Model Tests on the Penetration Resistance of Bucket Foundations for Offshore Wind Turbines in Sand

Abstract

:1. Introduction

2. Model Test

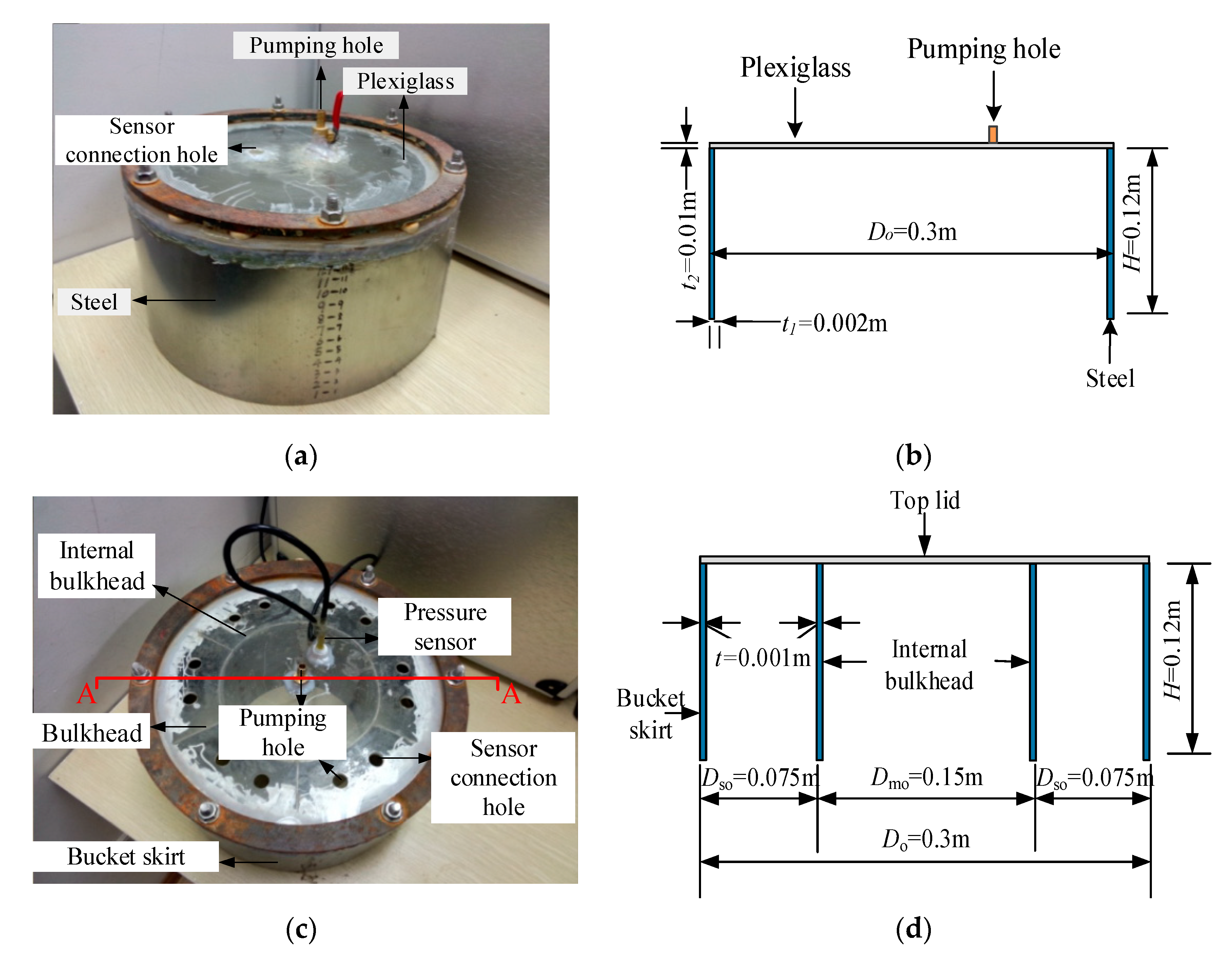

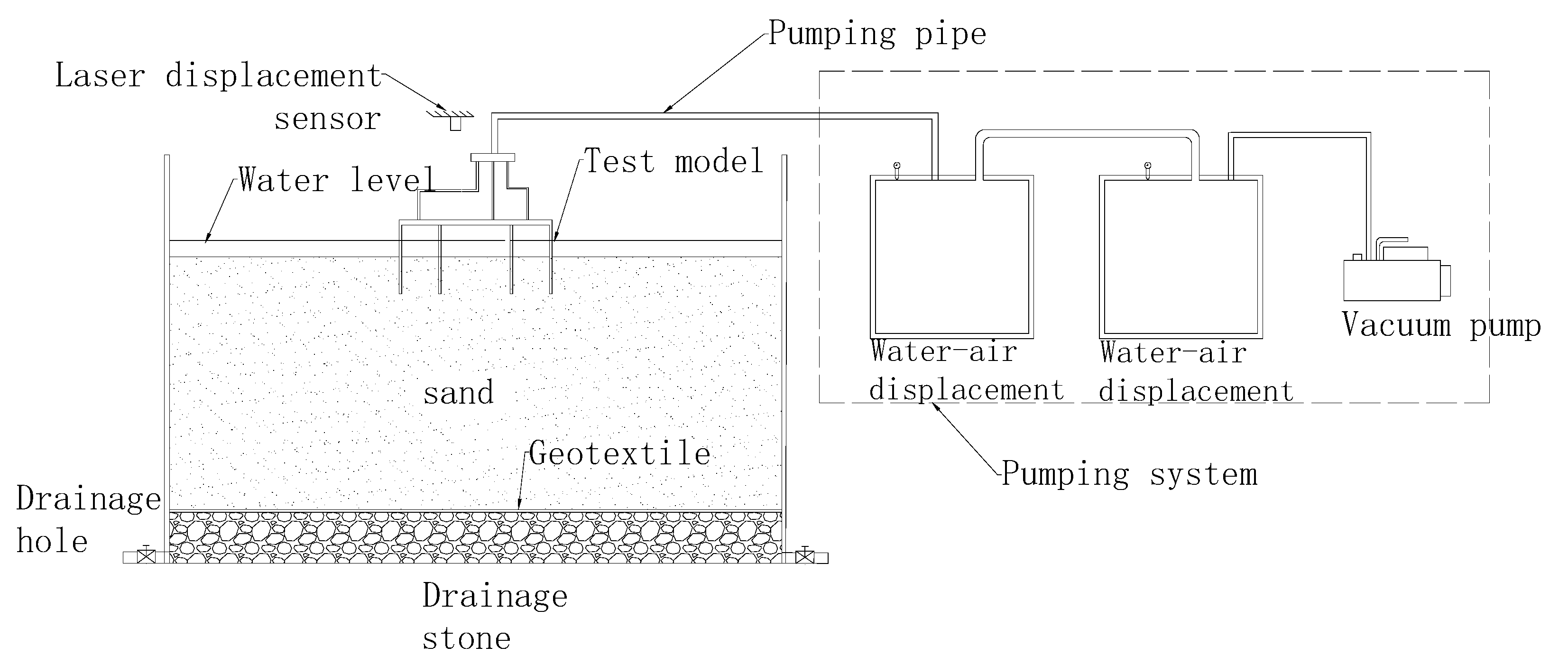

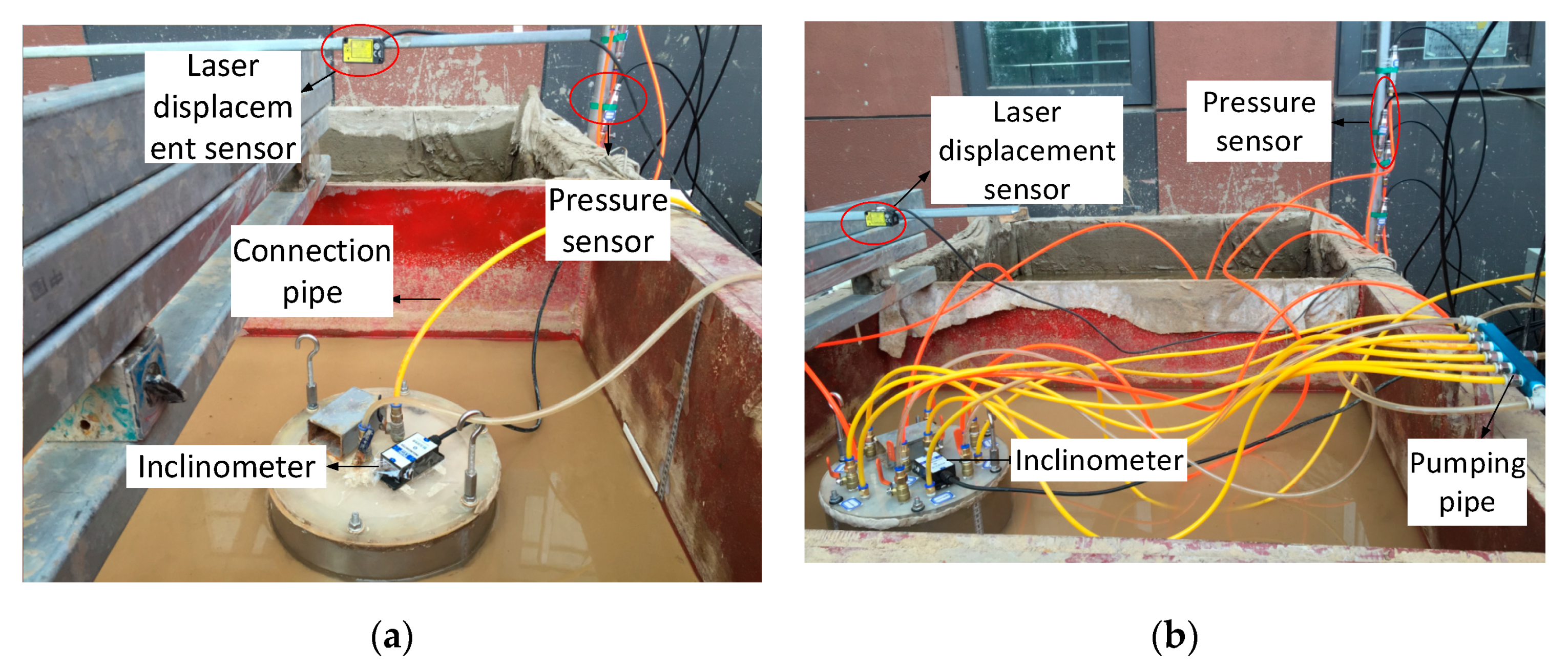

2.1. Test Model and Test Procedures

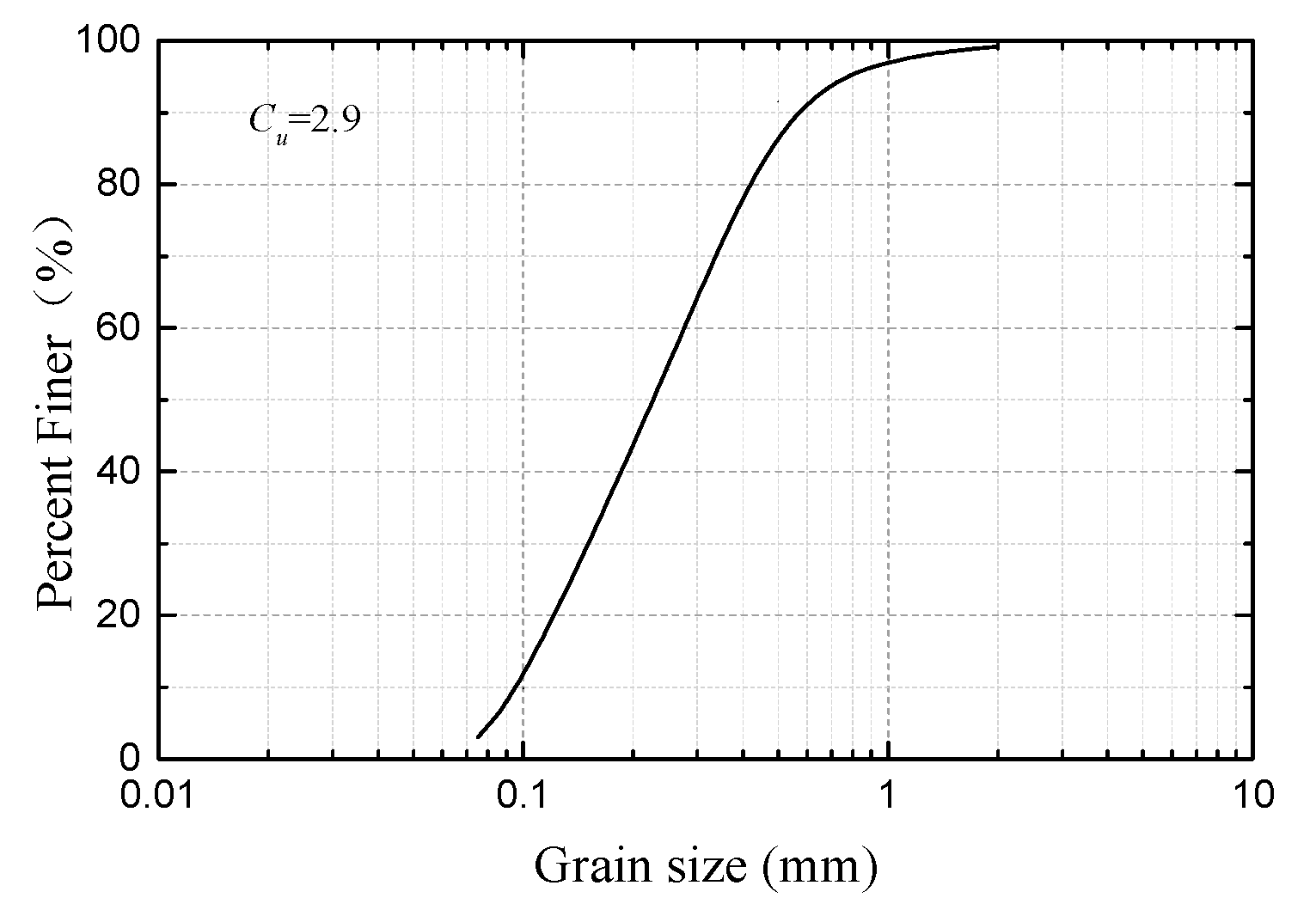

2.2. Sand Preparation

2.3. Test Process and Test Conditions

3. Test Results

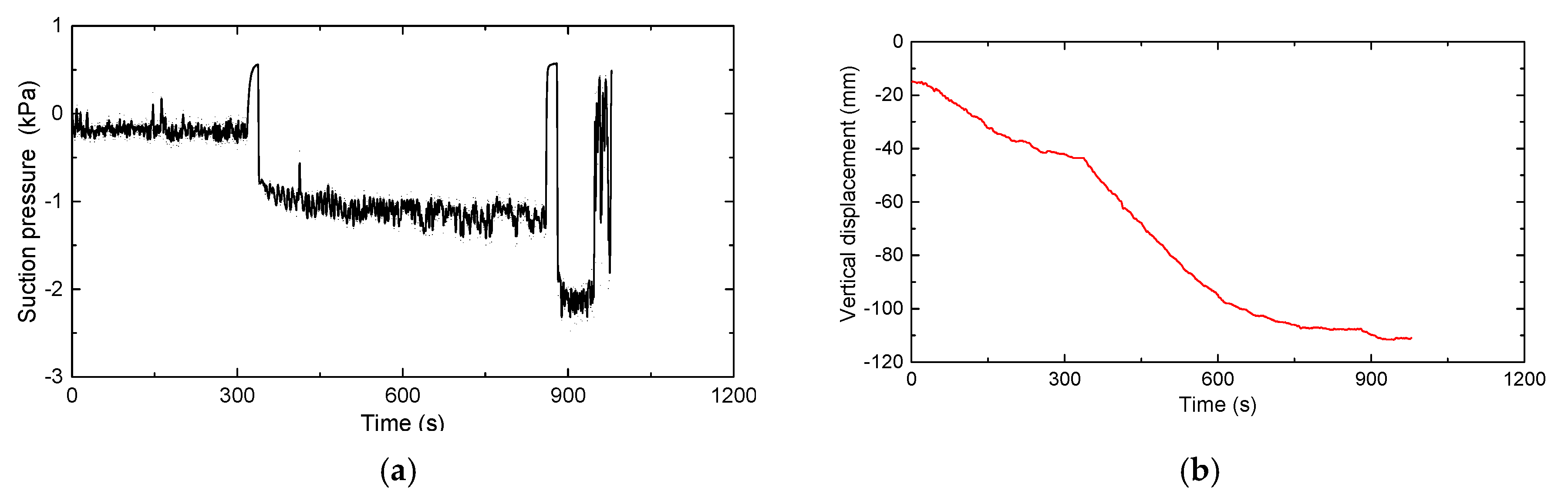

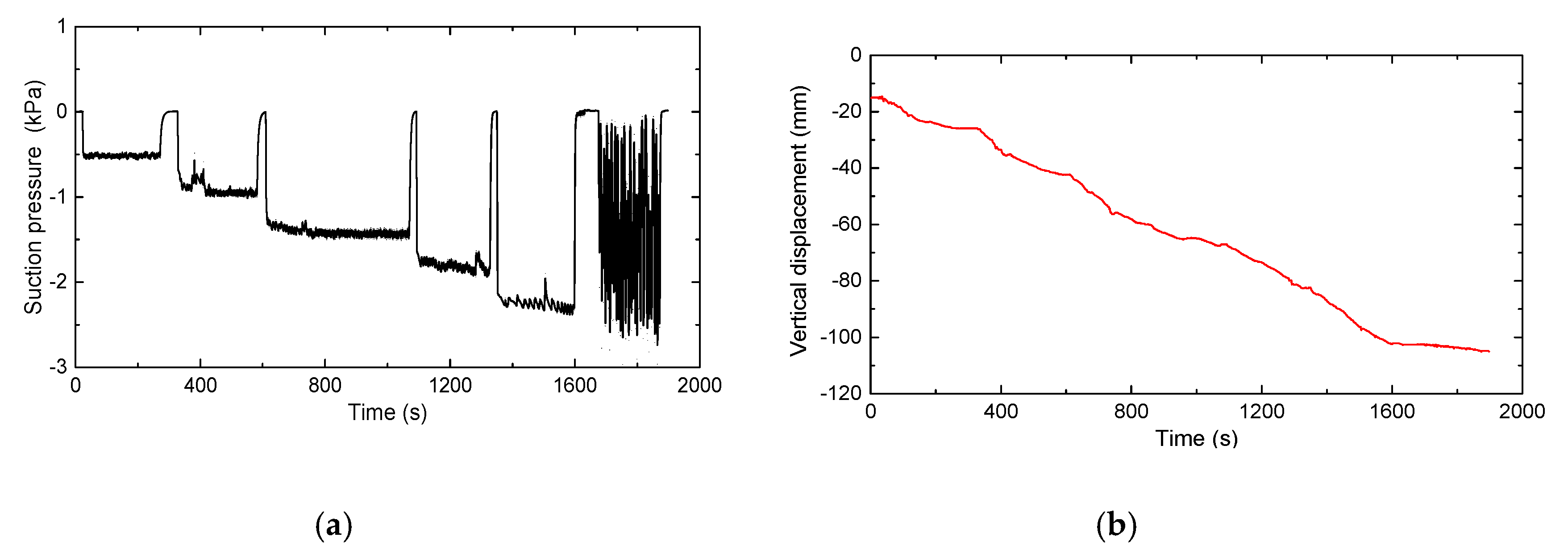

3.1. Effect of the Mode of Suction Application on Penetration Resistance

