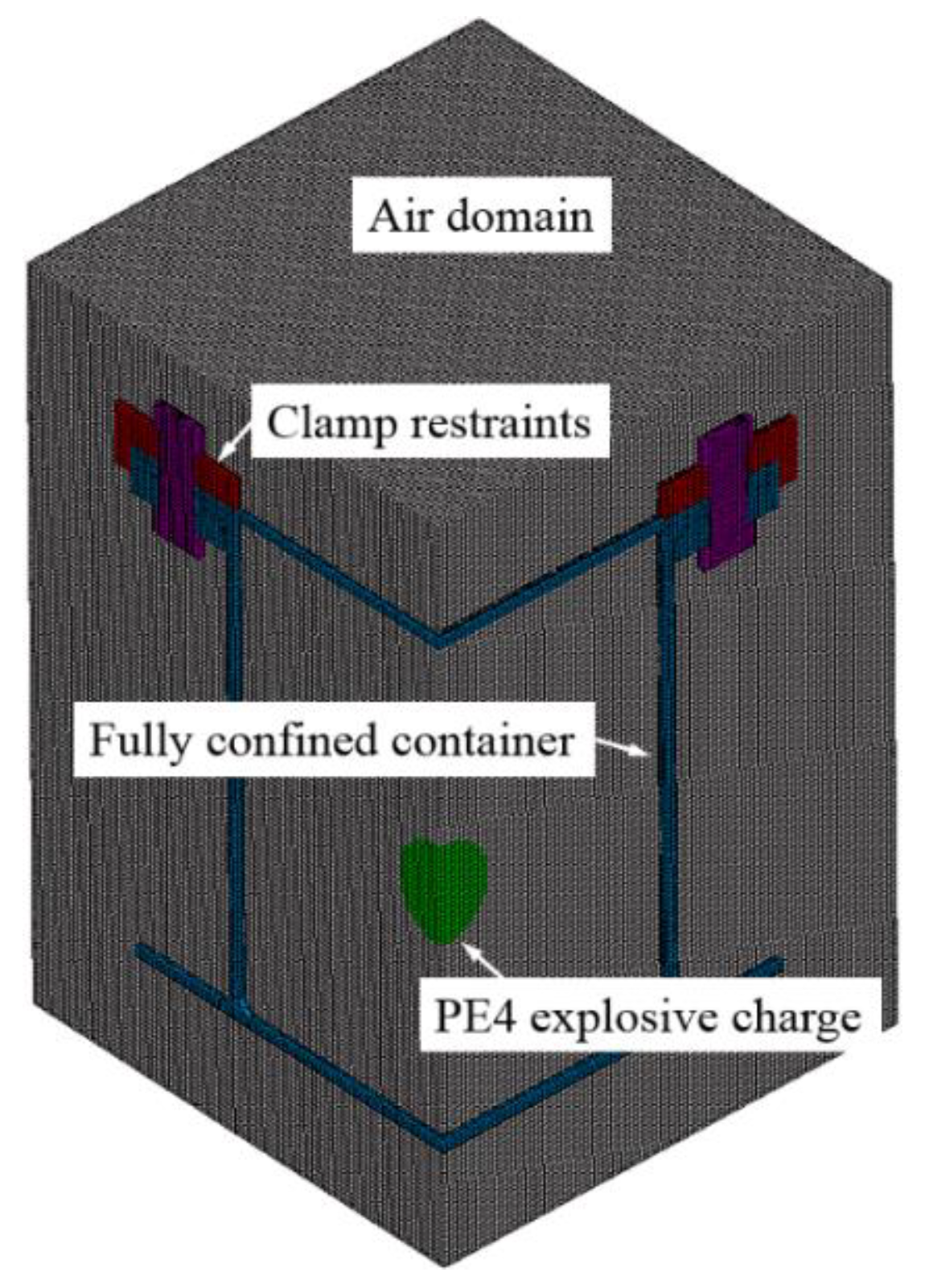

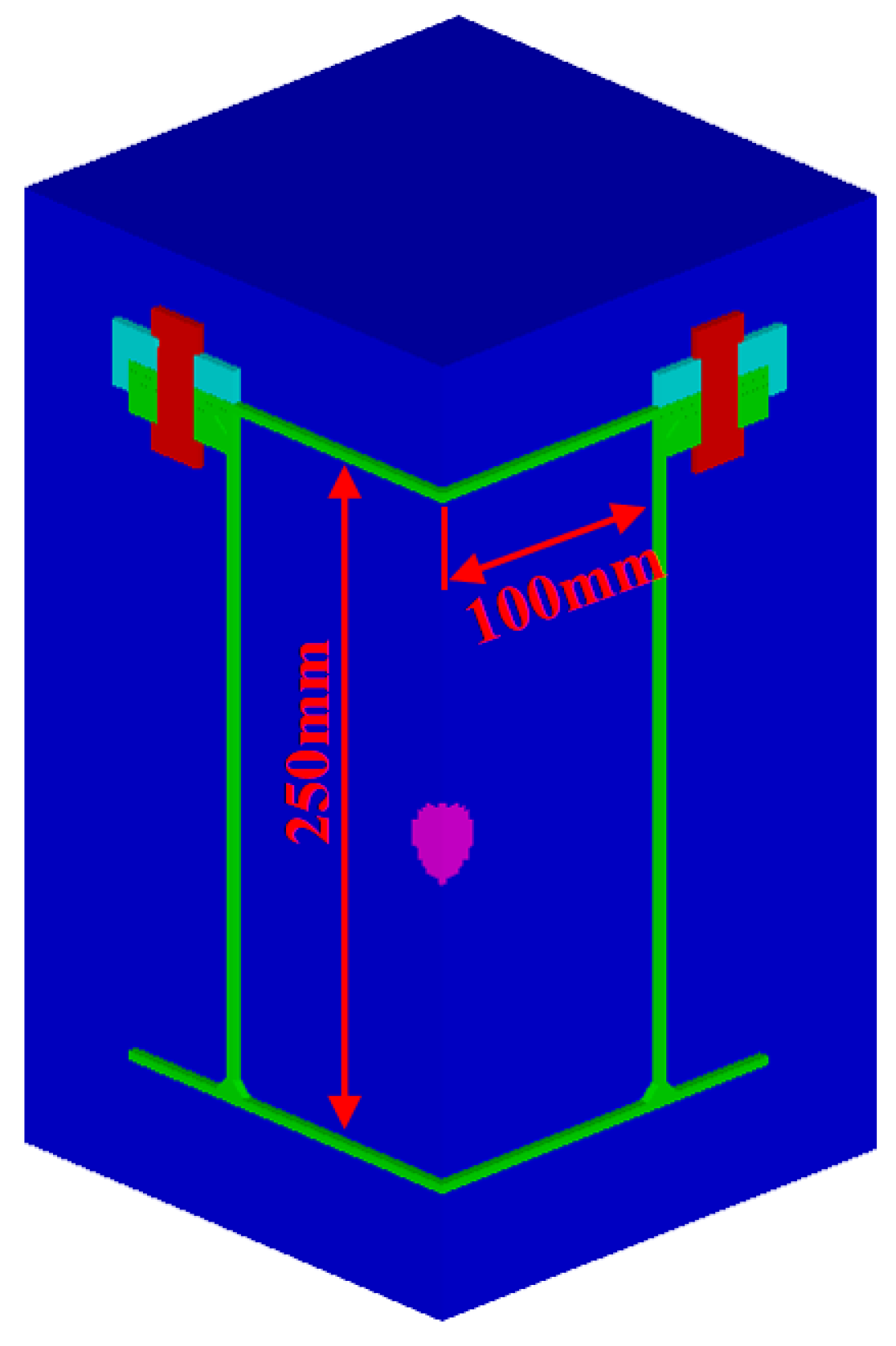

4.1.1. Numerical Modeling

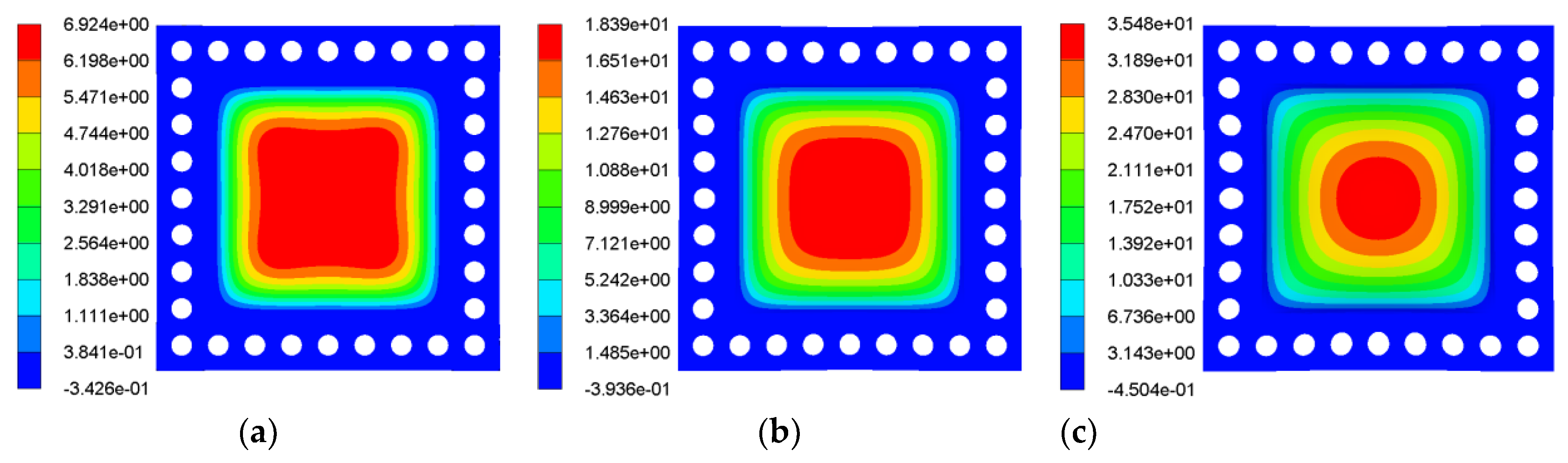

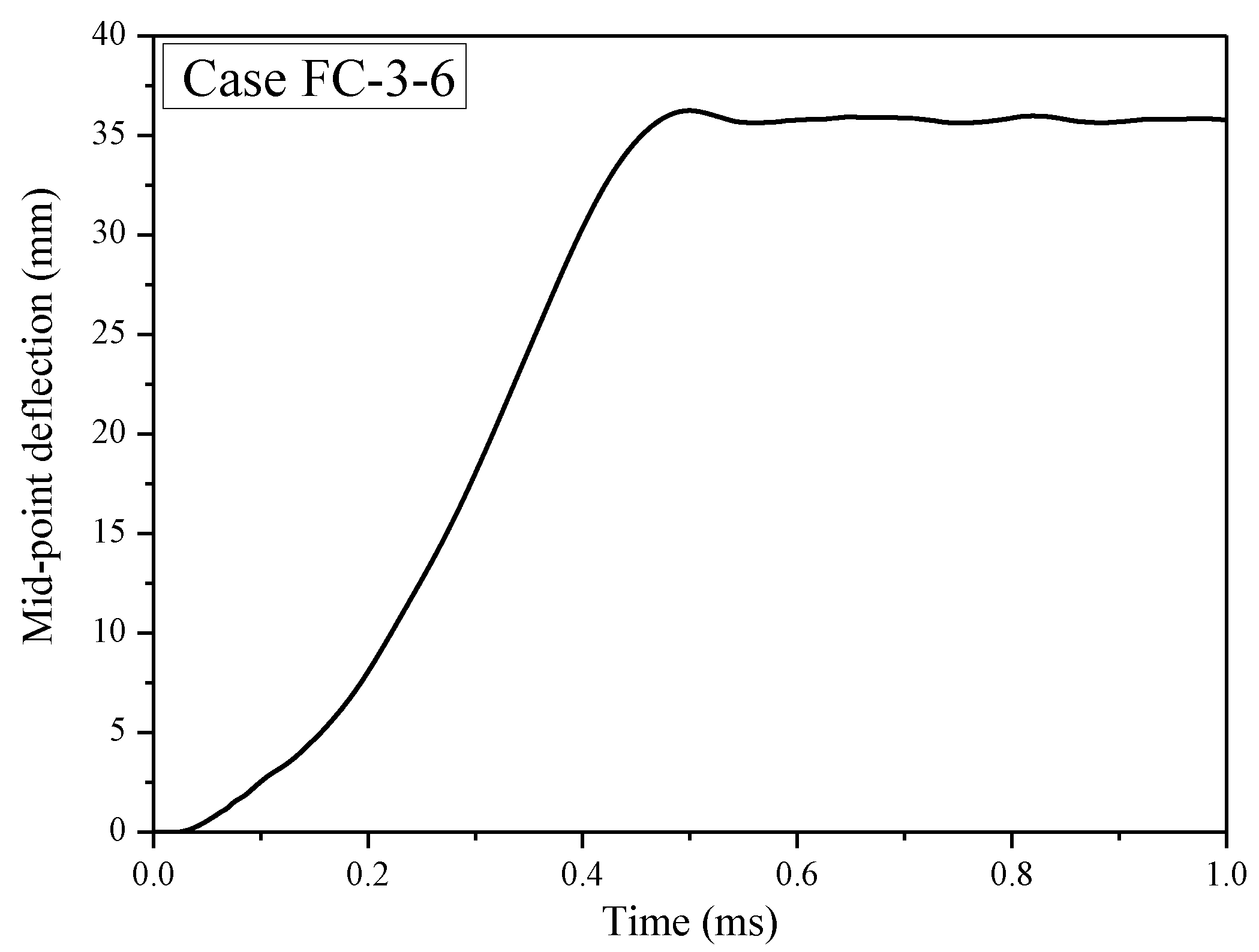

