Nitrogen Oxides and Particulate Matter from Marine Diesel Oil (MDO), Emulsified MDO, and Dimethyl Ether Fuels in Auxiliary Marine Engines

Abstract

:1. Introduction

2. Materials and Research Methods

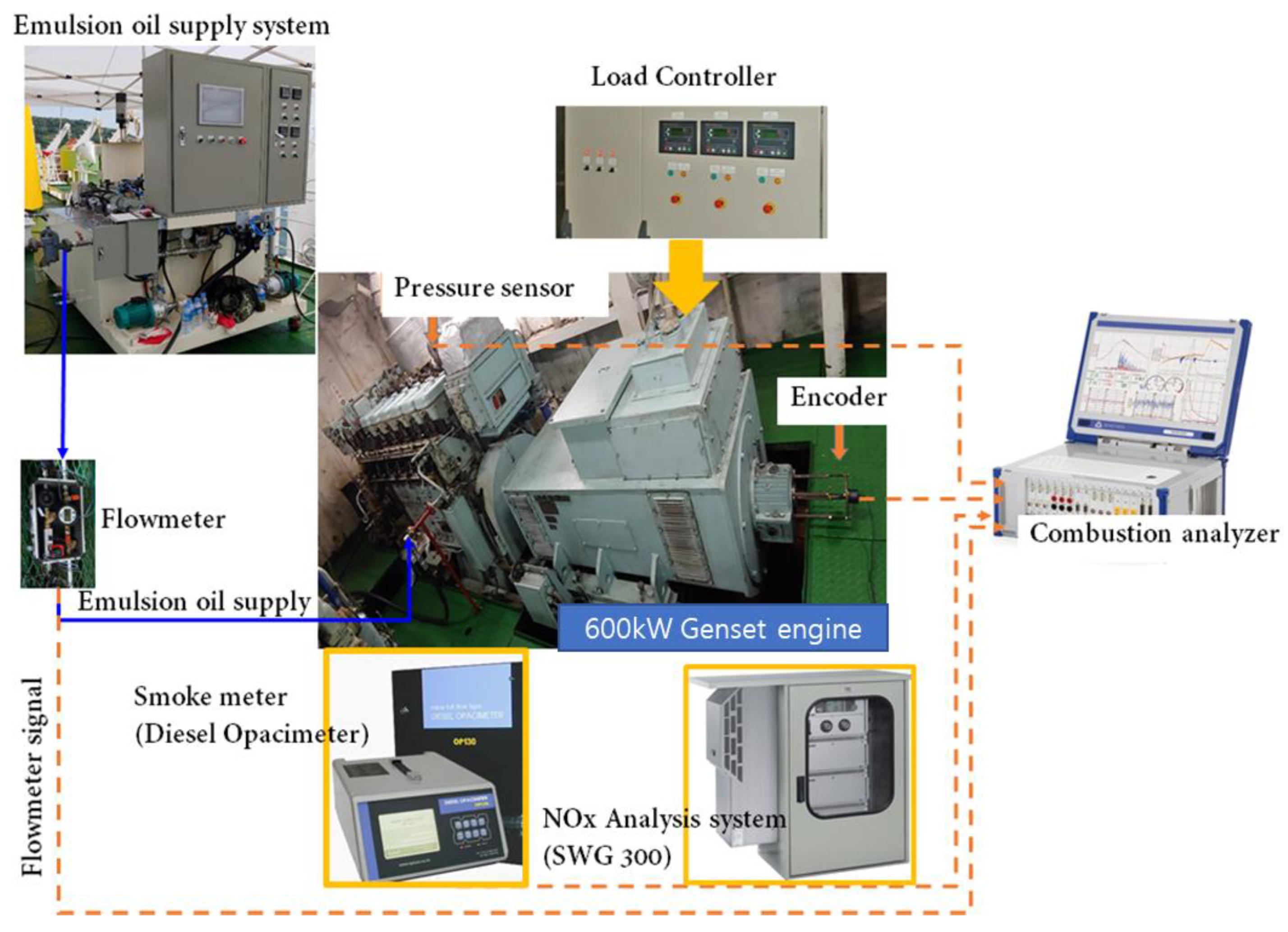

2.1. Experimental Method

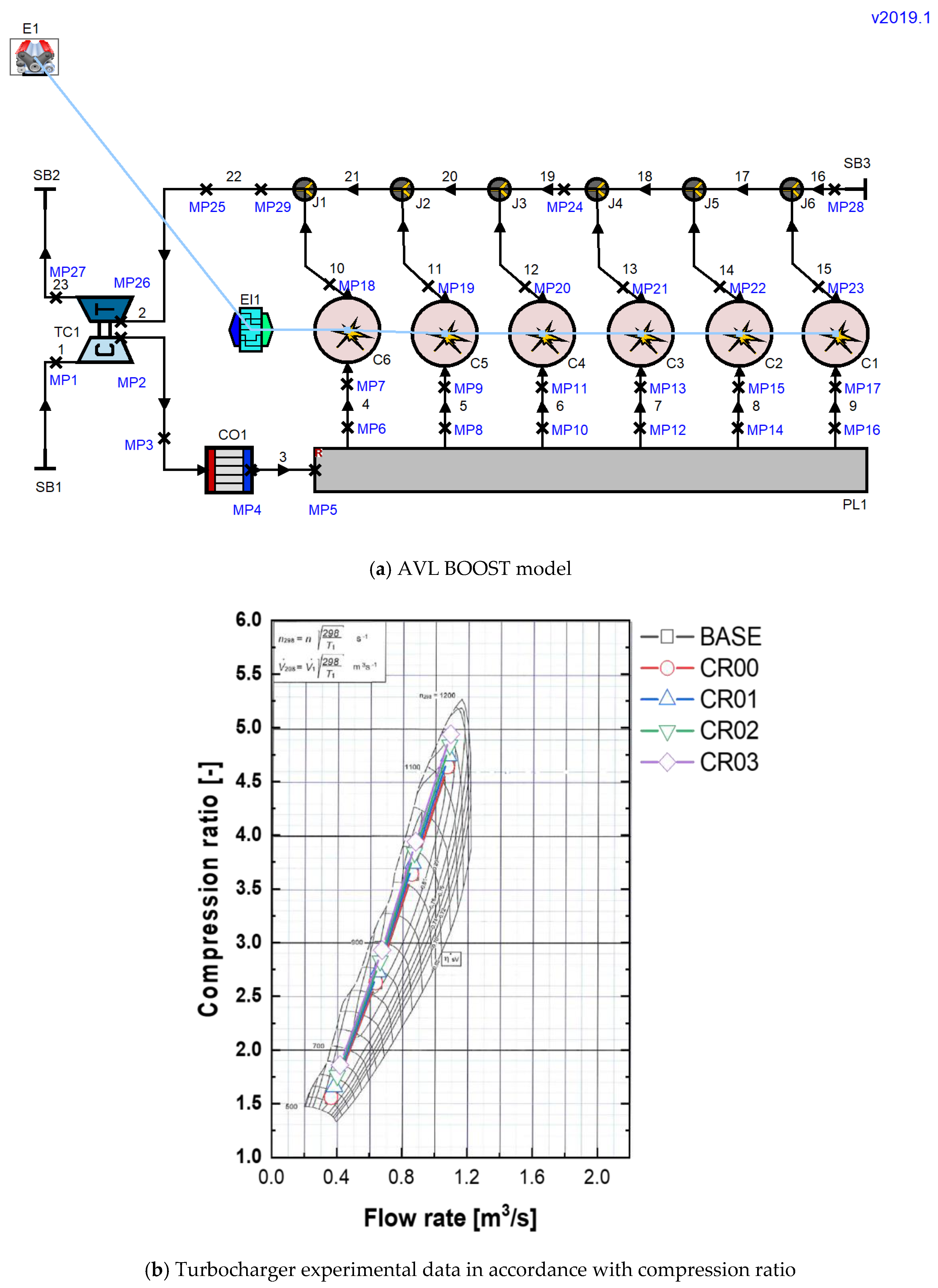

2.2. Numerical Analysis Method

3. Results and Investigation

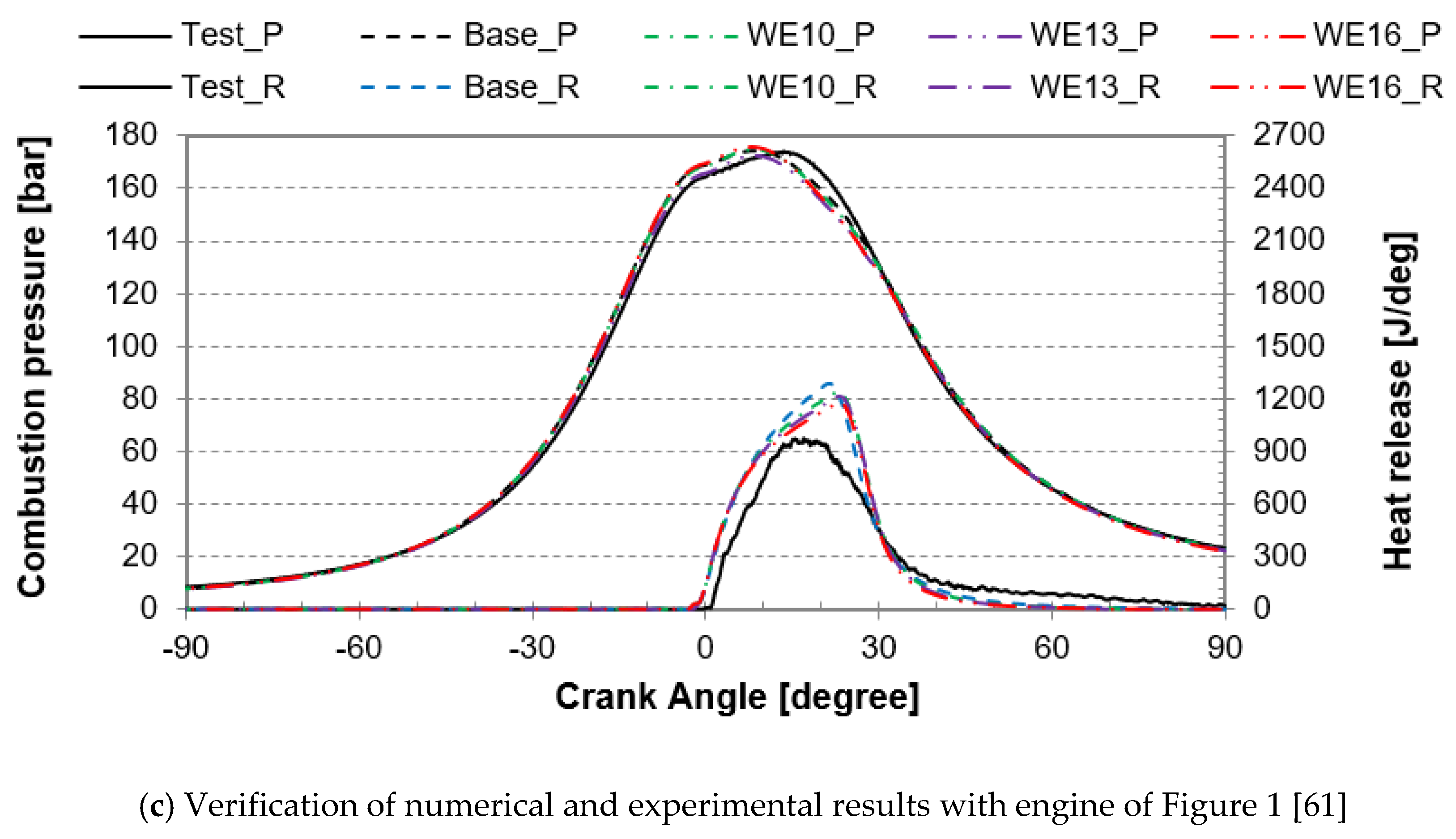

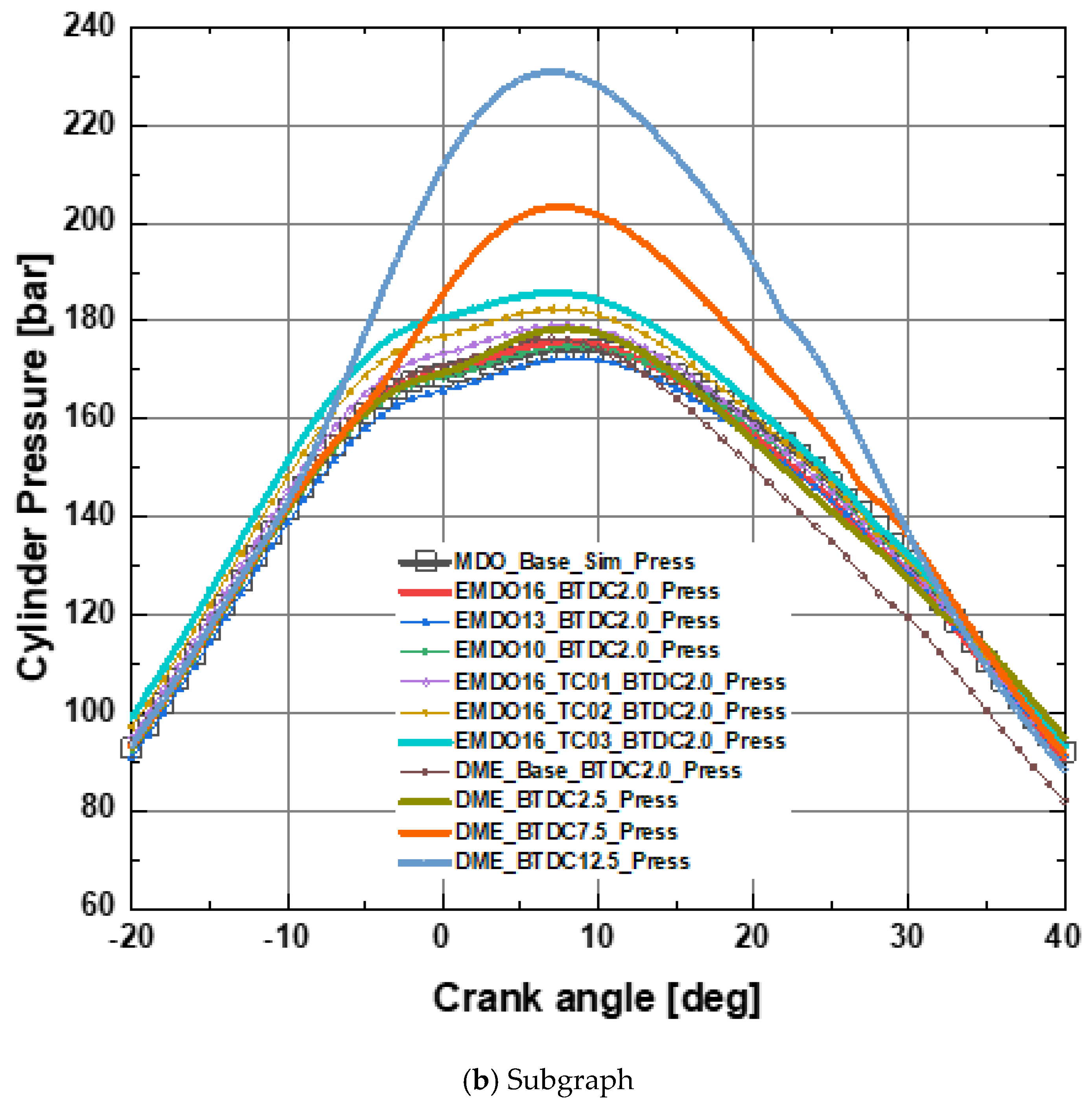