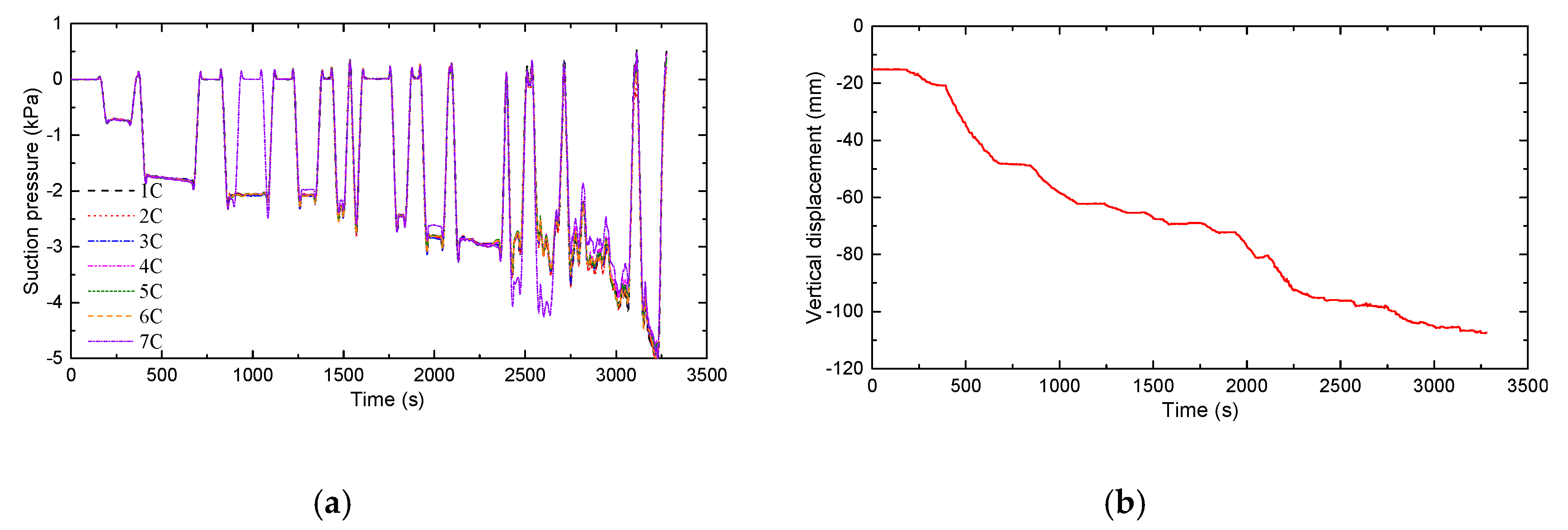

3.2. Effects of Inner Skirt Plates and Bulkheads on Penetration Resistance

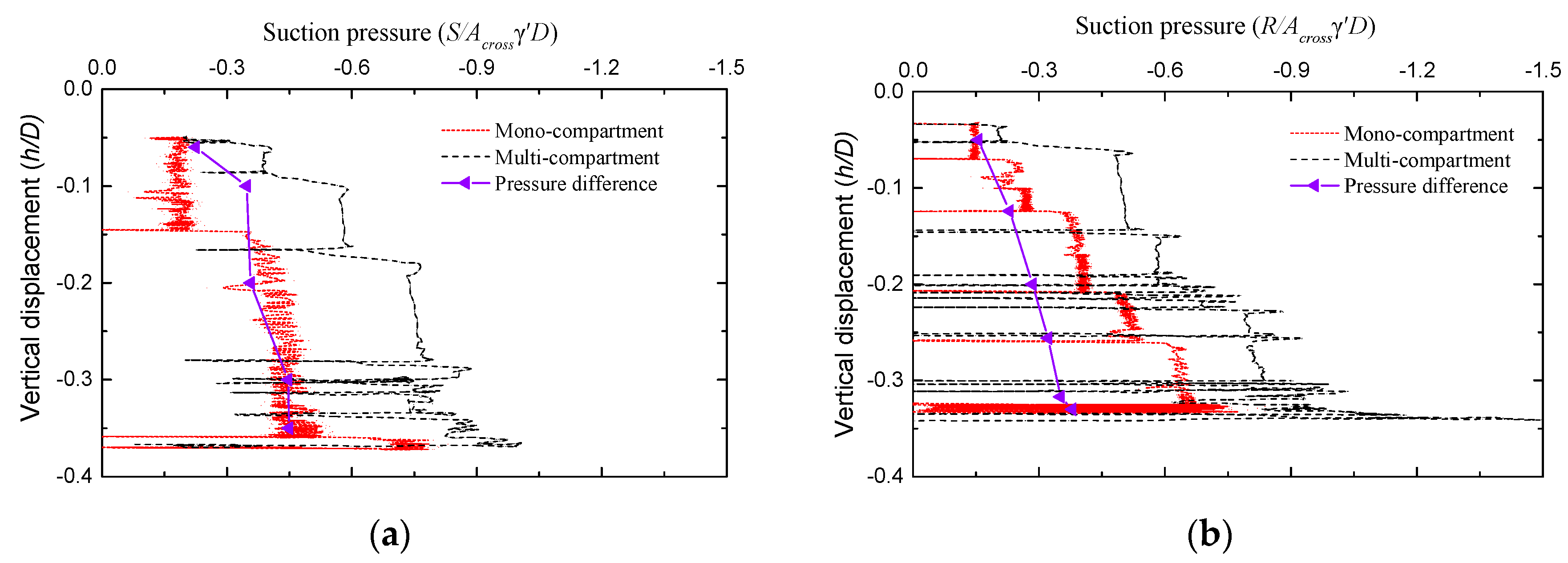

3.3. Critical Suction in the Penetration Process of the Bucket Foundation in Sand

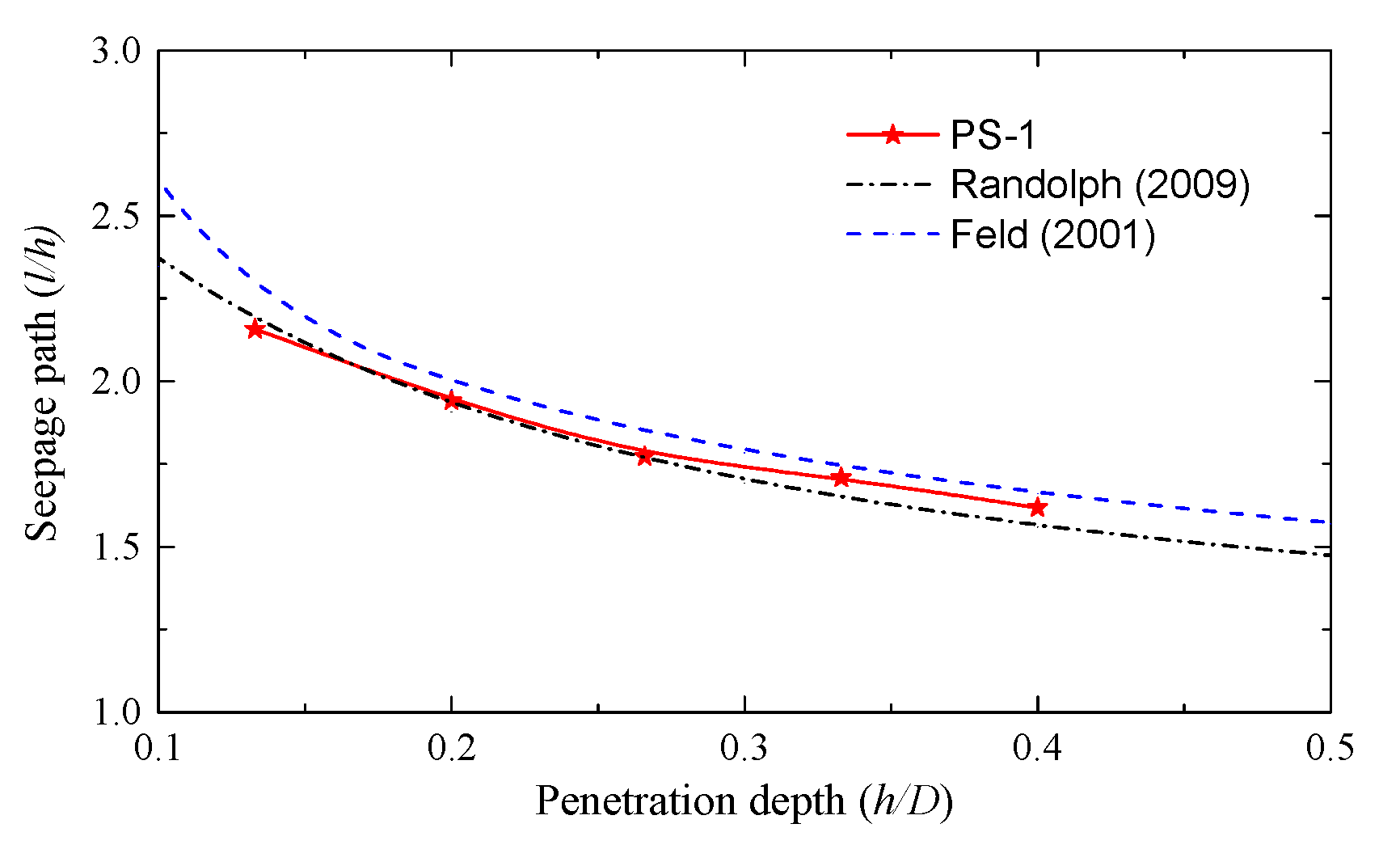

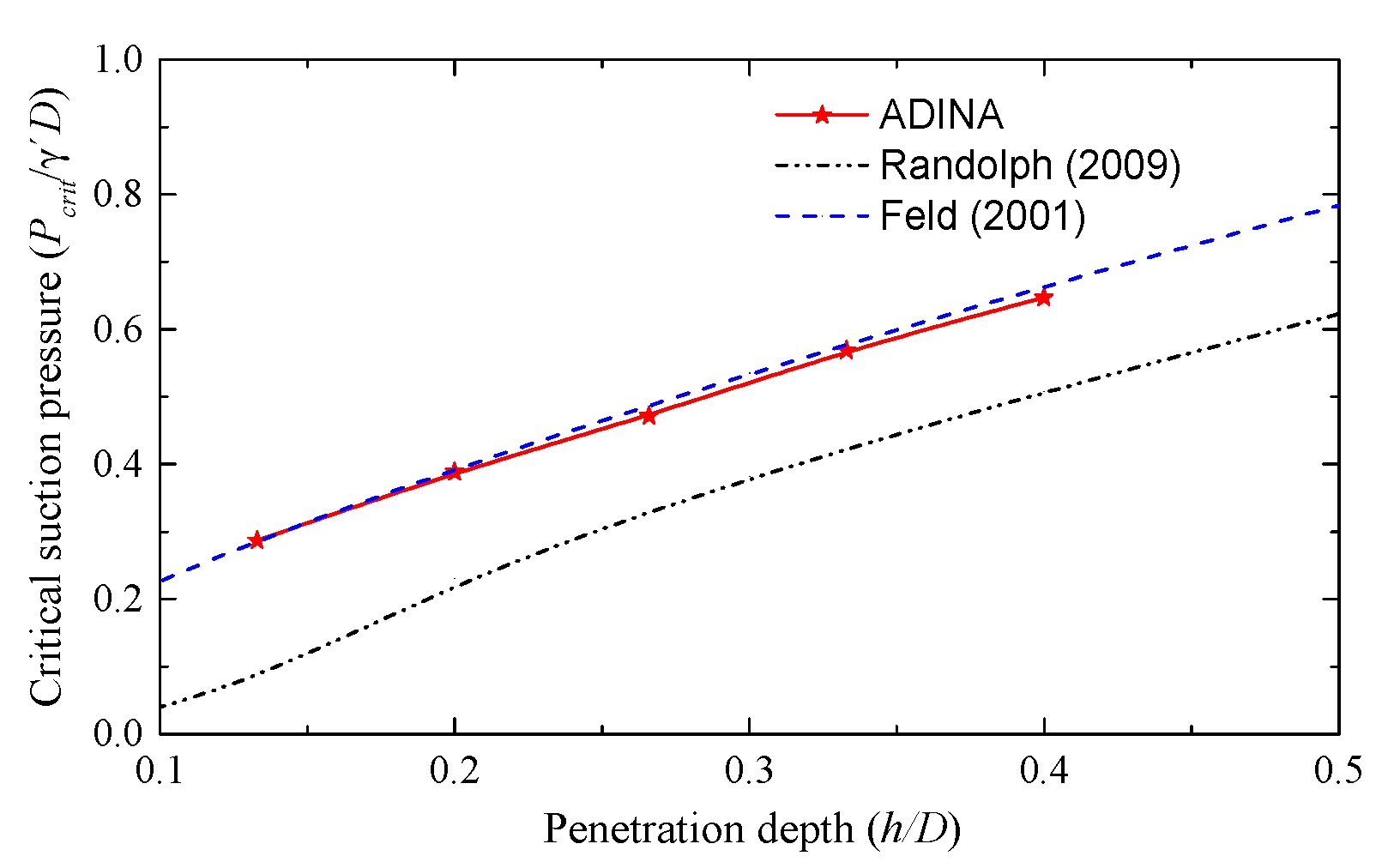

3.3.1. Verification of the Critical Suction in the Penetration Process of the Mono-Compartment Bucket Foundation

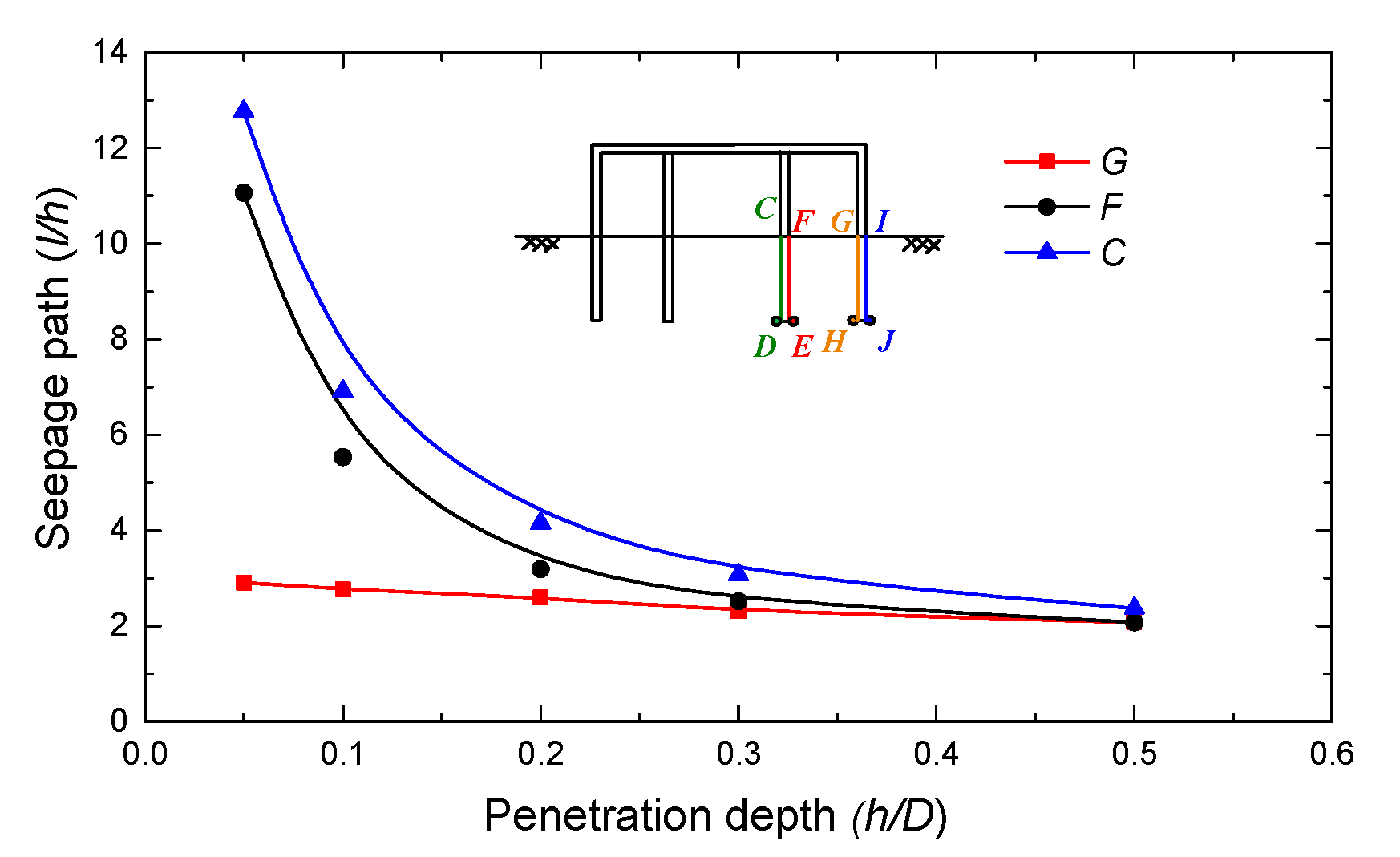

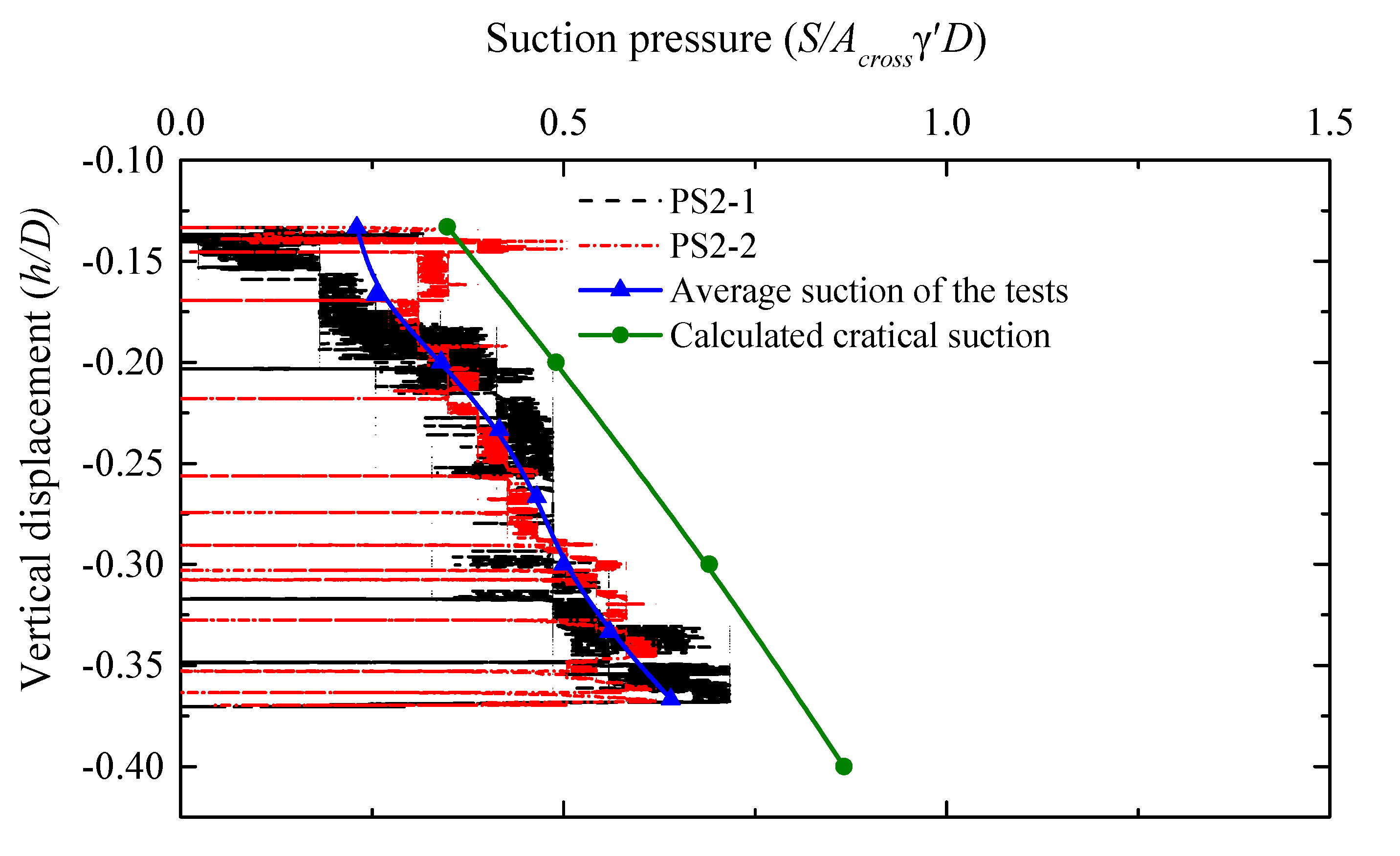

3.3.2. Critical Suction in the Penetration Process of the Multi-Compartment Bucket Foundation