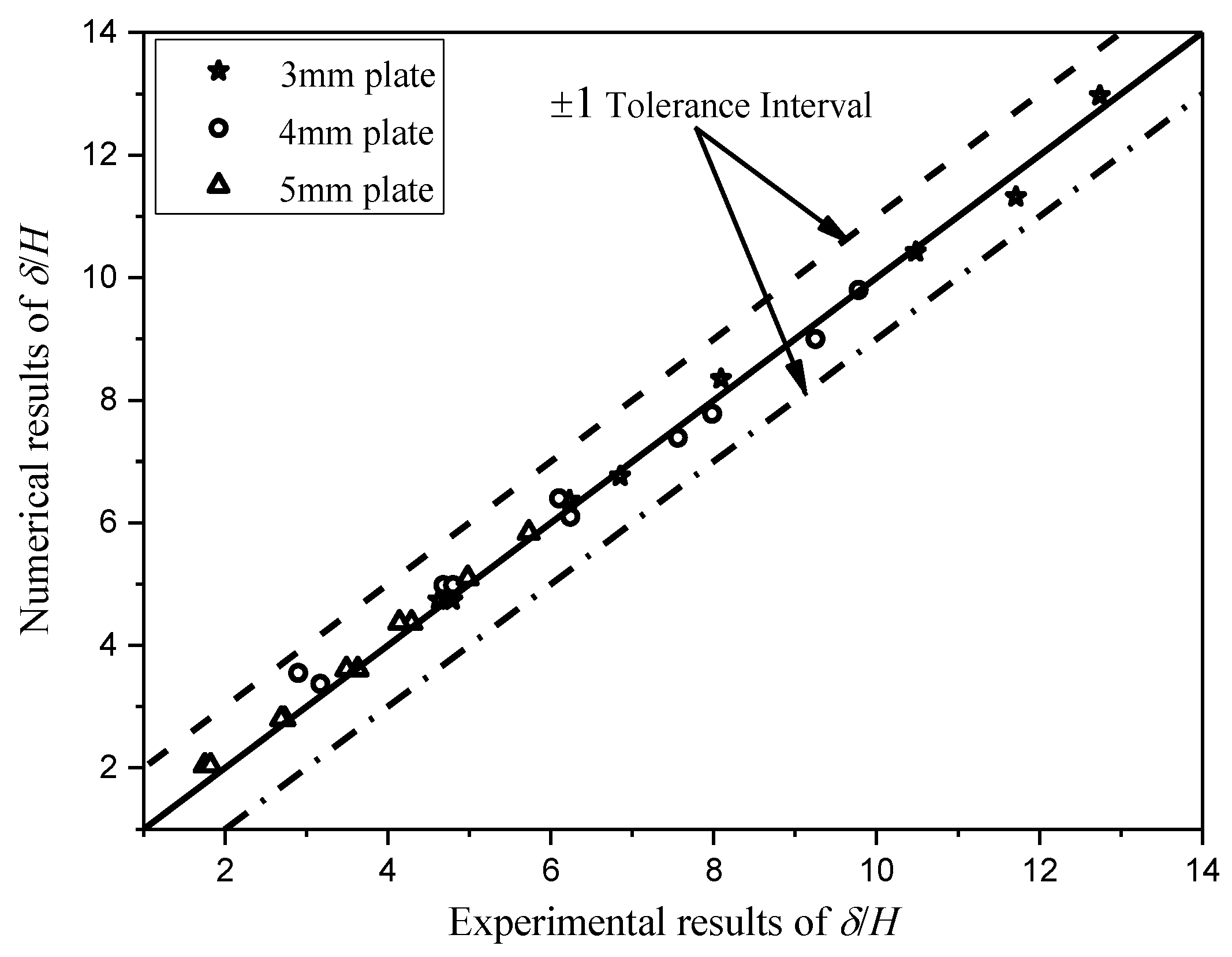

4.1.2. Numerical Result

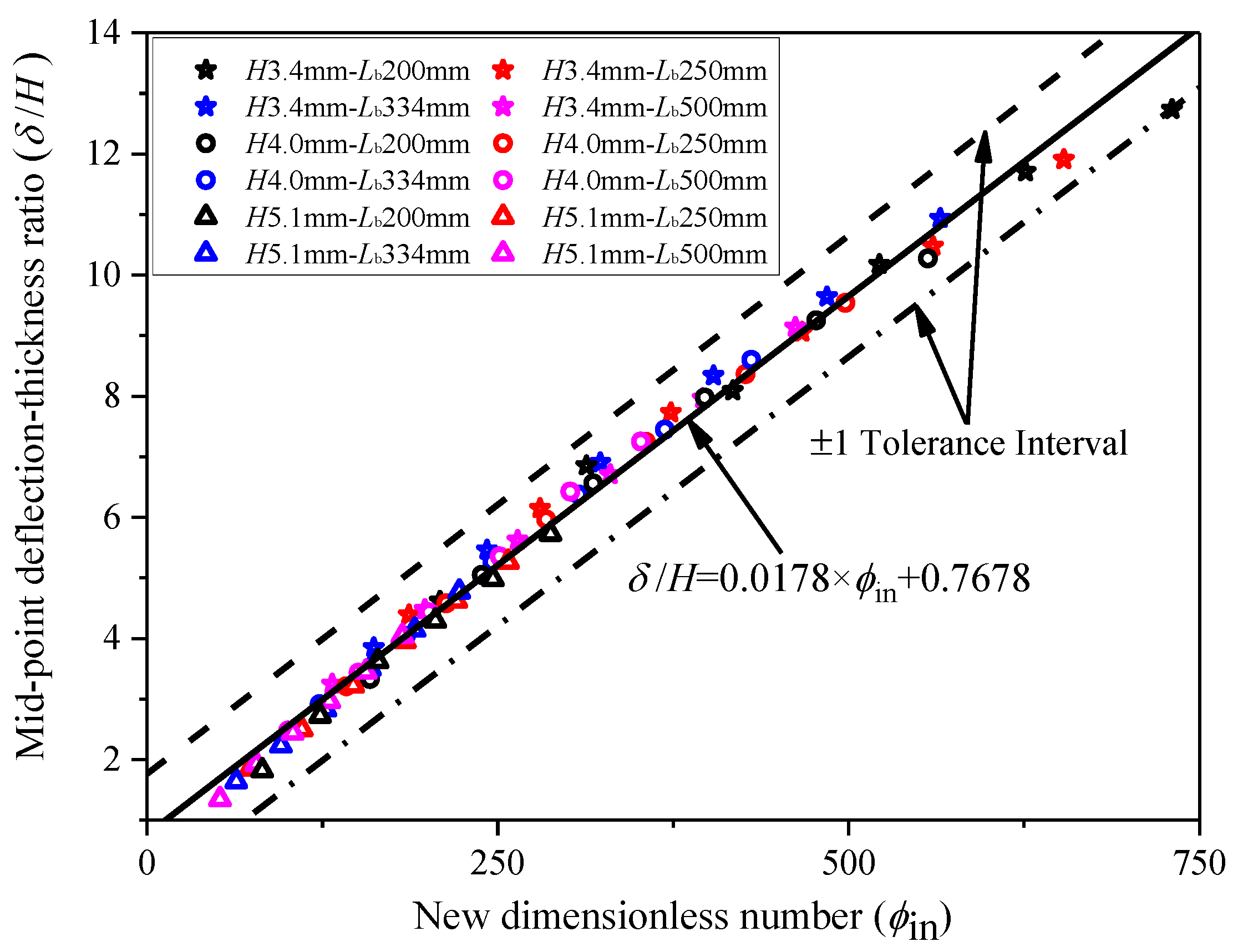

4.2. Application of the New Dimensionless Number for Confined Explosion in the Cuboid Chamber