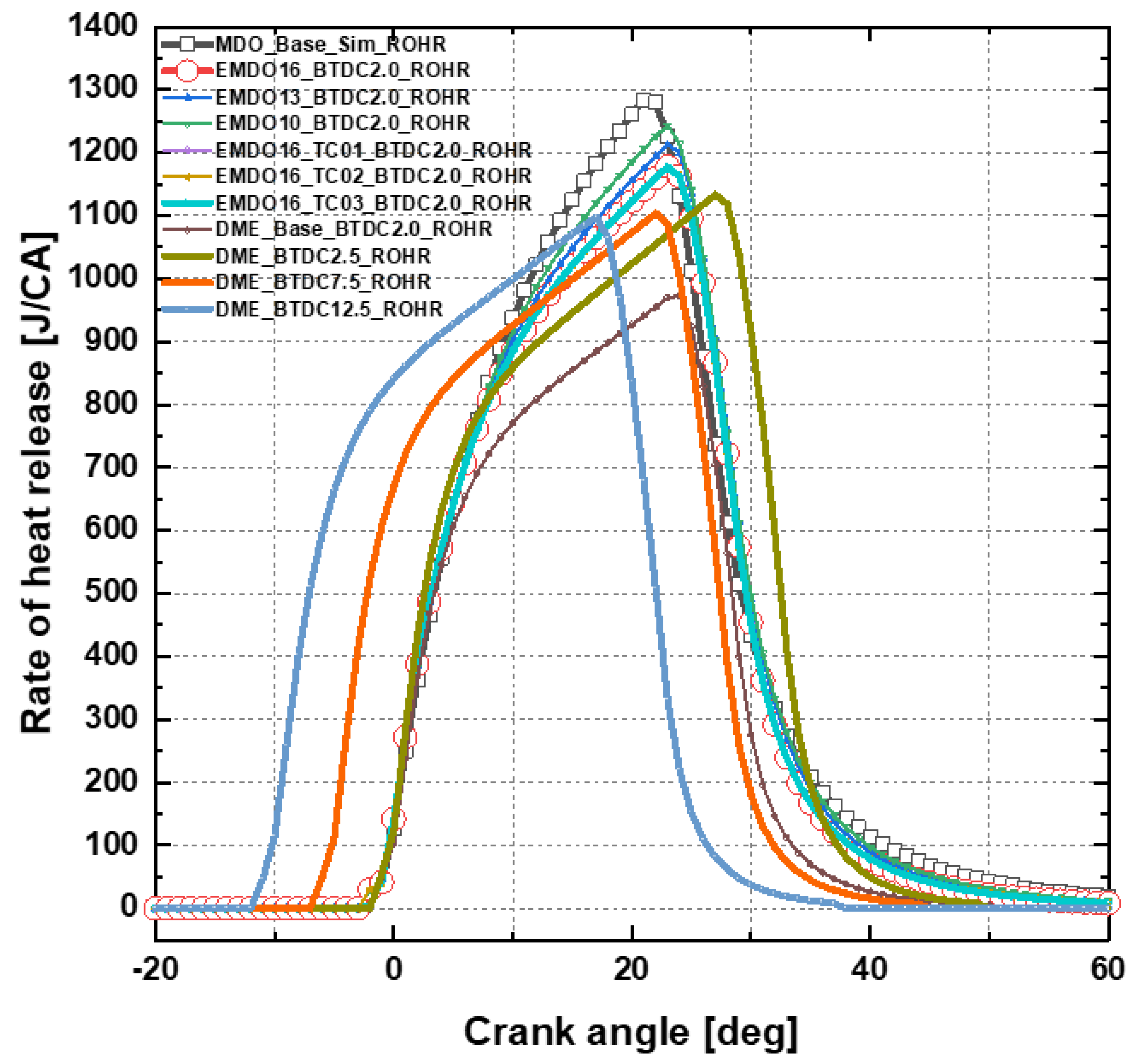

3.1. Combustion Characteristics in Accordance with MDO, EMDO, and DME Fuels

3.2. Location Characteristics on Peak Combustion Pressure in Accordance with EMDO, MDO, and DME Fuels

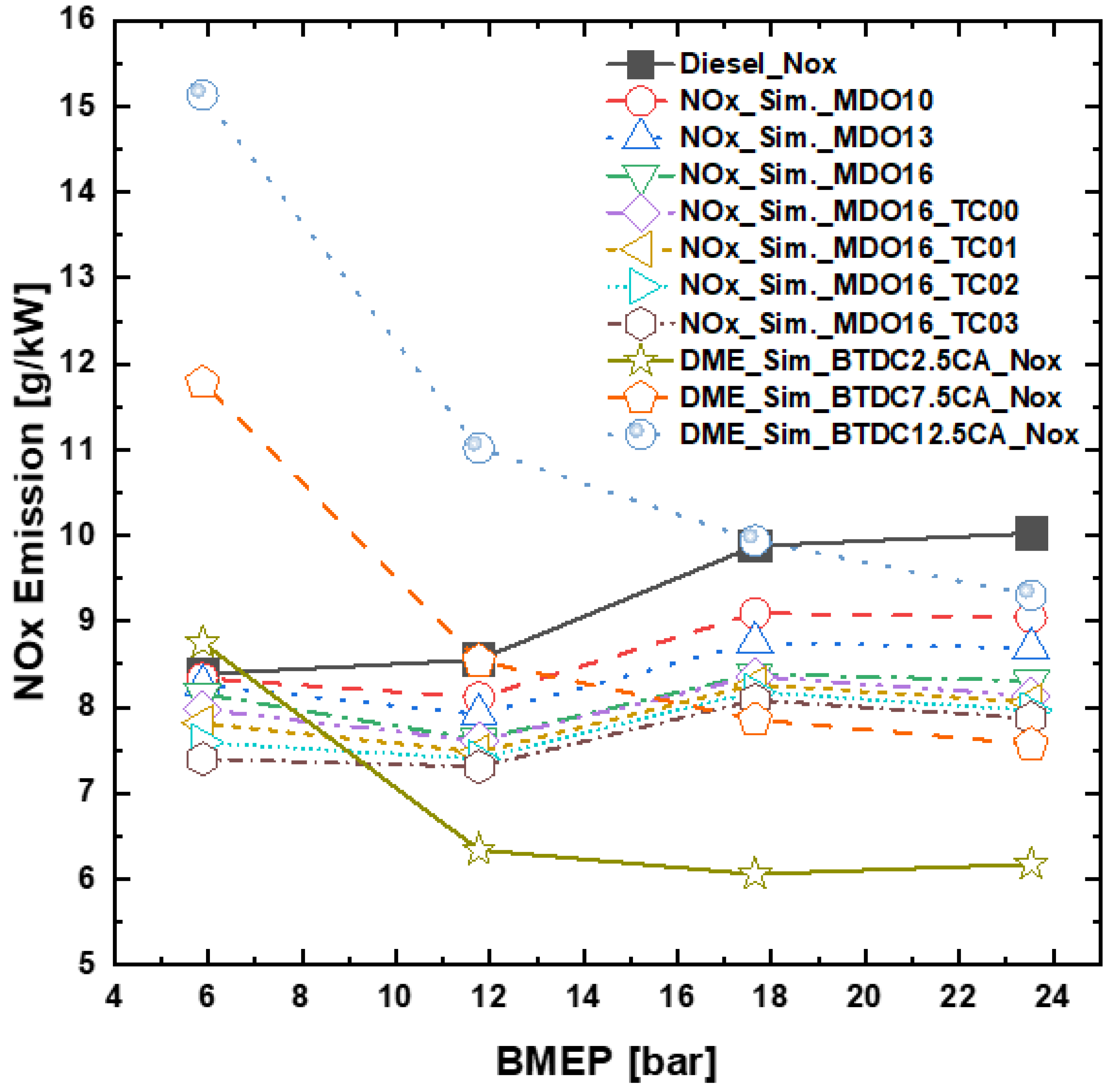

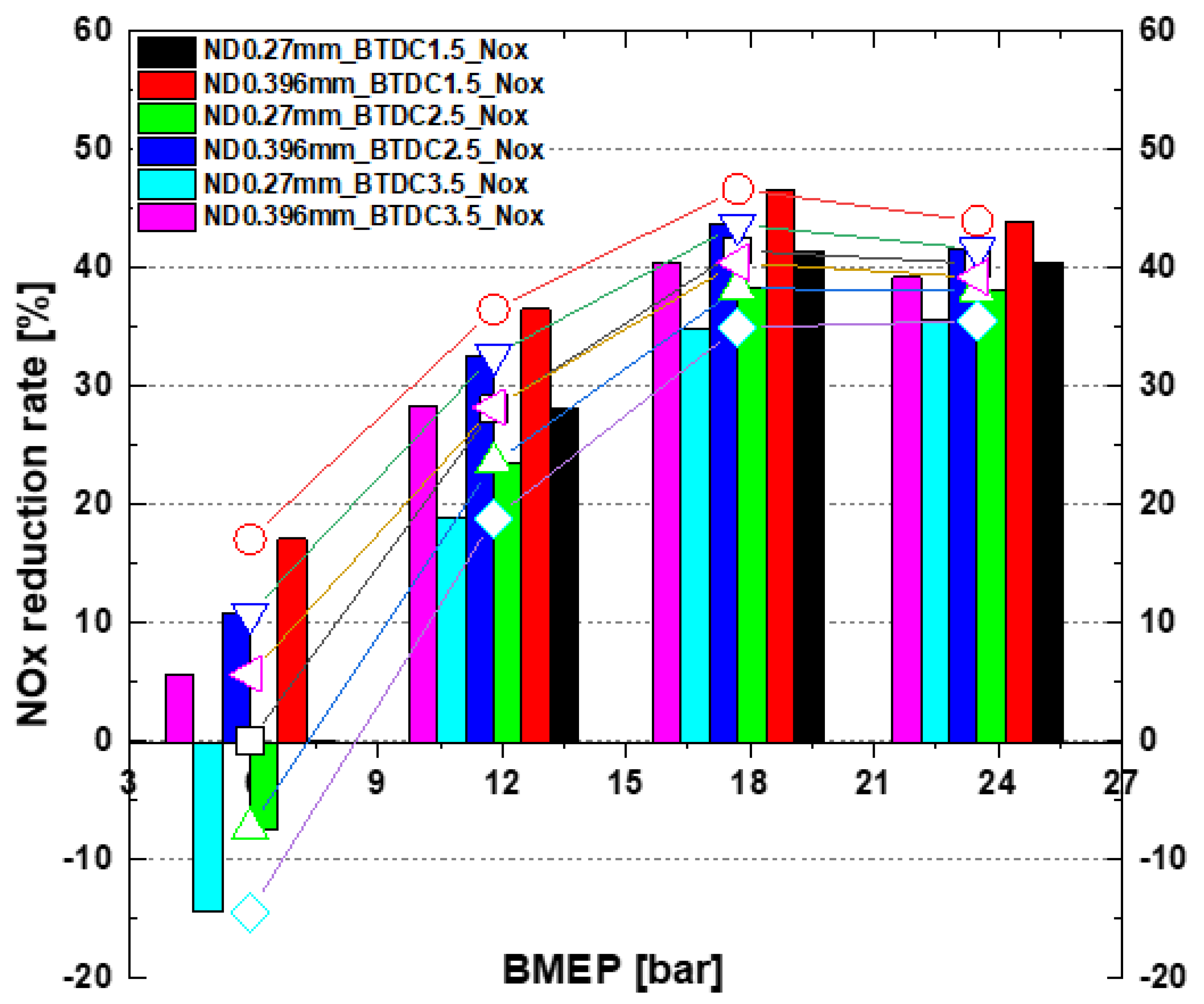

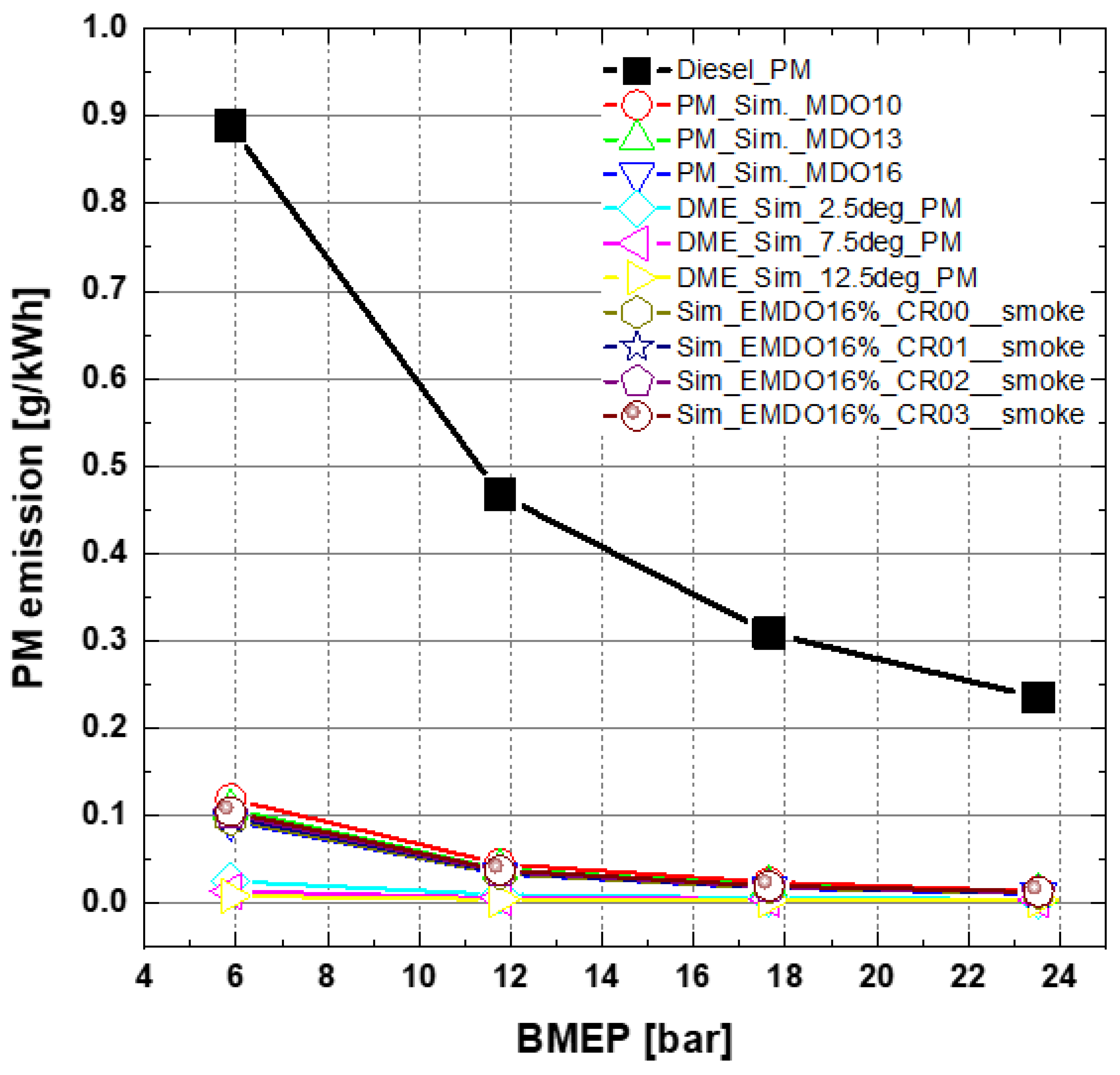

3.3. NOx Reduction with EMDO, MDO, and DME Fuels

4. Conclusions

- 1)

- Based on the results of the heat generation rate in accordance with the change in the injection timing using MDO, EMDO, and DME fuels, the MDO fuel shows a rapid heat generation rate and a longer post-combustion property in comparison with EMDO and DME fuels.

- 2)

- For the case of emulsified fuel with a moisture content of 16%, the pressure of the turbocharger is adjusted to increase the amount of intake air. In addition to the micro-explosions, sufficient air is injected to promote the combustion of emulsified fuel. This is considered a factor that can be controlled for NOx emission by controlling the compression ratio of the emulsified fuel and the turbocharger.

- 3)

- By increasing the water content of the emulsified fuel, NOx are reduced. The NOx are reduced due to the lower combustion temperature caused by the latent heat of evaporation from the phase change of water in the fuel.