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Zhang, L.X.; Shi, W.; Karimirad, M.; Michailides, C.; Jiang, Z. Second-order hydrodynamic effects on the response of three semisubmersible floating offshore wind turbine. Ocean Eng. 2020, 207, 107371. [Google Scholar] [CrossRef]

- Tang, Y.; Shi, W.; You, J.K.; Michailides, C. Effects of nonlinear wave loads on large monopile offshore wind turbines with and without ice-breaking cone configuration. J. Mar. Sci. Technol. 2020, 1–17. [Google Scholar] [CrossRef]

- Fu, D.F.; Zhang, Y.H.; Yan, Y.; Jostad, H.P. Effects of tension gap on the holding capacity of suction anchors. Mar. Struct. 2020, 69, 102679. [Google Scholar] [CrossRef]

- Wang, X.F.; Zeng, X.; Li, J. Vertical performance of suction bucket foundation for offshore wind turbines in sand. Ocean Eng. 2019, 180, 40–48. [Google Scholar] [CrossRef] [Green Version]

- Tjelta, T.I. Geotechnical experience from installation of the Europipe jacket with bucket foundation. In Proceedings of the Offshore Technology Conference OTC7795, Houston, TX, USA, 1–4 May 1995; pp. 897–908. [Google Scholar]

- Houlsby, G.T.; Ibsen, L.B.; Byrne, B.W. Suction caissons for wind turbines. In Frontiers in Offshore Geotechnics; ISFOG-Gourvenec & Cassidy , Ed.; Taylor & Francis Group: London, UK, 2005; pp. 75–93. ISBN 0 41539063X. [Google Scholar]

- LeBlanc, C. Design of Offshore Wind Turbine Support Structures. Ph.D. Thesis, Aalborg University, Aalborg, Denmark, 2009. [Google Scholar]

- Villalobos, F.A. Model Testing of Foundations for Offshore Wind Turbines. Ph.D. Thesis, University of Oxford, Oxford, UK, 2006. [Google Scholar]

- Ding, H.Y.; Lian, J.J.; Li, A.D.; Zhang, P.Y. One-step-installation of offshore wind turbine