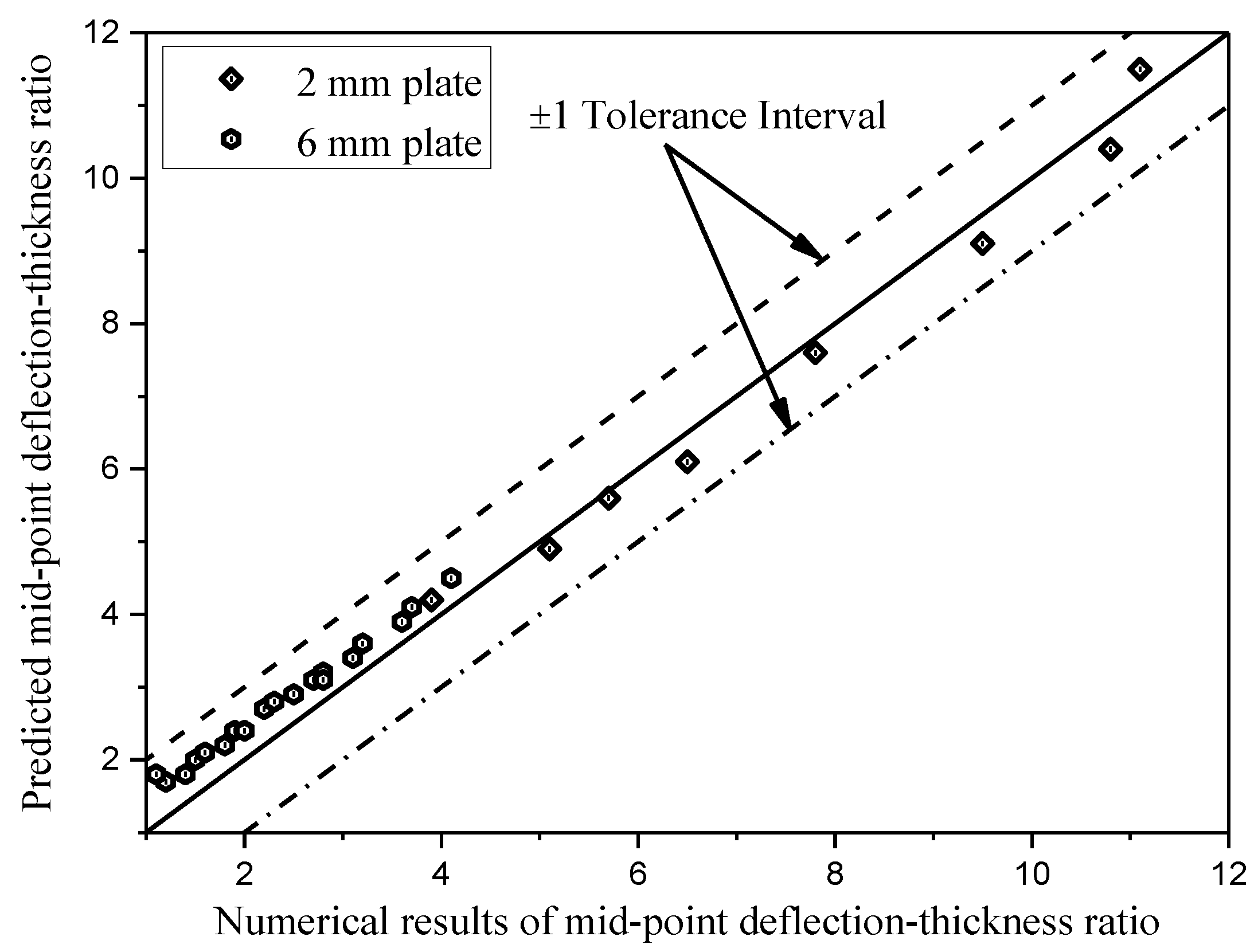

5. Discussions

6. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Kong, X.S.; Wu, W.G.; Li, J.; Chen, P.; Liu, F. Experimental and numerical investigation on a multi-layer protective structure under the synergistic effect of blast and fragment loadings. Int. J. Impact Eng. 2014, 65, 146–162. [Google Scholar] [CrossRef]