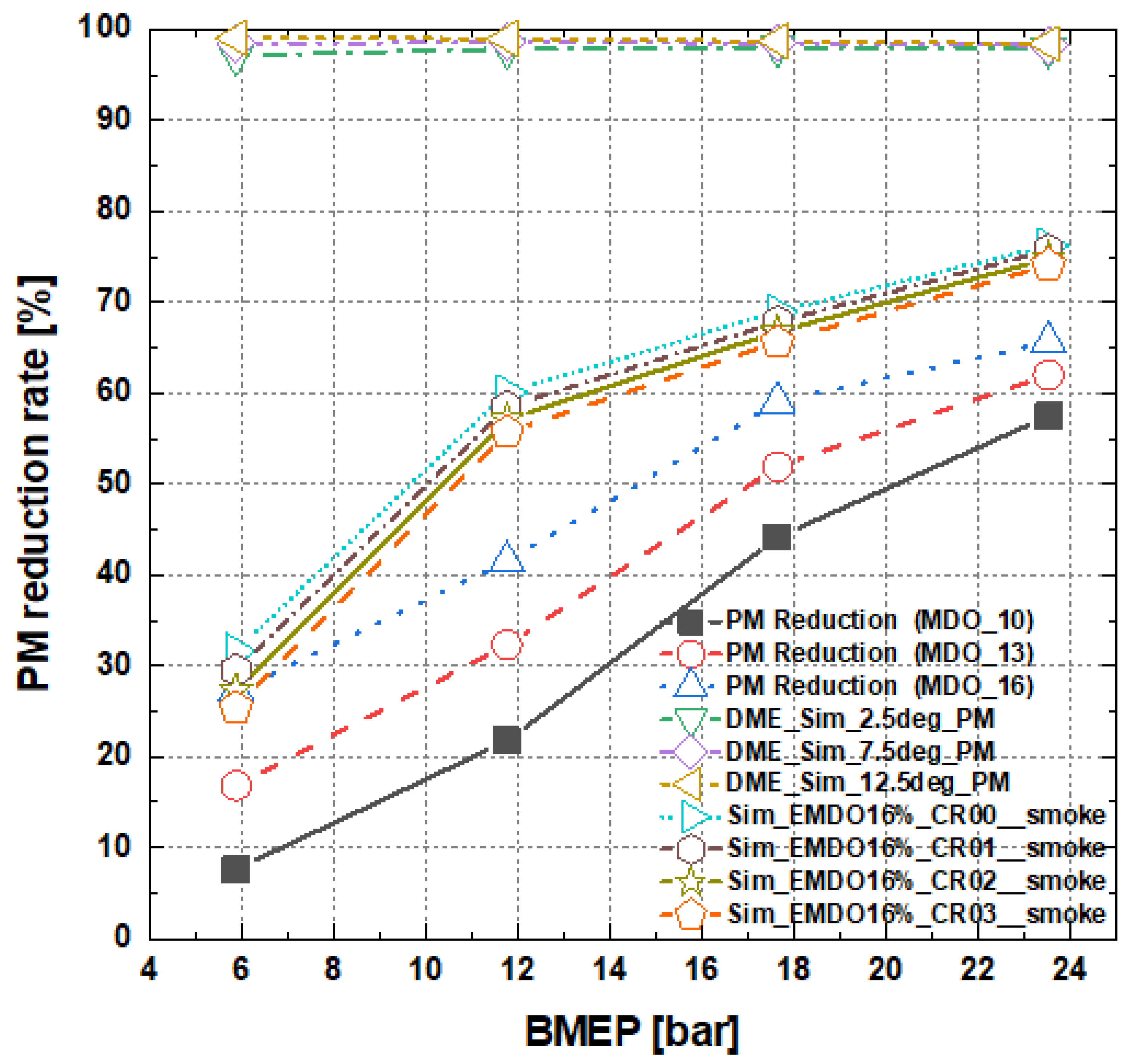

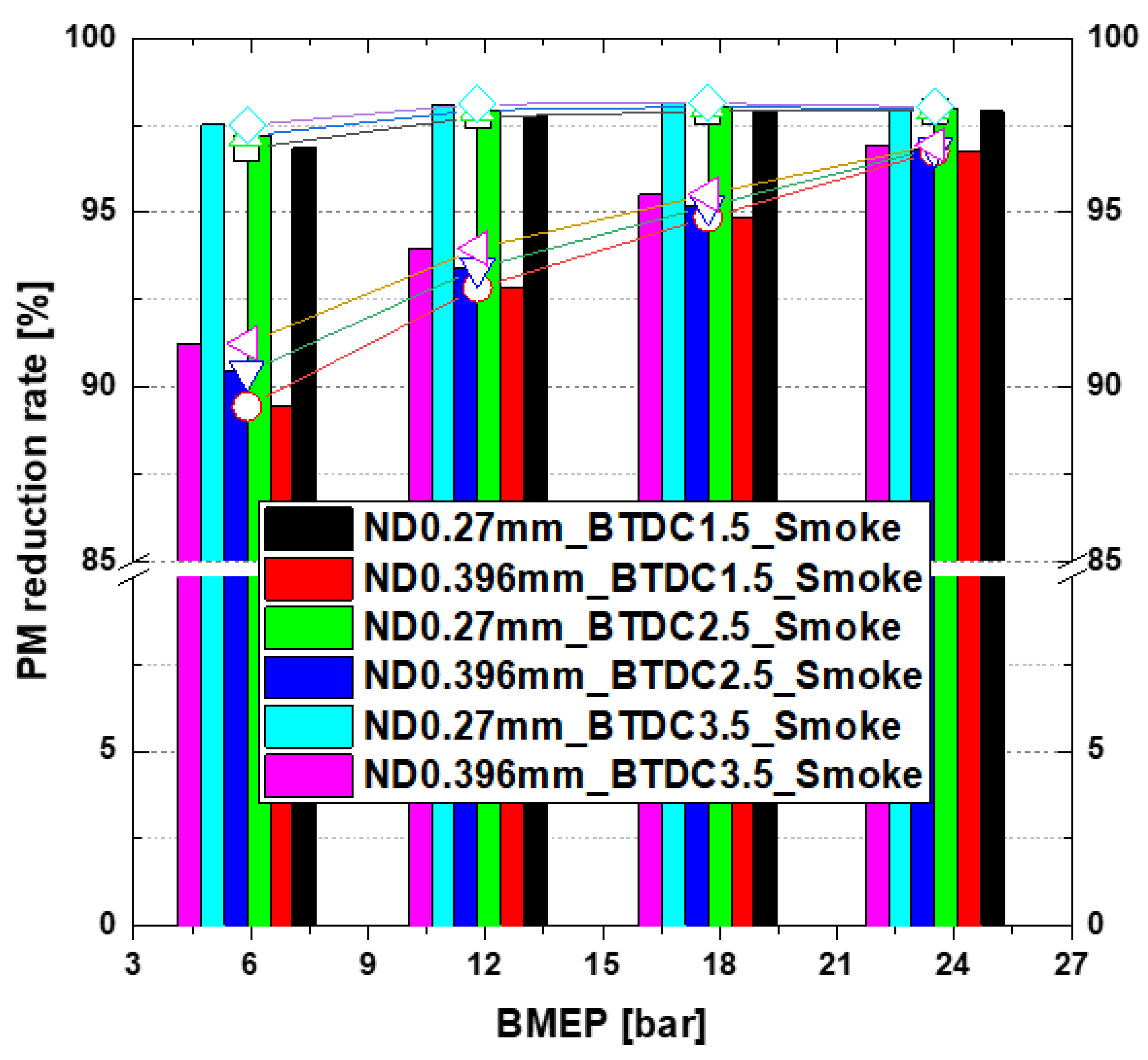

- 4)

- By increasing the water content of the emulsified fuel, the particulate matter has a reduction efficiency of up to 60% or more. When DME fuel is used, it reduces the particulate matter by more than 97% when comparing the results of using the existing MDO fuel and the emulsified fuel. The conditions that are suitable for combustion are believed to be satisfied because of the supplied oxygen that is required for post-combustion.

Author Contributions

Funding

Conflicts of Interest

References

- IMO. Annex VI of MARPOL 73/78 Regulations for the Prevention of Air Pollution from Ships and NOx Technical Code; International Maritime Organization: London, UK, 1998.

- Marine Environment Protection Committee. Proposal to Designate an Emission Control Area for Nitrogen Oxides, Sulphur Oxides and Particulate Matter. Available online: http://www.epa.gov/nonroad/marine/ci/mepc-59-eca-proposal-es.pdf (accessed on 7 December 2010).

- Lim, J.K.; Cho, S.G.; Hwang, S.J.; Yoo, D.H. Effect on characteristics of exhaust emissions by using emulsified fuel in diesel engine. J. Korean Soc. Mar. Eng. 2007, 31, 44–50. (In Korean) [Google Scholar]

- Lim, J.K.; Cho, S.G.; Hwang, S.J.; Yoo, D.H. Effects of emulsified fuel on combustion characteristics in a diesel engine. J. Korean Soc. Power Sys. Eng. 2007, 11, 51–55. (In Korean) [Google Scholar]

- Bertola, A.; Li, R.; Boulouchos, K. Influence of water-diesel fuel emulsions and EGR on combustion and exhaust emissions of heavy-duty diesel engines equipped with common-rail injection system. SAE Tech. Pap. Ser. 2003. [Google Scholar] [CrossRef]

- Guo, Z.; Wang, S.; Wang, X. Stability mechanism investigation of emulsion fuels from biomass pyrolysis oil and diesel. Energy 2014, 66, 250–255. [Google Scholar] [CrossRef]

- Chauhan, B.S.; Kumar, N.; Cho, H.M.; Lim, H.C. A study on the performance and emission of a diesel engine fueled with Karanja biodiesel and its blends. Energy 2013, 56, 1–7. [Google Scholar] [CrossRef]

- Oh, J.; Im, M.; Oh, S.; Lee, C. Comparison of NOx and smoke characteristics of water-in-oil emulsion and marine diesel oil in 400-kW marine generator engine. Energies 2019, 12, 228. [Google Scholar] [CrossRef] [Green Version]

- Kim, M.; Oh, J.; Lee, C. Study on combustion and emission characteristics of marine diesel oil and water-in-oil emulsified marine diesel oil. Energies 2018, 11, 1830. [Google Scholar] [CrossRef] [Green Version]

- Tsuji, Y.; Tanaka, I. Simulation technology for large marine diesel engine in dynamic response. Report Mitsui Ship. 2011, 204, 1–6. (In Japanese) [Google Scholar]