on large-scale bucket-top-bearing bucket foundation. Trans. Tianjin Univ. 2013, 19, 188–194. [Google Scholar] [CrossRef]

- Zhang, P.Y.; Ding, H.Y.; Le, C.H. Motion analysis on integrated transportation technique for offshore wind turbines. J. Renew. Sustain. Energy 2013, 5, 053117. [Google Scholar] [CrossRef]

- Ding, H.Y.; Liu, Y.G.; Le, C.H.; Zhang, P.Y. Model tests on the bearing capacity of wide-shallow composite bucket foundations for offshore wind turbines in clay. Ocean Eng. 2015, 103, 114–122. [Google Scholar] [CrossRef]

- Zhang, P.Y.; Ding, H.Y.; Le, C.H. Seismic response of large-scale prestressed concrete bucket foundation for offshore wind turbines. J. Renew. Sustain. Energy 2014, 6, 13127. [Google Scholar] [CrossRef]

- Zhang, P.Y.; Ding, H.Y.; Le, C.H. Hydrodynamic motion of a large prestressed concrete bucket foundation for offshore wind turbines. J. Renew. Sustain. Energy 2013, 5, 063126. [Google Scholar] [CrossRef]

- Ding, H.Y.; Hu, R.Q.; Zhang, P.Y.; Le, C.H. Load bearing behaviors of composite bucket foundations for offshore wind turbines on layered soil under combined loading. Ocean Eng. 2020, 198, 106997. [Google Scholar] [CrossRef]