- Pickerd, V.; Bornstein, H.; Mccarthy, P.; Buckland, M. Analysis of the structural response and failure of containers subjected to internal blast loading. Int. J. Impact Eng. 2016, 95, 40–53. [Google Scholar] [CrossRef]

- Edri, I.; Savir, Z.; Feldgun, V.R.; Karinski, Y.S.; Yankelevsky, D.Z. On blast pressure analysis due to a partially confined explosion: I. experimental studies. Int. J. Prot. Struct. 2011, 2, 1–20. [Google Scholar] [CrossRef]

- Dragos, J.; Wu, C.; Oehlers, D.J. Simplification of fully confined blasts for structural response analysis. Eng. Struct. 2013, 56, 312–326. [Google Scholar] [CrossRef]

- Wu, C.; Lukaszewicz, M.; Schebella, K.; Antanovskii, L. Experimental and numerical investigation of confined explosion in a blast chamber. J. Loss Prev. Process Ind. 2013, 26, 737–750. [Google Scholar] [CrossRef]

- Geretto, C.; Chung Kim Yuen, S.; Nurick, G.N. An experimental study of the effects of degrees of confinement on the response of square mild steel plates subjected to blast loading. Int. J. Impact Eng. 2015, 79, 32–44. [Google Scholar] [CrossRef]

- Duffey, T.A.; Romero, C. Strain growth in spherical explosive chambers subjected to internal blast loading. Int. J. Impact Eng. 2003, 28, 967–983. [Google Scholar] [CrossRef]

- Karpp, R.R.; Duggry, T.A.; Neal, T.R. Response of containment vessels to explosive blast loading. J. Press. Vessel Technol. 1983, 105, 23–27. [Google Scholar] [CrossRef]

- Dong, Q.; Li, Q.M.; Zheng, J.Y. Interactive mechanisms between the internal blast loading and the dynamic elastic response of spherical containment vessels. Int. J. Impact Eng. 2010, 37, 349–358. [Google Scholar] [CrossRef] [Green Version]

- Burman, N.M.; Saunders, D.S.; Ritzel, D.V.; Buckland, M.E. Deformation and Fracture of Compartments Subjected to Internal Blast Loading. In 5th Australian Aeronautical Conference: Preprints of Papers; Institution of Engineers: Barton, Australia, 1993; pp. 533–540. [Google Scholar]

- Turner, T. Deformation and Failure in Compartments Subjected to Internal Blast Loading: Part 1 Experimental Series; DSTO technical report, DSTO-TR-1038; Defence Science & Technology Organisation (DSTO) Press: Melbourne, Australia, 2000.

- Rushton, N.; Schleyer, G.K.; Clayton, A.M.; Thompson, S. Internal explosive loading of steel pipes. Thin-Walled Struct. 2008, 46, 870–877. [Google Scholar] [CrossRef]

- Clubley, S.K. Non-linear long duration blast loading of cylindrical shell structures. Eng. Struct. 2014, 59, 113–126. [Google Scholar] [CrossRef] [Green Version]

- Ma, L.; Hu, Y.; Zheng, J.Y.; Deng, G.D.; Chen, Y.J. Failure analysis for cylindrical explosion containment vessels. Eng. Fail. Anal. 2010, 17, 1221–1229. [Google Scholar] [CrossRef]

- Zillacus, S.; Phyillaier, W.E.; Shorrow, P.K. The Response of Clamped Circular Plates to Confined Explosive Loadings; DTIC Document; Naval Ship Research and Development Center: Bethesda, MD, USA, 1974.

- Zheng, C.; Kong, X.S.; Wu, W.G.; Liu, F. The elastic-plastic dynamic response of stiffened plates under confined blast load. Int. J. Impact Eng. 2016, 95, 141–153. [Google Scholar] [CrossRef]

- Zheng, C.; Kong, X.S.; Wu, W.G.; Xu, S.X.; Guan, Z.W. Experimental and numerical studies on the dynamic response of steel plates subjected to confined blast loading. Int. J. Impact Eng. 2018, 113, 144–160. [Google Scholar] [CrossRef]

- Zhao, N.; Yao, S.; Zhang, D.; Lu, F.; Sun, C. Experimental and numerical studies on the dynamic response of stiffened plates under confined blast loads. Thin-Walled Struct. 2020, 154, 106839. [Google Scholar] [CrossRef]

- Rabczuk, T.; Areias, P.M.A.; Belytschko, T. A meshfree thin shell method for non-linear dynamic fracture. Int. J. Numer. Methods Eng. 2007, 72, 524–548. [Google Scholar] [CrossRef] [Green Version]

- Rabczuk, T.; Belytschko, T. A three-dimensional large deformation meshfree method for arbitrary evolving cracks. Comput. Methods Appl. Mech. Eng. 2007, 196, 2777–2799. [Google Scholar] [CrossRef] [Green Version]

- Rabczuk, T.; Gracie, R.; Song, J.H.; Belytschko, T. Immersed particle method for fluid–structure interaction. Int. J. Numer. Methods Eng. 2010, 81, 48–71. [Google Scholar] [CrossRef]

- Lin, C.C.; Segel, L.A. Mathematics Applied to Deterministic Problems in the Natural Sciences; Macmillan Publishing Co., Inc.: New York, NY, USA, 1974. [Google Scholar]

- Bridgman, P. Dimensional Analysis; Yale University Press: New Haven, CT, USA, 1922. [Google Scholar]

- Johnson, W. Impact Strength of Materials; Edward Arnold: London, UK, 1972. [Google Scholar]

- Jones, N. Structural Impact; Cambridge University Press: Cambridge, UK, 1989. [Google Scholar]

- Li, Q.M.; Jones, N. On dimensionless numbers for dynamic plastic response of structural members. Arch. Appl. Mech. 2000, 70, 245–254. [Google Scholar] [CrossRef]