- Ying, W.; Genbao, L.; Wei, Z.; Longbao, Z. Study on the application of DME/diesel blends in a diesel engine. Fuel Process. Technol. 2008, 89, 1272–1280. [Google Scholar] [CrossRef]

- Lee, S.; Oh, S.; Choi, Y. Performance and emission characteristics of an SI engine operated with DME blended LPG fuel. Fuel 2009, 88, 1009–1015. [Google Scholar] [CrossRef]

- Park, S. Optimization of combustion chamber geometry and engine conditioned for compression ignition engines fueled with dimethyl ether. Fuel 2012, 97, 61–71. [Google Scholar] [CrossRef]

- Yeom, K.; Bae, C. Knock characteristics in liquefied petroleum gas (LPG) = dimethyl ether (DME) and gasoline–DME homogeneous charge compression ignition engines. Energy Fuels 2009, 23, 1956–1964. [Google Scholar] [CrossRef]

- Park, S. Numerical study on optimal operating conditions of homogeneous charge compression ignition engines. Energy Fuels 2009, 23, 3909–3918. [Google Scholar] [CrossRef]

- Zhou, L.B.; Wang, H.W.; Jiang, D.M.; Huang, Z. Study of Performance and Combustion Characteristics of a DME Fuelled Light-Duty Direct Injection Diesel Engine. In Proceedings of the SAE International, Warrendale, PA, USA, 25 October 1999. [Google Scholar]

- Fleisch, T.; McCarthy, C.; Basu, A. A new clean diesel technology: Demonstration of ULEV emissions on a Navistar diesel engine fuelled with dimethyl ether. J. Fuel. Lubr. 1995, 104, 42–53. [Google Scholar]

- Clausen, L.R.; Elmegaard, B.; Houbak, N. Design of Novel DME/Methanol Synthesis Plants Based on Gasification of Biomass; DCAMM Special Report, No. S123; Technical University of Denmark (DTU): Lyngby, Denmark, 2011. [Google Scholar]

- Ying, W.; Li, H.; Jie, Z.; Longbao, Z. Study of HCCI–DI combustion and emissions in a DME engine. Fuel 2009, 88, 2255–2261. [Google Scholar] [CrossRef]

- Xinling, L.; Zhen, H. Emission reduction potential of using gas-to-liquid and dimethyl ether fuels on a turbocharged diesel engine. Sci. Total Environ. 2009, 407, 2234–2244. [Google Scholar] [CrossRef]

- Junjun, Z.; Xinqi, Q.; Zhen, W.; Bin, G.; Zhen, H. Experimental investigation of low-temperature combustion (LTC) in an engine fuelled with dimethyl ether (DME). Energy Fuels 2009, 23, 170–174. [Google Scholar] [CrossRef]

- Jang, J.; Bae, C. Effects of valve events on the engine efficiency in a homogeneous charge compression ignition engine fuelled by dimethyl ether. Fuel 2009, 88, 1228–1234. [Google Scholar] [CrossRef]

- AVL. AVL Global Emission Legislation Report 2011. Available online: https://www.avl.com/web/guest/avl-focus-2011 (accessed on 13 February 2019).