- Clausen, C.J.F.; Tjelta, T.I. Offshore platforms supported by bucket foundations. In Proceedings of the 15th IABSE, Copenhagen, Denmark, 16–20 June 1996; pp. 819–829. [Google Scholar]

- Sahota, B.; Wilson, Q. The breakout behavior of a suction anchor embedded in submerged sand. In Proceedings of the Offshore Technology Conference, Houston, TX, USA, 3–6 May 1982; pp. 117–132. [Google Scholar]

- Barari, A.; Ibsen, L.B. Undrained response of bucket foundations to moment loading. Appl. Ocean Res. 2012, 36, 12–21. [Google Scholar] [CrossRef]

- Villalobos, F.A.; Byrne, B.W.; Houlsby, G.T. Model testing of suction caissons in clay subjected to vertical loading. Appl. Ocean Res. 2010, 32, 414–424. [Google Scholar] [CrossRef]

- Achmus, M.; Akdag, C.T.; Thieken, K. Load-bearing behavior of suction bucket foundations in sand. Appl. Ocean Res. 2013, 43, 157–165. [Google Scholar] [CrossRef]

- Ibseb, L.B.; Thilsted, C.L. Numerical study of piping limits for suction installation of offshore skirted foundations and anchors in layered sand. In Proceedings of the International Symposium on Frontiers in Offshore, Perth, Australia, 8–10 November 2010. [Google Scholar]

- Erbrich, C.T.; Tjelta, T.I. Installation of bucket foundations and suction caissons in sand-geotechnical performance. In Proceedings of the Offshore Technology Conference, Houston, TX, USA, 3–6 May 1999. [Google Scholar]

- Guo, Z.; Wang, L.Z.; Yuan, F.; Li, L.L. Model tests on installation techniques of suction caissons in a soft clay seabed. Appl. Ocean Res. 2012, 34, 116–125. [Google Scholar] [CrossRef]

- Harireche, O.; Mehravar, M.; Alani, A.M. Soil conditions and bounds to suction during the installation of caisson foundations in sand. Ocean Eng. 2014, 88, 164–173. [Google Scholar] [CrossRef] [Green Version]

- Tran, M.N.; Randolph, M.F.; Airey, D.W. Study of sand heave formation in suction caissons using Particle Image Velocimetry(PIV). In Proceedings of the 1st International Symposium on Frontiers in Offshore Geotechnics, Perth, Australia, 19–21 September 2005; pp. 259–265. [Google Scholar]

- Senders, M.; Randolph, M.F. CPT-based method for the installation of suction caissons in sand. J. Geotech. Geoenvironmental Eng. 2009, 135, 14–25. [Google Scholar] [CrossRef]

- Feld, T. Suction Buckets, A New Innovative Foundation Concept, Applied to Offshore Wind Turbines. Ph.D. Thesis, Aalborg University, Aalborg, Denmark, 2001. [Google Scholar]

- Zhang, P.Y.; Guo, Y.H.; Liu, Y.G.; Ding, H.Y.; Le, C.H. Model tests on sinking technique of composite bucket foundations for offshore wind turbines in silty clay. Renew. Sustain. 2015, 7, 033113. [Google Scholar] [CrossRef]

- Zhang, P.Y.; Guo, Y.H.; Liu, Y.G.; Ding, H.Y. Experimental study on installation of hybrid bucket foundations for offshore wind turbines in silty clay. Ocean Eng. 2016, 114, 87–100. [Google Scholar] [CrossRef]

- Zhang, P.Y.; Han, Y.Q.; Ding, H.Y.; Zhang, S.Y. Field experiments on wet tows of an integrated transportation and installation vessel with two bucket foundations for offshore wind turbines. Ocean Eng. 2015, 108, 769–777. [Google Scholar] [CrossRef]

- Zhang, P.Y.; Zhang, Z.; Liu, Y.G.; Ding, H.Y. Experimental study on installation of composite bucket foundations for offshore wind turbines in silty sand. Offshore Mech. Arctic Eng. 2016, 138, 061901. [Google Scholar]

| Model | Diameter (m) | Middle Compartment Diameter (m) | Skirt Plate Thickness (mm) | Bulkhead Thickness (mm) | Head Cover Thickness (mm) | Bucket Skirt Height (m) | Total Height (m) | Total Weight (kg) |

|---|---|---|---|---|---|---|---|---|

| Model 1 | 0.3 | - | 1 | - | 10 | 0.12 | 0.13 | 3.265 |

| Model 2 | 0.3 | 0.15 | 1 | 1 | 10 | 0.12 | 0.13 | 5.015 |

| Texture | Water Content w (%) | Density (g/cm3) | Frictional Angle | Relative Density | Permeability Coefficient k (m/s) | Void Ratio e |

|---|---|---|---|---|---|---|

| Fine sand | 21.5 | 2.18 | 34.16 | 0.779 | 1.425×10−6 | 0.479 |

| Test Number | Foundation Type |

|---|---|

| PS1-1 | Mono-compartment bucket foundation |

| PS1-2 | |

| PS2-1 | Multi-compartment bucket foundation |

| PS2-2 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ding, H.; Peng, Y.; Zhang, P.; Zhai, H.; Jia, N. Model Tests on the Penetration Resistance of Bucket Foundations for Offshore Wind Turbines in Sand. J. Mar. Sci. Eng. 2020, 8, 368. https://doi.org/10.3390/jmse8050368

Ding H, Peng Y, Zhang P, Zhai H, Jia N. Model Tests on the Penetration Resistance of Bucket Foundations for Offshore Wind Turbines in Sand. Journal of Marine Science and Engineering. 2020; 8(5):368. https://doi.org/10.3390/jmse8050368

Chicago/Turabian StyleDing, Hongyan, Yanjian Peng, Puyang Zhang, Hanbo Zhai, and Nan Jia. 2020. "Model Tests on the Penetration Resistance of Bucket Foundations for Offshore Wind Turbines in Sand" Journal of Marine Science and Engineering 8, no. 5: 368. https://doi.org/10.3390/jmse8050368

APA StyleDing, H., Peng, Y., Zhang, P., Zhai, H., & Jia, N. (2020). Model Tests on the Penetration Resistance of Bucket Foundations for Offshore Wind Turbines in Sand. Journal of Marine Science and Engineering, 8(5), 368. https://doi.org/10.3390/jmse8050368