- Nurick, G.N.; Martin, J.B. Deformation of thin plates subjected to impulsive loading—A review: Part II: Experimental studies. Int. J. Impact Eng. 1989, 8, 171–186. [Google Scholar] [CrossRef]

- Zhao, Y.P. Suggestion of a new dimensionless number for dynamic plastic response of beams and plates. Arch. Appl. Mech. 1998, 68, 524–538. [Google Scholar] [CrossRef]

- Jacob, N.; Nurick, G.N.; Langdon, G.S. The effect of stand-off distance on the failure of fully clamped circular mild steel plates subjected to blast loads. Eng. Struct. 2007, 29, 2723–2736. [Google Scholar] [CrossRef]

- Mostofi, T.M.; Babaei, H.; Alitavoli, M.; Hosseinzadeh, S. On dimensionless numbers for predicting large ductile transverse deformation of monolithic and multi-layered metallic square targets struck normally by rigid spherical projectile. Thin-Walled Struct. 2017, 112, 118–124. [Google Scholar] [CrossRef]

- Feldgun, V.; Karinski, Y.; Edri, I.; Yankelevsky, D.Z. Prediction of the quasi-static pressure in confined and partially confined explosions and its application to blast response simulation of flexible structures. Int. J. Impact Eng. 2016, 90, 46–60. [Google Scholar] [CrossRef]

- Geretto, C. The Effects of Different Degrees of Confinement on the Deformation of Square Plates Subjected to Blast Loading. Ph.D. Dissertation, University of Cape Town, Cape Town, South Africa, 2012. [Google Scholar]

- ANSYS AUTODYN 14.0. Theory Manual; ANSYS, Inc.: Pittsburgh, PA, USA, 2005; pp. 147–148.

- Yao, S.J.; Zhang, D.; Lu, F.Y. Dimensionless number for dynamic response analysis of box-shaped structures under internal blast loading. Int. J. Impact Eng. 2016, 98, 13–18. [Google Scholar] [CrossRef]

| Test Number | Plate Thickness (mm) | Yield Strength (Mpa) | Mass of Explosive (g) | Top Plate Deflection (mm) | ||

|---|---|---|---|---|---|---|

| FC-3-1 | 3.4 | 233 | 20 | 16.3 | 4.79 | 208.7 |

| FC-3-2 | 3.4 | 233 | 20 | 15.7 | 4.62 | 208.7 |

| FC-3-3 | 3.4 | 233 | 30 | 23.3 | 6.85 | 313.1 |

| FC-3-4 | 3.5 | 233 | 30 | 21.8 | 6.23 | 295.4 |

| FC-3-5 | 3.4 | 233 | 40 | 27.5 | 8.09 | 417.4 |

| FC-3-6 | 3.3 | 233 | 50 | 34.6 | 10.48 | 553.9 |

| FC-3-7 | 3.4 | 233 | 60 | 39.8 | 11.71 | 626.1 |

| FC-3-8 | 3.4 | 233 | 20 | 16.3 | 4.79 | 208.7 |

| FC-4-1 | 4.0 | 222 | 20 | 11.6 | 2.90 | 158.3 |

| FC-4-2 | 4.1 | 222 | 30 | 19.2 | 4.68 | 226.0 |

| FC-4-3 | 4.0 | 222 | 40 | 24.4 | 6.10 | 316.5 |

| FC-4-4 | 4.1 | 222 | 40 | 25.6 | 6.24 | 301.3 |

| FC-4-5 | 4.1 | 222 | 30 | 19.7 | 4.80 | 226.0 |

| FC-4-6 | 4.1 | 222 | 20 | 13.0 | 3.17 | 150.6 |

| FC-4-7 | 4.0 | 222 | 50 | 31.9 | 7.98 | 395.7 |

| FC-4-8 | 4.1 | 222 | 50 | 31.0 | 7.56 | 376.6 |

| FC-4-9 | 4.0 | 222 | 60 | 37.0 | 9.25 | 474.8 |

| FC-5-1 | 5.1 | 263 | 20 | 8.9 | 1.75 | 82.2 |

| FC-5-2 | 5.1 | 263 | 20 | 9.3 | 1.82 | 82.2 |

| FC-5-3 | 5.1 | 263 | 30 | 13.9 | 2.73 | 123.3 |

| FC-5-4 | 5.1 | 263 | 30 | 13.7 | 2.69 | 123.3 |

| FC-5-5 | 5.1 | 263 | 40 | 17.8 | 3.49 | 164.4 |

| FC-5-6 | 5.1 | 263 | 40 | 18.5 | 3.63 | 164.4 |

| FC-5-7 | 5.1 | 263 | 50 | 21.9 | 4.29 | 205.4 |

| FC-5-8 | 5.1 | 263 | 50 | 21.1 | 4.14 | 205.4 |

| FC-5-9 | 5.1 | 263 | 60 | 25.4 | 4.98 | 246.5 |

| FC-5-10 | 5.1 | 263 | 70 | 29.2 | 5.73 | 287.6 |

| Model Ref. | Length (mm) | Thickness (mm) | Yield Strength (MPa) | Charge Mass (g) | Model Ref. | Length (mm) | Thickness (mm) | Yield Strength (MPa) | Charge Mass (g) |