- Loganathan, S.; Martin, M.L.J.; Nagalingam, B.; Prabhu, L. Heat release rate and performance simulation of DME fuelled diesel engine using oxygenate correction factor and load correction factor in double Wiebe function. Energy 2018, 150, 77–91. [Google Scholar] [CrossRef]

- Benajes, J.; Novella, R.; Pastor, J.M. Computational optimization of a combustion system for a stoichiometric DME fuelled compression ignition engine. Fuel 2018, 223, 20–31. [Google Scholar] [CrossRef]

- Lamani, V.T.; Yadav, A.K.; Narayanappa, K.G. Influence of low-temperature combustion and dimethyl ether-diesel blends on performance, combustion, and emission characteristics of common rail diesel engine: A CFD study. Environ. Sci. Pollut. Res. 2017, 24, 15500–15509. [Google Scholar] [CrossRef] [PubMed]

- Peng, G.; Cao, E.; Tan, Q.; Wei, L. Effect of alternative fuels on the combustion characteristics and emission products from diesel engines: A review. Renew Sustain. Energy Rev. 2017, 71, 523–534. [Google Scholar]

- Park, W.; Park, S.; Reitz, R.D.; Kurtz, E. The effect of oxygenated fuel properties on diesel spray combustion and soot formation. Combust. Flame 2017, 180, 276–283. [Google Scholar] [CrossRef] [Green Version]

- Arcoumanis, C.; Bae, C.; Crookes, R.; Kinoshita, E. The potential of di-methyl ether (DME) as an alternative fuel for compression-ignition engines: A review. Fuel 2008, 87, 1014–1030. [Google Scholar] [CrossRef]

- Cipolat, D. The Effect of Fuel Characteristics on the Fuel Injection Process in a CI Engine Fuelled on Diesel and DME. Available online: https://www.sae.org/publications/technical-papers/content/2007-24-0119/ (accessed on 15 April 2020).

- Cipolat, D.; Bhana, N. Fuelling of a compression ignition engine on ethanol with DME as ignition promoter: Effect of injector configuration. Fuel Process. Technol. 2009, 90, 1107–1113. [Google Scholar] [CrossRef]

- Selvan, V.A.M.; Anand, R.B.; Udayakumar, M. Combustion characteristics of diesohol using biodiesel as an additive in a direct injection compression ignition engine under various compression ratios. Energy Fuels 2009, 23, 5413–5422. [Google Scholar] [CrossRef]

- Hao, C.; He, J.; Hua, H. Investigation on combustion and emission performance of a common rail diesel engine fueled with diesel/biodiesel/PODE blends. Appl. Therm. Eng. 2018, 31, 43–55. [Google Scholar]

- Iannuzzi, S.E.; Barro, C.; Boulouchos, K.; Burger, J. POMDME-diesel blends: Evaluation of performance and exhaust emissions in a single cylinder heavy-duty diesel engine. Fuel 2017, 203, 57–67. [Google Scholar] [CrossRef]

- Bhide, S.; Morris, D.; Leroux, J.; Wain, K.; Pertez, J.M.; Boehman, A.L. Characterization of the viscosity of blends of dimethyl ether with various fuels and additives. Energy Fuels 2003, 17, 1126–1132. [Google Scholar] [CrossRef]

- Atadashi, I.M.; Aroua, M.K.; Aziz, A.A. High quality biodiesel and its diesel engine application: A review. Renew. Sustain. Energy Rev. 2010, 14, 1999–2008. [Google Scholar] [CrossRef]

- Rashedul, H.K.; Masjuki, H.H.; Kalam, M.A.; Ashraful, A.M.; Ashrafur, S.M.; Shahir, S.A. The effect of additives on properties, performance and emission of biodiesel fuelled compression ignition engine. Energy Convers. Manag. 2014, 88, 348–364. [Google Scholar] [CrossRef]

- Pullen, J.; Saeed, K. Factors affecting biodiesel engine performance and exhaust emissions Part II: Experimental study. Energy 2014, 2, 17–34. [Google Scholar] [CrossRef]

- An, P.; Sun, W.; Li, G.; Tan, M.; Lai, C.; Chen, S. Characteristics of particle size distributions about emissions in a common-rail diesel engine with biodiesel blends. Proced. Environ. Sci. 2011, 11, 1371–1378. [Google Scholar]

- Chapman, E.M.; Boehman, A.L. Pilot ignited premixed combustion of dimethyl ether in a turbodiesel engine. Fuel Process. Technol. 2009, 89, 1262–1271. [Google Scholar] [CrossRef]

- Curran, H.J.; Fischer, S.L.; Dryer, F.L. The reaction kinetics of dimethyl ether. II: Low-temperature oxidation in flow reactors. Int. J. Chem. Kinet. 2000, 32, 741–759. [Google Scholar]

- Wang, Y.; Zhou, L.B.; Yang, Z.J.; Dong, H.Y. Study on combustion and emission characteristic of a vehicle engine fuelled with DME. Proc. Inst. Mech. Eng. Part D 2005, 219, 263–269. [Google Scholar]

- Youn, I.M.; Park, S.H.; Roh, H.G.; Lee, C.S. Investigation on the fuel spray and emission reduction characteristics for dimethyl ether (DME) fuelled multi-cylinder diesel engine with common-rail injection system. Fuel Process. Technol. 2011, 92, 1280–1287. [Google Scholar] [CrossRef]

- Kim, H.J.; Park, S.H.; Lee, K.S.; Lee, C.S. A study of spray strategies on improvement of engine performance and emissions reduction characteristics in a DME fuelled diesel engine. Energy 2011, 36, 1802–1813. [Google Scholar] [CrossRef]

- Cocco, D.; Tola, V.; Cau, G. Performance evaluation of chemically recuperated gas turbine (CRGT) power plants fuelled by di-methyl-ether (DME). Energy 2005, 31, 1446–1458. [Google Scholar] [CrossRef]

- Yoon, S.H.; Cha, J.P.; Lee, C.S. An investigation of the effects of spray angle and injection strategy on dimethyl ether (DME) combustion and exhaust emission characteristics in a common-rail diesel engine. Fuel Process. Technol. 2010, 91, 1364–1372. [Google Scholar] [CrossRef]

- Park, S.H.; Kim, H.J.; Lee, C.S. Effects of dimethyl-ether (DME) spray behavior in the cylinder on the combustion and exhaust emissions characteristics of a high-speed diesel engine. Fuel Process. Technol. 2010, 91, 504–513. [Google Scholar] [CrossRef]

- Ying, W.; Li, H.; Longbao, Z.; Wei, L. Effects of DME pilot quantity on the performance of a DME PCCI–DI engine. Energy Convers. Manag. 2010, 51, 648–654. [Google Scholar] [CrossRef]

- Kim, M.Y.; Yoon, S.H.; Ryu, B.W.; Lee, C.S. Combustion and emission characteristics of DME as an alternative fuel for compression ignition engines with a high-pressure injection system. Fuel 2008, 87, 2779–2786. [Google Scholar] [CrossRef]