|---|---|---|---|---|---|---|---|---|---|

| GK250-3-1 | 250 | 3.4 | 233 | 20 | GK334-4-4 | 334 | 4.0 | 222 | 50 |

| GK250-3-2 | 250 | 3.4 | 233 | 30 | GK334-4-5 | 334 | 4.0 | 222 | 60 |

| GK250-3-3 | 250 | 3.4 | 233 | 40 | GK334-4-6 | 334 | 4.0 | 222 | 70 |

| GK250-3-4 | 250 | 3.4 | 233 | 50 | GK500-4-1 | 500 | 4.0 | 222 | 20 |

| GK250-3-5 | 250 | 3.4 | 233 | 60 | GK500-4-2 | 500 | 4.0 | 222 | 30 |

| GK250-3-6 | 250 | 3.4 | 233 | 70 | GK500-4-3 | 500 | 4.0 | 222 | 40 |

| GK334-3-1 | 334 | 3.4 | 233 | 20 | GK500-4-4 | 500 | 4.0 | 222 | 50 |

| GK334-3-2 | 334 | 3.4 | 233 | 30 | GK500-4-5 | 500 | 4.0 | 222 | 60 |

| GK334-3-3 | 334 | 3.4 | 233 | 40 | GK500-4-6 | 500 | 4.0 | 222 | 70 |

| GK334-3-4 | 334 | 3.4 | 233 | 50 | GK250-5-1 | 250 | 5.1 | 263 | 20 |

| GK334-3-5 | 334 | 3.4 | 233 | 60 | GK250-5-2 | 250 | 5.1 | 263 | 30 |

| GK334-3-6 | 334 | 3.4 | 233 | 70 | GK250-5-3 | 250 | 5.1 | 263 | 40 |

| GK500-3-1 | 500 | 3.4 | 233 | 20 | GK250-5-4 | 250 | 5.1 | 263 | 50 |

| GK500-3-2 | 500 | 3.4 | 233 | 30 | GK250-5-5 | 250 | 5.1 | 263 | 60 |

| GK500-3-3 | 500 | 3.4 | 233 | 40 | GK250-5-6 | 250 | 5.1 | 263 | 70 |

| GK500-3-4 | 500 | 3.4 | 233 | 50 | GK334-5-1 | 334 | 5.1 | 263 | 20 |

| GK500-3-5 | 500 | 3.4 | 233 | 60 | GK334-5-2 | 334 | 5.1 | 263 | 30 |

| GK500-3-6 | 500 | 3.4 | 233 | 70 | GK334-5-3 | 334 | 5.1 | 263 | 40 |

| GK250-4-1 | 250 | 4.0 | 222 | 20 | GK334-5-4 | 334 | 5.1 | 263 | 50 |

| GK250-4-2 | 250 | 4.0 | 222 | 30 | GK334-5-5 | 334 | 5.1 | 263 | 60 |

| GK250-4-3 | 250 | 4.0 | 222 | 40 | GK334-5-6 | 334 | 5.1 | 263 | 70 |

| GK250-4-4 | 250 | 4.0 | 222 | 50 | GK500-5-1 | 500 | 5.1 | 263 | 20 |

| GK250-4-5 | 250 | 4.0 | 222 | 60 | GK500-5-2 | 500 | 5.1 | 263 | 30 |

| GK250-4-6 | 250 | 4.0 | 222 | 70 | GK500-5-3 | 500 | 5.1 | 263 | 40 |

| GK334-4-1 | 334 | 4.0 | 222 | 20 | GK500-5-4 | 500 | 5.1 | 263 | 50 |

| GK334-4-2 | 334 | 4.0 | 222 | 30 | GK500-5-5 | 500 | 5.1 | 263 | 60 |

| GK334-4-3 | 334 | 4.0 | 222 | 40 | GK500-5-6 | 500 | 5.1 | 263 | 70 |

| Model Ref. | Midpoint Deflection (mm) | Midpoint Deflection–Thickness Ratio | Model Ref. | Midpoint Deflection (mm) | Midpoint Deflection–Thickness Ratio | ||

|---|---|---|---|---|---|---|---|

| GK250-3-1 | 186.7 | 14.9 | 4.4 | GK334-4-4 | 307.6 | 25.5 | 6.4 |

| GK250-3-2 | 280.0 | 20.9 | 6.1 | GK334-4-5 | 369.1 | 29.8 | 7.4 |

| GK250-3-3 | 373.3 | 26.3 | 7.7 | GK334-4-6 | 430.6 | 34.4 | 8.6 |

| GK250-3-4 | 466.7 | 30.8 | 9.1 | GK500-4-1 | 100.5 | 9.9 | 2.5 |

| GK250-3-5 | 560.0 | 35.6 | 10.5 | GK500-4-2 | 150.8 | 13.7 | 3.4 |

| GK250-3-6 | 653.4 | 40.5 | 11.9 | GK500-4-3 | 201.1 | 17.7 | 4.4 |

| GK334-3-1 | 161.5 | 13.1 | 3.8 | GK500-4-4 | 251.4 | 21.4 | 5.4 |

| GK334-3-2 | 242.3 | 18.6 | 5.5 | GK500-4-5 | 301.6 | 25.7 | 6.4 |

| GK334-3-3 | 323.0 | 23.5 | 6.9 | GK500-4-6 | 351.9 | 29.0 | 7.3 |

| GK334-3-4 | 403.8 | 28.4 | 8.3 | GK250-5-1 | 73.5 | 9.4 | 1.8 |

| GK334-3-5 | 484.5 | 32.8 | 9.6 | GK250-5-2 | 110.3 | 12.8 | 2.5 |

| GK334-3-6 | 565.3 | 37.2 | 10.9 | GK250-5-3 | 147.0 | 16.4 | 3.2 |

| GK500-3-1 | 132.0 | 11.0 | 3.2 | GK250-5-4 | 183.8 | 20.2 | 4.0 |

| GK500-3-2 | 198.0 | 15.2 | 4.5 | GK250-5-5 | 220.5 | 23.6 | 4.6 |

| GK500-3-3 | 264.0 | 19.1 | 5.6 | GK250-5-6 | 257.3 | 26.9 | 5.3 |

| GK500-3-4 | 330.0 | 22.8 | 6.7 | GK334-5-1 | 63.6 | 8.4 | 1.6 |

| GK500-3-5 | 396.0 | 27.1 | 8.0 | GK334-5-2 | 95.4 | 11.4 | 2.2 |

| GK500-3-6 | 462.0 | 31.1 | 9.1 | GK334-5-3 | 127.2 | 14.4 | 2.8 |

| GK250-4-1 | 142.2 | 12.8 | 3.2 | GK334-5-4 | 159.0 | 17.9 | 3.5 |

| GK250-4-2 | 213.3 | 18.3 | 4.6 | GK334-5-5 | 190.8 | 21.1 | 4.1 |

| GK250-4-3 | 284.4 | 23.9 | 6.0 | GK334-5-6 | 222.6 | 24.4 | 4.8 |

| GK250-4-4 | 355.5 | 29.0 | 7.2 | GK500-5-1 | 52.0 | 6.9 | 1.3 |

| GK250-4-5 | 426.6 | 33.5 | 8.4 | GK500-5-2 | 78.0 | 9.8 | 1.9 |

| GK250-4-6 | 497.7 | 38.2 | 9.5 | GK500-5-3 | 103.9 | 12.5 | 2.4 |

| GK334-4-1 | 123.0 | 11.7 | 2.9 | GK500-5-4 | 129.9 | 15.1 | 3.0 |

| GK334-4-2 | 184.5 | 16.2 | 4.0 | GK500-5-5 | 155.9 | 17.6 | 3.5 |

| GK334-4-3 | 246.0 | 21.0 | 5.3 | GK500-5-6 | 181.9 | 20.6 | 4.0 |

| Serial Number | Thickness/mm | Chamber Length/mm | Charge/g | Midpoint Deflection/mm | Midpoint Deflection/Thickness Ratio | ||