- Kim, H.J.; Lee, K.S.; Lee, C.S. A study on the reduction of exhaust emissions through HCCI combustion by using a narrow spray angle and advanced injection timing in a DME engine. Fuel Process. Technol. 2011, 9, 1756–1763. [Google Scholar] [CrossRef]

- Park, S.; Choi, B.; Oh, B.S. A combined system of dimethyl ether (DME) steam reforming and lean NOx trap catalysts to improve NOx reduction in DME engines. Int. J. Hydrogen Energy 2011, 36, 6422–6432. [Google Scholar] [CrossRef]

- Ying, W.; Longbao, Z. Experimental study on exhaust emissions from a multi-cylinder DME engine operating with EGR and oxidation catalyst. Appl. Therm. Eng. 2008, 28, 1589–1595. [Google Scholar] [CrossRef]

- Dimethylether. Decreasing Emissions Caused by Seagoing Vessels. Available online: www.maritimesymposium-rotterdam.nl/uploads/Route/Dimethylether.pdf (accessed on 31 March 2020).

- Zhang, H.F.; Seo, K.; Zhao, H. Combustion and emission analysis of the direct DME injection enabled and controlled auto-ignition gasoline combustion engine operation. Fuel 2013, 107, 800–814. [Google Scholar] [CrossRef]

- Fleisch, T.H.; Meurer, C. DME, the diesel fuel for the 21st century? In Proceedings of the Conference Program at “International Congress: Engine and Environment”, Graz, Austria, 24–25 August 1995. [Google Scholar]

- Ishida, M.; Jung, S.; Ueki, H.; Sakaguchi, D. Combustion of premixed DME and natural gas in a HCCI engine. Combust. Engines 2005, 121, 20–29. [Google Scholar]

- Kapus, P.; Ofner, H. Development of fuel injection equipment and combustion system for DI diesels operated on di-methyl ether. J. Fuel. Lubr. 1995, 104, 54–69. [Google Scholar]

- DjebaÏLi, N.; Paillard, C. Burning velocities of dimethyl ether and air. Combust. Flame 2001, 125, 1329–1340. [Google Scholar]

- Sorenson, S.C.; Glensvig, M.; Abata, D. Di-metyl ether in diesel fuel injection systems. Trans. J. Fuel Lubr. 1998, 107, 438–449. [Google Scholar]

- AVL BOOST Theory Reference. v2019 R1. Available online: https://www.avl.com/-/avl-boost-2019-r1. (accessed on 6 November 2019).

- Choi, I.; Lee, C. Numerical study on nitrogen oxide and black carbon reduction of marine diesel engines using emulsified marine diesel oil. Sustainability 2019, 11, 6347. [Google Scholar] [CrossRef] [Green Version]

| Items/Descriptions | Specifications |

|---|---|

| Engine type | Four-stroke turbo-charged direct injection marine generator engine |

| Number of cylinders Compression ratio | 6 15.9 |

| Bore × Stroke (mm) | 165 × 265 |

| Displacement (cc) | 20,000 |

| Fuel injection system | Mechanical pumping system (Max. 1400 bar) |

| Engine’s maximum continuous rating (MCR) (kW/rpm) | 600 kW/900 rpm |

| Items | Specification |

|---|---|

| Dynamometer | Load controller (in a marine ship) |

| Exhaust gas Analyzer | cold-dry method and uses NDIR modules |

| Smoke meter | Diesel opacimeter (OP 130D) |

| Fuel | Marine Diesel Oil |

|---|---|

| Emulsified Marine Diesel Oil of 10%, 13%, and 16% Moisture Concentrations [8] | |

| DME Fuel | |

| Engine speed (rpm) | 900 |

| Load (kW) | 150, 300, 450, 600 |

| Property (Unit/Condition) | Unit | DME [57,59] | EMDO_10% [8] | EMDO_13% [8] | EMDO_16% [8] | Diesel Fuel [57,59] |

|---|---|---|---|---|---|---|

| Chemical structure | - | CH3–O– CH3 | – | – | – | – |

| Molar mass | g/mol | 46 | - | - | - | 170 |

| Carbon content | mass% | 52.2 | 79.1 | 77.6 | 76.1 | 86 |

| Hydrogen content | mass% | 13 | 13.1 | 12.9 | 12.0 | 14 |

| Oxygen content | mass% | 34.8 | 0 | 0 | 0 | 0 |

| Carbon-to-hydrogen ratio | - | 0.337 | - | - | - | 0.516 |

| Critical temperature | K | 400 | - | - | - | 708 |

| Critical pressure | MPa | 5.37 | - | - | - | 3.00 |

| Critical density | kg/m3 | 259 | - | - | - | – |

| Liquid density | kg/m3 | 667 | 872 | 878 | 882 | 831 |

| Relative gas density (air = 1) | - | 1.59 | - | - | - | – |

| Cetane number | - | >55 | - | - | - | 40–50 |

| Auto-ignition temperature | K | 508 | - | - | - | 523 |

| Stoichiometric air/fuel mass ratio | - | 9.0 | - | - | - | 14.6 |

| Boiling point at 1 atm | K | 248.1 | - | - | - | 450–643 |

| Enthalpy of vaporization | kJ/kg | 467.13 | - | - | - | 300 |

| Lower heating value | MJ/kg | 27.6 | 36.8 | 34.6 | 33.4 | 42.5 |

| Gaseous specific heat capacity | kJ/kg K | 2.99 | - | - | - | 1.7 |

| Ignition limits | vol% in air | 3.4/18.6 | - | - | - | 0.6/6.5 |

| Modulus of elasticity | N/m2 | 6.37 × 108 | - | - | - | 14.86 × 108 |

| Kinematic viscosity of liquid | cSt | <0.1 | - | - | - | 3 |

| Surface tension (at 298 K) | N/m | 0.012 | - | - | - | 0.027 |

| Vapor pressure (at 298 K) | kPa | 530 | 10 | 10 | 10 | 10 |

| Moisture | Vol% | 0 | 11 | 13.5 | 16.1 | 0 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Park, J.; Choi, I.; Oh, J.; Lee, C. Nitrogen Oxides and Particulate Matter from Marine Diesel Oil (MDO), Emulsified MDO, and Dimethyl Ether Fuels in Auxiliary Marine Engines. J. Mar. Sci. Eng. 2020, 8, 322. https://doi.org/10.3390/jmse8050322

Park J, Choi I, Oh J, Lee C. Nitrogen Oxides and Particulate Matter from Marine Diesel Oil (MDO), Emulsified MDO, and Dimethyl Ether Fuels in Auxiliary Marine Engines. Journal of Marine Science and Engineering. 2020; 8(5):322. https://doi.org/10.3390/jmse8050322

Chicago/Turabian StylePark, Jinkyu, Iksoo Choi, Jungmo Oh, and Changhee Lee. 2020. "Nitrogen Oxides and Particulate Matter from Marine Diesel Oil (MDO), Emulsified MDO, and Dimethyl Ether Fuels in Auxiliary Marine Engines" Journal of Marine Science and Engineering 8, no. 5: 322. https://doi.org/10.3390/jmse8050322

APA StylePark, J., Choi, I., Oh, J., & Lee, C. (2020). Nitrogen Oxides and Particulate Matter from Marine Diesel Oil (MDO), Emulsified MDO, and Dimethyl Ether Fuels in Auxiliary Marine Engines. Journal of Marine Science and Engineering, 8(5), 322. https://doi.org/10.3390/jmse8050322