|---|---|---|---|---|---|---|---|

| FEM | Empirical Formula | FEM | Empirical Formula | ||||

| 1 | 2 | 200 | 10 | 12.9 | 12.3 | 6.5 | 6.1 |

| 2 | 2 | 200 | 20 | 22.1 | 23.0 | 11.1 | 11.5 |

| 3 | 2 | 250 | 10 | 11.3 | 11.1 | 5.7 | 5.6 |

| 4 | 2 | 250 | 20 | 21.5 | 20.7 | 10.8 | 10.4 |

| 5 | 2 | 334 | 10 | 10.2 | 9.8 | 5.1 | 4.9 |

| 6 | 2 | 334 | 20 | 19.0 | 18.2 | 9.5 | 9.1 |

| 7 | 2 | 500 | 10 | 7.7 | 8.3 | 3.9 | 4.2 |

| 8 | 2 | 500 | 20 | 15.6 | 15.1 | 7.8 | 7.6 |

| 9 | 6 | 200 | 20 | 8.2 | 10.9 | 1.4 | 1.8 |

| 10 | 6 | 200 | 30 | 11.9 | 14.1 | 2.0 | 2.4 |

| 11 | 6 | 200 | 40 | 15.1 | 17.3 | 2.5 | 2.9 |

| 12 | 6 | 200 | 50 | 18.3 | 20.5 | 3.1 | 3.4 |

| 13 | 6 | 200 | 60 | 21.5 | 23.6 | 3.6 | 3.9 |

| 14 | 6 | 200 | 70 | 24.6 | 26.8 | 4.1 | 4.5 |

| 15 | 6 | 250 | 20 | 6.9 | 10.3 | 1.2 | 1.7 |

| 16 | 6 | 250 | 30 | 10.6 | 13.1 | 1.8 | 2.2 |

| 17 | 6 | 250 | 40 | 13.5 | 15.9 | 2.2 | 2.7 |

| 18 | 6 | 250 | 50 | 16.3 | 18.8 | 2.7 | 3.1 |

| 19 | 6 | 250 | 60 | 19.3 | 21.6 | 3.2 | 3.6 |

| 20 | 6 | 250 | 70 | 22.3 | 24.4 | 3.7 | 4.1 |

| 21 | 6 | 334 | 20 | 5.5 | 9.5 | 0.9 | 1.6 |

| 22 | 6 | 334 | 30 | 8.8 | 12.0 | 1.5 | 2.0 |

| 23 | 6 | 334 | 40 | 11.6 | 14.4 | 1.9 | 2.4 |

| 24 | 6 | 334 | 50 | 14.0 | 16.9 | 2.3 | 2.8 |

| 25 | 6 | 334 | 60 | 16.7 | 19.3 | 2.8 | 3.2 |

| 26 | 6 | 334 | 70 | 19.5 | 21.8 | 3.2 | 3.6 |

| 27 | 6 | 500 | 20 | 4.0 | 8.6 | 0.7 | 1.4 |

| 28 | 6 | 500 | 30 | 6.8 | 10.6 | 1.1 | 1.8 |

| 29 | 6 | 500 | 40 | 9.7 | 12.6 | 1.6 | 2.1 |

| 30 | 6 | 500 | 50 | 12.0 | 14.6 | 2.0 | 2.4 |

| 31 | 6 | 500 | 60 | 13.9 | 16.6 | 2.3 | 2.8 |

| 32 | 6 | 500 | 70 | 16.5 | 18.6 | 2.8 | 3.1 |

| Serial Number | Thickness/mm | Chamber Length /mm | Charge /g | Midpoint Deflection/Thickness Ratio | Midpoint Deflection/Thickness Ratio | ||

|---|---|---|---|---|---|---|---|

| FEM | Empirical Expression in Yao’s Study | FEM | Empirical Expression in Present Study | ||||

| 1 | 2 | 200 | 10 | 6.5 | 2.4 | 6.5 | 6.1 |

| 2 | 2 | 200 | 20 | 11.1 | 4.8 | 11.1 | 11.5 |

| 3 | 6 | 200 | 20 | 1.4 | 1.4 | 1.4 | 1.8 |

| 4 | 6 | 200 | 30 | 2.0 | 2.1 | 2.0 | 2.4 |

| 5 | 6 | 200 | 40 | 2.5 | 2.8 | 2.5 | 2.9 |

| 6 | 6 | 200 | 50 | 3.1 | 3.5 | 3.1 | 3.4 |

| 7 | 6 | 200 | 60 | 3.6 | 4.2 | 3.6 | 3.9 |

| 8 | 6 | 200 | 70 | 4.1 | 4.9 | 4.1 | 4.5 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zheng, C.; Wang, Y.; Kong, X.; Zhou, H.; Liu, H.; Wu, W. Predicting the Deflection of Square Plates Subjected to Fully Confined Blast Loading. J. Mar. Sci. Eng. 2020, 8, 1031. https://doi.org/10.3390/jmse8121031

Zheng C, Wang Y, Kong X, Zhou H, Liu H, Wu W. Predicting the Deflection of Square Plates Subjected to Fully Confined Blast Loading. Journal of Marine Science and Engineering. 2020; 8(12):1031. https://doi.org/10.3390/jmse8121031

Chicago/Turabian StyleZheng, Cheng, Yiwen Wang, Xiangshao Kong, Hu Zhou, Haibao Liu, and Weiguo Wu. 2020. "Predicting the Deflection of Square Plates Subjected to Fully Confined Blast Loading" Journal of Marine Science and Engineering 8, no. 12: 1031. https://doi.org/10.3390/jmse8121031

APA StyleZheng, C., Wang, Y., Kong, X., Zhou, H., Liu, H., & Wu, W. (2020). Predicting the Deflection of Square Plates Subjected to Fully Confined Blast Loading. Journal of Marine Science and Engineering, 8(12), 1031. https://doi.org/10.3390/jmse8121031